Selection of Optimal Process Parameters for Arc Metallization

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

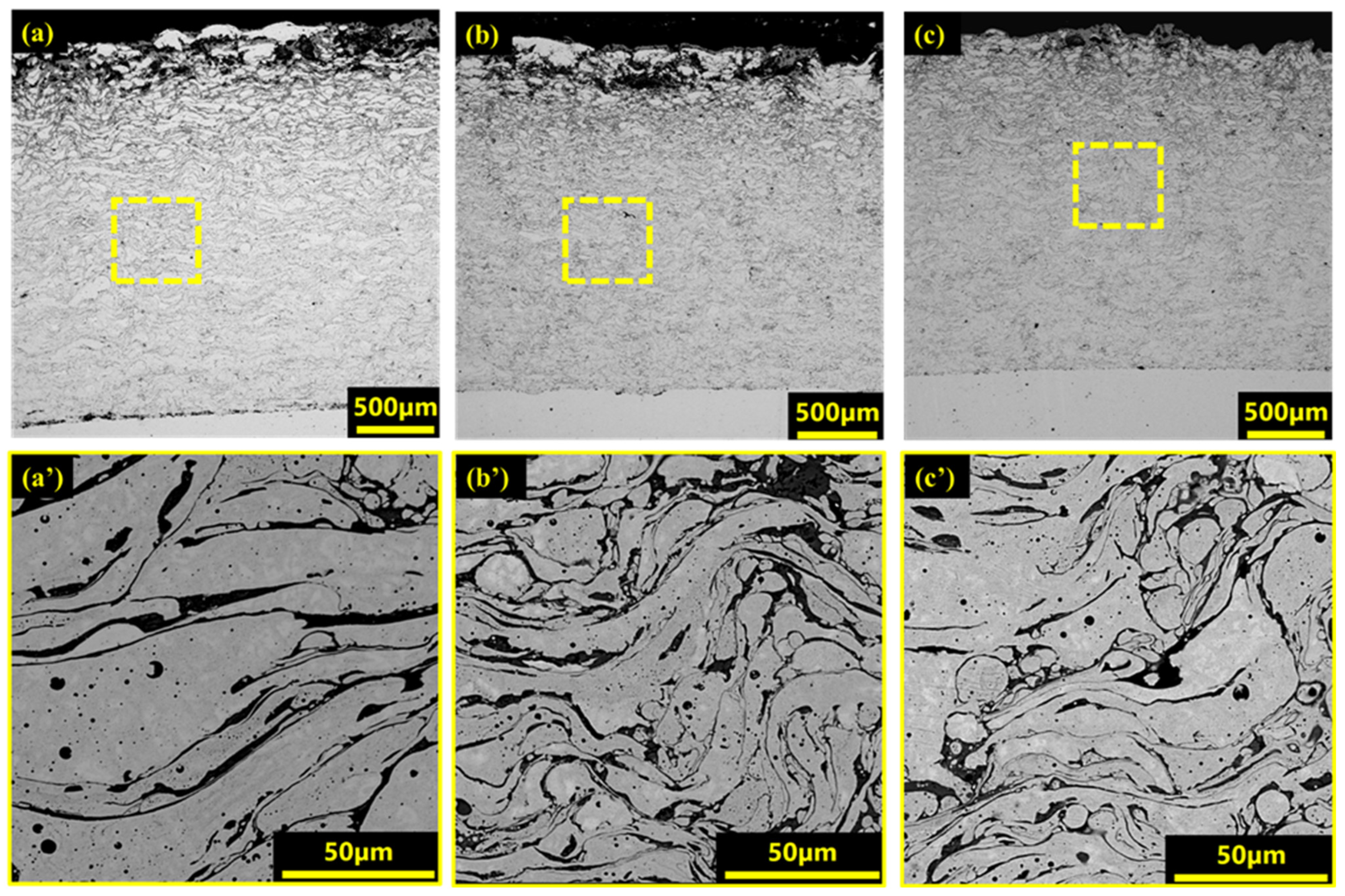

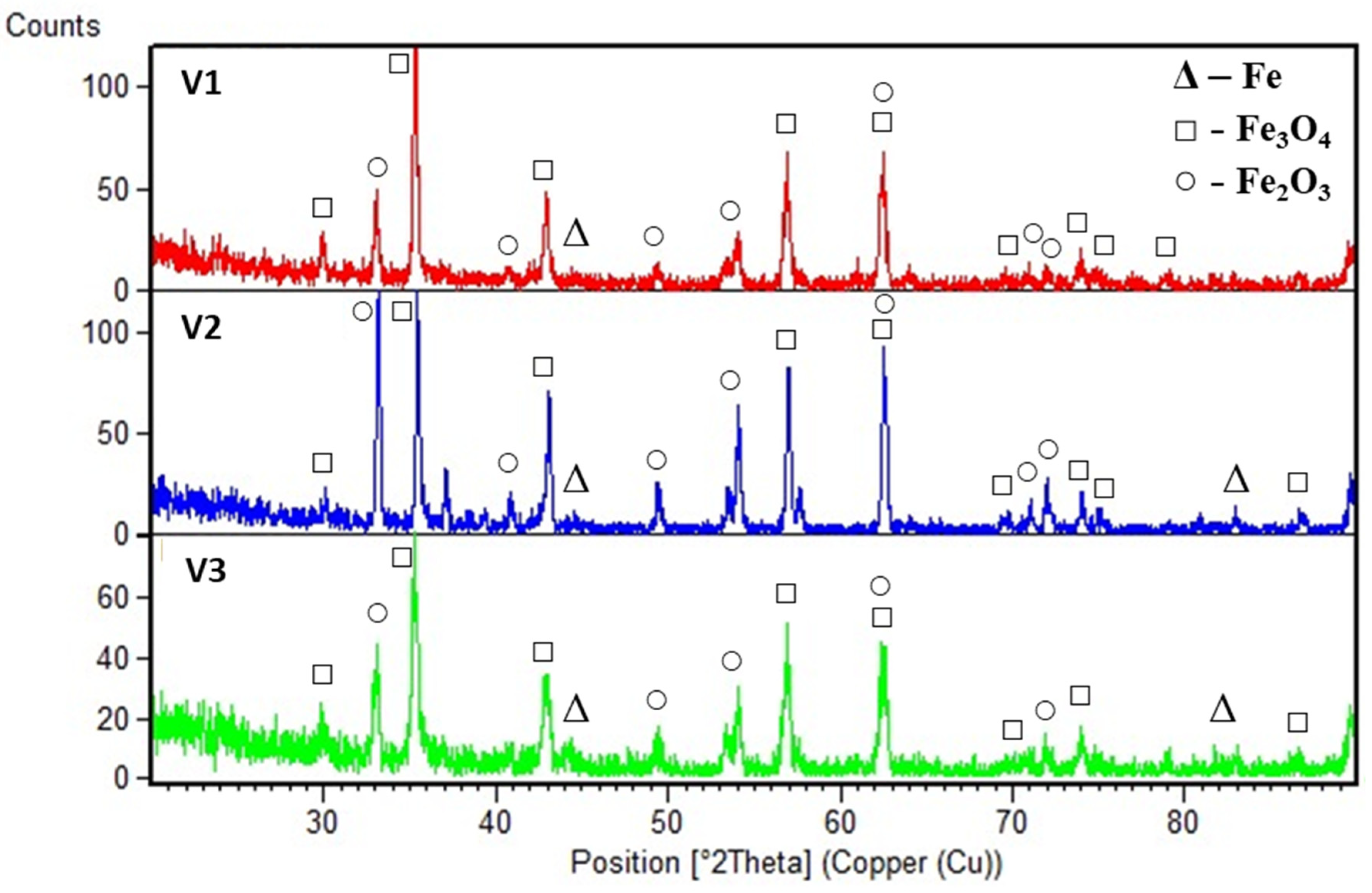

- The coatings obtained at 45 V have the lowest porosity (1.36%) and the most homogeneous structure, which is due to the increase in the kinetic energy of the molten particles. At 30 V, the porosity was 3.58%, which is explained by the insufficient energy of the particles for dense deposition on the substrate.

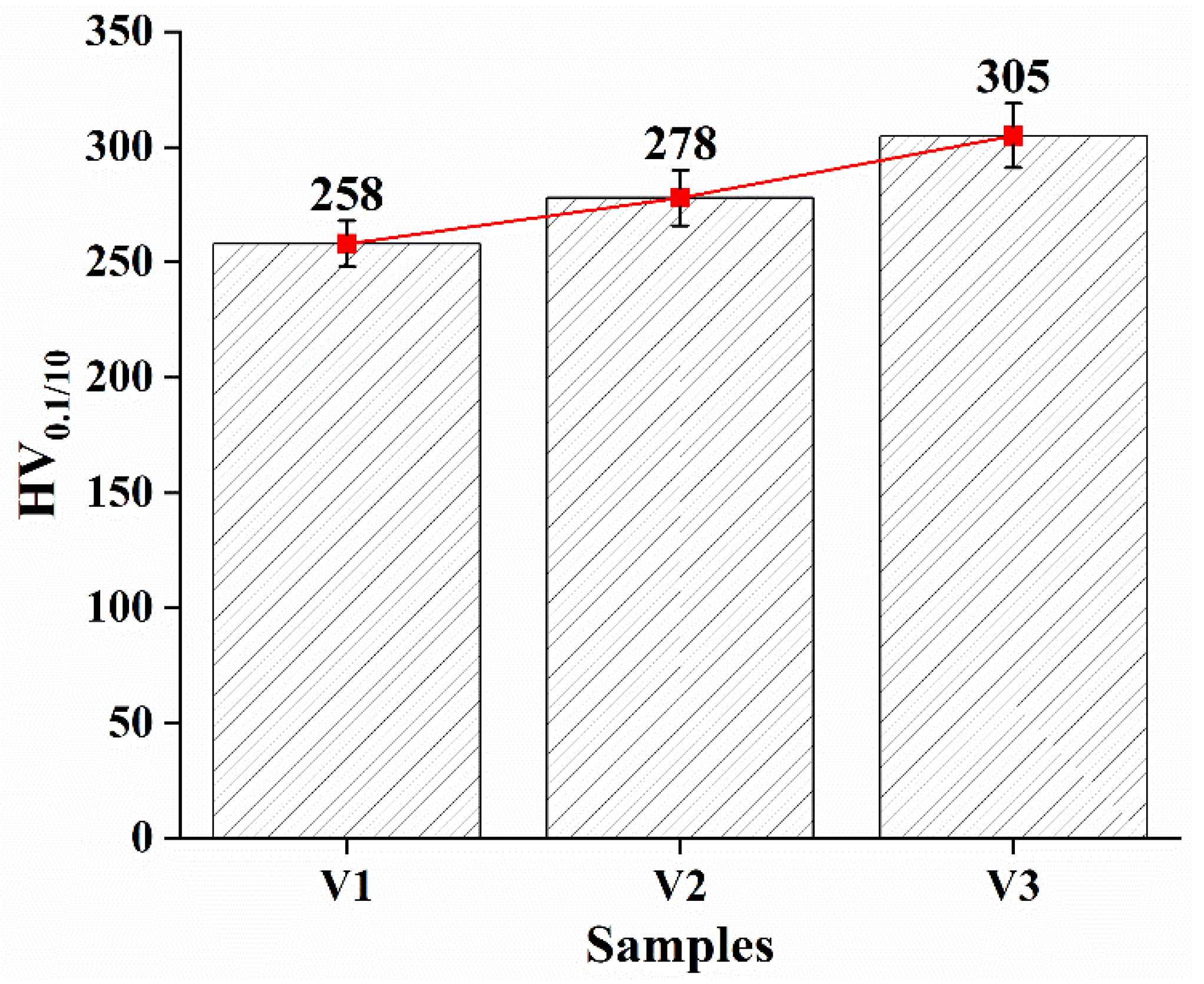

- The microhardness of the coating increases with increasing voltage. Sample V3 (45 V) shows a maximum microhardness of 305 HV, which is due to the improved density of the coating structure. At 30 V (sample V1), the microhardness was 258 HV, which corresponds to a less dense coating structure.

- Sample V3 (45 V) showed the lowest corrosion rate (0.12859 mm/yr) and the most favorable corrosion potential (−0.45 V). This is due to the minimal porosity and dense structure of the coating. Samples V1 and V2 showed higher values of corrosion rate (0.4087 mm/yr and 0.25178 mm/yr, respectively) due to the presence of defects and oxide inclusions.

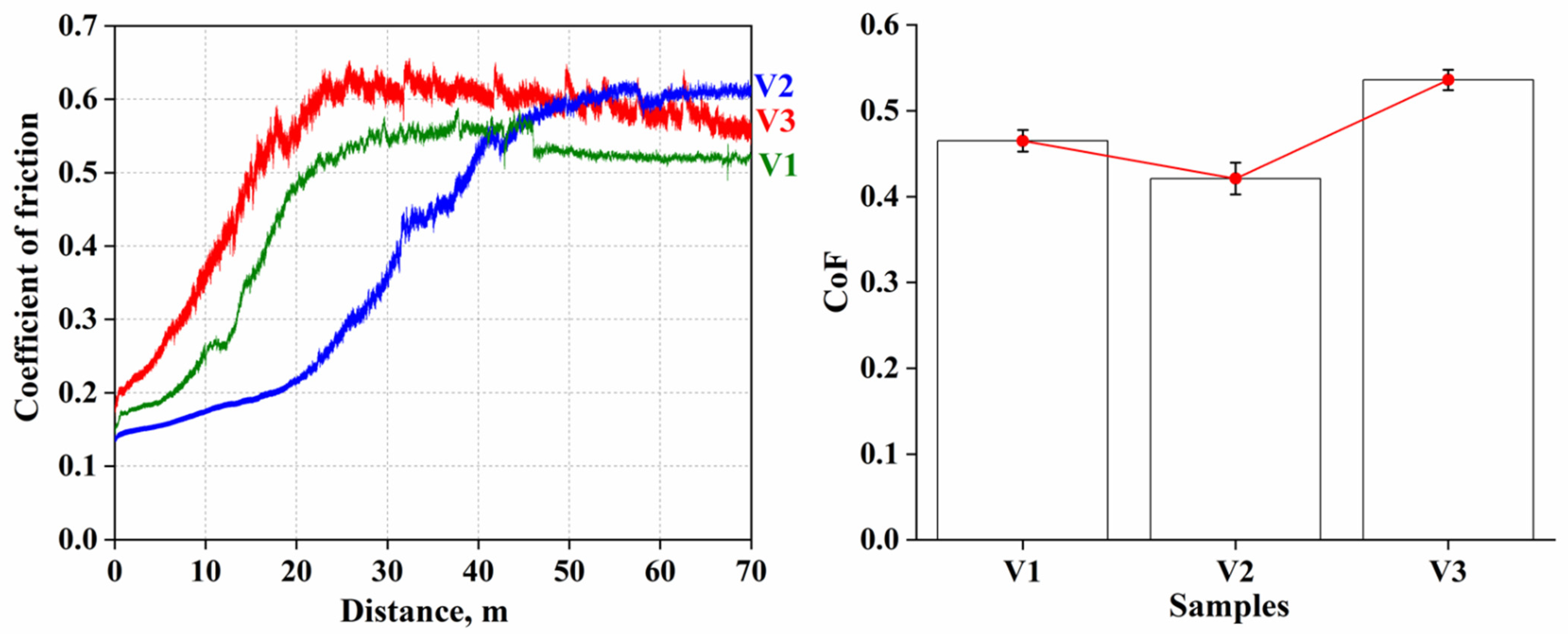

- The coefficient of friction stabilizes at a higher level for specimen V3 (0.53) compared to specimens V1 and V2 (0.46 and 0.42, respectively). This is due to the higher coating density and better wear resistance, although the higher density also results in higher contact friction force.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rakhadilov, B.; Zhurerova, L.; Sagdoldina, Z.; Kenesbekov, A.; Bayatanova, L. Morphological Changes in the Dislocation Structure of Structural Steel 20GL after Electrolytic-Plasma Hardening of the Surface. J. Surf. Investig. X-Ray Synchrotron Neutron Tech. 2021, 15, 408–413. [Google Scholar] [CrossRef]

- Wielage, B.; Wank, A.; Rupprecht, C. Tailoring of Wire Feedstock and Processing Conditions in High Velocity Combustion Wire Spraying. In Proceedings of the ITSC2006—ASM International, Seattle, WA, USA, 15–18 May 2006; pp. 1009–1014. [Google Scholar]

- Gornik, M.; Jonda, E.; Latka, L.; Nowakowska, M.; Godzierz, M. Influence of spray distance on mechanical and tribological properties of HVOF sprayed WC-Co-Cr coatings. Mater. Sci.-Pol. 2021, 39, 545–554. [Google Scholar] [CrossRef]

- Boinovich, L.B.; Domantovsky, A.G.; Emelyanenko, A.M.; Emelyanenko, K.A. Synergism of Arc Spraying, Laser Processing, and Hydrophobization for Long-Lasting Corrosion Protection of MA8 Magnesium Alloy. Adv. Eng. Mater. 2024; Early View. [Google Scholar] [CrossRef]

- Qiang, W.; Kang, M.; Liu, J.; Ndumia, J.N. Microstructure and Wear Performance of High-Velocity Arc Sprayed FeMnCrNiBNbAl Coating. Coatings 2024, 14, 428. [Google Scholar] [CrossRef]

- Szymański, K.; Hernas, A.; Moskal, G.; Myalska, H. Thermally Sprayed Coatings Resistant to Erosion and Corrosion for Power Plant Boilers—A Review. Surf. Coat. Technol. 2015, 268, 153–164. [Google Scholar] [CrossRef]

- Wielage, B.; Pokhmurska, H.; Student, M.; Gvozdeckii, V.; Stupnyckyj, T.; Pokhmurskii, V. Iron-Based Coatings Arc-Sprayed with Cored Wires for Applications at Elevated Temperatures. Surf. Coat. Technol. 2013, 220, 27–35. [Google Scholar] [CrossRef]

- Romankov, S.E.; Sagdoldina, Z.B.; Kaloshkin, S.D.; Kaevitser, E.V. Fabrication of Ti-Al composite coatings by the mechanical alloying method. Phys. Met. Metallogr. 2008, 106, 67–75. [Google Scholar] [CrossRef]

- Tabieva, E.E.; Zhurerova, L.G.; Baizhan, D. Influence of electrolyte-plasma hardening technological parameters on the structure and properties of banding steel 2. Key Eng. Mater. 2020, 839, 57–62. [Google Scholar] [CrossRef]

- Popova, N.A.; Zhurerova, L.G.; Nikonenko, E.L.; Skakov, M.K. Effect of plasma electrolytic nitrocarburizing on phase composition of 0.3 C-1Mn-1Si-fe steel. Inorg. Mater. Appl. Res. 2017, 8, 130–135. [Google Scholar] [CrossRef]

- Kakimzhanov, D.N.; Rakhadilov, B.K.; Tyurin, Y.N.; Kolisnichenko, O.V.; Zhurerova, L.G.; Dautbekov, M.K. Influence of pulsed plasma treatment on phase composition and hardness of Cr 3 C 2-NiCr coatings. Eurasian J. Phys. Funct. Mater. 2021, 5, 45–51. [Google Scholar] [CrossRef]

- Ramezani, M.; Mohd Ripin, Z.; Pasang, T.; Jiang, C.P. Surface engineering of metals: Techniques, characterizations and applications. Metals 2023, 13, 1299. [Google Scholar] [CrossRef]

- Kengesbekov, A.; Rakhadilov, B.; Sagdoldina, Z.; Buitkenov, D.; Dosymov, Y.; Kylyshkanov, M. Improving the efficiency of air plasma spraying of titanium nitride powder. Coatings 2022, 12, 1644. [Google Scholar] [CrossRef]

- Bauyrzhan, R.; Alexander, P.; Zhuldyz, S.; Dastan, B.; Vyacheslav, B.; Mukhamedova, A. Effect of Bilayer Thickness and Bias Potential on the Structure and Properties of (TiZr/Nb) N Multilayer Coatings as a Result of Arc-PVD Deposition. Materials 2022, 15, 7696. [Google Scholar] [CrossRef]

- Rakhadilov, B.K.; Baizhan, D.R.; Sagdoldina, Z.B.; Buitkenov, D.B.; Maulet, M. Phase composition and structure of composite Ti/HA coatings synthesized by detonation spraying. AIP Conf. Proc. 2020, 2297, 010001. [Google Scholar]

- Rakhadilov, B.K.; Kenesbekov, A.B.; Kowalevski, P.; Ocheredko, Y.A.; Sagdoldina, Z.B. Development of air-plasma technology for hardening cutting tools by applying wear-resistant coatings. News Natl. Acad. Sci. Repub. Kazakhstan 2020, 3, 54–62. [Google Scholar] [CrossRef]

- Yu, H.L.; Zhang, W.; Wang, H.M.; Ji, X.C.; Song, Z.Y.; Li, X.Y.; Xu, B.S. In-situ synthesis of TiC/Ti composite coating by high frequency induction cladding. J. Alloys Compd. 2017, 701, 244–255. [Google Scholar] [CrossRef]

- Sidorov, S.A.; Mironov, D.A.; Khoroshenkov, V.K.; Khlusova, E.I. Surfacing methods for increasing the service life of rapidly wearing working tools of agricultural machines. Weld. Int. 2016, 30, 808–812. [Google Scholar] [CrossRef]

- Sun, R.; Shi, Y.; Pei, Z.; Li, Q.; Wang, R. Heat transfer and temperature distribution during high-frequency induction cladding of 45 steel plate. Appl. Therm. Eng. 2018, 139, 1–10. [Google Scholar] [CrossRef]

- Hui, R.; Wang, Z.; Kesler, O.; Rose, L.; Jankovic, J.; Yick, S.; Ghosh, D. Thermal plasma spraying for SOFCs: Applications, potential advantages, and challenges. J. Power Sources 2007, 170, 308–323. [Google Scholar] [CrossRef]

- Chahal, H.K.; Matthews, S.; Jones, M.I. Fabrication of calcium phosphate coatings by the inflight reaction of precursor feedstocks using plasma spraying. J. Therm. Spray Technol. 2023, 32, 1465–1481. [Google Scholar] [CrossRef]

- Qadir, D.; Sharif, R.; Nasir, R.; Awad, A.; Mannan, H.A. A review on coatings through thermal spraying. Chem. Pap. 2024, 78, 71–91. [Google Scholar] [CrossRef]

- Liao, X.J.; Zhang, L.; Sun, Y.Q.; Luo, X.T.; Li, C.X.; Yang, G.J.; Li, C.J. Effect of Inter-Splat Bonding Quality on the Dependence of Wear Behavior of Plasma-Sprayed Stainless Steel Coating on Applied Load. J. Therm. Spray Technol. 2024, 33, 1–11. [Google Scholar] [CrossRef]

- Abdivakhidov, K.; Sharipov, K. Corrosion-resistant protective coatings for metals: A review of metallic and non-metallic coatings. AIP Conf. Proc. 2024, 3045, 060011. [Google Scholar]

- Liu, M.; Peng, Q.; Huang, Y.; Li, P.; Tan, G.; Luo, X.; Qiao, Q.; Wang, H.; Lang, W. Influencing Factors and Process Optimization of Al/SiC Powder-Cored Wires by Plasma Transferred Wire Arc Spraying. J. Therm. Spray Technol. 2024, 33, 2167–2183. [Google Scholar] [CrossRef]

- Yao, H.H.; Zhou, Z.; Wang, Y.M.; He, D.Y.; Bobzin, K.; Zhao, L.; Öte, M.; Königstein, T. Microstructure and Properties of FeCrB Alloy Coatings Prepared by Wire-Arc Spraying. J. Therm. Spray Tech. 2017, 26, 483–491. [Google Scholar] [CrossRef]

- Arizmendi-Morquecho, A.; Campa-Castilla, A.; Leyva-Porras, C.; Aguilar Martinez, J.A.; Vargas Gutiérrez, G.; Moreno Bello, K.J.; López López, L. Microstructural Characterization and Wear Properties of Fe-Based Amorphous-Crystalline Coating Deposited by Twin Wire Arc Spraying. Adv. Mater. Sci. Eng. 2014, 2014, 836739. [Google Scholar] [CrossRef]

- Kumar, D.; Murtaza, Q.; Singh, R.C. Sliding Wear Behavior of Aluminum Alloy Coating Prepared by Two-Wire Electric Arc Spray Process. Int. J. Adv. Manuf. Technol. 2016, 85, 237–252. [Google Scholar] [CrossRef]

- Johnston, A.L.; Hall, A.C.; McCloskey, J.F. Effect of Process Inputs on Coating Properties in the Twin-Wire Arc Zinc Process. J. Therm. Spray Tech. 2013, 22, 856–863. [Google Scholar] [CrossRef]

- Czupryński, A. Flame spraying of aluminum coatings reinforced with particles of carbonaceous materials as an alternative for laser cladding technologies. Materials 2019, 12, 3467. [Google Scholar] [CrossRef] [PubMed]

- Liang, S.; Neisius, N.M.; Gaan, S. Recent developments in flame retardant polymeric coatings. Prog. Org. Coat. 2013, 76, 1642–1665. [Google Scholar] [CrossRef]

- Xie, X.; Guo, H.; Gong, S.; Xu, H. Thermal cycling behavior and failure mechanism of LaTi2Al9O19/YSZ thermal barrier coatings exposed to gas flame. Surf. Coat. Technol. 2011, 205, 4291–4298. [Google Scholar] [CrossRef]

- Nakamura, M.; Akamatsu, F.; Kurose, R.; Katsuki, M. Combustion mechanism of liquid fuel spray in a gaseous flame. Phys. Fluids 2005, 17, 123301. [Google Scholar] [CrossRef]

- Pokhmursky, V.I.; Student, M.M.; Ryabtsev, I.A.; Sidorak, I.I.; Dzioba, Y.V.; Dovgunyk, V.M.; Formanek, B. Influence of electric arc metallizing modes and compositions of applied flux-cored wires on structure and abrasive wear resistance of coatings. Paton Weld. J. 2006, 7, 26. [Google Scholar]

- Degnan, C.C.; Shipway, P.H. A comparison of the reciprocating sliding wear behaviour of steel-based metal matrix composites processed from self-propagating high-temperature synthesised Fe–TiC and Fe–TiB₂ masteralloys. Wear 2002, 252, 832–841. [Google Scholar] [CrossRef]

- Kumar, D.; Pandey, K.N. Optimization of the process parameters in generic thermal barrier coatings using the Taguchi method and grey relational analysis. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2017, 231, 600–610. [Google Scholar] [CrossRef]

- Zhao, W.; Lu, Y.; Fu, H.; He, D.; Tan, Z.; Yao, H.; Yang, Y.; Zhou, Z. Developing Rotary Swaging Process for Improving the Performance of Wire-Arc Sprayed Al/Al2O3 Composite Coating. Surf. Coat. Technol. 2024, 484, 130840. [Google Scholar] [CrossRef]

- Lopata, A.; Lopata, V.; Kachynska, I.; Zaboykina, N. Influence of Factors of the Electric Arc Spraying Process on the Properties of Coatings. Probl. Tribol. 2024, 29, 79–86. [Google Scholar] [CrossRef]

- Steffens, H.-D.; Babiak, Z.; Wewel, M. Recent Developments in Arc Spraying. IEEE Trans. Plasma Sci. 1990, 18, 974–979. [Google Scholar] [CrossRef]

- Abedini, A.; Pourmousa, A.; Chandra, S.; Mostaghimi, J. Effect of Substrate Temperature on the Properties of Coatings and Splats Deposited by Wire Arc Spraying. Surf. Coat. Technol. 2006, 201, 3350–3358. [Google Scholar] [CrossRef]

- Ndumia, J.N.; Kang, M.; Gbenontin, B.V.; Lin, J.; Nyambura, S.M. A Review on the Wear, Corrosion and High-Temperature Resistant Properties of Wire Arc-Sprayed Fe-Based Coatings. Nanomaterials 2021, 11, 2527. [Google Scholar] [CrossRef]

- Planche, M.P.; Liao, H.; Coddet, C. Relationships between In-Flight Particle Characteristics and Coating Microstructure with a Twin Wire Arc Spray Process and Different Working Conditions. Surf. Coat. Technol. 2004, 182, 215–226. [Google Scholar] [CrossRef]

- Nguyen, T.V.; Le, T.D.; Le, Q.T.; Pham, H.T.; Nguyen, A.T.; Pham, L.T.; Dao, T.B.; Ly, C.Q. Characterization and Corrosion Resistance of the Twin-Wire Arc Spray Al-5Mg Alloy Coating Applied on a Carbon Steel Substrate. J. Therm. Spray Technol. 2024, 33, 381–397. [Google Scholar] [CrossRef]

- Wagner, N. Effect of Process Parameters on Twin Wire Arc Sprayed Steel Coatings. J. Mater. Eng. Perform. 2021, 30, 6650–6655. [Google Scholar] [CrossRef]

- Ndumia, J.N.; Kang, M.; Gbenontin, B.V.; Lin, J.; Liu, J.; Li, H.; Nyambura, S.M. Optimizing Parameters of Arc-Sprayed Fe-Based Coatings Using the Response Surface Methodology. J. Therm. Spray Technol. 2023, 32, 2202–2220. [Google Scholar] [CrossRef]

- Mykhailo, S.; Volodymyr, G.; Oleksandra, S.; Olegas, P.; Pavlo, M.; Olena, O.; Liudmyla, T. The Effect of Increasing the Air Flow Pressure on the Properties of Coatings During the Arc Spraying of Cored Wires. Stroj. Časopis—J. Mech. Eng. 2019, 69, 133–146. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Magazov, N.; Kakimzhanov, D.; Apsezhanova, A.; Molbossynov, Y.; Kengesbekov, A. Influence of Spraying Process Parameters on the Characteristics of Steel Coatings Produced by Arc Spraying Method. Coatings 2024, 14, 1145. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Shynarbek, A.; Kakimzhanov, D.; Kusainov, R.; Zhassulan, A.; Ormanbekov, K. Effect of Voltage on Properties of 30HGSA Steel Coatings by Supersonic Supersonic Arc Metallization Method. Adv. Sci. Technol. Res. J. 2024, 18, 113–124. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.R.; Li, D.Y.; Zhang, N.N.; Huang, H.; Wang, X. Wear mechanism of iron-based alloy coating by arc spraying. J. Iron Steel Res. Int. 2016, 23, 834–841. [Google Scholar] [CrossRef]

- Yao, H.; Zhou, Z.; Wang, G.; He, D.; Bobzin, K.; Zhao, L.; Öte, M.; Königstein, T. Influence of Feedstock Materials and Spray Parameters on Thermal Conductivity of Wire-Arc-sprayed Coatings. J. Mater. Eng. Perform. 2017, 26, 1108–1113. [Google Scholar] [CrossRef]

- Salavati, S.; Coyle, T.; Mostaghimi, J. Twin Wire Arc Spray Process Modification for Production of Porous Metallic Coatings. Surf. Coat. Technol. 2016, 286, 16–24. [Google Scholar] [CrossRef]

- Xu, W.-P.; Xu, B.-S.; Zhang, W.; Wu, Y.-X. High temperature behaviors of high velocity arc sprayed Fe-Al/Cr3C2 composite coatings. Int. J. Miner. Metall. Mater. 2005, 12, 340–346. [Google Scholar]

- Li, R.; Zhou, Z.; He, D.; Wang, Y.; Wu, X.; Song, X. Microstructure and high temperature corrosion behavior of wire-arc sprayed FeCrSiB coating. J. Therm. Spray Technol. 2015, 24, 857–864. [Google Scholar] [CrossRef]

| C | Si | Mn | Ni | S | P | Cr | Cu |

|---|---|---|---|---|---|---|---|

| 0.62–0.7 | 0.17–0.37 | 0.9–1.2 | 0.25 | <0.035 | <0.035 | <0.25 | <0.2 |

| C | Si | Mn | Ni | S | P | Cr | Cu |

|---|---|---|---|---|---|---|---|

| 0.28–0.34 | 0.9–1.2 | 0.8–1.1 | <0.3 | <0.025 | <0.025 | 0.8–1.1 | <0.3 |

| Sample Name | Voltage, V | Current Strength, A | Wire Feed Speed, cm/s | Compressed Air Pressure, Atm | Spraying Distance, mm | Number of Samples |

|---|---|---|---|---|---|---|

| V1 | 30 | 300 | 4.3 | 8 | 400 | 3 |

| V2 | 40 | 3 | ||||

| V3 | 45 | 3 |

| Samples | Hardness, HV | Porosity, % | Friction Coefficient | Corrosion Current Icorr (A/cm²) | Free Corrosion Potential Ecorr (V) | Corrosion Rate, mm/year |

|---|---|---|---|---|---|---|

| V1 | 258 ± 12.9 | 3.58 ± 0.25 | 0.46 ± 0.06 | 1.0 × 10−4 | −0.55 | 0.4087 ± 0.023 |

| V2 | 278 ± 13.9 | 2.72 ± 0.27 | 0.42 ± 0.05 | 1.0 × 10−⁶ | −0.60 | 0.25178 ± 0.021 |

| V3 | 305 ± 9.15 | 1.36 ± 0.06 | 0.53 ± 0.02 | 1.0 × 10−7 | −0.45 | 0.12859 ± 0.022 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rakhadilov, B.; Buitkenov, D.; Apsezhanova, A.; Kakimzhanov, D.; Nabioldina, A.; Magazov, N. Selection of Optimal Process Parameters for Arc Metallization. Coatings 2025, 15, 300. https://doi.org/10.3390/coatings15030300

Rakhadilov B, Buitkenov D, Apsezhanova A, Kakimzhanov D, Nabioldina A, Magazov N. Selection of Optimal Process Parameters for Arc Metallization. Coatings. 2025; 15(3):300. https://doi.org/10.3390/coatings15030300

Chicago/Turabian StyleRakhadilov, Bauyrzhan, Dastan Buitkenov, Akbota Apsezhanova, Dauir Kakimzhanov, Aiym Nabioldina, and Nurtoleu Magazov. 2025. "Selection of Optimal Process Parameters for Arc Metallization" Coatings 15, no. 3: 300. https://doi.org/10.3390/coatings15030300

APA StyleRakhadilov, B., Buitkenov, D., Apsezhanova, A., Kakimzhanov, D., Nabioldina, A., & Magazov, N. (2025). Selection of Optimal Process Parameters for Arc Metallization. Coatings, 15(3), 300. https://doi.org/10.3390/coatings15030300