A Study of the Hall Effect on Doped and Undoped Praseodymium Nickelate Perovskite Thin Films and the Impact of the Reduction Process

Abstract

1. Introduction

2. Experimental Section

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, D.; Lee, K.; Wang, B.Y.; Osada, M.; Crossley, S.; Lee, H.R.; Cui, Y.; Hikita, Y.; Hwang, H.Y. Superconductivity in infinite layer nickelates. Nature 2019, 572, 624–627. [Google Scholar] [CrossRef] [PubMed]

- Chow, L.E.; Ariando, A. Infinite-Layer Nickelate Superconductors: A Current Experimental Perspective of the Crystal and Electronic Structures. Front. Phys. 2022, 10, 834658. [Google Scholar] [CrossRef]

- Osada, M.; Wang, B.Y.; Lee, K.; Li, D.; Hwang, H.Y. Phase diagram of infinite layer praseodymium nickelate Pr1−xSrxNiO2 thin films. Phys. Rev. Mater. 2020, 4, 121801. [Google Scholar] [CrossRef]

- Lee, K.; Goodge, B.H.; Li, D.; Osada, M.; Wang, B.Y.; Cui, Y.; Kourkoutis, L.F.; Hwang, H.Y. Aspects of the Synthesis of Thin Film Superconducting Infinite-Layer Nickelates. APL Mater. 2020, 8, 041107. [Google Scholar] [CrossRef]

- Sahib, H.; Rosa, F.; Raji, A.; Merzoni, G.; Ghiringhelli, G.; Salluzzo, M.; Gloter, A.; Viart, N.; Preziosi, D. Superconductivity in PrNiO2 Infinite-Layer Nickelates. arXiv 2024, arXiv:2410.16147. [Google Scholar]

- Harisankar, S.; Chandra, M.; Das, S.; Soni, K.; Prajapat, M.; Mavani, K.R. Anomalous Hall effect and re-entrant metallic transitions in epitaxial PrNiO3−δ thin films. J. Appl. Phys. 2018, 125, 025102. [Google Scholar]

- Gutiérrez-Llorente, A.; Raji, A.; Zhang, D.; Divay, L.; Gloter, A.; Gallego, F.; Galindo, C.; Bibes, M.; Iglesias, L. Toward Reliable Synthesis of Superconducting Infinite Layer Nickelate Thin Films by Topochemical Reduction. Adv. Sci. 2024, 11, e2309092. [Google Scholar] [CrossRef] [PubMed]

- Venimadhav, A.; Lekshmi, I.C.; Hegde, M. Strain-induced metallic behavior in PrNiO3 epitaxial thin films. Mater. Res. Bull. 2002, 37, 201–208. [Google Scholar] [CrossRef]

- Harisankar, S.; Soni, K.; Yadav, E.; Mavani, K.R. Strain-mediated effects of oxygen deficiency and variation in non-Fermi liquid behavior of epitaxial PrNiO3−δ thin films. J. Phys. Condens. Matter 2019, 31, 135601. [Google Scholar] [CrossRef] [PubMed]

- Keenari, M. Study of Reduction Process on Perovskite Nickelates and Its Derivatives: A Bulk and Thin Film Approach. Ph.D. Thesis, Normandie Université, Caen, France, 2023. [Google Scholar]

- Torrance, J.B.; Lacorre, P.; Nazzal, A.I.; Ansaldo, E.J.; Niedermayer, C. Systematic study of insulator-metal transitions in perovskites RNiO3 (R = Pr, Nd, Sm, Eu) due to closing of charge-transfer gap. Phys. Rev. B 1992, 45, 8209–8212. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Singh, P.; Kaur, D.; Jesudasan, J.; Raychaudhuri, P. Substrate effect on electrical transport properties of RNiO3 thin films prepared by pulsed laser deposition. J. Phys. D Appl. Phys. 2006, 39, 5310. [Google Scholar] [CrossRef]

- Noun, W.; Berini, B.; Dumont, Y.; Dahoo, P.R.; Keller, N. Correlation between electrical and ellipsometric properties on high-quality epitaxial thin films of the conductive oxide LaNiO3 on STO (001). J. Appl. Phys. 2007, 102, 063709. [Google Scholar] [CrossRef]

- Medarde, M.L. Structural, magnetic and electronic properties of perovskites (R = rare earth). J. Phys. Condens. Matter 1997, 9, 1679. [Google Scholar] [CrossRef]

- Ha, S.D.; Jaramillo, R.; Silevitch, D.M.; Schoofs, F.; Kerman, K.; Baniecki, J.D.; Ramanathan, S. Hall effect measurements on epitaxial SmNiO3 thin films and implications for antiferromagnetism. Phys. Rev. B 2013, 87, 125150. [Google Scholar] [CrossRef]

- Yang, C.; Ortiz, R.; Wang, Y.; Putzky, D.; Benckiser, E.; Keimer, B.; van Aken, P.A. Generation of Ruddlesden-Popper faults in Sr doped NdNiO3. Microsc. Microanal. 2021, 27, 1198–1200. [Google Scholar] [CrossRef]

- Zhang, D.; Raji, A.; Vicente-Arche, L.M.; Gloter, A.; Bibes, M.; Iglesias, L. Achieving Superconductivity in Infinite-Layer Nickelate Thin Films by Aluminum Sputtering Deposition. arXiv 2024, arXiv:2411.04896. [Google Scholar]

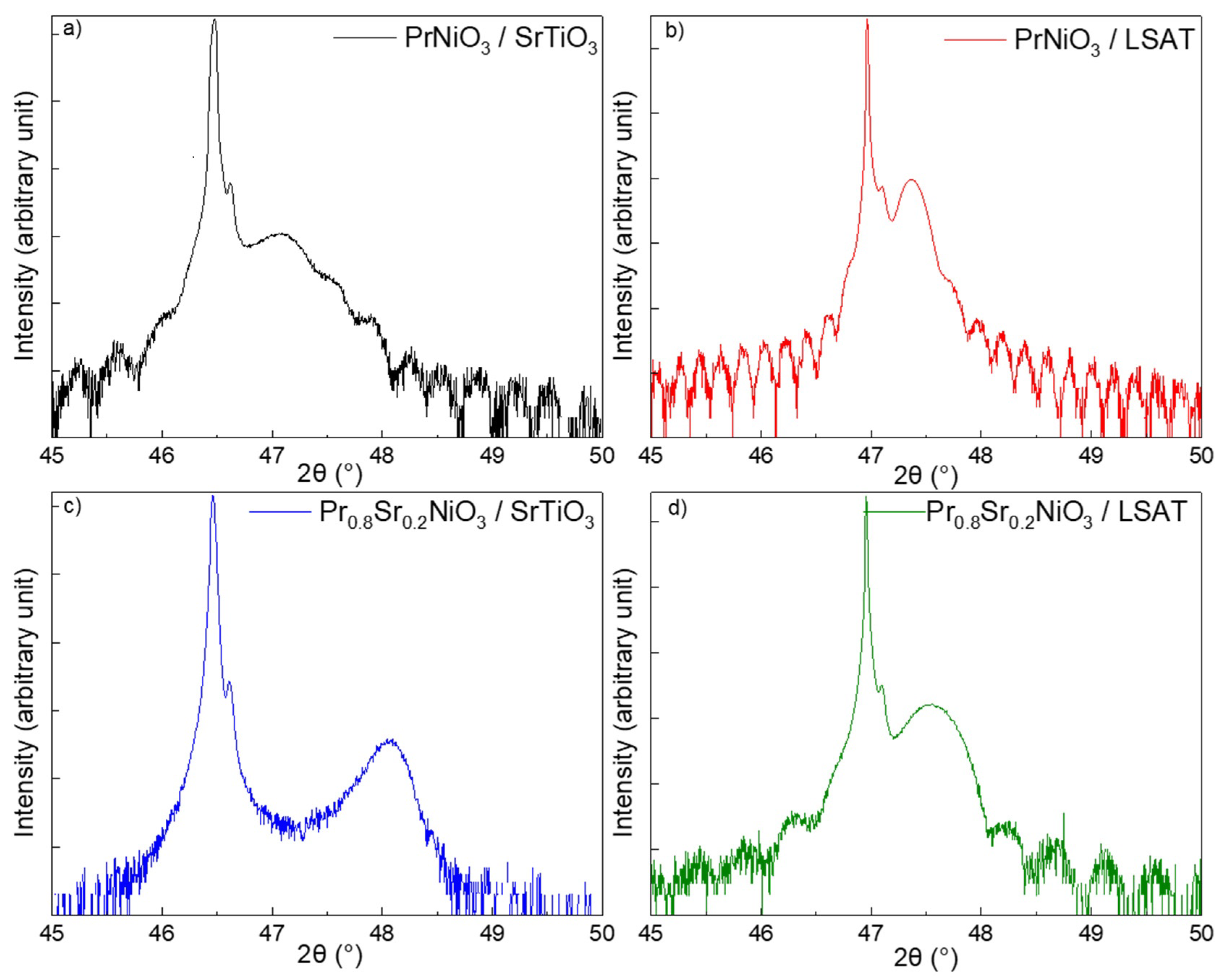

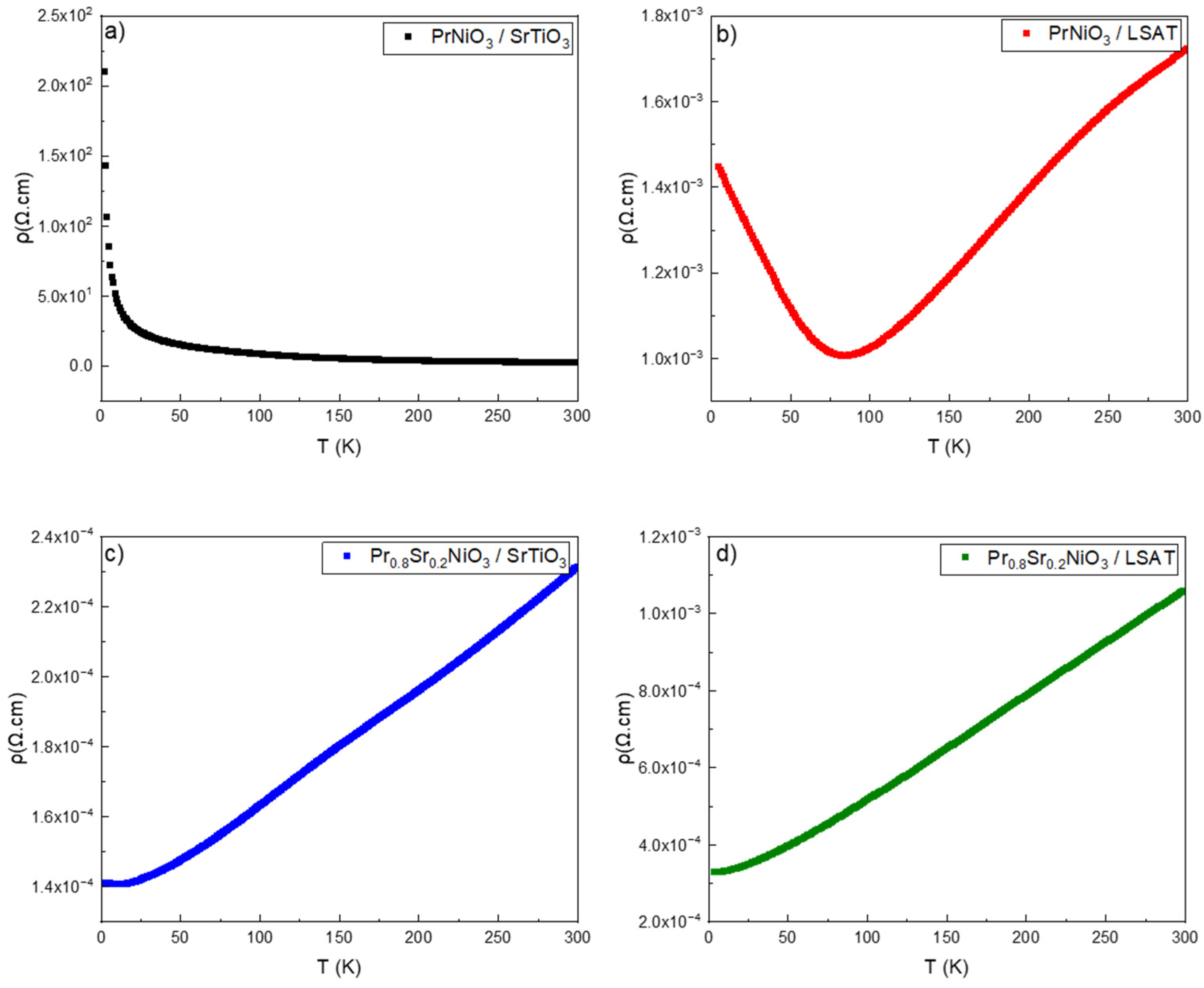

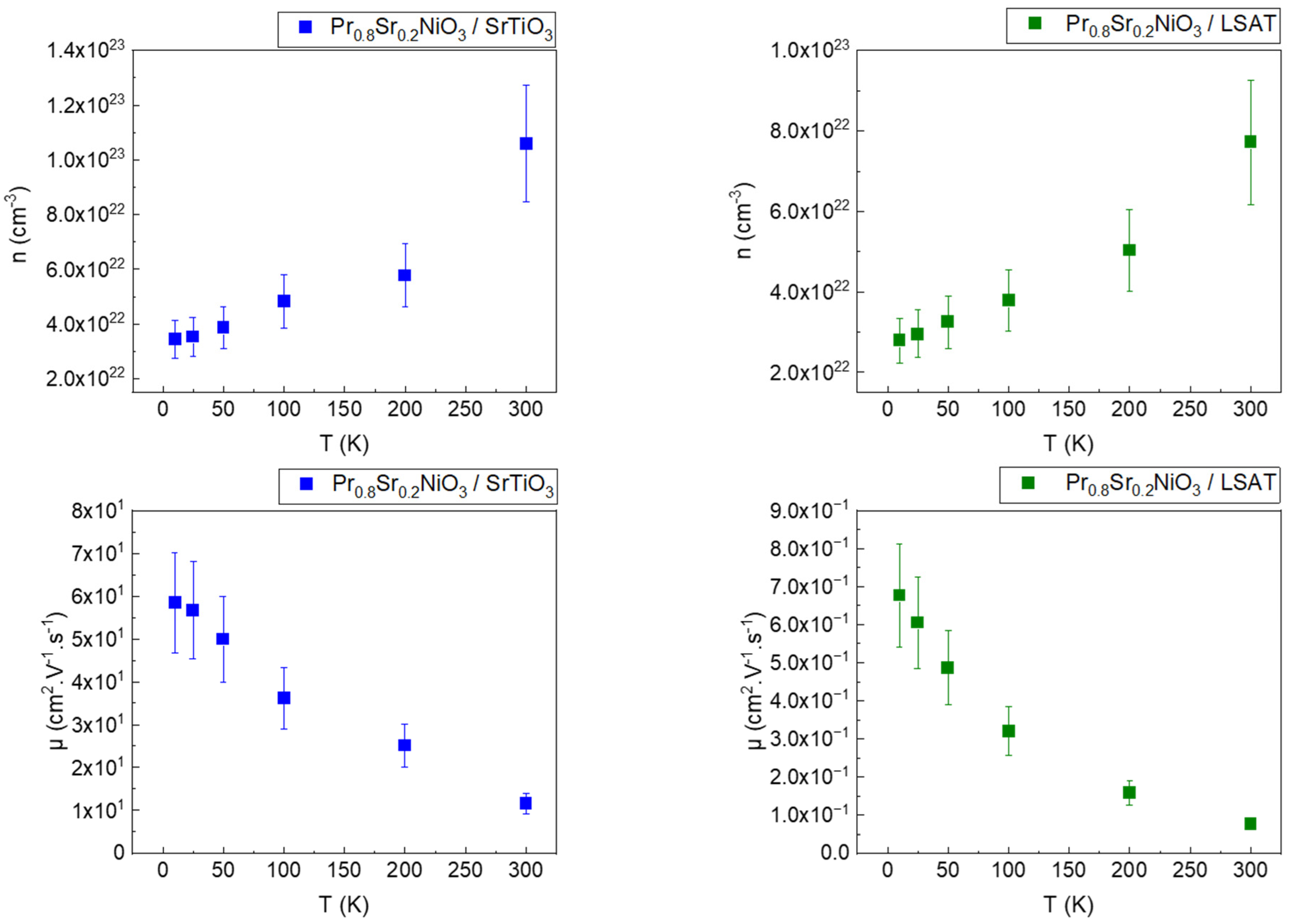

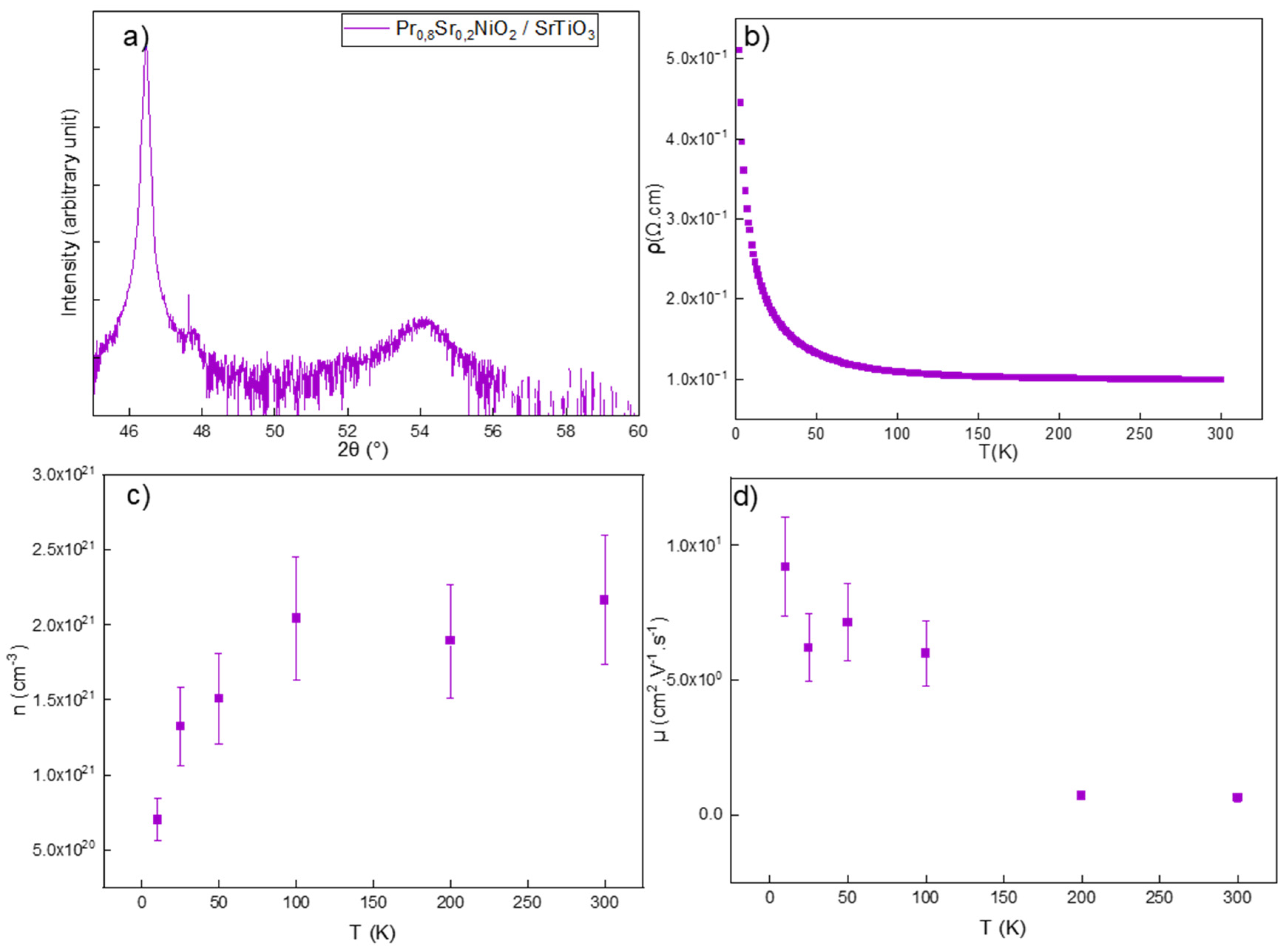

| Composition | Strain (%) |

|---|---|

| PrNiO3/SrTiO3 | 2.18 |

| PrNiO3/LSAT | 1.29 |

| Composition | Out-of-Plane Parameter (Å) |

|---|---|

| PrNiO3/SrTiO3 | 3.857 |

| PrNiO3/LSAT | 3.834 |

| Pr0.8Sr0.2NiO3/SrTiO3 | 3.783 |

| Pr0.8Sr0.2NiO3/LSAT | 3.822 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Misiak, A.; Keenari, M.; Breard, Y.; Prellier, W.; Pautrat, A.; David, A. A Study of the Hall Effect on Doped and Undoped Praseodymium Nickelate Perovskite Thin Films and the Impact of the Reduction Process. Coatings 2025, 15, 287. https://doi.org/10.3390/coatings15030287

Misiak A, Keenari M, Breard Y, Prellier W, Pautrat A, David A. A Study of the Hall Effect on Doped and Undoped Praseodymium Nickelate Perovskite Thin Films and the Impact of the Reduction Process. Coatings. 2025; 15(3):287. https://doi.org/10.3390/coatings15030287

Chicago/Turabian StyleMisiak, Alex, Mufeed Keenari, Yohann Breard, Wilfrid Prellier, Alain Pautrat, and Adrian David. 2025. "A Study of the Hall Effect on Doped and Undoped Praseodymium Nickelate Perovskite Thin Films and the Impact of the Reduction Process" Coatings 15, no. 3: 287. https://doi.org/10.3390/coatings15030287

APA StyleMisiak, A., Keenari, M., Breard, Y., Prellier, W., Pautrat, A., & David, A. (2025). A Study of the Hall Effect on Doped and Undoped Praseodymium Nickelate Perovskite Thin Films and the Impact of the Reduction Process. Coatings, 15(3), 287. https://doi.org/10.3390/coatings15030287