CFD-DPM Model of Gas–Solid Two-Phase Flow Erosion of Needle Throttle Valve

Abstract

1. Introduction

2. Problem Description

3. Methodology

3.1. Gas Phase Model

3.2. Particle Motion Model

3.3. Particle Erosion Model

4. Validation

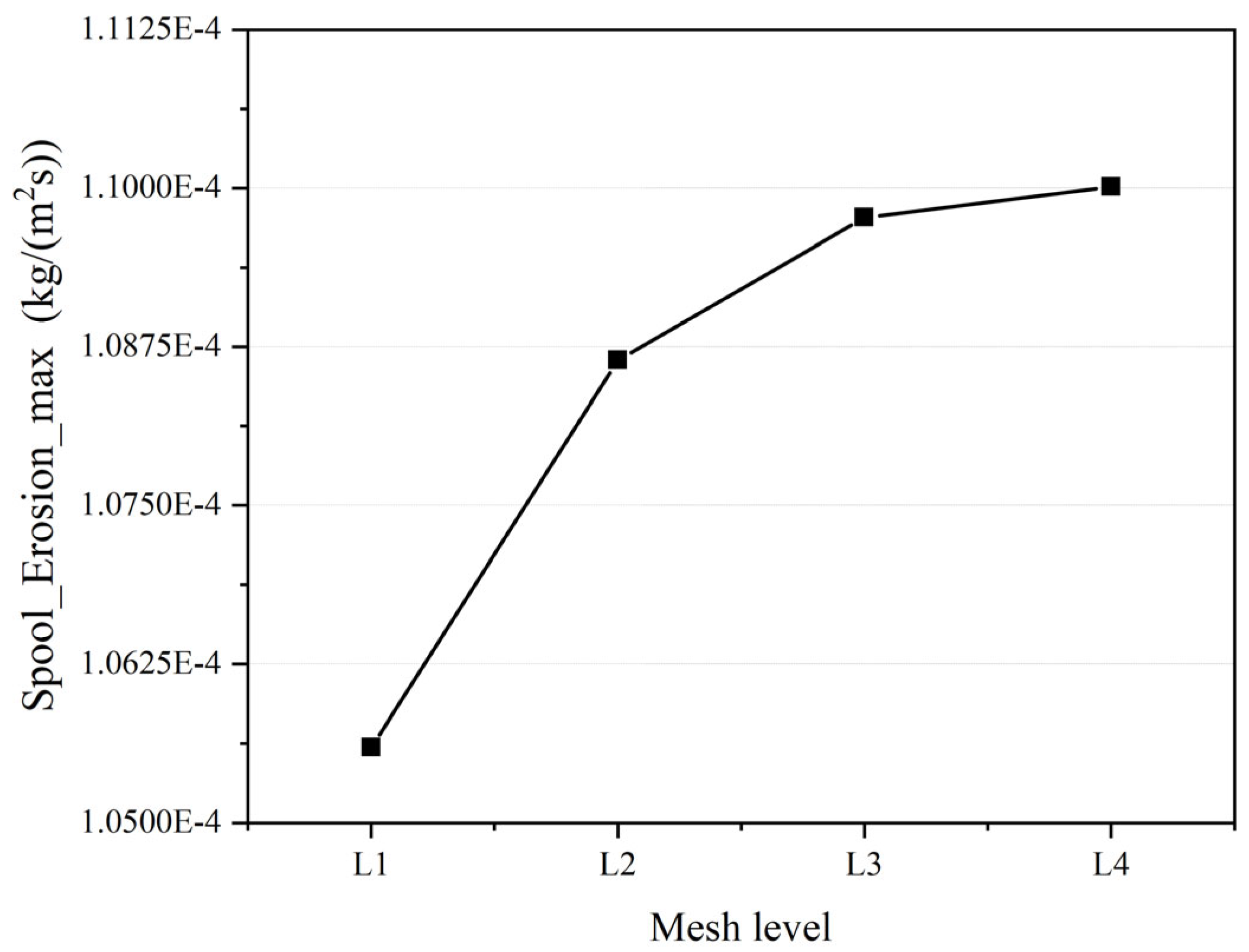

4.1. Mesh Independence

4.2. Flow Erosion Accuracy Validation

5. Result and Discussion

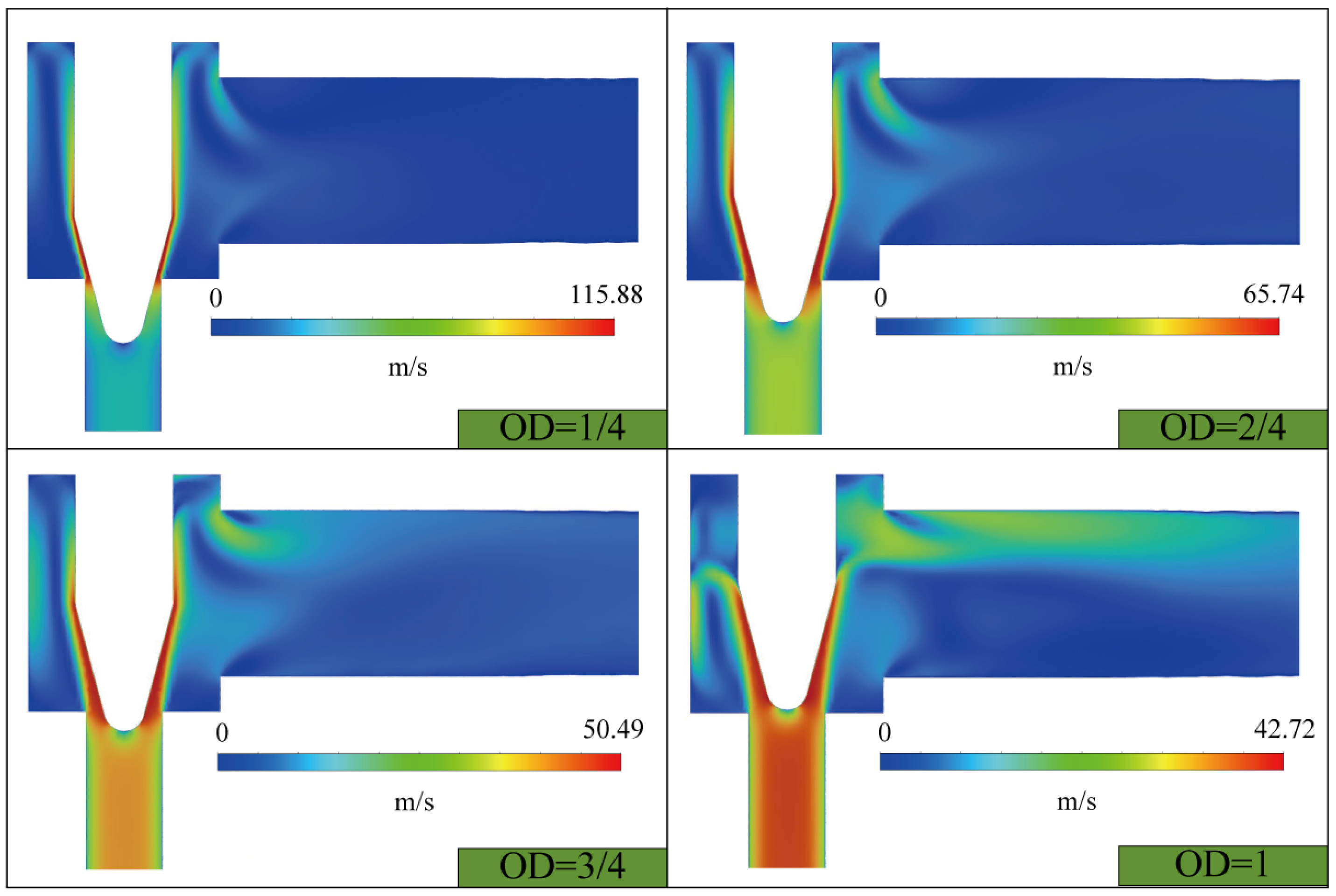

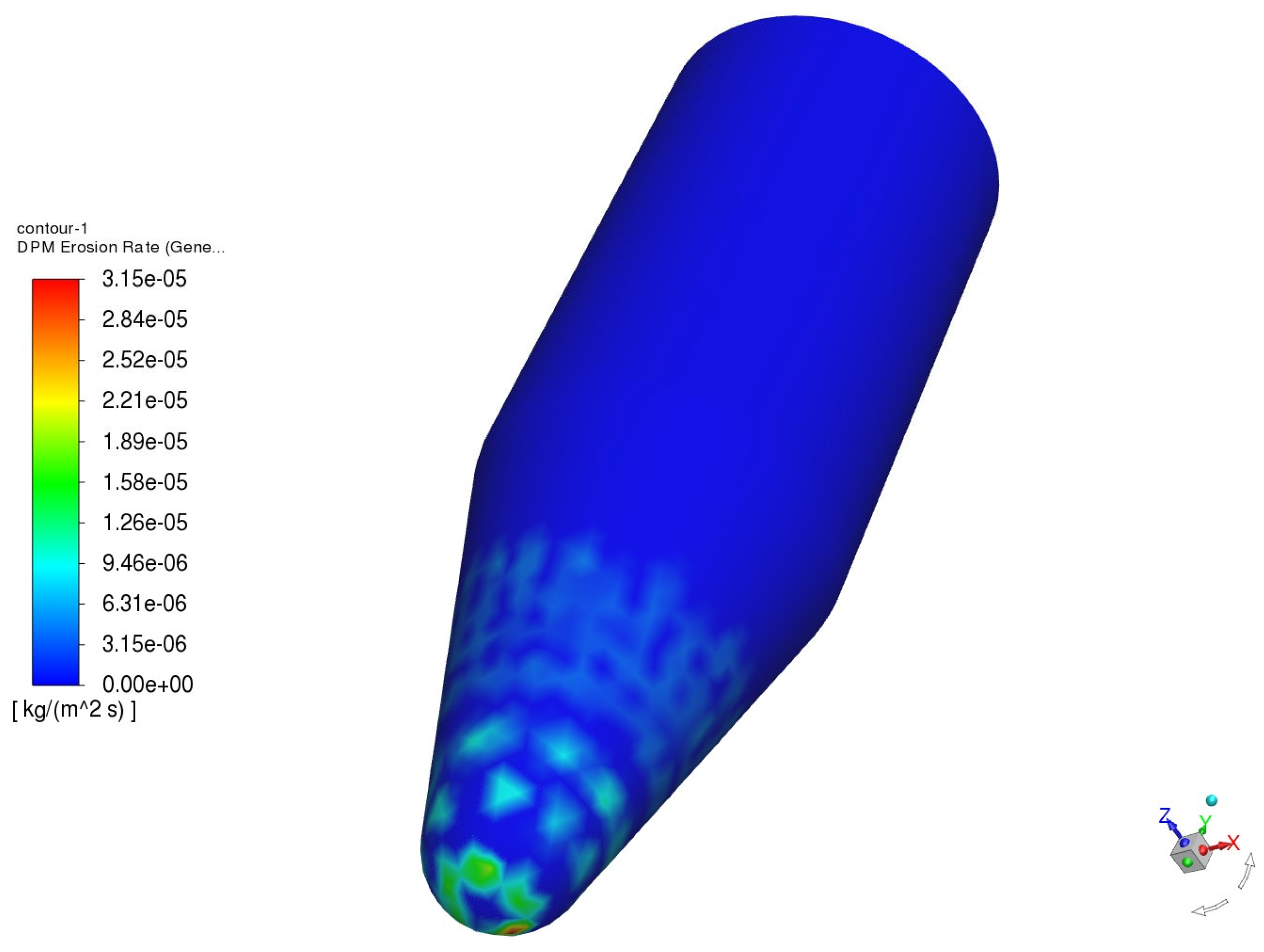

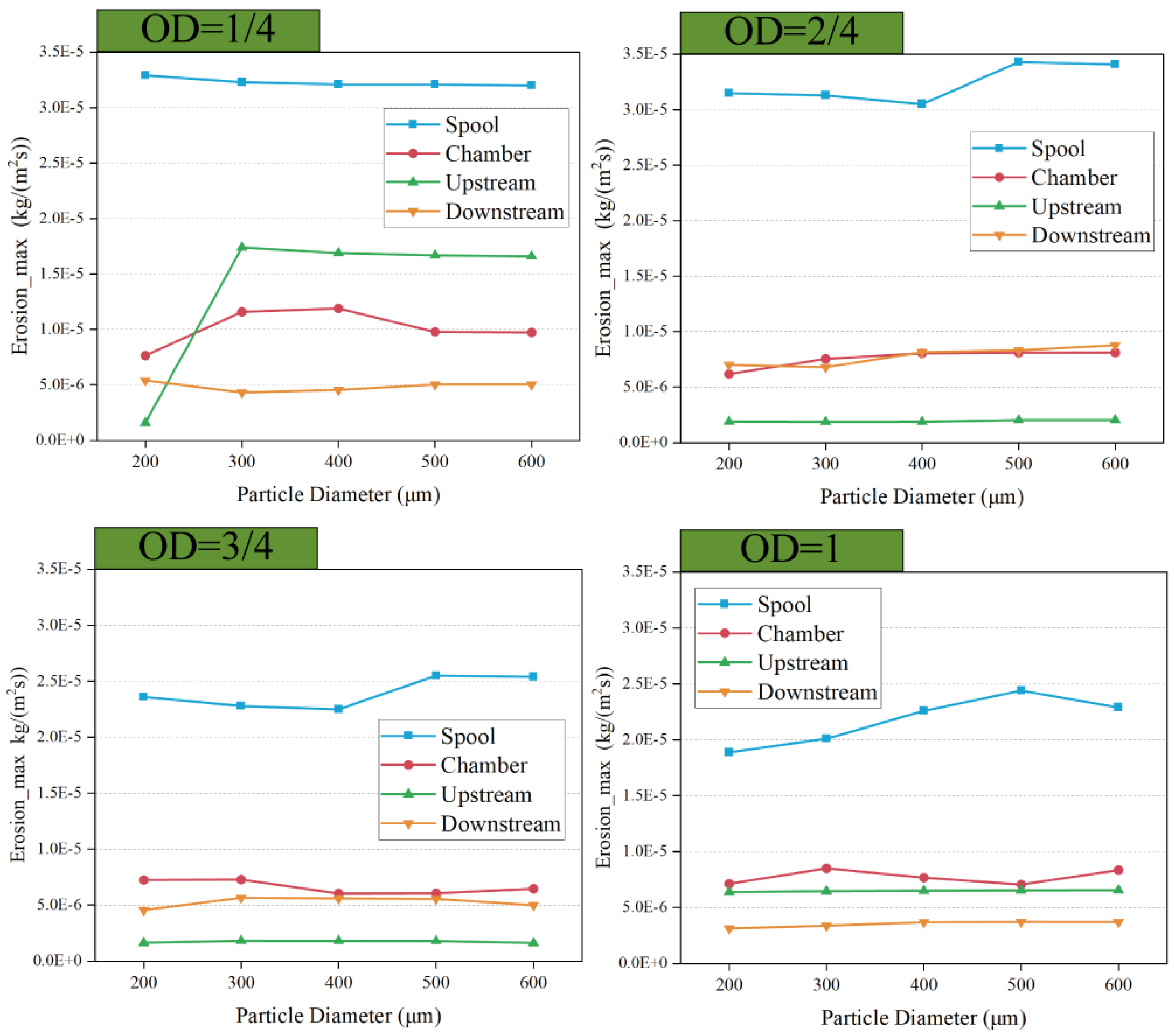

5.1. Effect of Particle Size and Opening on Erosion

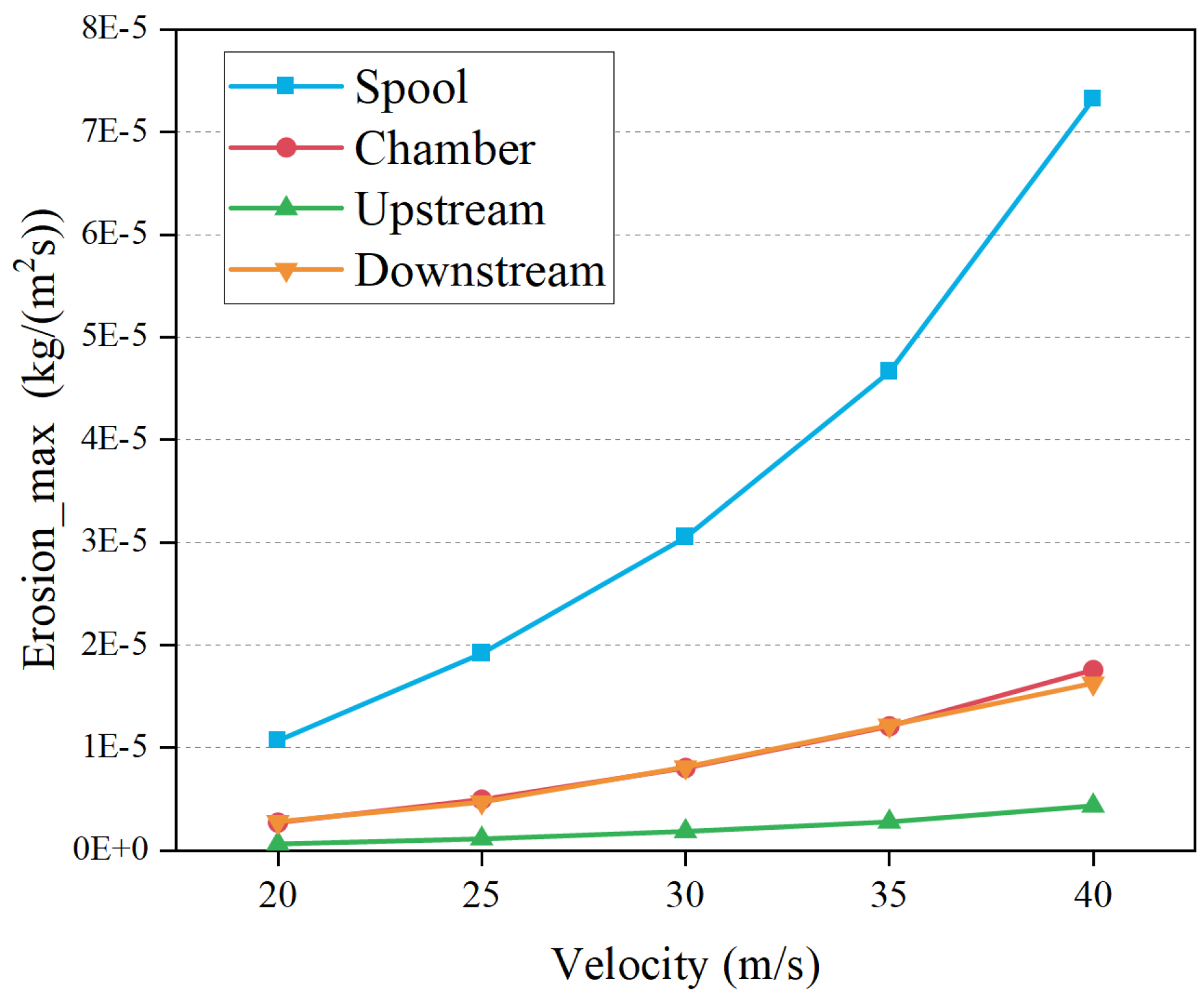

5.2. Effect of Flow Velocity on Erosion

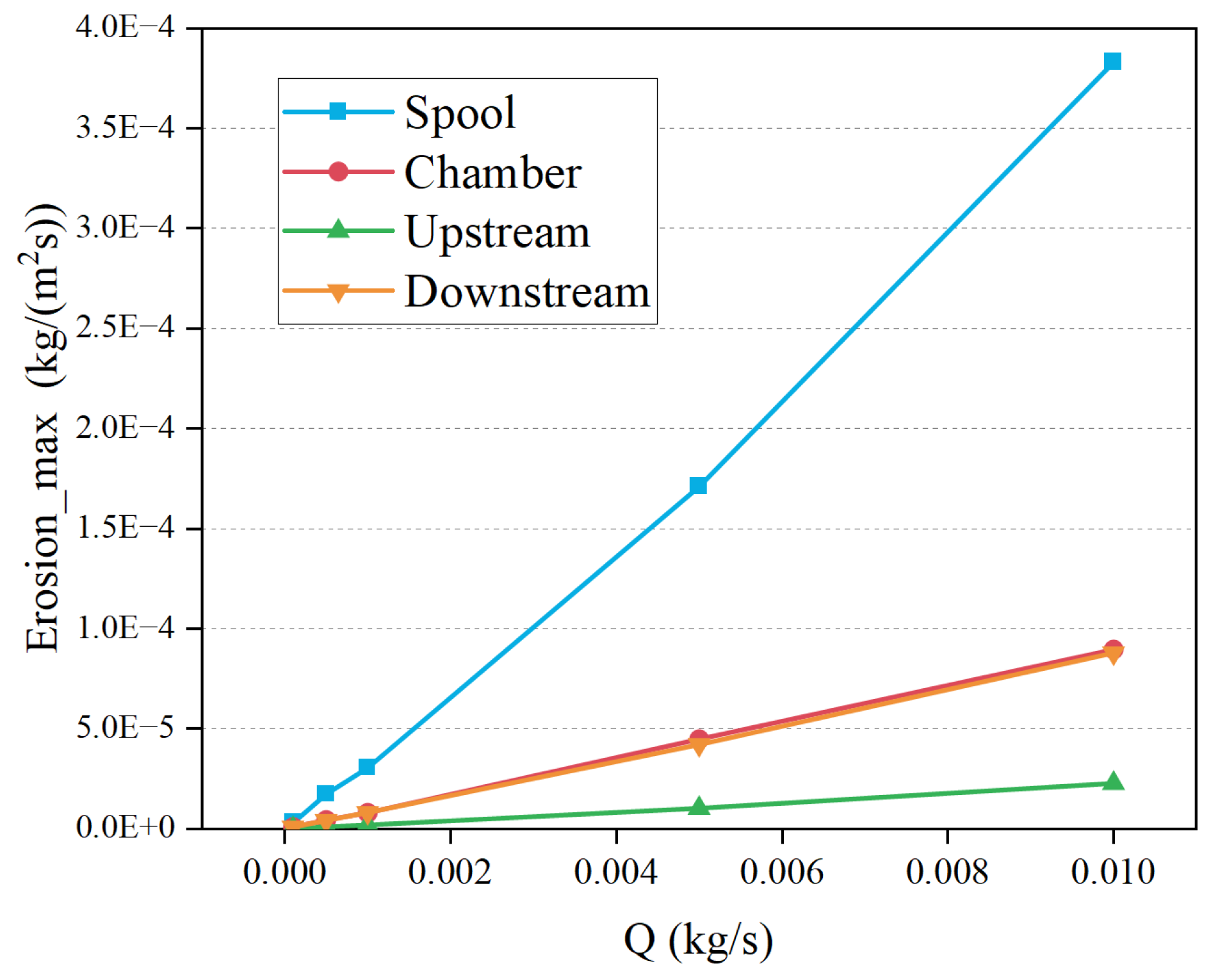

5.3. Effect of Particle Mass Flow Rate on Erosion

6. Conclusions

- Under all operating conditions, the erosion rate of the spool parts is greater than the other parts of the valve.

- The area where the spool is vulnerable to erosion is located at the front of the spool, which provides a reference for the later maintenance of the spool.

- At a 1/4 opening degree, the frequency and energy of the particles re-entering the upstream pipeline after collision with the spool increase significantly.

- When the valve opening is greater than 2/4, the maximum erosion rate of the valve chamber is greater than the upstream and downstream pipes.

- Some particles will fall into the upstream pipe after collision with the upstream pipe or the valve chamber, which can easily cause the blockage of upstream pipes with a narrow inner diameter.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| ave | Average value |

| CFD | Computational fluid dynamics |

| DPM | Discrete phase method |

| NTV | Needle throttle valve |

| OD | Opening degree |

| ) | |

| Particle diameter, (m) | |

| Equivalent Young’s Modulus, (Pa) | |

| Vicker’s hardness, (GPa) | |

| max | Maximum value |

| Static pressure, (Pa) | |

| ) | |

| kg/(m2s) | |

| Stokes number | |

| ) | |

References

- Hong, B.; Wang, C.; Zhang, K.; Lim, J.S.; Varbanov, P.S.; Jia, X.; Ji, M.; Tao, H.; Li, Z.; Wang, B. Carbon Emission Pinch Analysis for Shipping Fuel Planning Considering Multiple Period and Fuel Conversion Rates. J. Clean. Prod. 2023, 415, 137759. [Google Scholar] [CrossRef]

- Wen, K.; Jiao, J.; Zhao, K.; Yin, X.; Liu, Y.; Gong, J.; Li, C.; Hong, B. Rapid Transient Operation Control Method of Natural Gas Pipeline Networks Based on User Demand Prediction. Energy 2023, 264, 126093. [Google Scholar] [CrossRef]

- Liu, E.-B.; Huang, S.; Tian, D.-C.; Shi, L.-M.; Peng, S.-B.; Zheng, H. Experimental and Numerical Simulation Study on the Erosion Behavior of the Elbow of Gathering Pipeline in Shale Gas Field. Pet. Sci. 2024, 21, 1257–1274. [Google Scholar] [CrossRef]

- Zhou, J.; Lian, Z.H.; Wang, Y.H.; Liu, Y.; Wu, J. Failure Analysis and Structure Optimization of Throttle Valve Core. China Pet. Mach 2019, 47, 131–138. [Google Scholar]

- Hong, B.; Li, X.; Li, Y.; Li, Y.; Yu, Y.; Wang, Y.; Gong, J.; Ai, D. Numerical Simulation of Elbow Erosion in Shale Gas Fields under Gas-Solid Two-Phase Flow. Energies 2021, 14, 3804. [Google Scholar] [CrossRef]

- Mohammed, A.I.; Oyeneyin, B.; Atchison, B.; Njuguna, J. Casing Structural Integrity and Failure Modes in a Range of Well Types—A Review. J. Nat. Gas Sci. Eng. 2019, 68, 102898. [Google Scholar] [CrossRef]

- Fu, Y.; Wang, J. Experimental and Computational Failure Analysis of Flow Erosion on New Throttle in Gas Drilling. Pet. Coal 2015, 57, 246–252. [Google Scholar]

- Oka, Y.I.; Okamura, K.; Yoshida, T. Practical Estimation of Erosion Damage Caused by Solid Particle Impact: Part 1: Effects of Impact Parameters on a Predictive Equation. Wear 2005, 259, 95–101. [Google Scholar] [CrossRef]

- Forder, A.; Thew, M.; Harrison, D. A Numerical Investigation of Solid Particle Erosion Experienced within Oilfield Control Valves. Wear 1998, 216, 184–193. [Google Scholar] [CrossRef]

- Parsi, M.; Najmi, K.; Najafifard, F.; Hassani, S.; McLaury, B.S.; Shirazi, S.A. A Comprehensive Review of Solid Particle Erosion Modeling for Oil and Gas Wells and Pipelines Applications. J. Nat. Gas Sci. Eng. 2014, 21, 850–873. [Google Scholar] [CrossRef]

- Hong, B.; Li, Y.; Li, X.; Li, G.; Huang, A.; Ji, S.; Li, W.; Gong, J.; Guo, J. Experimental Investigation of Erosion Rate for Gas-Solid Two-Phase Flow in 304 Stainless/L245 Carbon Steel. Pet. Sci. 2022, 19, 1347–1360. [Google Scholar] [CrossRef]

- Deng, K.; Zhou, N.; Lin, Y.; Cheng, J.; Bing, L.; Jing, Z. Experimental and Numerical Study on the High-Speed Gas-Solid Nozzle Erosion of Choke Manifold Material in High Pressure and High Production Gas Well. Powder Technol. 2024, 438, 119628. [Google Scholar] [CrossRef]

- Wei, S.S.; Lee, M.C.; Chien, Y.H.; Chou, T.H.; Wu, J.S. Experimental Investigation of the Effect of Nozzle Throat Diameter on the Performance of a Hybrid Rocket Motor with Swirling Injection of High-Concentration Hydrogen Peroxide. Acta Astronaut. 2019, 164, 334–344. [Google Scholar] [CrossRef]

- Hong, B.; Li, Y.; Li, X.; Ji, S.; Yu, Y.; Fan, D.; Qian, Y.; Guo, J.; Gong, J. Numerical Simulation of Gas-Solid Two-Phase Erosion for Elbow and Tee Pipe in Gas Field. Energies 2021, 14, 6609. [Google Scholar] [CrossRef]

- Hong, B.; Li, Y.; Li, Y.; Gong, J.; Yu, Y.; Huang, A.; Li, X. Numerical Simulation of Solid Particle Erosion in the Gas-Liquid Flow of Key Pipe Fittings in Shale Gas Fields. Case Stud. Therm. Eng. 2023, 42, 102742. [Google Scholar] [CrossRef]

- Ou, G.; Cao, X.; Wang, C.; Duan, A.; Jin, H. CFD-DEM-Based Numerical Simulation of Erosion Characteristic of Multistage Pressure Relief String Regulating Valve. J. Appl. Fluid Mech. 2022, 15, 999–1015. [Google Scholar] [CrossRef]

- Perera, P.; Hayward, K.; Guzzomi, F.; Vafadar, A. Erosion Wear Characterisation of an Open Ductile Iron Butterfly Valve Subjected to Aluminium Oxide Particle Slurry Flow. Tribol. Int. 2024, 191, 109199. [Google Scholar] [CrossRef]

- Hu, G.; Zhang, P.; Wang, G.; Zhu, H.; Li, Q.; Zhao, S.; Qiao, K.; Wang, T. Performance Study of Erosion Resistance on Throttle Valve of Managed Pressure Drilling. J. Pet. Sci. Eng. 2017, 156, 29–40. [Google Scholar] [CrossRef]

- Wang, G.R.; Chu, F.; Tao, S.Y.; Jiang, L.; Zhu, H. Optimization Design for Throttle Valve of Managed Pressure Drilling Based on CFD Erosion Simulation and Response Surface Methodology. Wear 2015, 338–339, 114–121. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, W.; Sun, F.; Yu, Y.; Zhou, W.; Tan, H. Simulation and Structure Optimization of WC–Co Cemented Carbide Cage-Sleeve Type Throttle Valve Core Erosion. Trans. Indian Inst. Met. 2024, 77, 69–79. [Google Scholar] [CrossRef]

- Guo, L.; Wang, Y.; Xu, X.; Gao, H.; Yang, H.; Han, G. Study on the Erosion of Choke Valves in High-Pressure, High-Temperature Gas Wells. Processes 2022, 10, 2139. [Google Scholar] [CrossRef]

- Ma, H.; Jiang, Y.; Yin, Q.; Zhang, F.; Chen, S.; Lv, Y.; Lei, G. Investigation on Erosion Resistance of Downhole Throttle with Ultra-High Pressure. IOP Conf. Ser. Earth Environ. Sci. 2020, 453, 12059. [Google Scholar] [CrossRef]

- Rong, Z.; Zhao, C.; Zihan, Z.; Qiyu, H.; Pengbo, H.; Kuan, S. Simulation and Optimization Design of Tubular Throttle Valve Based on SolidWorks. Int. J. Front. Eng. Technol. 2023, 5, 050602. [Google Scholar] [CrossRef]

- Tarasevych, Y.; Sovenko, N. Modelling the Influence of Cylindrical Throttle Erosion Wear on Characteristics of Automatic Balancing Device. Tribologia 2019, 3, 107–113. [Google Scholar] [CrossRef]

- Hutchings, I.M.; Winter, R.E.; Field, J.E.; Tabor, D. Solid Particle Erosion of Metals: The Removal of Surface Material by Spherical Projectiles. Proc. R. Soc. London. A. Math. Phys. Sci. 1997, 348, 379–392. [Google Scholar] [CrossRef]

- Levy, A.V.; Chik, P. The Effects of Erodent Composition and Shape on the Erosion of Steel. Wear 1983, 89, 151–162. [Google Scholar] [CrossRef]

- Bruno, A.D.; Batkhin, A.B. Survey of Eight Modern Methods of Hamiltonian Mechanics. Axioms 2021, 10, 293. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, C.; Lang, R.; Li, Y.; Hong, B. The Distribution of Components in Hydrogen-Blended Pipelines under Different Gas Stream Injection Pattern. Fuel 2024, 375, 132577. [Google Scholar] [CrossRef]

- Lin, Z.; Sun, X.; Yu, T.; Zhang, Y.; Li, Y.; Zhu, Z. Gas–solid Two-Phase Flow and Erosion Calculation of Gate Valve Based on the CFD-DEM Model. Powder Technol. 2020, 366, 395–407. [Google Scholar] [CrossRef]

- Gosman, A.D.; Loannides, E. Aspects of Computer Simulation of Liquid-Fueled Combustors. J. Energy 1983, 7, 482–490. [Google Scholar] [CrossRef]

- Zhu, H.; Pan, Q.; Zhang, W.; Feng, G.; Li, X. CFD Simulations of Flow Erosion and Flow-Induced Deformation of Needle Valve: Effects of Operation, Structure and Fluid Parameters. Nucl. Eng. Des. 2014, 273, 396–411. [Google Scholar] [CrossRef]

| Unit | Gas Stream | Particle | Valve | |

|---|---|---|---|---|

| Material | CH4 | Sand | Steel | |

| ) | kg/m3 | 0.6679 | 2800 | 8030 |

| ) | 10−5 |

| Point | Angle | Value |

|---|---|---|

| 1 | 0 | 0 |

| 2 | 20 | 0.8 |

| 3 | 30 | 1 |

| 4 | 45 | 0.5 |

| 5 | 90 | 0.4 |

| Mesh Level | Boi Mesh | Surface Mesh | Mesh Quantity | Minimum Orthogonality Quality | Maximum Aspect Ratio |

|---|---|---|---|---|---|

| L1 | 3 | 3/24 | 242,461 | 0.30 | 59.6 |

| L2 | 2.5 | 2.5/20 | 368,219 | 0.34 | 37.1 |

| L3 | 2 | 2/16 | 670,224 | 0.38 | 34.2 |

| L4 | 1.5 | 1.5/12 | 1,295,620 | 0.40 | 29.7 |

| Case | OD | (μm) | (m/s) | (kg/s) |

|---|---|---|---|---|

| 1 | 1/4, 1/2, 3/4, 1 | - | 30 | 0 |

| 2 | 1/4 | 200, 300, 400, 500, 600 | 30 | |

| 3 | 1/2 | 200, 300, 400, 500, 600 | 30 | |

| 4 | 3/4 | 200, 300, 400, 500, 600 | 30 | |

| 5 | 1 | 200, 300, 400, 500, 600 | 30 | |

| 6 | 1/2 | 400 | 20, 25, 35, 40 | |

| 7 | 1/2 | 400 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Wu, Z.; Wang, W.; Wang, X.; Du, S.; Chen, X.; Li, P.; Wang, Y. CFD-DPM Model of Gas–Solid Two-Phase Flow Erosion of Needle Throttle Valve. Coatings 2025, 15, 248. https://doi.org/10.3390/coatings15020248

Zhao Z, Wu Z, Wang W, Wang X, Du S, Chen X, Li P, Wang Y. CFD-DPM Model of Gas–Solid Two-Phase Flow Erosion of Needle Throttle Valve. Coatings. 2025; 15(2):248. https://doi.org/10.3390/coatings15020248

Chicago/Turabian StyleZhao, Zhihui, Zhe Wu, Weiqiang Wang, Xingyu Wang, Shengnan Du, Xianlei Chen, Panfeng Li, and Yingying Wang. 2025. "CFD-DPM Model of Gas–Solid Two-Phase Flow Erosion of Needle Throttle Valve" Coatings 15, no. 2: 248. https://doi.org/10.3390/coatings15020248

APA StyleZhao, Z., Wu, Z., Wang, W., Wang, X., Du, S., Chen, X., Li, P., & Wang, Y. (2025). CFD-DPM Model of Gas–Solid Two-Phase Flow Erosion of Needle Throttle Valve. Coatings, 15(2), 248. https://doi.org/10.3390/coatings15020248