Microstructure and Mechanical Properties of a Novel Lightweight and Heat-Resistant Al-3.0Ce-0.9Ca-1.9Mn-1.2Zr Alloy Fabricated by Selective Laser Melting

Abstract

1. Introduction

2. Experimental Procedure

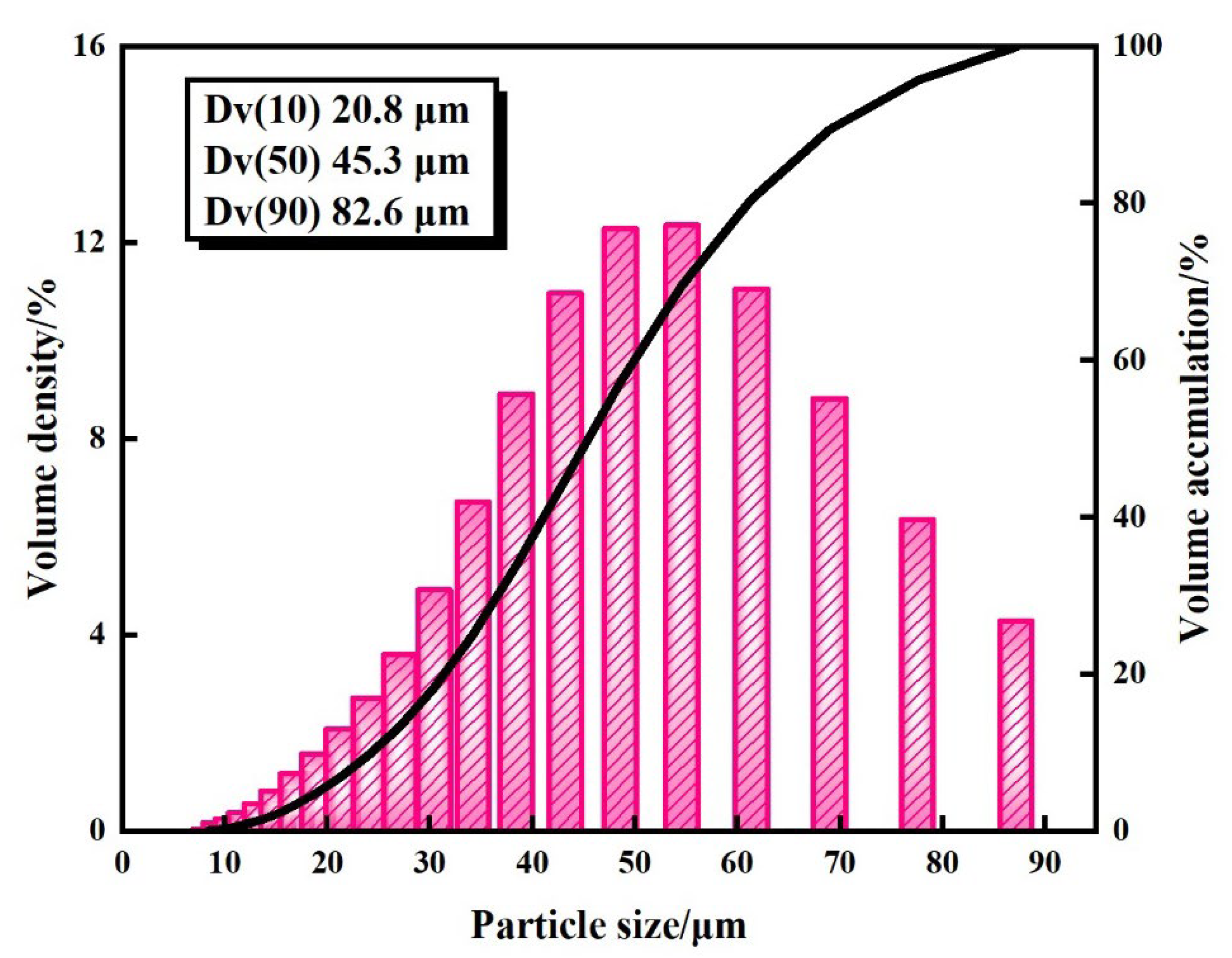

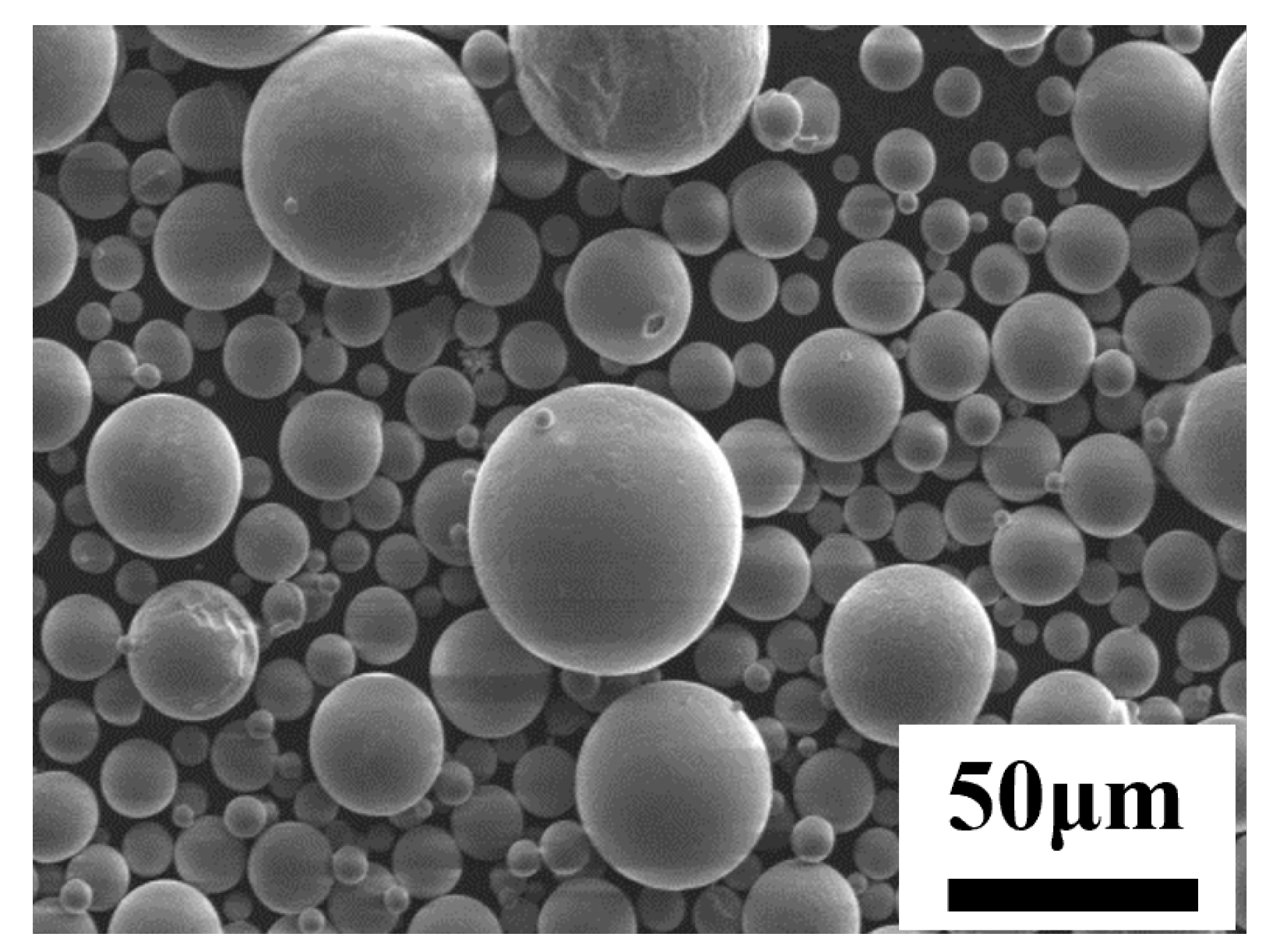

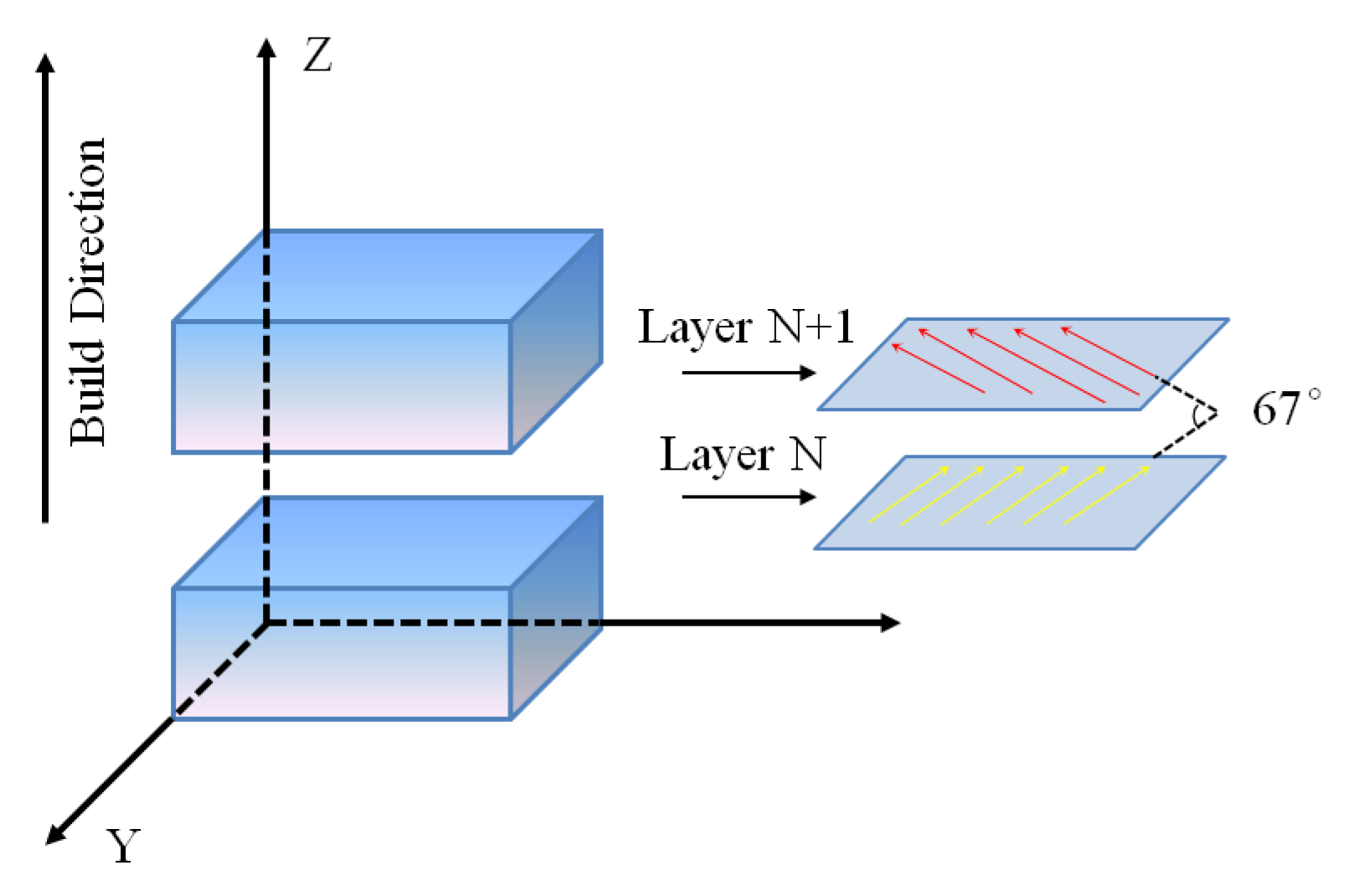

Materials and Processing

3. Results and Discussion

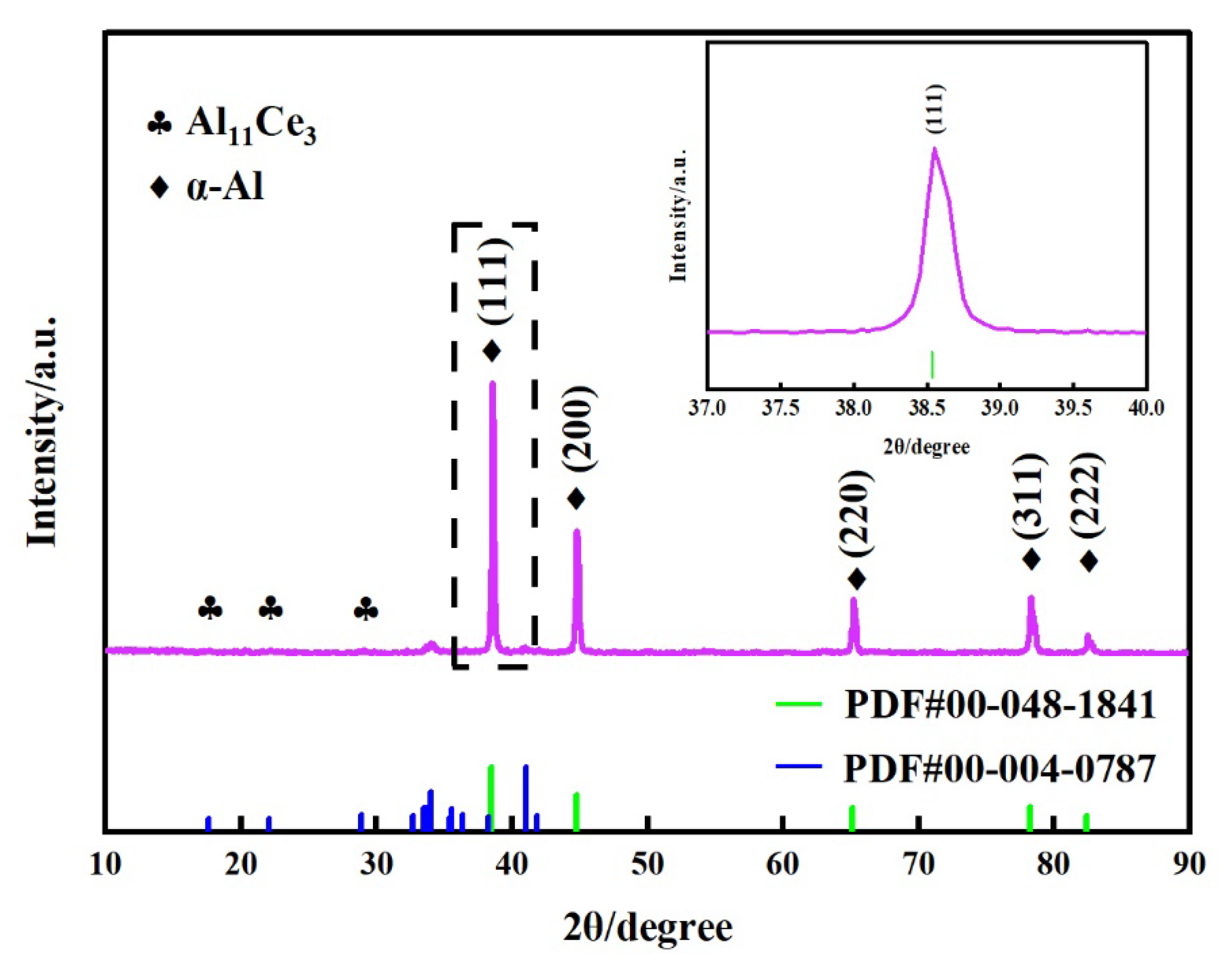

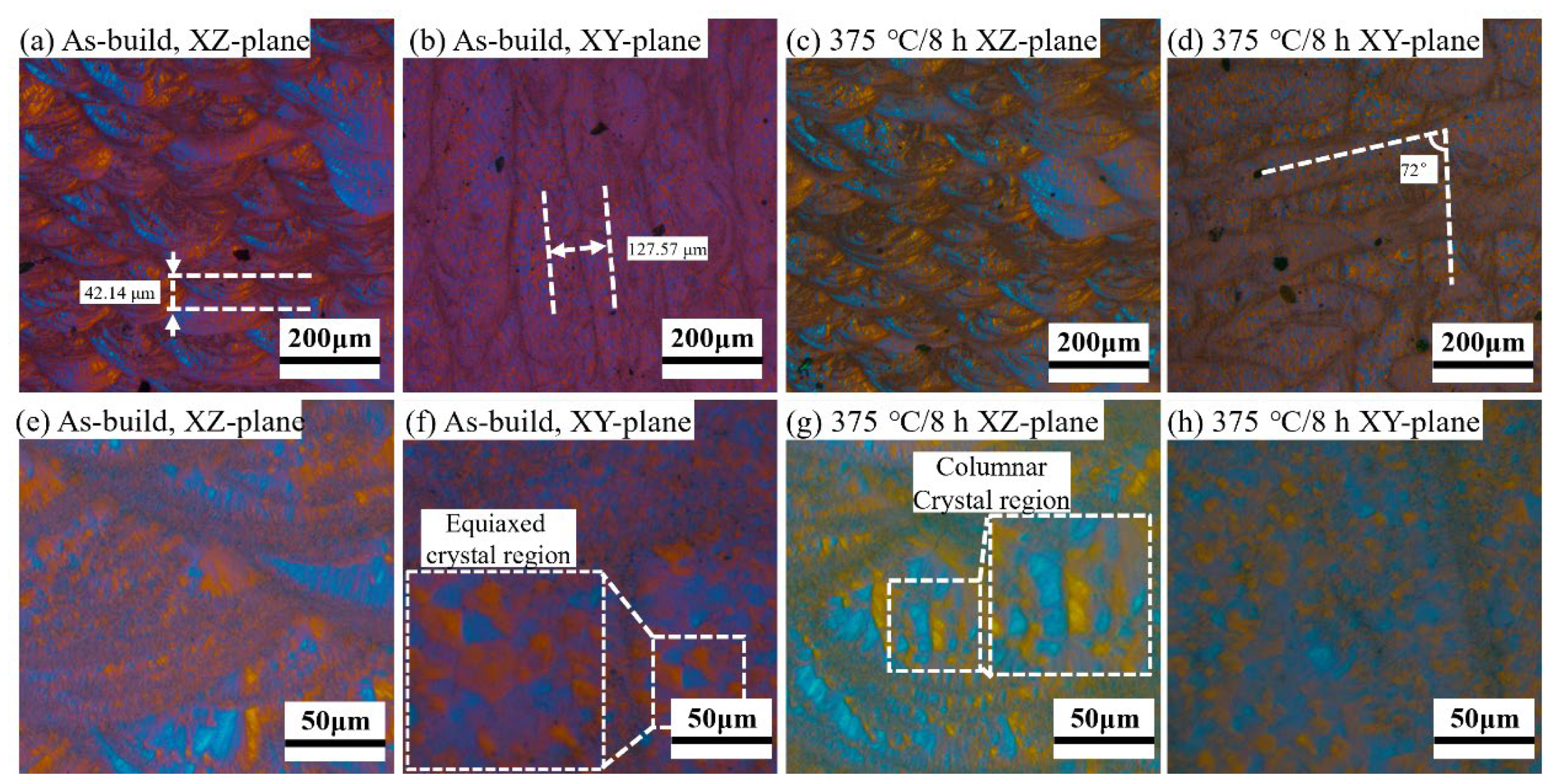

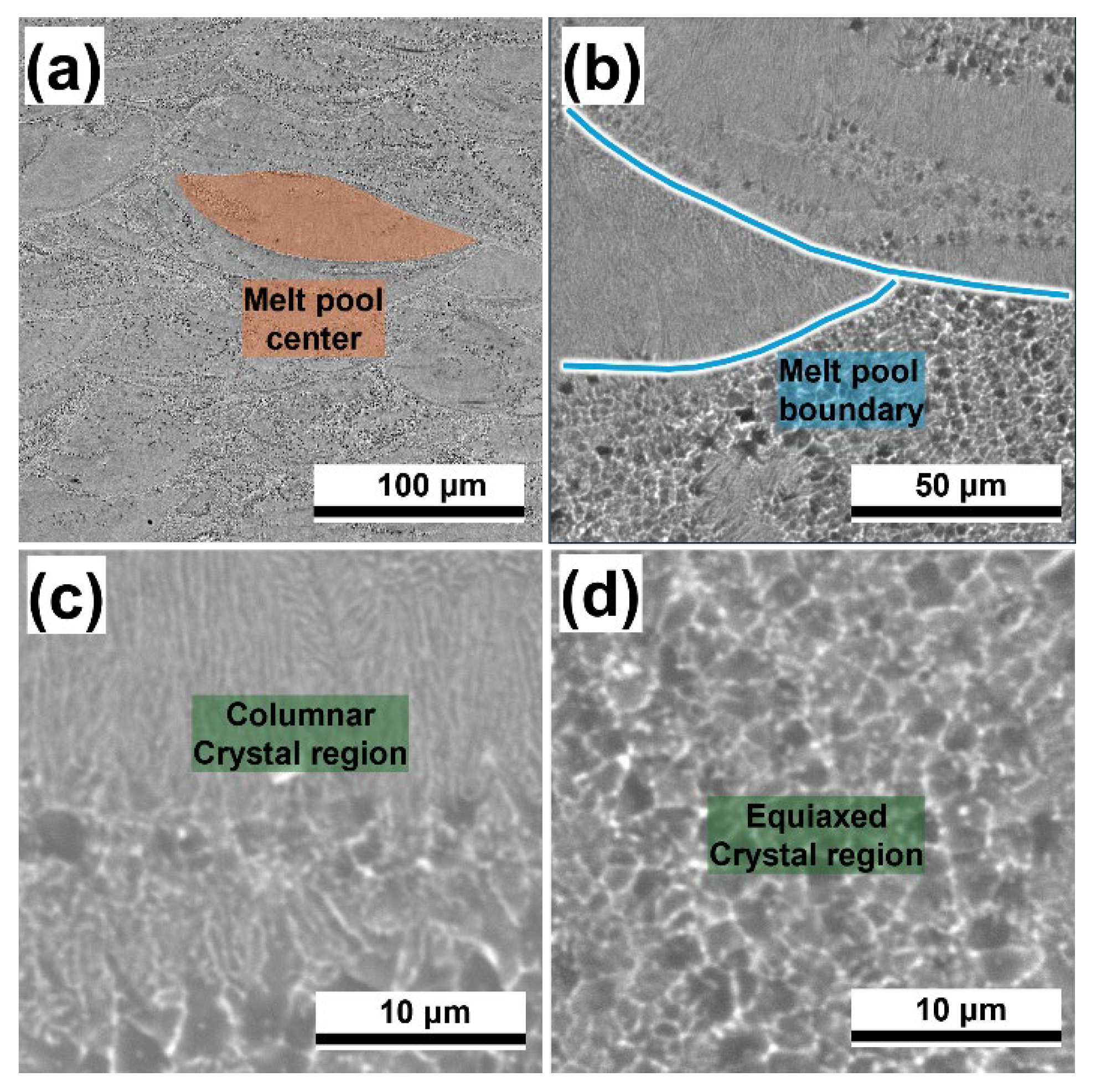

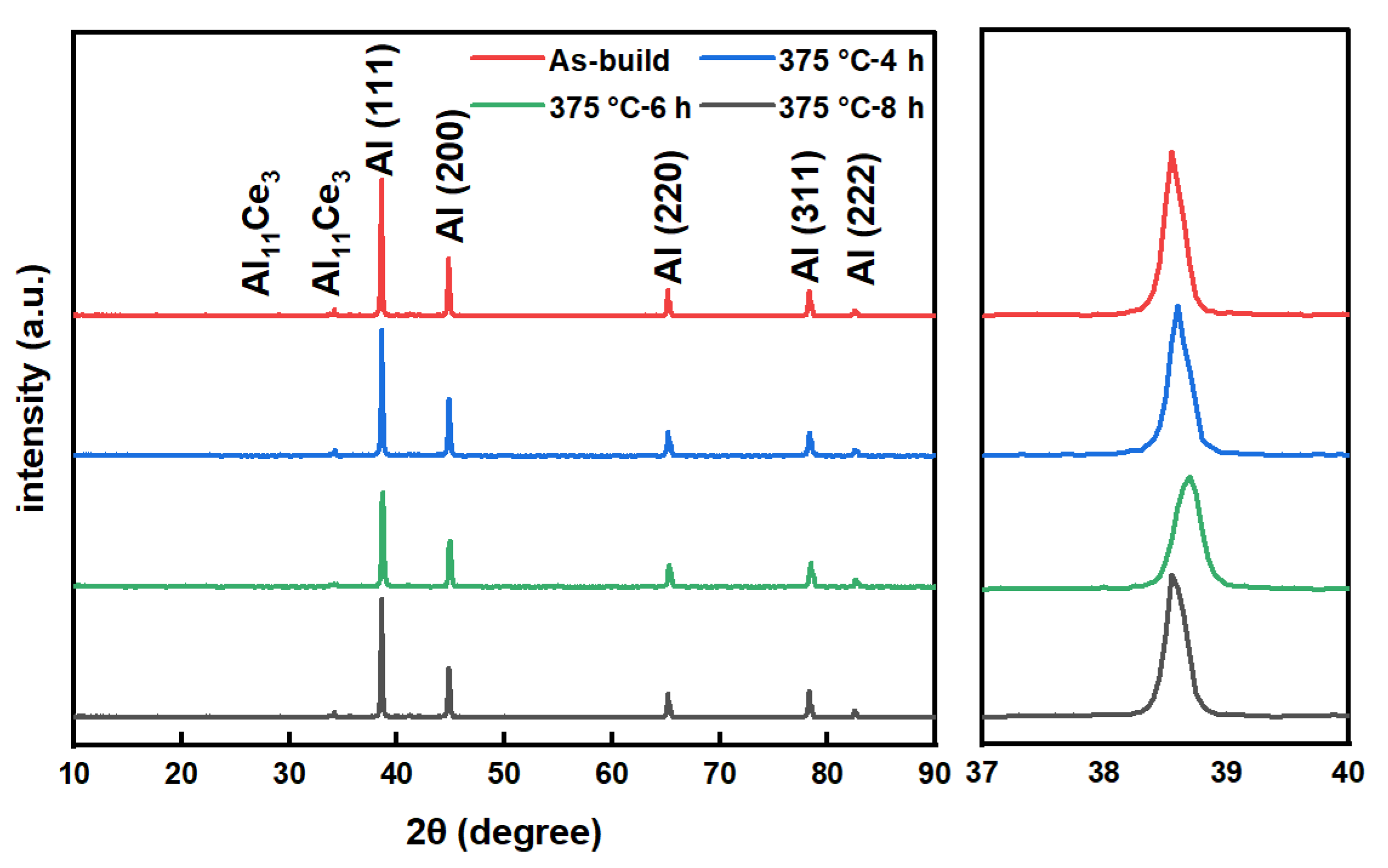

3.1. Microstructural Analysis

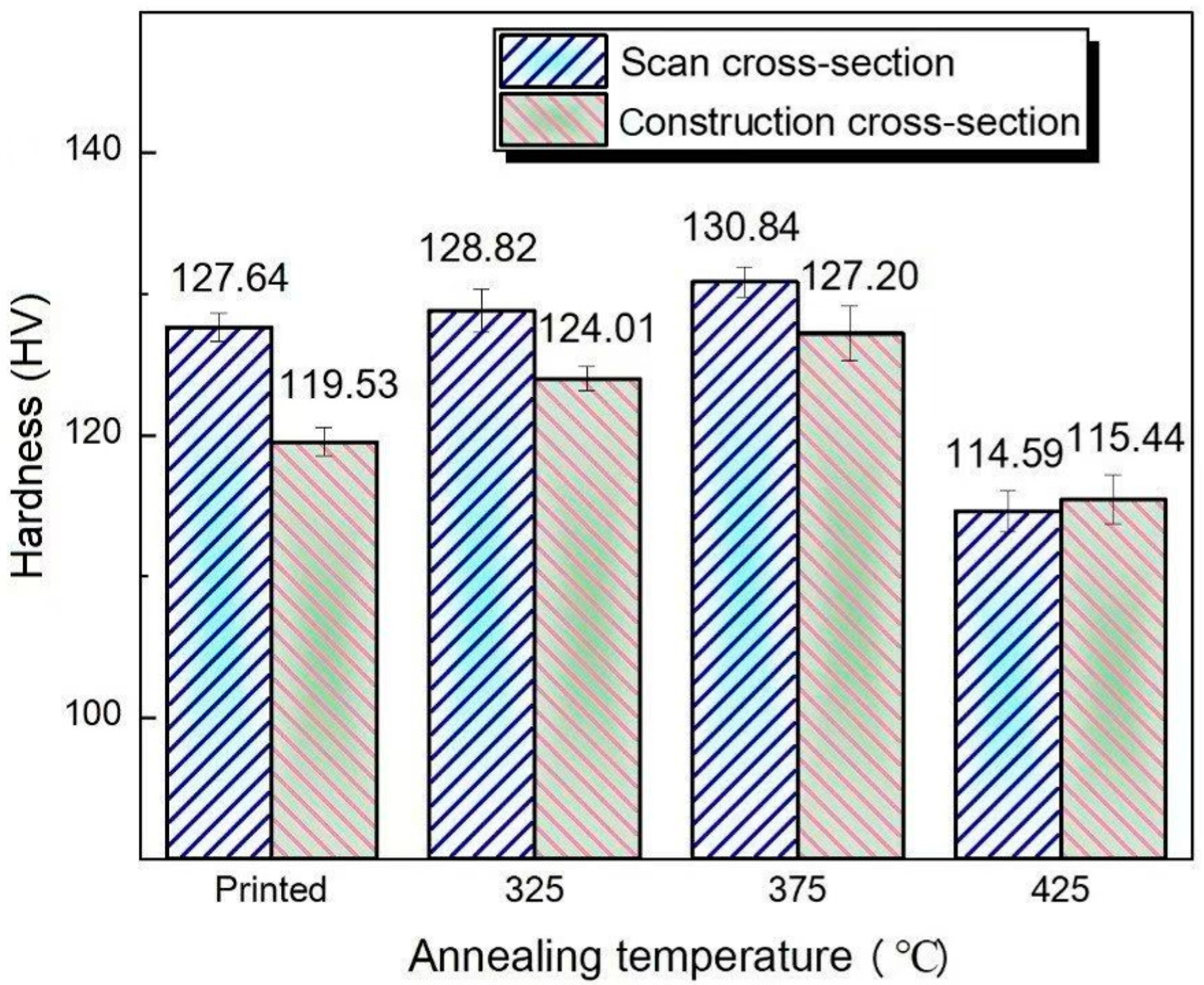

3.2. Hardness

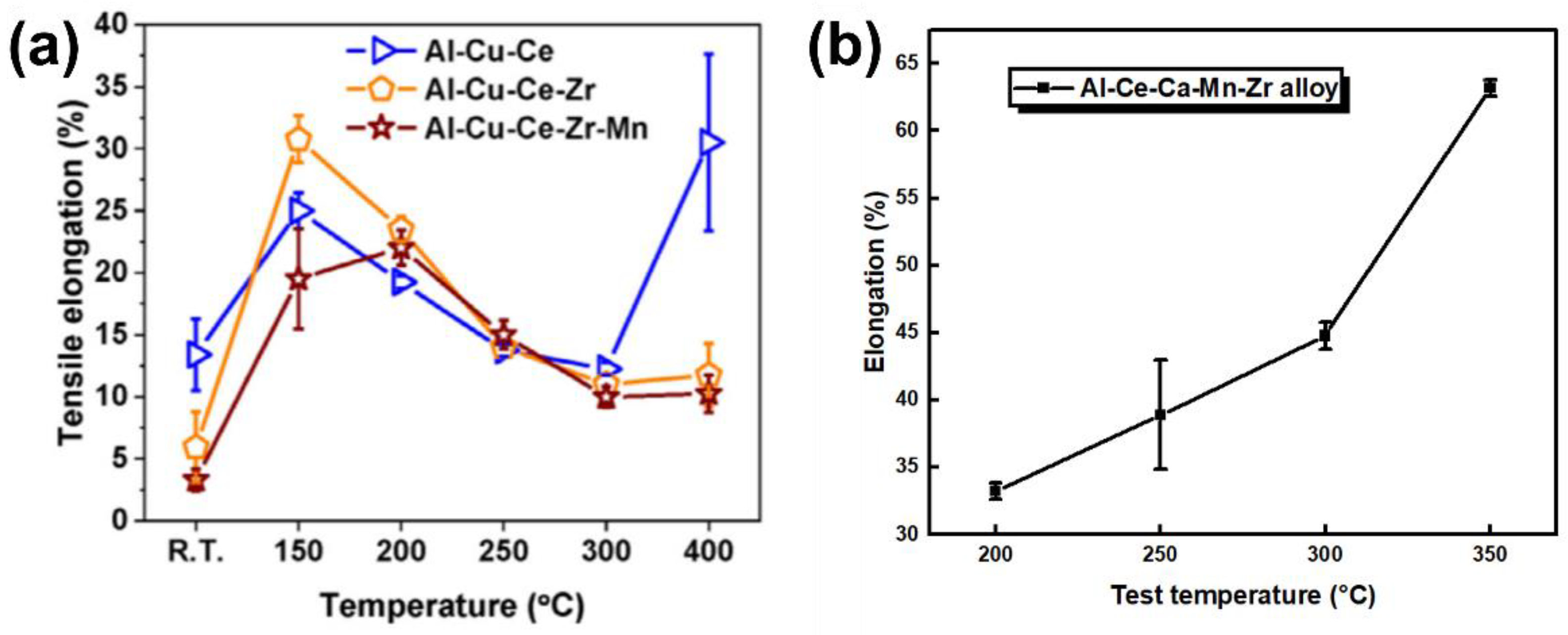

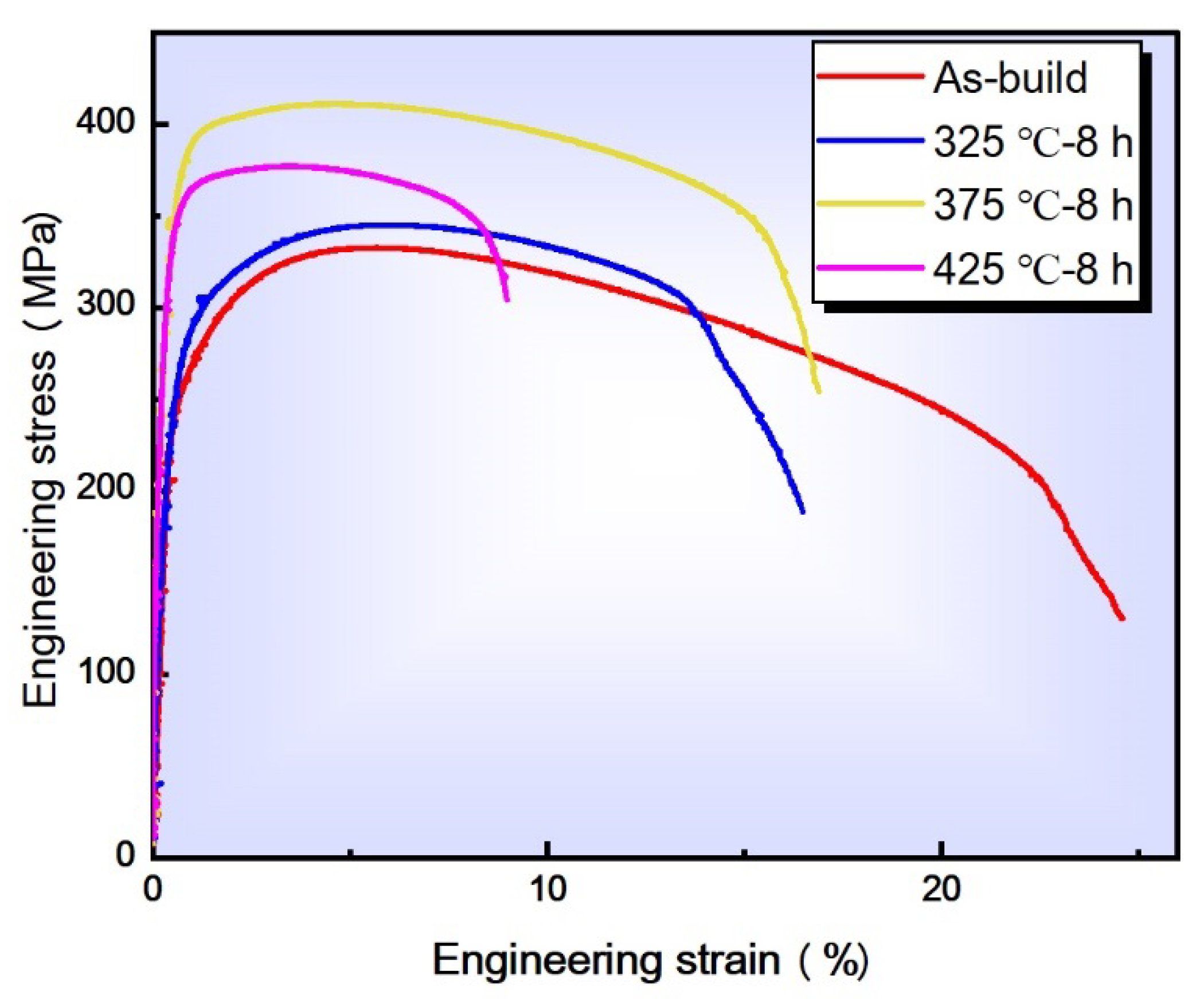

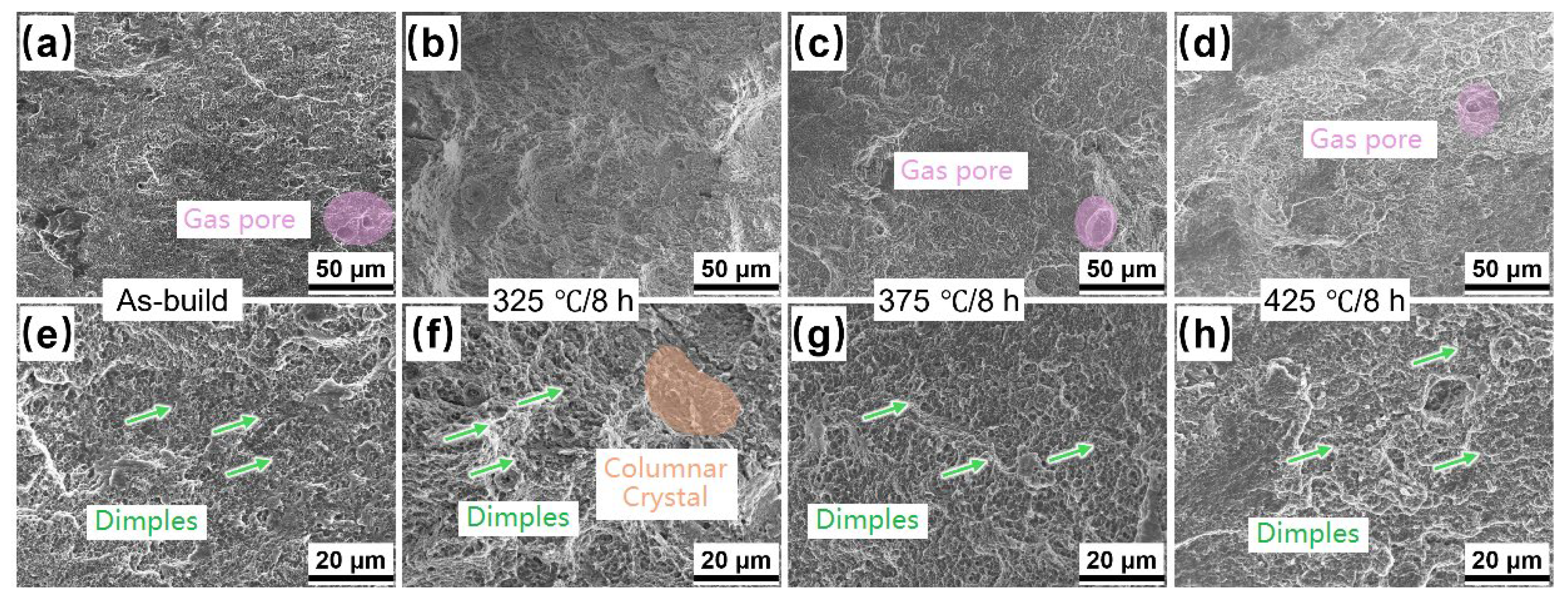

3.3. Tensile Property

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Buchanan, C.; Gardenr, L. Metal 3D printing in construction: A review methods, research, applications, opportunities and challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Dalmau, A.; Richard, C.; Igual–Munoz, A. Degradation mechanisms in martensitic stainless steels: Wear, corrosion and tribocorrosion appraisal. Tribol. Int. 2018, 121, 167. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Z.; Chen, J.; Ma, Y.; Yan, Y.; Qiao, L. Effect of frictional frequency on the subsurface evolution of 316 L stainless steel in tribocorrosion and its influence on the synergistic effect between corrosion and wear. Tribol. Int. 2023, 178, 108026. [Google Scholar] [CrossRef]

- Cajner, F.; Kovacic, S.; Rafael, H.; Vugrinčić, A.; Šimunović, V.; Gržeta, B. Influence of nitriding on corrosion resistance of martensitic X17CrNi16-2 stainless steel. Mater. Werkst. 2015, 46, 69. [Google Scholar] [CrossRef]

- Guo, S.; Li, Y.; Gu, J.; Liu, J.; Peng, Y.; Wang, P.; Zhou, Q.; Wang, K. Microstructure and mechanical properties of Ti6Al4V/B4C titanium matrix composite fabricated by selective laser melting (SLM). J. Mater. Res. Technol. 2023, 23, 1934–1946. [Google Scholar] [CrossRef]

- Cain, V.; Thijs, L.; Van Humbeeck, J.; Van Hooreweder, B.; Knutsen, R. Crack propagation and fracture toughness of Ti6Al4V alloy produced by selective laser melting. Addit. Manuf. 2015, 5, 68–76. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Pramanik, A.; Basak, A.K.; Dong, Y.; Prakash, C.; Debnath, S.; Shankar, S.; Jawahir, I.S.; Dixit, S.; Buddhi, D. A critical review on additive manufacturing of Ti-6Al-4V alloy: Microstructure and mechanical properties. J. Mater. Res. Technol. 2022, 18, 4641–4661. [Google Scholar] [CrossRef]

- Li, G.; Brodu, E.; Soete, J.; Wei, H.; Liu, T.; Yang, T.; Liao, W.; Vanmeensel, K. Exploiting the rapid solidification potential of laer powder bed fusion in high strength and crack-free Al-Cu-Mg-Mn-Zr alloys. Addit. Manuf. 2021, 47, 102210. [Google Scholar]

- Mehta, A.; Zhou, L.; Huynh, T.; Park, S.; Hyer, H.; Song, S.; Bai, Y.; Imholte, D.D.; Woolstenhulme, N.E.; Wachs, D.M.; et al. Additive manufacturing and mechanical properties of the dense and crack free Zr-modified aluminum alloy 6061 fabricated by the laser-powder bed fusion. Addit. Manuf. 2021, 41, 101966. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–3296. [Google Scholar] [CrossRef]

- Yang, K.V.; Rometsch, P.; Jarvis, T.; Rao, J.; Cao, S.; Davies, C.; Wu, X. Porosity formation mechanisms and fatigue response in Al-Si-Mg alloys made by selective laser melting. Mater. Sci. Eng. A 2018, 712, 166–174. [Google Scholar] [CrossRef]

- Hyer, H.; Zhou, L.; Park, S.; Gottsfritz, G.; Benson, G.; Tolentino, B.; McWilliams, B.; Cho, K.; Sohn, Y. Understanding the laser powder bed fusion of AlSi10Mg alloy. Metallogr. Microstruct. Anal. 2020, 9, 484–502. [Google Scholar] [CrossRef]

- Ishfaq, K.; Abdullah, M.; Mahmood, M.A. A state-of-the-art direct metal laser sintering of Ti6Al4V and AlSi10Mg alloys: Surface roughness, tensile strength, fatigue strength and microstructure. Opt. Laser Technol. 2021, 143, 107366. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.Q.; Wang, W.; Attallah, M.M.; Loretto, M.H. Microstructure and strength of selective laser melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef]

- Fousova, M.; Dvorsky, D.; Michalcoval, A.; Vojtěch, D. Changes in the microstructure and mechanical properties of additively manufactured AlSi10Mg alloy after exposure to elevated temperatures. Mater. Charact. 2018, 137, 119–126. [Google Scholar] [CrossRef]

- Weiss, D. Improved high-temperature aluminum alloys containing cerium. J. Mater. Eng. Perform. 2019, 28, 1903–1908. [Google Scholar] [CrossRef]

- Weiss, D.; Rios, O.; Sims, Z.; McCall, S.; Ott, R. Casting Characteristics of High Cerium Content Aluminum Alloys. In Light Metals; Springer International Publishing: San Diego, CA, USA, 2017. [Google Scholar]

- Czrwinski, F. Thermal stability of aluminum-cerium binary alloys containing the Al-Al11Ce3 eutectic. Mater. Sci. Eng. A 2021, 809, 140973. [Google Scholar] [CrossRef]

- Tradowsky, U.; White, J.; Ward, R.M.; Read, N.; Reimers, W.; Attallah, M.M. Selective laser melting of AlSi10Mg: Influence of post-processing on the microstructural and tensile properties development. Mater. Des. 2016, 105, 212–222. [Google Scholar] [CrossRef]

- Nie, X.; Zhang, H.; Zhu, H.; Hu, Z.; Ke, L.; Zeng, X. Analysis of processing parameters and characteristics of selective laser melted high strength Al-Cu-Mg alloys: From single tracks to cubic samples. J. Mater. Process. Technol. 2018, 256, 69–77. [Google Scholar] [CrossRef]

- Yang, K.V.; Rometsch, P.; Davies, C.H.; Huang, A.; Wu, X. Effect of heat treatment on the microstructure and anisotropy in mechanical properties of A357 alloy produced by selective laser melting. Mater. Des. 2018, 154, 275–290. [Google Scholar] [CrossRef]

- Takata, N.; Kodaira, H.; Sekizawa, K.; Suzuki, A.; Kobashi, M. Change in microstructure of selectively laser melted AlSi10Mg alloy with heat treatments. Mater. Sci. Eng. A 2017, 704, 218–228. [Google Scholar] [CrossRef]

- Plotkowski, A.; Rios, O.; Sridharan, N.; Sims, Z.; Unocic, K.; Ott, R.; Dehoff, R.; Babu, S. Evaluation of an Al-Ce alloy for laser additive manufacturing. Acta Mater. 2017, 126, 507–519. [Google Scholar] [CrossRef]

- Sims, Z.C.; Rios, O.R.; Weiss, D.; Turchi, P.E.; Perron, A.; Lee, J.R.; Li, T.T.; Hammons, J.A.; Bagge-Hansen, M.; Willey, T.M. High performance aluminum-cerium alloys for high temperature applications. Mater. Horiz. 2017, 4, 1070–1078. [Google Scholar] [CrossRef]

- Liu, Y.; Michi, R.A.; Dunand, D.C. Cast near-eutectic Al-12.5%Ce alloy with high coarsening and creep resistance. Mater. Sci. Eng. A 2019, 767, 138440. [Google Scholar] [CrossRef]

- Su, Z.; Zeng, Z.; Zhang, S.; Meng, X.; Xu, S. Trace Ca alloying enhance simultaneously strength and ductility of squeeze-cast Al-5Cu-0.5Mn-Based Alloys. J. Mater. Sci. Technol. 2024, 191, 89–105. [Google Scholar] [CrossRef]

- Akopyan, T.; Sviridova, T.; Belov, N.; Letyagin, N.; Korotitskiy, A. Intermetallic compounds in equilibrium with aluminum in Al–Ca–Cu ternary alloying system. Trans. Nonferrous Met. Soc. China 2024, 34, 1380–1392. [Google Scholar] [CrossRef]

- Belov, N.; Akopyan, T.; Tsydenov, K.; Sviridova, T.; Cherkasov, S.; Kovalev, A. Effect of Ca addition on structure, phase composition and hardness of Al–6% Cu–2% Mn sheet alloy. J. Alloys Compd. 2024, 1009, 176955. [Google Scholar] [CrossRef]

- Akopyan, T.K.; Belov, N.A.; Letyagin, N.V.; Sviridova, T.A.; Cherkasov, S.O. New quaternary eutectic Al-Cu-Ca-Si system for designing precipitation hardening alloys. J. Alloys Compd. 2024, 993, 174695. [Google Scholar] [CrossRef]

- Du, H.; Zhang, S.; Zhang, B.; Tao, X.; Yao, Z.; Belov, N.; van der Zwaag, S.; Liu, Z. Ca-modified Al–Mg–Sc alloy with high strength at elevated temperatures due to a hierarchical microstructure. J. Mater. Sci. 2021, 56, 16145–16157. [Google Scholar] [CrossRef]

- Shurkin, P.; Letyagin, N.; Yakushkova, A.; Samoshina, M.; Ozherelkov, D.Y.; Akopyan, T. Remarkable thermal stability of the Al-Ca-Ni-Mn alloy manufactured by laser-powder bed fusion. Mater. Lett. 2021, 285, 129074. [Google Scholar] [CrossRef]

- Biffi, C.A.; Fiocchi, J.; Tuissi, A. Selective laser melting of AlSi10Mg: Influence of process parameters on Mg2Si precipitation and Si spheroidization. J. Alloys Compd. 2018, 755, 100–107. [Google Scholar] [CrossRef]

- Ren, Y.; Dong, P.; Zeng, Y.; Yang, T.; Huang, H.; Chen, J. Effect of heat treatment on properties of Al-Mg-Sc-Zr alloy printed by selective laser melting. Appl. Surf. Sci. 2022, 574, 151471. [Google Scholar] [CrossRef]

- Bahl, S.; Plotkowski, A.; Sisco, K.; Leonard, D.N.; Allard, L.F.; Michi, R.A.; Poplawsky, J.D.; Dehoff, R.; Shyam, A. Elevated temperature ductility dip in an additively manufactured Al-Cu-Ce alloy. Acta Mater. 2021, 220, 117285. [Google Scholar] [CrossRef]

| Al | Ce | Ca | Mn | Zr | Fe |

|---|---|---|---|---|---|

| Bal. | 3.0 | 0.9 | 1.9 | 1.2 | <0.05 |

| Construction Surface/μm | Scanning Surface/μm | |

|---|---|---|

| As-build state | 4.25 | 2.59 |

| Annealed state | 3.37 | 3.34 |

| Temperature/°C | Printing State | 325 | 375 | 425 |

|---|---|---|---|---|

| Construction surface/HV | 120 | 124 | 127 | 115 |

| Scanning surface/HV | 128 | 129 | 131 | 114 |

| Average/HV | 124 | 126 | 129 | 115 |

| Difference/HV | 8 | 5 | 4 | −1 |

| Temperature/°C | UTS/MPa | YS/MPa | El/% |

|---|---|---|---|

| 200 | 217 ± 0 | 167 ± 17 | 33.2 ± 0.6 |

| 250 | 156 ± 9 | 144 ± 8 | 39.9 ± 4.1 |

| 300 | 91 ± 4. | 84 ± 4 | 44.8 ± 1.0 |

| 350 | 61 ± 5 | 57 ± 5 | 63.2 ± 0.6 |

| Annealing Temperature/°C | Holding Time/ h | Tensile Strength/MPa | Yield Strength/MPa | Elongation/ % |

|---|---|---|---|---|

| 20 | 0 | 333 | 245 | 24.4 |

| 325 | 8 | 345 | 267 | 16.4 |

| 375 | 8 | 411 | 359 | 16.8 |

| 425 | 8 | 377 | 349 | 9.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Wang, M.; Yu, X.; Zhang, Z.; Cai, D.; Shen, B.; Long, J.; Sun, Y. Microstructure and Mechanical Properties of a Novel Lightweight and Heat-Resistant Al-3.0Ce-0.9Ca-1.9Mn-1.2Zr Alloy Fabricated by Selective Laser Melting. Coatings 2025, 15, 247. https://doi.org/10.3390/coatings15020247

Zhang W, Wang M, Yu X, Zhang Z, Cai D, Shen B, Long J, Sun Y. Microstructure and Mechanical Properties of a Novel Lightweight and Heat-Resistant Al-3.0Ce-0.9Ca-1.9Mn-1.2Zr Alloy Fabricated by Selective Laser Melting. Coatings. 2025; 15(2):247. https://doi.org/10.3390/coatings15020247

Chicago/Turabian StyleZhang, Wanwen, Mengmeng Wang, Xiaodan Yu, Zhigang Zhang, Dongting Cai, Baoxiang Shen, Jianzhou Long, and Yufeng Sun. 2025. "Microstructure and Mechanical Properties of a Novel Lightweight and Heat-Resistant Al-3.0Ce-0.9Ca-1.9Mn-1.2Zr Alloy Fabricated by Selective Laser Melting" Coatings 15, no. 2: 247. https://doi.org/10.3390/coatings15020247

APA StyleZhang, W., Wang, M., Yu, X., Zhang, Z., Cai, D., Shen, B., Long, J., & Sun, Y. (2025). Microstructure and Mechanical Properties of a Novel Lightweight and Heat-Resistant Al-3.0Ce-0.9Ca-1.9Mn-1.2Zr Alloy Fabricated by Selective Laser Melting. Coatings, 15(2), 247. https://doi.org/10.3390/coatings15020247