Research on the Weakening Process at the Interface of Bonded-Layer Composite Structures Using Ultrasonic Longitudinal Waves

Abstract

1. Introduction

2. Theoretical Calculation of Ultrasonic Wave Propagation

2.1. Theoretical Calculation Model

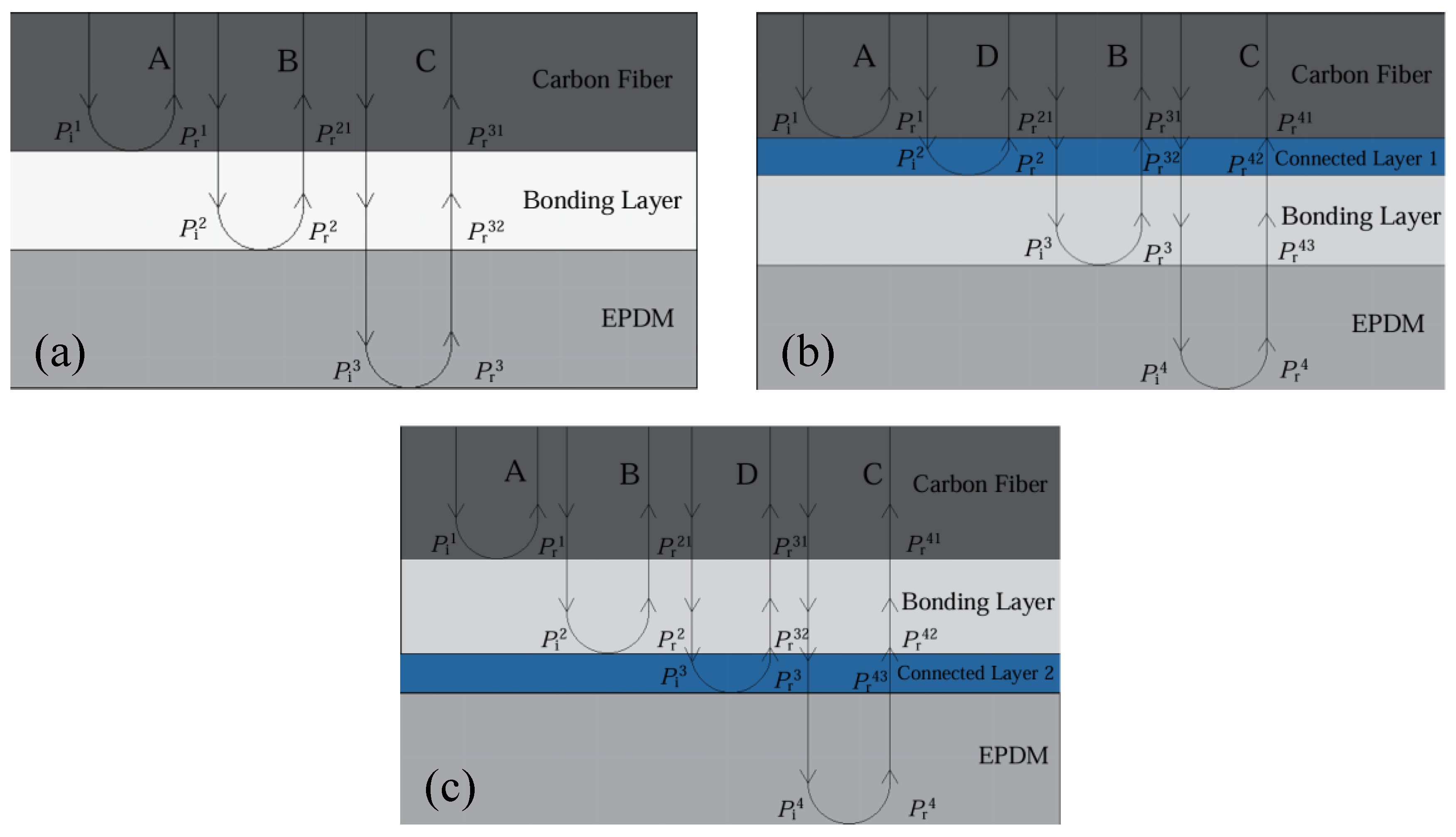

2.2. Theoretical Calculation Derivation

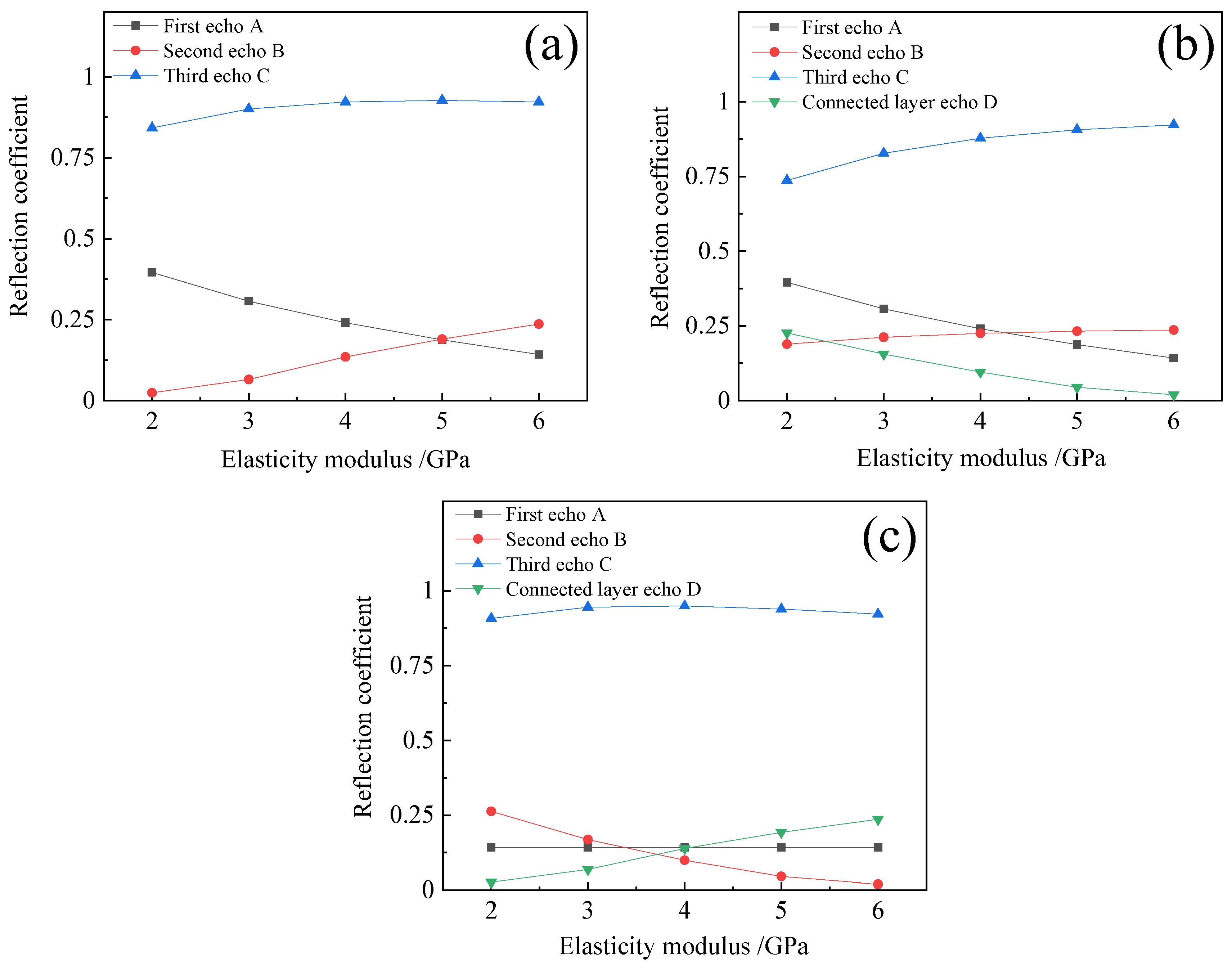

2.3. Theoretical Calculation Results and Analysis

3. Finite Element Simulation of Bonded-Layer Composite Structures

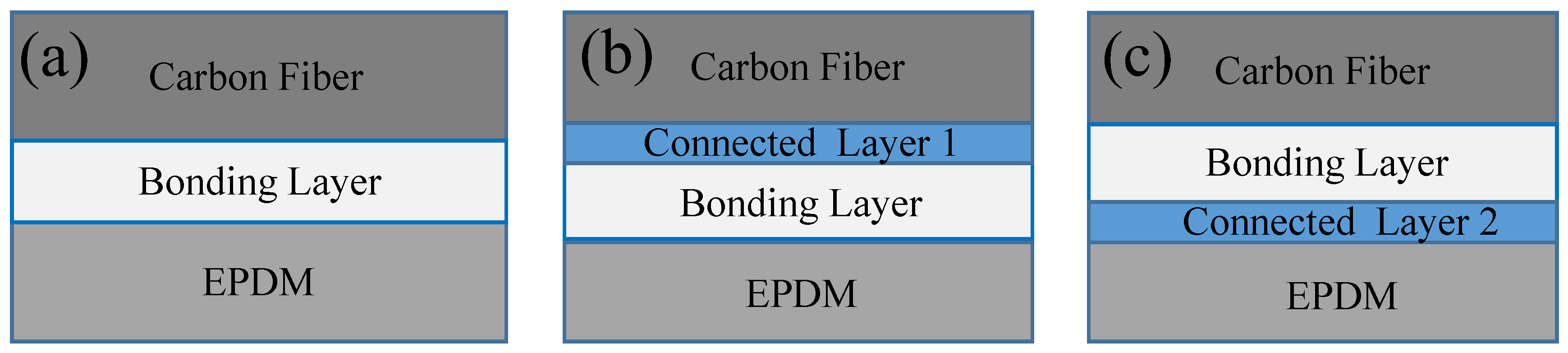

3.1. Establishment of Finite Element Simulation Model

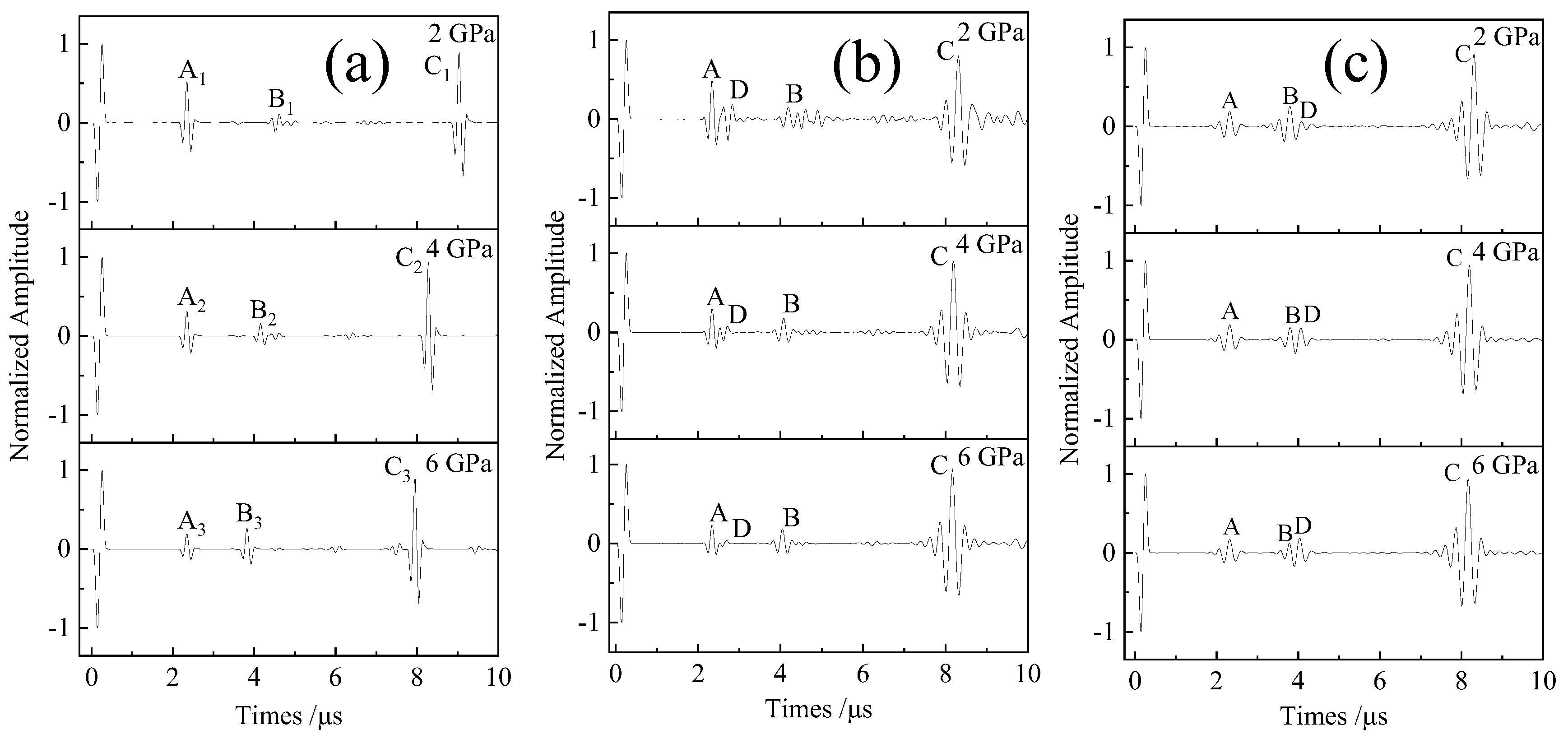

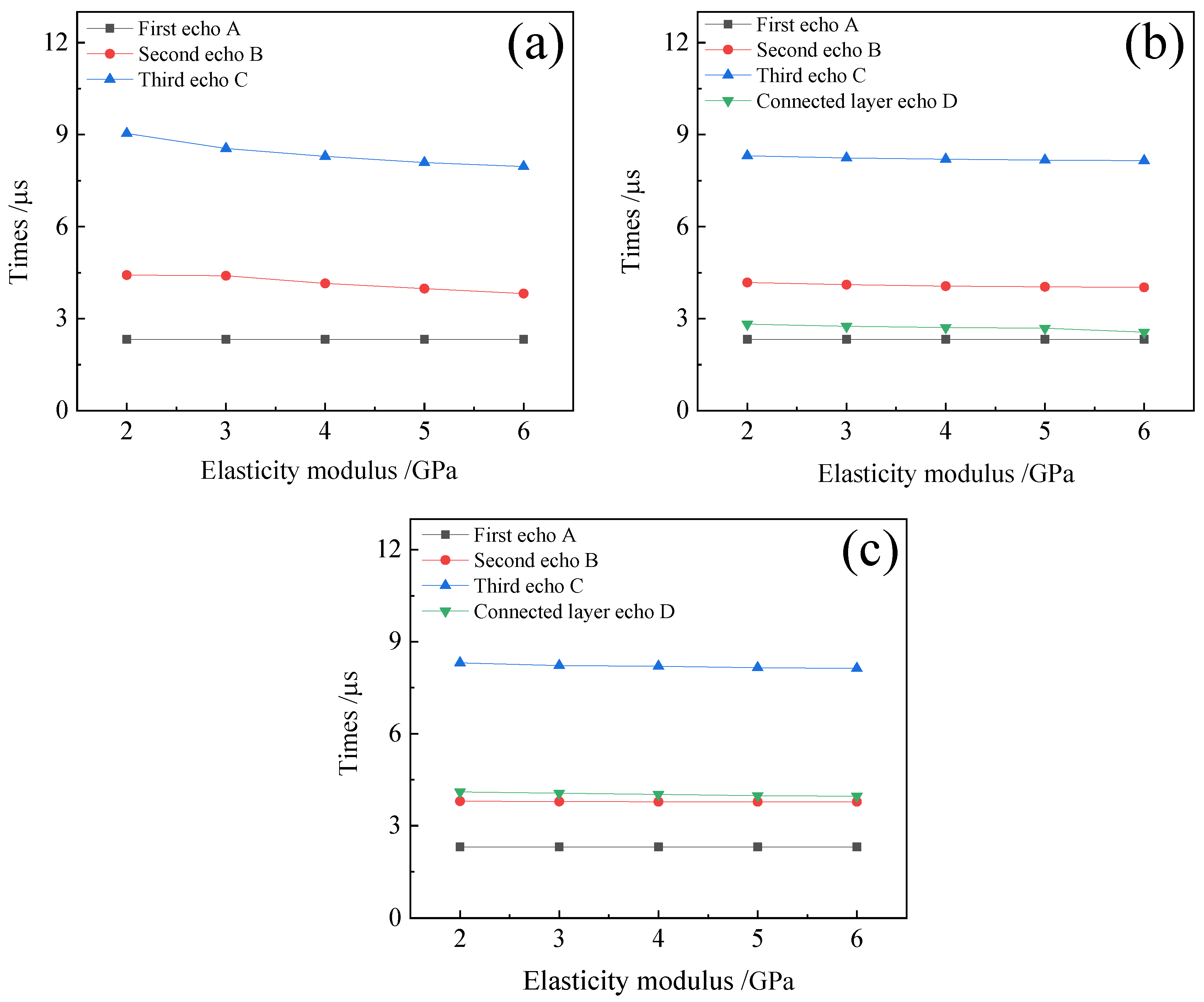

3.2. Time-Domain Analysis of Bonded-Layer Composite Structures

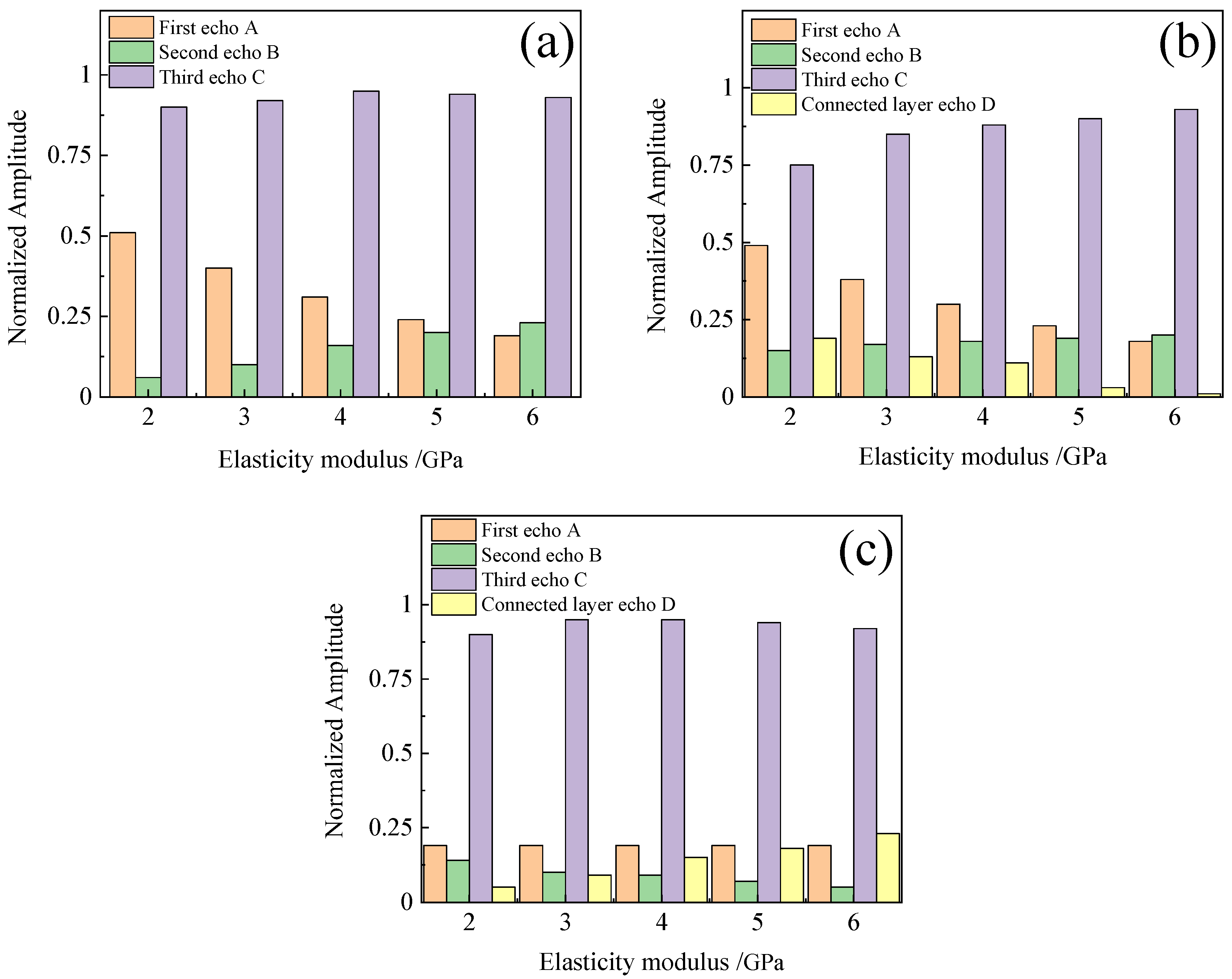

3.3. Echo Amplitudes Under Different Simulation Conditions

4. Ultrasonic Inspection Experiment Using Bonded-Layer Composite Structures

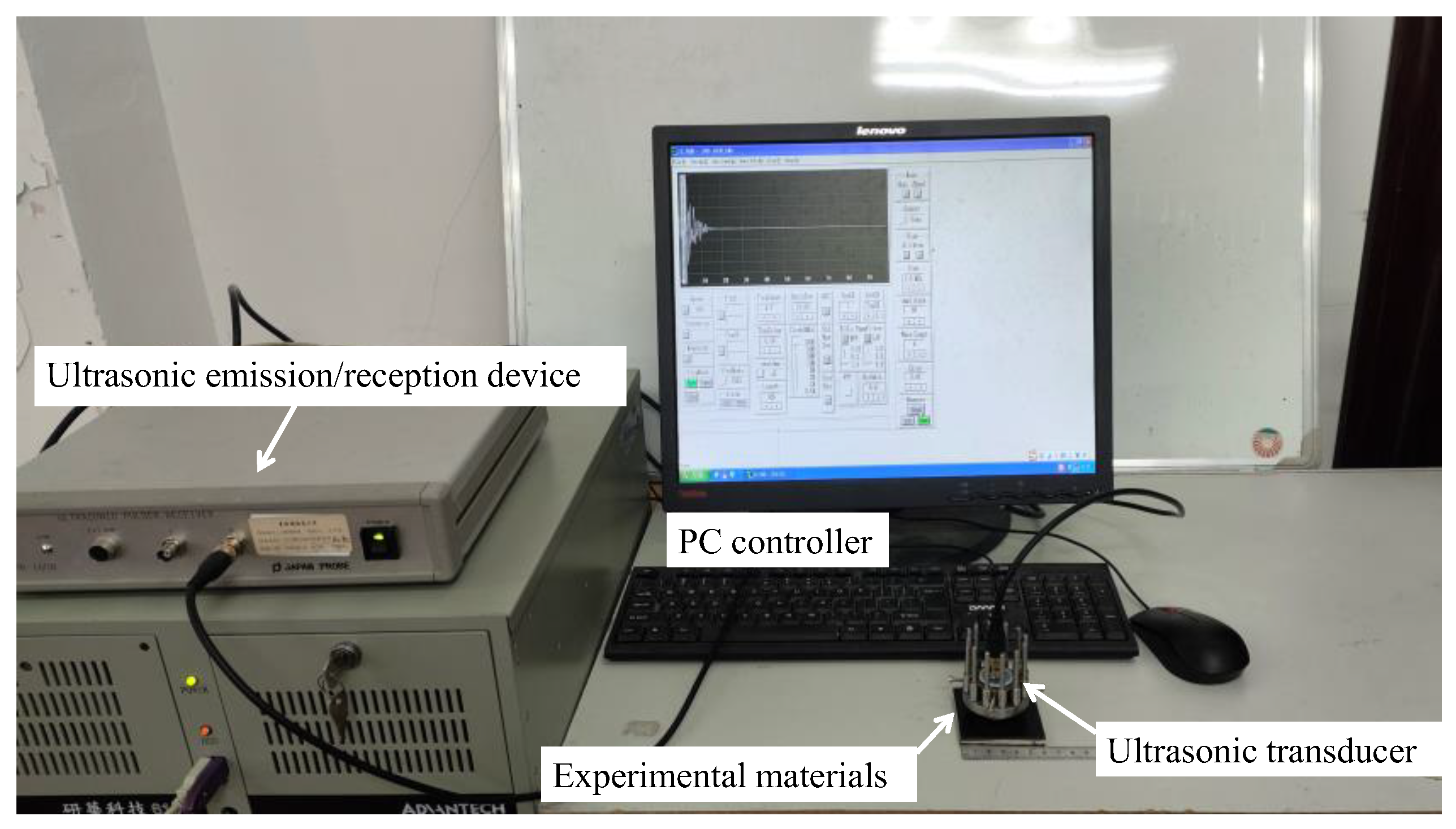

4.1. Equipment and Methods

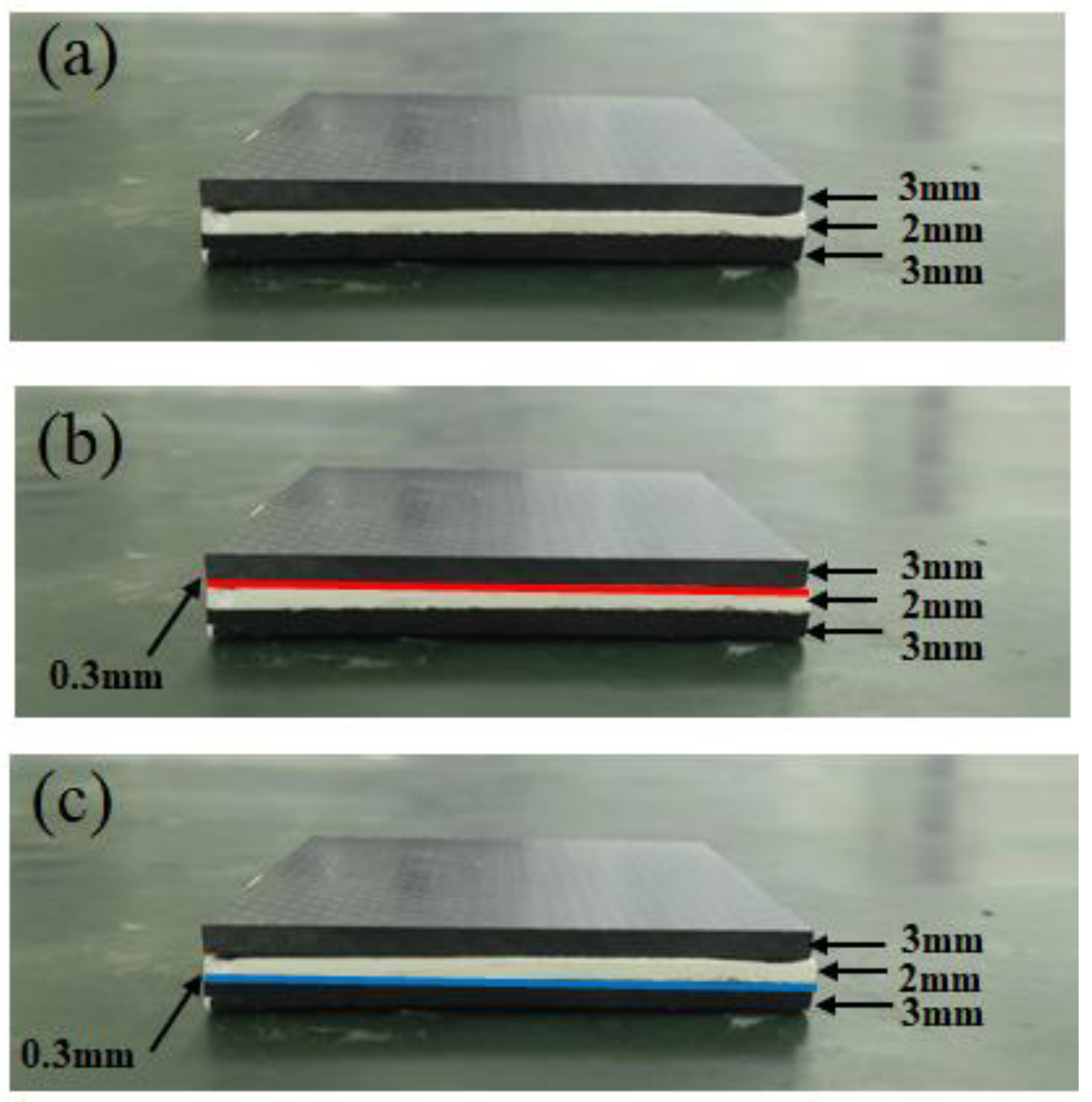

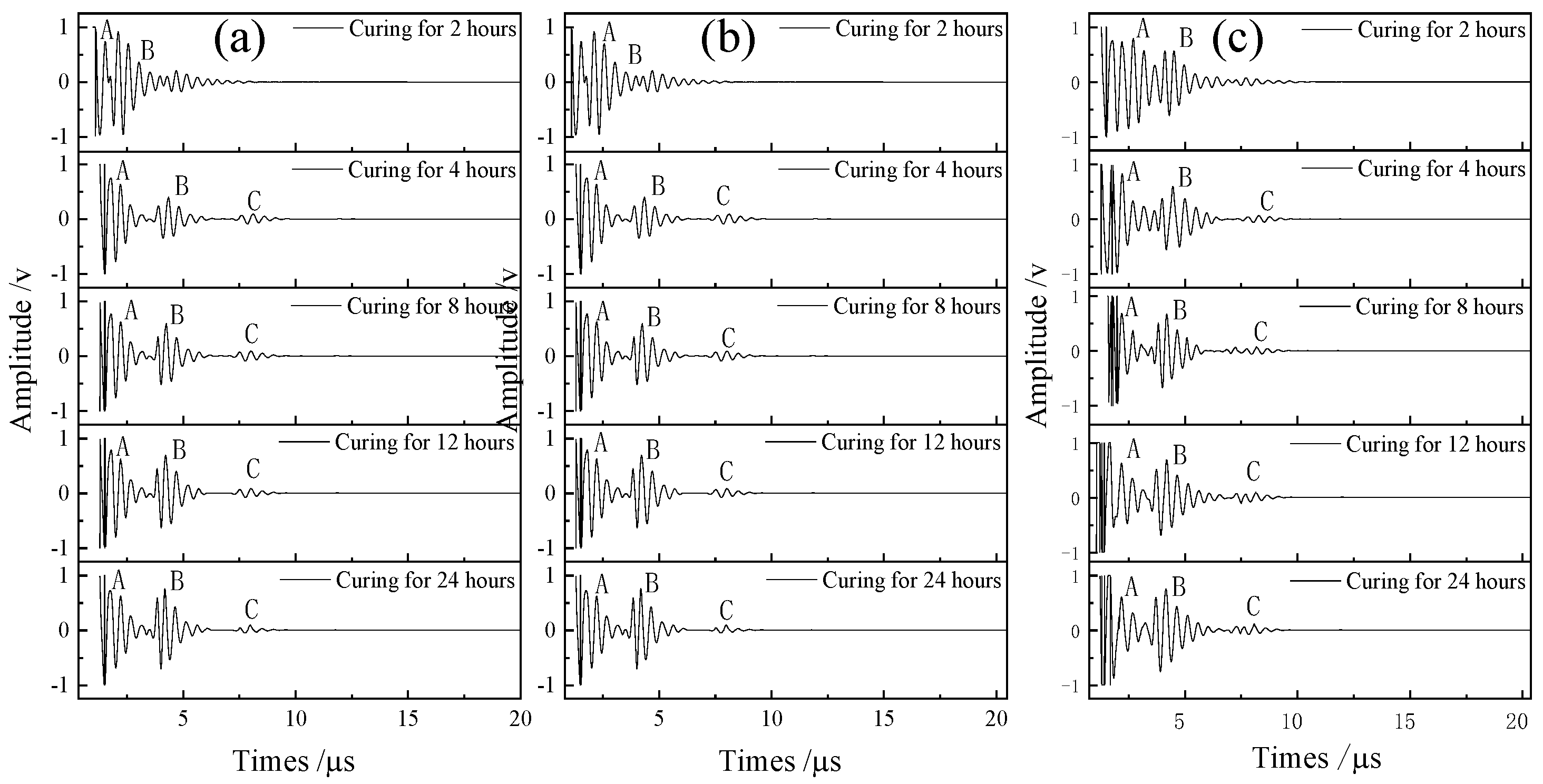

4.2. Experimental Schemes and Results Analysis for the Testing of Bonded-Layer Composite Structures

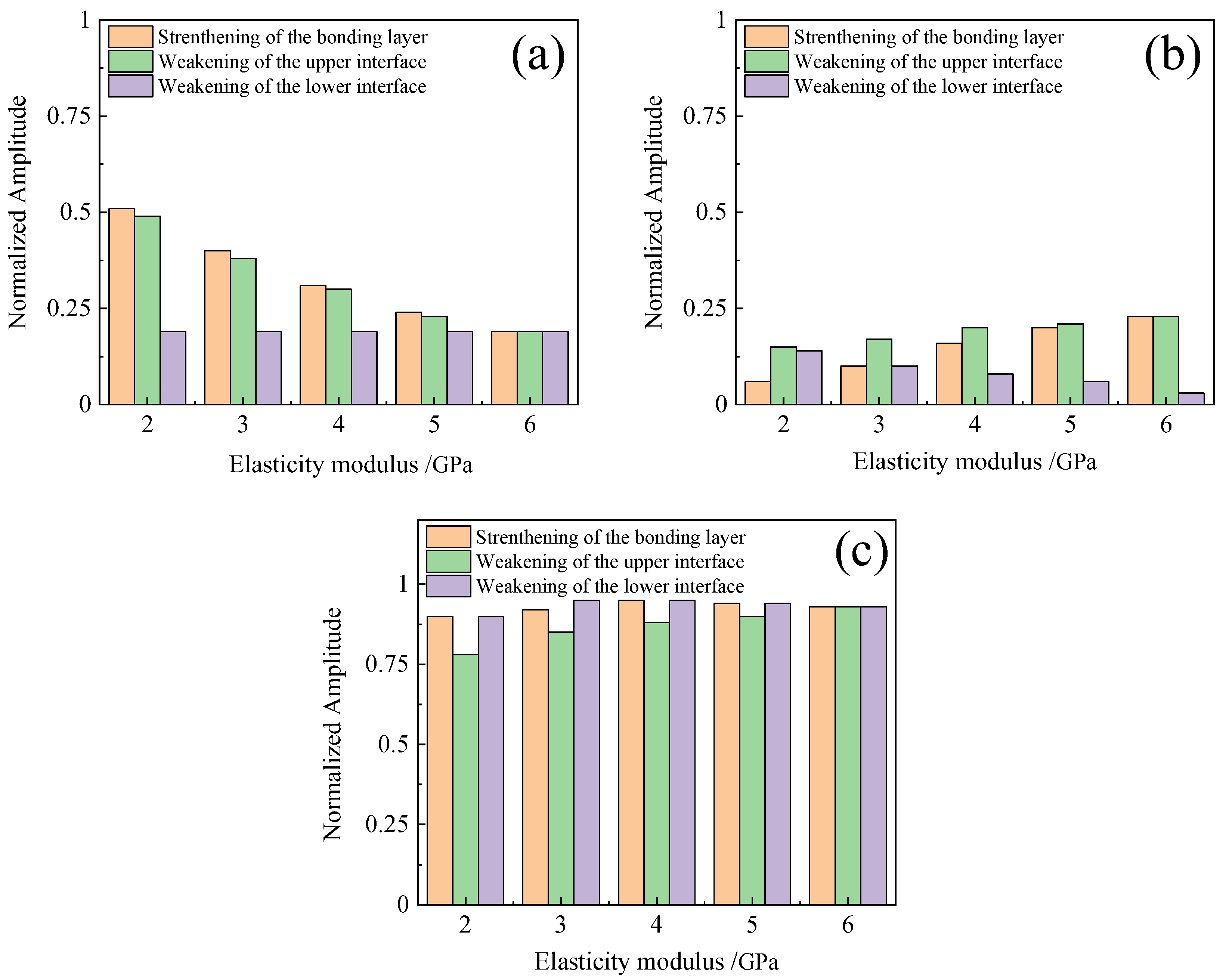

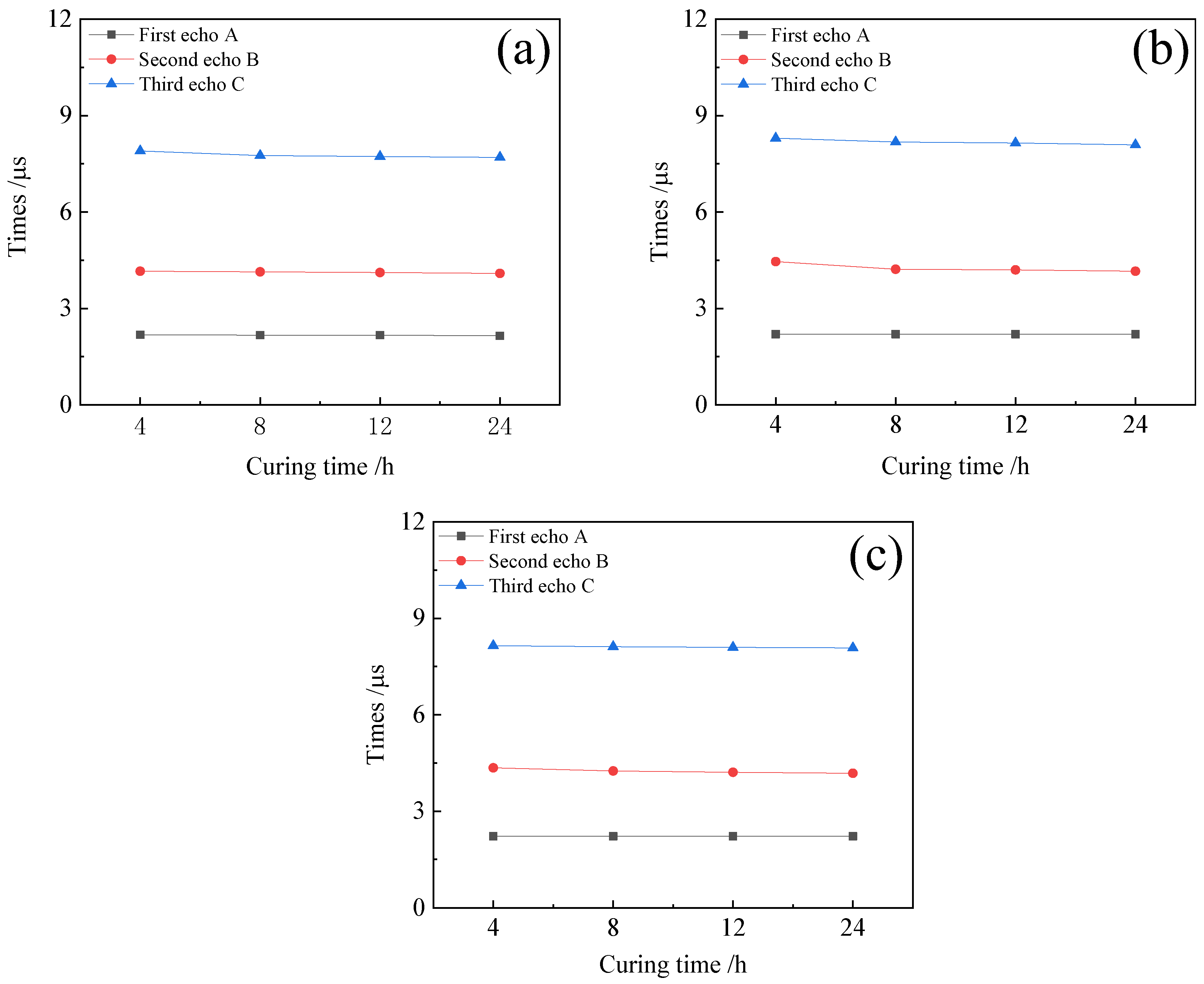

4.3. Echo Amplitudes Under Different Conditions in the Experiment

5. Conclusions

- When the bonding strength of the bonding layer changed from weak to strong, the amplitude of the first echo slowly declined, the amplitude of the second echo gradually increased, and the amplitude of the third echo remained basically unchanged. The time of first echo remained basically unchanged, and the times of the second and third echoes gradually decreased.

- When the bonding strength of the upper interface changed from weak to strong, the amplitude of the first echo gradually decreased, the amplitude of the second echo increased, and the amplitude of the third echo slightly increased. The times of the three echoes exhibited a similar trend as that observed in Conclusion 1.

- When the bonding strength of the lower interface changed from weak to strong, the amplitude of the first and third echoes remained basically unchanged. The amplitude of the second echo gradually reduced in the theoretical calculation and the simulation, but increased during the experiment due to the fact that the second echo overlapped with the echo originating from the interface under the connected layer. In addition, the time variations in the three echoes were the same as those mentioned above.

- The individual trends in the amplitude changes for the first, second, and third echoes remained consistent across the theoretical calculations, simulations, and experiments, except for the second echo in the lower interface weakening experiment, which exhibited an opposite trend to that observed in other experiments. It is noteworthy that the amplitudes of the third echo in all experiments were relatively lower compared to those obtained through theoretical calculations and simulations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fan, S.J.; Zhang, J.M.; Wang, B.; Chen, J.P.; Yang, W.D.; Liu, W.P.; Li, Y. A deep learning method for fast predicting curing process-induced deformation of aeronautical composite structures. Compos. Sci. Technol. 2023, 232, 109844. [Google Scholar] [CrossRef]

- Dong, Y.F.; Li, Y. A review on the mechanical property evaluation and optimization design of fabric rubber composite structure. Compos. Part C 2022, 8, 100289. [Google Scholar] [CrossRef]

- SJ, A.; Natarajan, A. Review on the advancements and relevance of emerging joining techniques for aluminium to polymers/carbon fibre-reinforced polymer lightweight hybrid structures. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 2394–2435. [Google Scholar] [CrossRef]

- Wang, X.G.; Wang, J.X.; Shen, G.L.; Li, X.G.; Huang, Z.C. Research on interface bonding characteristics of layered medium using ultrasonic oblique incidence. Compos. Struct. 2022, 295, 11573. [Google Scholar] [CrossRef]

- Li, P.X.; Wang, X.G.; Li, X.G.; Shen, G.L.; Ma, C.W.; Huang, Z.C.; Su, S.Y. Evaluating interfacial bonding quality of multilayered structure based on ultrasonic testing technology. Meas. Sci. Technol. 2023, 34, 095117. [Google Scholar] [CrossRef]

- Li, M.X.; Wang, X.M.; An, Z.W. Ultrasonic detection and evaluation of adhesive interface properties. Appl. Acoust. 2013, 32, 190–198. [Google Scholar]

- Yang, X.; Zhang, M.; Zhan, L.; Ma, B.; Wu, X.; Liu, C.; Xiang, H. Effects of curing defects in adhesive layers on carbon fiber–quartz fiber bonded joint performance. Polymers 2024, 16, 1406. [Google Scholar] [CrossRef] [PubMed]

- Scarselli, G.; Corcione, C.; Nicassio, F.; Maffezzoli, A. Adhesive joints with improved mechanical properties for aerospace applications. Int. J. Adhes. Adhes. 2017, 75, 174–180. [Google Scholar] [CrossRef]

- Jasiūnienė, E.; Mažeika, L.; Samaitis, V.; Cicėnas, V.; Mattsson, D. Ultrasonic non-destructive testing of complex titanium/carbon fibre composite joints. Ultrasonics 2019, 95, 13–21. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, D.V.; Idapalapati, S. Review of debonding techniques in adhesively bonded composite structures for sustainability. Sustain. Mater. Technol. 2021, 30, e00345. [Google Scholar] [CrossRef]

- Budhe, S.; Banea, M.D.; Barros, S.; Silva, L.F. An updated review of adhesively bonded joints in composite materials. Int. J. Adhes. Adhes. 2017, 72, 30–42. [Google Scholar] [CrossRef]

- Vykintas, S.; Bengisu, Y.; Elena, J. Adhesive bond quality classification using machine learning algorithms based on ultrasonic pulse-echo immersion data. J. Sound Vib. 2023, 546, 117457. [Google Scholar] [CrossRef]

- Chen, Y.P.; Zhao, M.; Ma, S.Y.; Wu, Z.J.; Wu, H.Q.; Ma, Y.L. Effect of longitudinal guided wave modal transformation on damage identification at pipeline damage locations. Eng. Mech. 2016, 33, 215–221. [Google Scholar]

- Zhang, K.; Zhou, Z.; Zhou, J.; Sun, G. Characteristics of laser ultrasound interaction with multi-layered dissimilar metals adhesive interface by numerical simulation. Appl. Surf. Sci. 2015, 353, 284–290. [Google Scholar] [CrossRef]

- Moreno, M.S.; Cela, J.L.; Vicente, J.M.; Vecino, J.G. Adhesively bonded joints as a dissipative energy mechanism under impact loading. Appl. Math. Model. 2015, 39, 3496–3505. [Google Scholar] [CrossRef]

- Qi, H.; Cai, L.M.; Pan, X.N.; Zhang, Y. Dynamic analysis of SH-type guided wave inside a strip medium for cylindrical holes. Eng. Mech. 2015, 32, 9–14. [Google Scholar] [CrossRef]

- Thomson, W.T. Transmission of elastic waves through a stratified solid medium. J. Appl. Phys. 1950, 21, 89–93. [Google Scholar] [CrossRef]

- Ai, C.A.; Liu, Y.; Xu, Z.G.; Li, J. Reflection characteristics of “sandwich” structures with weakened strength. J. Appl. Mech. 2013, 30, 179–183. [Google Scholar] [CrossRef]

- Qiu, Z.G.; Wu, B.; He, C.F. Research on bonding layer depth and frequency in weak interface of bonded structures. Insight Non Destr. Test. Cond. Monit. 2011, 53, 302–306. [Google Scholar] [CrossRef]

- Wu, B.; Ding, J.; He, C.; Liu, Z.; Zheng, M. Wave propagation in water-immersed adhesive structure with the substrates of finite thickness. NDT E Int. 2016, 80, 35–47. [Google Scholar] [CrossRef]

- Kumar, R.V.; Bhat, M.R.; Murthy, C.R. Some studies on evaluation of degradation in composite adhesive joints using ultrasonic techniques. Ultrasonics 2013, 53, 1150–1162. [Google Scholar] [CrossRef]

- Wu, B.; Song, X.H.; Gao, J.; Song, G.R.; Lv, Y.; He, C.F. Ultrasonic reflection characteristics of weakly bonded structures of thick adhesive laminated composites. J. Acoust. 2024, 49, 137–145. [Google Scholar] [CrossRef]

- Chen, D.; Xiao, H.F.; Lai, M.; Wang, S.C.; Xu, J.W. Numerical simulation of ultrasonic detection of nonmetallic inclusions inside metallic materials. J. Eng. Sci. 2015, 37, 942–949. [Google Scholar] [CrossRef]

- Chen, X.B.; Li, X.L.; Zhou, J.G. Ultrasonic Testing Technology; Aviation Industry Press: Beijing, China, 2021. [Google Scholar]

- Yang, H.Y.; Zhao, X.Y.; Wang, L. A review of data normalization methods. Comput. Eng. Appl. 2023, 59, 13–22. [Google Scholar] [CrossRef]

- Zheng, H.; Lin, S.Q. Ultrasonic Inspection; China Labor and Social Security Press: Beijing, China, 2008. [Google Scholar]

- Xu, Q.H. Study on the Effect of Humid and Hot Environments on the Mechanical Properties of CFRP-Al Honeycomb Sandwich Bonded Structures. Ph.D. Thesis, Jilin University, Jilin, China, 2022. [Google Scholar]

- Meng, H. Temperature Sensitivity Study of Mechanical Properties of Elastically Bonded Structures. Master’s Thesis, Jilin University, Jilin, China, 2022. [Google Scholar]

- Wei, B.X. Research on Co-Curing Characteristics of Carbon Fiber/Epoxy Resin and EPDM Composite System. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2020. [Google Scholar]

- Zhang, C.H.; Chen, Z.M.; Li, S.D. Preparation and performance test of low-temperature curing agent for epoxy resin. Thermosetting Resin. 2016, 31, 25–27. [Google Scholar] [CrossRef]

- Zhu, C.; Li, W.; Wang, H. Analysis of interlayer crack propagation and strength prediction of steel bridge deck asphalt pavement based on extended finite element method and cohesive zone model (XFEM–CZM) coupling. Coatings 2023, 13, 1973. [Google Scholar] [CrossRef]

- Sun, S.K.; Cheng, L.J.; Shi, L.J.; Qian, H.H.; Liu, G.; Zhao, W.B. Nondestructive testing of fabric reinforcing rubber composites. Elastomerics 2020, 30, 48–51. [Google Scholar] [CrossRef]

- Li, Y.Y.; Chang, J.J.; Huang, L.; Tang, Y.H. Comparative study on viscoelastic evaluation methods of polymer materials based on ultrasonic method. Materials 2019, 12, 2948. [Google Scholar] [CrossRef]

| Material | Longitudinal Wave Velocity (m/s) | Density (g/cm3) | Poisson’s Ratio | Young’s Modulus (MPa) |

|---|---|---|---|---|

| Carbon fiber | 2830 | 1.500 | 0.348 | 7591 |

| Epoxy resin | 2700 | 1.180 | 0.32 | 6000 |

| EPDM | 1440 | 1.352 | 0.39 | 1430 |

| Echo | Elastic Modulus | Theoretical Echo Time | Simulated Echo Time | Error |

|---|---|---|---|---|

| A1 | 2 GPa | 2.12 μs | 2.33 μs | 9.9% |

| B1 | 4.68 μs | 4.42 μs | 5.6% | |

| C1 | 8.78 μs | 9.04 μs | 3.0% | |

| A2 | 2.12 μs | 2.33 μs | 9.9% | |

| B2 | 4 GPa | 3.94 μs | 4.15 μs | 5.3% |

| C2 | 8.04 μs | 8.29 μs | 3.0% | |

| A3 | 2.12 μs | 2.33 μs | 9.9% | |

| B3 | 6 GPa | 3.6 μs | 3.82 μs | 6.1% |

| C3 | 7.77 μs | 7.96 μs | 2.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bu, F.; Gui, L.; Wang, X.; Li, X.; Shen, G.; Ma, C.; Tang, G. Research on the Weakening Process at the Interface of Bonded-Layer Composite Structures Using Ultrasonic Longitudinal Waves. Coatings 2025, 15, 151. https://doi.org/10.3390/coatings15020151

Bu F, Gui L, Wang X, Li X, Shen G, Ma C, Tang G. Research on the Weakening Process at the Interface of Bonded-Layer Composite Structures Using Ultrasonic Longitudinal Waves. Coatings. 2025; 15(2):151. https://doi.org/10.3390/coatings15020151

Chicago/Turabian StyleBu, Fanqiang, Liangqin Gui, Xingguo Wang, Xiaogao Li, Guolang Shen, Chengwen Ma, and Guoxing Tang. 2025. "Research on the Weakening Process at the Interface of Bonded-Layer Composite Structures Using Ultrasonic Longitudinal Waves" Coatings 15, no. 2: 151. https://doi.org/10.3390/coatings15020151

APA StyleBu, F., Gui, L., Wang, X., Li, X., Shen, G., Ma, C., & Tang, G. (2025). Research on the Weakening Process at the Interface of Bonded-Layer Composite Structures Using Ultrasonic Longitudinal Waves. Coatings, 15(2), 151. https://doi.org/10.3390/coatings15020151