Self-Driven Miniature Sensing Technology Based on Cellulose-Based Triboelectric Nanogenerators in a Wearable Human Health Status Monitoring System

Abstract

1. Introduction

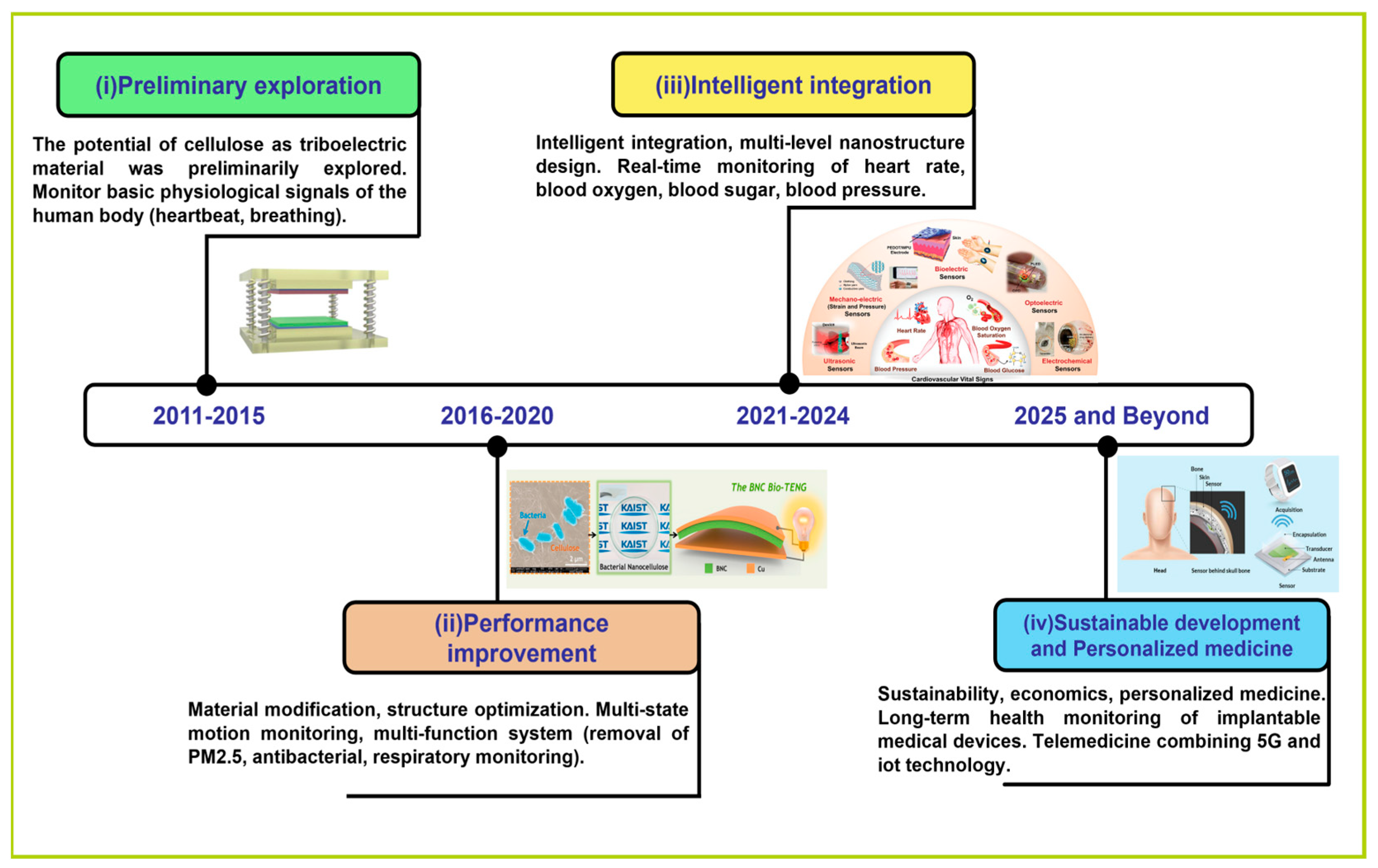

2. Overview of TENG and Cellulose-Based TENG

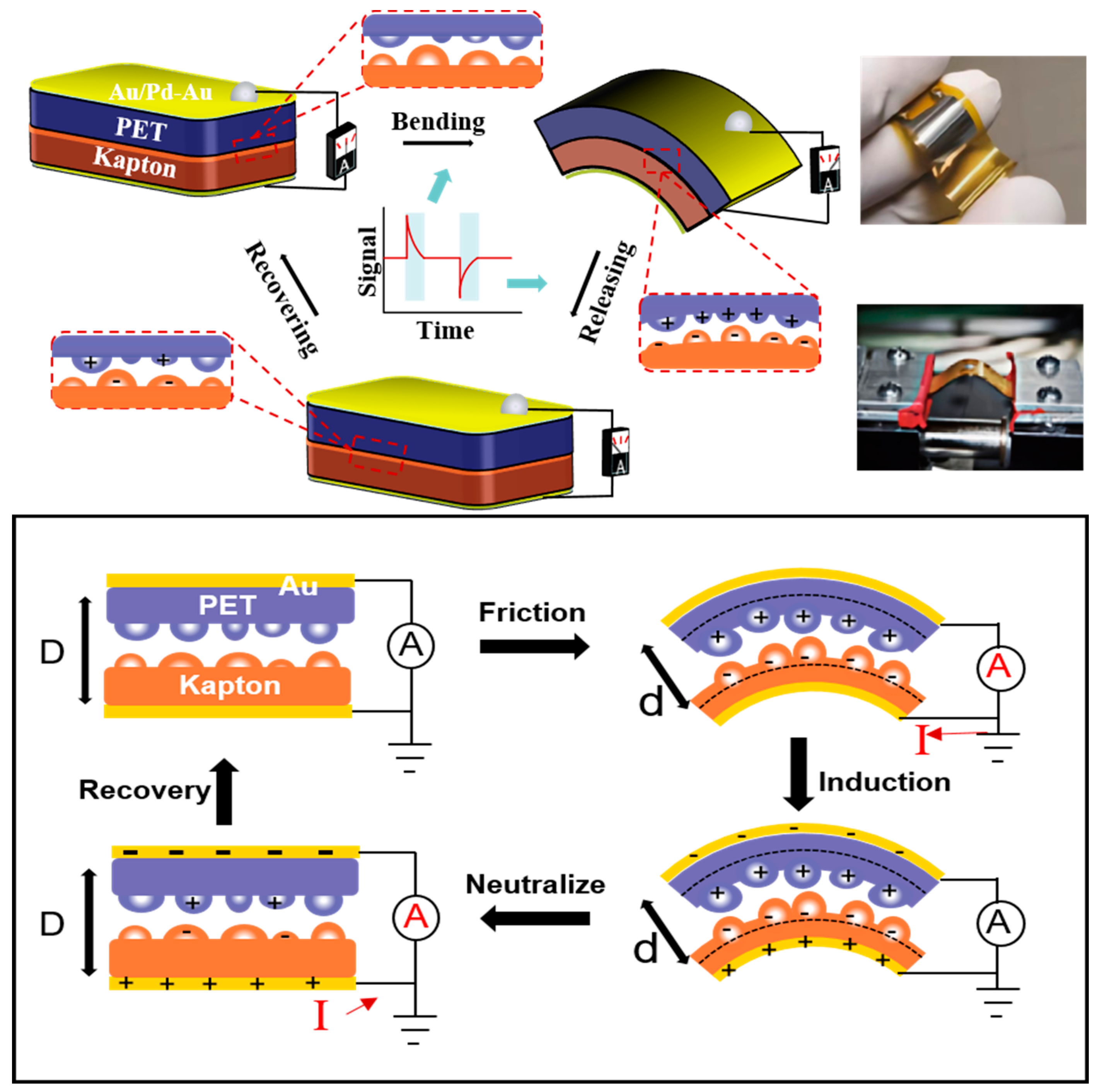

2.1. Working Principle

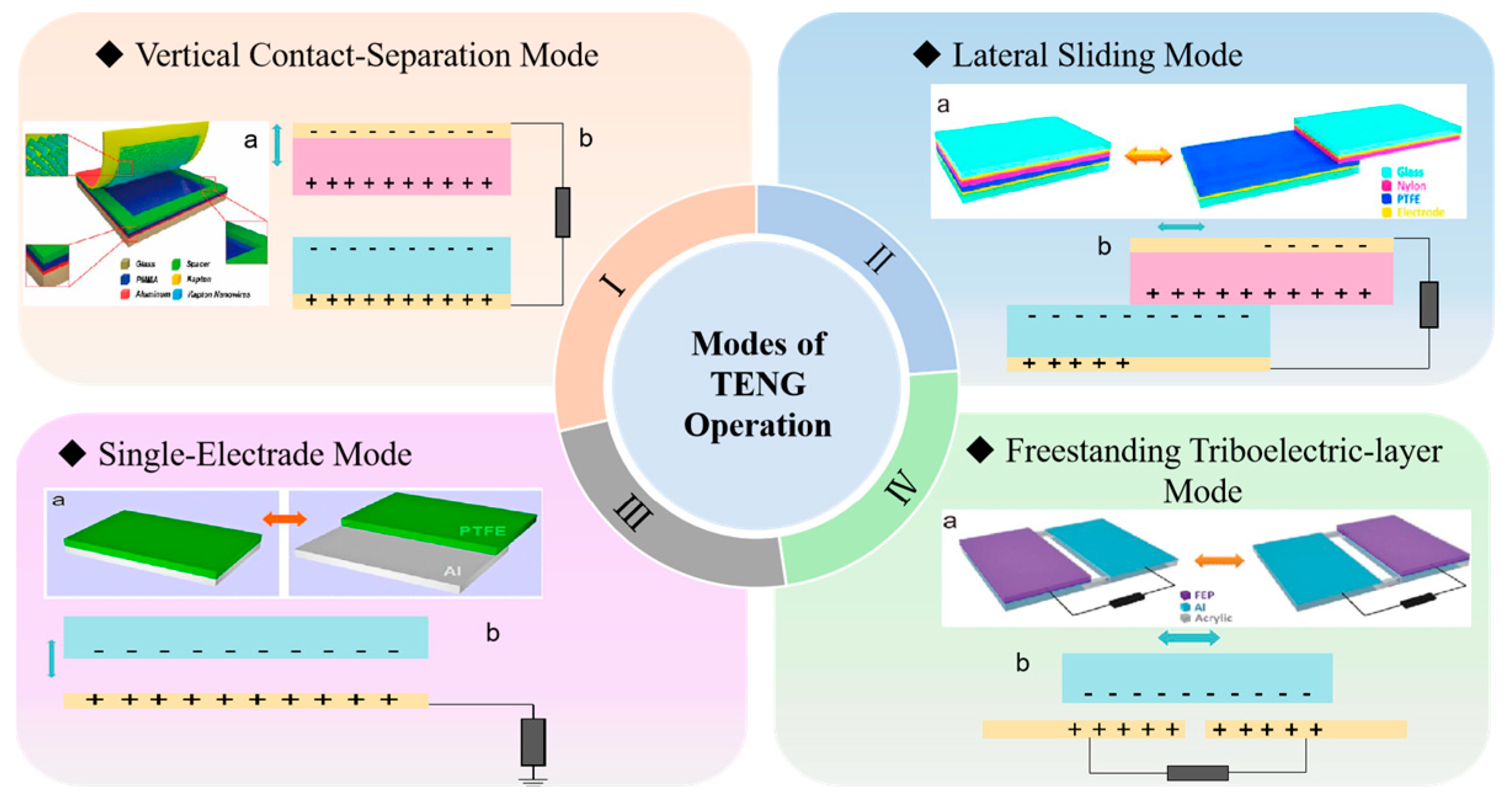

2.2. Operating Modes

2.2.1. Vertical Contact Separation Mode

2.2.2. Lateral Sliding Mode

2.2.3. Single-Electrode Mode

2.2.4. Freestanding Triboelectric Layer Mode

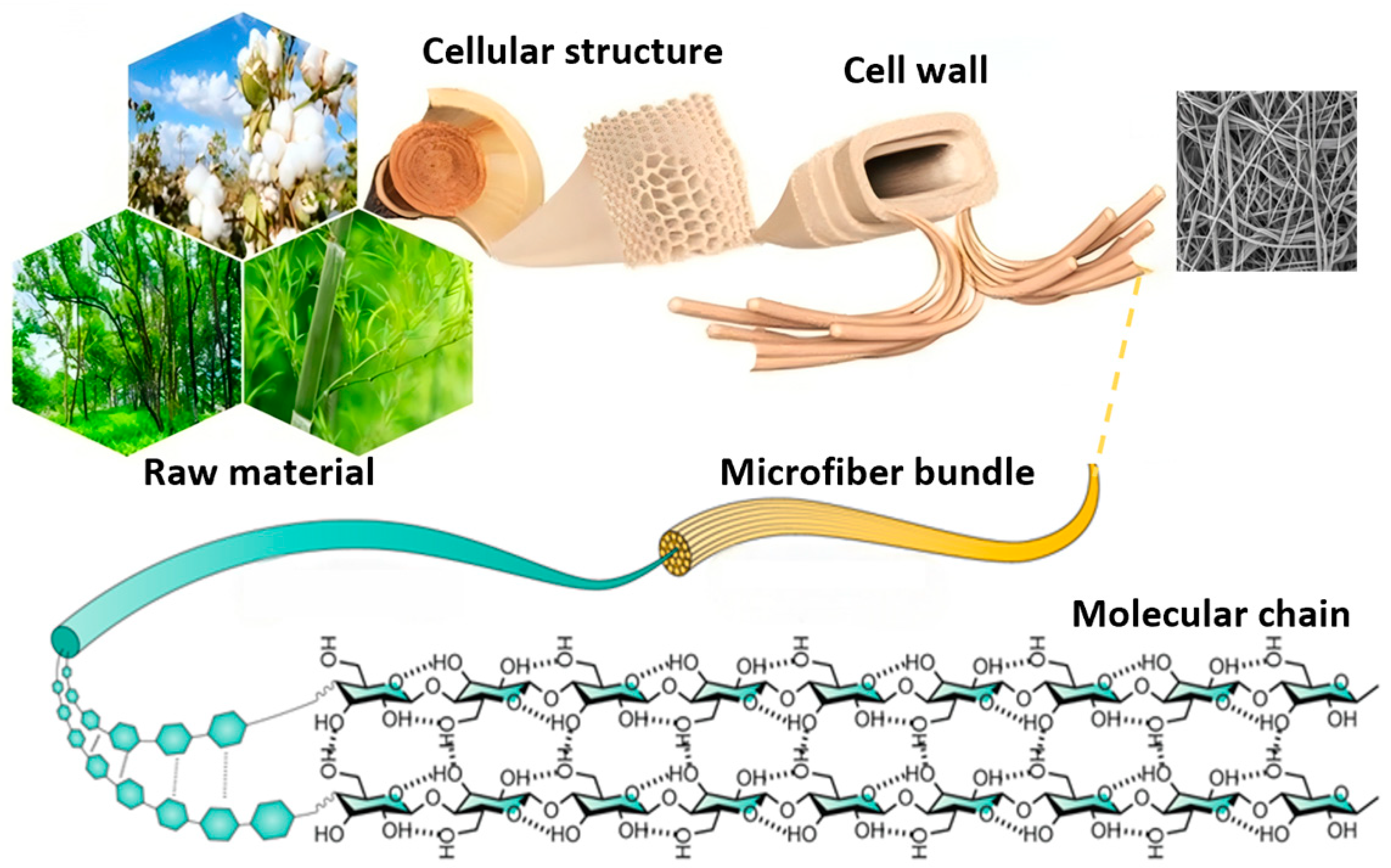

2.3. Cellulose-Based TENG for Sensing Technology

2.3.1. Basic Properties of Cellulose

2.3.2. Nanocellulose and Cellulose Derivatives

2.3.3. Advantages of Cellulose-Based TENG

3. Cellulose-Based TENG Sensing Technology for Health Monitoring Applications

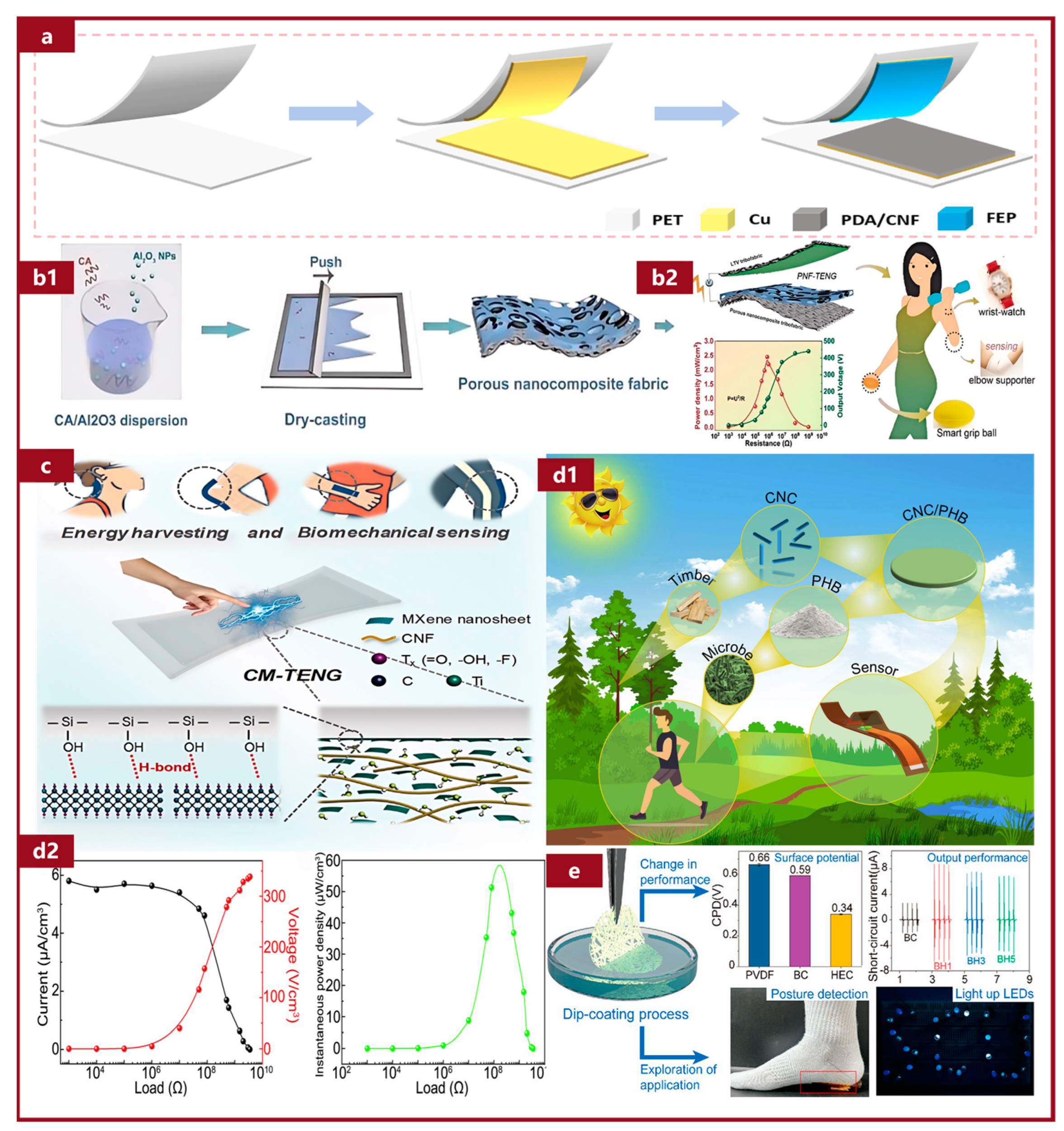

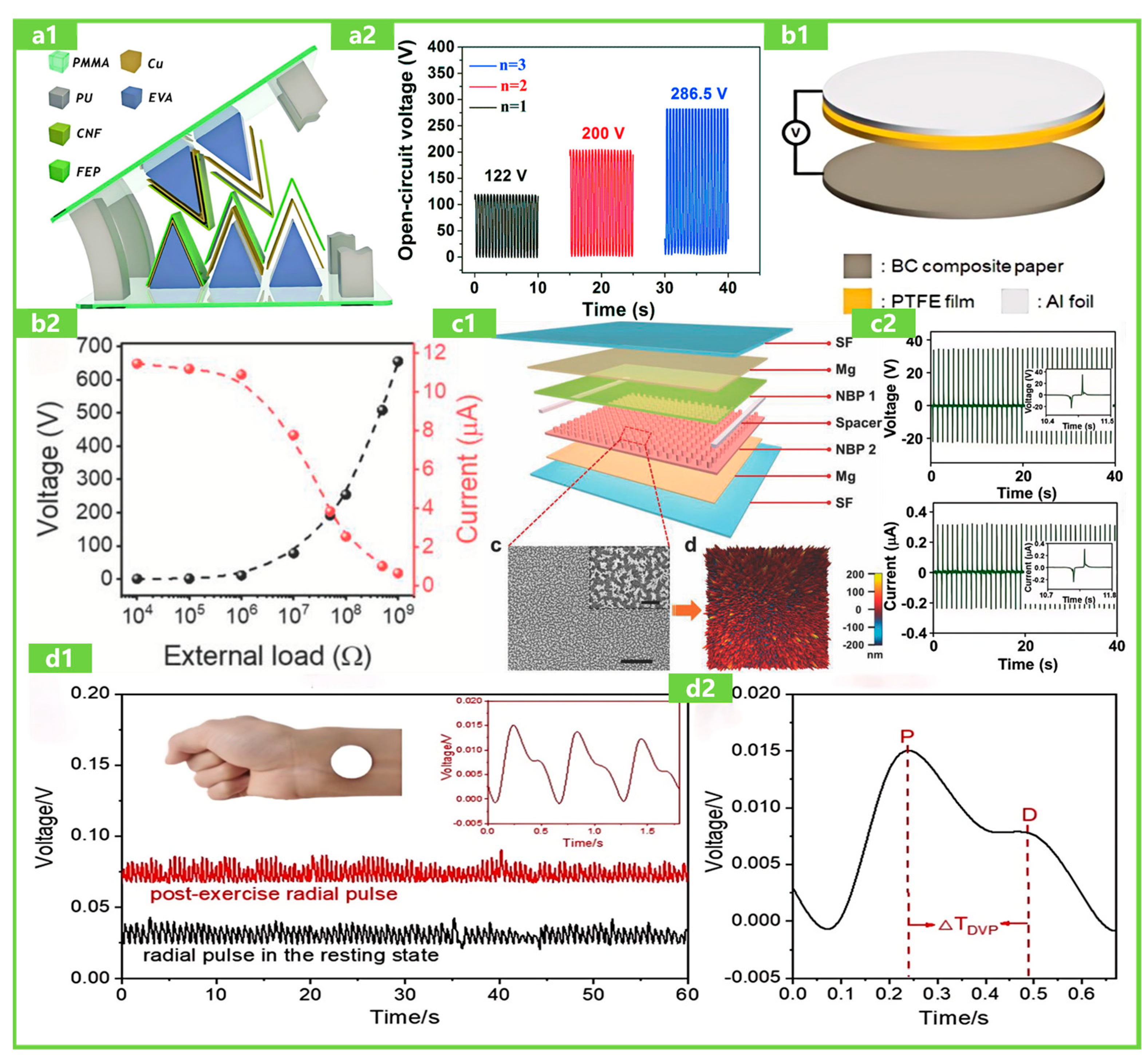

3.1. Motion Sensors

3.2. Breathing Sensors

3.3. Heart and Pulse Sensors

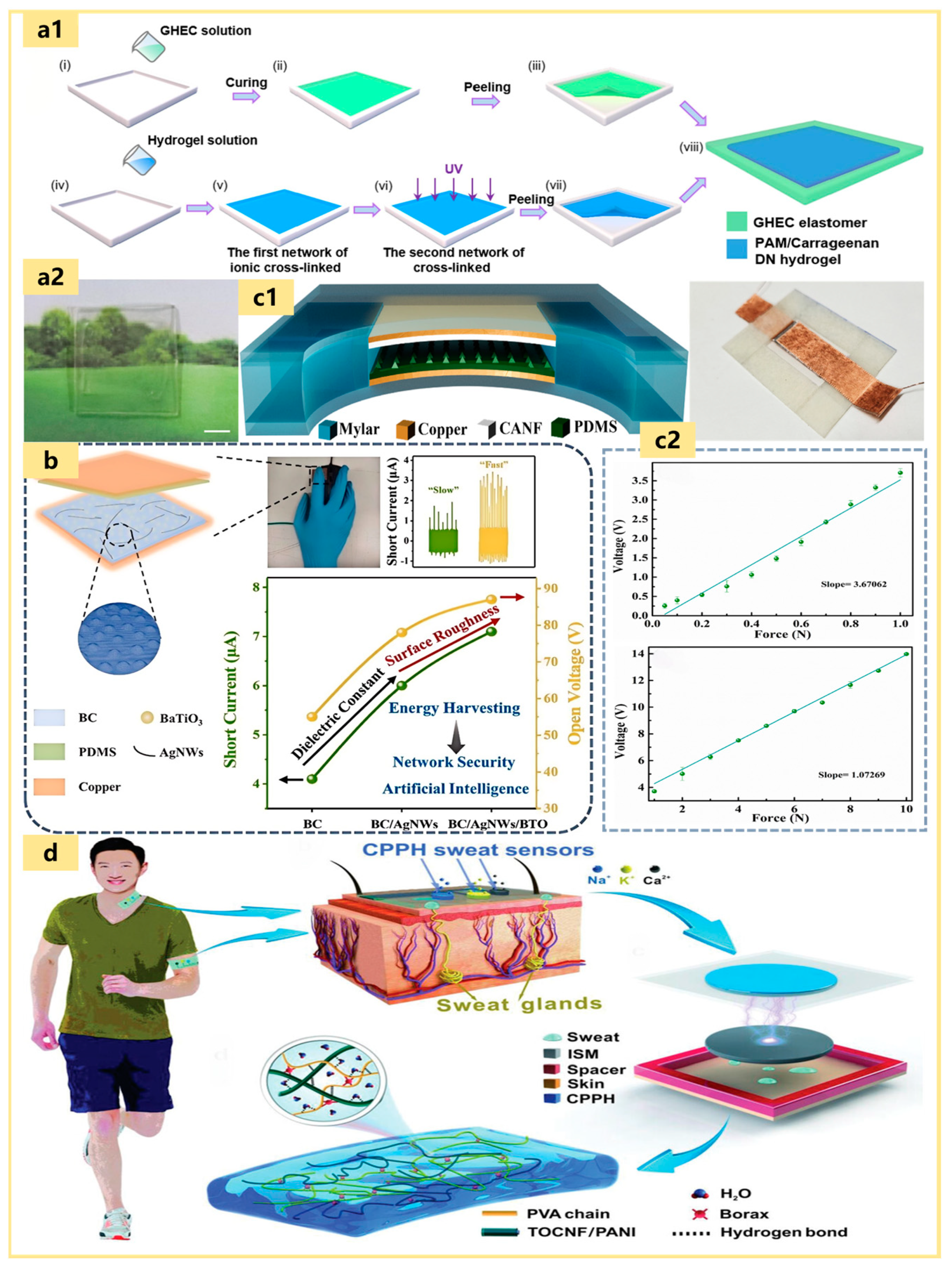

3.4. Tactile and Sweat Sensors

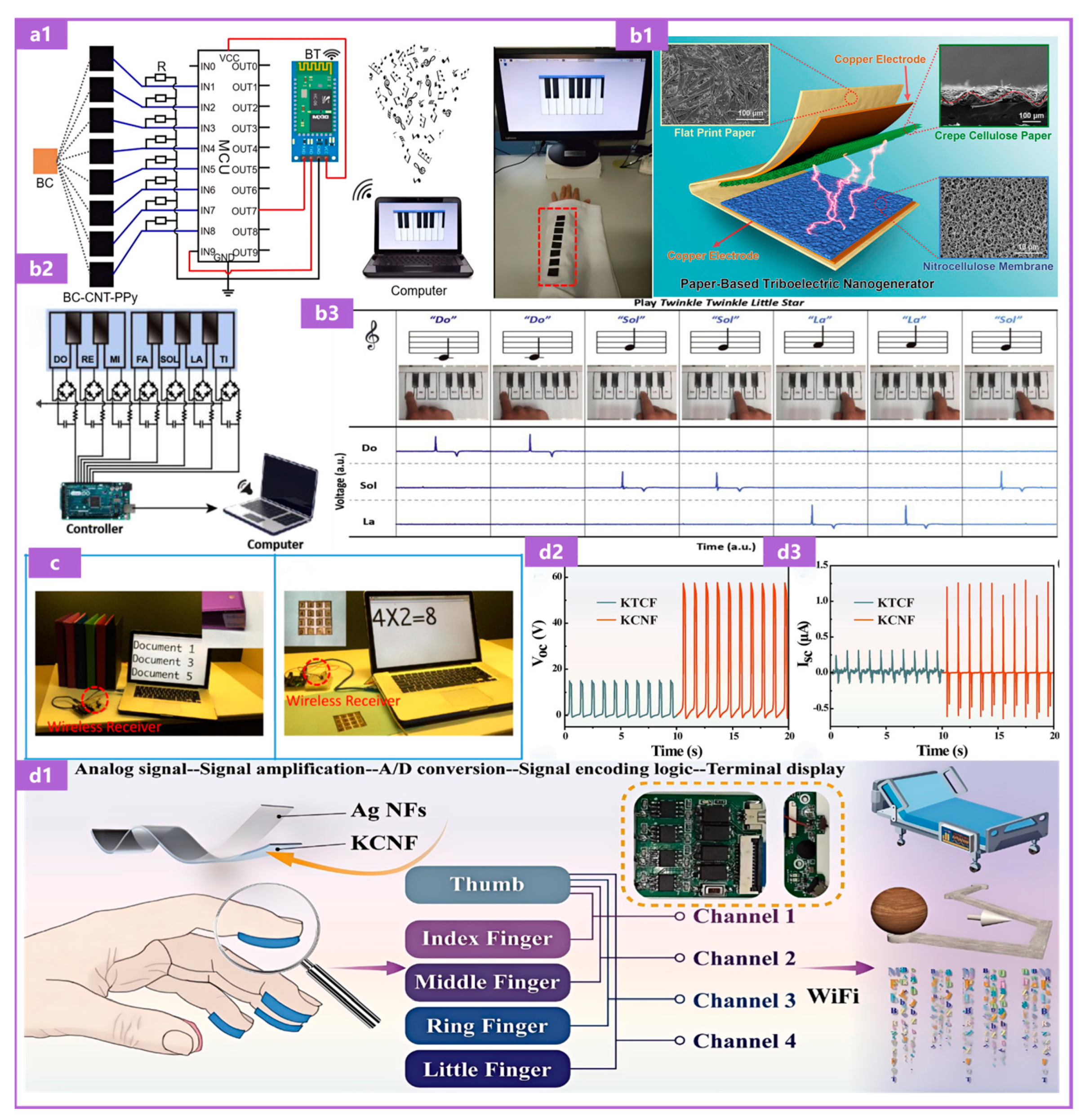

3.5. Human–Computer Interaction

| Type of Material | Application Scenario | Material Effects | Reference |

|---|---|---|---|

| Cellulose and nitrocellulose paper | Harvests energy from human movement | As a friction layer, excellent triboelectric properties | [67] |

| HCP | Harvests energy from human movement | As a friction layer, waterproof | [112] |

| BC | Harvests energy from human movement | As a friction layer, good flexibility | [95] |

| PDA/CNF | Human motion sensor | As a friction layer, it can be degraded naturally | [94] |

| Al2O3/CA | Human motion sensor | As a friction layer, non-toxic and non-irritating | [36] |

| CNF | Human motion sensor | As a friction layer, dispersant and interlocking agent | [96] |

| CNC/PHB | Human motion sensor | As a friction layer, excellent triboelectric properties | [97] |

| BC/HEC | Human motion sensor | As a friction layer, excellent triboelectric properties | [98] |

| CNC/MC | Respiratory rate sensor | As a friction layer, it is lightweight and biodegradable | [88] |

| CNF/DF/AgNW | Respiratory rate sensor | As a friction layer, low-cost, high-strength | [68] |

| CMFs/CNFs | Respiratory rate sensor | As a friction layer, low-cost and sustainable | [99] |

| CNT/Ecoflex | Respiratory rate sensor | As a friction layer, biodegradable | [100] |

| CNF | Heart sensor | As a friction layer, increases the friction area | [101] |

| BC/NWs/NPs | Heart sensor | As a friction layer, high-strength | [102] |

| BN | Heart sensor | As a friction layer, biodegradable | [87] |

| PEO/CCP | Pulse sensor | As a friction layer, excellent triboelectric properties | [103] |

| BaTiO3/BC | Tactile sensors | As a friction layer, excellent triboelectric properties | [104] |

| GHEC | Tactile sensors | As a friction layer, it provides self-healing ability | [105] |

| CANF | Tactile sensors | As a friction layer, low-cost | [106] |

| TOCNF/ISM | Sweat sensor | As a friction layer, excellent triboelectric properties | [107] |

| BC/CNT/PPy | Human–computer interaction | As a friction layer, biodegradable, high-strength | [108] |

| CCP/NCM | Human–computer interaction | Durable as a friction layer | [109] |

| KCNF | Human–computer interaction | Biodegradable as friction layer, high sensitivity | [110] |

| CaCl2/PVA/Keratin/Ecoflex | Human–computer interaction | High sensitivity as a friction layer | [89] |

4. Summary and Prospects

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yao, S.; Swetha, P.; Zhu, Y. Nanomaterial-Enabled Wearable Sensors for Healthcare. Adv. Healthc. Mater. 2018, 7, 1700889. [Google Scholar] [CrossRef] [PubMed]

- Khan, B.; Riaz, Z.; Ahmad, R.U.S.; Khoo, B.L. Advancements in wearable sensors for cardiovascular disease detection for health monitoring. Mater. Sci. Eng. R-Rep. 2024, 159, 100804. [Google Scholar] [CrossRef]

- Liu, W.; Wang, X. Recent advances of nanogenerator technology for cardiovascular sensing and monitoring. Nano Energy 2023, 117, 108910. [Google Scholar] [CrossRef] [PubMed]

- Hu, S.; Chang, S.; Xiao, G.; Lu, J.; Gao, J.; Zhang, Y.; Tao, Y. A Stretchable Multimode Triboelectric Nanogenerator for Energy Harvesting and Self-Powered Sensing. Adv. Mater. Technol. 2022, 7, 2100870. [Google Scholar] [CrossRef]

- Mule, A.R.; Dudem, B.; Graham, S.A.; Yu, J.S. Humidity Sustained Wearable Pouch-Type Triboelectric Nanogenerator for Harvesting Mechanical Energy from Human Activities. Adv. Funct. Mater. 2019, 29, 1807779. [Google Scholar] [CrossRef]

- Kadarina, T.; Priambodo, R. Monitoring heart rate and SpO2 using Things board IoT platform for mother and child preventive healthcare. IOP Conf. Ser. Mater. Sci. Eng. 2018, 453, 012028. [Google Scholar]

- Zois, D.-S. IEEE: Sequential Decision-Making in Healthcare IoT: Real-Time Health Monitoring, Treatments and Interventions. In Proceedings of the IEEE 3rd World Forum on Internet of Things (WF-IoT), Reston, VA, USA, 12–14 December 2016; pp. 24–29. [Google Scholar]

- An, J.; Wang, Z.M.; Jiang, T.; Liang, X.; Wang, Z.L. Whirling-Folded Triboelectric Nanogenerator with High Average Power for Water Wave Energy Harvesting. Adv. Funct. Mater. 2019, 29, 1904867. [Google Scholar] [CrossRef]

- Chen, J.; Yang, J.; Li, Z.; Fan, X.; Zi, Y.; Jing, Q.; Guo, H.; Wen, Z.; Pradel, K.C.; Niu, S.; et al. Networks of Triboelectric Nanogenerators for Harvesting Water Wave Energy: A Potential Approach toward Blue Energy. ACS Nano 2015, 9, 3324–3331. [Google Scholar] [CrossRef]

- Jiang, T.; Pang, H.; An, J.; Lu, P.; Feng, Y.; Liang, X.; Zhong, W.; Wang, Z.L. Robust Swing-Structured Triboelectric Nanogenerator for Efficient Blue Energy Harvesting. Adv. Energy Mater. 2020, 10, 2000064. [Google Scholar] [CrossRef]

- Chen, X.; Xie, X.; Liu, Y.; Zhao, C.; Wen, M.; Wen, Z. Advances in healthcare electronics enabled by triboelectric nanogenerators. Adv. Funct. Mater. 2020, 30, 2004673. [Google Scholar] [CrossRef]

- Cheng, M.; Zhu, G.; Zhang, F.; Tang, W.; Jianping, S.; Yang, J.; Zhu, L. A review of flexible force sensors for human health monitoring. J. Adv. Res. 2020, 26, 53–68. [Google Scholar] [CrossRef]

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.-M. Fiber-Based Wearable Electronics: A Review of Materials, Fabrication, Devices, and Applications. Adv. Mater. 2014, 26, 5310–5336. [Google Scholar] [CrossRef]

- Rao, J.; Chen, Z.; Zhao, D.; Ma, R.; Yi, W.; Zhang, C.; Liu, D.; Chen, X.; Yang, Y.; Wang, X.; et al. Tactile electronic skin to simultaneously detect and distinguish between temperature and pressure based on a triboelectric nanogenerator. Nano Energy 2020, 75, 105073. [Google Scholar] [CrossRef]

- Ren, Z.; Wang, Z.; Liu, Z.; Wang, L.; Guo, H.; Li, L.; Li, S.; Chen, X.; Tang, W.; Wang, Z.L. Energy Harvesting from Breeze Wind (0.7–6 ms−1) Using Ultra-Stretchable Triboelectric Nanogenerator. Adv. Energy Mater. 2020, 10, 2001770. [Google Scholar] [CrossRef]

- Rong, X.; Zhao, J.; Guo, H.; Zhen, G.; Yu, J.; Zhang, C.; Dong, G. Material Recognition Sensor Array by Electrostatic Induction and Triboelectric Effects. Adv. Mater. Technol. 2020, 5, 2000641. [Google Scholar] [CrossRef]

- Aladren, A.; Lopez-Nicolas, G.; Puig, L.; Guerrero, J.J. Navigation Assistance for the Visually Impaired Using RGB-D Sensor with Range Expansion. IEEE Syst. J. 2016, 10, 922–932. [Google Scholar] [CrossRef]

- Ramadhan, A.J. Wearable Smart System for Visually Impaired People. Sensors 2018, 18, 843. [Google Scholar] [CrossRef] [PubMed]

- Jiang, P.; Zhang, L.; Guo, H.; Chen, C.; Wu, C.; Zhang, S.; Wang, Z. Signal output of triboelectric nanogenerator at oil–water–solid multiphase interfaces and its application for dual-signal chemical sensing. Adv. Mater. 2019, 31, 1902793. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Wang, X.; Song, Y.; Cao, R.; Wang, L.; Yan, Z.; Shan, G. Self-powered forest fire alarm system based on impedance matching effect between triboelectric nanogenerator and thermosensitive sensor. Nano Energy 2020, 73, 104843. [Google Scholar] [CrossRef]

- Luo, J.; Wang, Z.; Xu, L.; Wang, A.C.; Han, K.; Jiang, T.; Lai, Q.; Bai, Y.; Tang, W.; Fan, F.R.; et al. Flexible and durable wood-based triboelectric nanogenerators for self-powered sensing in athletic big data analytics. Nat. Commun. 2019, 10, 5147. [Google Scholar] [CrossRef]

- Chao, S.; Ouyang, H.; Jiang, D.; Fan, Y.; Li, Z. Triboelectric nanogenerator based on degradable materials. EcoMat 2021, 3, e12072. [Google Scholar] [CrossRef]

- Yang, W.; Chen, J.; Zhu, G.; Yang, J.; Bai, P.; Su, Y.; Jing, Q.; Cao, X.; Wang, Z.L. Harvesting energy from the natural vibration of human walking. ACS Nano 2013, 7, 11317–11324. [Google Scholar] [CrossRef] [PubMed]

- Zhao, K.; Wang, Z.L.; Yang, Y. Self-Powered Wireless Smart Sensor Node Enabled by an Ultra-Stable, Highly-Efficient, and Super-Hydrophobic-Surfaces-Based Triboelectric Nanogenerator. ACS Nano 2016, 10, 9044. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Muhammad, M.; Cheng, L.; Xie, E.; Han, W. Improved output performance of triboelectric nanogenerators based on polydimethylsiloxane composites by the capacitive effect of embedded carbon nanotubes. Appl. Phys. Lett. 2020, 117, 143903. [Google Scholar] [CrossRef]

- Li, H.; Zhao, S.; Du, X.; Wang, J.; Cao, R.; Xing, Y.; Li, C. A Compound Yarn Based Wearable Triboelectric Nanogenerator for Self-Powered Wearable Electronics. Adv. Mater. Technol. 2018, 3, 1800065. [Google Scholar] [CrossRef]

- Zhu, M.; Huang, Y.; Ng, W.S.; Liu, J.; Wang, Z.; Wang, Z.; Hu, H.; Zhi, C. 3D spacer fabric based multifunctional triboelectric nanogenerator with great feasibility for mechanized large-scale production. Nano Energy 2016, 27, 439–446. [Google Scholar] [CrossRef]

- Ahn, J.; Kim, J.S.; Jeong, Y.; Hwang, S.; Yoo, H.; Jeong, Y.; Gu, J.; Mahato, M.; Ko, J.; Jeon, S.; et al. All-Recyclable Triboelectric Nanogenerator for Sustainable Ocean Monitoring Systems. Adv. Energy Mater. 2022, 12, 2201341. [Google Scholar] [CrossRef]

- Rajabi-Abhari, A.; Li, P.; Bagheri, M.H.; Khan, A.A.; Hao, C.; Tanguy, N.R.; Ban, D.; Yu, L.; Yan, N. Self-healable, recyclable, and mechanically robust vitrimer composite for high-performance triboelectric nanogenerators and self-powered wireless electronics. Nano Energy 2024, 131, 110306. [Google Scholar] [CrossRef]

- Muhd Julkapli, N.; Bagheri, S. Nanocellulose as a green and sustainable emerging material in energy applications: A review. Polym. Adv. Technol. 2017, 28, 1583–1594. [Google Scholar] [CrossRef]

- Zhang, M.; Du, H.; Liu, K.; Nie, S.; Xu, T.; Zhang, X.; Si, C. Fabrication and applications of cellulose-based nanogenerators. Adv. Compos. Hybrid Mater. 2021, 4, 865–884. [Google Scholar] [CrossRef]

- Niu, Z.; Cheng, W.; Cao, M.; Wang, D.; Wang, Q.; Han, J.; Long, Y.; Han, G. Recent advances in cellulose-based flexible triboelectric nanogenerators. Nano Energy 2021, 87, 106175. [Google Scholar] [CrossRef]

- De France, K.; Zeng, Z.; Wu, T.; Nystrom, G. Functional Materials from Nanocellulose: Utilizing Structure-Property Relationships in Bottom-Up Fabrication. Adv. Mater. 2021, 33, 2000657. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Otoni, C.G.; De France, K.J.; Barud, H.S.; Lona, L.M.F.; Cranston, E.D.; Rojas, O.J. Porous nanocellulose gels and foams: Breakthrough status in the development of scaffolds for tissue engineering. Mater. Today 2020, 37, 126–141. [Google Scholar] [CrossRef]

- Vanderfleet, O.M.; Cranston, E.D. Production routes to tailor the performance of cellulose nanocrystals. Nat. Rev. Mater. 2021, 6, 124–144. [Google Scholar] [CrossRef]

- Bai, Z.; Xu, Y.; Li, J.; Zhu, J.; Gao, C.; Zhang, Y.; Wang, J.; Guo, J. An Eco-friendly Porous Nanocomposite Fabric-Based Triboelectric Nanogenerator for Efficient Energy Harvesting and Motion Sensing. Acs Appl. Mater. Interfaces 2020, 12, 42880–42890. [Google Scholar] [CrossRef]

- Yang, M.; Tian, X.; Hua, T. Green and recyclable cellulose based TENG for sustainable energy and human-machine interactive system. Chem. Eng. J. 2022, 442, 136150. [Google Scholar] [CrossRef]

- Chung, H.U.; Kim, B.H.; Lee, J.Y.; Lee, J.; Xie, Z.; Ibler, E.M.; Lee, K.; Banks, A.; Jeong, J.Y.; Kim, J.; et al. Binodal, wireless epidermal electronic systems with in-sensor analytics for neonatal intensive care. Science 2019, 363, eaau0780. [Google Scholar] [CrossRef] [PubMed]

- Rajewsky, N.; Almouzni, G.; Gorski, S.A.; Aerts, S.; Amit, I.; Bertero, M.G.; Bock, C.; Bredenoord, A.L.; Cavalli, G.; Chiocca, S.; et al. LifeTime and improving European healthcare through cell-based interceptive medicine. Nature 2020, 587, 377–386. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.-R.; Tian, Z.-Q.; Wang, Z. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Baytekin, H.; Patashinski, A.; Branicki, M.; Baytekin, B.; Soh, S.; Grzybowski, B.A. The mosaic of surface charge in contact electrification. Science 2011, 333, 308–312. [Google Scholar] [CrossRef]

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 2250–2282. [Google Scholar] [CrossRef]

- Wang, Z. Triboelectric nanogenerators as new energy technology and self-powered sensors—Principles, problems and perspectives. Faraday Discuss. 2014, 176, 447–458. [Google Scholar] [CrossRef] [PubMed]

- Matsunaga, M.; Hirotani, J.; Kishimoto, S.; Ohno, Y. High-output, transparent, stretchable triboelectric nanogenerator based on carbon nanotube thin film toward wearable energy harvesters. Nano Energy 2020, 67, 104297. [Google Scholar] [CrossRef]

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric Nanogenerator: A Foundation of the Energy for the New Era. Adv. Energy Mater. 2019, 9, 1802906. [Google Scholar] [CrossRef]

- Chen, X.; Gao, L.; Chen, J.; Lu, S.; Zhou, H.; Wang, T.; Wang, A.; Zhang, Z.; Guo, S.; Mu, X.; et al. A chaotic pendulum triboelectric-electromagnetic hybridized nanogenerator for wave energy scavenging and self-powered wireless sensing system. Nano Energy 2020, 69, 104440. [Google Scholar] [CrossRef]

- Luo, J.; Xu, L.; Tang, W.; Jiang, T.; Fan, F.R.; Pang, Y.; Chen, L.; Zhang, Y.; Wang, Z.L. Direct-Current Triboelectric Nanogenerator Realized by Air Breakdown Induced Ionized Air Channel. Adv. Energy Mater. 2018, 8, 1800889. [Google Scholar] [CrossRef]

- Quan, T.; Yang, Y. Fully enclosed hybrid electromagnetic-triboelectric nanogenerator to scavenge vibrational energy. Nano Res. 2016, 9, 2226–2233. [Google Scholar] [CrossRef]

- Khandelwal, G.; Raj, N.P.M.J.; Kim, S.-J. Triboelectric nanogenerator for healthcare and biomedical applications. Nano Today 2020, 33, 100882. [Google Scholar] [CrossRef]

- Jiang, H.; Lv, X.; Wang, K. Application of triboelectric nanogenerator in self-powered motion detection devices: A review. APL Mater. 2024, 12, 070601. [Google Scholar] [CrossRef]

- Pan, Y.; Song, J.; Wang, K. Research Progress and Prospects of Liquid–Liquid Triboelectric Nanogenerators: Mechanisms, Applications, and Future Challenges. ACS Appl. Electron. Mater. 2024, 7, 1–12. [Google Scholar] [CrossRef]

- Pan, Y.; Zhu, Y.; Li, Y.; Liu, H.; Cong, Y.; Li, Q.; Wu, M. Homonuclear transition-metal dimers embedded monolayer C2N as promising anchoring and electrocatalytic materials for lithium-sulfur battery: First-principles calculations. Appl. Surf. Sci. 2023, 610, 155507. [Google Scholar] [CrossRef]

- Qi, G.; Du, G.; Wang, K. Progress in estimating the state of health using transfer learning-based electrochemical impedance spectroscopy of lithium-ion batteries. Ionics 2025, 1–13. [Google Scholar] [CrossRef]

- Gao, M.; Yang, Z.; Choi, J.; Wang, C.; Dai, G.; Yang, J. Triboelectric Nanogenerators for Preventive Health Monitoring. Nanomaterials 2024, 14, 336. [Google Scholar] [CrossRef] [PubMed]

- Dong, K.; Peng, X.; Wang, Z. Fiber/fabric-based piezoelectric and triboelectric nanogenerators for flexible/stretchable and wearable electronics and artificial intelligence. Adv. Mater. 2020, 32, 1902549. [Google Scholar] [CrossRef]

- Wang, S.; Lin, L.; Wang, Z. Triboelectric nanogenerators as self-powered active sensors. Nano Energy 2015, 11, 436–462. [Google Scholar] [CrossRef]

- Zhu, G.; Peng, B.; Chen, J.; Jing, Q.; Wang, Z. Triboelectric nanogenerators as a new energy technology: From fundamentals, devices, to applications. Nano Energy 2015, 14, 126–138. [Google Scholar] [CrossRef]

- Zhao, L.; Li, H.; Meng, J.; Li, Z. The recent advances in self-powered medical information sensors. Infomat 2020, 2, 212–234. [Google Scholar] [CrossRef]

- Xia, Z.; Feng, P.-Y.; Jing, X.; Li, H.; Mi, H.-Y.; Liu, Y. Design and optimization principles of cylindrical sliding triboelectric nanogenerators. Micromachines 2021, 12, 567. [Google Scholar] [CrossRef]

- Zhang, Z.; Bai, Y.; Xu, L.; Zhao, M.; Shi, M.; Wang, Z.L.; Lu, X. Triboelectric nanogenerators with simultaneous outputs in both single-electrode mode and freestanding-triboelectric-layer mode. Nano Energy 2019, 66, 104169. [Google Scholar] [CrossRef]

- Niu, S.; Liu, Y.; Chen, X.; Wang, S.; Zhou, Y.S.; Lin, L.; Xie, Y.; Wang, Z. Theory of freestanding triboelectric-layer-based nanogenerators. Nano Energy 2015, 12, 760–774. [Google Scholar] [CrossRef]

- Zhang, H.; Nie, S.; Qin, C.; Wang, S. Products Removal of hexenuronic acid to reduce AOX formation in hot chlorine dioxide bleaching of bagasse pulp. Ind. Crops Prod. 2019, 128, 338–345. [Google Scholar] [CrossRef]

- Beaumont, M.; Tran, R.; Vera, G.; Niedrist, D.; Rousset, A.; Pierre, R.; Shastri, V.P.; Forget, A. Hydrogel-forming algae polysaccharides: From seaweed to biomedical applications. Biomacromolecules 2021, 22, 1027–1052. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.; Zhang, Y.; Phillips, G.O.; Yang, G. Utilization of bacterial cellulose in food. Food Hydrocoll. 2014, 35, 539–545. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating biopolymer and sustainable raw material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Luo, W.; Ciesielski, P.N.; Fang, Z.; Zhu, J.; Henriksson, G.; Himmel, M.E.; Hu, L. Wood-derived materials for green electronics, biological devices, and energy applications. Chem. Rev. 2016, 116, 9305–9374. [Google Scholar] [CrossRef]

- Gu, L.; German, L.; Li, T.; Li, J.; Shao, Y.; Long, Y.; Wang, J.; Wang, X. Interfaces Energy harvesting floor from commercial cellulosic materials for a self-powered wireless transmission sensor system. ACS Appl. Mater. Interfaces 2021, 13, 5133–5141. [Google Scholar] [CrossRef] [PubMed]

- Rajabi-Abhari, A.; Kim, J.-N.; Lee, J.; Tabassian, R.; Mahato, M.; Youn, H.J.; Lee, H.; Oh, I.-K. Diatom bio-silica and cellulose nanofibril for bio-triboelectric nanogenerators and self-powered breath monitoring masks. ACS Appl. Mater. Interfaces 2020, 13, 219–232. [Google Scholar] [CrossRef]

- Sardana, S.; Kaur, H.; Arora, B.; Aswal, D.K.; Mahajan, A. Self-powered monitoring of ammonia using an MXene/TiO2/cellulose nanofiber heterojunction-based sensor driven by an electrospun triboelectric nanogenerator. ACS Sens. 2022, 7, 312–321. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Wang, H.; Du, C.; Zhang, D.; Lin, H.; Chen, Y.; Xiong, J. Cellulose for sustainable triboelectric nanogenerators. Adv. Energy Sustain. Res. 2022, 3, 2100161. [Google Scholar] [CrossRef]

- Hao, X.; Mou, K.; Jiang, X.; Cha, R. High-value applications of nanocellulose. Pap. Biomater. 2017, 2, 58–64. [Google Scholar] [CrossRef]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef]

- Mondal, S. Preparation, properties and applications of nanocellulosic materials. Carbohydr. Polym. 2017, 163, 301–316. [Google Scholar] [CrossRef]

- Sun, Y.; Chu, Y.; Wu, W.; Xiao, H. Nanocellulose-based lightweight porous materials: A review. Carbohydr. Polym. 2021, 255, 117489. [Google Scholar] [CrossRef] [PubMed]

- Tortorella, S.; Vetri Buratti, V.; Maturi, M.; Sambri, L.; Comes Franchini, M.; Locatelli, E. Surface-modified nanocellulose for application in biomedical engineering and nanomedicine: A review. Int. J. Nanomed. 2020, 15, 9909–9937. [Google Scholar] [CrossRef] [PubMed]

- Ren, J.; Ma, J.; Wang, H.; Yu, T.; Wang, K. A comprehensive review on research methods for lithium-ion battery of state of health estimation and end of life prediction: Methods, properties, and prospects. Prot. Control Mod. Power Syst. 2024, 1–20. [Google Scholar] [CrossRef]

- Shang, Y.; Wang, S.; Tang, N.; Fu, Y.; Wang, K. Research progress in fault detection of battery systems: A review. J. Energy Storage 2024, 98, 113079. [Google Scholar] [CrossRef]

- Wang, W.; Yang, D.; Huang, Z.; Hu, H.; Wang, L.; Wang, K. Electrodeless nanogenerator for dust recover. Energy Technol. 2022, 10, 2200699. [Google Scholar] [CrossRef]

- Xing, Q.; Zhang, M.; Fu, Y.; Wang, K. Transfer learning to estimate lithium-ion battery state of health with electrochemical impedance spectroscopy. J. Energy Storage 2025, 110, 115345. [Google Scholar] [CrossRef]

- Yi, Z.; Wang, S.; Li, Z.; Wang, L.; Wang, K. A Novel Approach for State of Health Estimation and Remaining Useful Life Prediction of Supercapacitors Using an Improved Honey Badger Algorithm Assisted Hybrid Neural Network. Prot. Control Mod. Power Syst. 2024, 9, 1–18. [Google Scholar] [CrossRef]

- Nie, S.; Fu, Q.; Lin, X.; Zhang, C.; Lu, Y.; Wang, S. Enhanced performance of a cellulose nanofibrils-based triboelectric nanogenerator by tuning the surface polarizability and hydrophobicity. Chem. Eng. J. 2021, 404, 126512. [Google Scholar] [CrossRef]

- Kim, H.-J.; Yim, E.-C.; Kim, J.-H.; Kim, S.-J.; Park, J.-Y.; Oh, I.-K. Bacterial Nano-Cellulose Triboelectric Nanogenerator. Nano Energy 2017, 33, 130–137. [Google Scholar] [CrossRef]

- Somseemee, O.; Sae-Oui, P.; Siriwong, C. Bio-based epoxidized natural rubber/chitosan/cellulose nanocrystal composites for enhancing mechanical properties, self-healing behavior and triboelectric nanogenerator performance. Cellulose 2022, 29, 8675–8693. [Google Scholar] [CrossRef]

- Fan, C.; Huang, J.; Mensah, A.; Long, Z.; Sun, J.; Wei, Q. A high-performance and biodegradable tribopositive poly-e-caprolactone/ethyl cellulose material. Cell Rep. Phys. Sci. 2022, 3, 101012. [Google Scholar] [CrossRef]

- Bai, Z.; Xu, Y.; Zhang, Z.; Zhu, J.; Gao, C.; Zhang, Y.; Jia, H.; Guo, J. Highly flexible, porous electroactive biocomposite as attractive tribopositive material for advancing high-performance triboelectric nanogenerator. Nano Energy 2020, 75, 104884. [Google Scholar] [CrossRef]

- Wang, N.; Yang, D.; Zhang, W.; Feng, M.; Li, Z.; Ye, E.; Loh, X.J.; Wang, D. Deep Trap Boosted Ultrahigh Triboelectric Charge Density in Nanofibrous Cellulose-Based Triboelectric Nanogenerators. Acs Appl. Mater. Interfaces 2023, 15, 997–1009. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Li, H.; Liu, Z.; Li, Z.; Tian, J.; Shi, B.; Zou, Y.; Ouyang, H.; Zhao, C.; Zhao, L.; et al. Fully Bioabsorbable Natural-Materials-Based Triboelectric Nanogenerators. Adv. Mater. 2018, 30, 1801895. [Google Scholar] [CrossRef]

- Wang, T.; Li, S.; Tao, X.; Yan, Q.; Wang, X.; Chen, Y.; Huang, F.; Li, H.; Chen, X.; Bian, Z. Fully biodegradable water-soluble triboelectric nanogenerator for human physiological monitoring. Nano Energy 2022, 93, 106787. [Google Scholar] [CrossRef]

- Zhang, Z.; Cai, J. A Triboelectric Joint Sensor Imitating Soft Robot for Human Joint Rehabilitation Monitoring. Nano 2022, 17, 2250059. [Google Scholar] [CrossRef]

- Bai, J.; Lian, S.; Liu, Z.; Wang, K.; Liu, D. Smart Guiding Glasses for Visually Impaired People in Indoor Environment. IEEE Trans. Consum. Electron. 2017, 63, 258–266. [Google Scholar] [CrossRef]

- Shi, K.; Zou, H.; Sun, B.; Jiang, P.; He, J.; Huang, X. Dielectric modulated cellulose paper/PDMS-based triboelectric nanogenerators for wireless transmission and electropolymerization applications. Adv. Funct. Mater. 2020, 30, 1904536. [Google Scholar] [CrossRef]

- Ashammakhi, N.; Hernandez, A.L.; Unluturk, B.D.; Quintero, S.A.; de Barros, N.R.; Hoque Apu, E.; Bin Shams, A.; Ostrovidov, S.; Li, J.; Contag, C. Biodegradable implantable sensors: Materials design, fabrication, and applications. Adv. Funct. Mater. 2021, 31, 2104149. [Google Scholar] [CrossRef]

- Chen, S.; Qi, J.; Fan, S.; Qiao, Z.; Yeo, J.C.; Lim, C. Flexible wearable sensors for cardiovascular health monitoring. Adv. Healthc. Mater. 2021, 10, 2100116. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Wang, T.; Wei, Y.; Sun, X.; Zhang, S.; Wang, X.; Luo, L. Low-cost, environmentally friendly and high-performance cellulose-based triboelectric nanogenerator for self-powered human motion monitoring. Cellulose 2022, 29, 8733–8747. [Google Scholar] [CrossRef]

- Shao, Y.; Feng, C.; Deng, B.; Yin, B.; Yang, M. Facile method to enhance output performance of bacterial cellulose nanofiber based triboelectric nanogenerator by controlling micro-nano structure and dielectric constant. Nano Energy 2019, 62, 620–627. [Google Scholar] [CrossRef]

- Cao, W.; Ouyang, H.; Xin, W.; Chao, S.; Ma, C.; Li, Z.; Chen, F.; Ma, M. A Stretchable Highoutput Triboelectric Nanogenerator Improved by MXene Liquid Electrode with High Electronegativity. Adv. Funct. Mater. 2020, 30, 2004181. [Google Scholar] [CrossRef]

- Wang, C.; Lu, L.; Li, W.; Shao, D.; Zhang, C.; Lu, J.; Yang, W. Green-in-green biohybrids as transient biotriboelectric nanogenerators. iScience 2022, 25, 105494. [Google Scholar] [CrossRef]

- Luo, C.; Shao, Y.; Yu, H.; Ma, H.; Zhang, Y.; Yin, B.; Yang, M. Improving the Output Performance of Bacterial Cellulose-Based Triboelectric Nanogenerators by Modulating the Surface Potential in a Simple Method. Acs Sustain. Chem. Eng. 2022, 10, 13050–13058. [Google Scholar] [CrossRef]

- He, X.; Zou, H.; Geng, Z.; Wang, X.; Ding, W.; Hu, F.; Zi, Y.; Xu, C.; Zhang, S.L.; Yu, H.; et al. A Hierarchically Nanostructured Cellulose Fiber-Based Triboelectric Nanogenerator for Self-Powered Healthcare Products. Adv. Funct. Mater. 2018, 28, 1805540. [Google Scholar] [CrossRef]

- Zhang, M.; Wen, Y.; Xie, Z.; Liu, B.; Sun, F.; An, Z.; Zhong, Y.; Feng, Q.; Zhao, T.; Mao, Y. Wireless Sensing System Based on Biodegradable Triboelectric Nanogenerator for Evaluating Sports and Sleep Respiratory. Macromol. Rapid Commun. 2024, 45, 2400151. [Google Scholar] [CrossRef]

- Zhang, C.; Lin, X.; Zhang, N.; Lu, Y.; Wu, Z.; Liu, G.; Nie, S. Chemically functionalized cellulose nanofibrils-based gear-like triboelectric nanogenerator for energy harvesting and sensing. Nano Energy 2019, 66, 104126. [Google Scholar] [CrossRef]

- Oh, H.; Kwak, S.S.; Kim, B.; Han, E.; Lim, G.-H.; Kim, S.-W.; Lim, B. Highly Conductive Ferroelectric Cellulose Composite Papers for Efficient Triboelectric Nanogenerators. Adv. Funct. Mater. 2019, 29, 1904066. [Google Scholar] [CrossRef]

- Lin, C.; Zhao, H.; Huang, H.; Ma, X.; Cao, S. PEO/cellulose composite paper based triboelectric nanogenerator and its application in human-health detection. Int. J. Biol. Macromol. 2023, 228, 251–260. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Shao, Y.; Luo, C.; Li, Y.; Ma, H.-Z.; Zhang, Y.-H.; Yin, B.; Shen, J.; Yang, M. Bacterial cellulose nanofiber triboelectric nanogenerator based on dielectric particles hybridized system. Compos. Part A-Appl. Sci. Manuf. 2021, 151, 106646. [Google Scholar] [CrossRef]

- Li, X.; Xiang, S.; Ling, D.; Zhang, S.; Li, C.; Dai, R.; Zhu, P.; Liu, X.; Pan, Z. Stretchable, self-healing, transparent macromolecular elastomeric gel and PAM/carrageenan hydrogel for self-powered touch sensors. Mater. Sci. Eng. B Adv. Funct. Solid-State Mater. 2022, 283, 115832. [Google Scholar] [CrossRef]

- Varghese, H.; Hakkeem, H.M.A.; Farman, M.; Thouti, E.; Pillai, S.; Chandran, A. Self-powered flexible triboelectric touch sensor based on micro-pyramidal PDMS films and cellulose acetate nanofibers. Results Eng. 2022, 16, 100550. [Google Scholar] [CrossRef]

- Qin, Y.; Mo, J.; Liu, Y.; Zhang, S.; Wang, J.; Fu, Q.; Wang, S.; Nie, S. Stretchable Triboelectric Self-Powered Sweat Sensor Fabricated from Self-Healing Nanocellulose Hydrogels. Adv. Funct. Mater. 2022, 32, 1904066. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, S.; Shi, Z.; Wang, Y.; Lei, Y.; Han, J.; Xiong, Y.; Sun, J.; Zheng, L.; Sun, Q.; et al. Eco-friendly and recyclable all cellulose triboelectric nanogenerator and self-powered interactive interface. Nano Energy 2021, 89, 106354. [Google Scholar] [CrossRef]

- Chen, S.; Jiang, J.; Xu, F.; Gong, S. Crepe cellulose paper and nitrocellulose membrane-based triboelectric nanogenerators for energy harvesting and self-powered human-machine interaction. Nano Energy 2019, 61, 69–77. [Google Scholar] [CrossRef]

- He, X.; Zi, Y.; Yu, H.; Zhang, S.L.; Wang, J.; Ding, W.; Zou, H.; Zhang, W.; Lu, C.; Wang, Z.L. An ultrathin paper-based self-powered system for portable electronics and wireless human-machine interaction. Nano Energy 2017, 39, 328–336. [Google Scholar] [CrossRef]

- Shi, Y.; Lin, C.; Deng, P.; Cao, L.N.; Wang, W.; Li, W.; Lin, H.; Yang, Y.; Wang, H.; Ye, M.; et al. Self-powered wearable human-computer interaction system based on kapok cellulose nanofibers. Chem. Eng. J. 2024, 488, 151059. [Google Scholar] [CrossRef]

- Lin, C.; Huang, H.; Zhao, H.; Cao, S.; Ma, X. Acid- and Alkali-Resistant and High-Performance Cellulose Paper-Based Triboelectric Nanogenerator by Controlling the Surface Hydrophobicity. ACS Sustain. Chem. Eng. 2022, 10, 13669–13679. [Google Scholar] [CrossRef]

| Number | Operating Mode | Advantage | Drawback |

|---|---|---|---|

| 1 | Vertical contact separation mode | Stable and high output, difficult to achieve air fault conditions | More complex structures and manufacturing processes |

| 2 | Lateral sliding mode | Charge due to back and forth motion | Wear and tear issues |

| 3 | Single-electrode mode | Easy to design and manufacture with one free layer | Negatively affected by the electrostatic shielding effect |

| 4 | Freestanding triboelectric layer mode | High output performance, high energy conversion efficiency | Complex structures and manufacturing processes |

| Nanocellulose | Categorization | Effect | Reference | |

| CNF | As a friction layer, it enhances the hardness and tensile strength of the composite material, so that the mechanical properties of the material can be improved. | [81] | ||

| BC | As a friction layer, the abundance of polar hydroxyl groups on the surface gives it strong chemical reaction activity, while the large aspect ratio of CNF can provide mechanical support for the TENG, and make it have certain strength and flexibility. | [82] | ||

| CNC | As a friction layer, it enhances the flexibility, biocompatibility, and eco-friendliness of the TENG. | [83] | ||

| Cellulose derivative | Categorization | Modification method | Modification effect | Reference |

| Ethyl cellulose (EC) | Etherification | Enhanced friction electrical properties | [84] | |

| Cellulose acetate (CA) | Esterification | Enhanced friction electrical properties | [85] | |

| CNF-SO3Na | Sulfonation | Enhanced friction electrical properties | [86] | |

| Comparison Item | Cellulose Triboelectric Materials | Metal Triboelectric Materials | Polymer Triboelectric Materials |

|---|---|---|---|

| Source and Sustainability | Renewable, widely available (e.g., plant fibers) | Non-renewable, based on metal ores | Non-renewable, petroleum-based synthetic materials |

| Environmental Friendliness | Biodegradable, environmentally friendly | Non-biodegradable, potential for resource waste and environmental pollution | Most are non-biodegradable, with potential environmental impact |

| Cost | Low cost | Higher cost, especially for precious metals | Varies by material, some are expensive |

| Mechanical Properties | Good flexibility, foldable, cuttable | Rigid, some metals are brittle | Flexibility varies by material, some are brittle |

| Triboelectric Performance | Can be significantly enhanced through modification (e.g., chemical grafting, composite modification) | Good conductivity, but limited triboelectric performance | Some materials (e.g., PTFE) have excellent triboelectric performance |

| Biocompatibility | High, suitable for biomedical and wearable applications | Low, some metals may cause allergic reactions | Some materials have poor biocompatibility |

| Electrode Compatibility | Can be used as electrode materials (e.g., conductive cellulose paper) | High conductivity, but may increase device weight | Conductivity varies by material, but some require additional electrodes |

| Processability | Easy to process, can be modified through various methods | Processing is more complex and requires specific techniques | Diverse processing methods, but some materials are difficult to process |

| Extreme Environment Resistance | Resistant to high temperatures, humidity, and strong light | High-temperature resistance, but corrosion resistance needs optimization | Some polymers experience performance degradation in high-temperature and high-humidity environments |

| Application Fields | Self-powered wearable devices, high-temperature sensing, intelligent monitoring | Electronic devices, sensors, etc. | Energy harvesting, electronic devices, etc. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, N.; He, L.; Wang, K. Self-Driven Miniature Sensing Technology Based on Cellulose-Based Triboelectric Nanogenerators in a Wearable Human Health Status Monitoring System. Coatings 2025, 15, 149. https://doi.org/10.3390/coatings15020149

Xiao N, He L, Wang K. Self-Driven Miniature Sensing Technology Based on Cellulose-Based Triboelectric Nanogenerators in a Wearable Human Health Status Monitoring System. Coatings. 2025; 15(2):149. https://doi.org/10.3390/coatings15020149

Chicago/Turabian StyleXiao, Na, Longqing He, and Kai Wang. 2025. "Self-Driven Miniature Sensing Technology Based on Cellulose-Based Triboelectric Nanogenerators in a Wearable Human Health Status Monitoring System" Coatings 15, no. 2: 149. https://doi.org/10.3390/coatings15020149

APA StyleXiao, N., He, L., & Wang, K. (2025). Self-Driven Miniature Sensing Technology Based on Cellulose-Based Triboelectric Nanogenerators in a Wearable Human Health Status Monitoring System. Coatings, 15(2), 149. https://doi.org/10.3390/coatings15020149