Microchemical Analysis of Rammed Earth Residential Walls Surface in Xiaochikan Village, Guangdong

Abstract

1. Introduction

1.1. Research Background

1.2. Literature Review

1.3. Problem Statement and Objectives

2. Materials and Methods

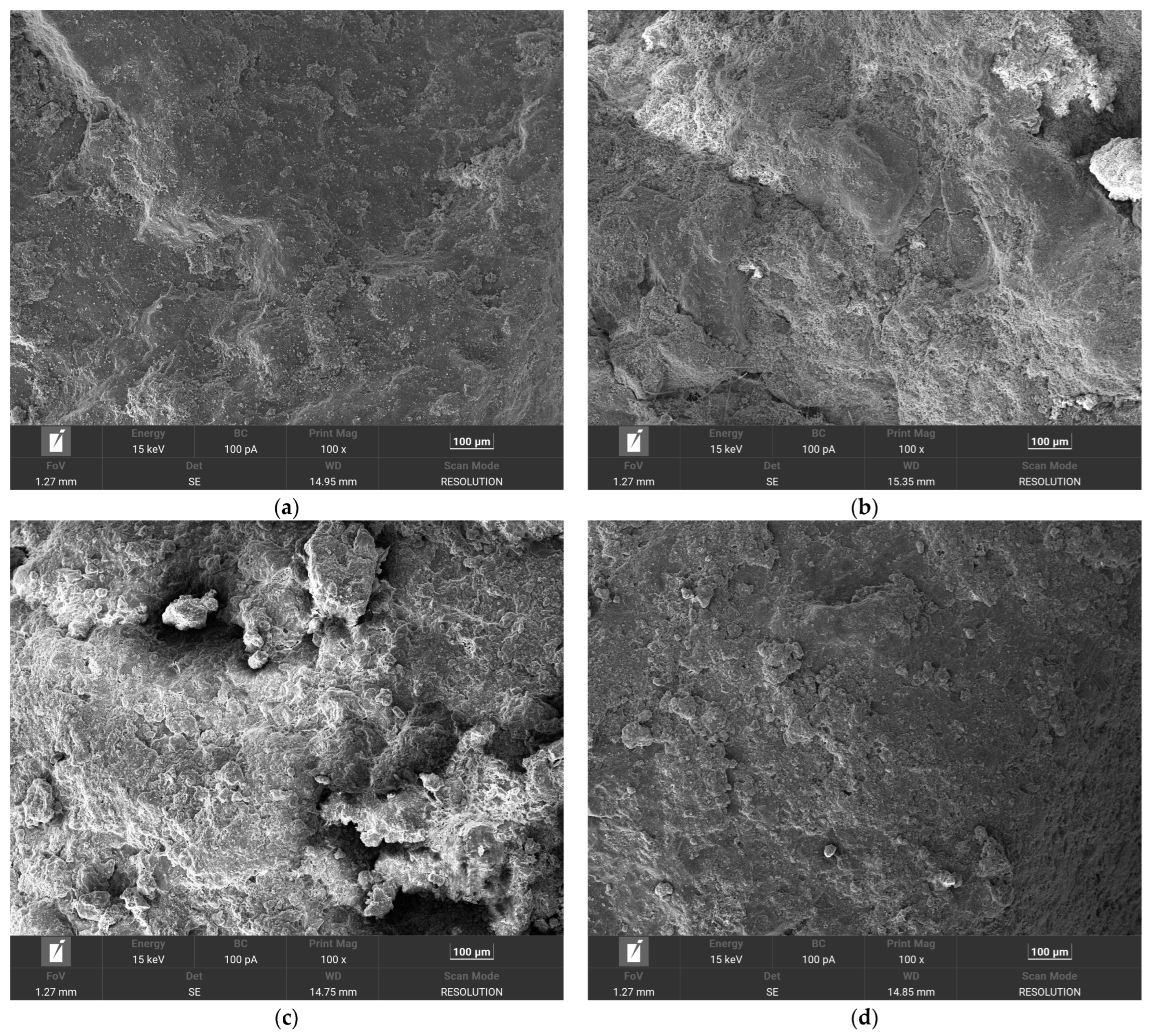

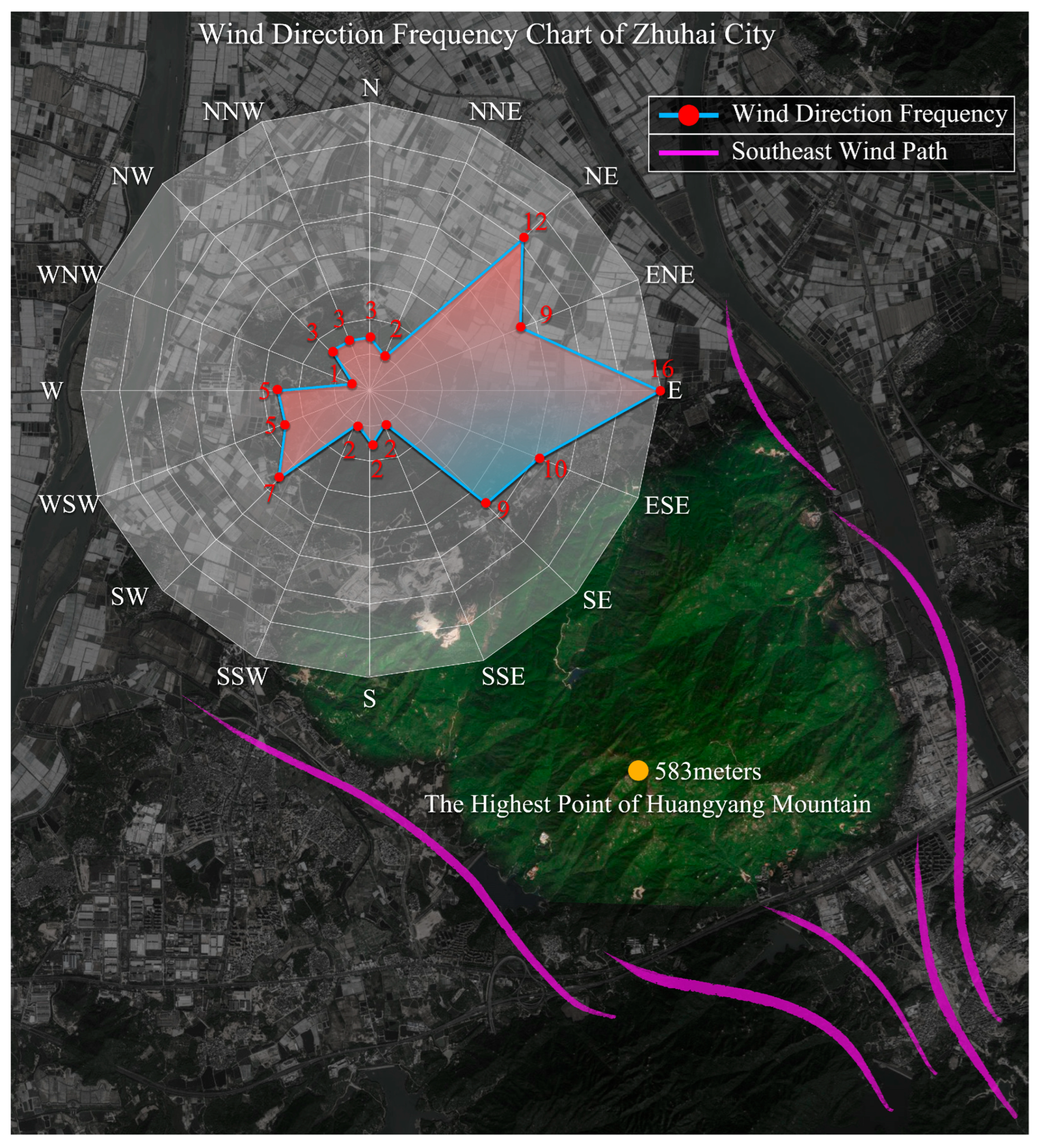

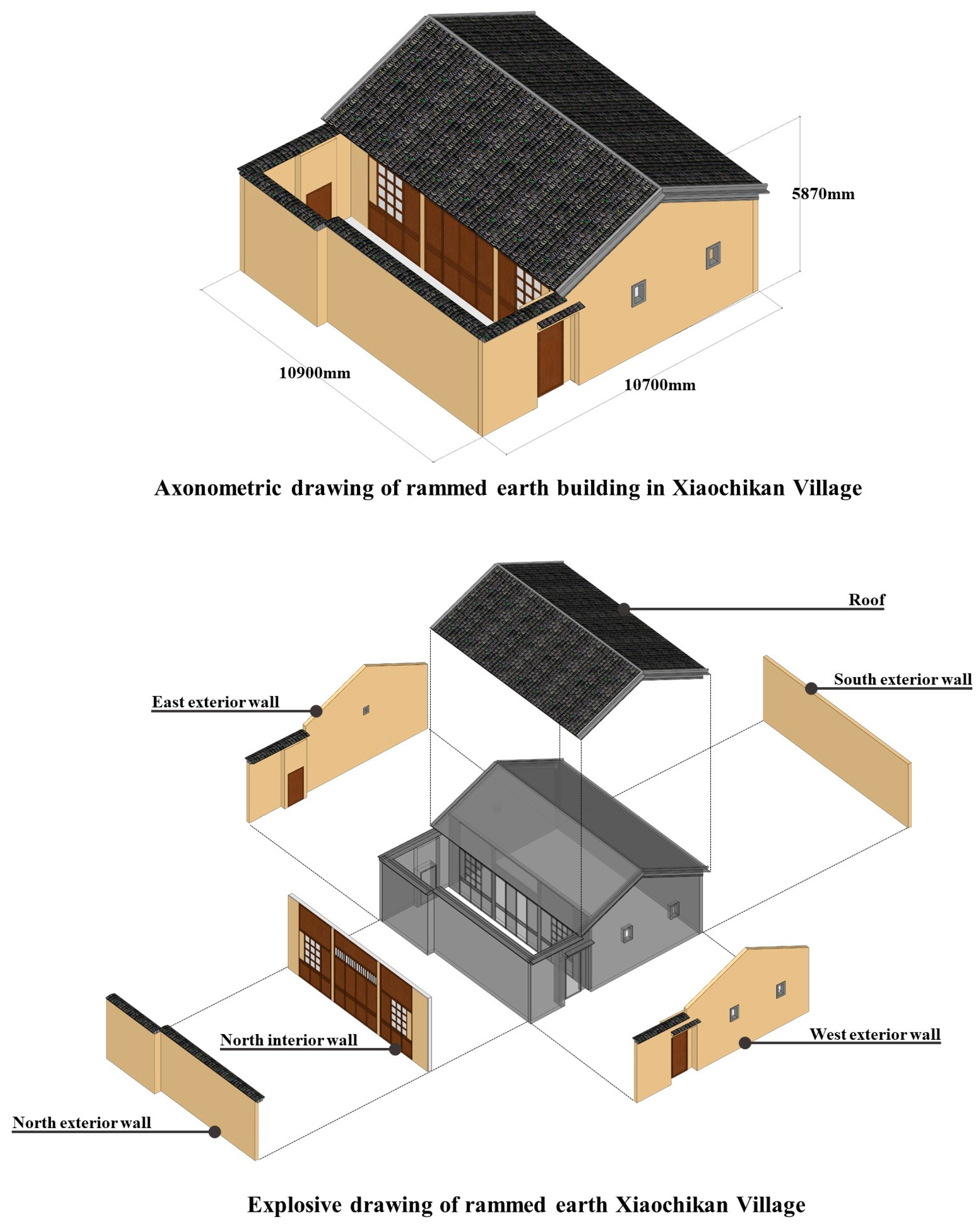

2.1. Study Area: Xiaochikan Village in Guangdong

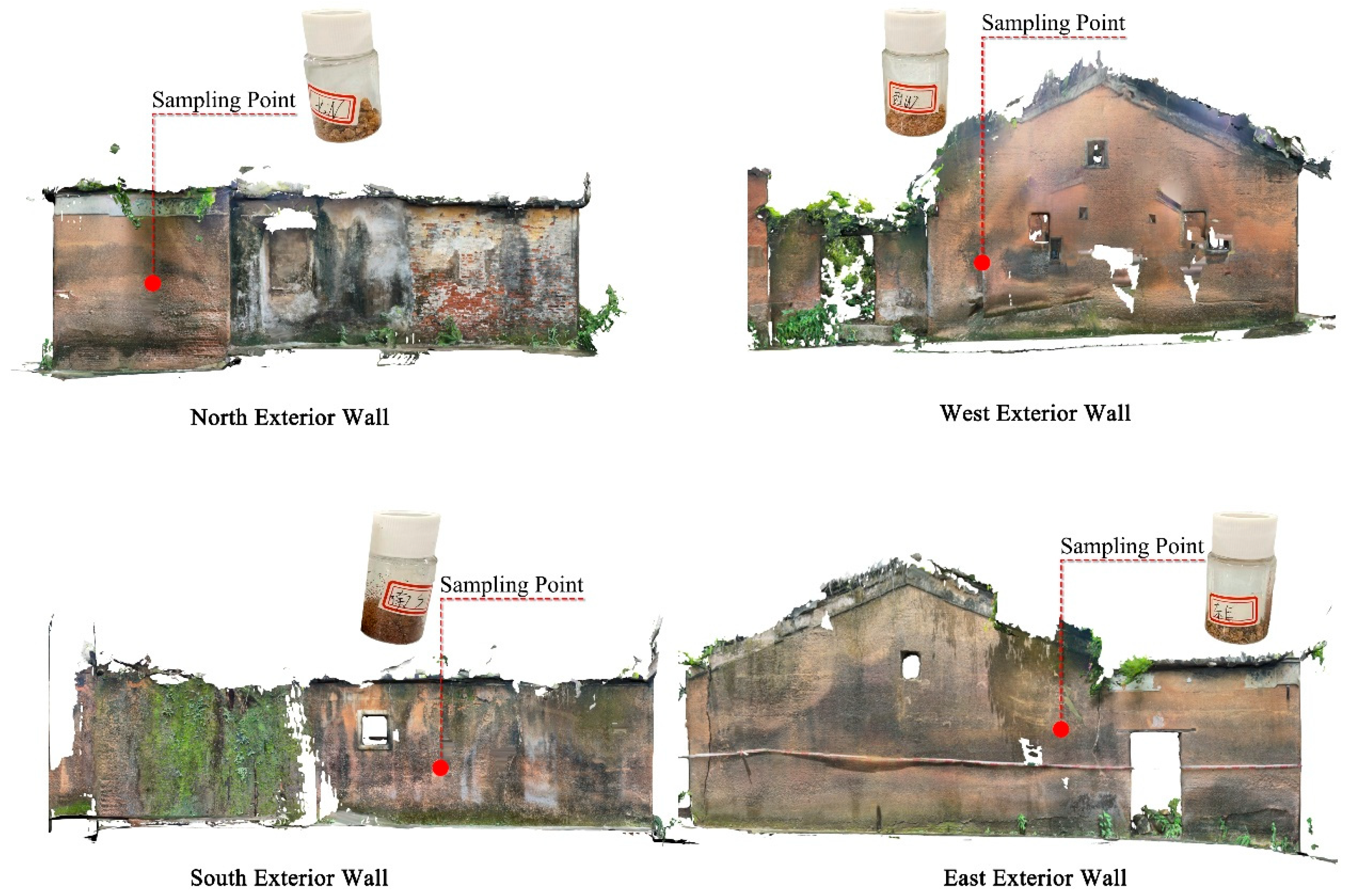

2.2. Field Investigation and Sample Collection

2.3. Analytical Techniques

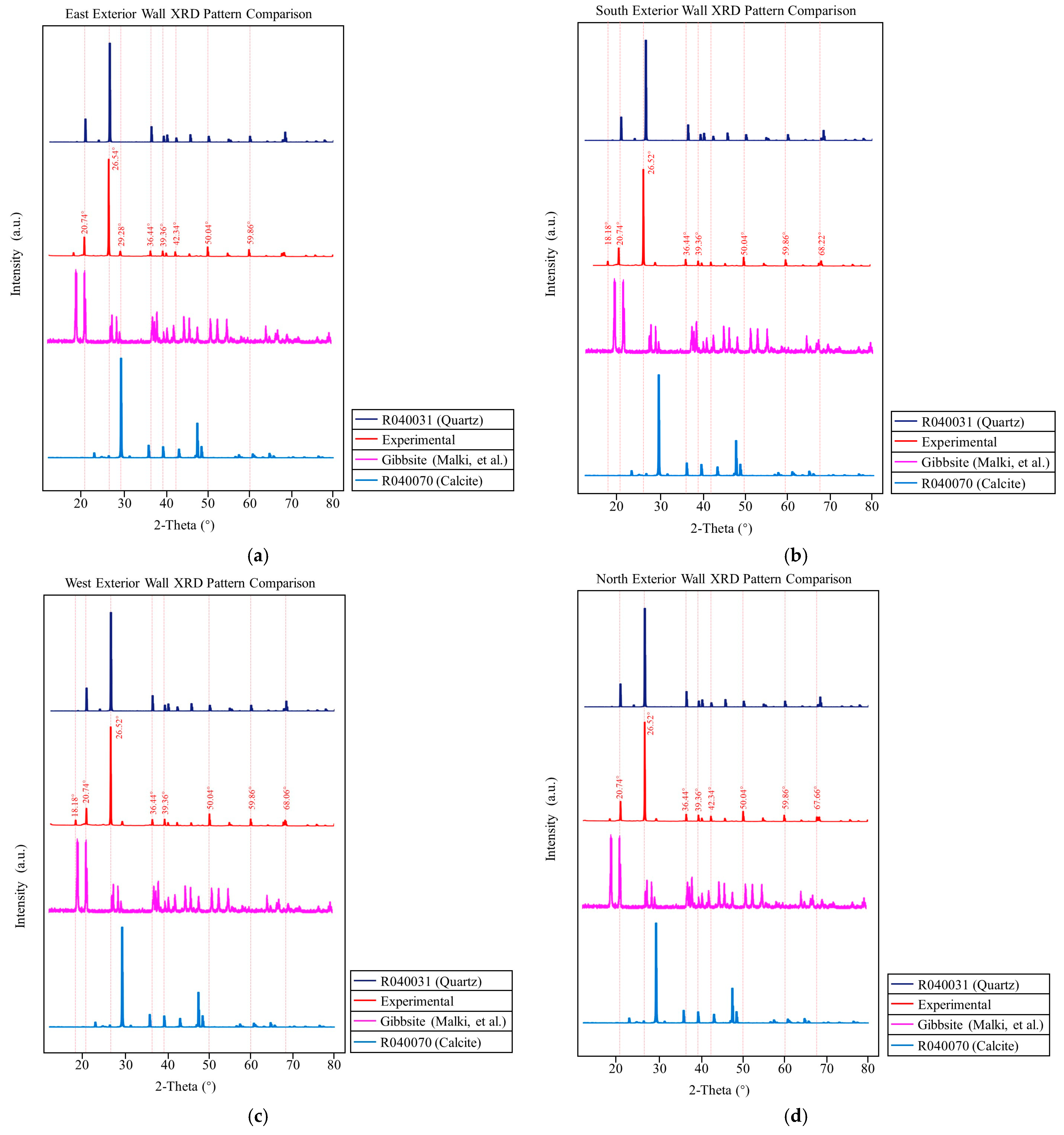

2.3.1. X-Ray Diffraction Analysis

2.3.2. SEM-EDS Analysis

3. Results

3.1. Mineral Composition Comparison Results

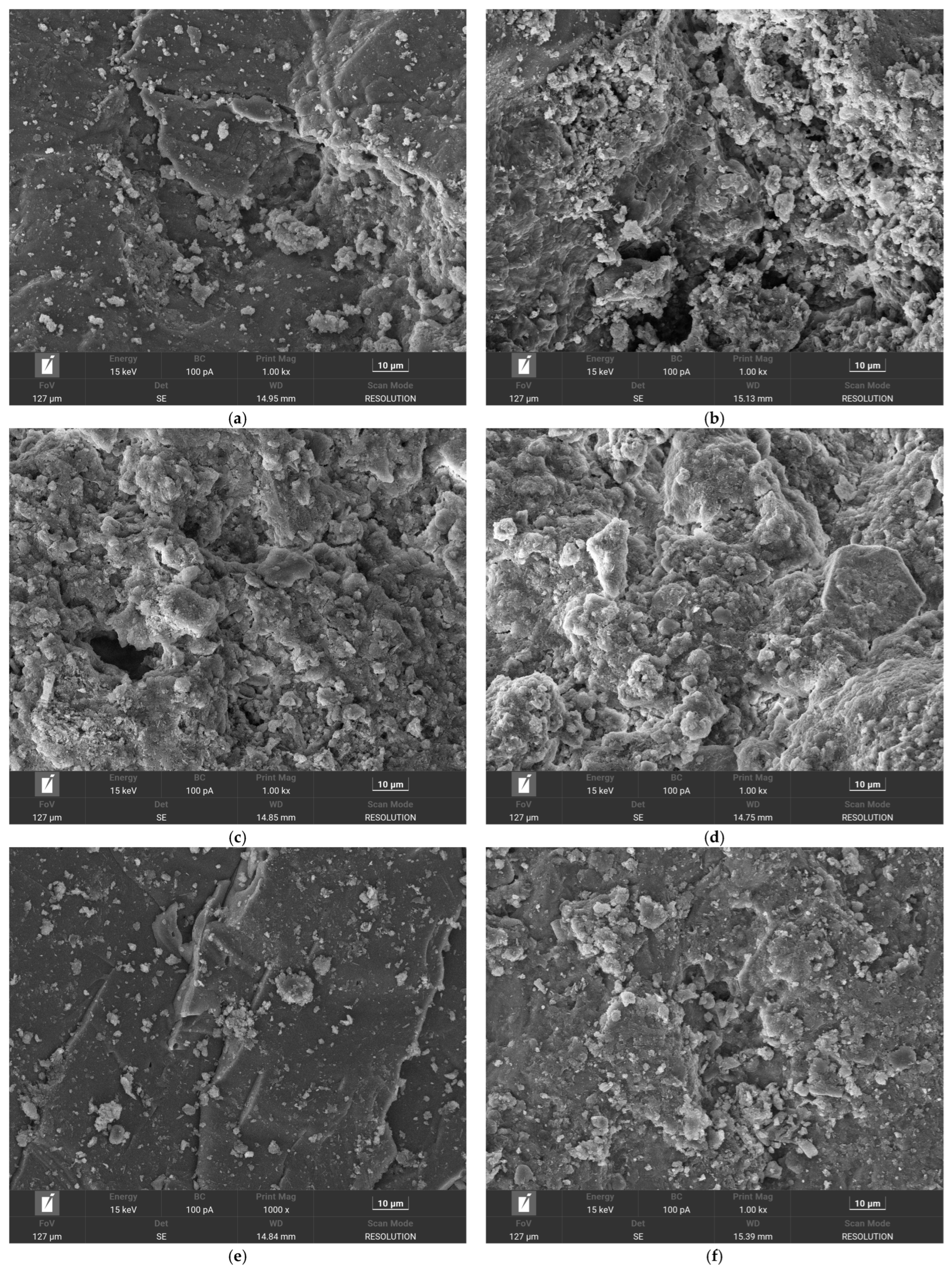

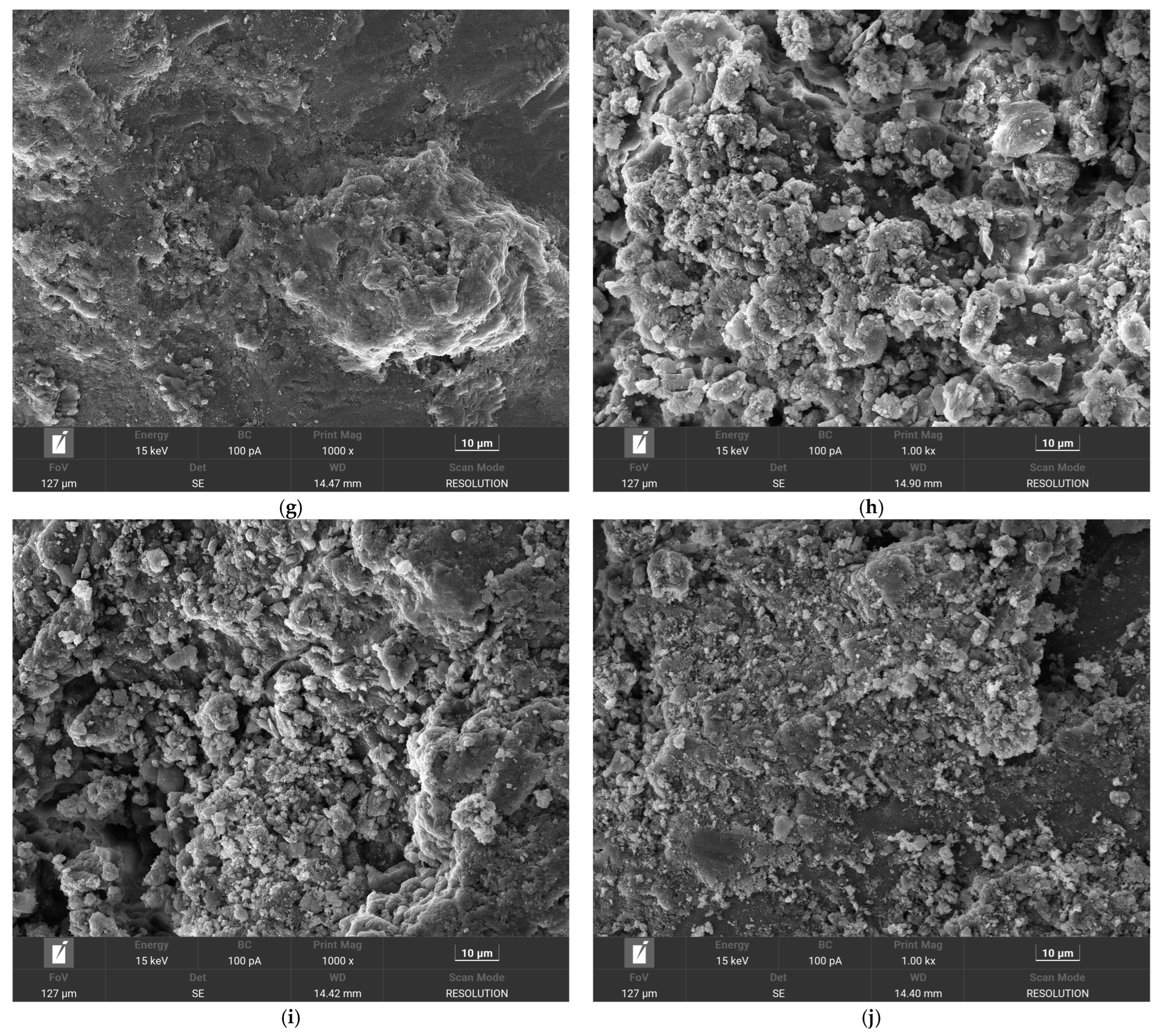

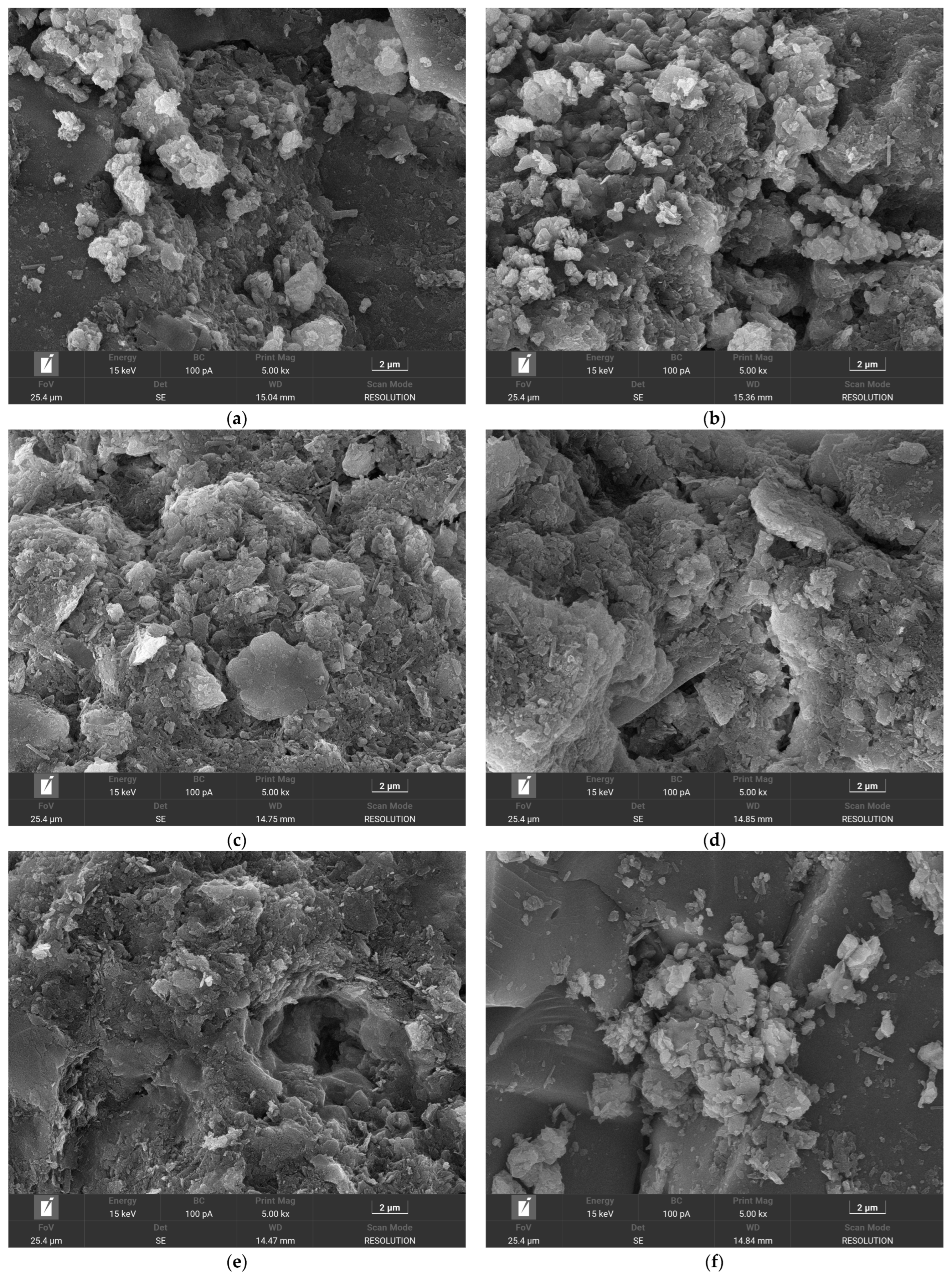

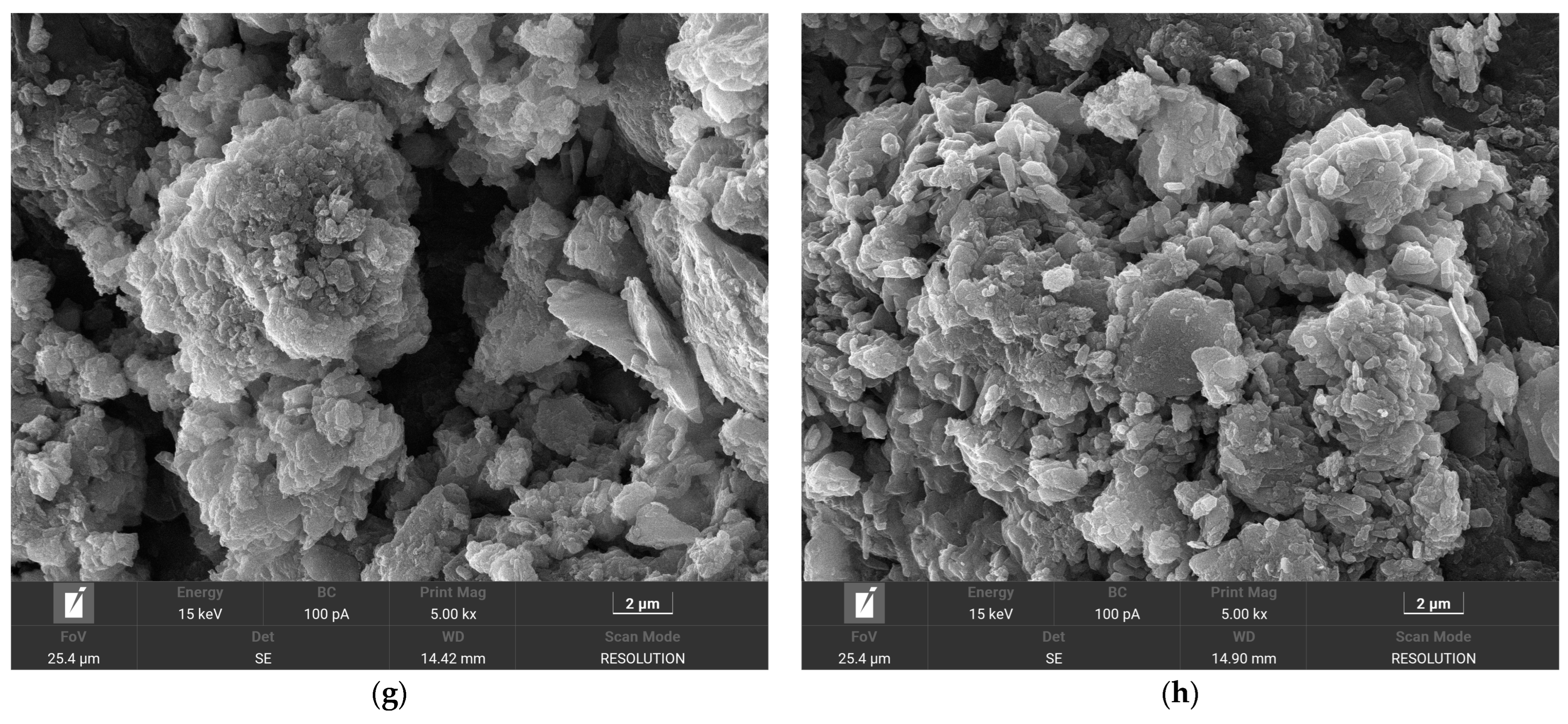

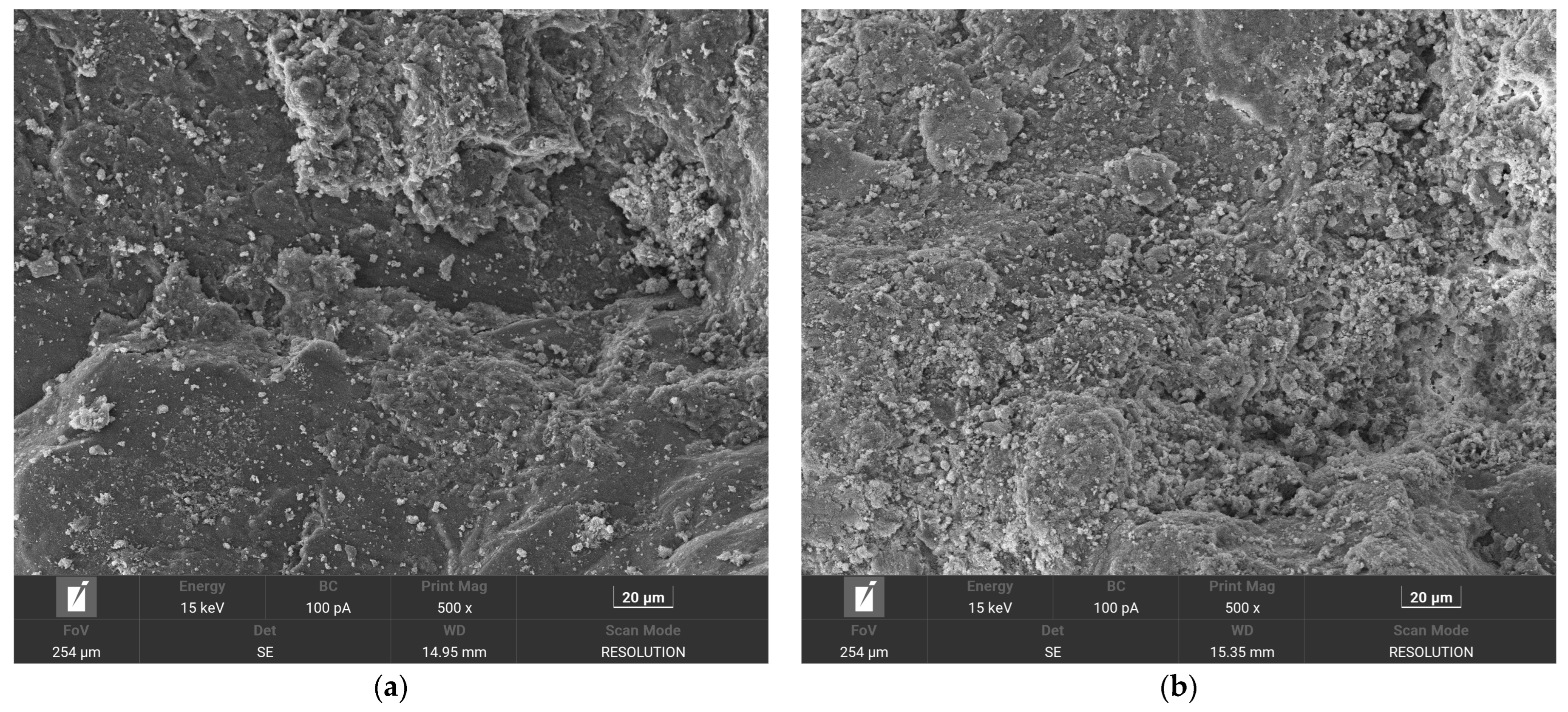

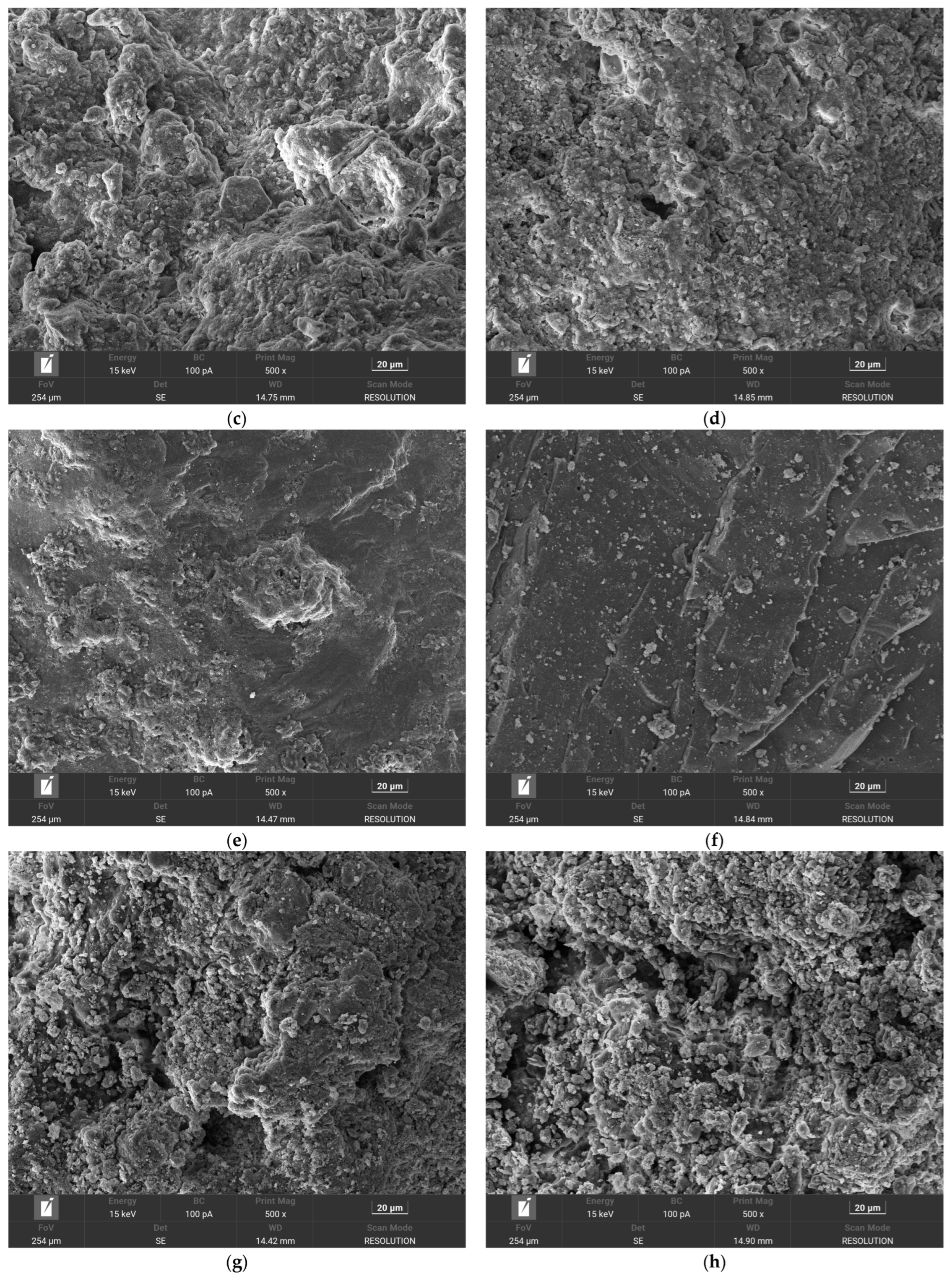

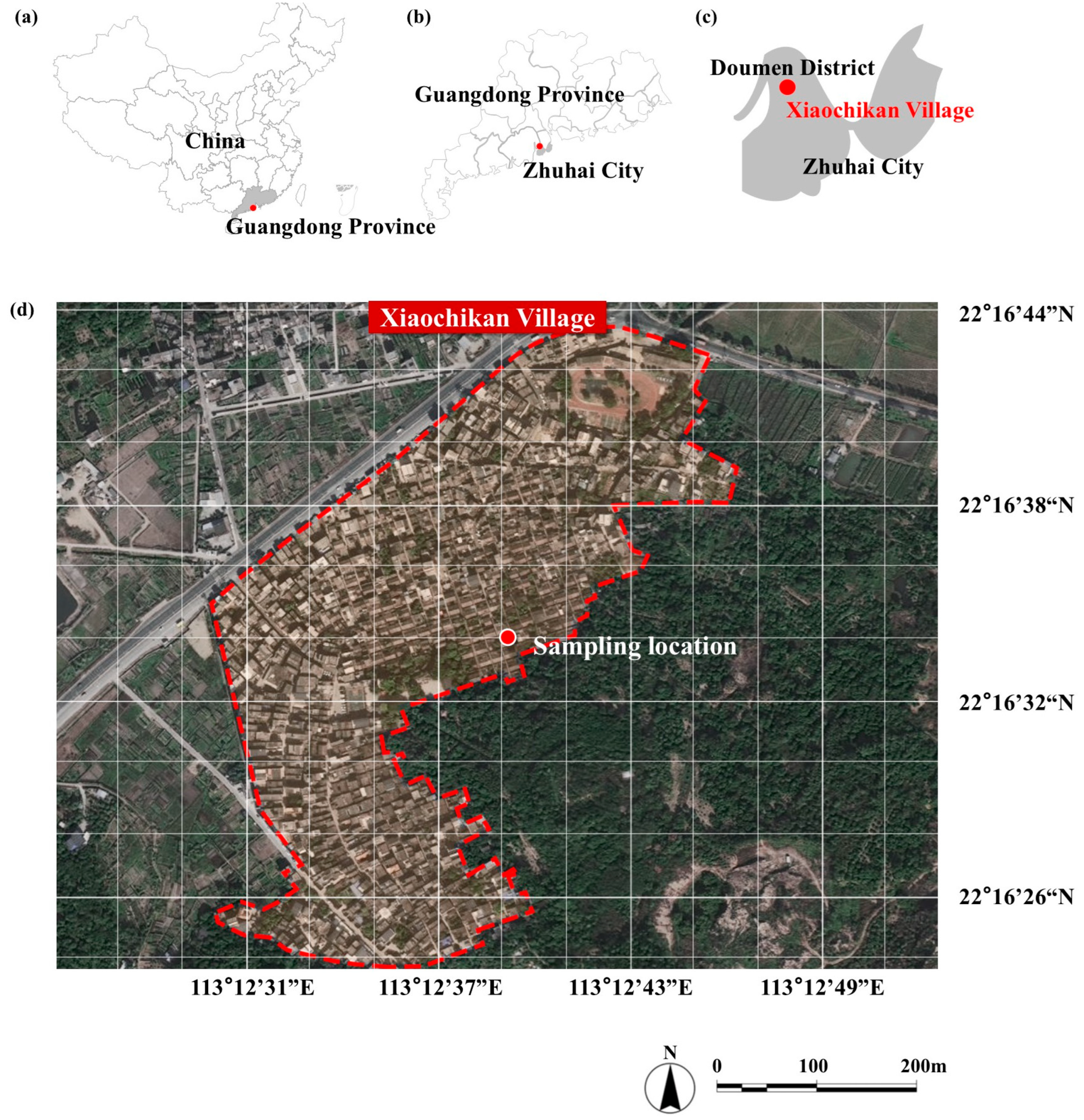

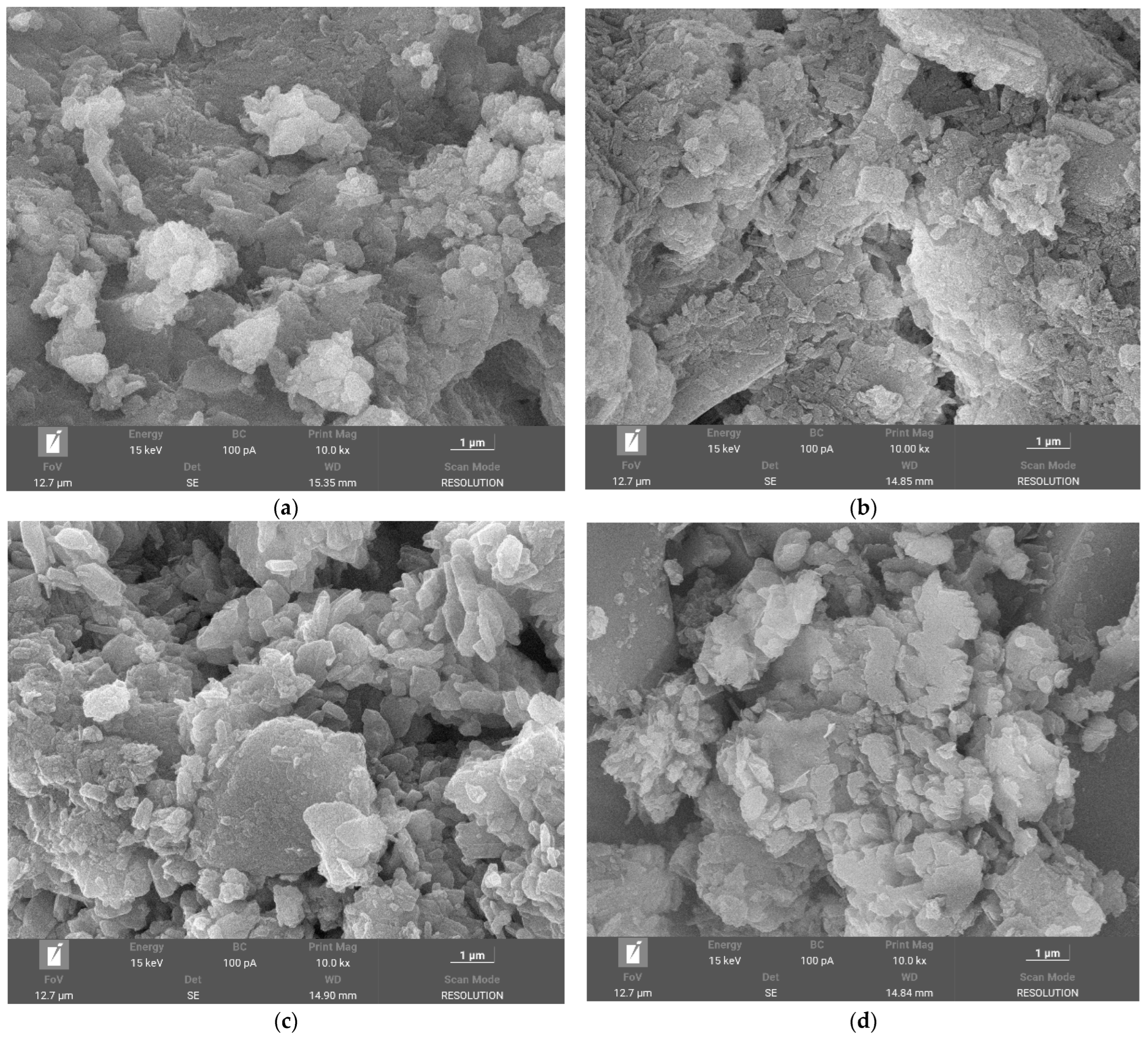

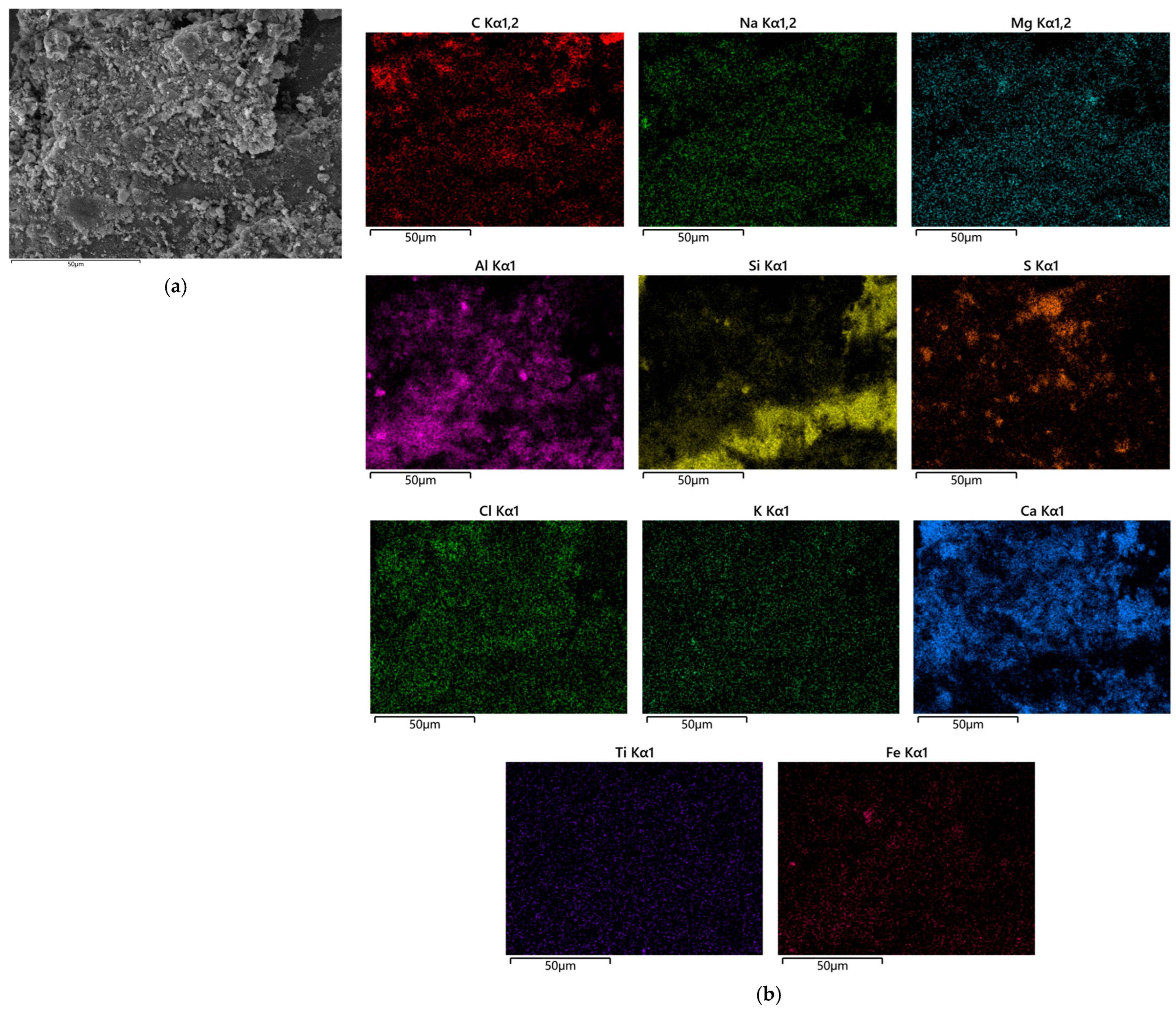

3.2. Comparison Results of SEM Images

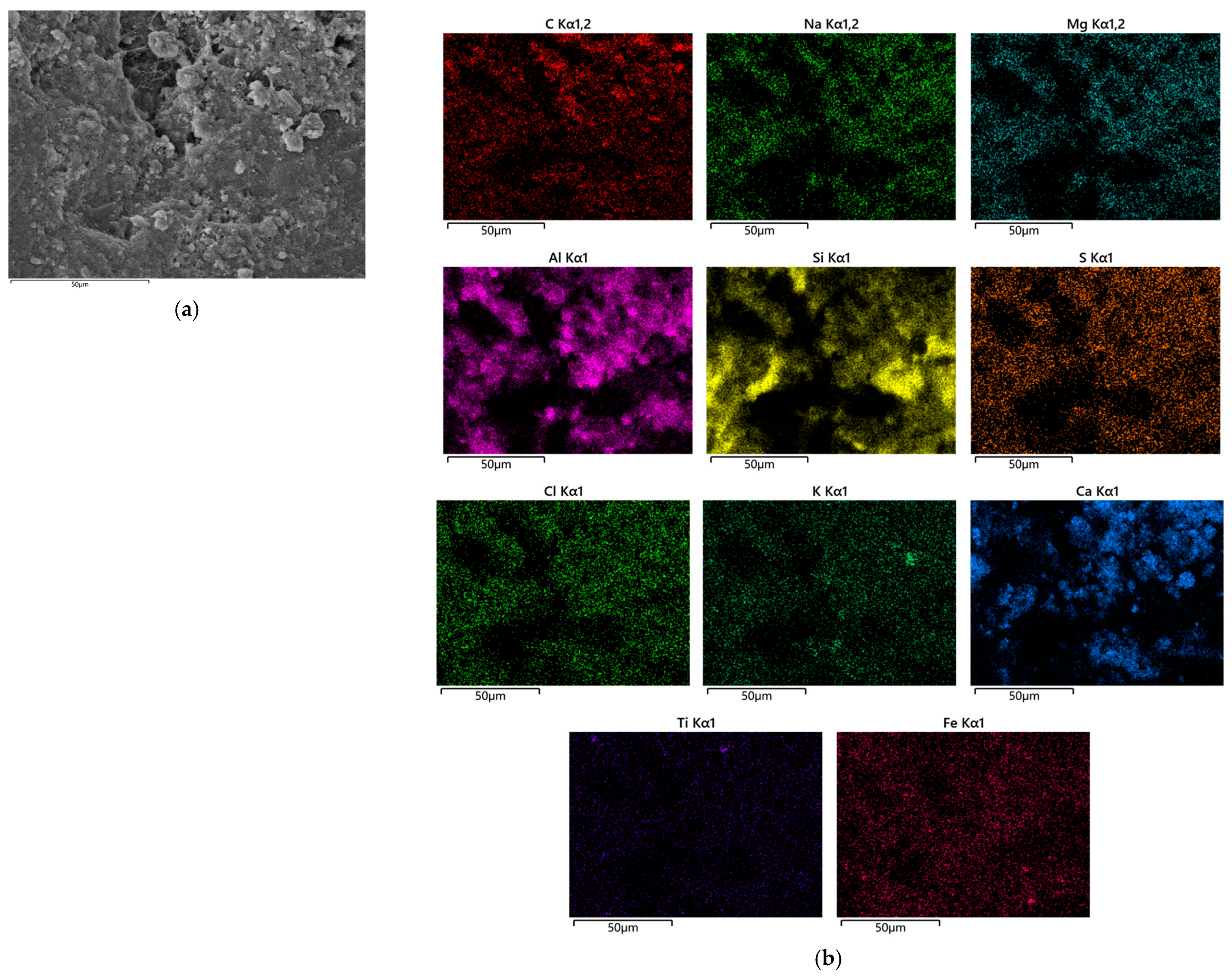

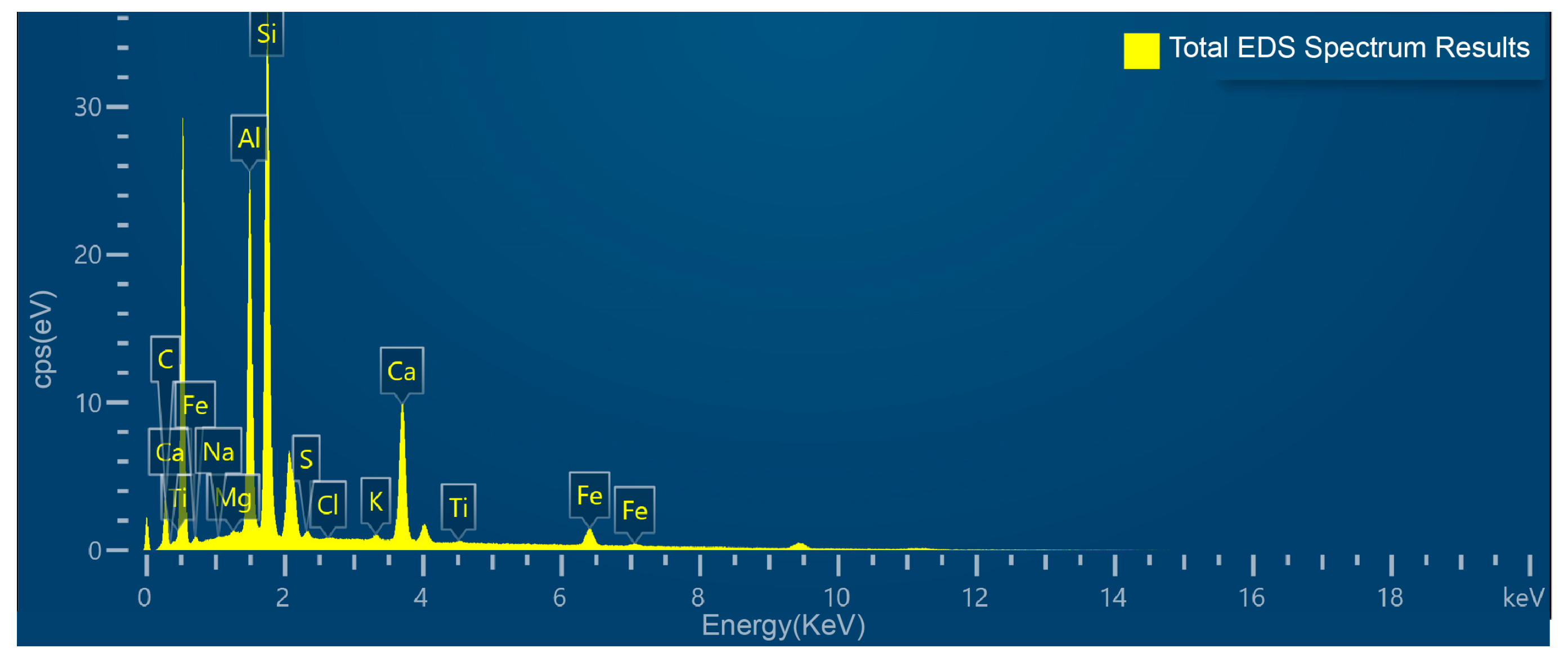

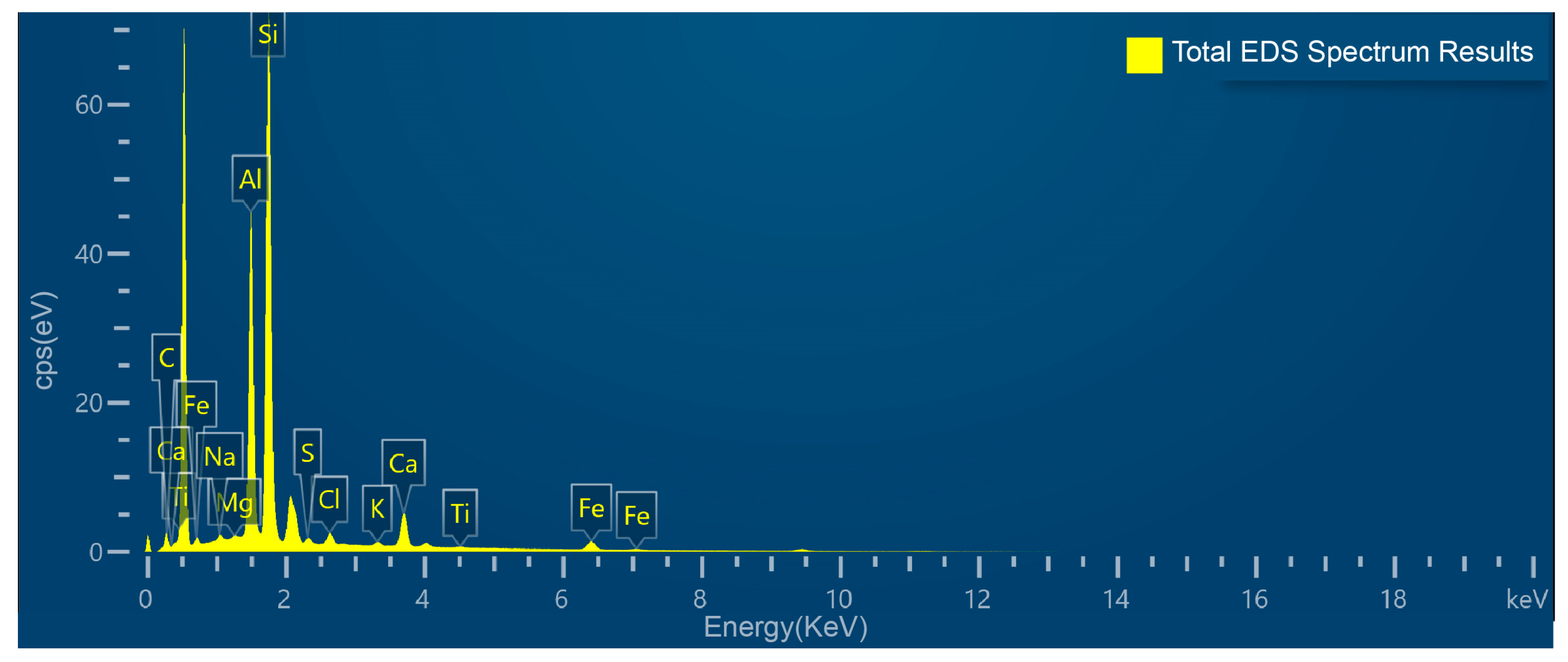

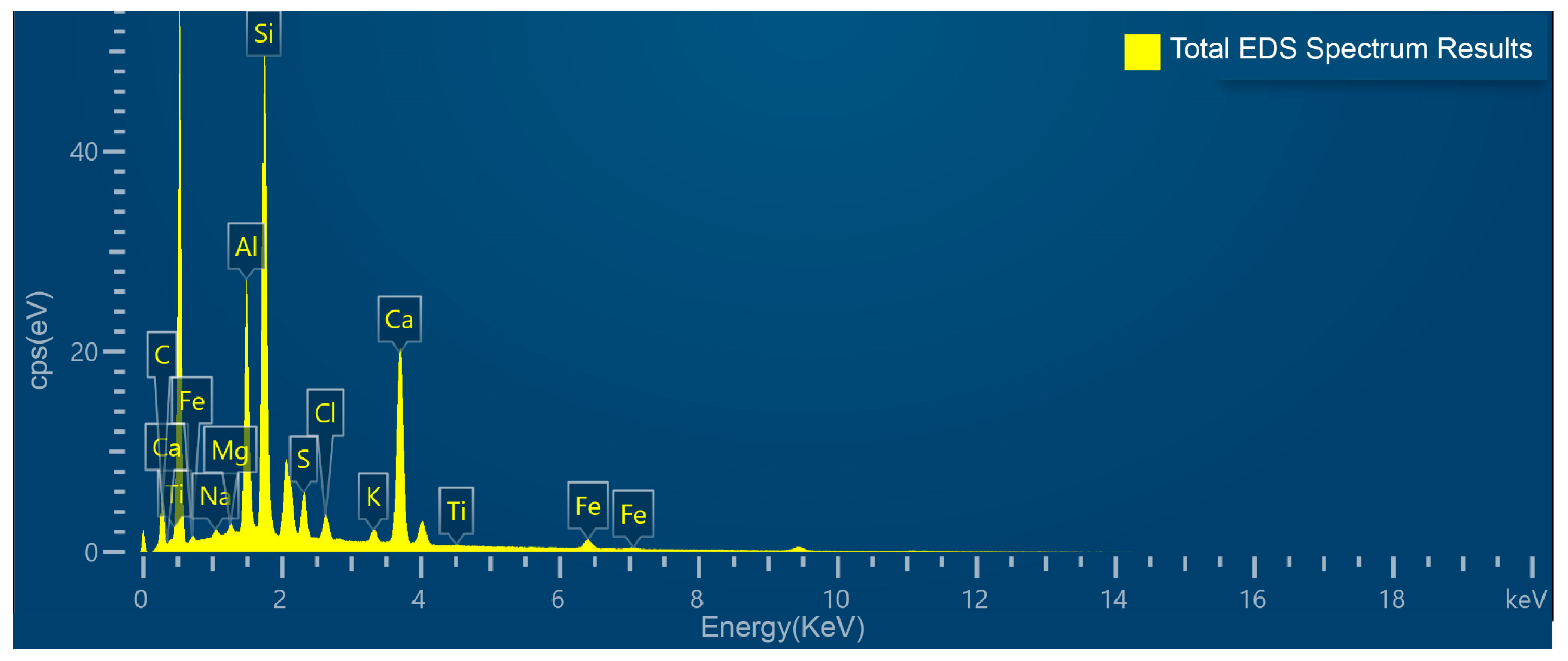

3.3. Comparison Results of EDS Element

3.3.1. East Wall Sample

3.3.2. South Wall Sample

3.3.3. West Wall Sample

3.3.4. North Wall Sample

4. Discussion

4.1. East Wall: Potential Impacts of Carbonate Balance and Diurnal Temperature Variation

4.2. South Wall: Synergistic Impacts of High Temperature and Heavy Rainfall

4.3. West Wall: Weathering Effects of Salt Fog Enrichment and Insufficient Cementation

4.4. North Wall: Synergistic Destruction by High Humidity and Biological Activity

5. Conclusions

- (1)

- There are significant differences in orientation between the four walls. The east wall is characterized by high carbonate cementation (Ca = 30.36 wt%), with regular and dense particles. The west wall is dominated by a silicate skeleton, with the highest Si and Al contents (Si = 38.03 wt%, Al = 18.79 wt%) and the lowest Ca, indicating insufficient cementation and domination by particle friction and cohesion. The north wall shows marginal enrichment of soluble salt indicator elements (Cl = 1.69 wt%, S = 2.77 wt%), suggesting salinization risk. The south wall has irregular particles, fine cracks, and obvious agglomeration damage, reflecting the synergistic damage caused by strong sunshine, wind-driven rain, and rainstorm erosion. The above differences are consistent with the local dominant wind direction, rainfall, and sunshine exposure conditions.

- (2)

- Mineral assembling and engineering characteristics are obvious. The four-direction samples generally contain quartz, calcite, hydrous aluminum silicates (kaolinite group), and aluminum hydroxide (gibbsite). Quartz provides framework stability; calcite is dissolved in acidic/wet environments; layered aluminum silicates have water absorption and expansion properties, and the presence of aluminum hydroxide may also enhance the volume change effect during the wet–dry cycle, jointly triggering water absorption-swelling-contraction-surface erosion.

- (3)

- Mechanism chain and vulnerability pattern. Wind-driven rain, salt fog deposition, and high humidity in the marine climate drive carbonate dissolution, salt crystallization, and biological attachment. These effects dominate in different directions, forming a vulnerability pattern where the east wall is relatively stable, the south wall is prone to cracking, the west wall is prone to erosion, and the north wall is prone to tidal salt. This pattern provides a basis for proposing a directional protection and restoration method for rammed earth walls.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Other SEM Image Results

References

- Niroumand, H.; Zain, M.F.M.; Jamil, M. Various types of earth buildings. Procedia-Soc. Behav. Sci. 2013, 89, 226–230. [Google Scholar] [CrossRef]

- Schroeder, H. Sustainable Building with Earth; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Li, T.T.; Zhao, L.H. Investigation of Existing Situation and Study on Energy-Saving Potential of Rural Residential Buildings in Pearl River Delta. Adv. Mater. Res. 2012, 374, 199–203. [Google Scholar] [CrossRef]

- Tao, J.; Zhuo, X.; Qin, Q.; Xiao, D.; Zhang, S.; Chen, H. Conflict, fortification, and settlement patterns: A study of the vernacular villages in Guangdong, South China. War Hist. 2021, 28, 237–262. [Google Scholar] [CrossRef]

- Communist Youth League Committee of South China Normal University. Impressions of Xiaochikan: Explore Historical Sites and Admire Cultural Charm. Available online: https://youth.scnu.edu.cn/news/2018/0725/11209.html (accessed on 4 October 2025). (In Chinese).

- Chen, J.; Chen, Y. Research on the Conservation and Development Paths of Traditional Rammed Earth Architecture in Zhuhai and Macau. In Proceedings of the 2022 Annual Conference and Academic Symposium of the Architectural History Branch of the Architectural Society of China: Evolving Architectural History Research and Heritage Conservation, Hangzhou, China, 11–13 November 2022; Architectural History Branch of the Architectural Society of China, School of Architecture, Huaqiao University: Xiamen, China, 2022; Volume 5. Available online: https://chn.oversea.cnki.net/KCMS/detail/detail.aspx?dbcode=CPFD&dbname=CPFDLAST2023&filename=JZSX202207001068&uniplatform=OVERSEA&v=2bCrDrC04gYfgwEr6rCrAhZnFU4MP4uiXTeEgyybWhj2_ChTLzHpsRmmi44QzRnCtDK1rPQK_pA%3d (accessed on 4 October 2025). (In Chinese).

- Discovering Heritage and Treasures—Experiencing Traditional Rammed Earth Building Techniques, by Antiquities and Monuments Office (Hong Kong). Available online: https://www.amo.gov.hk/tc/about-us/online-articles/20240411/index.html (accessed on 4 October 2025).

- Fu, Z.; Chen, P. Research on the ecological construction techniques of traditional Hakka residential buildings in Lingnan. J. Shaoguan Univ. 2024, 45, 1–6. (In Chinese) [Google Scholar]

- Luo, Y.; Zhong, H.; Bao, F.; Guo, Z.; Ni, P. Insights into natural and carbonation curing of ancient Chinese rammed earth mixed with brown sugar. Constr. Build. Mater. 2022, 317, 125969. [Google Scholar] [CrossRef]

- Liang, R.; Stanislawski, D.; Hota, G. Material characterization and structural response under earthquake loads of hakka rammed earth buildings. Sustain. Struct. 2021, 1, 3. [Google Scholar] [CrossRef]

- Song, Y.; Liao, C. Structural Materials, Ventilation Design and Architectural Art of Traditional Buildings in Guangdong, China. Buildings 2022, 12, 900. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, Y.; Wu, Y.; Yang, Y. Assessment of Architectural Typologies and Comparative Analysis of Defensive Rammed Earth Dwellings in the Fujian Region, China. Buildings 2024, 14, 3652. [Google Scholar] [CrossRef]

- Chen, D.; Sun, D.; Lin, Y. Preservation or revitalization? Examining the conservation status and destructive mechanisms of Tulou heritage in Raoping, Chaozhou, China. Int. J. Archit. Herit. 2025, 19, 441–456. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, J.; Yan, S. Study on the degradation characteristics and mechanism of Kizil mudstone under periodic salt expansion. Saf. Environ. Eng. 2025, 32, 189–196. (In Chinese) [Google Scholar]

- Liu, H.; Chen, Y.; Li, J.; Zhang, T.; Jiang, Y.; Ye, W.; He, H. Weathering disease types, mechanisms and protection and reinforcement of rammed earth sites: Status and prospects. Earth Sci. 2025, 50, 2284–2297. (In Chinese) [Google Scholar]

- Qi, Z.; Lopez-Manzanares, F.V.; Mileto, C.; Trizio, F. Rammed earth techniques in China and the Mediterranean area: A comparative analysis. Int. J. Archit. Herit. 2024, 18, 1727–1748. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, Y.; Wang, C.-C.; Hou, M.; Li, A. Recent progress in instrumental techniques for architectural heritage materials. Herit. Sci. 2019, 7, 36. [Google Scholar] [CrossRef]

- Costa, T.G.; Richter, F.A.; Castro, E.T.; Gonçalves, S.; Spudeit, D.A.; Micke, G.A. Elemental identification of blue paintings traces present in historic cemeteries in the São Martinho region, southern Brazil. J. Mol. Struct. 2018, 1155, 434–442. [Google Scholar] [CrossRef]

- Liang, R.; Hota, G.; Lei, Y.; Li, Y.; Stanislawski, D.; Jiang, Y. Nondestructive Evaluation of Historic Hakka Rammed Earth Structures. Sustainability 2013, 5, 298–315. [Google Scholar] [CrossRef]

- Luo, Y.; Yang, M.; Ni, P.; Peng, X.; Yuan, X. Degradation of rammed earth under wind-driven rain: The case of Fujian Tulou, China. Constr. Build. Mater. 2020, 261, 119989. [Google Scholar] [CrossRef]

- Cui, K.; Yu, L.; Zhang, X.; Dang, X.; Pan, Y.; Wang, D. Research on the Quality Evaluation System of Rammed Earth Sites in Arid Areas. Int. J. Archit. Herit. 2025, 1–21. [Google Scholar] [CrossRef]

- Zhujiang Evening News. Available online: https://pub-zhtb.hizh.cn/a/202407/27/AP66a478fae4b072e1214e34e6.html (accessed on 4 October 2025). (In Chinese).

- Xiaochikan Village (Doumen District, Zhuhai City, Guangdong Province, China) on Google Maps. Available online: https://www.google.com/maps/place/%E4%B8%AD%E5%9B%BD%E5%B9%BF%E4%B8%9C%E7%9C%81%E7%8F%A0%E6%B5%B7%E5%B8%82%E6%96%97%E9%97%A8%E5%8C%BA%E5%B0%8F%E8%B5%A4%E5%9D%8E%E6%9D%91+%E9%82%AE%E6%94%BF%E7%BC%96%E7%A0%81:+529147/@22.2789096,113.21113,15z/data=!3m1!4b1!4m6!3m5!1s0x340185eb402252a7:0x1b0d6ce2a71bfc7e!8m2!3d22.27891!4d113.21113!16s%2Fg%2F11c61l8_88?entry=ttu&g_ep=EgoyMDI1MTAwMS4wIKXMDSoASAFQAw%3D%3D (accessed on 4 October 2025).

- Introduction to Zhuhai City and Its Climate Characteristics, by China Weather Website. Available online: https://www.weather.com.cn/zt/qxfwzt/1135158.shtml (accessed on 4 October 2025). (In Chinese).

- Liu, T.; Ni, X.; Sun, J.; Peng, Z. Effectiveness of Emergency Response to Typhoons: Lessons Learned from Historical Typhoon Disasters in Zhuhai, China. In Proceedings of the International ISCRAM Conference, Münster, Germany, 25–29 May 2024. [Google Scholar] [CrossRef]

- Song, J.; Chen, Y.; Zheng, L.; Tang, Q. The evolution of traditional ancient towns in South China: Tangjiawan Ancient Town in Zhuhai city. J. Asian Archit. Build. Eng. 2025, 24, 2114–2132. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, Z. Centuries and Millennia: Tracing and Interpreting the Origins of Xiangshan Culture; Guangdong People’s Publishing: Guangzhou, China, 2006. [Google Scholar]

- Xie, H.; Tho-ard, M. Folk culture patterns and dissemination in Xiangshan cultural area of Guangdong Province. J. Sch. Comunity 2025, 3, 198–207, (In Thai and English). [Google Scholar]

- Doumen District Library. Xiaochikan Village, Doumen Town, by Doumen District Library Official Website. Available online: https://www.dmlib.cn/information/903 (accessed on 4 October 2025). (In Chinese).

- SY/T 5163-2018; X-ray Diffraction Analysis Method for Clay Minerals and Common Non-Clay Minerals in Sedimentary Rocks. Standardization Administration of the People’s Republic of China: Beijing, China, 2018.

- Malki, A.; Mekhalif, Z.; Detriche, S.; Fonder, G.; Boumaza, A.; Djelloul, A. Calcination products of gibbsite studied by X-ray diffraction, XPS and solid-state NMR. J. Solid State Chem. 2014, 215, 8–15. [Google Scholar] [CrossRef]

- Gu, T.; Yang, X.; Shi, D.; Yang, S.; Ma, Y.; Zheng, X.; Wu, J.; Zhang, Y.; Song, G. Scientific and technological analysis and research on rammed earth materials of Shang Dynasty buildings in Zhengzhou area: Taking Zhengzhou Shang City and Zhengzhou Xiaoshuangqiao site as examples. Cult. Relics Prot. Archaeol. Sci. 2024, 36, 89–100. (In Chinese) [Google Scholar]

- Liang, M.; Li, L. A Study of Lingnan Garden’s Adaptability to Hot and Humid Climate. In Proceedings of the International Conference on Human-Computer Interaction, Orlando, FL, USA, 26–31 July 2019; Springer International Publishing: Cham, Switzerland, 2019; pp. 61–73. [Google Scholar] [CrossRef]

- Leung, E.Y.W. Roofs of Clans: Chinese Roofs of Vernacular Architectures of Branches of Communities in Hong Kong and Respective Restoration Techniques. In Proceedings of the International Conference on East Asian Architectural Culture, Tianjin, China, 13–17 October 2017; Springer International Publishing: Cham, Switzerland, 2017; pp. 393–406. [Google Scholar] [CrossRef]

- Tao, J.; Xiao, D.; Qin, Q.; Zhuo, X.; Wang, J.; Chen, H.; Wang, Q. Climate-adaptive design of historic villages and dwellings in a typhoon-prone region in southernmost Mainland China. Int. J. Archit. Herit. 2022, 16, 117–135. [Google Scholar] [CrossRef]

- Lai, D. Waterproofing Technology in Traditional Lingnan Architecture. In Proceedings of the Fifth Annual Academic Conference of China Cultural Relics Protection Technology Association, Nanjing, China, 4 September 2007; Shenzhen Cultural Relics Management Office: Shenzhen, China; China Cultural Relics Protection Technology Association, Cultural Relics Protection Technology Department of the Palace Museum: Beijing, China, 2007; pp. 91–96. Available online: https://chn.oversea.cnki.net/KCMS/detail/detail.aspx?dbcode=CPFD&dbname=CPFD9908&filename=ZGWA200709001013&uniplatform=OVERSEA&v=G3hoaHiCKsYqSvaO3HUwCz_Nx3pihet1Fyf-WJuLxpcGBdU5h6JJyVkbeWVK-0mMxnCImUtRAOM%3d (accessed on 4 October 2025). (In Chinese).

- Xia, J.; Zhao, X.; Zhao, Z.; Chen, Y.; Liu, J. Characteristics of soil water and salt migration and their interaction effects at different groundwater depths. Trans. Chin. Soc. Agric. Eng. 2015, 31, 93–100. (In Chinese) [Google Scholar]

- Chu, J.; Liang, H. Study on the performance of slag-tung oil-glutinous rice juice raw earth wall materials. Sci. Technol. Inf. 2008, 30, 374+385. Available online: https://chn.oversea.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFD&dbname=CJFD2008&filename=KJXX200830308&uniplatform=OVERSEA&v=agGTHgkq-F-iPby70rRrfXhSbcRuxJpRMwEolpS61oiBl1M-OXujPIdt-rNThqwt (accessed on 4 October 2025). (In Chinese).

- Zhang, Z. Research on the Creation Strategy of Contemporary Lingnan Green Buildings Based on the Inheritance of Guangfu Construction Wisdom. Master’s Thesis, South China University of Technology, Guangzhou, China, 2021. Available online: https://chn.oversea.cnki.net/KCMS/detail/detail.aspx?dbcode=CMFD&dbname=CMFD202301&filename=1021894386.nh&uniplatform=OVERSEA&v=hs6HnjviKy2EFTfz2YWweTjAFS1nZL1wM3YJfsC-Rm4Wast4xCVBR6Zs7udeKYhy (accessed on 4 October 2025). (In Chinese).

- Stanaszek-Tomal, E. Environmental Factors Causing the Development of Microorganisms on the Surfaces of National Cultural Monuments Made of Mineral Building Materials—Review. Coatings 2020, 10, 1203. [Google Scholar] [CrossRef]

- Tiano, P. Biodegradation of Cultural Heritage: Decay Mechanisms and Control Methods. Seminar Article, New University of Lisbon, Department of Conservation and Restoration. 2002, pp. 7–12. Available online: https://www.semanticscholar.org/paper/Biodegradation-of-Cultural-Heritage-%3A-Decay-and-Tiano/ace1c3025c5a93a05e361e09efefe03609564981?utm_source=direct_link (accessed on 4 October 2025).

- Li, H.; An, X.; Wang, Y.; Wang, W.; Zhao, Y. Research status of antibacterial coatings. Chem. Fiber Text. Technol. 2024, 53, 35–37. (In Chinese) [Google Scholar]

- Zuo, B.; Kitagawa, K.; Chen, Y. Coincidental values of responding to climate in contemporary Chinese architectural design. J. Asian Archit. Build. Eng. 2025, 24, 154–177. [Google Scholar] [CrossRef]

| Element | Line Type | Wt% | Wt% Sigma | At% |

|---|---|---|---|---|

| C | K-series | 35.1 | 0.63 | 60.48 |

| Na | K-series | 0.4 | 0.03 | 0.36 |

| Mg | K-series | 0.14 | 0.03 | 0.12 |

| Al | K-series | 12.76 | 0.14 | 9.78 |

| Si | K-series | 14.35 | 0.15 | 10.57 |

| S | K-series | 0.22 | 0.03 | 0.14 |

| Cl | K-series | 1.42 | 0.04 | 0.83 |

| K | K-series | 0.45 | 0.03 | 0.24 |

| Ca | K-series | 30.36 | 0.31 | 15.68 |

| Ti | K-series | 0.29 | 0.05 | 0.12 |

| Fe | K-series | 4.51 | 0.11 | 1.68 |

| Element | Line Type | Wt% | Wt % Sigma | At% |

|---|---|---|---|---|

| C | K-series | 40.77 | 0.74 | 64.7 |

| Na | K-series | 0.07 | 0.03 | 0.06 |

| Mg | K-series | 0.09 | 0.03 | 0.07 |

| Al | K-series | 13.81 | 0.19 | 9.75 |

| Si | K-series | 23.39 | 0.31 | 15.87 |

| S | K-series | 0.31 | 0.04 | 0.18 |

| Cl | K-series | 0.09 | 0.03 | 0.05 |

| K | K-series | 0.48 | 0.04 | 0.23 |

| Ca | K-series | 14.15 | 0.2 | 6.73 |

| Ti | K-series | 0.3 | 0.06 | 0.12 |

| Fe | K-series | 6.56 | 0.16 | 2.24 |

| Element | Line Type | wt% | Wt % Sigma | At% |

|---|---|---|---|---|

| C | K-series | 29.53 | 0.58 | 50.89 |

| Na | K-series | 0.38 | 0.02 | 0.34 |

| Mg | K-series | 0.13 | 0.02 | 0.11 |

| Al | K-series | 18.79 | 0.16 | 14.42 |

| Si | K-series | 38.03 | 0.32 | 28.03 |

| S | K-series | 0.48 | 0.02 | 0.31 |

| Cl | K-series | 1.33 | 0.03 | 0.77 |

| K | K-series | 0.55 | 0.02 | 0.29 |

| Ca | K-series | 5.63 | 0.06 | 2.91 |

| Ti | K-series | 0.24 | 0.03 | 0.1 |

| Fe | K-series | 4.92 | 0.08 | 1.83 |

| Element | Line Type | Wt% | Wt % Sigma | At% |

|---|---|---|---|---|

| C | K-series | 39.98 | 0.63 | 64.35 |

| Na | K-series | 0.37 | 0.03 | 0.31 |

| Mg | K-series | 0.37 | 0.03 | 0.29 |

| Al | K-series | 9.65 | 0.11 | 6.92 |

| Si | K-series | 20.4 | 0.22 | 14.04 |

| S | K-series | 2.77 | 0.05 | 1.67 |

| Cl | K-series | 1.69 | 0.04 | 0.92 |

| K | K-series | 1.13 | 0.04 | 0.56 |

| Ca | K-series | 20.19 | 0.23 | 9.74 |

| Ti | K-series | 0.14 | 0.04 | 0.06 |

| Fe | K-series | 3.30 | 0.1 | 1.15 |

| Wall | East | South | West | North | ||||

|---|---|---|---|---|---|---|---|---|

| Metric | wt% | At% | wt% | At% | wt% | At% | wt% | At% |

| C | 35.1 | 60.48 | 40.77 | 64.7 | 29.53 | 50.89 | 39.98 | 64.35 |

| Na | 0.4 | 0.36 | 0.07 | 0.06 | 0.38 | 0.34 | 0.37 | 0.31 |

| Mg | 0.14 | 0.12 | 0.09 | 0.07 | 0.13 | 0.11 | 0.37 | 0.29 |

| Al | 12.76 | 9.78 | 13.81 | 9.75 | 18.79 | 14.42 | 9.65 | 6.92 |

| Si | 14.35 | 10.57 | 23.39 | 15.87 | 38.03 | 28.03 | 20.4 | 14.04 |

| S | 0.22 | 0.14 | 0.31 | 0.18 | 0.48 | 0.31 | 2.77 | 1.67 |

| Cl | 1.42 | 0.83 | 0.09 | 0.05 | 1.33 | 0.77 | 1.69 | 0.92 |

| K | 0.45 | 0.24 | 0.48 | 0.23 | 0.55 | 0.29 | 1.13 | 0.56 |

| Ca | 30.36 | 15.68 | 14.15 | 6.73 | 5.63 | 2.91 | 20.19 | 9.74 |

| Ti | 0.29 | 0.12 | 0.3 | 0.12 | 0.24 | 0.1 | 0.14 | 0.06 |

| Fe | 4.51 | 1.68 | 6.56 | 2.24 | 4.92 | 1.83 | 3.3 | 1.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, L.; Deng, Q.; Liang, J.; Guo, Z.; Zhu, Y.; Liu, W.; Chen, Y. Microchemical Analysis of Rammed Earth Residential Walls Surface in Xiaochikan Village, Guangdong. Coatings 2025, 15, 1351. https://doi.org/10.3390/coatings15111351

Zheng L, Deng Q, Liang J, Guo Z, Zhu Y, Liu W, Chen Y. Microchemical Analysis of Rammed Earth Residential Walls Surface in Xiaochikan Village, Guangdong. Coatings. 2025; 15(11):1351. https://doi.org/10.3390/coatings15111351

Chicago/Turabian StyleZheng, Liang, Qingnian Deng, Jingwei Liang, Zekai Guo, Yufei Zhu, Wei Liu, and Yile Chen. 2025. "Microchemical Analysis of Rammed Earth Residential Walls Surface in Xiaochikan Village, Guangdong" Coatings 15, no. 11: 1351. https://doi.org/10.3390/coatings15111351

APA StyleZheng, L., Deng, Q., Liang, J., Guo, Z., Zhu, Y., Liu, W., & Chen, Y. (2025). Microchemical Analysis of Rammed Earth Residential Walls Surface in Xiaochikan Village, Guangdong. Coatings, 15(11), 1351. https://doi.org/10.3390/coatings15111351