Ultrahigh-Speed Deposition of Diamond-like Carbon on a Pipe Surface Using a Scanning Deposition Method via Local High-Density Plasma

Abstract

1. Introduction

2. Experimental Method

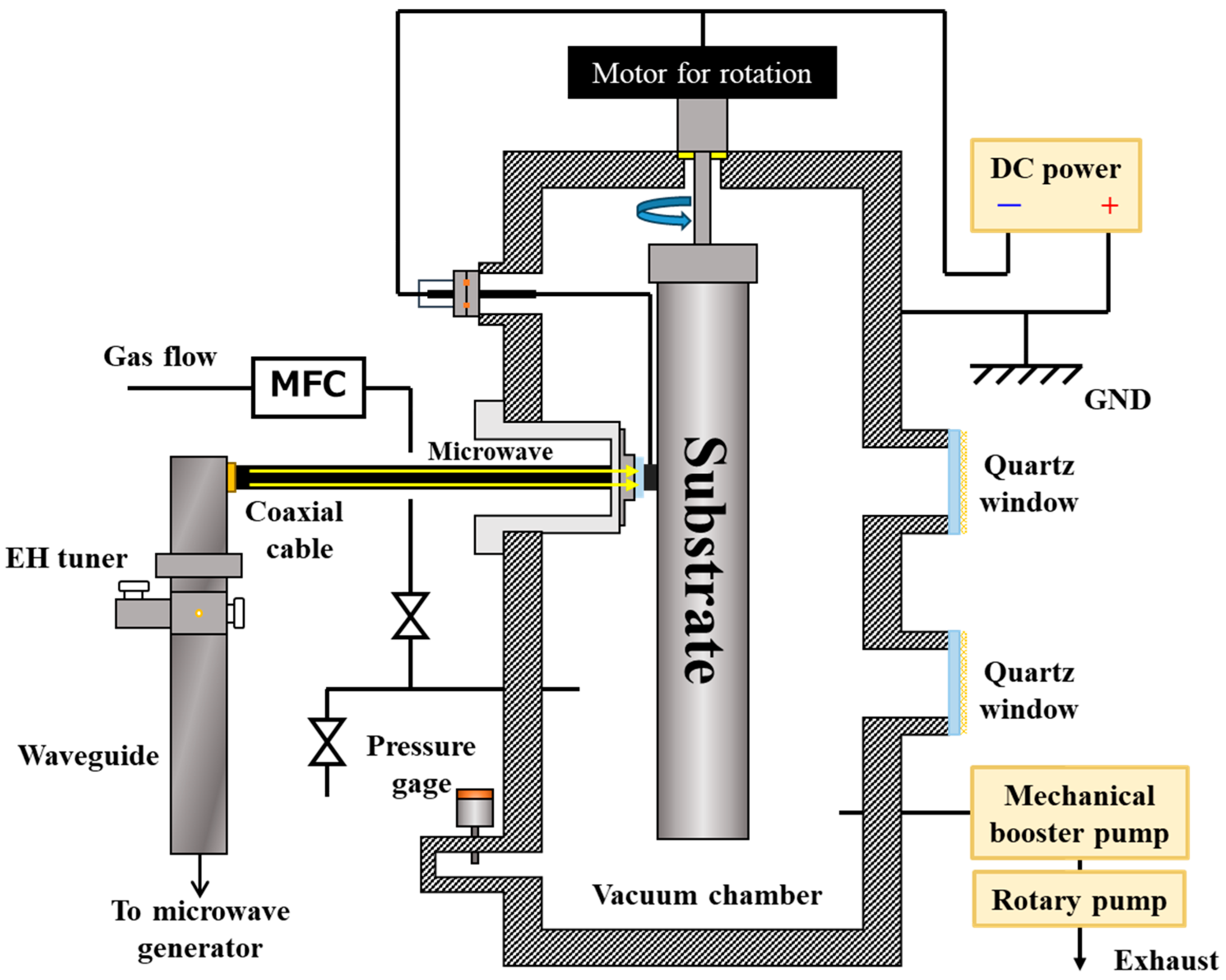

2.1. Deposition

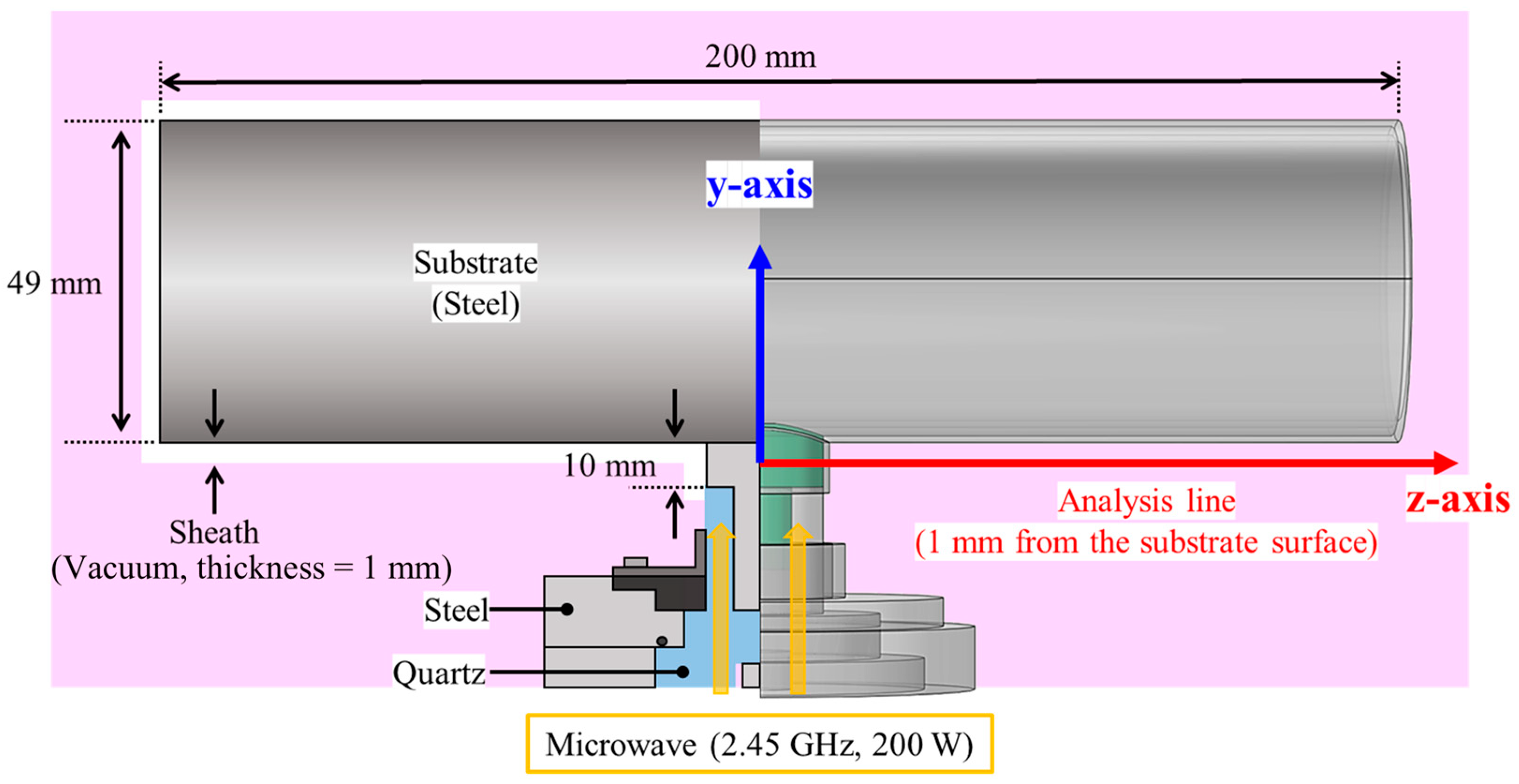

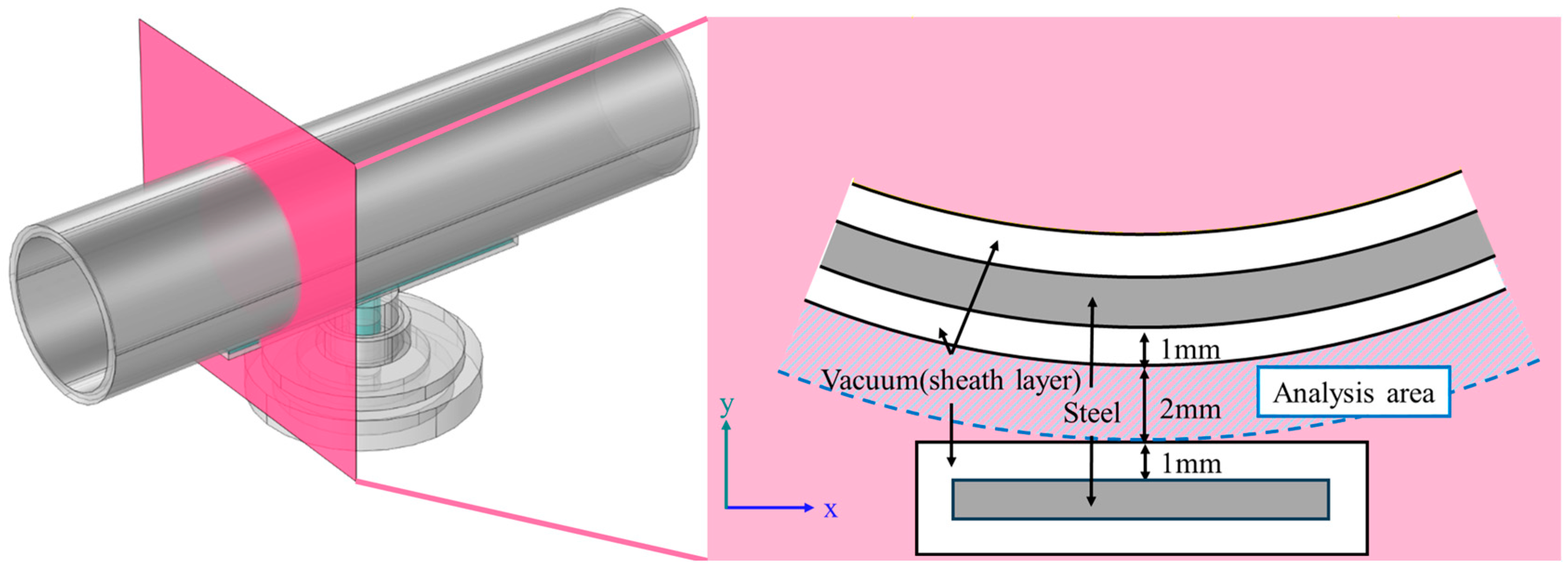

2.2. Electromagnetic Wave Simulation

3. Results and Discussion

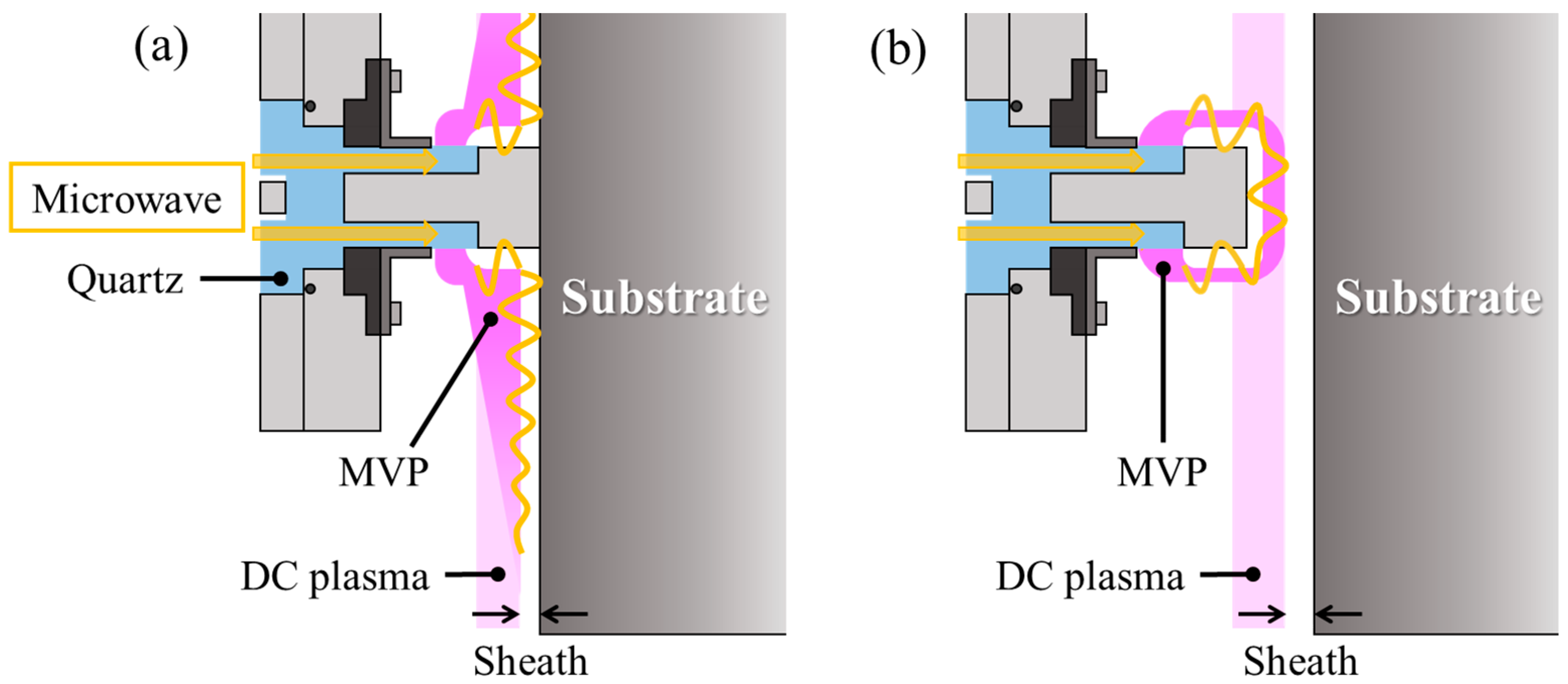

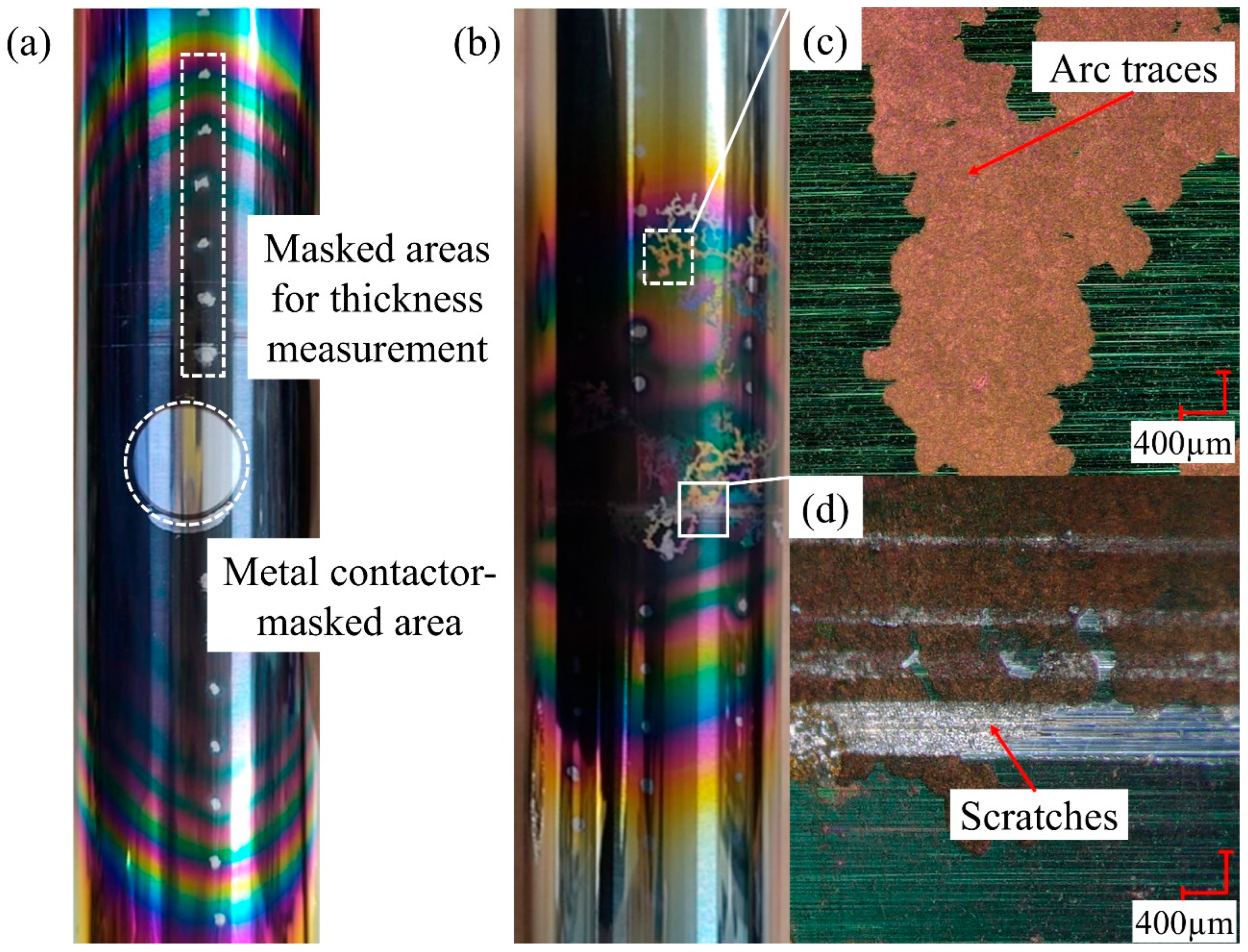

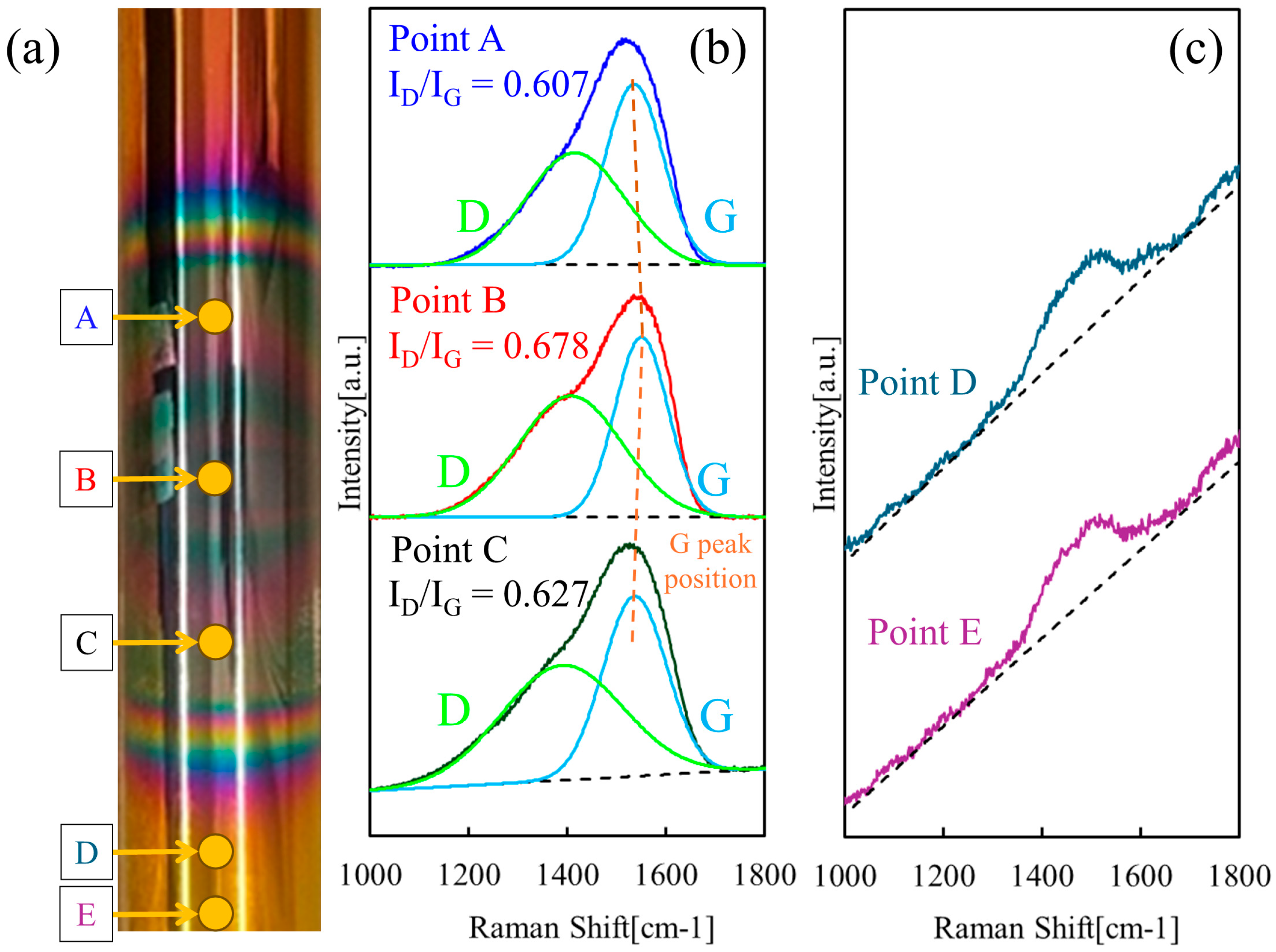

3.1. Contact Deposition with Metal Contactor

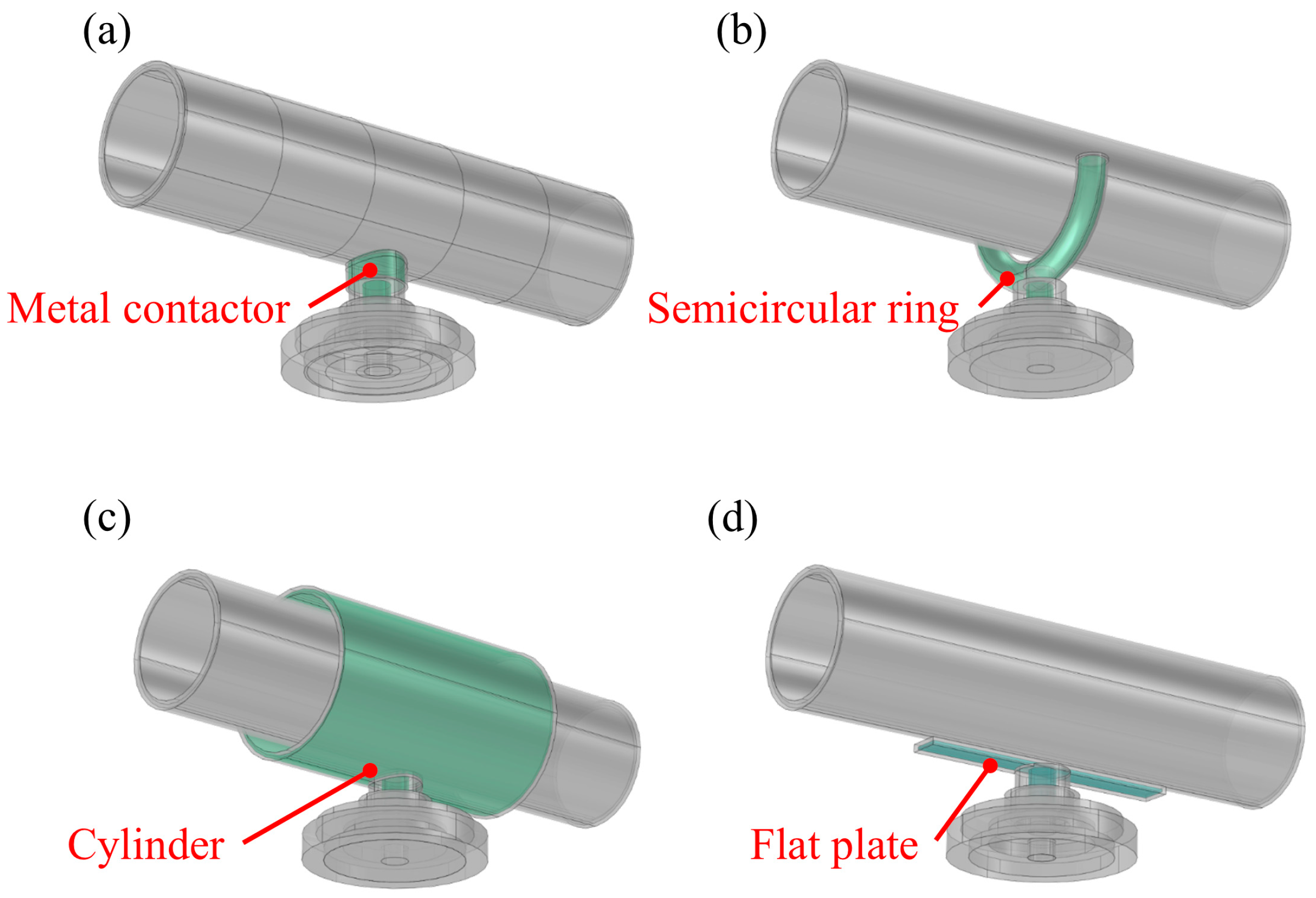

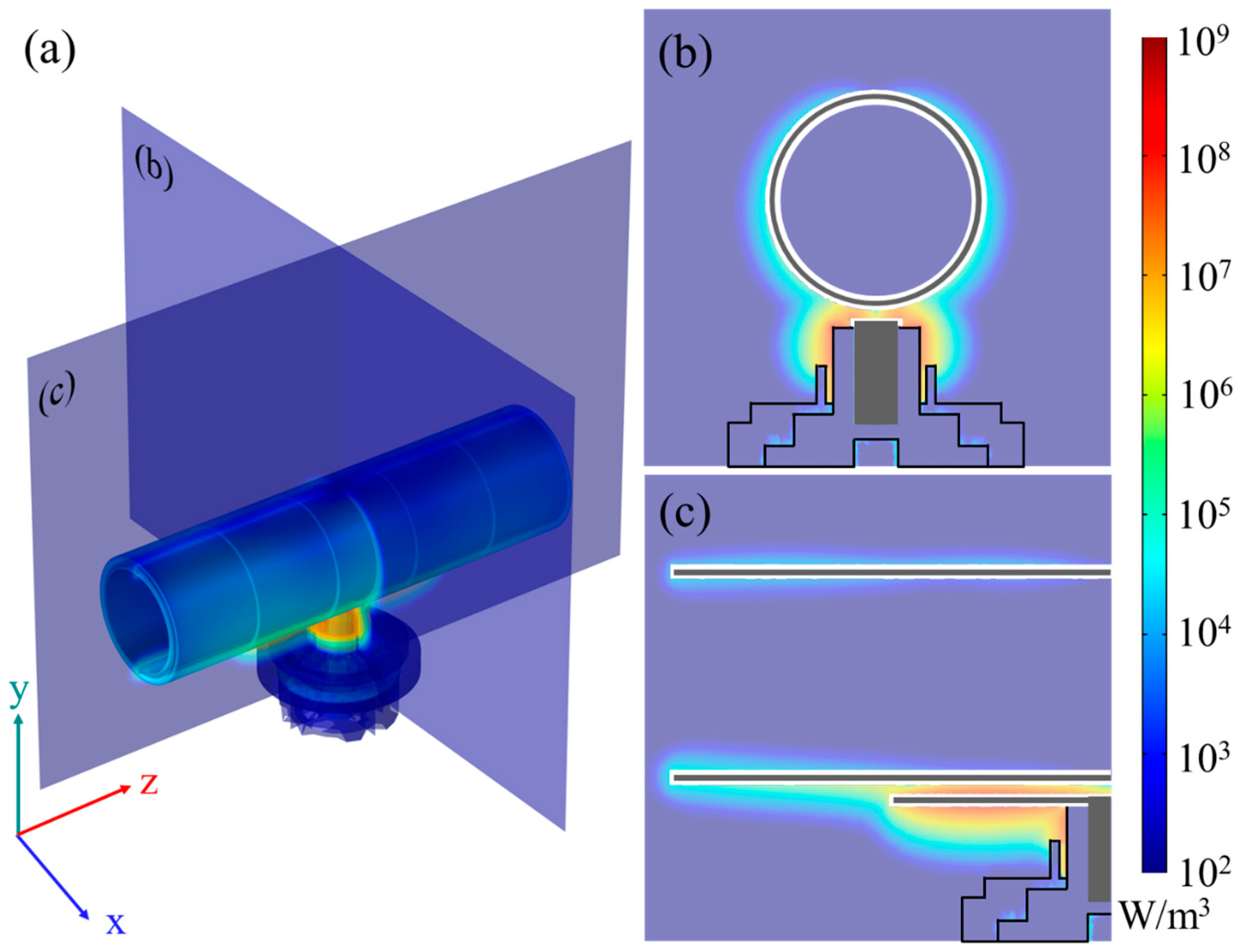

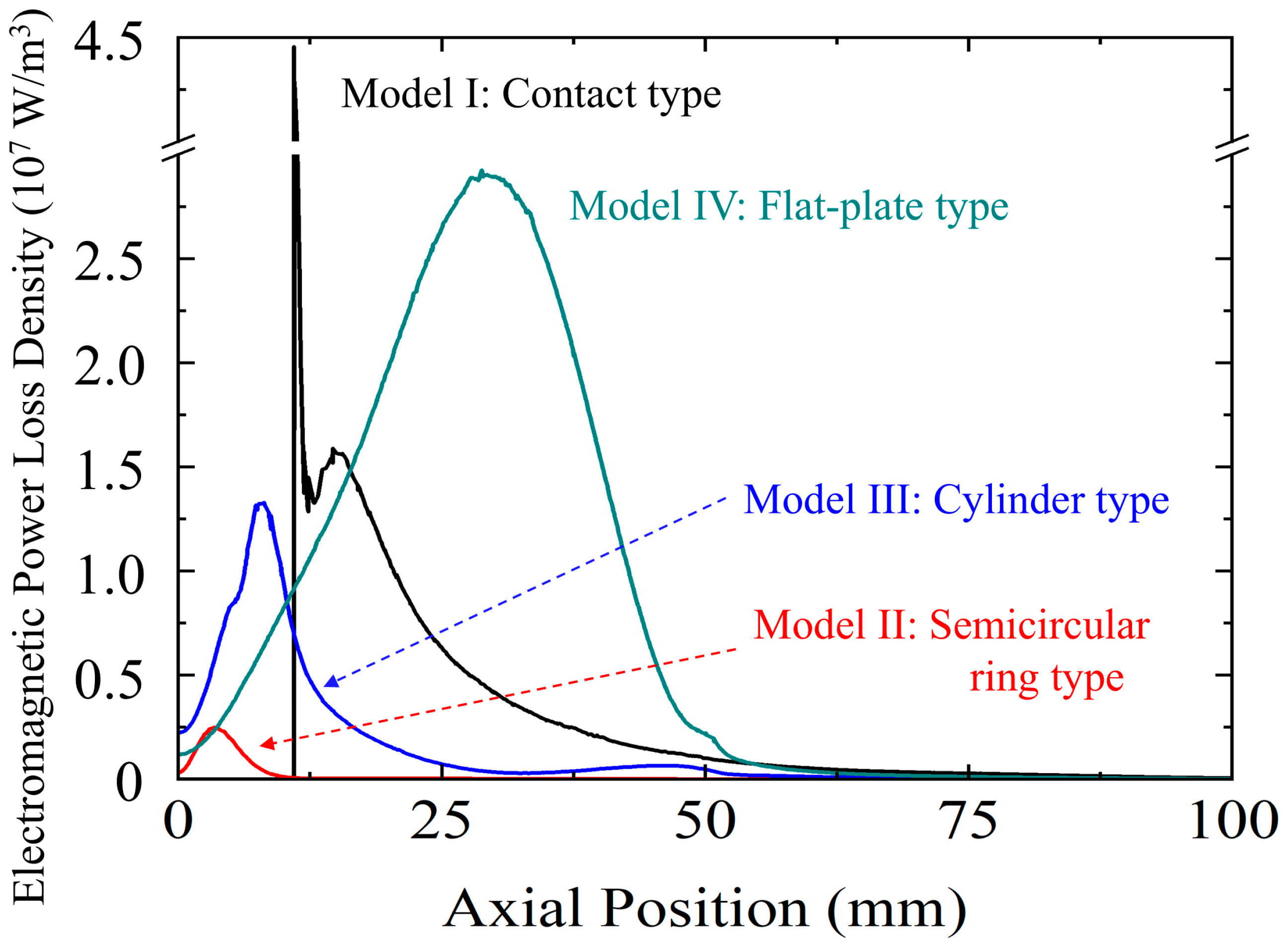

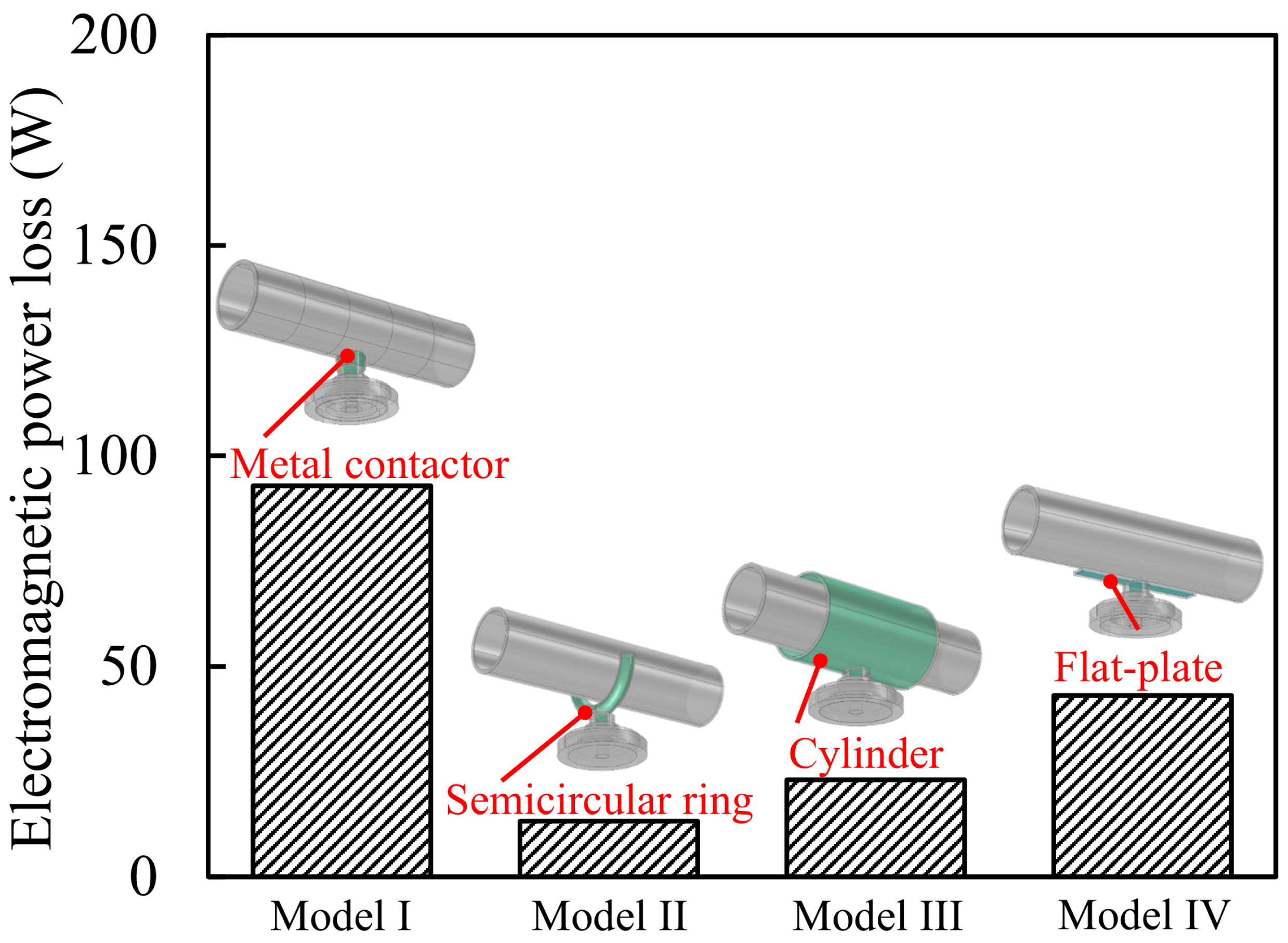

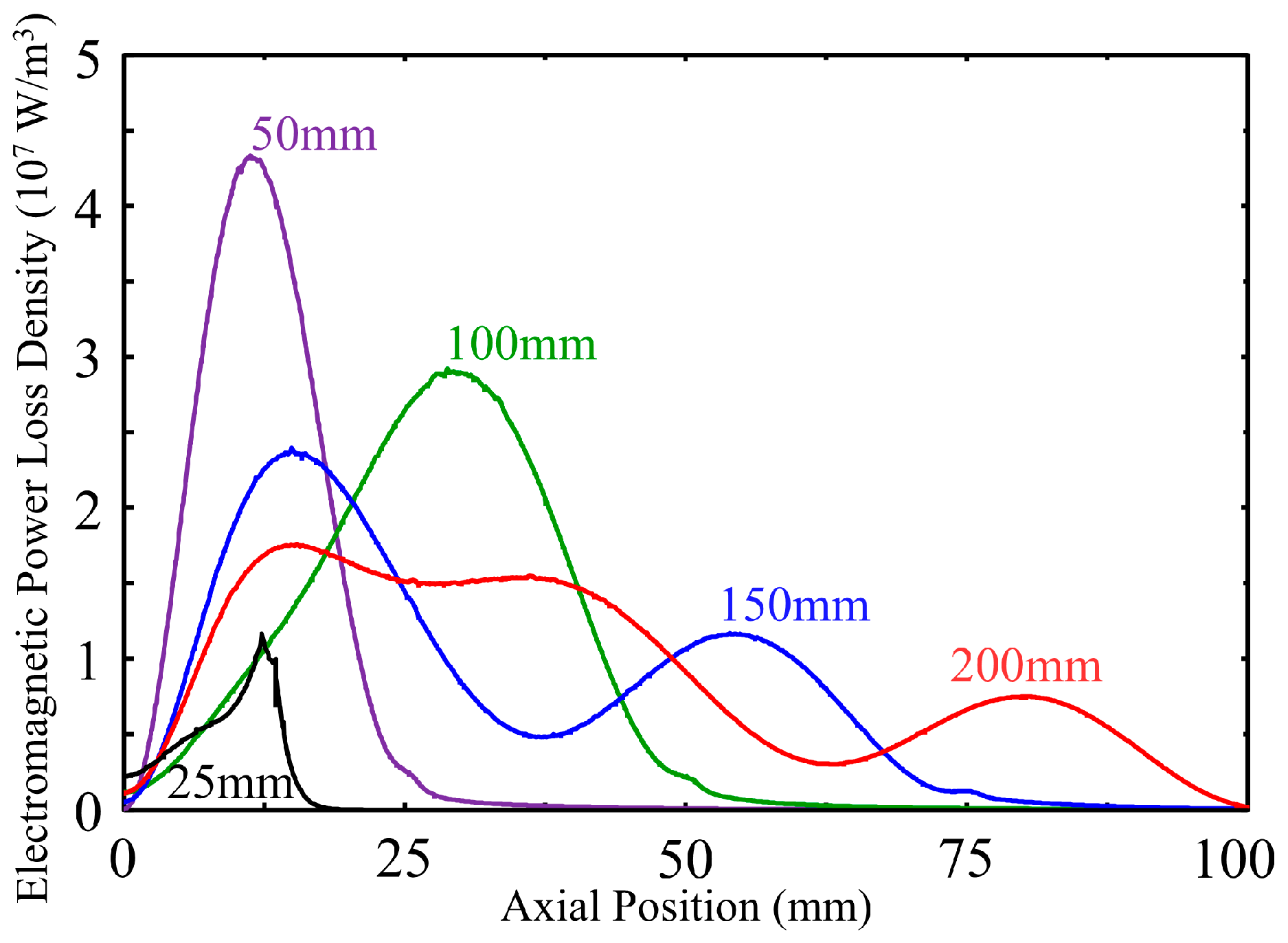

3.2. Simulation of Microwave Propagation for Metal Antennas

3.3. Non-Contact Deposition with Flat-Plate Antenna

4. Conclusions

- Contact deposition with scanning was initially attempted to achieve a localized UHS Si-DLC deposition using a circumferential scanning mechanism. However, this approach results in deposition defects due to arcs and surface scratches caused by physical contact. To address these problems, we developed a non-contact deposition employing a metal antenna.

- To optimize the geometry of the metal antenna used in the non-contact deposition process, we analyzed microwave power absorption using COMSOL Multiphysics simulations. The results indicated that a flat-plate antenna exhibited the highest microwave absorption near the pipe surface, with an absorption power of 43.17 W under a 200 W input.

- Antennas with lengths of 50, 100, 150, and 200 mm exhibited power loss density profiles characteristic of standing wave formation, with one or two distinct peaks depending on the specific length, whereas the 25 mm antenna did not display such features. These findings indicate that effective standing wave formation, and consequently improved microwave confinement, is achieved only when the antenna length exceeds a certain threshold.

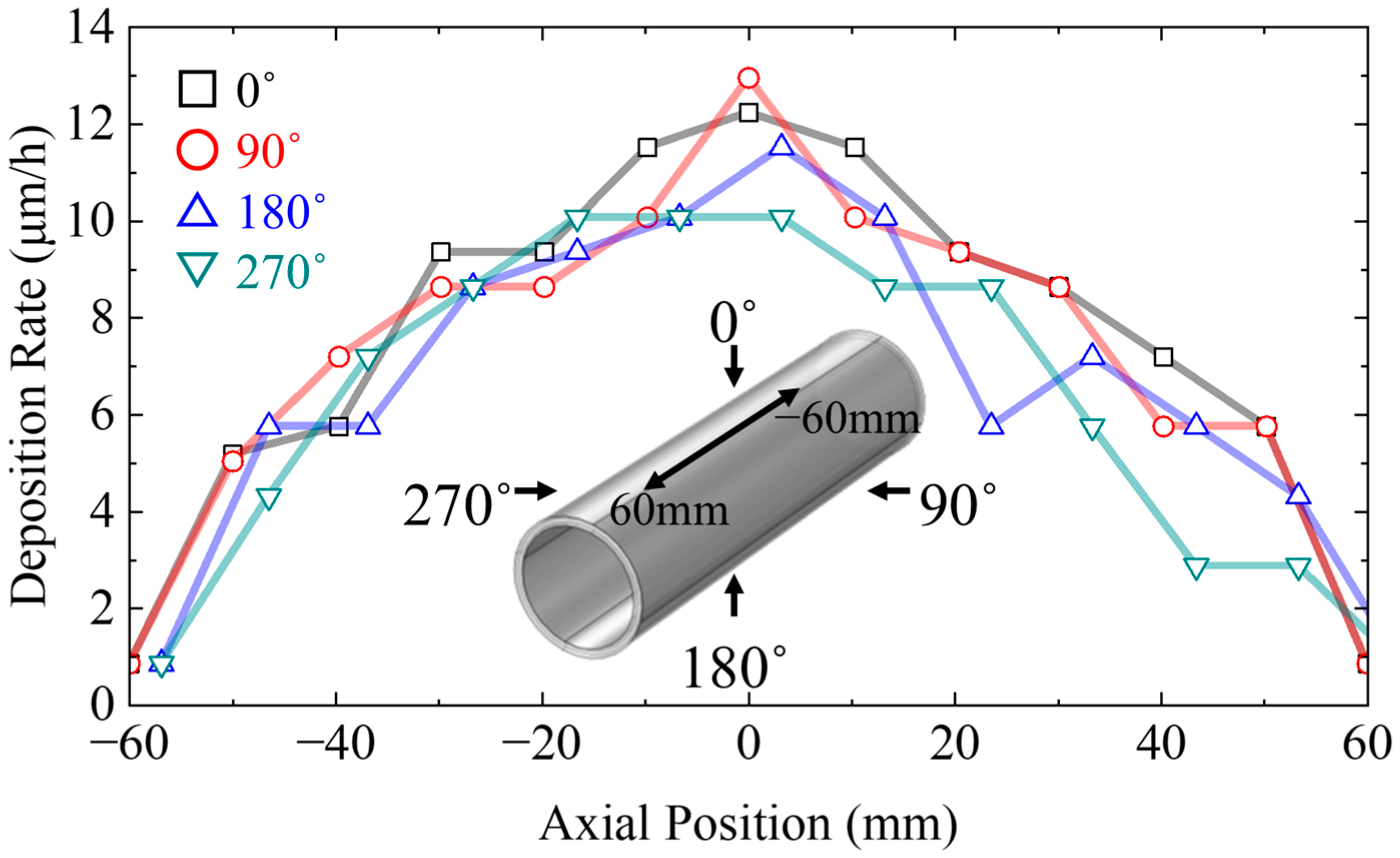

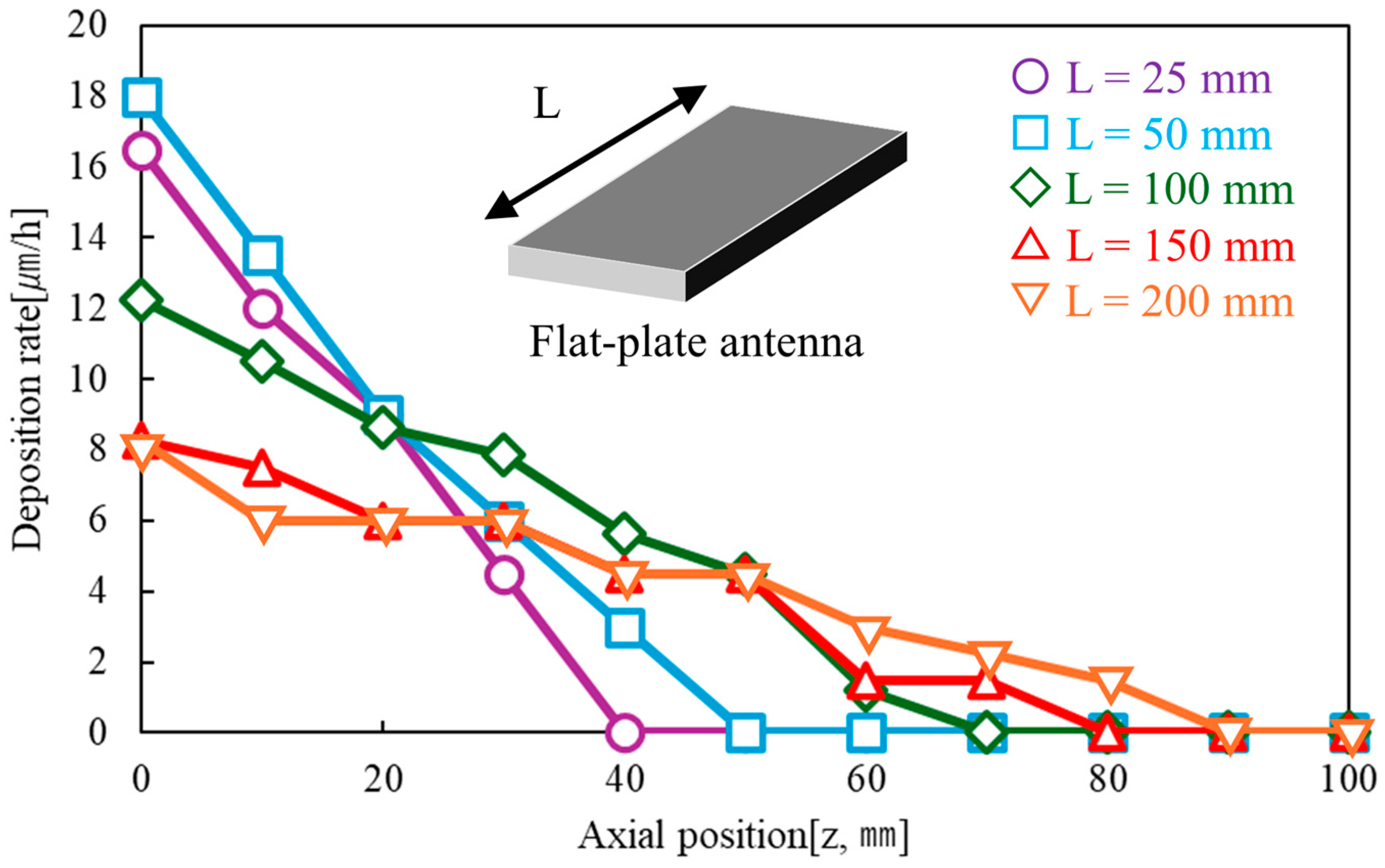

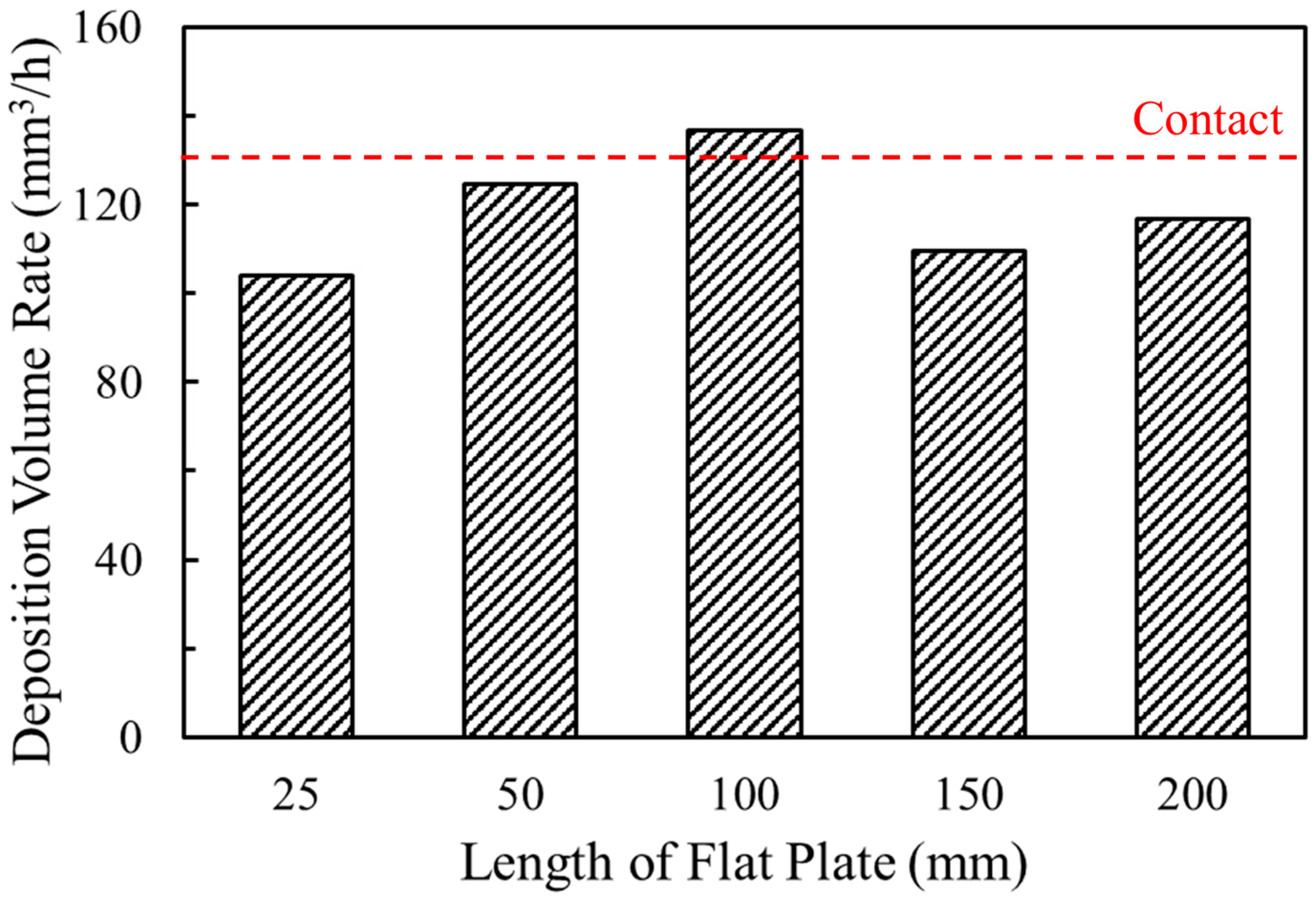

- Non-contact UHS Si-DLC deposition experiments were conducted using flat-plate antennas of different lengths. The deposition rate was evaluated within a range of −100 to 100 mm along the pipe. As a result, deposition volume rate of 137 mm3/h was achieved using 100 mm antenna, exceeding the 131 mm3/h rate obtained with the contact deposition.

- Pipe rotation during non-contact deposition enables a uniform film thickness along the pipe circumference.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kano, M. Progress and Prospect of DLC Coating Applied Technologies to Automotive Engie Component. Jpn. J. Tribol. 2016, 61, 680–686. [Google Scholar] [CrossRef]

- Yamaguchi, Y.; Matsuoka, T.; Hirayama, T.; Asano, M.; Hanamoto, N. Tribological Property of DLC/DLC Sliding under Lubricated Condition with Oiliness Additive. J. Jpn. Soc. Mech. Eng. 2012, 2012, J111032. [Google Scholar] [CrossRef]

- Okubo, H.; Sasaki, S. Effects of lubricant additives on tribological properties of DLC films. Jpn. J. Tribol. 2018, 63, 11–19. [Google Scholar] [CrossRef]

- Kousaka, H.; Okamoto, T.; Umehara, N. Ultrahigh-Speed Coating of DLC at Over 100 μm/h by Using Microwave-Excited High-Density Near Plasma. IEEE Trans. Plasma Sci. 2013, 41, 1830–1836. [Google Scholar] [CrossRef]

- Deng, X.; Takaoka, Y.; Kousaka, H.; Umehara, N. Axial uniformity of diamond-like carbon film deposited on metal rod by using microwave–sheath voltage combination plasma. Surf. Coat. Technol. 2014, 238, 80–86. [Google Scholar] [CrossRef]

- Ito, A.; Nonomura, K.; Kousaka, H.; Furuki, T. Ultra-Fast Si-DLC Deposition using Non-Uniform High-Density Plasma Generated by Microwave Input from the Side of a Cylinder. J. Surf. Finish. Soc. Jpn. 2025, 76, 183–189. [Google Scholar] [CrossRef]

- Hioki, T.; Noda, S.; Isogai, A. Formation and Solid Lubricating Property of DLC(Diamond-Like Carbon). J. Surf. Sci. Soc. Jpn. 1991, 12, 227–232. [Google Scholar] [CrossRef]

- Mori, H.; Takahashi, N.; Nakanishi, K.; Tachikawa, H.; Ohmori, T. Low Friction Property of DLC-Si Films under Dry Sliding Condition. J. Surf. Finish. Soc. Jpn. 2008, 59, 401–407. [Google Scholar] [CrossRef]

- Mori, H.; Nakanishi, K.; Takahashi, N.; Kato, N.; Ohmori, T. Low Friction Mechanism of DLC-Si Films under Mineral Oil without Additive. Jpn. J. Tribol. 2009, 54, 40–47. [Google Scholar]

- Mori, H. Effect of Water in Lubricated Oil on Friction Property of DLC-Si Films. Jpn. J. Tribol. 2020, 65, 610–615. [Google Scholar] [CrossRef]

- Volosova, M.A.; Lyakhovetsky, M.; Mitrofanov, A.P.; Melnik, Y.A.; Okunkova, A.A.; Fedorov, S.V. Influence of Cr-Al-Si-N and DLC-Si Thin Coatings on Wear Resistance of Titanium Alloy Samples with Different Surface Conditions. Coatings 2023, 13, 1581. [Google Scholar] [CrossRef]

- Siddiqui, S.A.; Favaro, G.; Maros, M.B. Investigation of the damage mechanism of CrN and diamond-like carbon coatings on precipitation-hardened and duplex-treated X42Cr13/W tool steel by 3D scratch testing. J. Mater. Eng. Perform. 2022, 31, 7830–7842. [Google Scholar] [CrossRef]

- Zaidi, H.; Djamai, A.; Mathia, T. Characterisation of DLC coating adherence by scratch testing. Tribol. Int. 2006, 39, 124–128. [Google Scholar] [CrossRef]

- Choi, J.; Ishii, K.; Kato, T.; Kawaguchi, M. Evaluation and Prediction of Mechanical Properties of DLC Films by Raman Spectroscopy (Part 1). Jpn. J. Tribol. 2013, 58, 596–602. [Google Scholar] [CrossRef]

- Choi, J.; Ishii, K.; Kato, T.; Kawaguchi, M.; Lee, W. Structural and mechanical properties of DLC films prepared by bipolar PBII&D. Diam. Relat. 2011, 20, 845–848. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-Like Amorphous Carbon. Mater. Sci. Eng. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Adamopoulos, G.; Robertson, J.; Morrison, N.A.; Godet, C. Hydrogen content estimation of hydrogenated amorphous carbon by visible Raman spectroscopy. J. Appl. Phys. 2004, 96, 6348–6352. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman Spectra of Disordered and Amorphous Carbon. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef]

- Choi, J.; Hibi, T.; Furuno, A.; Kawaguchi, M.; Kato, T. Evaluation and Prediction of Mechanical Properties of DLC Films by Raman Spectroscopy (Part 2). Jpn. J. Tribol. 2017, 62, 228–235. [Google Scholar] [CrossRef]

- Choi, J.; Nakao, S.; Miyagawa, S.; Ikeyama, M.; Miyagawa, Y. The effects of Si incorporation on the thermal and tribological properties of DLC films deposited by PBII&D with bipolar pulses. Surf. Coat. Technol. 2007, 201, 8357–8361. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, H.; Zhang, S.; Yan, M.; Lu, Y.; Hao, J.; Liu, W. The effect of acetylene flow rate on the uniform deposition of thick DLC coatings on the inner surface of pipes with different draw ratios. Vacuum 2022, 196, 110720. [Google Scholar] [CrossRef]

| Precursor | DC | Microwave | Duration [s] | |||||

|---|---|---|---|---|---|---|---|---|

| Gas | Flow [sccm] | Pressure [Pa] | Voltage [−V] | Power [W] | Pulse Frequency [kHz] | Duty [%] | ||

| Cleaning | Ar | 40 | 50 | 500 | - | - | - | 600 |

| H2 | 20 | |||||||

| Intermediate layer | Ar | 40 | 75 | 500 | - | - | - | 10 |

| C2H2 | 200 | |||||||

| TMS | 35 | |||||||

| Top layer | Ar | 40 | 75 | 500 | 1000 | 0.5 | 20 | 240 |

| CH4 | 200 | |||||||

| TMS | 20 | |||||||

| Temperature [K] | 350 |

| Pressure [Pa] | 75 |

| Electron density [m−3] | 5 × 1017 |

| Microwave input power [W] | 200 |

| Microwave oscillation frequency [GHz] | 2.45 |

| Material Property | Vacuum | Steel | Quartz | Plasma |

|---|---|---|---|---|

| Relative permittivity | 1 | 4000 | 4.2 | |

| Relative magnetic permeability | 1 | 1 | 1 | 1 |

| Electrical conductivity [s/m] | 0 | 1.12 × 107 | 1 × 10−14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ito, A.; Esaki, M.; Bae, S.-M.; Nagai, T.; Kousaka, H.; Harigai, T. Ultrahigh-Speed Deposition of Diamond-like Carbon on a Pipe Surface Using a Scanning Deposition Method via Local High-Density Plasma. Coatings 2025, 15, 1348. https://doi.org/10.3390/coatings15111348

Ito A, Esaki M, Bae S-M, Nagai T, Kousaka H, Harigai T. Ultrahigh-Speed Deposition of Diamond-like Carbon on a Pipe Surface Using a Scanning Deposition Method via Local High-Density Plasma. Coatings. 2025; 15(11):1348. https://doi.org/10.3390/coatings15111348

Chicago/Turabian StyleIto, Akihiko, Masahiro Esaki, Su-Min Bae, Taketo Nagai, Hiroyuki Kousaka, and Toru Harigai. 2025. "Ultrahigh-Speed Deposition of Diamond-like Carbon on a Pipe Surface Using a Scanning Deposition Method via Local High-Density Plasma" Coatings 15, no. 11: 1348. https://doi.org/10.3390/coatings15111348

APA StyleIto, A., Esaki, M., Bae, S.-M., Nagai, T., Kousaka, H., & Harigai, T. (2025). Ultrahigh-Speed Deposition of Diamond-like Carbon on a Pipe Surface Using a Scanning Deposition Method via Local High-Density Plasma. Coatings, 15(11), 1348. https://doi.org/10.3390/coatings15111348