Evaluation of Particle Deposition Characteristics in Bent Tubes at Different Dimple Locations

Abstract

1. Introduction

2. Numerical Methodology

2.1. Continuous Phase

| Parameter Symbol | Name | Numerical Value |

|---|---|---|

| Cμ | Turbulent viscosity coefficient | 0.0845 |

| C1ε | ε Equation Production Item Coefficient | 1.42 |

| C2ε | ε Equation Dissipation Coefficient | 1.68 |

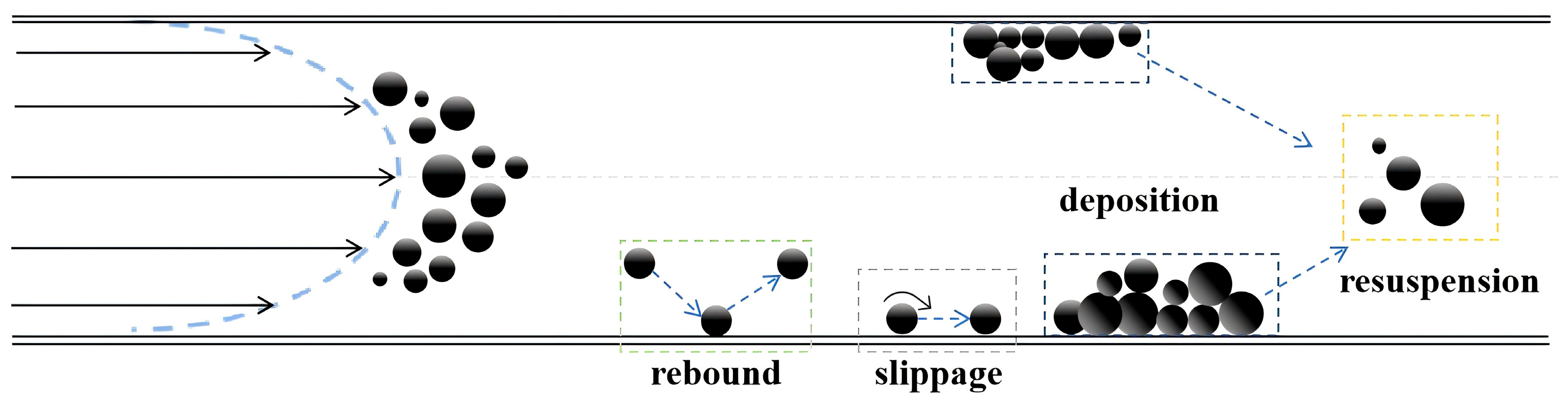

2.2. Discrete Phase Model

- Under all simulation scenarios, the tracked particles are defined as rigid spheres with uniform diameter and constant density throughout the population.

- The particle phase is diluted, and inter-particle collisions are neglected.

- The particles are smooth spherical particles in a monodisperse system.

- Due to the relatively high particle density and gas flow velocity, forces such as pressure gradient force, virtual mass force, and Brownian force are not considered.

2.2.1. Drag Force

2.2.2. Gravity and Buoyancy

2.3. Turbulent Dispersion of Particles

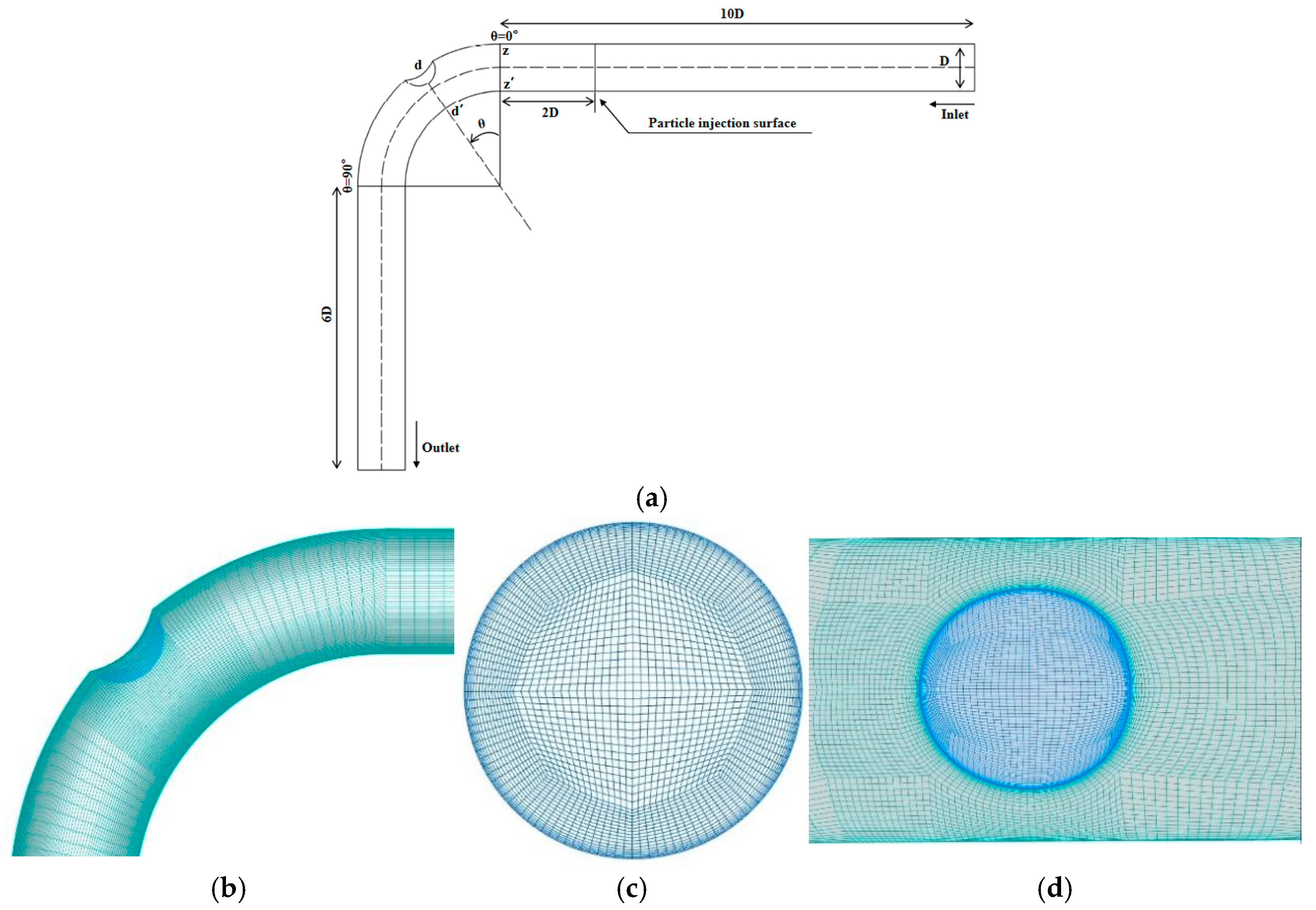

3. Case Description and Solution

3.1. Case Description

3.2. Boundary Conditions

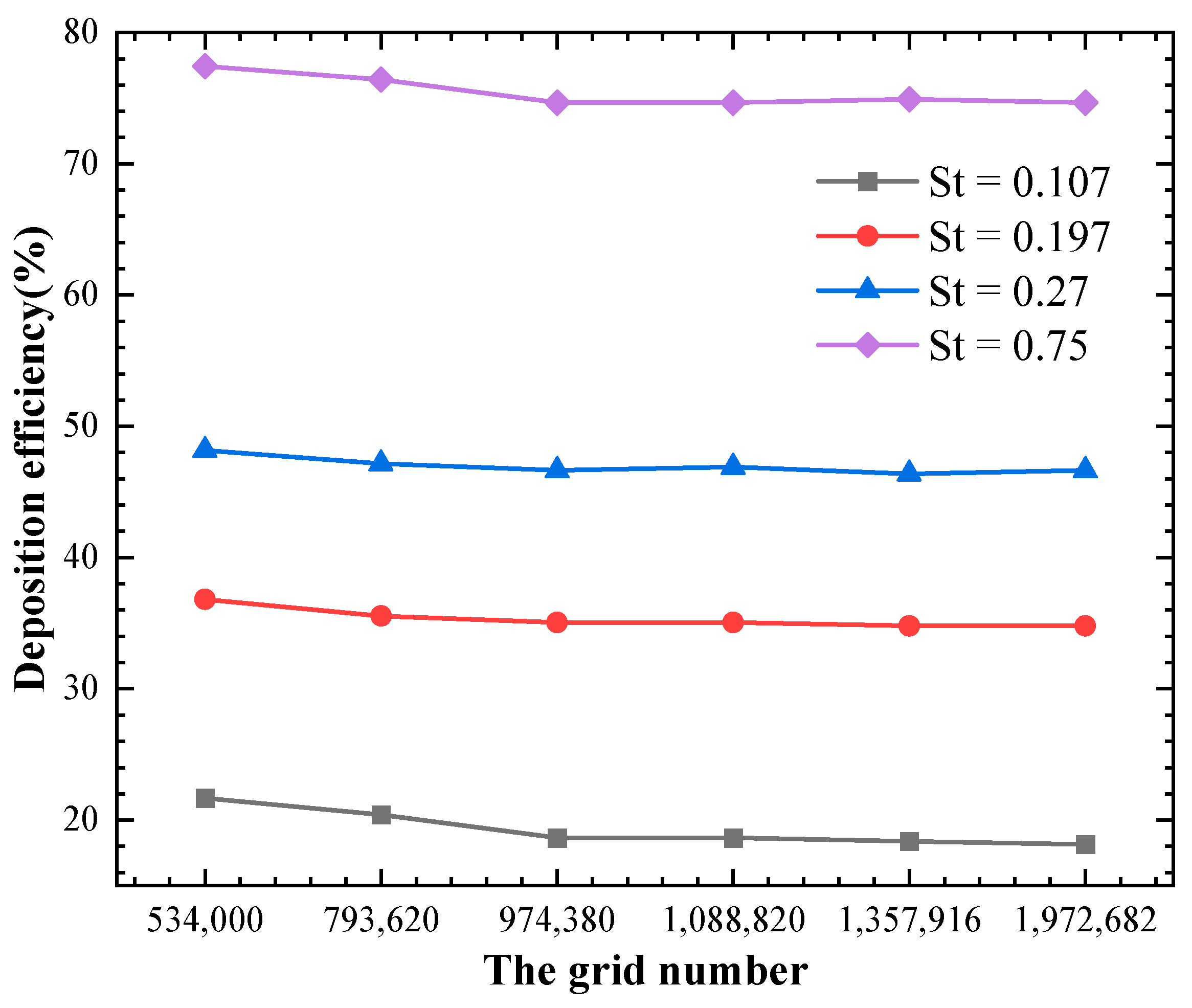

3.3. Structured Grids and Grid Independence Analysis

4. Results and Discussion

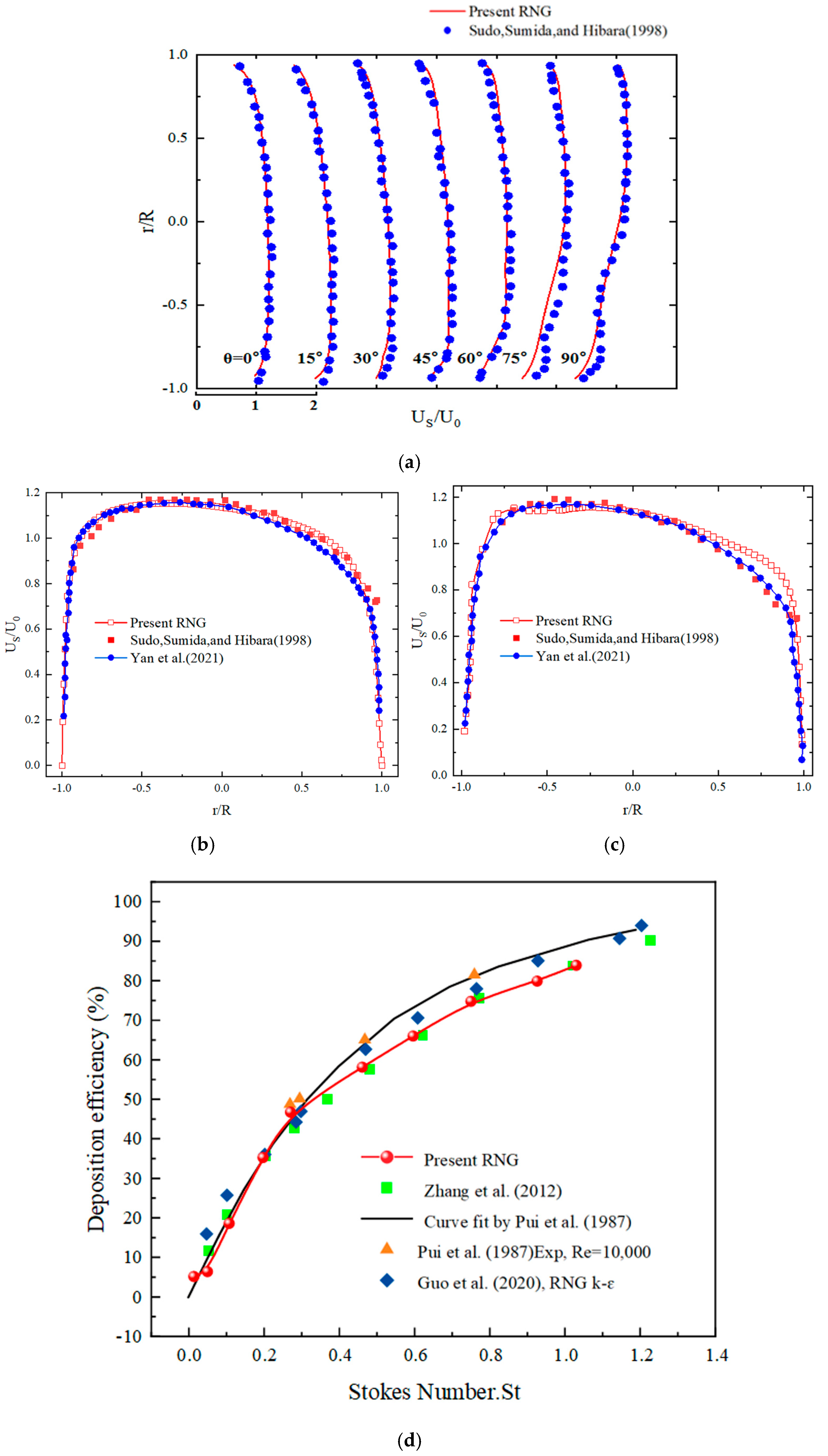

4.1. Numerical Analysis

Turbulent Flow Validation

4.2. Turbulent Flow Field Analysis

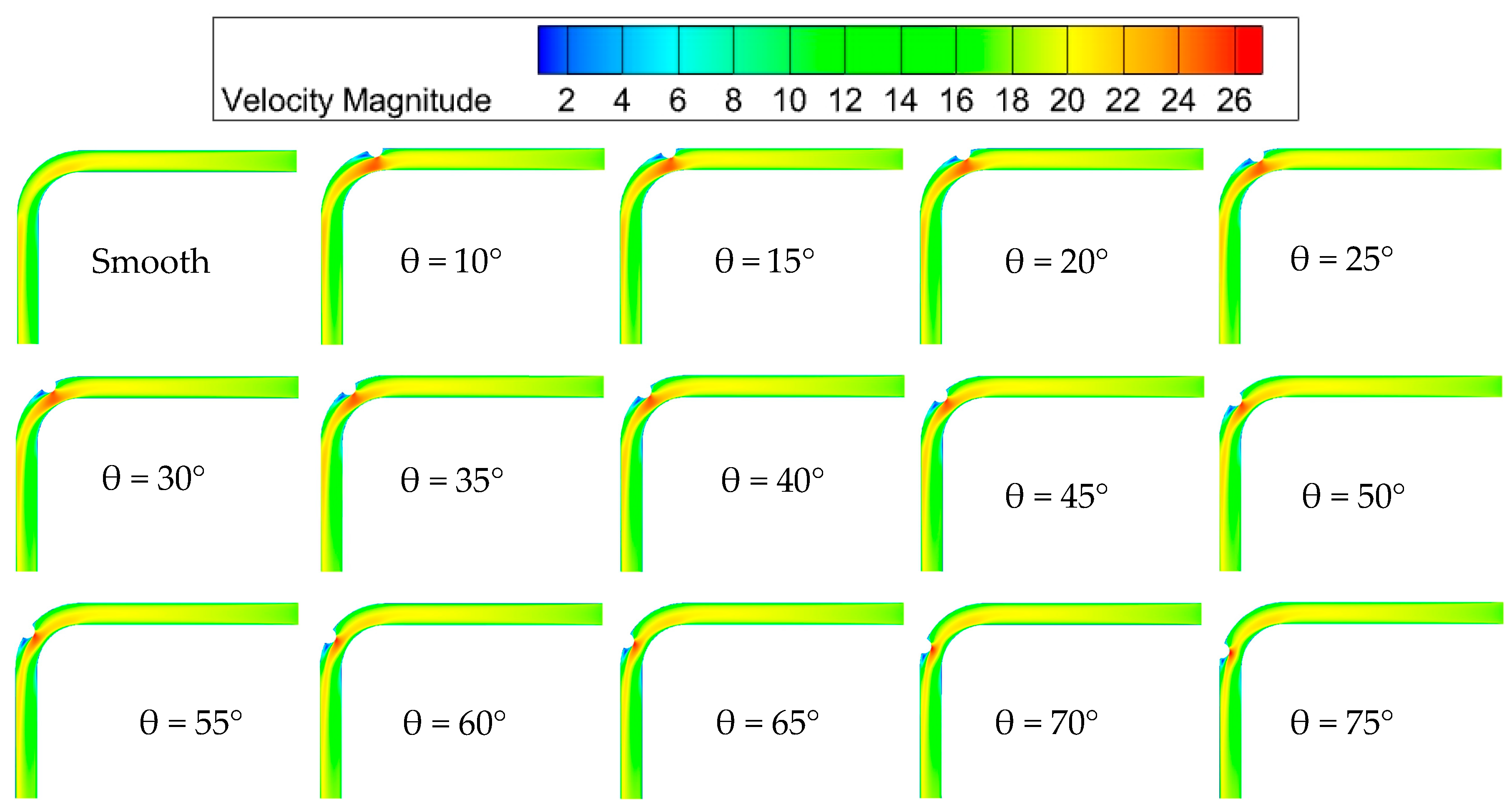

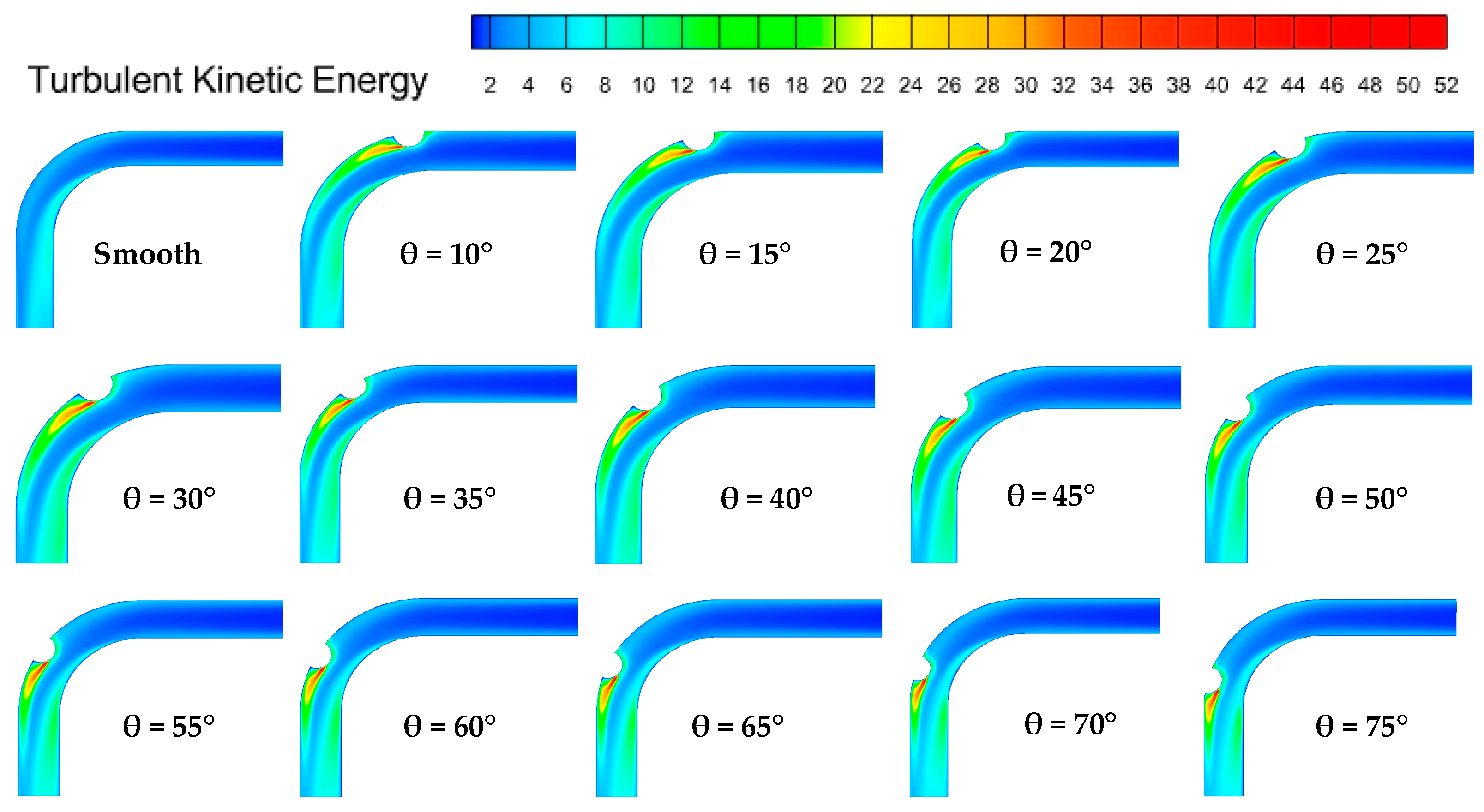

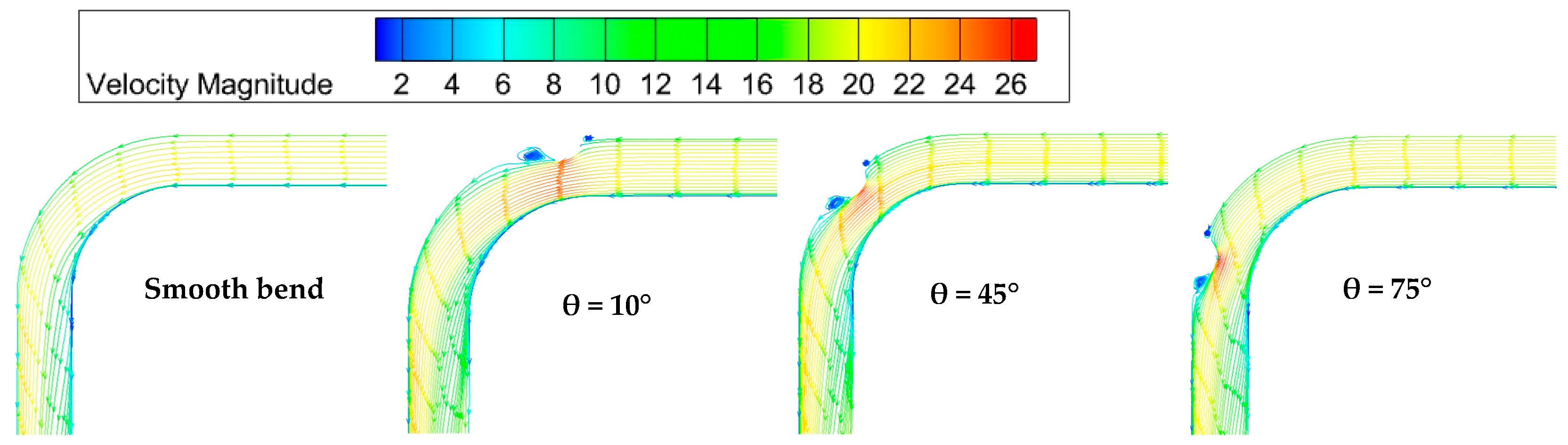

Flow Field Analysis

5. Limitations

6. Conclusions

- (1)

- The formation of dimple structures leads to vortex generation, resulting in a complex flow field within the dimpled channels. A high TKE region forms on the leeward side of the dimple structure. This is due to the presence of induced vortices and strong vortex clusters at this location, which in turn affect particle deposition. Additionally, on the leeward side of the dimple structure, a significant change in pressure drop occurs, attributed to the vortex formation resulting from the dimple effect on the leeward surface.

- (2)

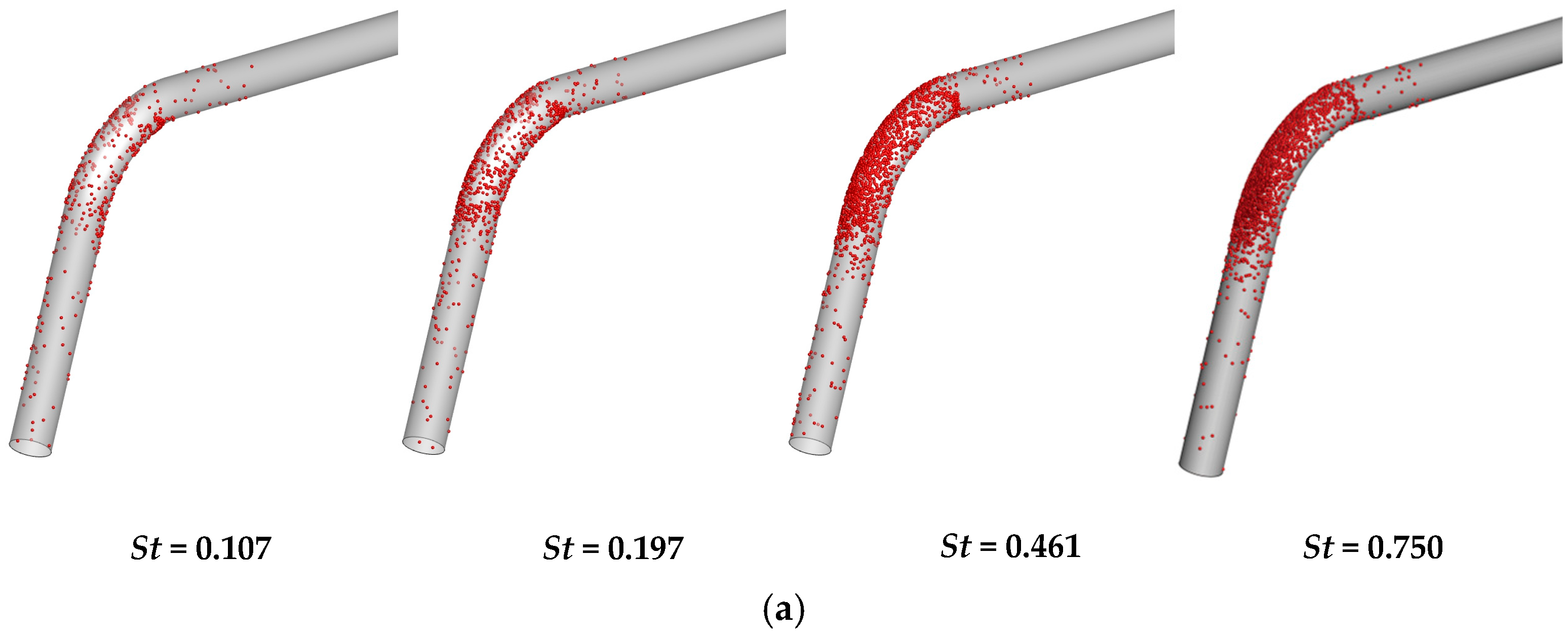

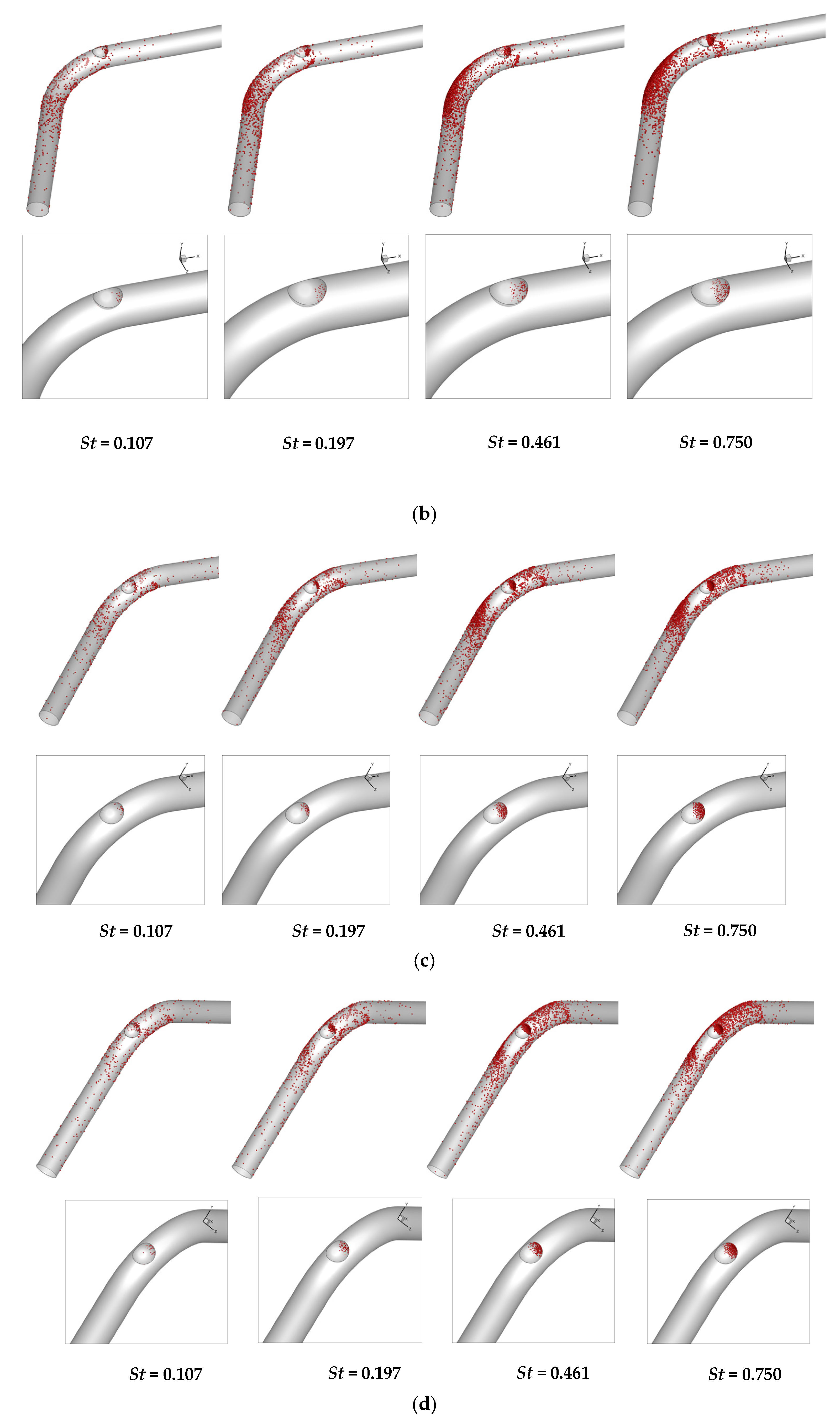

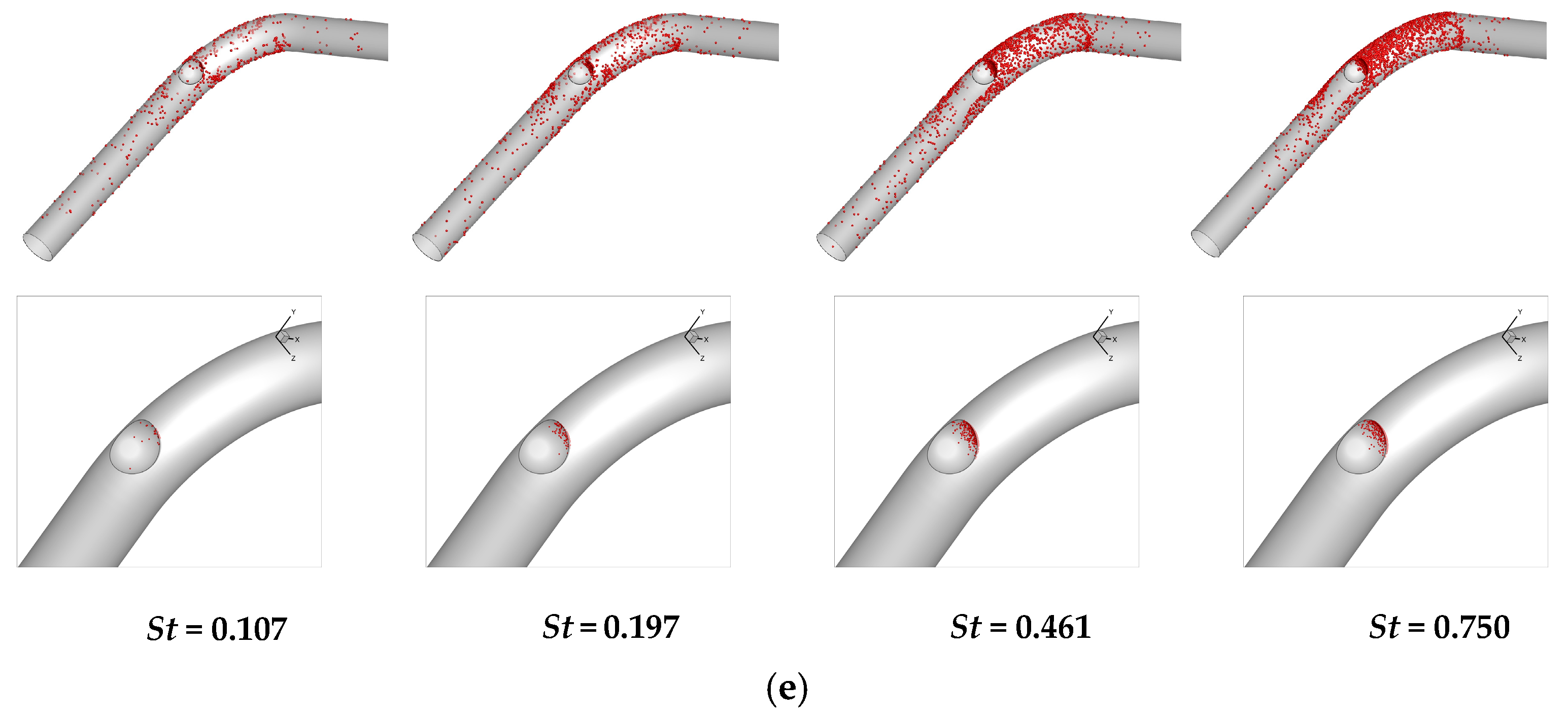

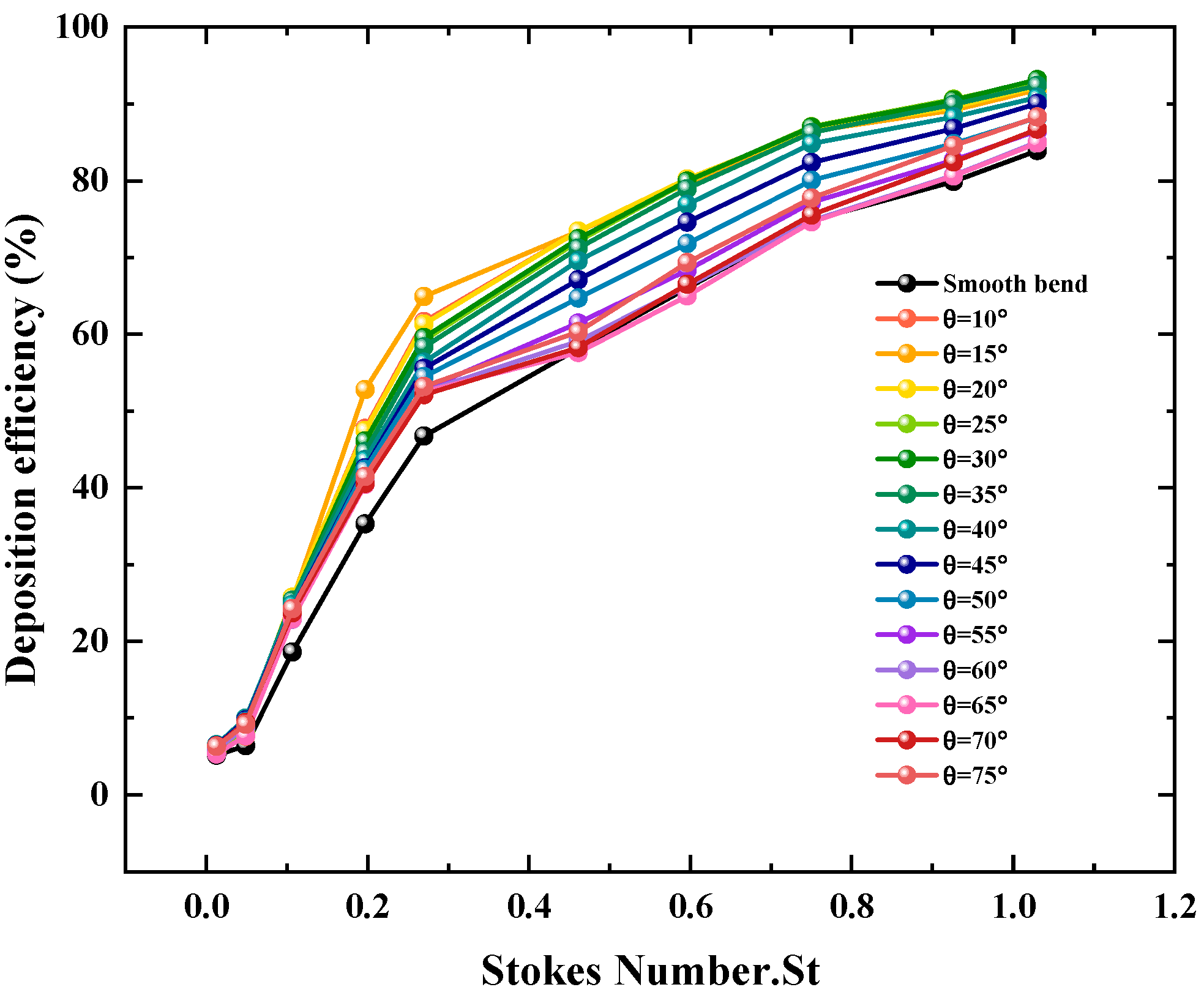

- The presence of dimple structures affects the sedimentation rate of particles. The deposition rate of dimple structures varies depending on their installation location. For operating conditions where St ≤ 0.27, an installation angle θ = 15° for the dimple yields the optimal effect on enhancing the particle deposition rate, with the maximum deposition rate increasing by 18.2%. For operating conditions where St ≥ 0.461, the optimal angle is θ = 30°, achieving a 14.126% increase in the maximum deposition rate. When θ < 40°, the overall deposition rate remains largely unchanged. When θ ranges between 45° and 65°, the particle deposition rate decreases significantly as θ increases, reaching its lowest value at θ = 65°. At this point, when St is 0.461, 0.596, and 0.75, the particle deposition rate decreases by 0.7%, 1.5%, and 0.6%, respectively, compared to the smooth bend. When θ > 65°, the deposition rate on the bend begins to increase as the installation angle increases. Channels incorporating this structure can be applied to removal or air purification equipment.

- (3)

- The presence of dimple structures influences the deposition location of particles. The windward side of the dimple structure acts as an obstacle within the channel, intercepting and depositing incoming particles at this location. On the leeward side and bottom surface of the dimple structure, there is very little particle deposition. The dimple structure can serve as a sacrificial component, absorbing direct impacts from particles and protecting the rest of the bend.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Cunningham correction factor | |

| drag coefficient | |

| diameter of dust particle (μm) | |

| Pipe diameter (m) | |

| Young’s moduli of channel wall (Gpa) | |

| Young’s moduli of the particle (Gpa) | |

| Drag force (N) | |

| Gravitation and buoyancy (N) | |

| gravitational acceleration (m/s2) | |

| turbulent kinetic energy generated by the mean velocity gradient | |

| turbulent kinetic energy (m2/s2) | |

| K | effective stiffness parameter |

| particle mass | |

| The number of deposited particles | |

| The total number of released particles | |

| Average pressure (cm) | |

| kinematic restitution coefficient | |

| Re | Reynolds number |

| the modulus of the mean strain rate tensor | |

| St | Stokes number |

| critical deposition velocity (m/s) | |

| particle velocity (m/s) | |

| friction velocity (m/s) | |

| averaged velocity (m/s) | |

| average flow velocity (m/s) | |

| normalized mean flow velocity (m/s) | |

| kinetic viscosity of air | |

| Poisson’s ratios of the channel wall | |

| Poisson’s ratios of the particle | |

| particle deposition velocity | |

| dimensionless particle deposition velocity | |

| dimensionless distance from the wall | |

| dissipation rate of turbulent kinetic energy | |

| density of particle (kg/m3) | |

| density of fluid (kg/m3) | |

| particle relaxation time | |

| system response time | |

| random number that follows a normal distribution | |

| deposition rate of particles | |

| mean free path of air | |

| μ | dynamic viscosity |

| effective dynamic viscosity | |

| turbulent viscosity |

References

- Erraghroughi, F.Z.; Bah, A.; El Maakoul, A.; Abdellah, A.B. Numerical Assessment of Particle Deposition Reduction in Turbulent Bend Pipe Flow with a Rib Insertion. Int. J. Heat Fluid Flow 2024, 106, 109290. [Google Scholar] [CrossRef]

- Chen, Q. Ventilation Performance Prediction for Buildings: A Method Overview and Recent Applications. Build. Environ. 2009, 44, 848–858. [Google Scholar] [CrossRef]

- Hofmann, W. Modelling Inhaled Particle Deposition in the Human Lung—A Review. J. Aerosol Sci. 2011, 42, 693–724. [Google Scholar] [CrossRef]

- Lu, H.; Lu, L. CFD Investigation on Particle Deposition in Aligned and Staggered Ribbed Duct Air Flows. Appl. Therm. Eng. 2016, 93, 697–706. [Google Scholar] [CrossRef]

- Zhan, F.; Zhuang, D.; Ding, G.; Tang, J. Numerical Model of Particle Deposition on Fin Surface of Heat Exchanger. Int. J. Refrig. 2016, 72, 27–40. [Google Scholar] [CrossRef]

- Li, A.; Ahmadi, G.; Bayer, R.G.; Gaynes, M.A. Aerosol Particle Deposition in an Obstructed Turbulent Duct Flow. J. Aerosol Sci. 1994, 25, 91–112. [Google Scholar] [CrossRef]

- Lai, A.C.K. Modeling Indoor Coarse Particle Deposition onto Smooth and Rough Vertical Surfaces. Atmos. Environ. 2005, 39, 3823–3830. [Google Scholar] [CrossRef]

- Lai, A.C.K.; Nazaroff, W.W. Supermicron Particle Deposition from Turbulent Chamber Flow onto Smooth and Rough Vertical Surfaces. Atmos. Environ. 2005, 39, 4893–4900. [Google Scholar] [CrossRef]

- Lu, H.; Wang, Y. Particle Deposition in Ventilation Ducts: A Review. Build. Simul. 2019, 12, 723–734. [Google Scholar] [CrossRef]

- Pui, D.Y.H.; Romay-Novas, F.; Liu, B.Y.H. Experimental Study of Particle Deposition in Bends of Circular Cross Section. Aerosol Sci. Technol. 1987, 7, 301–315. [Google Scholar] [CrossRef]

- Peters, T.M.; Leith, D. Particle Deposition in Industrial Duct Bends. Ann. Occup. Hyg. 2004, 48, 483–490. [Google Scholar] [CrossRef]

- Li, Q.; Song, J.; Li, C.; Wei, Y.; Chen, J. Numerical and Experimental Study of Particle Deposition on Inner Wall of 180° Bend. Powder Technol. 2013, 237, 241–254. [Google Scholar] [CrossRef]

- Kadia, S.; Larsson, I.A.S.; Billstein, M.; Rüther, N.; Lia, L.; Pummer, E. Investigating Supercritical Flow Characteristics and Movement of Sediment Particles in a Narrow Channel Bend Using PTV and Video Footage. Adv. Water Resour. 2024, 193, 104827. [Google Scholar] [CrossRef]

- Wu, F.; Yu, C.; Yu, J.; Zhou, S.; Fan, Z.; Xu, R. Experimental Study on Particle Deposition Behavior in Air Supply Ducts of a High-Speed Train. Build. Environ. 2025, 269, 112494. [Google Scholar] [CrossRef]

- Sun, K.; Lu, L.; Jiang, H. A Numerical Study of Bend-Induced Particle Deposition in and behind Duct Bends. Build. Environ. 2012, 52, 77–87. [Google Scholar] [CrossRef]

- Guo, J.; Chen, Z.; Shen, B.; Wang, J.; Yang, L. Numerical Study on Characteristics of Particle Deposition Efficiency on Different Walls of 90° Square Bend. Powder Technol. 2020, 364, 572–583. [Google Scholar] [CrossRef]

- Seyfi, S.; Mirzayi, B.; Seyyedbagheri, H. CFD Modeling of Black Powder Particles Deposition in 3D 90-Degree Bend of Natural Gas Pipelines. J. Nat. Gas Sci. Eng. 2020, 78, 103330. [Google Scholar] [CrossRef]

- Yan, Y.; Zhao, Y.; Yao, J.; Wang, C.-H. Investigation of Particle Transport by a Turbulent Flow through a 90° Bend Pipe with Electrostatic Effects. Powder Technol. 2021, 394, 547–561. [Google Scholar] [CrossRef]

- Yan, Y.; Mortimer, L.F.; Wolde, B.; Fairweather, M.; Zhao, Y.; Yao, J. Effect of Secondary Flow and Wall Collisions on Particle-Laden Flows in 90° Pipe Bends. Int. J. Multiph. Flow 2024, 179, 104925. [Google Scholar] [CrossRef]

- Ladino, A.; Duque-Daza, C.A.; Lain, S. Effect of Walls with Large Scale Roughness in Deposition Efficiency for 90-Degree Square Bend Configurations. J. Aerosol Sci. 2023, 167, 106093. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, J.; Li, H.; He, H. A Comprehensive Evaluation of the Anti-Erosion Characteristics of Several New Structural Elbows in the Pneumatic Conveying System. Powder Technol. 2022, 412, 117976. [Google Scholar] [CrossRef]

- Li, R.; Sun, Z.; Li, A.; Li, Y.; Wang, Z. Design Optimization of Hemispherical Protrusion for Mitigating Elbow Erosion via CFD-DPM. Powder Technol. 2022, 398, 117128. [Google Scholar] [CrossRef]

- Zhang, H.; Nunayon, S.S.; Lai, A.C. Performance Evaluation of Flow Resistance and Ultrafine Particle Deposition Enhancement in an Air Duct Equipped with V-Shaped Winglet Vortex Generators. Build. Environ. 2020, 183, 107194. [Google Scholar] [CrossRef]

- Lu, H.; Quan, Y. A CFD Study of Particle Deposition in Three-Dimensional Heat Exchange Channel Based on an Improved Deposition Model. Int. J. Heat Mass Transf. 2021, 178, 121633. [Google Scholar] [CrossRef]

- Shuvo, M.S.; Sakib, M.N.; Rahman, R.; Saha, S. Particle Deposition and Characteristics of Turbulent Flow in Converging and Diverging Nozzles Using Eulerian-Lagrangian Approach. Results Eng. 2022, 16, 100669. [Google Scholar] [CrossRef]

- Han, Z.; Lu, H. Numerical Simulation of Turbulent Flow and Particle Deposition in Heat Transfer Channels with Concave Dimples. Appl. Therm. Eng. 2023, 230, 120672. [Google Scholar] [CrossRef]

- Liu, L.; Xi, Y.; Zhang, L.; Xu, W.; Zhao, R.; Liu, Y.; Wang, Z.; Wu, B.; Dong, K. Numerical Study of Particle Deposition Characteristics in a New Type of Reinforced Pipe. Chem. Eng. Process.-Process Intensif. 2023, 189, 109371. [Google Scholar] [CrossRef]

- Sakib, M.N.; Shuvo, M.S.; Rahman, R.; Saha, S. Particle Deposition and Fluid Flow Characteristics in Turbulent Corrugated Pipe Flow Using Eulerian-Lagrangian Approach. Heliyon 2023, 9, e14603. [Google Scholar] [CrossRef] [PubMed]

- Akter, F.; Saha, S. Deposition of Aerosol Particles and Characteristics of Turbulent Flow inside Wavy Pipe Using Eulerian-Lagrangian Approach. Chem. Eng. Process.-Process Intensif. 2024, 205, 109971. [Google Scholar] [CrossRef]

- Wang, Z.; Han, Z.; Lu, H.; Zhao, W. Particle Deposition Characteristics in Concave Dimple Heat Transfer Channels with Different Inclination Angles. Powder Technol. 2025, 452, 120545. [Google Scholar] [CrossRef]

- Liu, P.; Gong, K.; Lin, D.; Guo, S.; Ma, Z.; Liu, Z.; Zhang, H. Numerical Study of Particle Deposition and Removal Behavior in the Water-Cooled Flue of a Submerged Arc Furnace. Chem. Eng. Process.-Process Intensif. 2025, 216, 110404. [Google Scholar] [CrossRef]

- Jin, Y.; Feng, M.; Li, M.; Shao, H.; Hu, X.; Cui, J. Particle Deposition Characteristics on Different Finned Tube Types in Industrial Flue Gas Waste Heat Recovery. Int. Commun. Heat Mass Transf. 2025, 166, 109180. [Google Scholar] [CrossRef]

- Yakhot, V.; Orszag, S.A.; Thangam, S.; Gatski, T.B.; Speziale, C.G. Development of Turbulence Models for Shear Flows by a Double Expansion Technique. Phys. Fluids A Fluid Dyn. 1992, 4, 1510–1520. [Google Scholar] [CrossRef]

- Kim, J.; Yadav, M.; Kim, S. Characteristics of Secondary Flow Induced by 90-Degree Elbow in Turbulent Pipe Flow. Eng. Appl. Comput. Fluid Mech. 2014, 8, 229–239. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, Y.; Xiao, Y.; Yang, W. Study of Gas-Solid Two-Phase Flow in Pipeline Elbows Using an LES-DPM Coupling Method. Powder Technol. 2023, 413, 118012. [Google Scholar] [CrossRef]

- Caciolo, M.; Stabat, P.; Marchio, D. Numerical Simulation of Single-Sided Ventilation Using RANS and LES and Comparison with Full-Scale Experiments. Build. Environ. 2012, 50, 202–213. [Google Scholar] [CrossRef]

- Van Hooff, T.; Blocken, B.; Tominaga, Y. On the Accuracy of CFD Simulations of Cross-Ventilation Flows for a Generic Isolated Building: Comparison of RANS, LES and Experiments. Build. Environ. 2017, 114, 148–165. [Google Scholar] [CrossRef]

- Vahaji, S.; Nguyen, N.-H.; Shang, Y.; Inthavong, K. Sedimentation Effects on Particle Position and Inertial Deposition in 90° Circular Bends. Powder Technol. 2021, 393, 722–733. [Google Scholar] [CrossRef]

- Brach, R.M.; Dunn, P.F. A Mathematical Model of the Impact and Adhesion of Microsphers. Aerosol Sci. Technol. 1992, 16, 51–64. [Google Scholar] [CrossRef]

- Arsalanloo, A.; Abbasalizadeh, M. Numerical Study on Deposition of Particles in a 90° Bend in the Presence of Swirling Flow Using Eulerian-Lagrangian Method. Powder Technol. 2017, 320, 285–294. [Google Scholar] [CrossRef]

- Sudo, K.; Sumida, M.; Hibara, H. Experimental Investigation on Turbulent Flow in a Circular-Sectioned 90-Degree Bend. Exp. Fluids 1998, 25, 42–49. [Google Scholar] [CrossRef]

- Zhang, P.; Roberts, R.M.; Bénard, A. Computational Guidelines and an Empirical Model for Particle Deposition in Curved Pipes Using an Eulerian-Lagrangian Approach. J. Aerosol Sci. 2012, 53, 1–20. [Google Scholar] [CrossRef]

| Investigators | Geometric Model | Particle Characteristics | Particle Size | Fluid | Relevance/Finding |

|---|---|---|---|---|---|

| Zhang et al. [23] | Air duct equipped with a vortex generator | Ultrafine particles (UFPs) | 5–100 nm | Air | V-shaped vortex generator enhances particle deposition. |

| Lu et al. [24] | Heat exchange channel in a three-dimensional ribbed structure | Monodisperse spherical particles | 1, 3, 5, 10, 30, 50 μm | Air | Effect of ribs on particle deposition in straight-tube heat exchange channels |

| Shuvo et al. [25] | Tapered or flared nozzle | Monodisperse spherical particles | 2, 3, 4.1, 4.82, 6.32, 7.2, 8.09, 9, 9.5, 10 μm | Air | The deposition rate increases with increasing Re. |

| Han et al. [26] | Heat transfer channel with dimpled structure | Monodisperse spherical particles | 1, 3, 5, 10, 20, 30, 40, 50 μm | Air | Influence of dimple structures on particle deposition in straight-tube heat exchange channels. |

| Ladino et al. [20] | Bent pipe containing large-scale roughness structures | Monodisperse spherical particles | 3–30 μm | Air | Large-scale roughness enhances deposition efficiency in bent pipes. |

| Liu et al. [27] | Cylindrical straight tubes, corrugated tubes, new enhanced heat exchange tubes | CaCO3 particles | 5–50 μm | Water | The new enhanced tube reduces particle deposition. |

| Sakib et al. [28] | Cylindrical bellows | Spherical particles | 1–30 μm | Air | Increased corrugation height enhances particle deposition. |

| Akter et al. [29] | Cylindrical bellows | Aerosol particles | 1–30 μm | Air | Large pipe diameters and low flow rates enhance sedimentation efficiency. |

| Erraghroughi et al. [1] | Circular bent pipe with ribbed structure | Spherical particles | 2–11.4 μm | Air | Ribs can provide better protection for bent pipes with low curvature ratios. |

| Wang et al. [30] | Inclined heat transfer channel with dimpled structure | Monodisperse spherical particles | 1, 3, 5, 10, 20, 30, 40, 50 μm | Air | Influence of dimple structures on particle deposition in inclined straight-tube heat exchange channels. |

| Liu et al. [31] | Submerged arc furnace | Particles | 5–140 μm | Flue gas, water | Proposing a novel water-cooled flue to mitigate particulate pollution. |

| Jin et al. [32] | Fin-tube heat exchange channel | Pulverised coal particles | 1–10 μm | Flue gas | Larger particles settle in regions of lower vorticity, thereby reducing sedimentation. |

| Particle Size (μm) | 1.00 | 2.00 | 3.00 | 4.10 | 4.82 | 6.32 | 7.20 | 8.09 | 9.00 | 9.50 |

|---|---|---|---|---|---|---|---|---|---|---|

| Stokes number | 0.013 | 0.05 | 0.107 | 0.197 | 0.270 | 0.461 | 0.596 | 0.750 | 0.926 | 1.030 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Lu, H.; Han, Z. Evaluation of Particle Deposition Characteristics in Bent Tubes at Different Dimple Locations. Coatings 2025, 15, 1336. https://doi.org/10.3390/coatings15111336

Wang Z, Lu H, Han Z. Evaluation of Particle Deposition Characteristics in Bent Tubes at Different Dimple Locations. Coatings. 2025; 15(11):1336. https://doi.org/10.3390/coatings15111336

Chicago/Turabian StyleWang, Zeyu, Hao Lu, and Zunshi Han. 2025. "Evaluation of Particle Deposition Characteristics in Bent Tubes at Different Dimple Locations" Coatings 15, no. 11: 1336. https://doi.org/10.3390/coatings15111336

APA StyleWang, Z., Lu, H., & Han, Z. (2025). Evaluation of Particle Deposition Characteristics in Bent Tubes at Different Dimple Locations. Coatings, 15(11), 1336. https://doi.org/10.3390/coatings15111336