Distributed Fiber Optic Sensing for Monitoring Mining-Induced Overburden Deformation

Abstract

1. Introduction

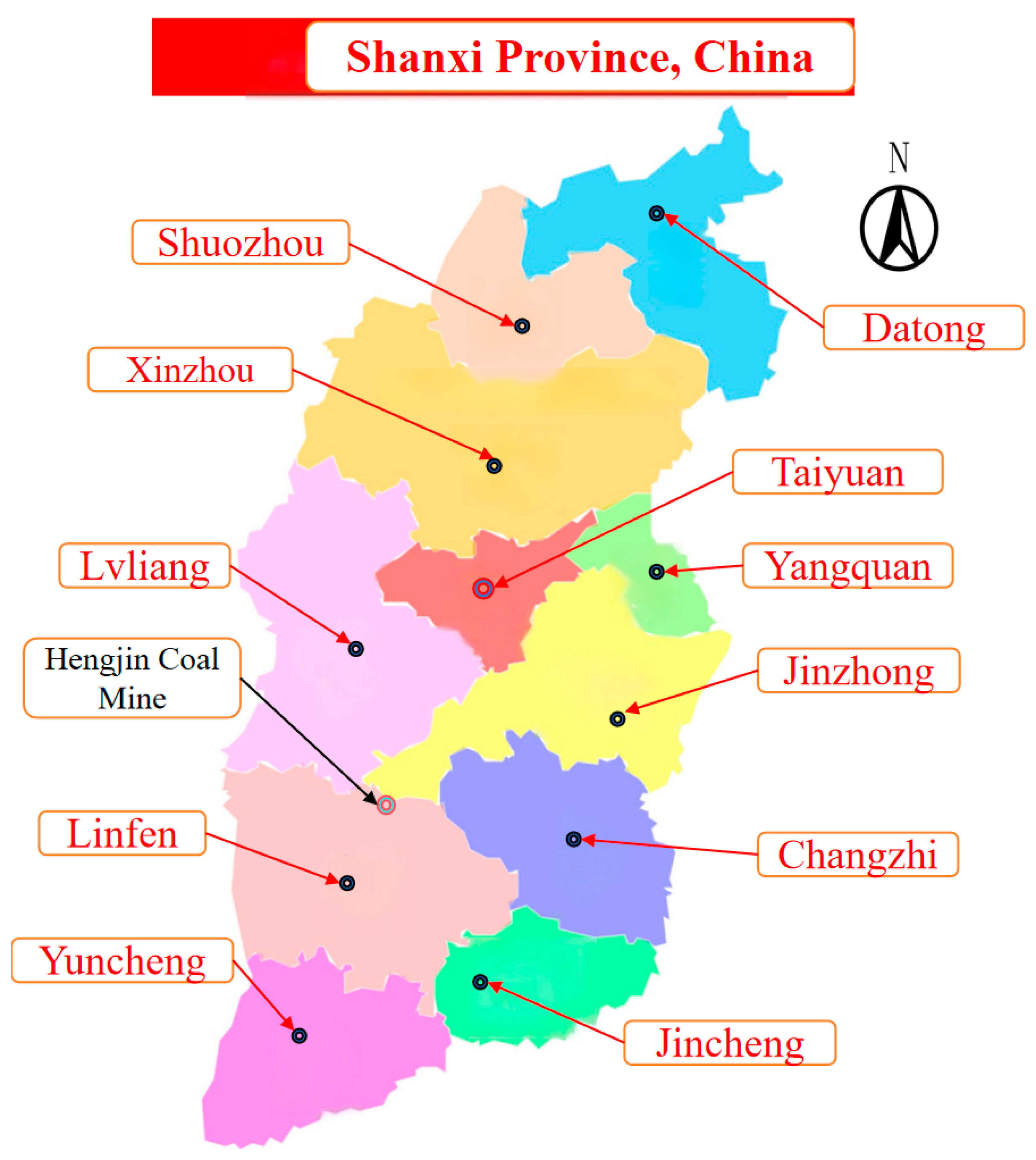

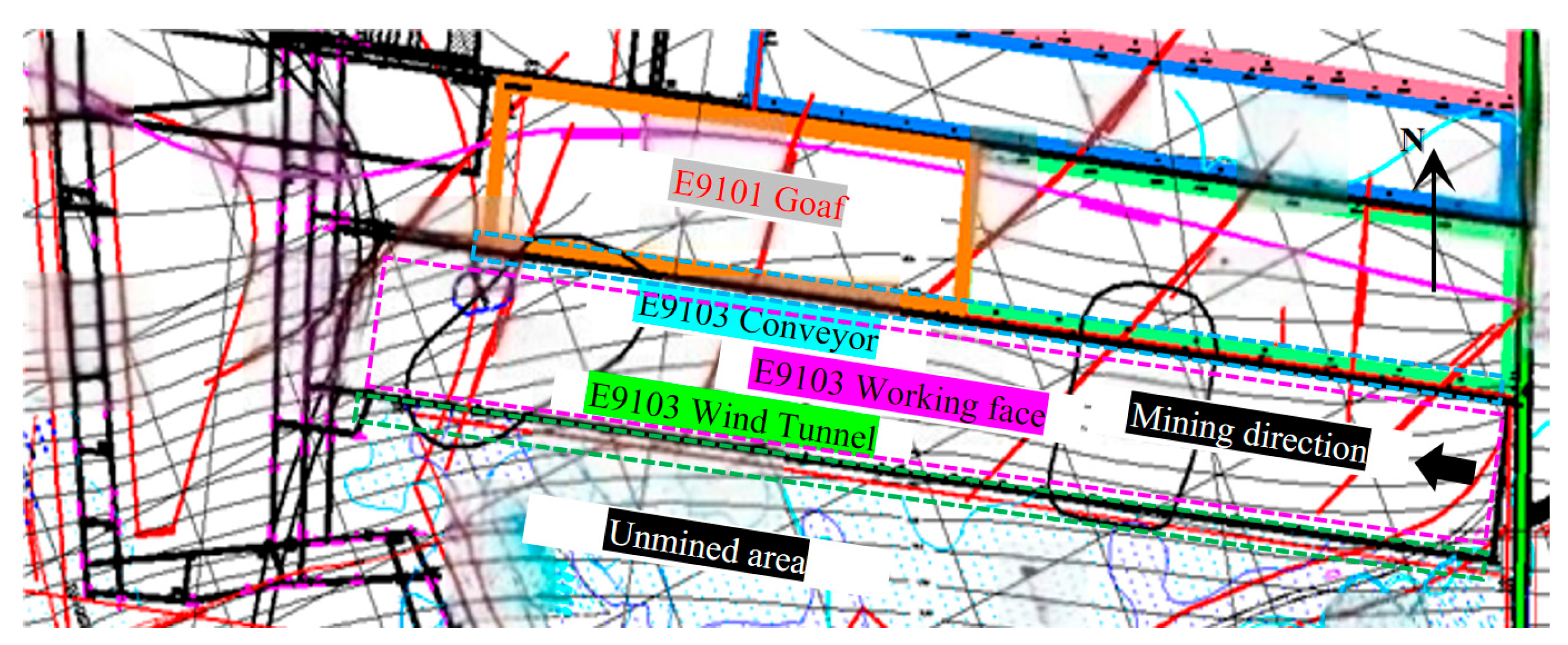

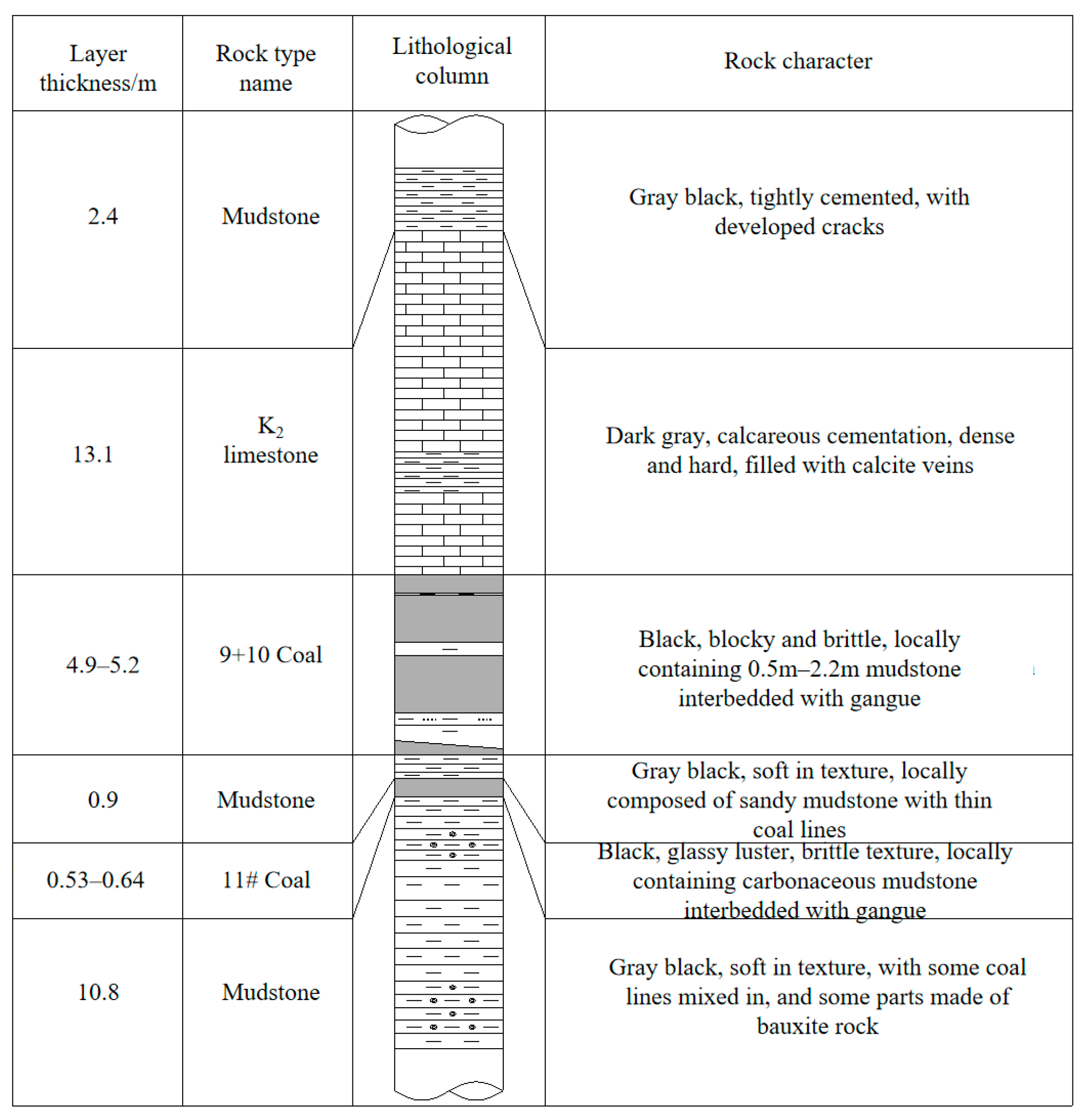

2. Geological Characteristics of Mine Engineering

2.1. Geological Setting

2.2. Theoretical Calculation of the Three Zones of Overburden Failure and the Caving-to-Mining Ratio

| Rock Character | Calculation Formula (a) | Calculation Formula (b) |

|---|---|---|

| Weak rock | ||

| Medium hard rock | ||

| Hard rock |

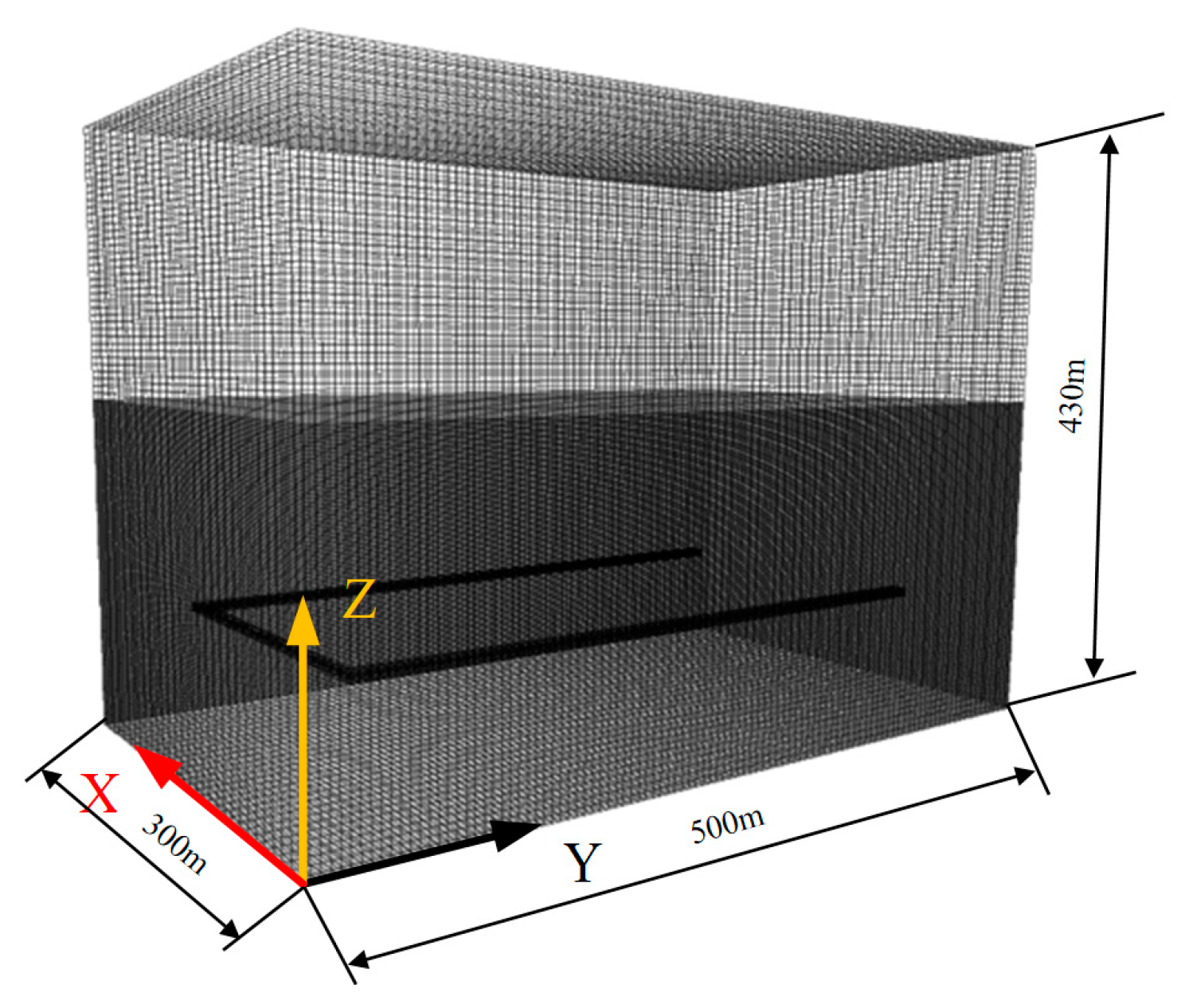

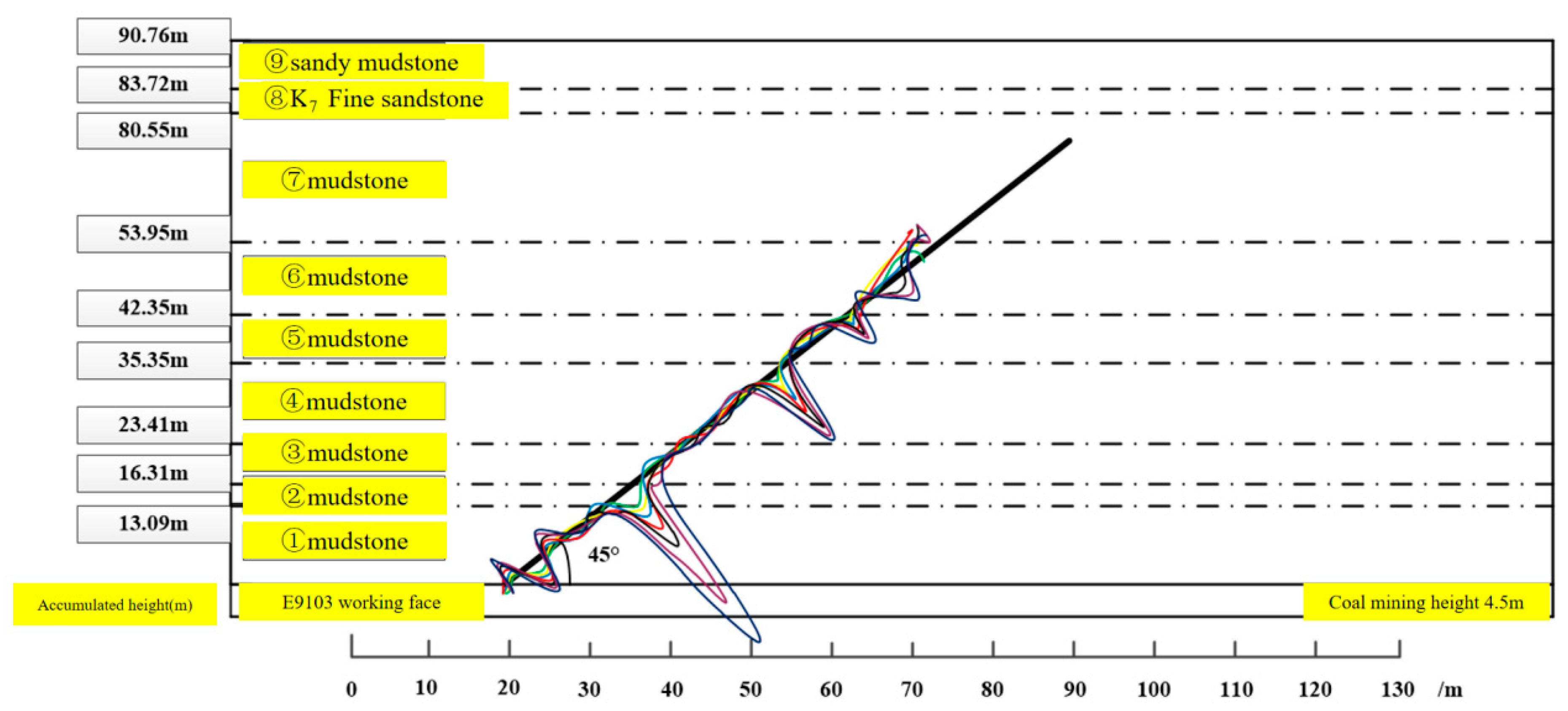

3. Numerical Simulation Analysis

3.1. FLAC Numerical Simulation

3.2. Computational Model and Parameters

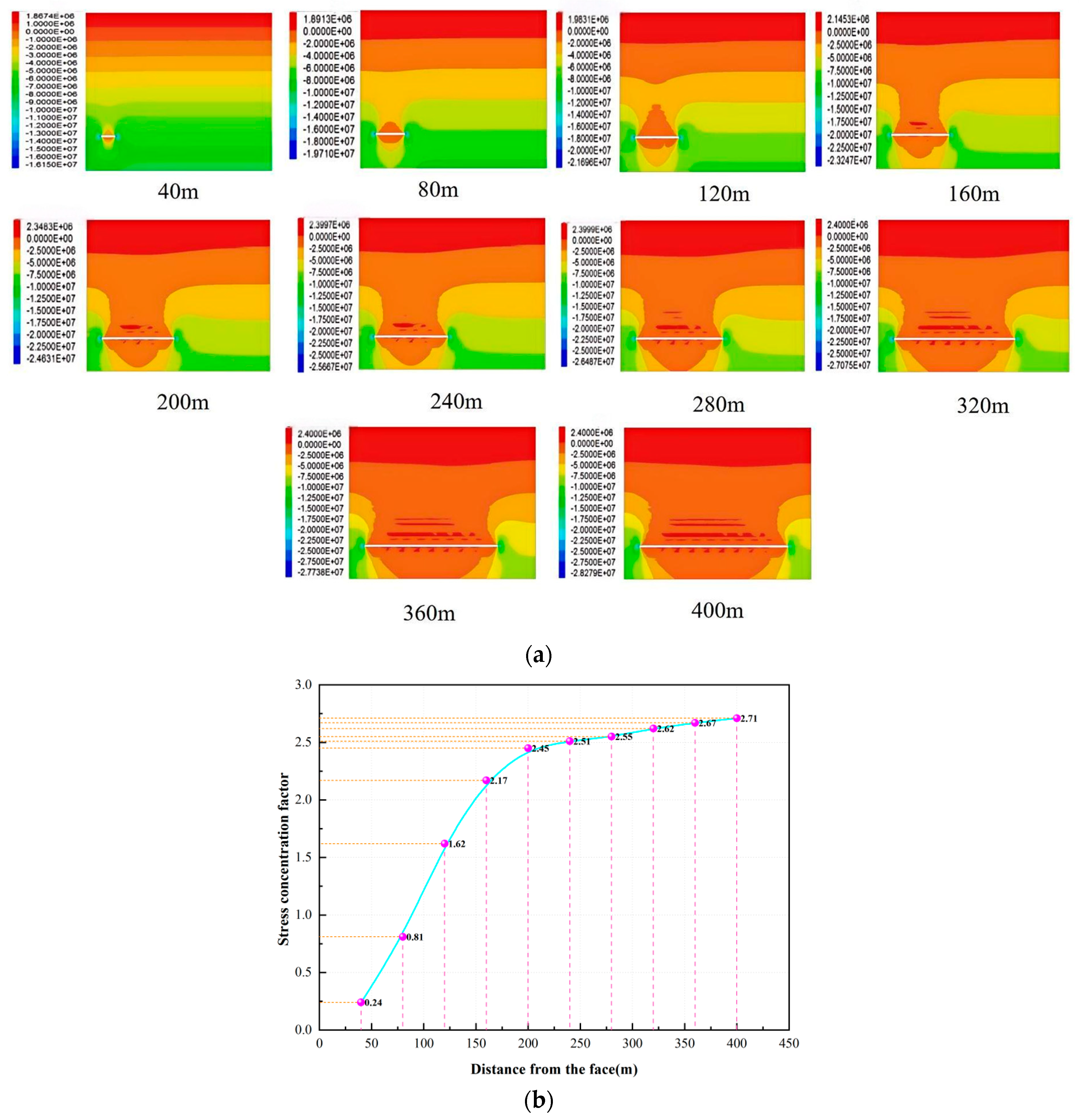

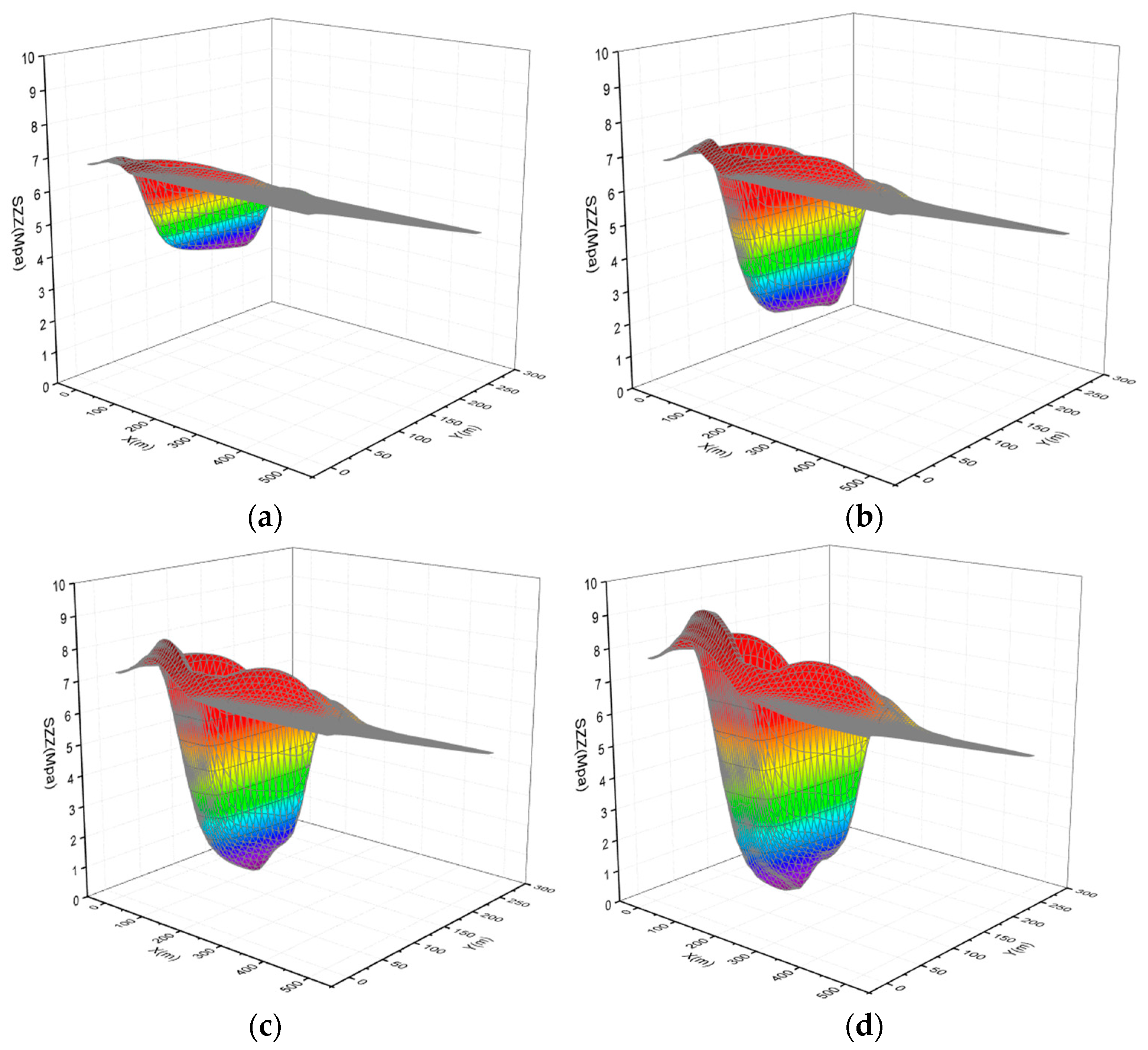

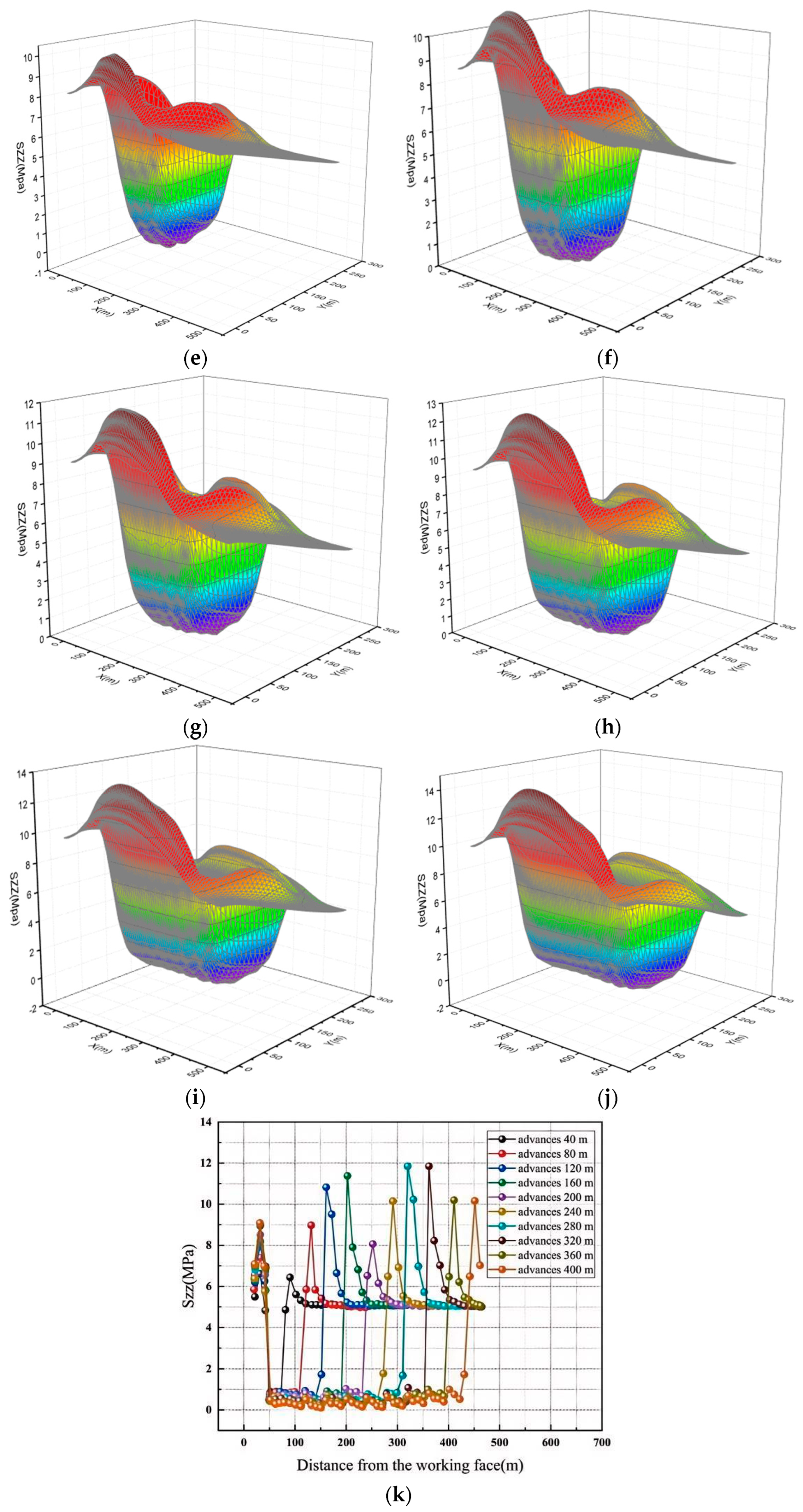

3.3. Analysis of Simulation Results

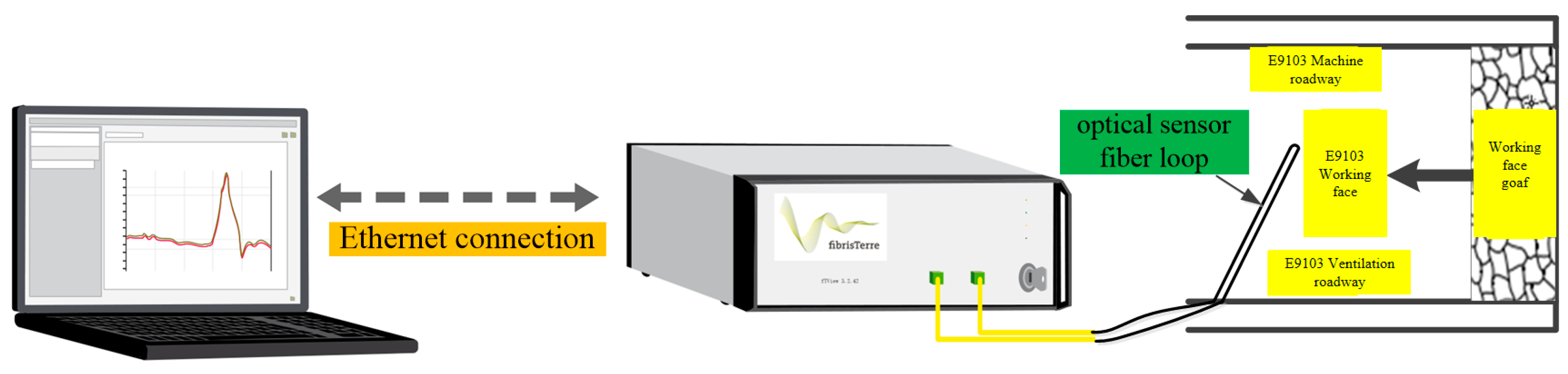

4. On-Site Measurement of Distributed Optical Fiber in Overlying Strata of Fully Mechanized Top Coal Mining

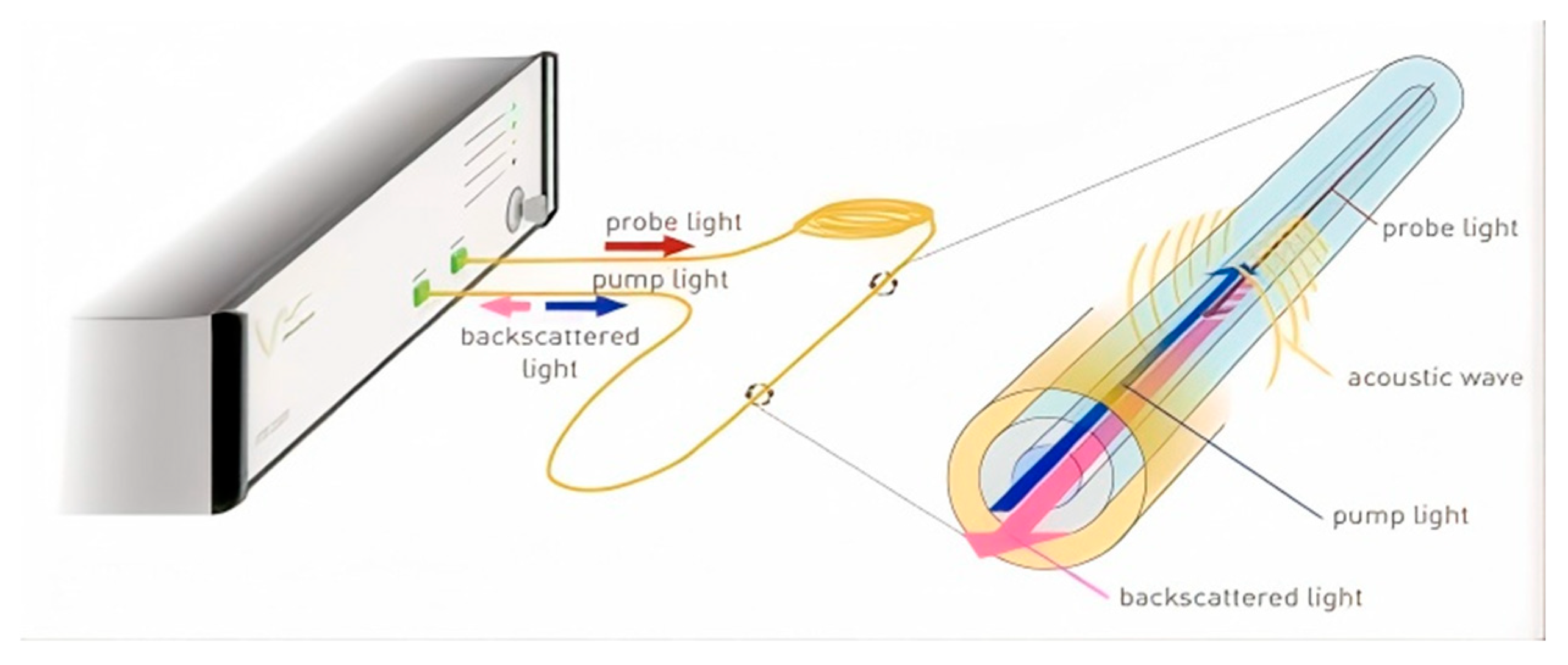

4.1. Principle of Brillouin Optical Time Domain Analysis (BOTDA) Testing

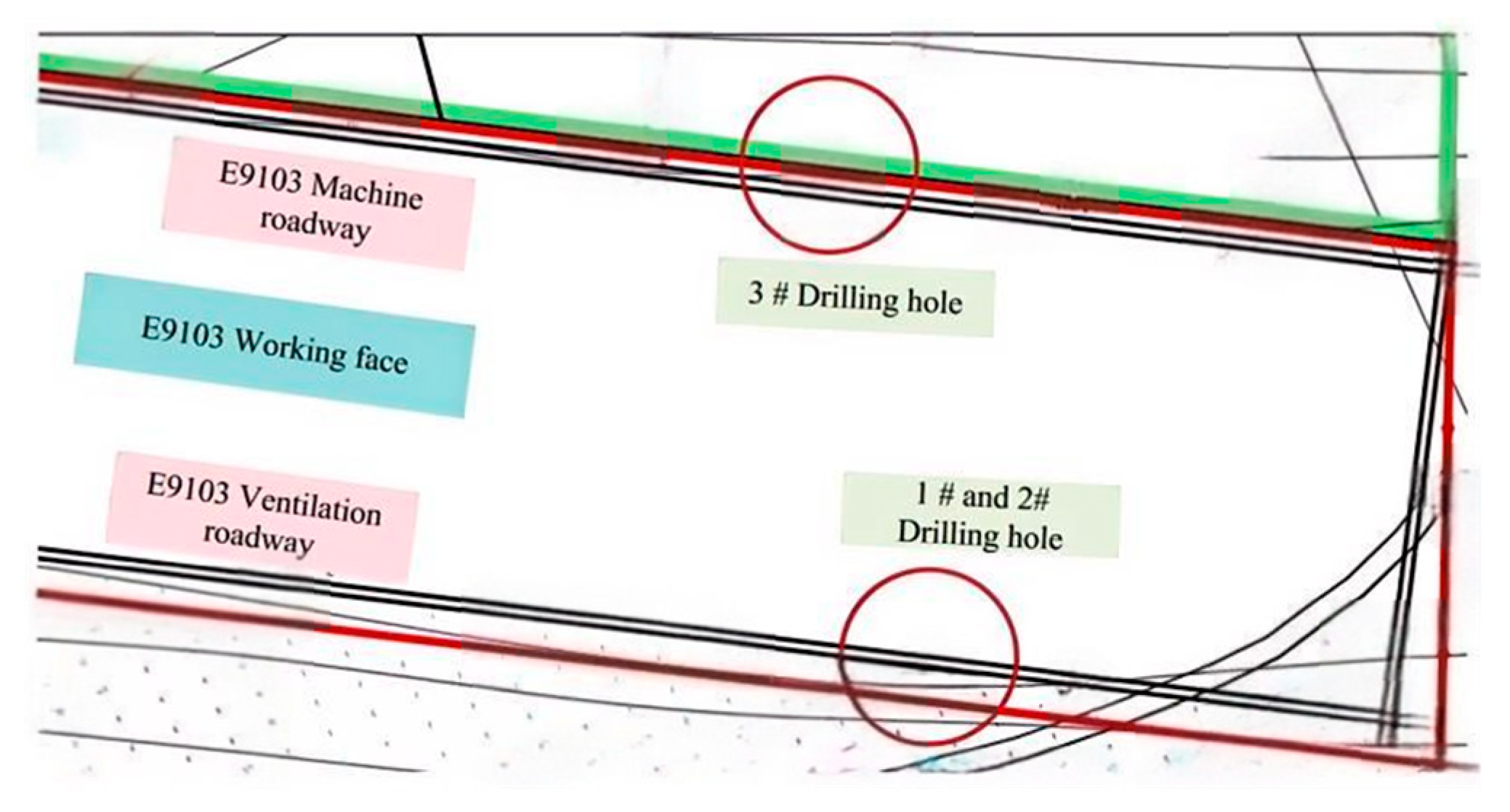

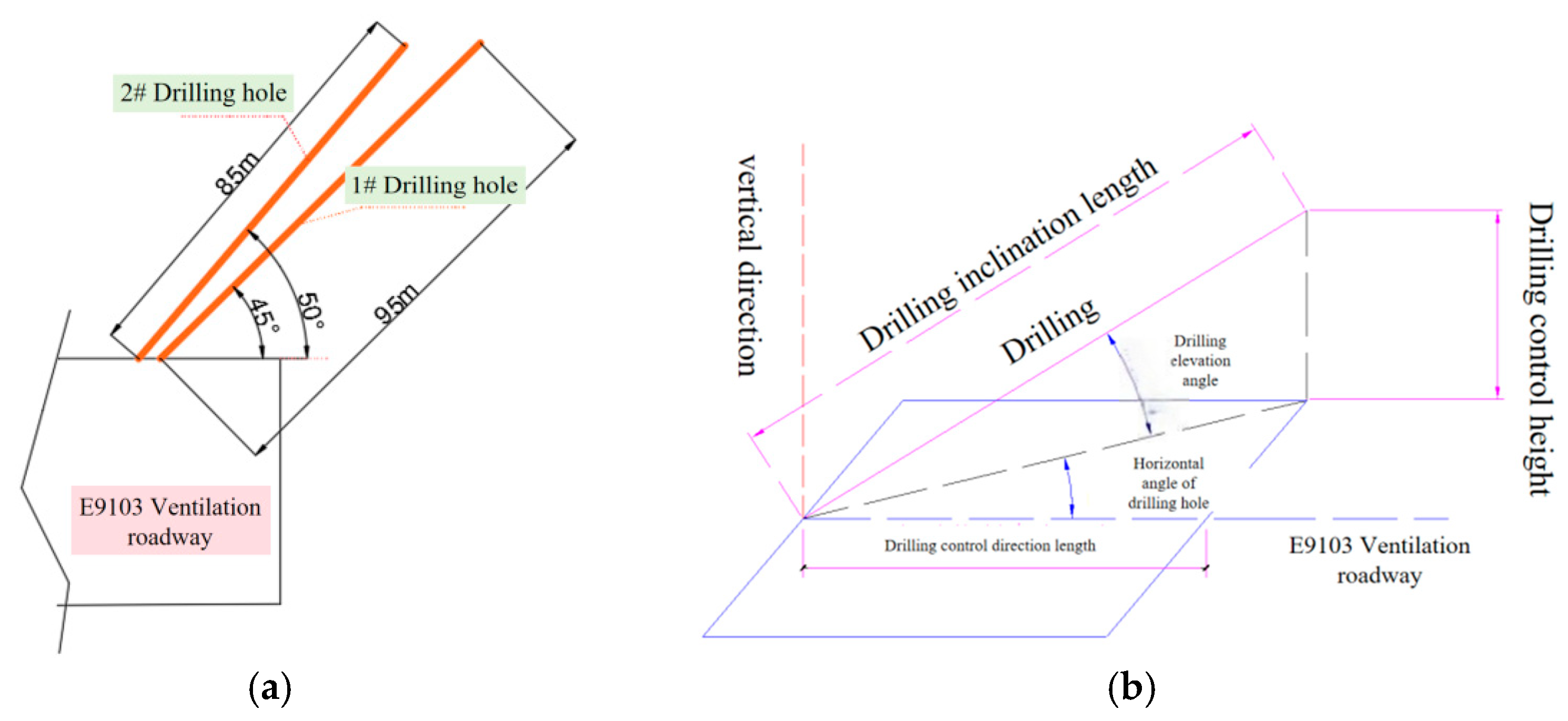

4.2. Experimental Program

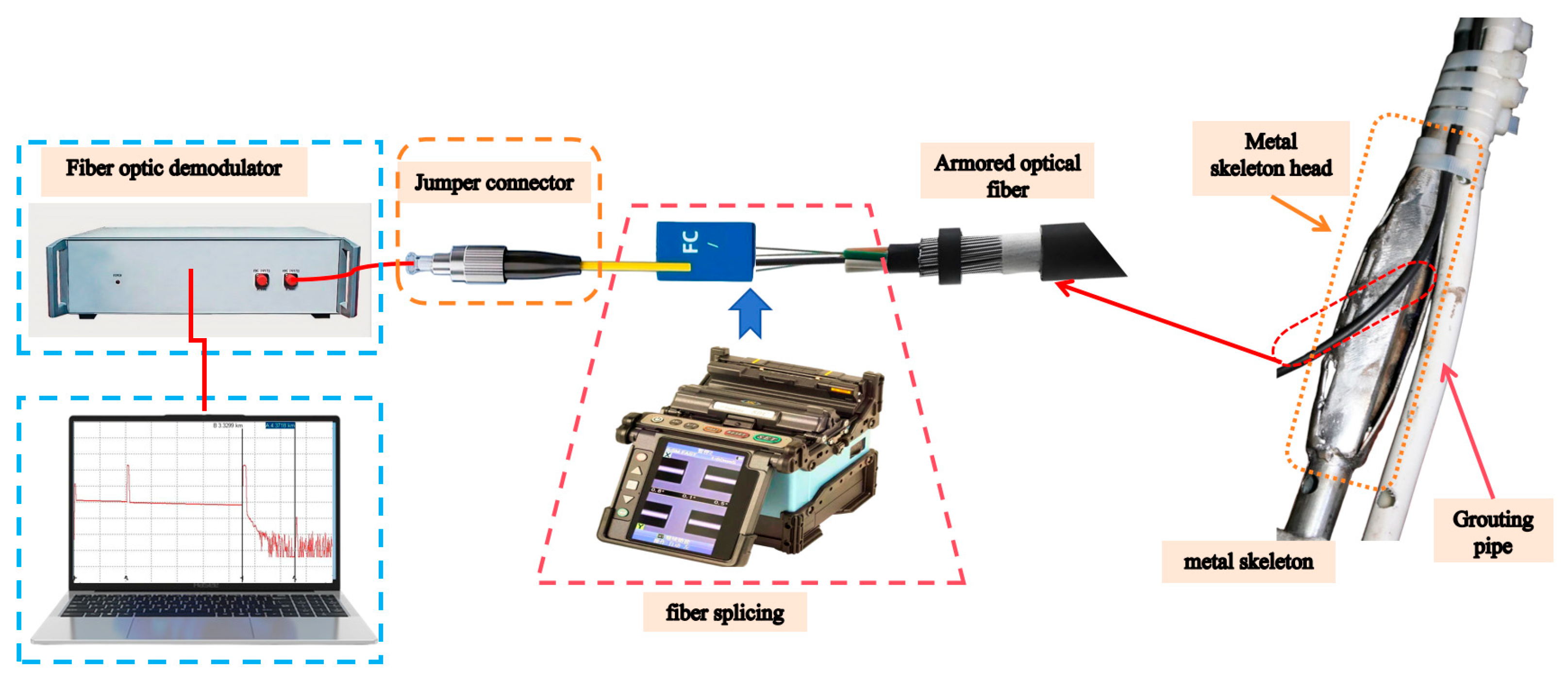

4.3. Equipment Installation

4.3.1. Pre-Installation Requirements

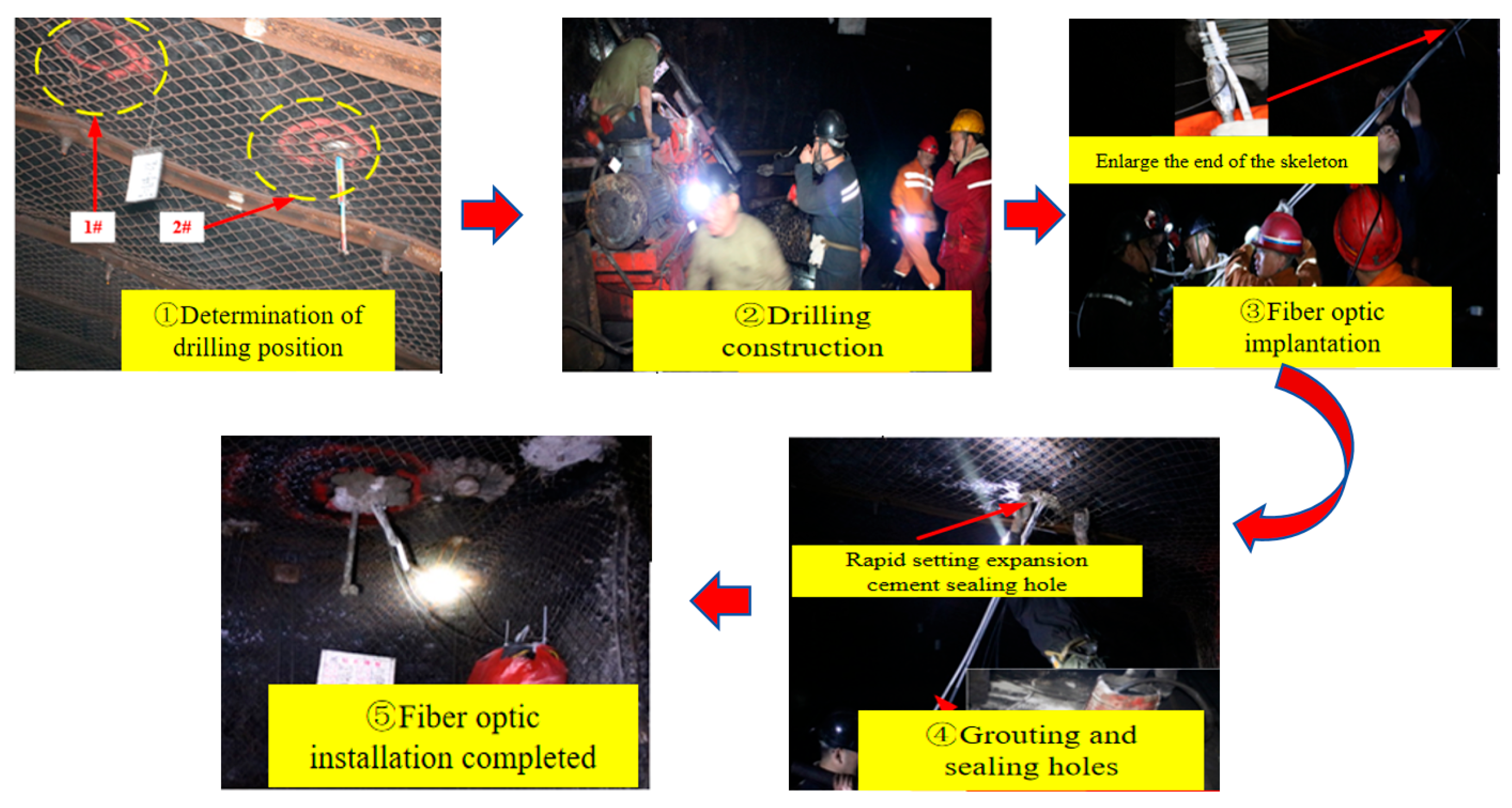

4.3.2. Distributed Fiber Optic Installation

- (a)

- Carefully feed the sensing cable (often a more robust steel tube cable is selected) to the designated bottom of the hole. The borehole is drilled toward the goaf or rock layer (depth and angle must comply with design requirements).

- (b)

- Seal the borehole (by injecting cement mortar or specialized sealing agent) to ensure effective coupling between the cable and the rock mass, as well as to protect the cable. This step is critical for monitoring performance.

- (c)

- Use specialized clamps or zip ties to firmly secure the cable to non-moving, compression-resistant components such as belt conveyor frames or hydraulic support columns. Attachment to moving parts is strictly prohibited. In areas prone to impact, crushing, or water influx (such as roadway intersections, low-lying areas, and equipment access points), heavy-duty protective conduits must be installed. The installation process is illustrated in Figure 14.

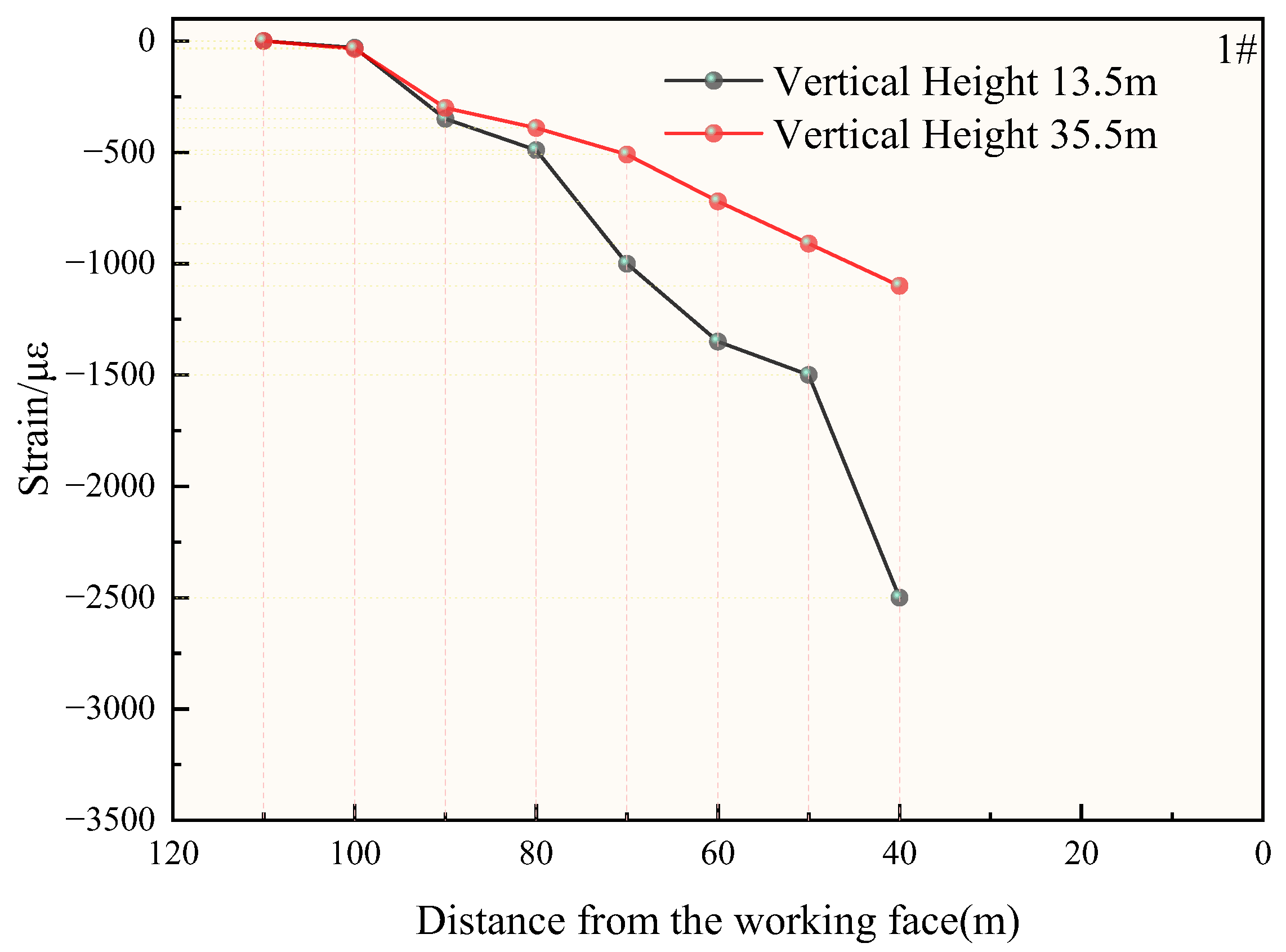

4.4. Test Results and Analysis

4.4.1. Data Collection

4.4.2. Result Analysis

- (1)

- Strain Distribution and Evolution Characteristics in Borehole 1#

- (2)

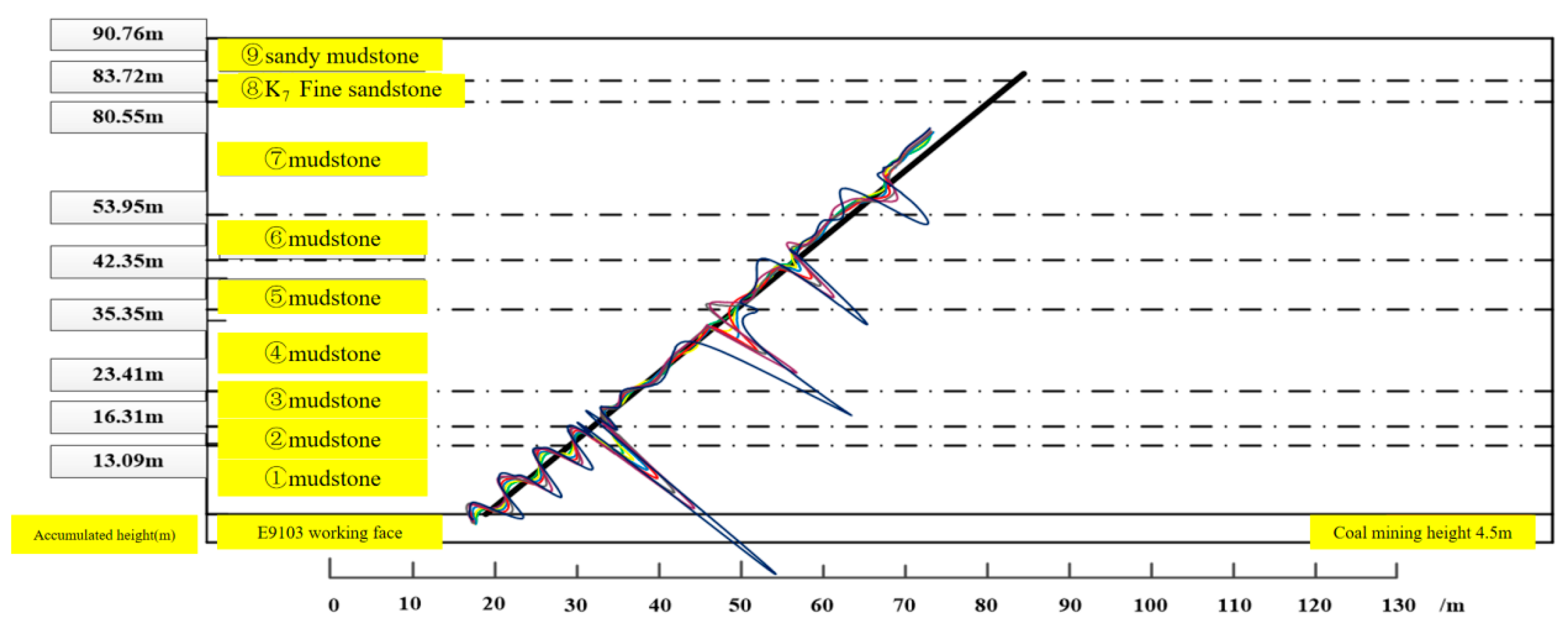

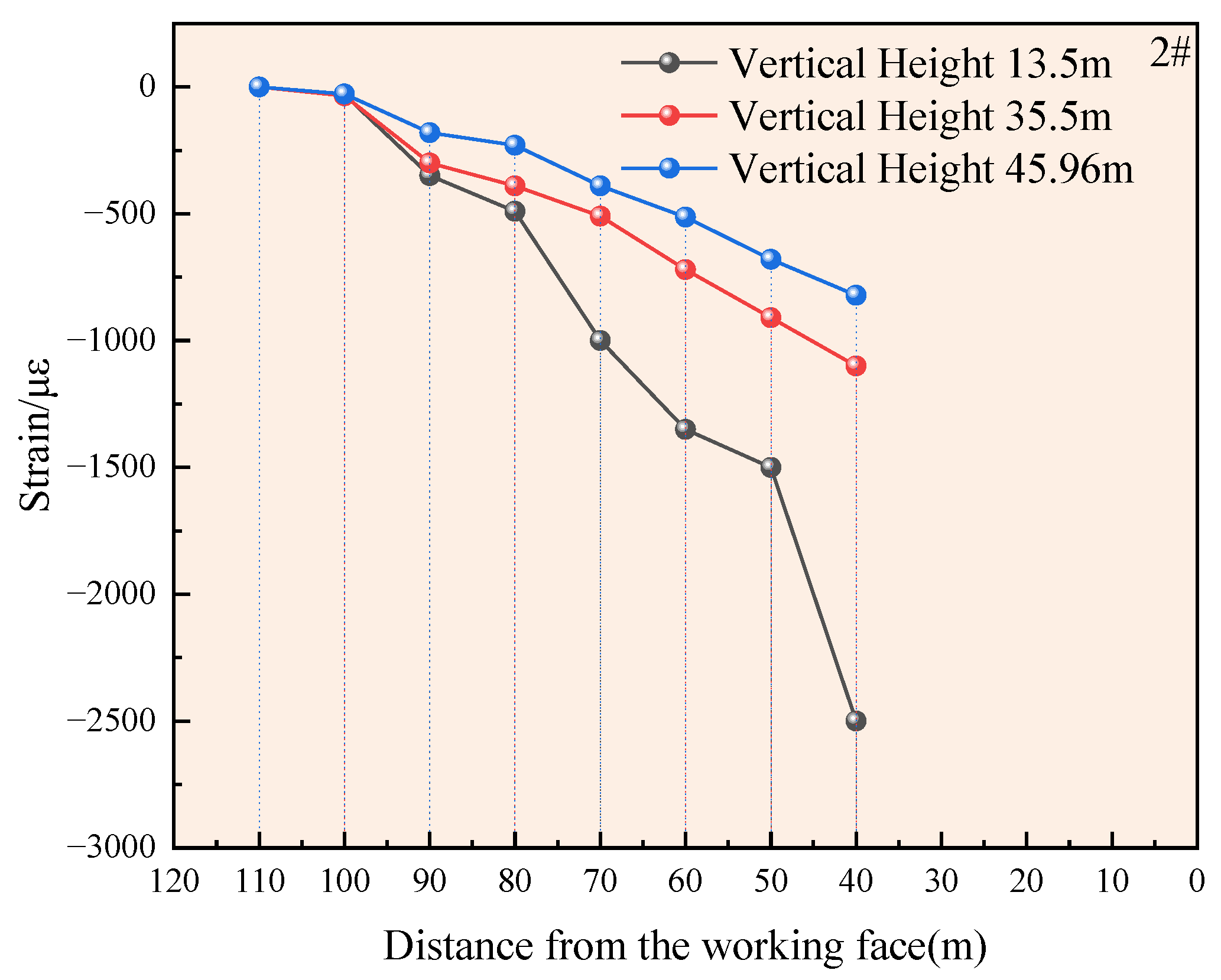

- Strain Distribution and Evolution Characteristics in Borehole 2#

- (3)

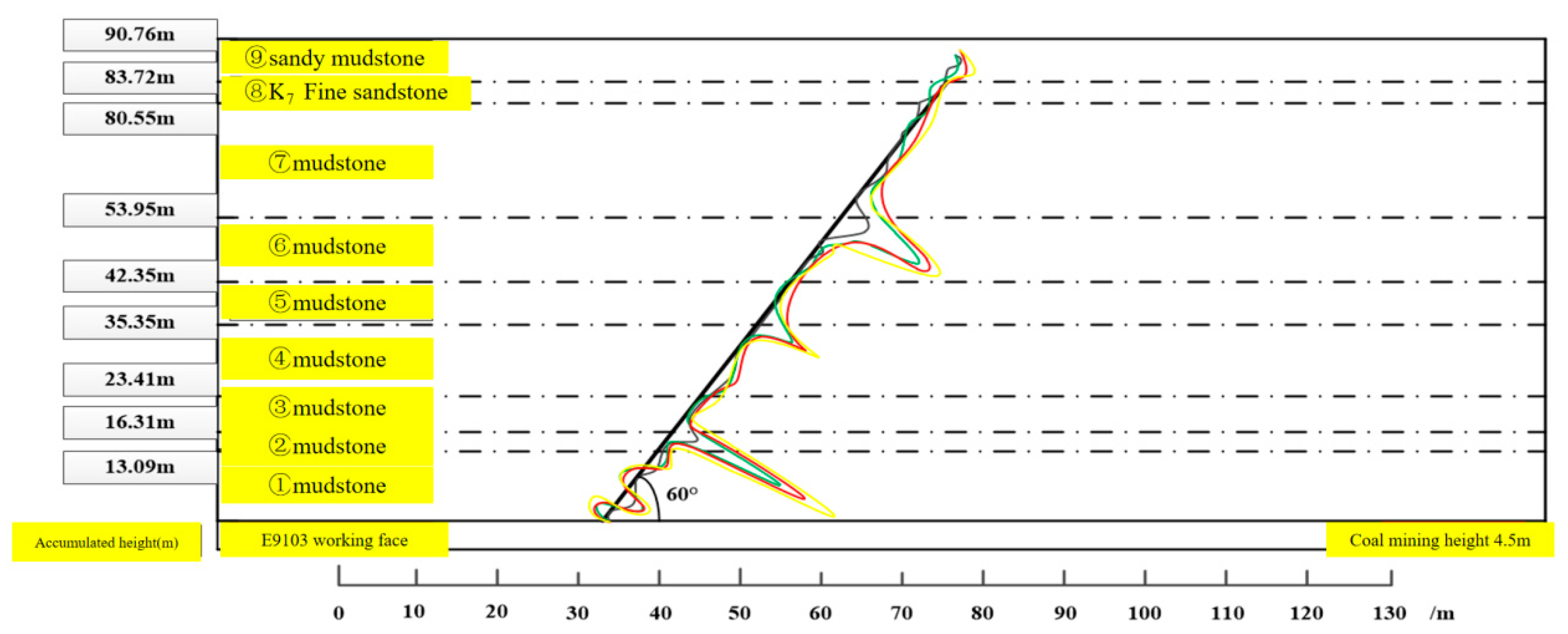

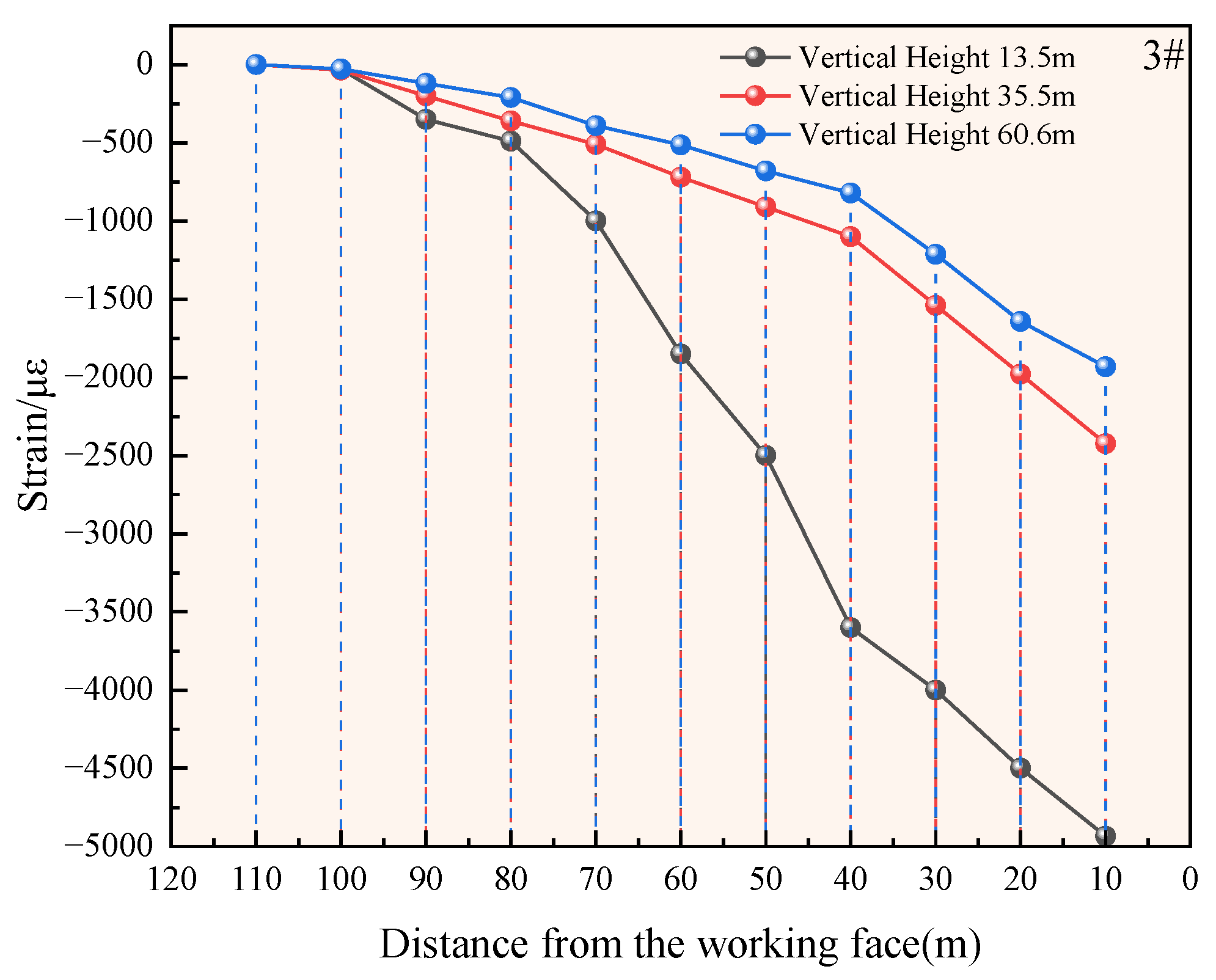

- Strain Distribution and Evolution Characteristics in Borehole 3#

5. Analysis of Overburden Evolution Mechanism Based on Fiber Optic Monitoring

6. Conclusions

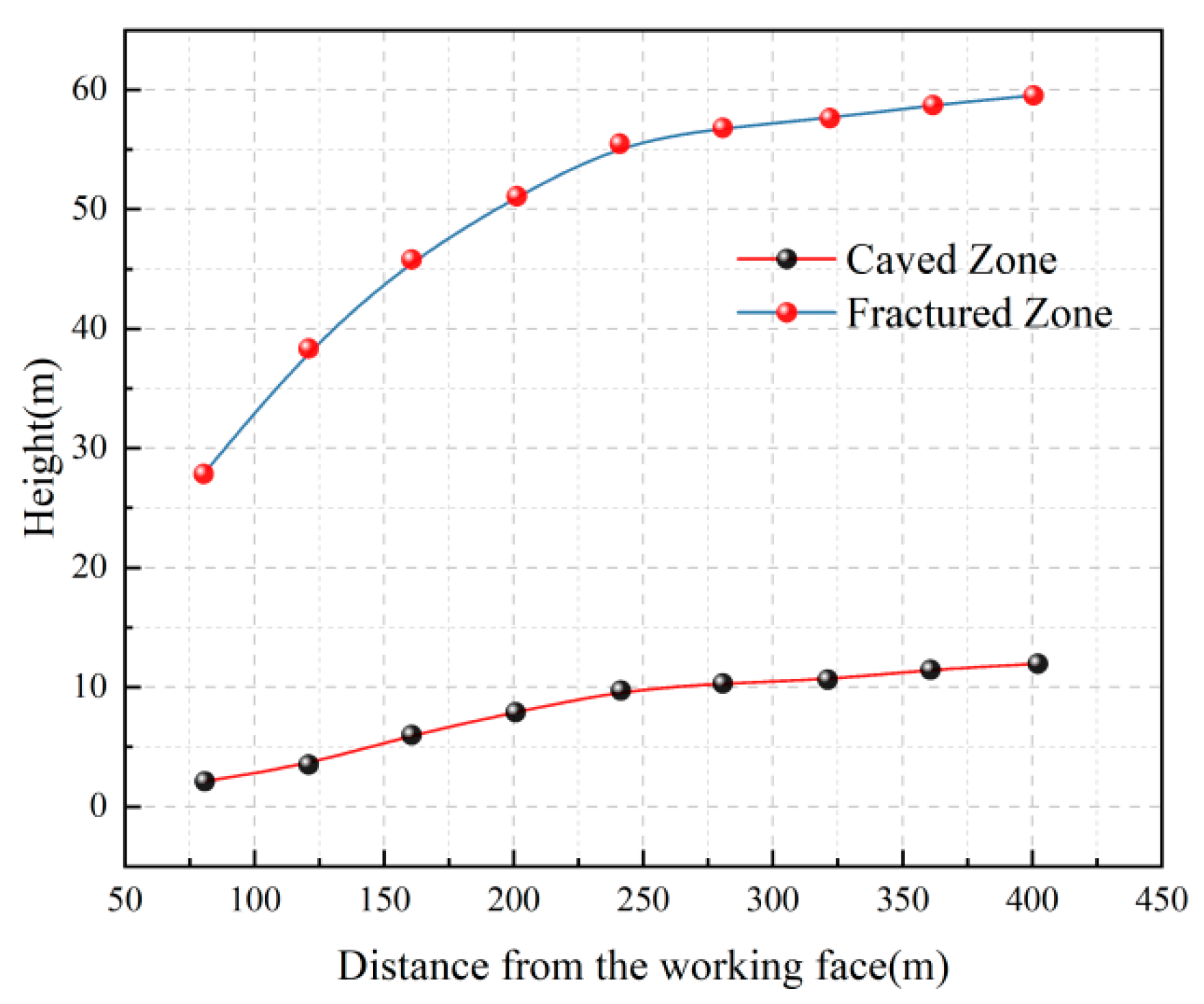

- (1)

- Through numerical calculations, it is found that the relationship between the height of the overburden caving zone and the advancing distance of the working face is not significant. The height of the caving zone increases slowly with the increase in the advancing distance of the working face, with a development height ranging from 7.2 to 13.13 m. The development height of the water-conducting fracture zone increases rapidly with the increase in the advancing distance of the working face. After the working face is once squared, the development height of the water-conducting fracture zone tends to be stable and remains at a steady value, with a development height ranging from 30.8 to 59.2 m.

- (2)

- We have innovatively integrated distributed optical fibers with rigid metal skeletons to develop a new type of in-hole measurement station. This structure can effectively deliver optical fibers to designated locations, providing key technical support for reliable strain monitoring throughout the entire development process of the “three zones” in mining-induced overburden strata.

- (3)

- Based on the strain distribution characteristics and variation process of the sensing fiber, as well as the highest position of the fiber breakpoint, combined with the lithology and combination of the roof strata, it can be determined that the height of the caving zone is 13.1~16.3 m, and the development height of the water conducting fracture zone is 58–60.6 m.

- (4)

- The use of distributed fiber optic sensing technology can achieve full process monitoring of the deformation and failure process of overlying strata during coal seam mining, providing a new technical means for determining the caving zone and water conducting fracture zone of overlying strata.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qian, M.; Shi, P. Mining Pressure and Rock Control; China University of Mining and Technology Press: Xuzhou, China, 2003. [Google Scholar]

- Yavuz, H. An estimation method for cover pressure re-establishment distance and pressure distribution in the goaf of longwall coal mines. Int. J. Rock Mech. Min. Sci. 2004, 41, 193–205. [Google Scholar] [CrossRef]

- Cheng, G.; Ma, T.; Tang, C.; Liu, H.; Wang, S. A zoning model for coal mining—Induced strata movement based on microseismic monitoring. Int. J. Rock Mech. Min. Sci. 2017, 94, 123–138. [Google Scholar] [CrossRef]

- Liu, Y.; Kong, D.; Li, P.; Wen, Z.; Li, F.; Zuo, Y.; Wu, G. The migration and evolution law of overlying strata and the instability and failure characteristics of end face roof under the condition of ascending mining in close distance coal seam: Case study. Eng. Fail. Anal. 2024, 165, 108809. [Google Scholar] [CrossRef]

- Jiang, L.; Wu, Q.; Wu, Q.; Wang, P.; Xue, Y.; Kong, P.; Gong, B. Fracture failure analysis of hard and thick key layer and its dynamic response characteristics. Eng. Fail. Anal. 2019, 98, 118–130. [Google Scholar] [CrossRef]

- Jing, Q.; Wang, P.; Wu, Q.; Zhang, P. Evolution laws and prediction of separated stratum space under overlying high-position magmatic rocks. Chin. J. Geotech. Eng. 2015, 37, 1769–1779. [Google Scholar]

- Mirghaderi, S.R.; Taheri, G.; Ebrahimi, S. Improving a Conventional Connection of Beam-to-Weak Axis of H-shaped Column to Modify Load Path in Panel Zone. J. Earthq. Tsunami 2024, 18, 2450001. [Google Scholar] [CrossRef]

- Gao, B.; Wang, X.; Zhu, M.; Zhou, J. The dynamic development characteristics of the “two zones” of overlying rock in the fully mechanized top coal caving face with high gas content and thick coal seam composite roof. J. Rock Mech. Eng. 2012, 31 (Suppl. S1), 3444–3451. [Google Scholar]

- Li, Y.; Yang, J.; Gao, X. Fault slip amplification mechanisms in deep mining due to heterogeneous geological layers. Eng. Fail. Anal. 2025, 169, 109155. [Google Scholar] [CrossRef]

- Lu, D.; Wu, W. Controlling Borehole Geometry as a Feasible Strategy for Optimization of Heat Extraction in Geothermal Systems. Rock Mech. Rock Eng. 2024, 57, 7461–7472. [Google Scholar] [CrossRef]

- Ganguwar, S.; Nistane, V.M. Numerical Study on the Determination of Crack Initiation Angle, Stress Field and Stress Triaxiality at Crack Tip in a Cracked Beam of Functionally Graded Material. J. Fail. Anal. Prev. 2024, 24, 2847–2862. [Google Scholar] [CrossRef]

- Kim, S.D.; Kim, S.S.; Ju, Y.K. Strength evaluation of beam–column connection in the weak axis of H-shaped column. Eng. Struct. 2008, 30, 1699–1710. [Google Scholar] [CrossRef]

- Zhu, P.; Wang, J.; Yan, S.; Wang, J. Analysis of dynamic response and impact resistance of corrugated plate-reinforced concrete under simulated rockfall. Eng. Fail. Anal. 2025, 167, 108922. [Google Scholar] [CrossRef]

- Xu, X.; He, F.; Li, X.; He, W. Research on mechanism and control of asymmetric deformation of gob side coal roadway with fully mechanized caving mining. Eng. Fail. Anal. 2021, 120, 105097. [Google Scholar] [CrossRef]

- Li, Z.X.; Yin, D.W.; Liu, H.M.; Tan, Y.; Li, X.-L. Mechanical properties of cemented coal gangue–flyash backfill under coupled effects of water pressure and chloride salt erosion. J. Cent. South Univ. 2024, 31, 1574–1591. [Google Scholar] [CrossRef]

- Wang, E.; Yin, S.; Cheng, Z.; Xie, S.; Chen, L.; Kang, Q.; Duan, Y. Failure mechanism analysis of ultra-large-section soft-rock roadway in kilometer deep coal mine and its collaborative control of "grouting-anchoring-pouring. Eng. Fail. Anal. 2025, 170, 109338. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, C.; Ren, Z. Parameter determination and effect evaluation of gob-side entry retaining by directional roof cutting and pressure releasing. Eng. Fail. Anal. 2024, 156, 107847. [Google Scholar] [CrossRef]

- Feng, W.; Li, M.; Zhang, J.; Wang, H.; Liu, S.; Wang, W. Load-bearing deformation and strength evolution of a filling body prepared by compacting a gangue waste–slurry mixture. J. Clean. Prod. 2025, 493, 144990. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, J.X.; Yin, W.; Zhou, N.; Liu, Y. Study of stability of surrounding rock and characteristic of overburden strata movement with longwall roadway backfill coal mining. J. China Coal Soc. 2017, 42, 404–412. [Google Scholar] [CrossRef]

- Zhang, C.; Bai, Q.; Han, P. A review of water rock interaction in underground coal mining: Problems and analysis. Bull. Eng. Geol. Environ. 2023, 82, 157. [Google Scholar] [CrossRef]

- Liu, A.; Liu, S. A fully-coupled water-vapor flow and rock deformation/damage model for shale and coal: Its application for mine stability evaluation. Int. J. Rock Mech. Min. Sci. 2021, 146, 104880. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, Q.; Zhang, Q. The Study of Roadway Backfill Coal Mining Technology with Water-Preserved in Western Eco-Environment Frangible Area. In Proceedings of the 12th International Conference on Mining with Backfill 2017: 12th International Conference on Mining with Backfill, Denver, CO, USA, 19–22 February 2017. [Google Scholar]

- Fedorko, M.T.M. Influence of selected characteristics on failures of the conveyor belt cover layer material. Eng. Fail. Anal. 2018, 94, 145–156. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, C.; Jiang, X.; Zhao, Y.; Tulujun, G.; Zhang, B. Differential salt-related structural deformation in the Eastern segment of the Qiulitage fold and thrust belt, Kuqa Foreland Basin: Evidences from seismic interpretation and numerical simulation analysis. J. Struct. Geol. 2025, 194, 105372. [Google Scholar] [CrossRef]

- Barrias, A.; Casas, J.R.; Villalba, S. A Review of Distributed Optical Fiber Sensors for Civil Engineering Applications. Sensors 2016, 16, 748. [Google Scholar] [CrossRef] [PubMed]

- Arslan Kelam, A.; Akgün, H.; Kokar, M.K. Application of an optical fiber-based system for mass movement monitoring. Environ. Earth Sci. 2022, 81, 170. [Google Scholar] [CrossRef]

- Chen, E.; Li, Y.; Zhang, S. Quantitative monitoring of localized pitting corrosion in steel bars through a combined use of distributed optical fiber sensors and finite element analyses. Constr. Build. Mater. 2024, 438, 136970. [Google Scholar] [CrossRef]

- Jiang, L. The Study of Analysis Method for Engineering Geological Structure Model and Basic Information of Geological Condition. Sci. Technol. Innov. Her. 2016, 13, 174–175. [Google Scholar]

- Zhang, T.; Gan, Q.; Zhao, Y.; Zhu, G.; Nie, X.; Yang, K.; Li, J. Investigations into Mining-Induced Stress–Fracture–Seepage Field Coupling Effect Considering the Response of Key Stratum and Composite Aquifer. Rock Mech. Rock Eng. 2019, 52, 4017–4031. [Google Scholar] [CrossRef]

- Han, P.; Wang, K.; Pang, J.; Ji, X.; Zhang, C. Response properties of geometries of coal penetrating fracture on seepage behavior. Int. J. Min. Sci. Technol. 2025, 35, 191–211. [Google Scholar] [CrossRef]

- Yang, J.; Hu, B.; Wang, Z. Study on distribution characteristics of collapse zone, fissure zone and curved subsidence zone and layered settlement of overburden on 8.8 m super–large mining height coal mining face. J. Coal Sci. Technol. 2020, 48, 42–48. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, W.; Bai, E.; Zhang, Z.; Kang, Y.; Chai, H.; Chen, J. Characteristics and mechanism of overlying strata movement due to high-intensity mining. J. Coal Ind. 2018, 43 (Suppl. S1), 28–35. [Google Scholar] [CrossRef]

- Cheng, X.; Qiao, W.; Li, L.; Jiang, C.; Ni, L. Coupling model of stress-seepage and water inflow prediction in coal seam overburden mining fractures. J. China Coal Soc. 2020, 45, 2890–2900. [Google Scholar]

- GB 50218-2014; Standard for Engineering Classification of Rock Masses. National Standard of the People’s Republic of China; China Planning Press: Beijing, China, 2014.

- Barton, N.; Lien, R.; Lunde, J. Engineering classification of rock masses for the design of tunnel support. Rock Mech. Rock Eng. 1974, 6, 279–315. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. Engineering Rock Mass Classifications; John Wiley & Sons: Hoboken, NJ, USA, 1989. [Google Scholar]

- Jaeger, J.C.; Cook, N. Fundamentals of Rock Mechanics, 2nd ed.; Publication of Chapman & Hall: London, UK, 1976. [Google Scholar]

- Saroglou, C. The Challenge of Rock Mass Classification of Anisotropic Rockmasses. Rock Mech. Rock Eng. 2025, 58, 11195–11215. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T.; Corkum, B. Hoek-Brown failure criterion—2002 edition. In Proceedings of the North American Rock Mechanics Society Annual Meeting, Toronto, ON, Canada, 7–10 July 2002. [Google Scholar]

- Jaeger, J.C.; Cook, N.G.W.; Zimmerman, R.W. Fundamentals of Rock Mechanics, 4th ed.; Blackwell Publishing: Ames, IA, USA, 2007. [Google Scholar]

- State Administration of Work Safety; National Coal Mine Safety Administration; National Energy Administration; National Railway Administration. Guiding Regulations for Coal Pillar Design and Mining Under Structures, Water Bodies, Railways and Main Shafts and Tunnels; State Administration of Coal Mine Safety: Beijing, China, 2017. [Google Scholar]

- Yu, G.; Han, Y.; Ren, B.; Wei, T.; Zheng, Q.; Wang, Y.; Mou, W. Research on mining-induced failure of grouted rock mass around collapse column based on micro-seismic monitoring. Coal Mine Saf. 2024, 55, 206–213. [Google Scholar] [CrossRef]

- Bin, S.; Xing, W. The Monitoring of Segments Dislocation Deformation in Shield Tunnel Based on BOFDA. In Engineering Challenges for Sustainable Underground Use, Proceedings of the GeoMEast 2017. Sustainable Civil Infrastructures, Sharm Elsheikh, Egypt, 15–19 July 2017; Agaiby, S., Grasso, P., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar]

| Classification Dimension | BQ (GB 50218-2014) [34] | Q (Barton et al., 1974) [35] | RMR (Bieniawski, 1989) [36] |

|---|---|---|---|

| Core Indices | Rock uniaxial compressive strength (σᵣ), rock mass intactness coefficient (Kᵥ) | Rock quality designation (RQD), discontinuity spacing, roughness, alteration, groundwater, stress reduction factor | Rock strength, discontinuity spacing/orientation, groundwater, and discontinuity condition |

| Weighting of Rock Hardness | ~60% (σᵣ is the primary index) | ~33% (RQD) | ~25% (rock strength) |

| Application Scope | Mandatory standard for Chinese civil/hydropower engineering | Global rock mass stability assessment (especially tunnels) | Global underground engineering (tunnels, mines) |

| Sensitivity to Brittle Failure | Moderate (supplemented by in situ stress calibration) | High (emphasizes discontinuity shear behavior) | High (integrates discontinuity characteristics) |

| Rock Character | Calculation Formula | Remarks |

|---|---|---|

| Weak rock | Low compressive strength, fragile characteristics | |

| Medium hard rock | Moderate compressive strength | |

| Hard rock | High compressive strength, moderate joint fissures |

| Lithology | B/GPa | S/GPa | T/MPa | C/MPa | φ/(°) | γ/(kg·m−3) |

|---|---|---|---|---|---|---|

| Fine-grained sandstone | 4.15 | 3.2 | 1.5 | 3.6 | 34 | 2335 |

| Mudstone | 5.93 | 4.74 | 2.74 | 3.52 | 28 | 2382 |

| Coal | 3.8 | 1.63 | 0.6 | 1.9 | 27 | 1421 |

| Coarse-grained sandstone | 6.1 | 4.79 | 2.68 | 3.25 | 28 | 2210 |

| Medium-grained sandstone | 5.4 | 4.1 | 1.89 | 4.7 | 35 | 2082 |

| Model | Diameter (mm) | Center Frequency (GHz) | Core Type | Average Dissipation (db/km) | Radius of Curvature (mm) | Strain Coefficient (MHz/10−6) |

|---|---|---|---|---|---|---|

| NZS-DSS-C02 | 5.0 mm | 10.850 | Single mode | 0.22 | 18 | 0.04998 |

| Drill Number | Hole Length (m) | Azimuth (°) | Elevation (°) | Strike Length (m) | Control Height (m) |

|---|---|---|---|---|---|

| 1# | 55 m | 346° | 45° | 47.50 m | 68.67 m |

| 2# | 65 m | 351° | 50° | 41.86 m | 66.61 m |

| 3# | 90 m | 90° | 60° | 22.50 m | 79.44 m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.; Meng, X.; Zhao, G.; Cheng, X.; Wang, X.; Xia, K. Distributed Fiber Optic Sensing for Monitoring Mining-Induced Overburden Deformation. Coatings 2025, 15, 1317. https://doi.org/10.3390/coatings15111317

Huang S, Meng X, Zhao G, Cheng X, Wang X, Xia K. Distributed Fiber Optic Sensing for Monitoring Mining-Induced Overburden Deformation. Coatings. 2025; 15(11):1317. https://doi.org/10.3390/coatings15111317

Chicago/Turabian StyleHuang, Shunjie, Xiangrui Meng, Guangming Zhao, Xiang Cheng, Xiangqian Wang, and Kangshuo Xia. 2025. "Distributed Fiber Optic Sensing for Monitoring Mining-Induced Overburden Deformation" Coatings 15, no. 11: 1317. https://doi.org/10.3390/coatings15111317

APA StyleHuang, S., Meng, X., Zhao, G., Cheng, X., Wang, X., & Xia, K. (2025). Distributed Fiber Optic Sensing for Monitoring Mining-Induced Overburden Deformation. Coatings, 15(11), 1317. https://doi.org/10.3390/coatings15111317