Abstract

The Ti-Al-Si composite coatings were effectively fabricated on Ti6Al4V (TC4) substrates via coaxial powder feeding laser cladding technology. This study systematically investigated the influence of in situ synthesized Ti-Si ceramic reinforcement phases and Si content on the microstructure, microhardness, and wear resistance of the composite coatings. An excellent metallurgical bond between the coating and the substrate can be formed during the cladding coating process. When the temperature of the molten pool drops, the Ti and Si elements in situ react to form a Ti5Si3 ceramic reinforced phase originating from the Si-rich zone in the liquid phase. The microhardness of the cladding coatings exhibits a positive correlation with increasing Si content, reaching a maximum value of 820.83 HV. The in situ synthetic Ti5Si3 ceramic reinforced phases can effectively improve the coating’s wear resistance. Notably, the laser cladding coating with 25 wt% Si content exhibits the lowest wear weight loss rate of 0.140 mg·min−1 and the lowest average friction coefficient of 0.412. Analysis of the wear mechanism reveals a combination of adhesive wear and microscopic wear characteristics.

1. Introduction

Titanium alloys are extensively employed in the aerospace, aviation, petroleum, and chemical sectors owing to their exceptional properties, including low density, remarkable strength-to-weight ratio, and considerable resistance to elevated temperatures [1,2,3]. However, due to the low surface hardness of titanium alloys, the load-bearing capacity is poor, which limits their wide application under adhesive wear and fretting wear conditions [4,5,6,7]. To strengthen the properties of titanium alloys, it is not uncommon for surface modifications to be implemented. Laser cladding stands as a precision coating technique, distinguished by its use of a focused, high-energy laser beam [8,9]. This method deposits a metallurgically bonded layer onto a component, offering significant benefits over conventional processes like thermal spraying. These advantages encompass a stronger interfacial bond, reduced thermal impact on the substrate, and enhanced control over the final coating’s properties [10]. Laser cladding offers a viable method for the enhancement of surface hardness on titanium alloys [11,12,13,14]. Recently, this technology was used to fabricate Al-Cr-Ti ternary alloy coatings by Li et al. [15]. Microhardness measurements revealed similar values for the two coatings: 526 ± 37 HV for AlCr and 510 ± 24 HV for AlCrTi0.5. The effects of graphene (Gr) addition (0–2 wt%) on the microhardness of laser-cladding (TiC + TiBx)/Ti composite coatings were investigated by Miao et al. [16]. The results showed that the coating with 1 wt% Gr exhibited the maximum microhardness of 886.3 HV0.3. Su et al.’s investigation into YF-modified NiTi-Si coatings fabricated on Ti-6Al-4V substrates via laser cladding revealed that the post-treatment processes significantly influence the phase transformation characteristics of the coatings [17]. Jiang et al. [18] employed laser cladding to fabricate a Cr-AlSi12 composite coating on Ti-6Al-4V alloy. Phase analysis revealed that in situ alloying reactions produced Al8Cr5, AlCr2, (Si, Al)2Cr, and Cr5Si3 within the coating. Meanwhile, the intermetallic compounds Al3Ti and Ti5Si4 formed due to interdiffusion at the interface. Chen et al. [19] fabricated TiC/TiAl laser cladding composite coatings with varying TiC content (5–20 vol%) on a TC4 substrate. The coating with 15 vol% TiC achieved a peak microhardness of 799 HV1.0.

Ti-Al intermetallic compounds are considered a promising candidate for laser cladding coatings on titanium alloys owing to their superior combination of properties, like high melting point, low density, and exceptional stability [20,21]. The enhancement in the microhardness of the Ti-Al coating upon the addition of Si is primarily attributed to the synthesis of the hard Ti5Si3 ceramic phase [22]. In recent years, researchers have conducted in-depth studies on Ti-Al-Si composite coatings. Cui et al. [23] fabricated in situ particle reinforced TixAl/Ti5Si3 composite coatings, which not only have good metallurgical bonding with the substrate, but also have high wear resistance. Li et al. [24] synthesized TiC-reinforced Ti-Al-Si composite coatings with excellent microhardness and wear resistance.

In the laser cladding process, the powder material is applied to the substrate surface either through coaxial powder feeding or pre-coating deposition. However, most research focuses on the preparation of laser cladding coating by pre-coating technology. The coaxial powder feeding laser cladding technology enables the production of complex near-net-shape parts and the repair of damaged or worn components. As an emerging technological innovation, this technique has not yet been extensively studied. So far, there is almost no research on coaxial powder feeding laser cladding Ti-Al-Si composite coating. In the present investigation, the Ti-Al-Si composite coatings containing in situ synthetic Ti-Si ceramic reinforced phase and Ti-Al intermetallic compound were fabricated on TC4 substrate via coaxial powder feeding laser cladding technology. This paper explores the effect of the in situ synthesized Ti-Si ceramic reinforcement phase and the Si content within the Ti-Al-Si system on the microstructure, microhardness, and wear resistance of the composite cladding coatings.

2. Experimental Methods

2.1. Materials and Laser Cladding Process

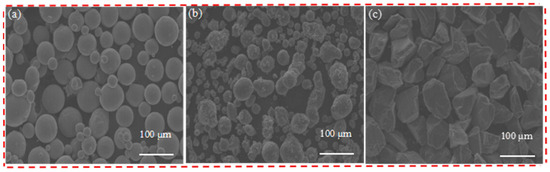

The TC4 alloy substrate measuring 50 × 50 × 10 mm was prepared by sanding its surface until a smooth and flat finish was achieved. Following this, the substrate was thoroughly cleaned using absolute ethanol or acetone, wiped dry, and blown clean. High-purity (>99.9%) Ti, Al, and Si powders were employed as cladding materials. Figure 1 illustrates the micromorphology of the powders, which exhibit a particle size range of 45–105 μm. Then the weighed powders were mixed in a glove box with different proportions. The composite powders were placed in a mixer, mechanically alloyed for 6 h, and subsequently dehydrated under vacuum conditions. The composite coatings were fabricated using a 20F600 laser cladding system (Tianjin Huirui Co., Ltd., Tianjin, China), with argon gas serving as the protective atmosphere. Processing parameters employed include the following: laser power of 1000 watts, scanning velocity of 8 mm per second, powder feed rate of 0.6 revolutions per minute, and an overlap ratio of 40%, defocus amount of 17 mm, spot diameter of 3 mm. Three samples with varying compositions, labeled S1–S3, were prepared as detailed in Table 1.

Figure 1.

SEM micrographs of laser cladding powders: (a) Ti powders, (b) Al powders, (c) Si powders.

Table 1.

The composition of the samples (wt%).

2.2. Characterization

The phase compositions of the laser cladding Ti-Al-Si composite coatings were characterized by X-ray diffraction (XRD, UltimaIV, Japan, Rigaku Corporation, Tokyo, Japan). The morphological features and spatial element mappings of the powder composites and coatings were performed by scanning electron microscopy (SEM, Tescan Maia3, TESCAN, Brno, Czechia) and energy dispersive spectrometry (EDS, Oxford X-Max 20, Oxford Instruments, High Wycombe, UK), respectively. The accelerating voltage and beam current for electron backscattered diffraction (EBSD) scan were 20 kV and 2.6 nA, respectively. The analysis of the data was performed via Oxford HKL Channel 5 software 2019V5.12. The average microhardness of the composite coatings was determined by averaging five measurements conducted on a Vickers hardness tester under a load of 300 g maintained for 10 s. At room temperature, the friction test was performed on a reciprocating friction and wear machine (MFT-5000, Rtec Instrument Technology Co., Ltd., Nanjing, China). The zirconia friction pair was selected, and the grinding material consisted of silicon nitride. The wear tests were conducted under a normal load of 10 N at a frequency of 3 Hz, a friction speed of 60 r/min, and a wear track diameter of 5 mm for a test duration of 30 min.

3. Results and Discussion

3.1. Phase Identification and Composition Analysis

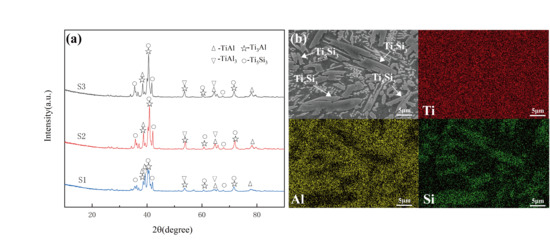

Figure 2a displays the XRD patterns of the cladding coatings. As is evident from the figure, the cladding coatings with different compositions primarily consist of TiAl, Ti3Al, TiAl3, and Ti5Si3 phases. Combined with the SEM micrographs and EDS (Figure 2b), it can be observed that the bright thin strips, dots, and black-gray matrix in the microstructure mainly contain Ti and Al elements, which are intermetallic compound phases formed by TiAl, Ti3Al, and TiAl3. While the lath-like, honeycombs and large granular microstructures mainly contain Ti and Si elements, which are in situ synthetic Ti5Si3 ceramic phases.

Figure 2.

The XRD patterns of laser cladding coatings (a), SEM micrograph of S3 coating (b) and the mapping results of (b).

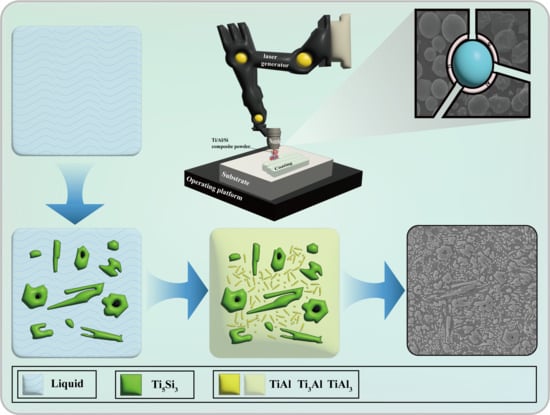

The schematic diagram illustrating the process is shown in Figure 3. When the high-energy laser beam touches the surface of the substrate, the powders and the substrate will absorb a large amount of heat and melt instantaneously to form a high-temperature molten pool, which is the liquid phase in the initial stage. When the temperature drops, the Ti element and Si element react in situ to form the primary Ti5Si3 ceramic reinforced phase from the Si-rich region in the liquid phase [25]. These ceramic phases, characterized by high hardness, excellent wear resistance, and superior corrosion resistance, are crucial to enhancing the overall performance of the composite coating. With further cooling, TiAl, TiAl3, and Ti3Al binary intermetallic compounds are precipitated in the process of the reaction.

5Ti + 3Si → Ti5Si3

Ti + Al → TiAl

3Ti + Al → Ti3Al

Ti + 3Al → TiAl3

Figure 3.

Solidification process of laser cladding Ti-Al-Si composite coating.

3.2. Microstructure Analysis

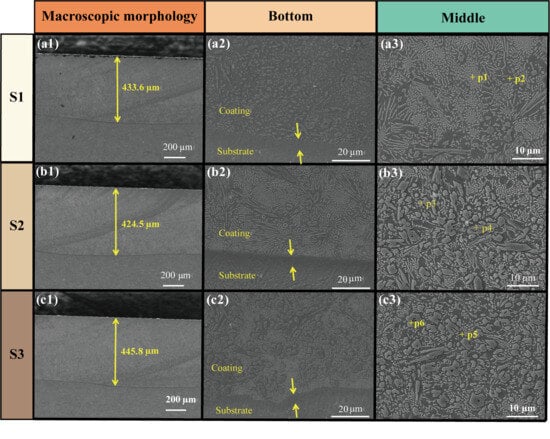

Figure 4(a1–c1) shows low-magnification cross-sectional SEM micrographs of laser-cladded Ti-Al-Si coatings. As evident from the images, the surfaces of the cladding coatings are smooth and clean. The cross-sectional structure is uniform and continuous. The molding effect is excellent without observable porosity or cracking. For S1, S2, and S3 coatings, a distinct and well-defined interfacial boundary is observed between the cladding layer and the substrate, suggesting a good metallurgical bond. All specimens showed comparable coating thickness (424.5–445.8 µm), with less than 5% variation across the sample set.

Figure 4.

Cross-sectional SEM micrographs of laser cladding Ti-Al-Si coatings: (a1–a3) S1, (b1–b3) S2, (c1–c3) S3.

The bottom zone micrographs of the laser cladding Ti-Al-Si coatings are displayed in Figure 4(a2–c2). It can be seen from the figure that the boundary between the cladding coating and the substrate is distinct, exhibiting an absence of any observable defects like cracks or porosity. The metallurgical bonding zone is thin because the dilution rate is low. During the laser cladding process, the mixed powders are transported to the molten pool of the substrate material via the powder feeder. The powders are instantaneously melted to form a melt bath by the high-power laser beam, while the substrate surface undergoes slight melting. The molten pools coalesce with one another to form a metallurgical bonding zone of a certain thickness, which results from the interaction between elements in the substrate and the coating [26,27]. Following the laser treatment, when the molten pool is cooled, the substrate has a certain extremely cold effect on the molten pool due to the good thermal conductivity. A large degree of supercooling is generated at the interface, which makes the crystallization start and grow along the direction of heat flow. Since there is not enough time and energy for the grains to grow in the binding zone, the microstructure of the binding zone is finer than in other regions. Additionally, the in situ synthesis of Ti5Si3, which has a high melting point, absorbs a considerable amount of energy. With the addition of the Ti5Si3 ceramic phase (S3 coating, as displayed in Figure 4(c2)), the dilution rate of the substrate into the laser-cladded coating is further reduced.

Figure 4(a3–c3) displays the middle zone micrographs of laser-cladded Ti-Al-Si coatings. The cladding coating exhibits a uniform and dense microstructure, without porosity, inclusions, and other defects. Due to the least Si of the cladding coating, the micromorphology of the S1 coating was mainly TiAl, Ti3Al, and TiAl3 in bright, thin strips, dots, and black-gray matrix structure. SEM micrographs of S2 and S3 coatings show that with the increase in Si content, the lath-like, honeycombs and large granular Ti5Si3 ceramic structure in the cladding coating gradually increase. The convection exists in the molten pool, and there is a blowing of shielding gas from the outside, which causes the temperature to tend to homogenize, resulting in the growth of grains in different directions (Table 2).

Table 2.

EDS analysis of each point marked in Figure 4.

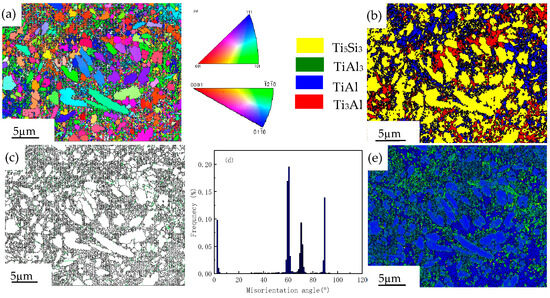

3.3. EBSD Analysis

The EBSD analysis result of the S3 laser cladding coating is displayed in Figure 5. The inverse pole figure map intuitively displays the relationship between the crystallographic orientation of each grain in the sample and a given sample direction (such as the rolling direction RD, normal direction ND, or transverse direction TD) through colors. The concentration of colors directly reflects the strength of the preferred orientation. Figure 5a shows a completely scattered distribution of grain colors, so no preferred orientation is observed among the grains. In Figure 5b, EBSD phase map, the lath-like, honeycomb, and large granular yellow phases correspond to the Ti5Si3 ceramic reinforced phase. The content of the Ti5Si3 phase is approximately 37%, and the remaining fraction is TiAl, Ti3Al, and TiAl3 intermetallic compound phases. The picture in Figure 5c shows the grain boundary diagrams. The black lines correspond to the large-angle grain boundaries (orientation difference > 15°), while the green lines denote the small-angle grain boundaries (orientation difference between 2° and 15°). As observed, grain boundaries predominantly exist as large-angle grain boundaries, and small-angle boundaries are sparsely distributed. Furthermore, Figure 5d shows that grain misorientation angles mainly focus on near 60° and 90°, while grain misorientation angles of 0° and 70° are rather less. Figure 5e is a KAM (kernel average misorientation) diagram of the S3 laser cladding coating. The green lines in KAM diagram can be nearly considered as dislocations. An abundance of dislocations is concentrated and entangled near the TiAl, Ti3Al, and TiAl3 intermetallic compounds.

Figure 5.

EBSD results of S3 coating: (a) inverse pole figure, (b) phase map, (c) grain boundary diagram, (d) misorientation histogram, (e) KAM diagram.

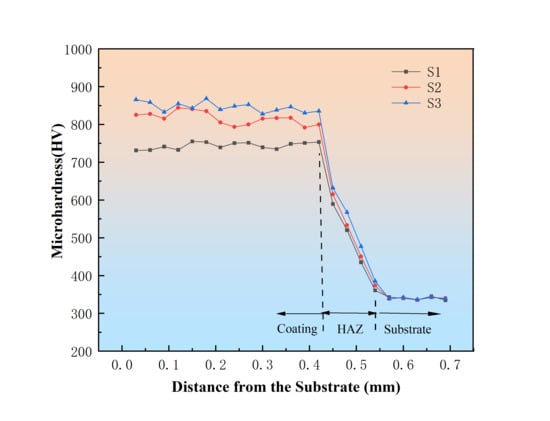

3.4. Microhardness Analysis

Figure 6 shows the curve of the microhardness of each coating. As can be seen from the figure, the microhardness trends across all cladding coatings are similar, with each coating exhibiting significantly higher microhardness values compared to the TC4 substrate. The average microhardness of S1, S2, and S3 cladding coatings is 722.25 HV, 813.84 HV, and 820.83 HV, which is 2.13 times, 2.40 times, and 2.42 times that of the substrate. With increasing Si content, the microhardness of the cladding coating rises. The primary factor for this phenomenon is the difference in the phase hardness. TiAl and Ti3Al matrices are relatively soft. In contrast, ceramic reinforcement phases are hard. In S1 cladding coating with lower Si content, Ti5Si3 reinforcing particles are sparsely dispersed within the matrix, separated by large volumes of relatively soft TiAl and Ti3Al matrix material. When external force is applied, the load is primarily transmitted through the soft matrix and is difficult to transfer effectively to the limited amount of hard Ti5Si3 reinforcing phase. As a result, the overall deformation of the material remains predominantly governed by the matrix, leading to a limited increase in hardness. In contrast, in the S3 coating with a higher volume of Ti5Si3 reinforcing phases, the reinforcing phases are closely spaced and may even form a continuous network or skeleton. External forces can be transmitted more efficiently through direct contact between reinforcing phases or via extremely short matrix bridges, allowing the hard reinforcing phases to bear the majority of the load. This results in a significant improvement in the overall hardness of the material [28]. A lot of dislocations can be seen accumulating and entangled near the TiAl, Ti3Al, and TiAl3 intermetallic compounds (as shown in Figure 5e). This implies higher residual stress within the S3 coating. This also contributes to the improvement of the hardness of the S3 coating. The bonding zone exhibits a substantially lower microhardness value compared to the cladding coating, which is attributable to the dilution effect of reinforcing elements in the surface layer caused by upward diffusion from the substrate [29]. Moreover, the microhardness of the coating region adjacent to the substrate shows a slight increase, owing to the cooling effect of the substrate on the coating. The effectiveness of the reinforcing elements was diminished by contamination from the underlying substrate.

Figure 6.

Microhardness distribution of the laser cladding coating area.

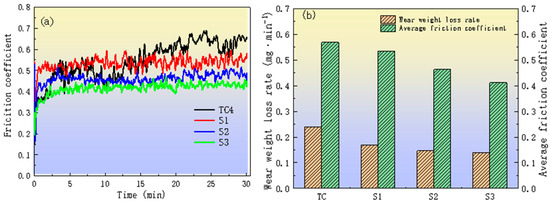

3.5. Wear Resistance Tests

Figure 7 shows wear-resistant properties of the TC4 substrate and the coatings. As illustrated by the friction coefficient curve in Figure 7a, the friction coefficient exhibits a rapid increase within the initial period. This behavior is due to the limited contact area in the initial wear stage, leading to high localized stress. As wear progresses and the contact area increases, the friction coefficient stabilizes. In Figure 7a, the mean friction coefficient of the TC4 substrate is 0.569; the corresponding values for the S1, S2, and S3 coatings are 0.535, 0.463, and 0.412, all of which are lower than that of the substrate. Si atoms preferentially react with Ti atoms to form the Ti5Si3 ceramic reinforced phase, which has a lower Gibbs free energy than other potential compounds [30]. The resulting increase in the volume of this hard Ti5Si3 strengthening phase enhances the composite’s hardness, which directly improves its wear resistance [31]. As the Si content in the coating increases, the in situ synthesized Ti5Si3 content also rises. Consequently, S3 coating, with the highest Si content, demonstrates the best tribological performance. The results demonstrate that the Ti-Al-Si composite coating exhibits a definite improvement in anti-wear and friction-reduction properties, which serves to effectively protect the substrate. Figure 7b illustrates the wear weight loss of the coatings and substrate. Among them, the wear weight loss rates of S1, S2, and S3 coatings and the substrate are 0.170 mg·min−1, 0.146 mg·min−1, 0.140 mg·min−1, and 0.240 mg·min−1, respectively. The S1, S2, and S3 coatings demonstrate a reduction in wear weight loss rates by factors of 1.41, 1.64, and 1.71, respectively, relative to the TC4 substrate. The marked enhancement in wear resistance observed in the cladding coatings originates from their high microhardness and the inclusion of a ceramic phase with self-lubricating properties.

Figure 7.

Wear-resistant properties of TC4 substrate and coatings: (a) friction coefficient versus time curve, (b) wear weight loss rate and average wear coefficient histogram.

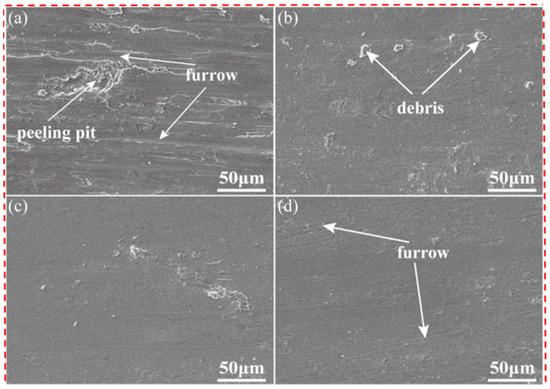

For a deeper understanding of the wear mechanisms governing the substrate and the S1, S2, and S3 coatings, the corresponding micrographs of the worn surfaces are provided in Figure 8. Compared to the TC4 substrate, the friction wheel possesses significantly greater hardness under dry sliding friction conditions. The micro-convex body on the surface of the friction wheel has a cutting effect on the surface of the substrate during the friction process, forming a deep groove. The large pieces of grinding debris in the groove are in the shape of a squid. Under the action of periodic forward pressure and tangential shear force, fatigue cracks are generated on the surface of the substrate or in the shallow layer below it, and the cracks continue to extend, resulting in the flake or block of the cladding coating peeling off and forming significant peeling pits and deep furrows, as illustrated in Figure 8a. The wear mechanism of the substrate is primarily adhesive wear. As evidenced by the smoother worn surface of the laser cladding coating shown in Figure 8b–d compared to the TC4 substrate, the coating demonstrates strong interfacial bonding and, consequently, excellent wear resistance. As shown in Figure 8b, there is a shallow pear groove on the wear surface of the laser cladding coating of S1 coating, which is adhesive wear, but the plasticity is relatively strong. The spalling pits formed by the micro-convex body on the surface of the friction wheel cutting the cladding coating are small, and the surface exhibits a limited presence of coarse abrasive particles. S2 coating and S3 coating have a relatively high ceramic phase content, so they have high microhardness and smooth wear morphology, as illustrated in Figure 8c,d. Due to the increased Si content, all available silicon reacts with Ti to form hard phases. The progressive increase in these hard phases imparts an increasingly significant hindering effect on the movement of the friction pair. When the grinding marks encounter some hard phases, they are blocked, and the pear groove is shallow where there is a hard phase. The wear marks on the worn surface of the S2 coating are shallow, the size of the wear debris is small and few. Its wear mechanism is microscopic spalling. The worn surface of the S3 coating is also shallow, and there is a small amount of furrow on the surface, and the size is small. The wear mechanism is adhesive wear and microscopic wear.

Figure 8.

Wear morphology of (a) TC4substrate, (b) S1 coating, (c) S2 coating, (d) S3 coating.

4. Conclusions

The cladding coating exhibits a uniform and dense structure, without porosity, inclusions, and other defects. As the Si content increases, the presence of lath-like, honeycomb, and large granular Ti5Si3 ceramic phases within the coatings becomes more pronounced. The average microhardness of S1, S2, and S3 cladding coatings is 722.25 HV, 813.84 HV, and 820.83 HV, which is 2.13 times, 2.40 times, and 2.42 times that of the substrate. Furthermore, the wear weight loss rates of S1, S2, and S3 coatings are 1.41, 1.64, and 1.71 times lower than those of the TC4 substrate, respectively. The wear mechanism of the composite coatings is characterized by microscopic spalling, adhesive wear, and microscopic wear. Among the coatings, the S3 cladding coating demonstrates the best wear resistance, primarily due to its high microhardness and ideal microstructure.

Author Contributions

Conceptualization, Z.W. and H.Z.; methodology, Z.W., H.Z., and L.L.; validation, Z.W. and H.C.; formal analysis, Z.W. and H.Z.; investigation, Z.W.; resources, H.Z., L.L., and Y.C.; data Curation, L.L.; writing—original draft preparation, Z.W.; writing—review and editing, Z.W. and H.Z.; visualization, H.Z. and Y.C.; supervision, H.Z.; project administration, L.L.; funding acquisition, H.Z. and Y.C. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Department of Science and Technology of Liaoning Province (2023JH2/10700022) and Foundation of Liaoning Province Education Administration (LJ212510144006).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhang, H.W.; Cui, H.Z.; Song, X.J.; Pang, K.; Man, C.; Liu, F.Y.; Wang, X.Y.; Cui, Z.Y. Excellent tribocorrosion resistance of additively manufactured Ti-based heterogeneous composite coating via hardening and toughening effects. J. Mater. Sci. Technol. 2024, 190, 76–92. [Google Scholar] [CrossRef]

- Ding, H.H.; Zhang, J.; Liu, J.Y.; Wang, J.H.; Niu, L.H.; Chen, Y.F. Effect of volume energy density on microstructure and mechanical properties of TC4 alloy by selective laser melting. J. Alloys Compd. 2023, 968, 14. [Google Scholar] [CrossRef]

- Zhao, H.J.; Yu, C.Y.; Liu, Z.H.; Liu, C.S.; Zhan, Y. A novel finite element method for simulating residual stress of TC4 alloy produced by laser additive manufacturing. Opt. Laser Technol. 2023, 157, 11. [Google Scholar] [CrossRef]

- Qi, K.; Yang, Y.; Liang, W.X.; Jin, K.; Xiong, L. Effect of magnetic field on the microstructure and wear properties of TiB2/metal composite layers synthesized in situ by laser cladding on Ti–6Al–4V alloy. Ceram. Int. 2021, 47, 29463–29474. [Google Scholar] [CrossRef]

- Miao, X.J.; Wu, M.; Cui, C.; Jie, D.D.; He, R.; Wang, H.; Ma, C.L.; Wang, Q.L. Microstructure and water erosion resistance of in situ synthesized (TiBx + TiC)/Ti composite coatings produced by laser cladding. J. Mater. Res. Technol. 2023, 23, 4089–4104. [Google Scholar] [CrossRef]

- Jiang, J.; Hou, W.T.; Feng, X.M.; Shen, Y.F. Oxidation resistant FeCoNiCrAl high entropy alloy/AlSi12 composite coatings with excellent adhesion on Ti-6Al-4 V alloy substrate via mechanical alloying and subsequent laser cladding. Surf. Coat. Technol. 2023, 464, 129577. [Google Scholar] [CrossRef]

- Wang, L.X.; Huang, Y.M.; Yuan, Y.X.; Jia, L.J. Microstructure, wear and oxidation resistance of Al-doped Ti-Si3N4 coatings by laser cladding. Surf. Coat. Technol. 2022, 429, 127942. [Google Scholar] [CrossRef]

- Meng, Y.; Yang, Y.; Zhang, C.; Cui, X.; Liu, E.; Jin, G.; Kang, J.; She, P. Influence of Bioactive Glass Addition on TC4 Laser Cladding Coatings: Microstructure and Electrochemical Properties. Coatings 2023, 13, 1621. [Google Scholar] [CrossRef]

- Liu, H.; He, X.; Yu, G. Numerical simulation of powder transport behavior in laser cladding with coaxial powder feeding. Sci. China Phys. Mech. Astron. 2015, 58, 104701. [Google Scholar] [CrossRef]

- Kovalev, O.B.; Bedenko, D.V.; Zaitsev, A.V. Development and application of laser cladding modeling technique: From coaxial powder feeding to surface deposition and bead formation. Appl. Math. Model. 2018, 57, 339–359. [Google Scholar] [CrossRef]

- He, R.; Wu, M.P.; Cui, C.; Jie, D.D.; Mao, X.J. Laser cladding manufacturing of TiC + TiBx reinforced FeNiCrTi0.3Al0.3 high entropy alloy composite coating: Effects on corrosion and tribology. J. Alloys Compd. 2024, 970, 172631. [Google Scholar] [CrossRef]

- Chen, J.B.; Lian, G.F.; Lin, T.X.; Lu, H.; Wang, Y. Effects of the proportions of carbon on the microstructure and properties of NbC-reinforced Ni-WC composite coatings by laser cladding in-situ synthesis. Mater. Today Commun. 2024, 38, 107896. [Google Scholar] [CrossRef]

- Wang, L.; Chai, L.J.; Xu, S.; Liu, X.J.; He, X.X. Study on the corrosion behavior of laser surface remelted and laser cladding of ferritic/martensitic steels after exposure to lead-bismuth eutectic at 700 °C. J. Nucl. Mater. 2024, 590, 154888. [Google Scholar] [CrossRef]

- Hua, K.; Ding, H.T.; Sun, L.H.; Cao, Y.; Li, X.L.; Wu, H.X.; Wang, H.F. Enhancing high-temperature fretting wear resistance of TC21 titanium alloys by laser cladding self-lubricating composite coatings. J. Alloys Compd. 2024, 977, 173360. [Google Scholar] [CrossRef]

- Li, Z.H.; Chai, L.J.; Qi, L.; Wang, Y.Y.; Yang, T.; Wang, H. Laser-cladded Al-Cr-Ti ternary alloy coatings on Ti-4Al-2V alloy: Specific microstructure and enhanced surface performance. Surf. Coat. Technol. 2023, 452, 129073. [Google Scholar] [CrossRef]

- Miao, X.J.; Wu, M.P.; Cui, C.; Ma, C.L.; Wang, Q.L. Effect of graphene addition on the performance of in-situ (TiC + TiBx)/Ti composite coatings by laser cladding: Microstructure and water droplet erosion resistance. Surf. Coat. Technol. 2023, 459, 129381. [Google Scholar] [CrossRef]

- Su, W.N.; Zhang, C.; Cui, X.F.; Jin, G.; Liu, C.H.; Liu, E.B.; Li, J.; Zhao, H.N.; Cao, B.Y.; Tian, H.L. Effect of heat and cryogenic treatments on the microstructure and properties of YF3 modified NiTi-Si laser cladding coatings. Opt. Laser Technol. 2023, 165, 109614. [Google Scholar] [CrossRef]

- Jiang, J.; Hou, W.T.; Feng, X.M.; Shen, Y.F. Microstructure and properties of Cr–AlSi12 composite coatings pre-coated on Ti–6Al–4V alloy substrate via mechanical alloying and subsequent laser cladding treatment. Mater. Chem. Phys. 2023, 305, 127928. [Google Scholar] [CrossRef]

- Chen, N.; Xiao, H.Q.; Ren, L.R.; Huang, F.L.; Chen, Y.M.; Cao, S.Q.; Wu, H.L.; Zhu, L.D. Microstructure and tribological properties of laser-cladded TiCx/TiAl composite coatings on TC4 alloy. Tribol. Int. 2024, 192, 109236. [Google Scholar] [CrossRef]

- Sadeq, F.O.; Sharifitabar, M.; Afarani, M.S. Synthesis of Ti–Si–Al coatings on the surface of Ti–6Al–4V alloy via hot dip siliconizing rout. Surf. Coat. Technol. 2018, 337, 349–356. [Google Scholar] [CrossRef]

- Shahzad, A.; Zadorozhnyy, V.Y.; Pavlov, M.D.; Zheleznyi, M.V.; Chirkov, A.M. Deposition of the Ti-Al coatings on different metallic substrates by mechanical alloying and subsequent laser treatment. J. Alloys Compd. 2017, 731, 1295–1302. [Google Scholar] [CrossRef]

- Dai, J.J.; Zhang, F.Y.; Wang, A.; Yu, H.J.; Chen, C.Z. Microstructure and properties of Ti-Al coating and Ti-Al-Si system coatings on Ti-6Al-4V fabricated by laser surface alloying. Surf. Coat. Technol. 2017, 309, 805–813. [Google Scholar] [CrossRef]

- Cui, J.X.; Lin, C.; Peng, X.M.; Yang, J.Y.; Ren, T.T.; Ma, Q.H. Phase transition and atomic competition mechanism of in-situ particle reinforced TixAl/Ti5Si3 composite coating prepared by laser cladding Al-xSi-2Nb alloy powder on Ti6Al4V alloy. Surf. Coat. Technol. 2024, 478, 130402. [Google Scholar] [CrossRef]

- Li, J.; Cui, X.F.; Guan, Y.J.; Jin, G.; Zheng, W.; Liu, E.B.; Wan, S.M.; Shi, Z.Z.; Liu, A.Y. Effect of SiC content on microstructural evolution and tribology properties of laser-clad TiC-reinforced Ti-Al-Si composite coatings. Mater. Today Commun. 2023, 35, 106019. [Google Scholar] [CrossRef]

- Li, S.; Yamaguchi, T. High-temperature oxidation performance of laser-cladded amorphous TiNiSiCrCoA high-entropy alloy coating on Ti-6Al-4V surface. Surf. Coat. Technol. 2022, 433, 128123. [Google Scholar] [CrossRef]

- Liu, R.; Dang, X.; Gao, Y.; Wu, T.; Zhu, Y. The Wear Behavior of the Laser Cladded Ti-Al-Si Composite Coatings on Ti-6Al-4V Alloy with Additional TiC. Materials 2021, 14, 4567. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, A.H.; Zhang, Z.; Zheng, R.R.; Xia, H.B.; Wang, Y.N. Laser alloying of Ti-Si compound coating on Ti-6Al-4V alloy for the improvement of bioactivity. Appl. Surf. Sci. 2014, 305, 16–23. [Google Scholar] [CrossRef]

- Huy, T.D.; Fujiwara, H.; Yoshida, R.; Binh, D.T.; Miyamoto, H. Microstructure and mechanical properties of TiAl3/Al2O3 in situ composite by combustion process. Mater. Trans. 2014, 55, 1091–1093. [Google Scholar] [CrossRef]

- Fei, W.; Yu, H.; Chen, C.; Dai, J. Microstructures and wear properties of laser cladding Co-based composite coatings on Ti–6Al–4V. Mater. Des. 2015, 80, 174–181. [Google Scholar] [CrossRef]

- Zhang, H.X.; Yu, H.J.; Chen, C.Z.; Dai, J.J. Microstructure and day sliding wear resistance of laser cladding Ti-Al-Si composite coating. Surf. Rev. Lett. 2017, 24, 1850009. [Google Scholar] [CrossRef]

- Zhang, H.F.; Wang, L.; Zhang, S.; Wu, C.L. An investigation on wear and cavitation erosion-corrosion characteristics of the TiC modified Fe-based composite coating via laser cladding. J. Mater. Res. Technol. 2023, 26, 8440–8455. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).