Theoretical Design and Experimental Study of a Piezoelectric Energy Harvesting System for Self-Powered Ski Boots

Abstract

1. Introduction

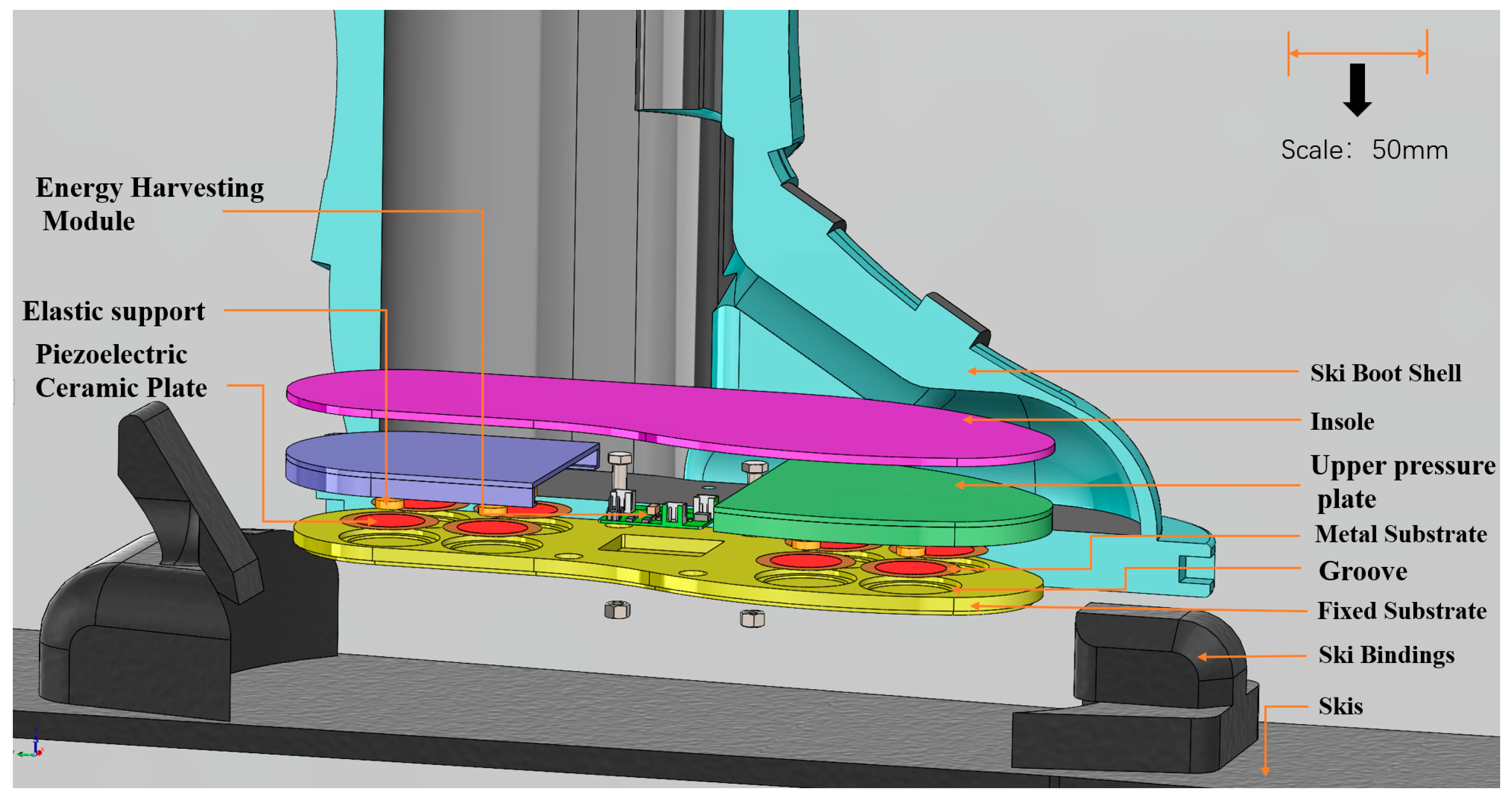

2. Structural Design and Working Principle

2.1. Available Energy in Skiing

2.2. Structural Design

2.3. Working Principle

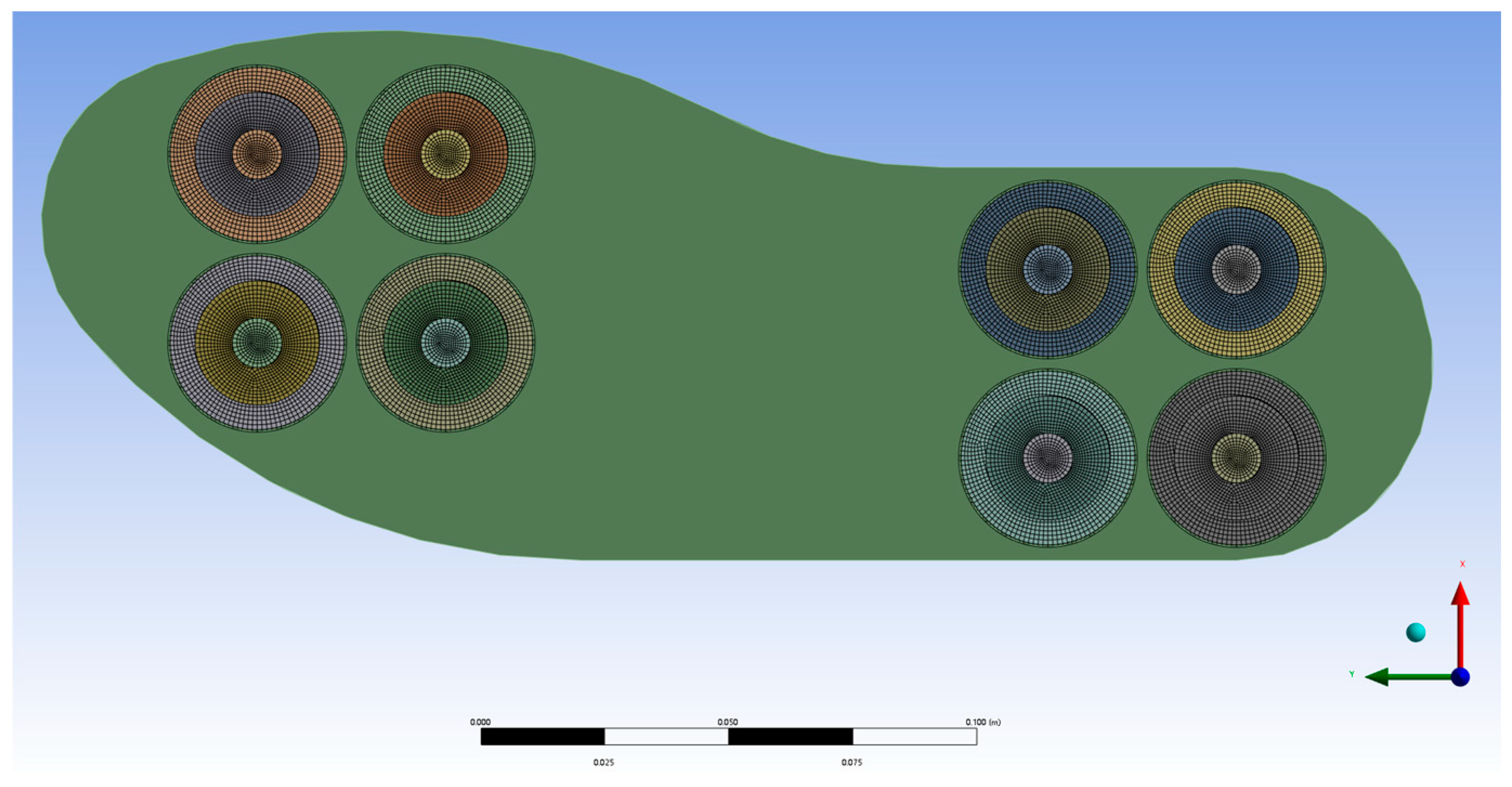

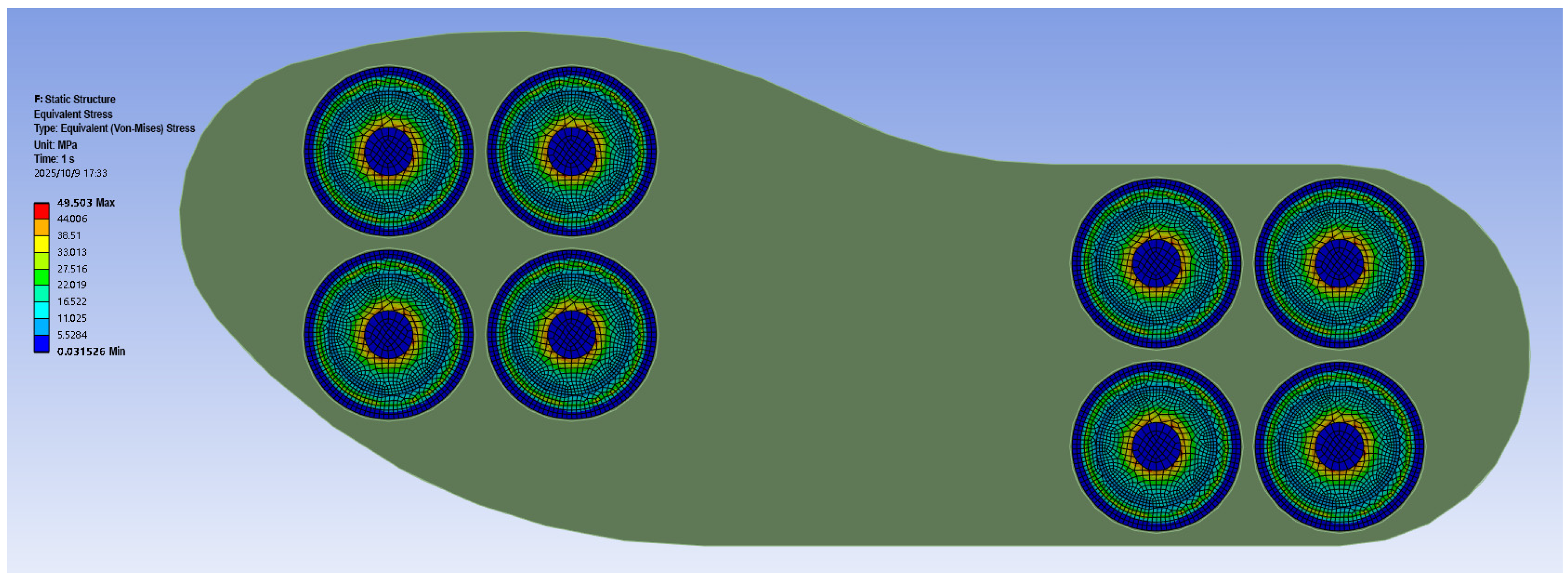

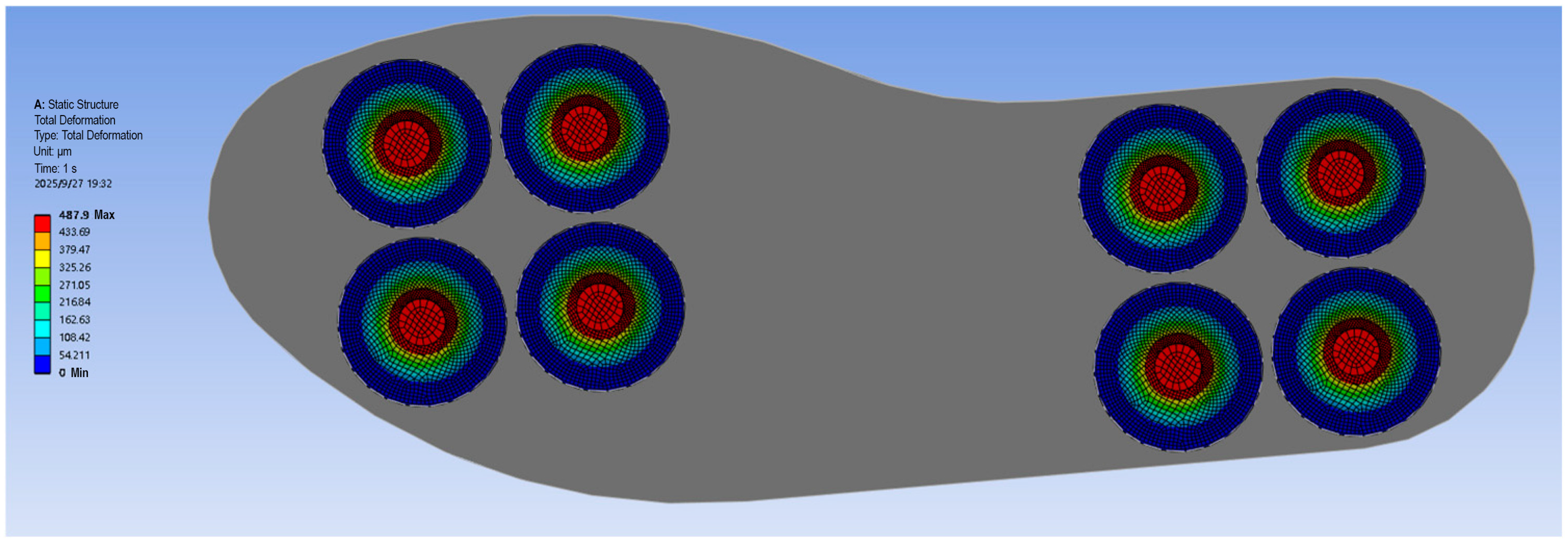

3. Modeling and Simulation for the PEHS

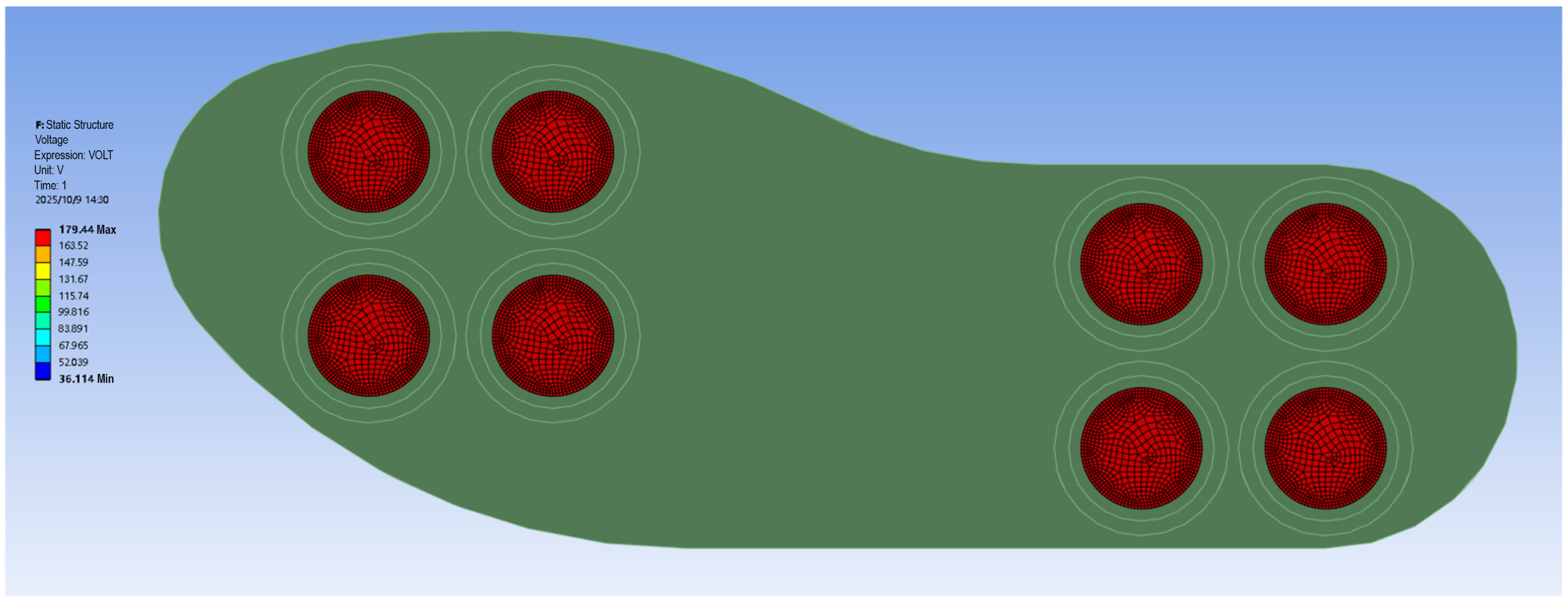

3.1. Static Strength Simulation Analysis for the PEHS

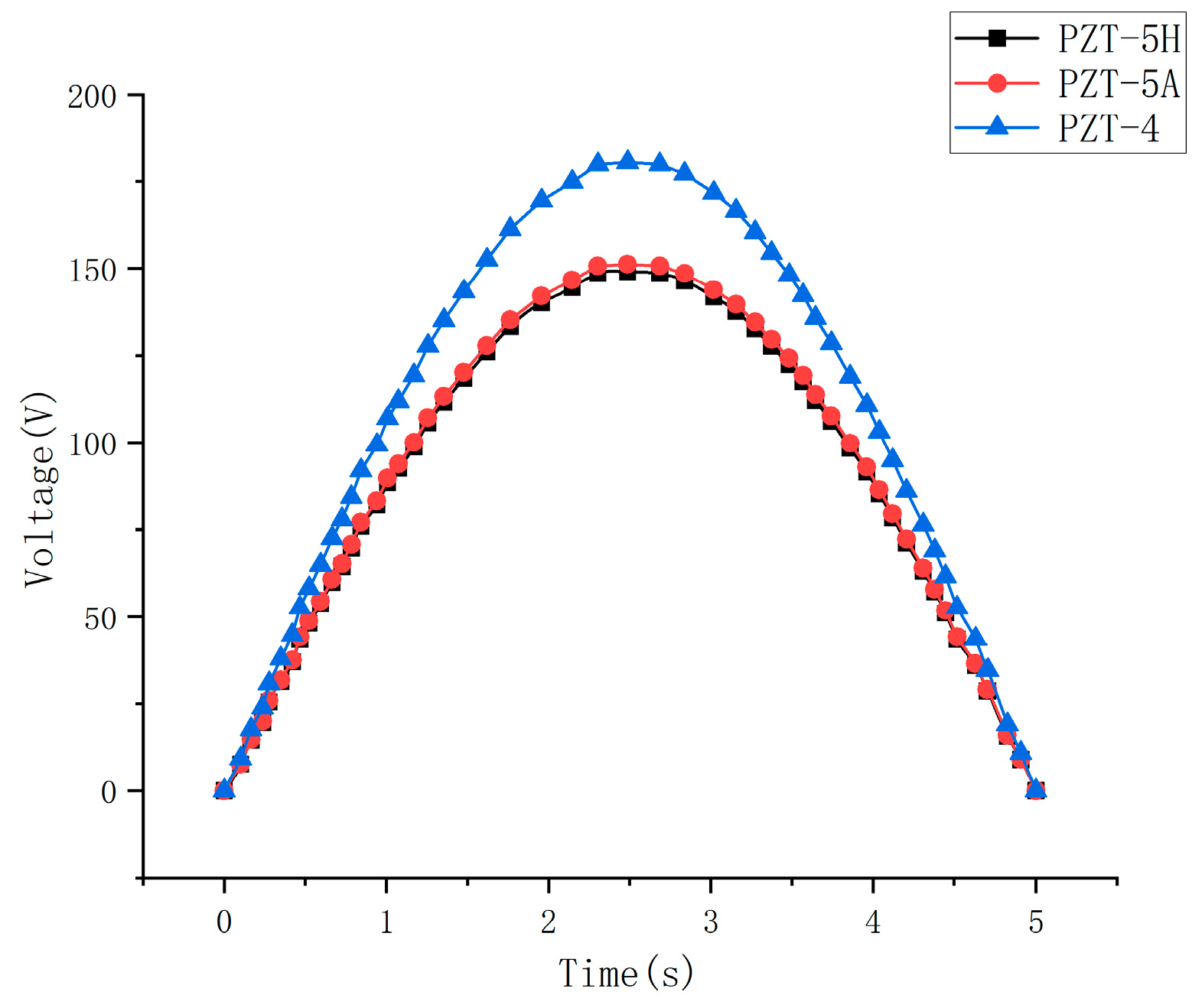

3.2. Simulation Analysis of the Voltage Generated by the PEHS

4. Experimental Setup and Results Analysis

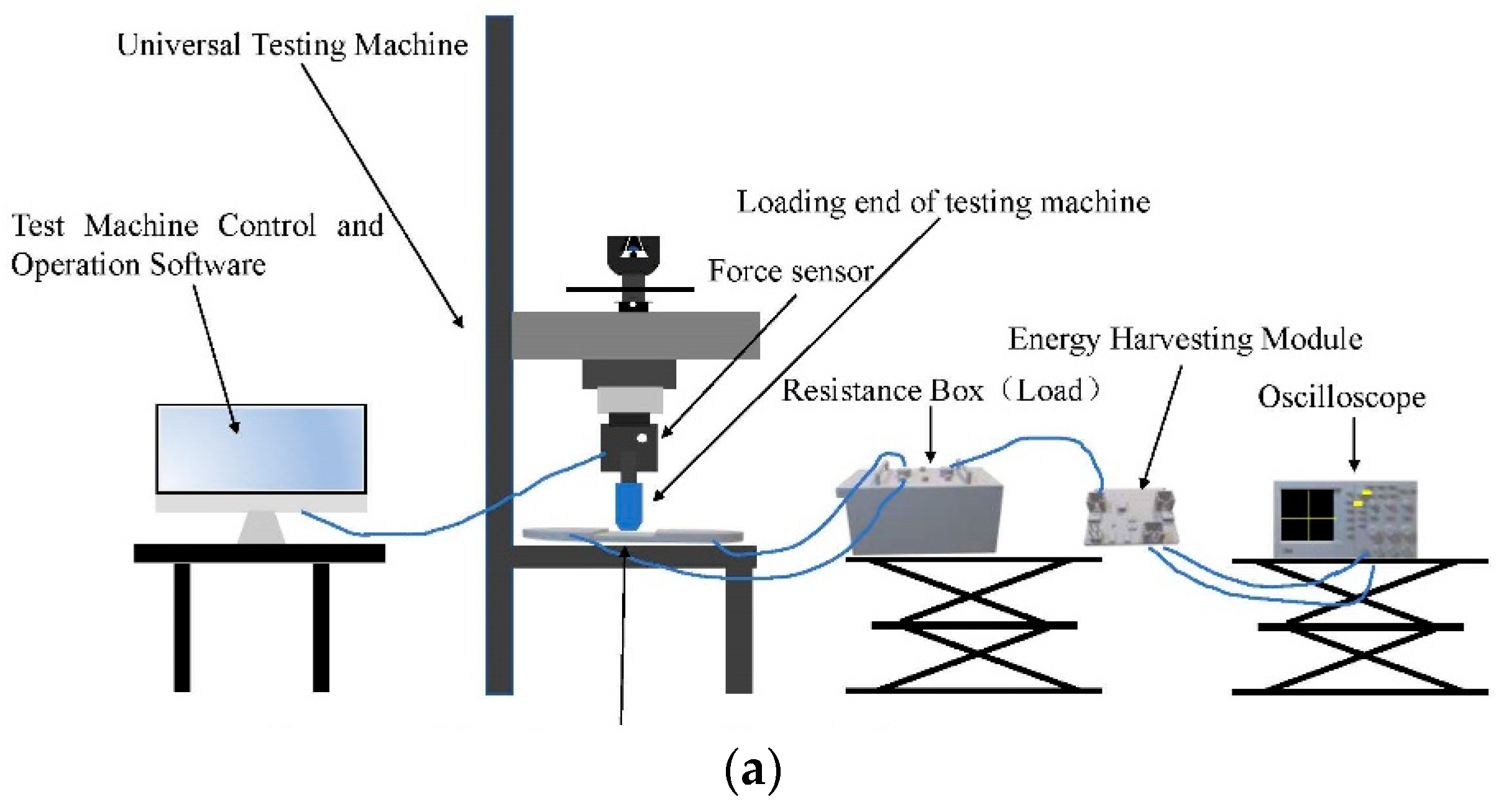

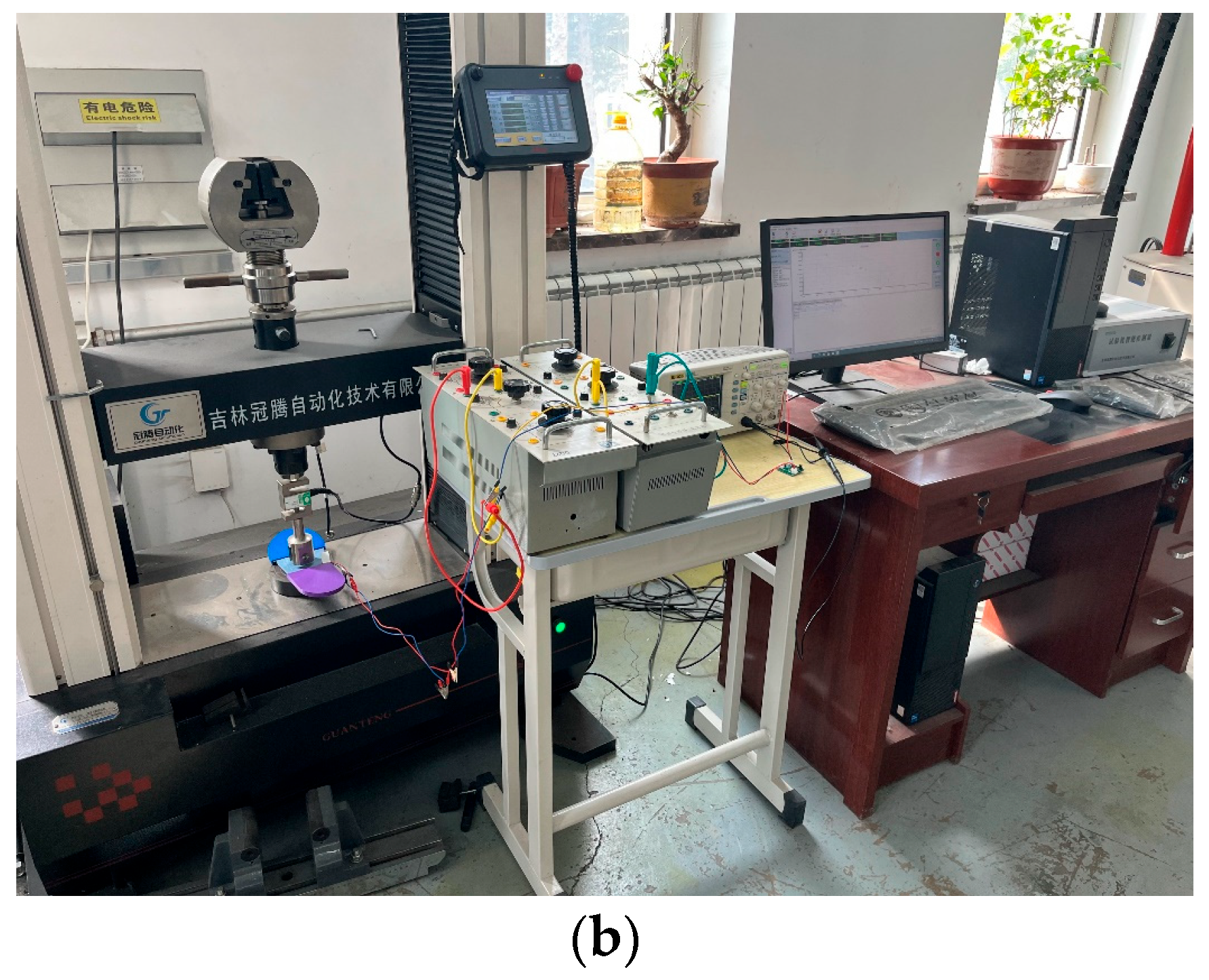

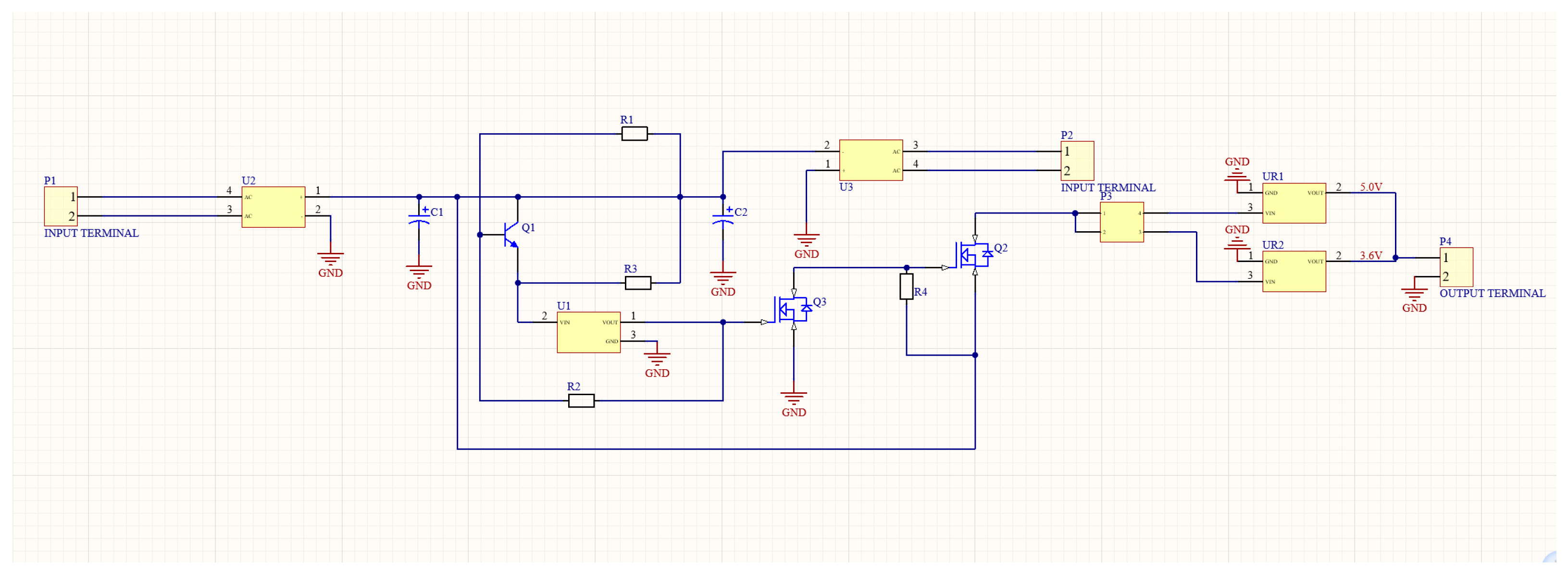

4.1. Energy-Harvesting Test of the Prototype Under Loading by a Universal Testing Machine

4.2. Energy-Harvesting Test with the Prototype Worn by a Skier

5. Conclusions

- (1)

- A finite element static strength simulation analysis was conducted for the structure of the PEHS for self-powered ski boots, and the design meets the strength requirements. The output voltages of the PEHS made with three different piezoelectric ceramic materials—PZT-5H, PZT-5A, and PZT-4—were simulated, yielding instantaneous open-circuit peak voltages of 149.1 V, 151.3 V, and 180.4 V, respectively. The causes of these results were analyzed.

- (2)

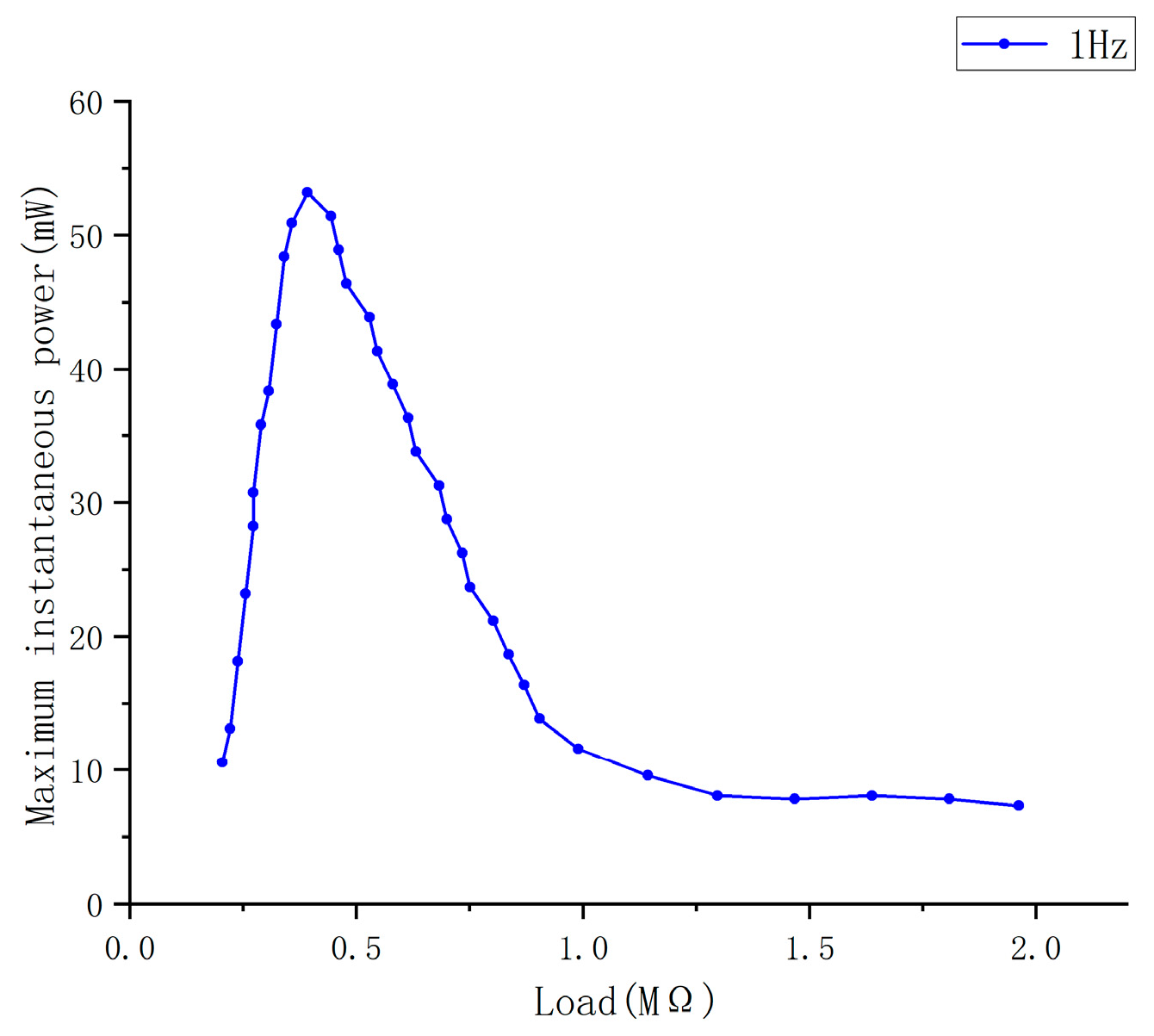

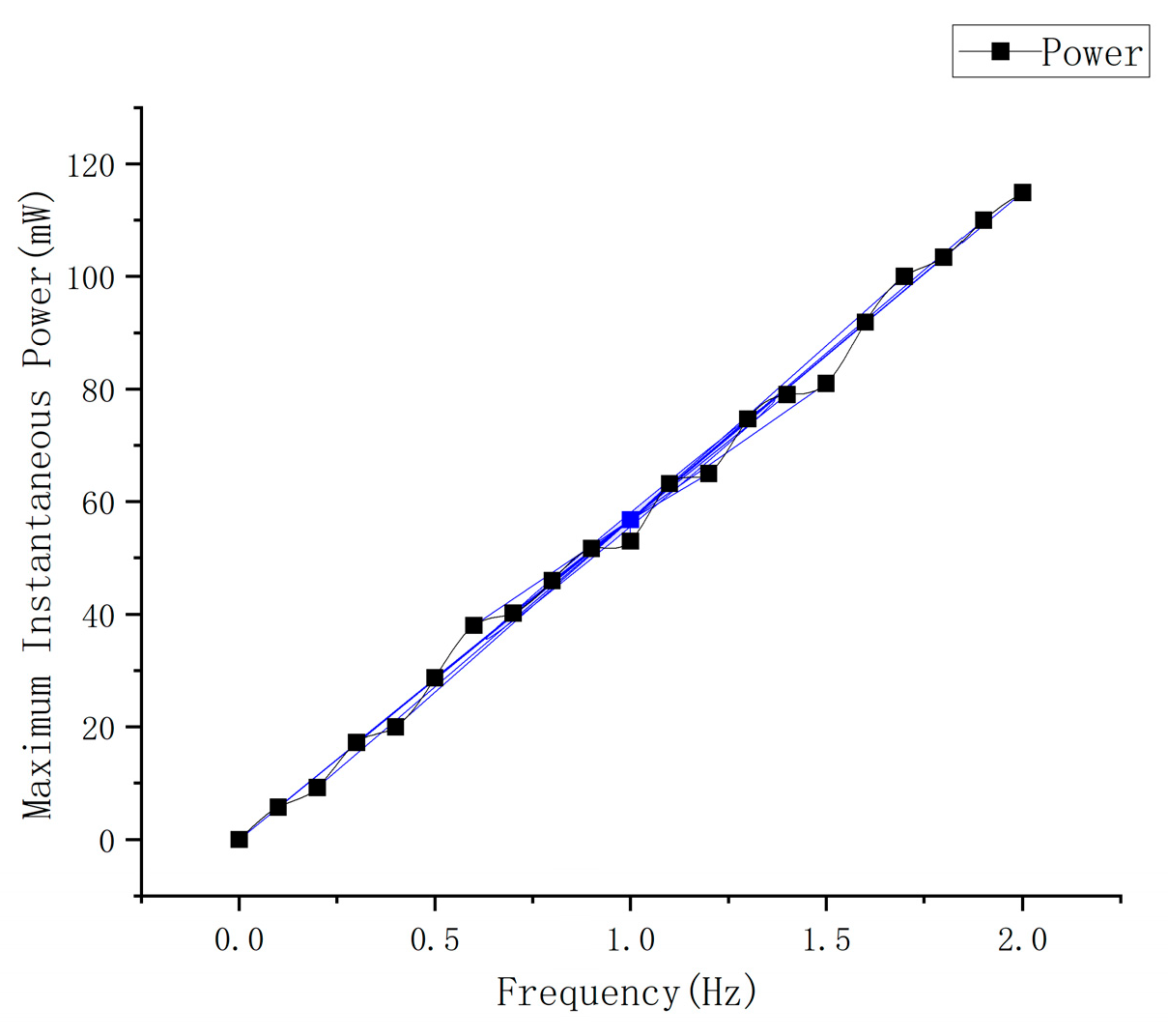

- A piezoelectric energy-harvesting test of the prototype was conducted under loading by a universal testing machine. Under a uniformly distributed load of 800 N at a frequency of 1 Hz, the maximum output power of the PEHS prototype for self-powered ski boots reached 57.44 mW, with a matching load resistance of 404 kΩ. Under uniformly distributed loads of 800 N at frequencies ranging from 0.1 to 2 Hz, the instantaneous maximum power generated by the prototype (at the optimal matching impedance for each frequency) exhibited an approximately linear relationship with the loading frequency.

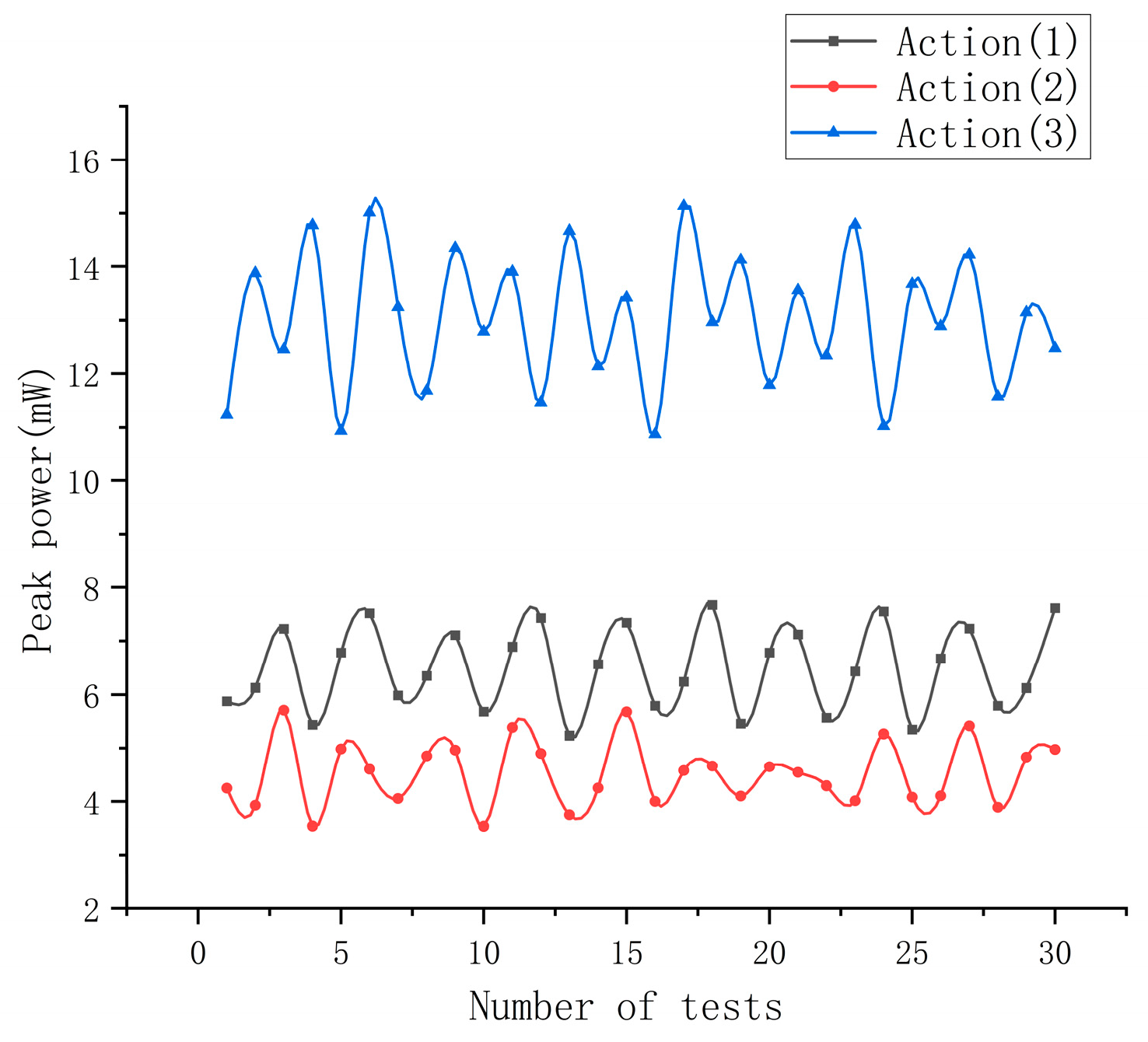

- (3)

- A piezoelectric energy-harvesting test was conducted with the prototype worn by a skier. The tester weighed 80 kg and wore the self-powered ski boots developed in this study. At a motion frequency of 1 Hz, three different skiing actions were performed:

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Z.; Li, J.; Song, W.; Lu, Y.; Cao, B. Smart Wireless Charging Heating Insoles: Improving Body Thermal Comfort of Young Males in an Extremely Cold Environment. Cloth. Text. Res. J. 2020, 3, 220–234. [Google Scholar] [CrossRef]

- Işik, H. Design and construction of thermoelectric footwear heating system for illness feet. J. Med. Syst. 2005, 29, 627–631. [Google Scholar] [CrossRef]

- Işik, H.; Saraçoğlu, E. The design of thermoelectric footwear heating system via fuzzy logic. J. Med. Syst. 2007, 31, 521–527. [Google Scholar] [CrossRef]

- Gołąbek, J.; Strankowski, M. A Review of Recent Advances in Human-Motion Energy Harvesting Nanogenerators, Self-Powering Smart Sensors and Self-Charging Electronics. Sensors 2024, 24, 1069. [Google Scholar] [CrossRef] [PubMed]

- Pu, X.; Hu, W.; Wang, Z. Toward wearable self-charging power systems: The integration of energy-harvesting and storage devices. Small 2018, 14, 1702817. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Luk, P.; Li, C. An electromagnetic wearable 3-DoF resonance human body motion energy harvester using ferrofluid as a lubricant. Appl. Energy 2017, 197, 364–374. [Google Scholar] [CrossRef]

- Hesham, R.; Soltan, A.; Madian, A. Energy harvesting schemes for wearable devices. AEU-Int. J. Electron. Commun. 2021, 138, 153888. [Google Scholar] [CrossRef]

- Kang, M.; Yeo, W.H. Advances in energy harvesting technologies for wearable devices. Micromachines 2024, 15, 884. [Google Scholar] [CrossRef] [PubMed]

- Sekhar, M.C.; Veena, E.; Kumar, N.S.; Naidu, K.C.B.; Mallikarjuna, A.; Basha, D.B. A review on piezoelectric materials and their applications. Cryst. Res. Technol. 2023, 58, 2200130. [Google Scholar] [CrossRef]

- Habib, M.; Lantgios, I.; Hornbostel, K. A review of ceramic, polymer and composite piezoelectric materials. J. Phys. D Appl. Phys. 2022, 55, 423002. [Google Scholar] [CrossRef]

- Uchino, K. (Ed.) The Development of Piezoelectric Materials and the New Perspective. In Advanced Piezoelectric Materials, 2nd ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 1–92. [Google Scholar]

- Han, Y.; Cao, Y.; Zhao, J.; Yin, Y.; Ye, L.; Wang, X.; You, Z. A Self-Powered Insole for Human Motion Recognition. Sensors 2016, 16, 1502. [Google Scholar] [CrossRef]

- Mitcheson, P.D.; Yeatman, E.M.; Rao, G.K.; Holmes, A.S.; Green, T.C. Energy Harvesting From Human and Machine Motion for Wireless Electronic Devices. Proc. IEEE 2008, 96, 1457–1486. [Google Scholar] [CrossRef]

- Qian, F.; Xu, T.; Zuo, L. Design, optimization, modeling and testing of a piezoelectric footwear energy harvester. Energy Convers. Manag. 2018, 171, 1352–1364. [Google Scholar] [CrossRef]

- Leinonen, M.; Juuti, J.; Jantunen, H.; Palosaari, J. Energy Harvesting with a Bimorph Type Piezoelectric Diaphragm Multilayer Structure and Mechanically Induced Pre-stress. Energy Technol. 2016, 4, 620–624. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, Q. Design and testing of a new dual-axial underfloor piezoelectric energy harvester. Sens. Actuators A Phys. 2020, 303, 111858. [Google Scholar] [CrossRef]

- Hou, W.; Zheng, Y.; Guo, W. Piezoelectric vibration energy harvesting for rail transit bridge with steel-spring floating slab track system. J. Clean. Prod. 2021, 291, 125283. [Google Scholar] [CrossRef]

- Asano, S.; Nishimura, S.; Ikeda, Y. Energy harvester for safety shoes using parallel piezoelectric links. Sens. Actuators A Phys. 2020, 309, 112000. [Google Scholar] [CrossRef]

- Yin, Z.; Gao, S. A shoe-mounted frequency up-converted piezoelectric energy harvester. Sens. Actuators A Phys. 2021, 318, 112530. [Google Scholar] [CrossRef]

- Vitorino, J.; Damas, B.; Víegas, V. Harvesting energy from a soldier’s gait using the piezoelectric effect. Energy Harvest. Syst. 2024, 11, 20230149. [Google Scholar] [CrossRef]

- Samuel, G.D.; Ghosh, D.K. Hybrid Power Generation System Based on Footsteps and Photovoltic (PV). In Proceedings of the 2024 1st International Conference on Advances in Computing, Communication and Networking (ICAC2N), Greater Noida, India, 16–17 December 2024. [Google Scholar]

- Spampinato, C.; Calogero, G.; Mannino, G.; Valastro, S.; Smecca, E.; Arena, V.; Alberti, A. A Sputtered Gig-Lox TiO2 Sponge Integrated with CsPbI3: EuI2 for Semitransparent Perovskite Solar Cells. J. Phys. Chem. C 2025, 36, 16338–16346. [Google Scholar] [CrossRef]

- Wang, S.; Kan, J.; Wang, H.; Li, Z.; Zhao, Z.; Wan, J.; Cao, D. Modeling and analysis of a circular PZT energy-generator used in hydraulic liquid absorber. J. Vib. Shock 2012, 31, 177–182. [Google Scholar]

| Parameters | Numerical and Material |

|---|---|

| size of prototypes (excluding skis) | 316 mm × 119 mm × 285 mm |

| diameter of piezoelectric ceramic plate | 25 mm |

| diameter of metal substrate | 35 mm |

| diameter of elastic support | 10 mm |

| height of piezoelectric ceramic plate | 0.25 mm |

| height of metal substrate | 0.35 mm |

| height of elastic support | 3.0 mm |

| materials of fixed substrate | PLA (3D-Printed) |

| materials of upper pressure plate | PLA (3D-Printed) |

| materials of elastic support | PLA (3D-Printed) |

| materials of metal substrate | beryllium Copper |

| density of piezoelectric ceramic plate (PZT-5H; PZT-5A; PZT-4) | 7480 kg·m−3 |

| density of metal substrate | 8295 kg·m−3 |

| density of PLA (3D-printed) | 1382 kg·m−3 |

| equivalent elastic modulus of piezoelectric ceramic plate (PZT-5H) | 52 GPa |

| equivalent elastic modulus of piezoelectric ceramic plate (PZT-5A) | 53 GPa |

| equivalent elastic modulus of piezoelectric ceramic plate (PZT-4) | 71 GPa |

| elastic modulus of metal substrate | 131 GPa |

| elastic modulus of PLA (3D-printed) | 2170 MPa |

| poisson’s ratio of piezoelectric ceramic plate | 0.36 |

| poisson’s ratio of metal substrate | 0.34 |

| poisson’s ratio of PLA (3D-printed) | 0.365 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jie, M.; Cai, L.; Jiang, D.; Qi, Z.; Sun, Z.; Zhang, F.; Zhao, Y.; Li, Z.; Chen, J.; Zhang, S. Theoretical Design and Experimental Study of a Piezoelectric Energy Harvesting System for Self-Powered Ski Boots. Coatings 2025, 15, 1288. https://doi.org/10.3390/coatings15111288

Jie M, Cai L, Jiang D, Qi Z, Sun Z, Zhang F, Zhao Y, Li Z, Chen J, Zhang S. Theoretical Design and Experimental Study of a Piezoelectric Energy Harvesting System for Self-Powered Ski Boots. Coatings. 2025; 15(11):1288. https://doi.org/10.3390/coatings15111288

Chicago/Turabian StyleJie, Meng, Lutong Cai, Delong Jiang, Zhenxiang Qi, Zhi Sun, Fei Zhang, Yejing Zhao, Zhihao Li, Jun Chen, and Shuai Zhang. 2025. "Theoretical Design and Experimental Study of a Piezoelectric Energy Harvesting System for Self-Powered Ski Boots" Coatings 15, no. 11: 1288. https://doi.org/10.3390/coatings15111288

APA StyleJie, M., Cai, L., Jiang, D., Qi, Z., Sun, Z., Zhang, F., Zhao, Y., Li, Z., Chen, J., & Zhang, S. (2025). Theoretical Design and Experimental Study of a Piezoelectric Energy Harvesting System for Self-Powered Ski Boots. Coatings, 15(11), 1288. https://doi.org/10.3390/coatings15111288