Enhanced Lateral Growth of Homoepitaxial (001) Diamond by Microwave Plasma Chemical Vapor Deposition with Nitrogen Addition

Abstract

1. Introduction

2. Materials and Methods

2.1. Substrate Preparation

2.2. MPCVD Growth Conditions

2.3. Structural Characterization

3. Results and Discussion

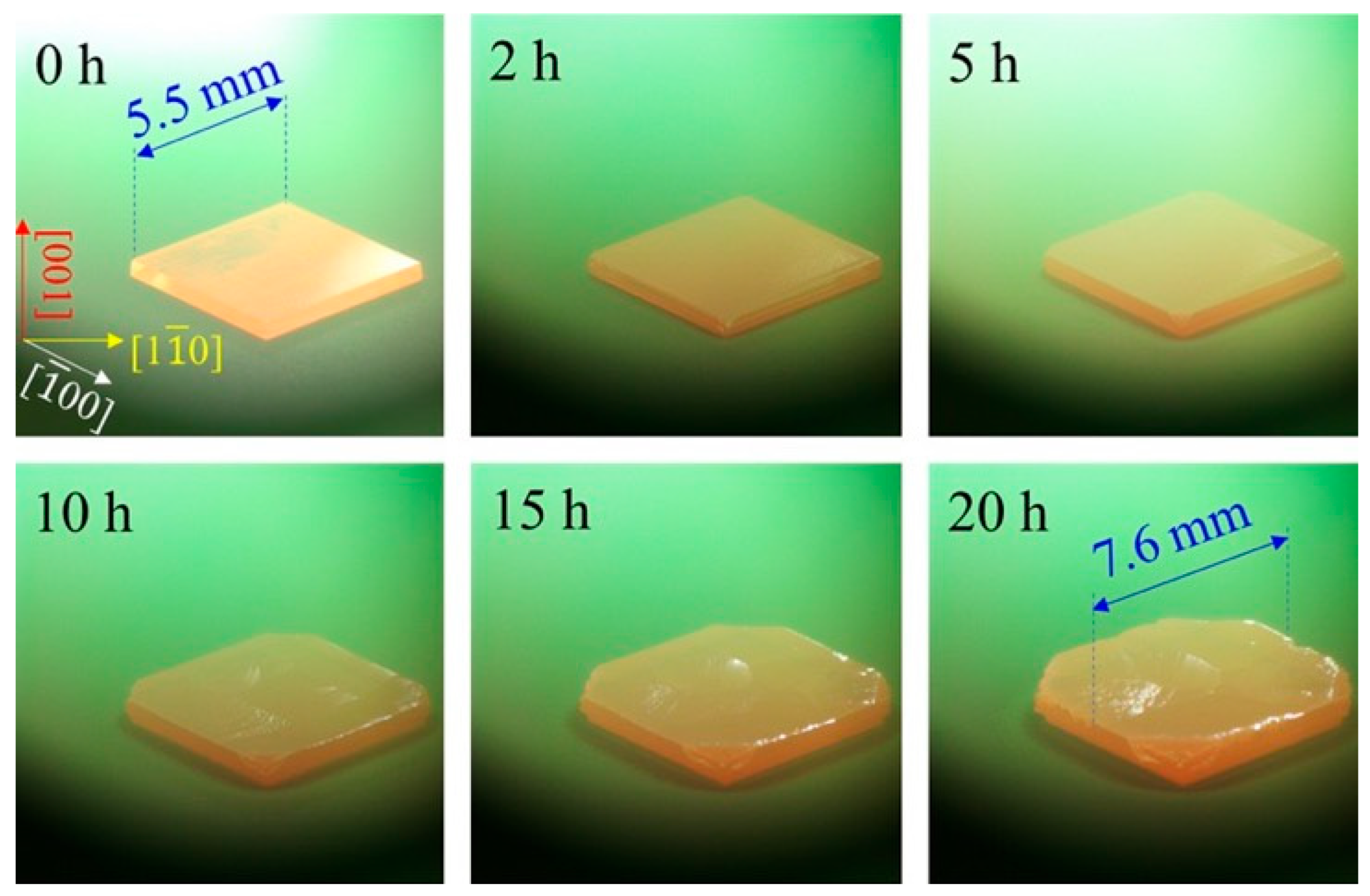

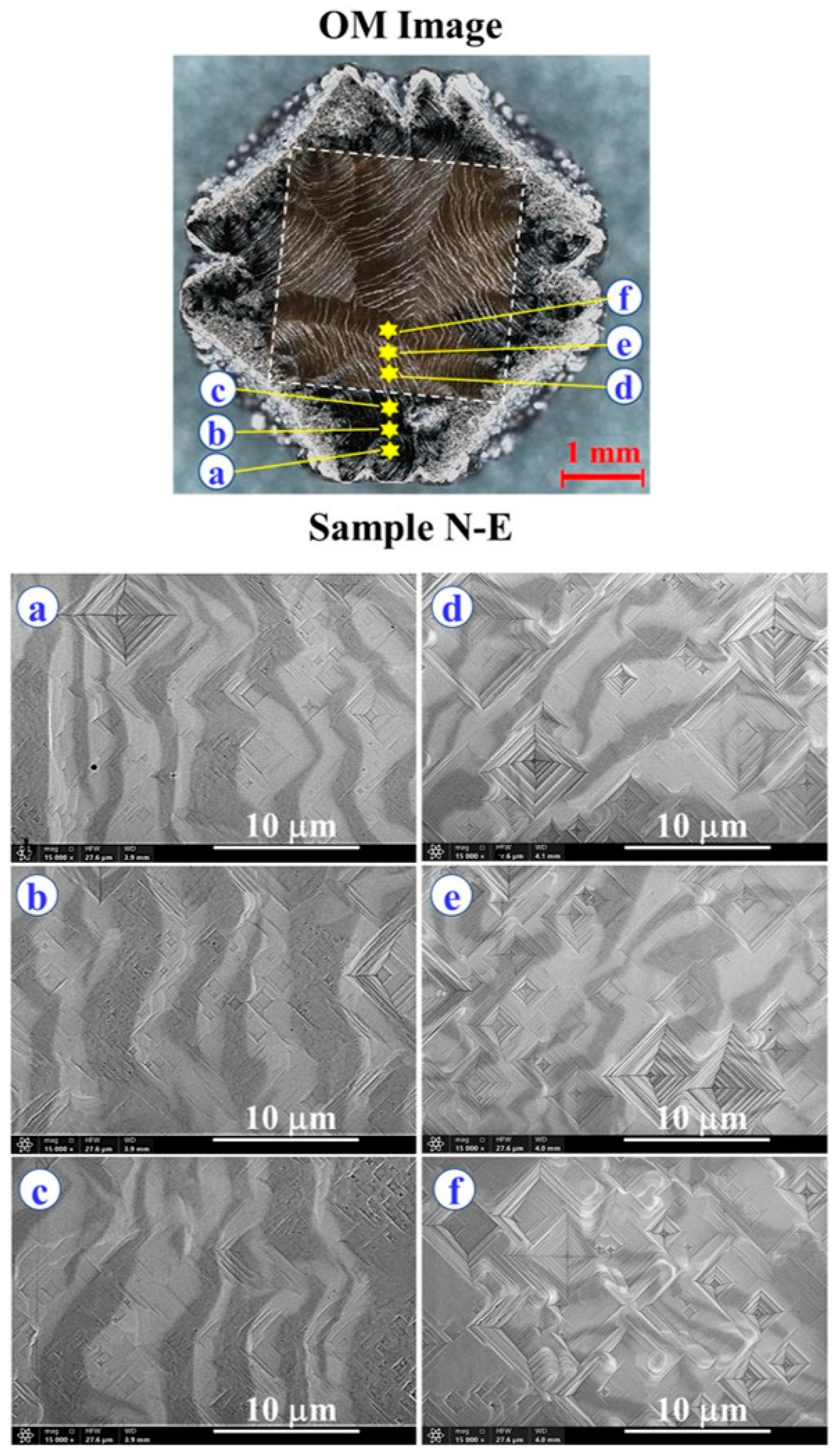

3.1. Surface Morphology Evolution with Nitrogen Addition

3.2. Growth Rates and Lateral Area Expansion

3.3. Surface Morphologies of the N180 Sample

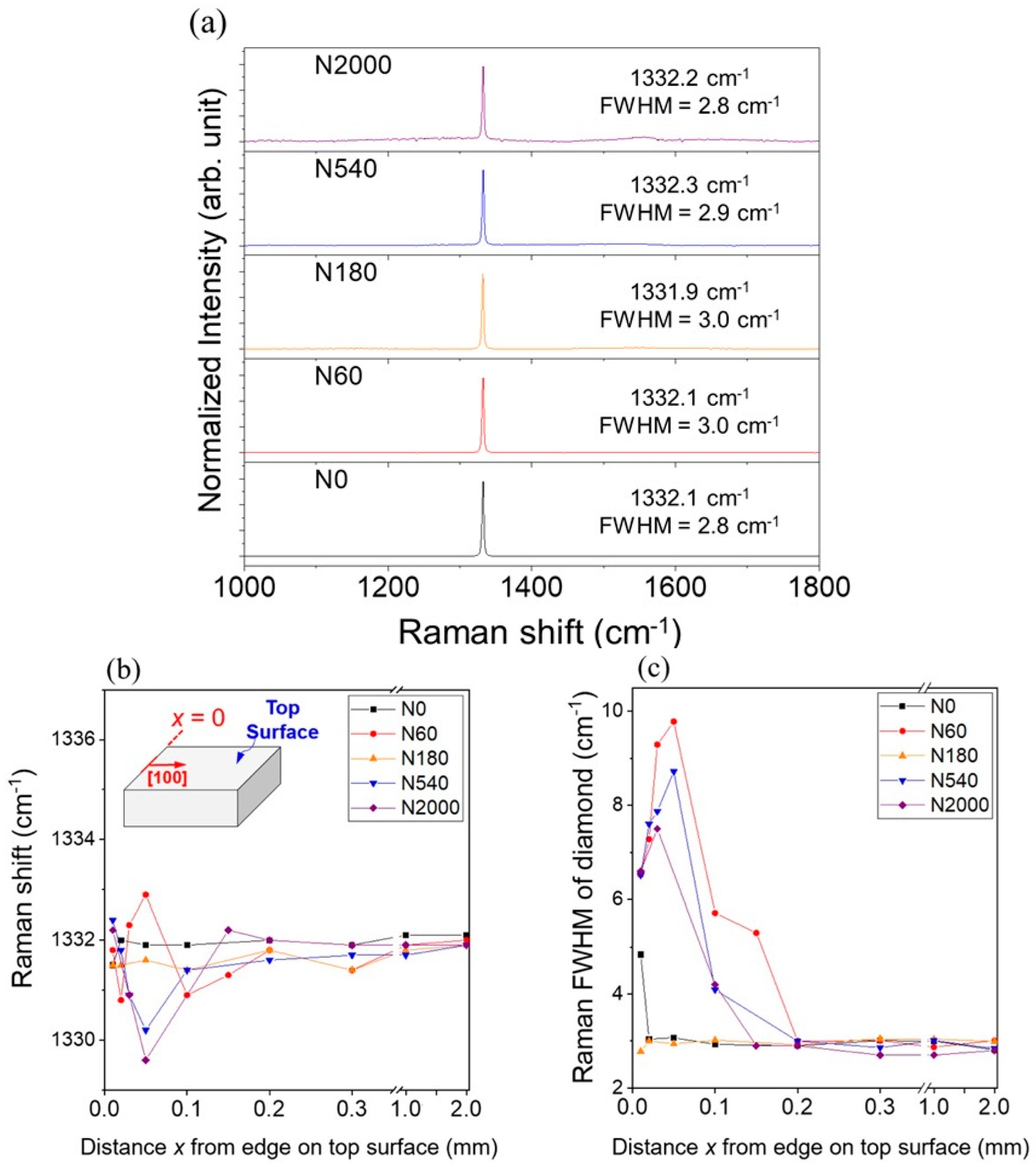

3.4. Raman Spectroscopy Analysis

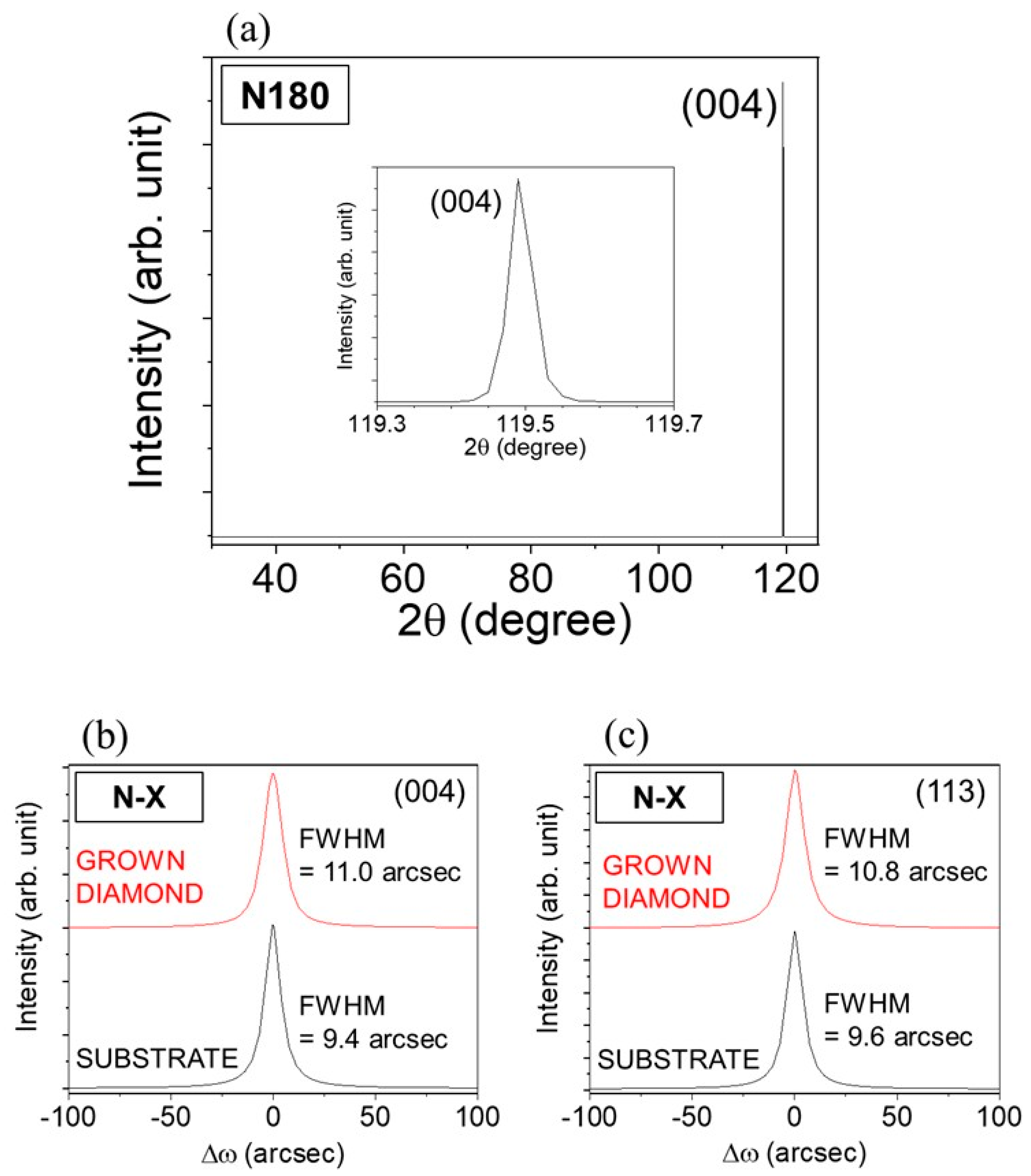

3.5. X-Ray Diffraction Characterization

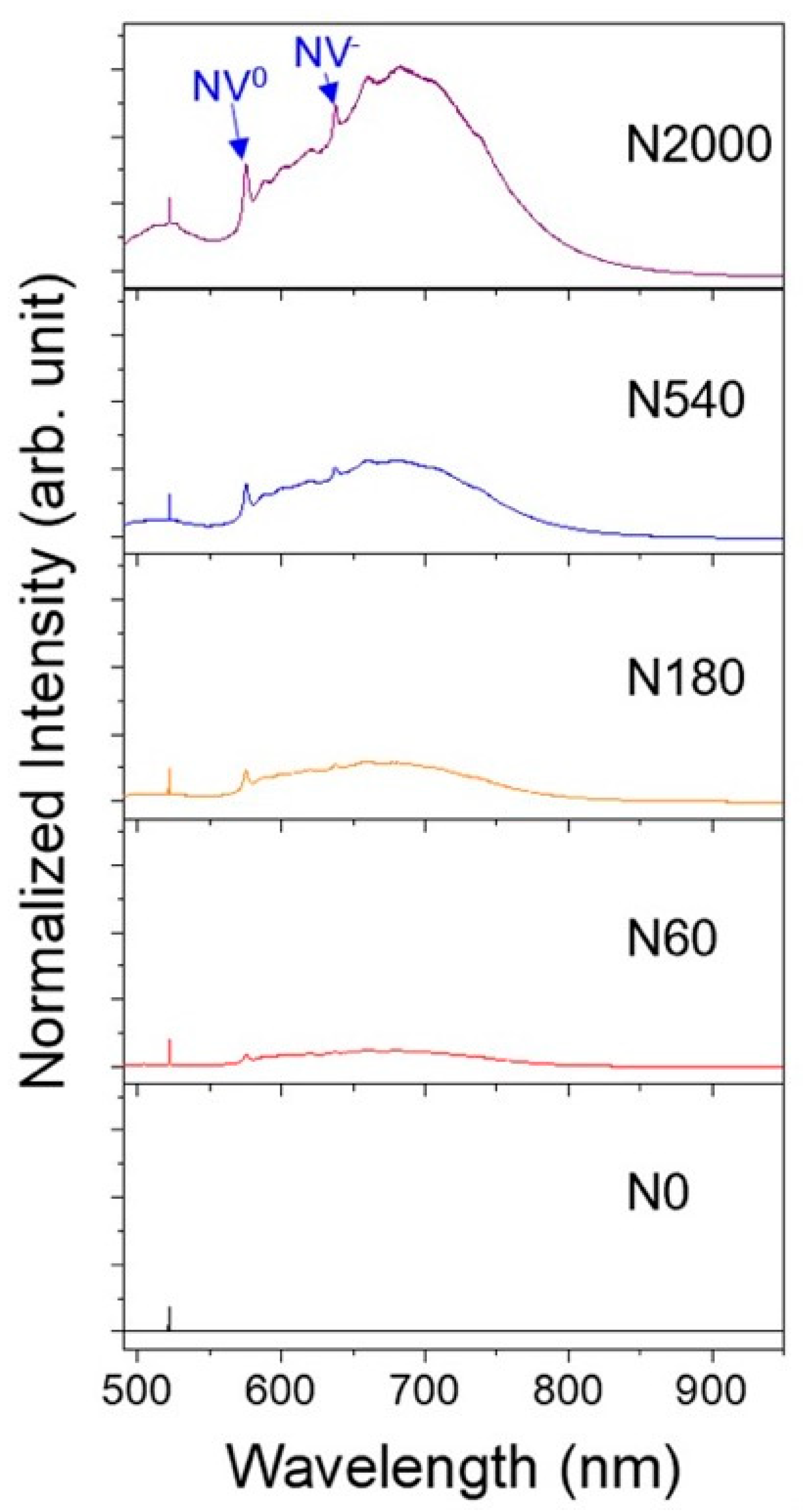

3.6. Photoluminescence and Nitrogen-Vacancy Centers

3.7. Etch Pit Density Analysis and Quality Enhancement

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Donato, N.; Rouger, N.; Pernot, J.; Longobardi, G.; Udrea, F. Diamond power devices: State of the art, modelling, figures of merit and future perspective. J. Phys. D Appl. Phys. 2019, 53, 093001. [Google Scholar] [CrossRef]

- Zulkharnay, R.; May, P.W. Applications of diamond films: A review. Funct. Diam. 2024, 4, 2410160. [Google Scholar] [CrossRef]

- Chang, X.; Gao, W.; An, J.; Chen, H.; Liu, Z.; Qi, Z.; Li, C.; Ding, J.; Li, W.; Wang, K. Optical-grade diamond: Characteristics, synthesis, and recent research progress. Funct. Diam. 2025, 5, 2476690. [Google Scholar] [CrossRef]

- Altukhov, A.; Afanas’ Ev, M.; Kvaskov, V.; Lyubchenko, V.; Mityagin, A.Y.; Murav’Ev, E.; Pomortsev, L.; Potapov, V.; Spitsyn, B. Application of diamond in high technology. Inorg. Mater. 2004, 40 (Suppl. S1), S50–S70. [Google Scholar] [CrossRef]

- Aharonovich, I.; Lee, J.C.; Magyar, A.; Buckley, B.B.; Yale, C.G.; Awschalom, D.D.; Hu, E. Homoepitaxial growth of single crystal diamond membranes for quantum information processing. Adv. Mater. 2012, 24, OP54–OP59. [Google Scholar] [CrossRef]

- Wan, N.H.; Lu, T.-J.; Chen, K.C.; Walsh, M.P.; Trusheim, M.E.; De Santis, L.; Bersin, E.A.; Harris, I.B.; Mouradian, S.L.; Christen, I.R. Large-scale integration of artificial atoms in hybrid photonic circuits. Nature 2020, 583, 226–231. [Google Scholar] [CrossRef]

- Kotomin, E.A.; Kuzovkov, V.N.; Lushchik, A.; Popov, A.I.; Shablonin, E.; Scherer, T.; Vasil’chenko, E. The Annealing Kinetics of Defects in CVD Diamond Irradiated by Xe Ions. Crystals 2024, 14, 546. [Google Scholar] [CrossRef]

- Luo, H.; Ajmal, K.M.; Liu, W.; Yamamura, K.; Deng, H. Polishing and planarization of single crystal diamonds: State-of-the-art and perspectives. Int. J. Extrem. Manuf. 2021, 3, 022003. [Google Scholar] [CrossRef]

- Schuelke, T.; Grotjohn, T.A. Diamond polishing. Diam. Relat. Mater. 2013, 32, 17–26. [Google Scholar] [CrossRef]

- Nebel, C.E. CVD diamond: A review on options and reality. Funct. Diam. 2023, 3, 2201592. [Google Scholar] [CrossRef]

- Nad, S.; Gu, Y.; Asmussen, J. Growth strategies for large and high quality single crystal diamond substrates. Diam. Relat. Mater. 2015, 60, 26–34. [Google Scholar] [CrossRef]

- Nad, S.; Charris, A.; Asmussen, J. MPACVD growth of single crystalline diamond substrates with PCD rimless and expanding surfaces. Appl. Phys. Lett. 2016, 109, 162103. [Google Scholar] [CrossRef]

- Cao, W.; Ma, Z.; Gao, D.; Wu, J.; Zhang, T.; Zhang, H.; Zhao, H.; Fu, Q. The effects of self-assembling off-angles on the homoepitaxial lateral outward growth of single-crystal diamond. Vacuum 2023, 212, 111989. [Google Scholar] [CrossRef]

- Li, K.; Zhang, J.; Mo, P.; Chen, J.; Pan, X.; Chen, C. Optimizing single crystal diamond mosaic growth: A study on seed thickness variation and pre-growth treatment. J. Cryst. Growth 2025, 649, 127953. [Google Scholar] [CrossRef]

- Weng, J.; Liu, F.; Wang, Z.; Guo, N.; Fan, F.; Yang, Z.; Wang, J.; Wang, H.; Xiong, L.; Zhao, H. Investigation on the preparation of large area diamond films with 150–200 mm in diameter using 915 MHz MPCVD system. Vacuum 2023, 217, 112543. [Google Scholar] [CrossRef]

- Shao, J.; Cao, B.; Wu, X.; Sun, G.; Zhao, J.; Xu, S. The 4-inch free-standing diamond film prepared by MPCVD at 10 kW. Funct. Diam. 2024, 4, 2356570. [Google Scholar] [CrossRef]

- Schreck, M.; Asmussen, J.; Shikata, S.; Arnault, J.-C.; Fujimori, N. Large-area high-quality single crystal diamond. MRS Bull. 2014, 39, 504–510. [Google Scholar] [CrossRef]

- Teraji, T. Chemical vapor deposition of homoepitaxial diamond films. Phys. Status Solidi (A) 2006, 203, 3324–3357. [Google Scholar] [CrossRef]

- Feng, M.; Jin, P.; Meng, X.; Xu, P.; Wu, J.; Wang, Z. One-step growth of a nearly 2 mm thick CVD single crystal diamond with an enlarged surface by optimizing the substrate holder structure. J. Cryst. Growth 2023, 603, 127011. [Google Scholar] [CrossRef]

- Tallaire, A.; Brinza, O.; Mille, V.; William, L.; Achard, J. Reduction of dislocations in single crystal diamond by lateral growth over a macroscopic hole. Adv. Mater. 2017, 29. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, Y.; Weng, C.; Zhu, W.; Lou, L.; Wang, G. The quality of epitaxial lateral overgrown diamond on substrate with laser-cut holes of varying shapes and side orientations. Diam. Relat. Mater. 2024, 148, 111488. [Google Scholar] [CrossRef]

- Mehmel, L.; Issaoui, R.; Brinza, O.; Tallaire, A.; Mille, V.; Delchevalrie, J.; Saada, S.; Arnault, J.-C.; Bénédic, F.; Achard, J. Dislocation density reduction using overgrowth on hole arrays made in heteroepitaxial diamond substrates. Appl. Phys. Lett. 2021, 118, 061901. [Google Scholar] [CrossRef]

- Li, D.; Lv, X.; Wang, Q.; Wu, X.; Sun, G.; Xu, S.; Han, S.; Li, L.; Zou, G. Epitaxial lateral overgrowth of single crystalline diamond with different periodic trench geometries fabricated by laser cutting. Appl. Surf. Sci. 2025, 702, 163361. [Google Scholar] [CrossRef]

- Yan, C.-s.; Vohra, Y.K.; Mao, H.-k.; Hemley, R.J. Very high growth rate chemical vapor deposition of single-crystal diamond. Proc. Natl. Acad. Sci. USA 2002, 99, 12523–12525. [Google Scholar] [CrossRef]

- Liang, Q.; Chin, C.Y.; Lai, J.; Yan, C.-s.; Meng, Y.; Mao, H.-k.; Hemley, R.J. Enhanced growth of high quality single crystal diamond by microwave plasma assisted chemical vapor deposition at high gas pressures. Appl. Phys. Lett. 2009, 94, 24103. [Google Scholar] [CrossRef]

- Cao, W.; Ma, Z.; Zhao, H.; Gao, D.; Fu, Q. The lateral outward growth of single-crystal diamonds by two different structures of microwave plasma reactor. CrystEngComm 2022, 24, 1010–1016. [Google Scholar] [CrossRef]

- Achard, J.; Silva, F.; Tallaire, A.; Bonnin, X.; Lombardi, G.; Hassouni, K.; Gicquel, A. High quality MPACVD diamond single crystal growth: High microwave power density regime. J. Phys. D Appl. Phys. 2007, 40, 6175. [Google Scholar] [CrossRef]

- Wang, X.; Duan, P.; Cao, Z.; Liu, C.; Wang, D.; Peng, Y.; Hu, X. Homoepitaxy growth of single crystal diamond under 300 torr pressure in the MPCVD system. Materials 2019, 12, 3953. [Google Scholar] [CrossRef] [PubMed]

- Chayahara, A.; Mokuno, Y.; Horino, Y.; Takasu, Y.; Kato, H.; Yoshikawa, H.; Fujimori, N. The effect of nitrogen addition during high-rate homoepitaxial growth of diamond by microwave plasma CVD. Diam. Relat. Mater. 2004, 13, 1954–1958. [Google Scholar] [CrossRef]

- Achard, J.; Silva, F.; Brinza, O.; Tallaire, A.; Gicquel, A. Coupled effect of nitrogen addition and surface temperature on the morphology and the kinetics of thick CVD diamond single crystals. Diam. Relat. Mater. 2007, 16, 685–689. [Google Scholar] [CrossRef]

- Cao, W.; Gao, D.; Zhao, H.; Ma, Z. Epitaxial lateral growth of single-crystal diamond under high pressure by a plate-to-plate MPCVD. Funct. Diamond 2022, 1, 143–149. [Google Scholar] [CrossRef]

- Zaitsev, A.; Moe, K.; Wang, W. Optical centers and their depth distribution in electron irradiated CVD diamond. Diam. Relat. Mater. 2017, 71, 38–52. [Google Scholar] [CrossRef]

- Ashfold, M.N.; Goss, J.P.; Green, B.L.; May, P.W.; Newton, M.E.; Peaker, C.V. Nitrogen in diamond. Chem. Rev. 2020, 120, 5745–5794. [Google Scholar] [CrossRef]

- Tsubouchi, N.; Mokuno, Y.; Shikata, S. Characterizations of etch pits formed on single crystal diamond surface using oxygen/hydrogen plasma surface treatment. Diam. Relat. Mater. 2016, 63, 43–46. [Google Scholar] [CrossRef]

- Shimaoka, T.; Ichikawa, K.; Koizumi, S.; Watanabe, K.; Teraji, T. Detection of defects in diamond by etch-pit formation. Phys. Status Solidi (A) 2019, 216, 1900247. [Google Scholar] [CrossRef]

- Achard, J.; Silva, F.; Brinza, O.; Bonnin, X.; Mille, V.; Issaoui, R.; Kasu, M.; Gicquel, A. Identification of etch-pit crystallographic faces induced on diamond surface by H2/O2 etching plasma treatment. Phys. Status Solidi (A) 2009, 206, 1949–1954. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, T.-I.; Chuang, C.-Y.; Huang, J.-B.; Ko, C.-J.; Wang, W.-L.; Chang, L. Enhanced Lateral Growth of Homoepitaxial (001) Diamond by Microwave Plasma Chemical Vapor Deposition with Nitrogen Addition. Coatings 2025, 15, 1256. https://doi.org/10.3390/coatings15111256

Yang T-I, Chuang C-Y, Huang J-B, Ko C-J, Wang W-L, Chang L. Enhanced Lateral Growth of Homoepitaxial (001) Diamond by Microwave Plasma Chemical Vapor Deposition with Nitrogen Addition. Coatings. 2025; 15(11):1256. https://doi.org/10.3390/coatings15111256

Chicago/Turabian StyleYang, Tzu-I, Chia-Yen Chuang, Jun-Bin Huang, Cheng-Jung Ko, Wei-Lin Wang, and Li Chang. 2025. "Enhanced Lateral Growth of Homoepitaxial (001) Diamond by Microwave Plasma Chemical Vapor Deposition with Nitrogen Addition" Coatings 15, no. 11: 1256. https://doi.org/10.3390/coatings15111256

APA StyleYang, T.-I., Chuang, C.-Y., Huang, J.-B., Ko, C.-J., Wang, W.-L., & Chang, L. (2025). Enhanced Lateral Growth of Homoepitaxial (001) Diamond by Microwave Plasma Chemical Vapor Deposition with Nitrogen Addition. Coatings, 15(11), 1256. https://doi.org/10.3390/coatings15111256