A Vision-Based Approach for Precise Wear Evaluation of Abrasive Belts with Irregular Morphology in Flexible Grinding

Abstract

1. Introduction

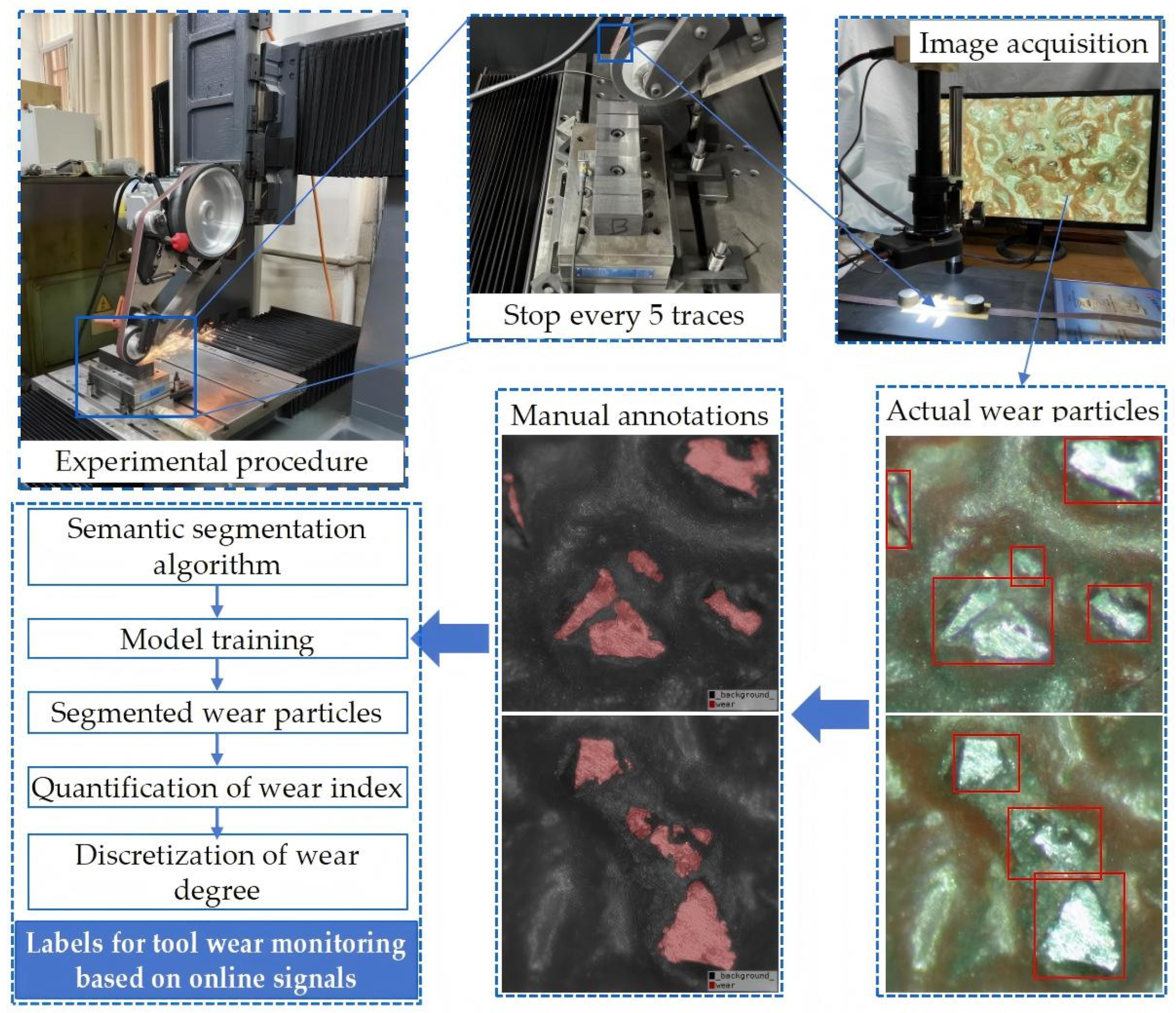

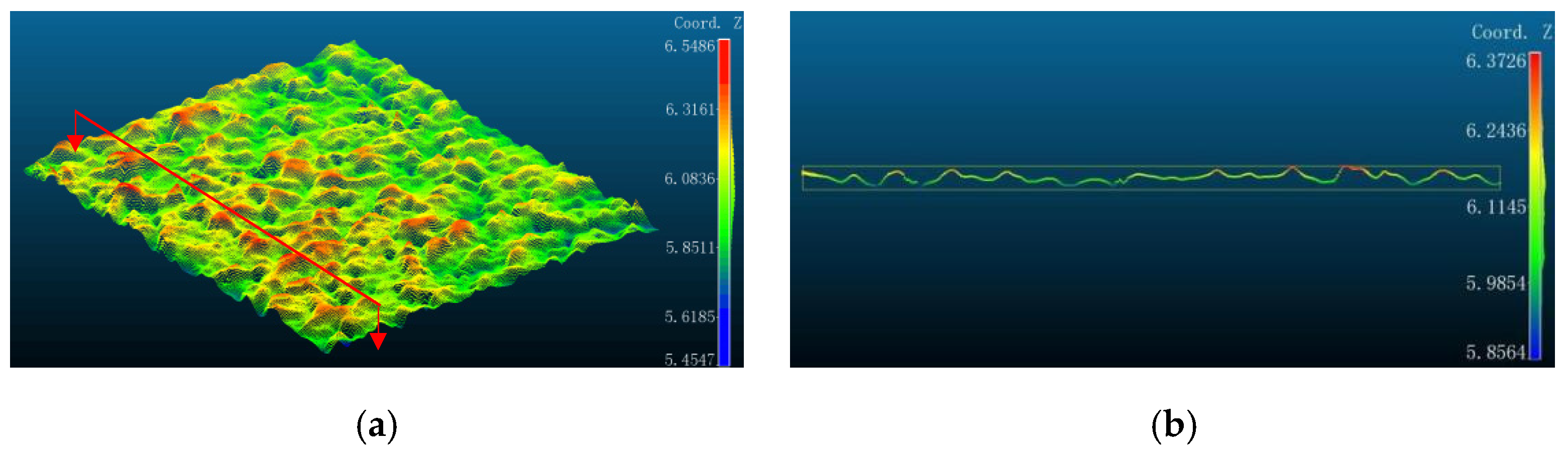

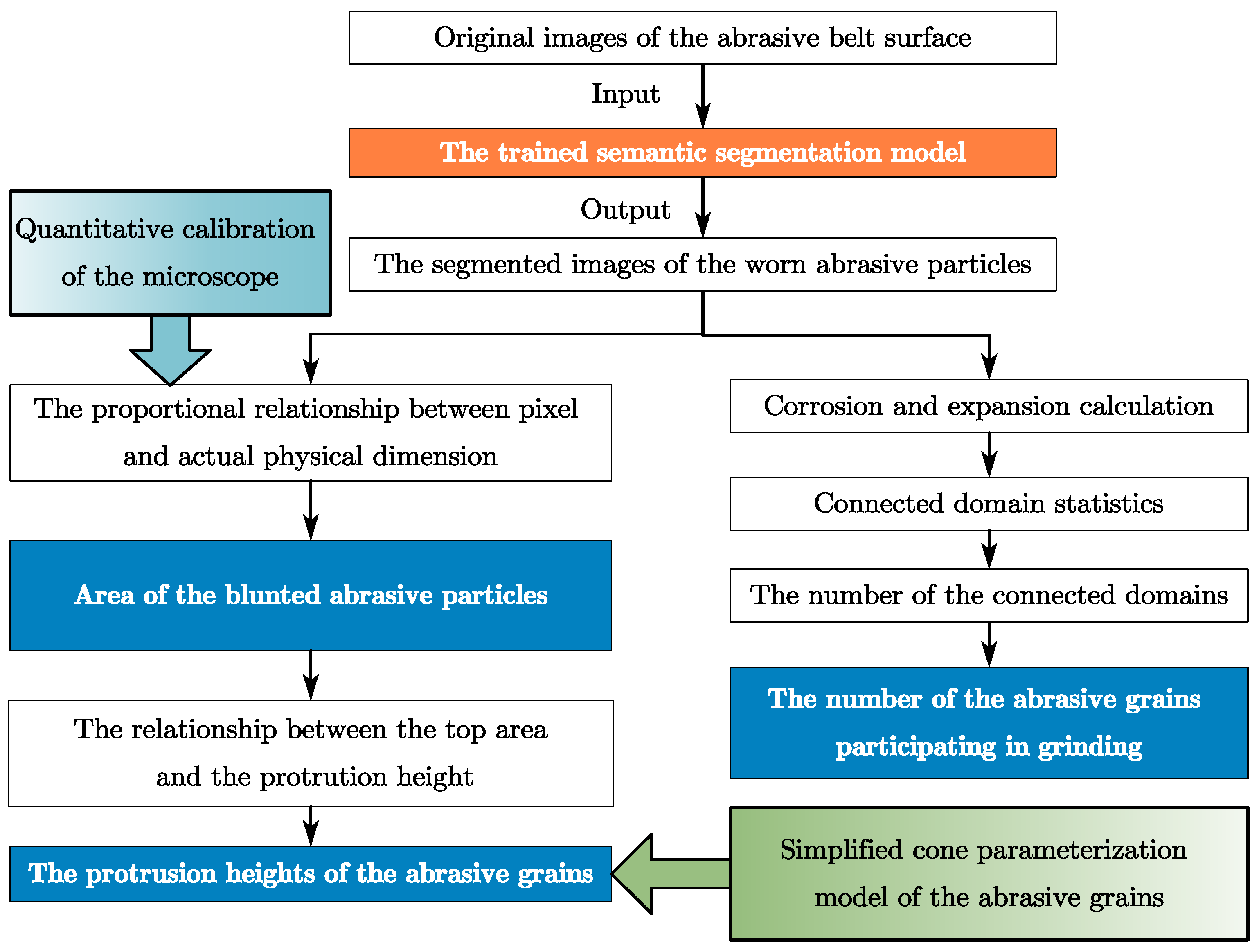

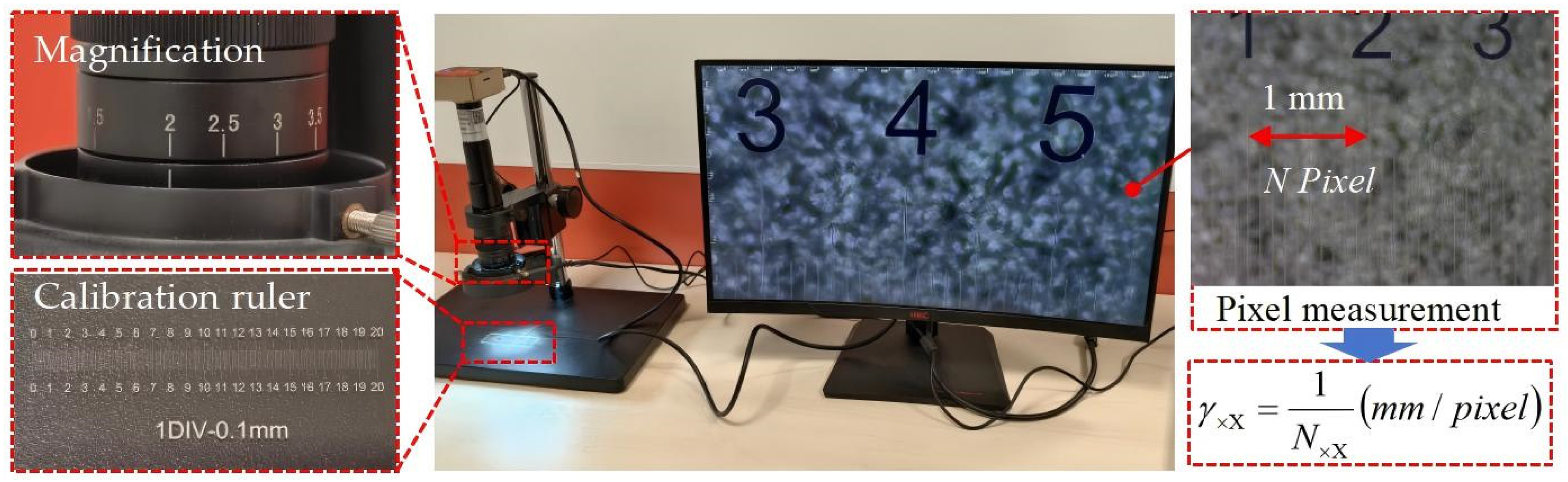

2. Experimental Procedure and Method

3. Wear Mechanism and Evaluation Method

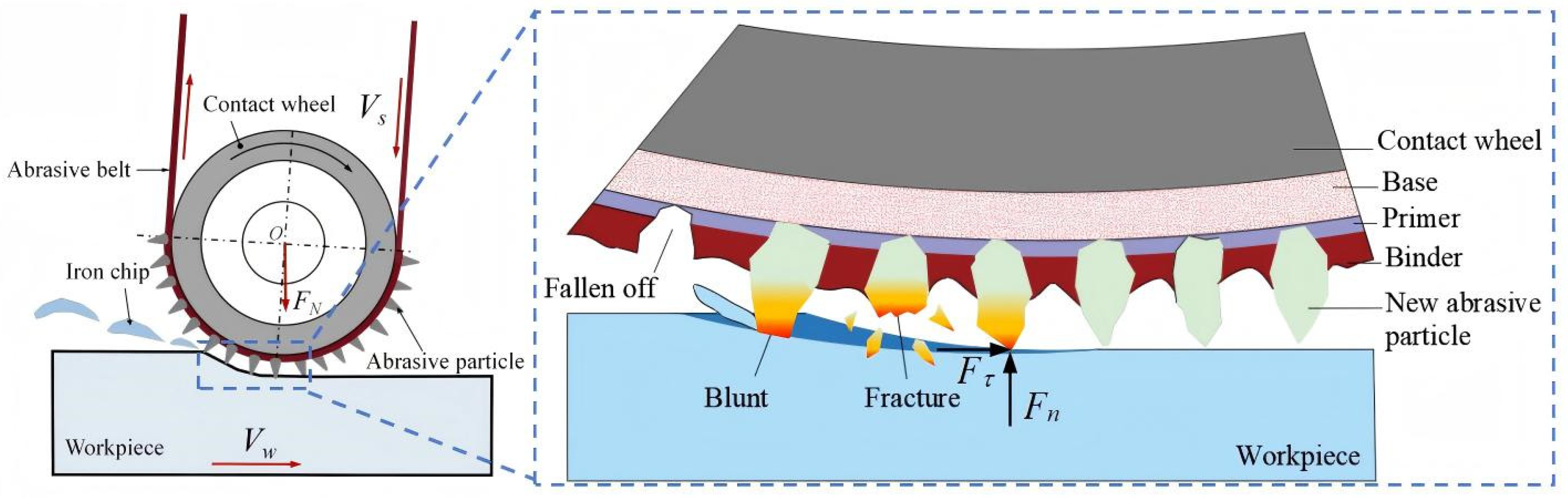

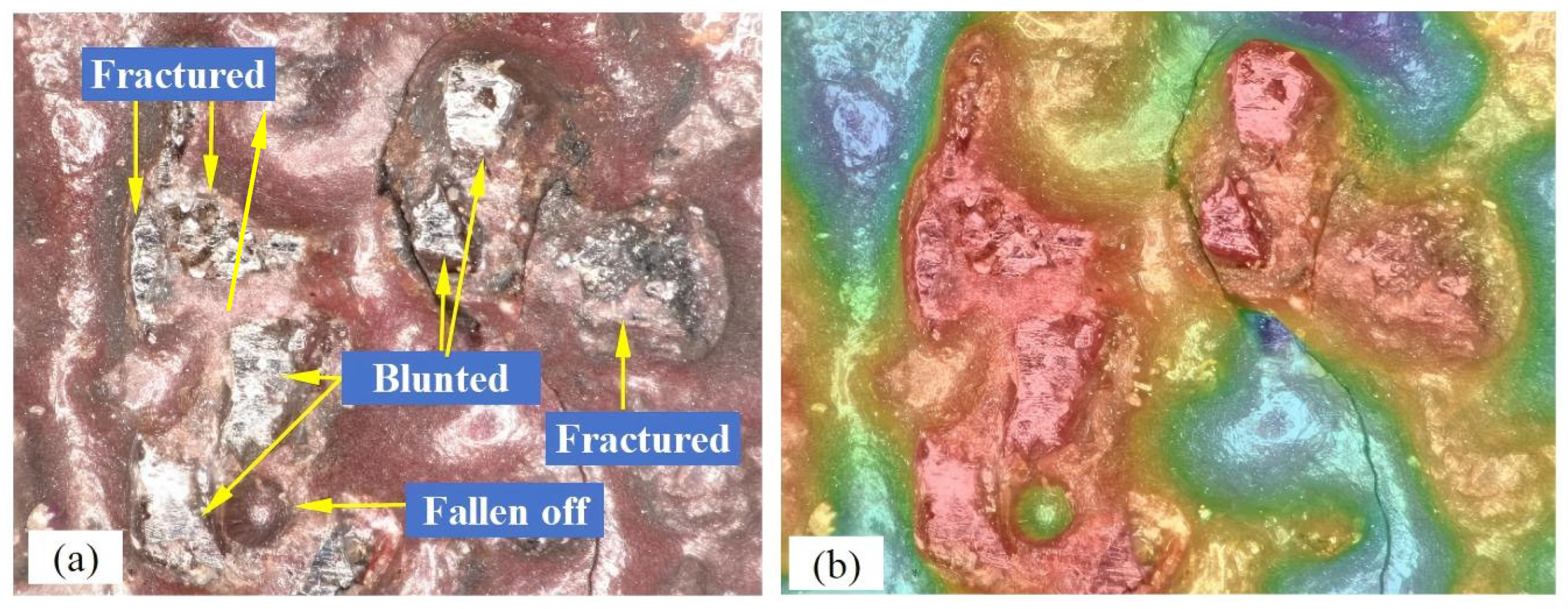

3.1. Wear Mechanism and Typical Forms of Abrasive Grains

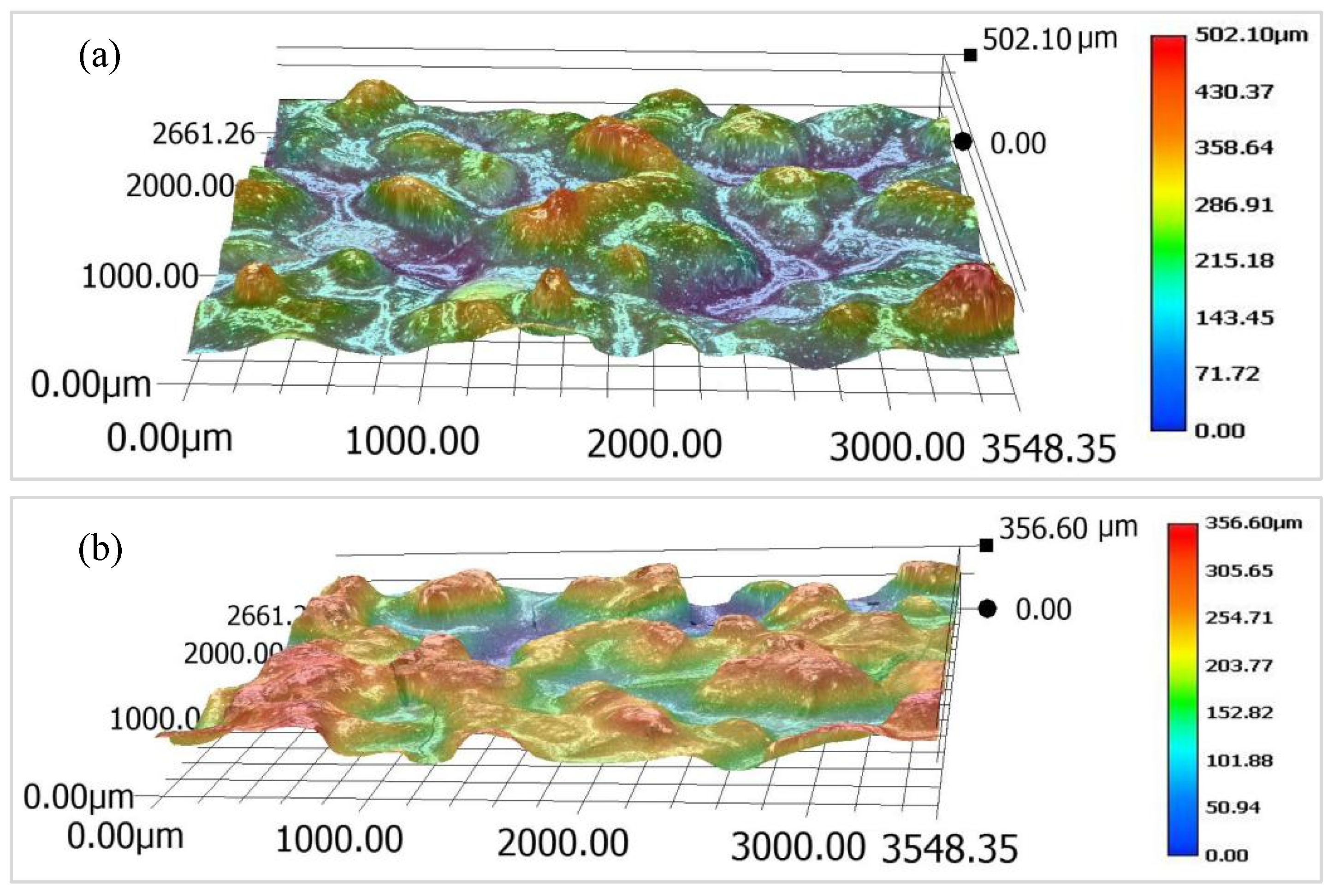

3.2. Evaluation Index of the Wear Degree of the Abrasive Belt

4. Semantic Segmentation Algorithms and Training Procedures

4.1. Image Preprocessing

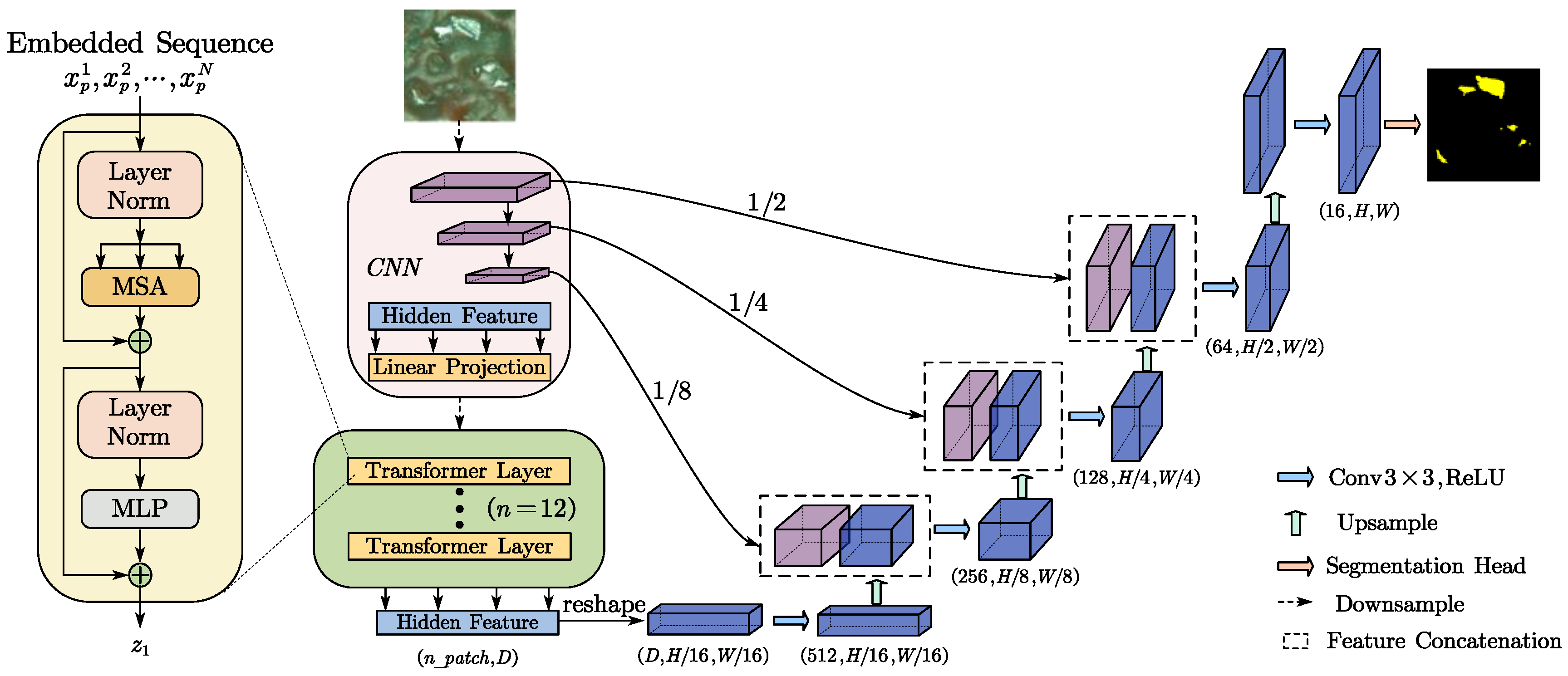

4.2. TransUNet Structure

4.3. Training Procedure

4.4. Evaluation Index

5. Results and Discussion

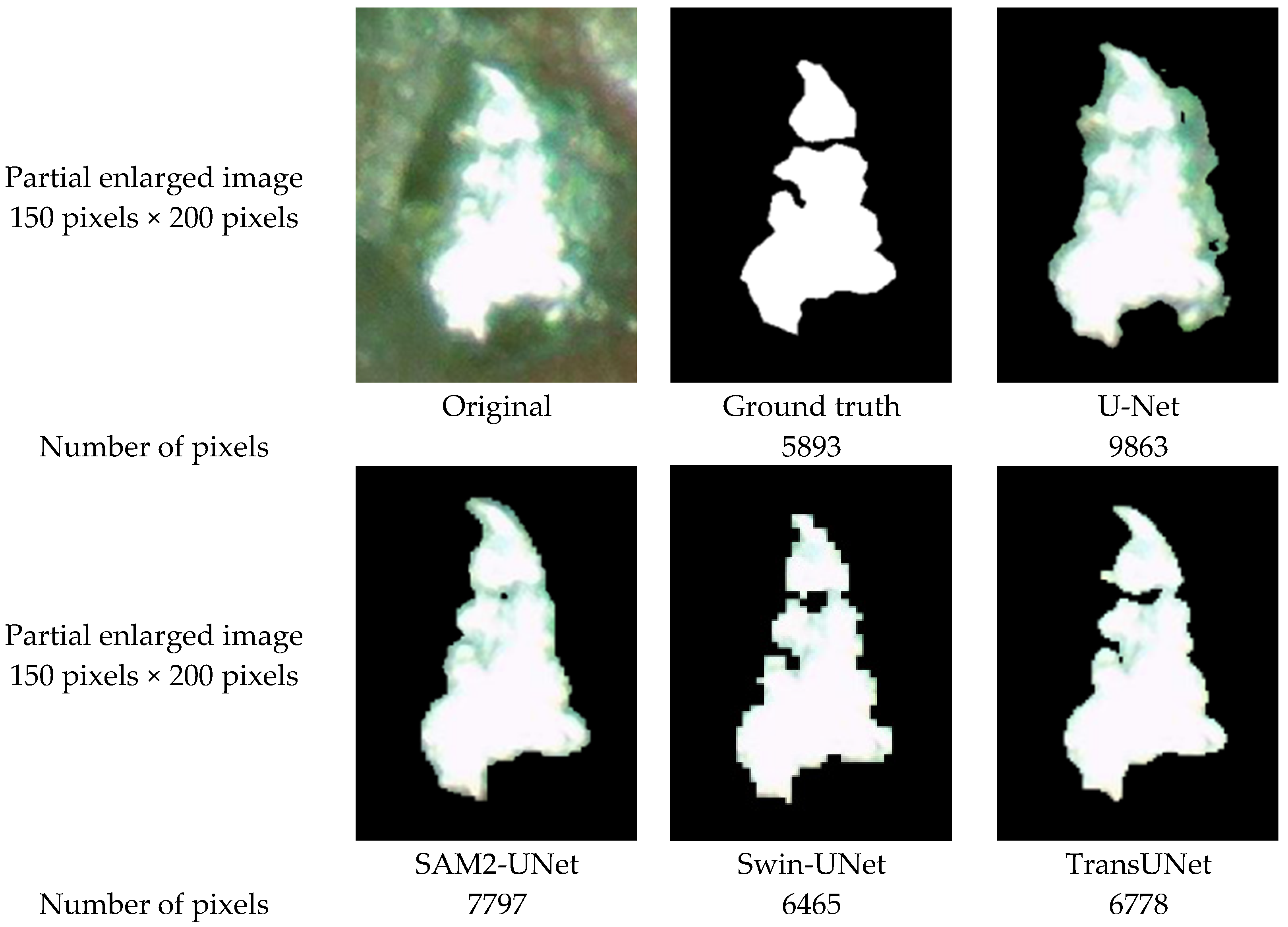

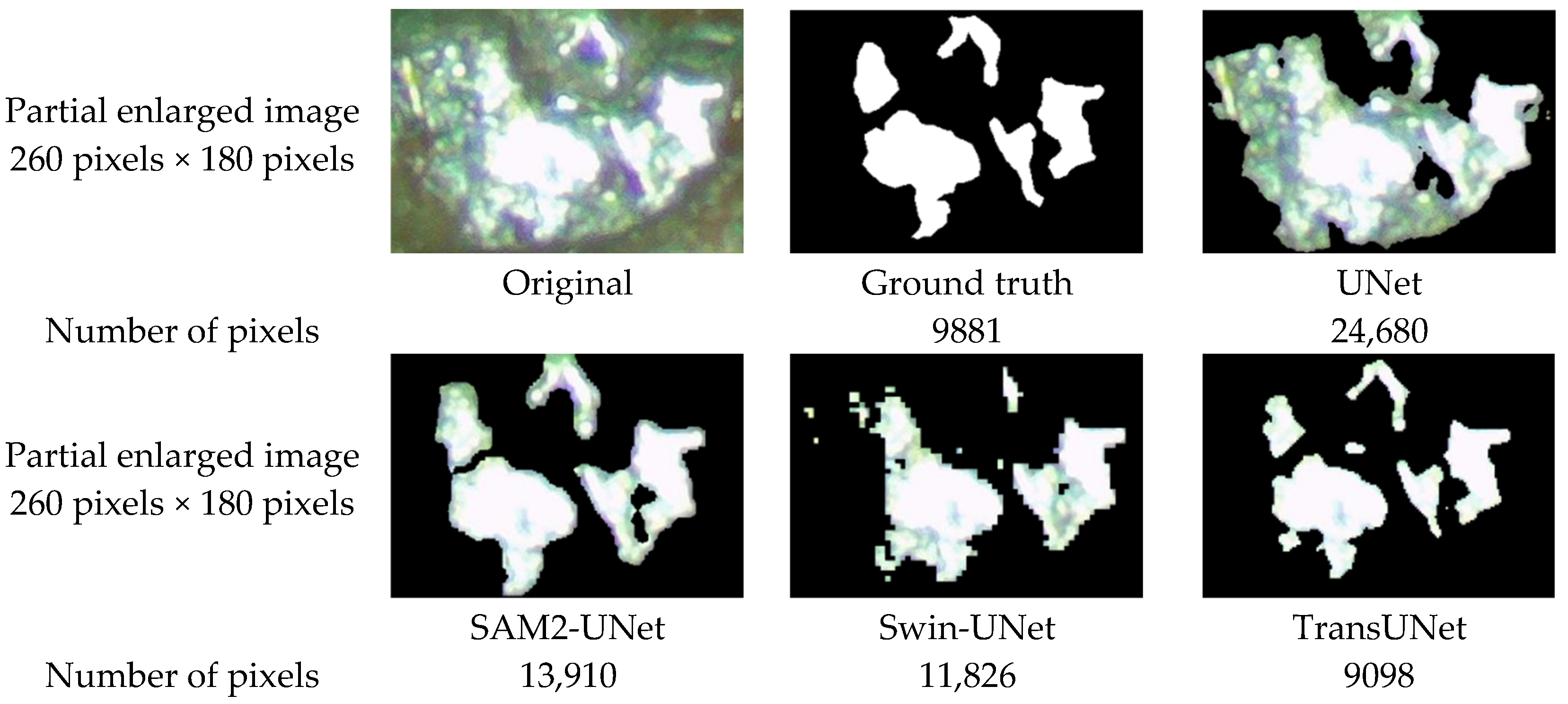

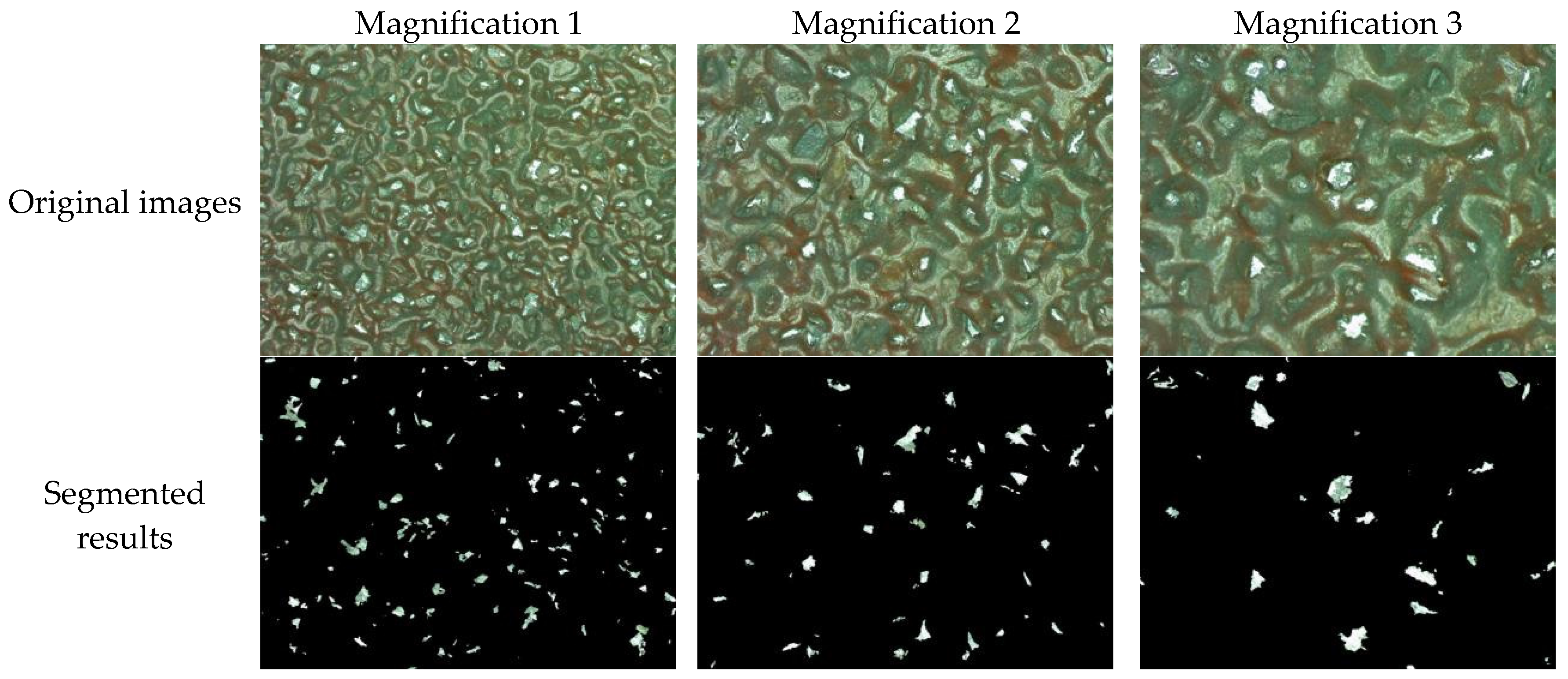

5.1. Segmentation of Blunted Abrasive Particles

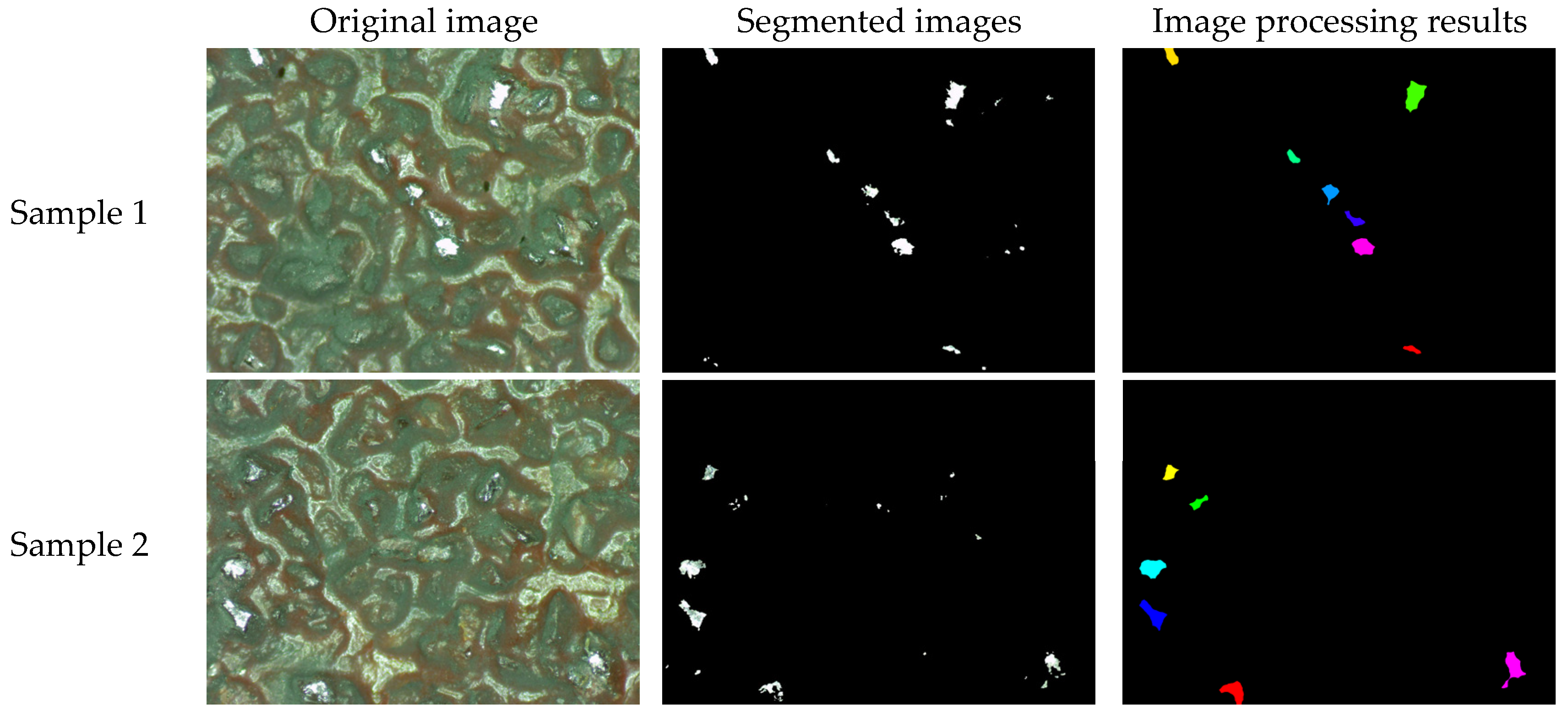

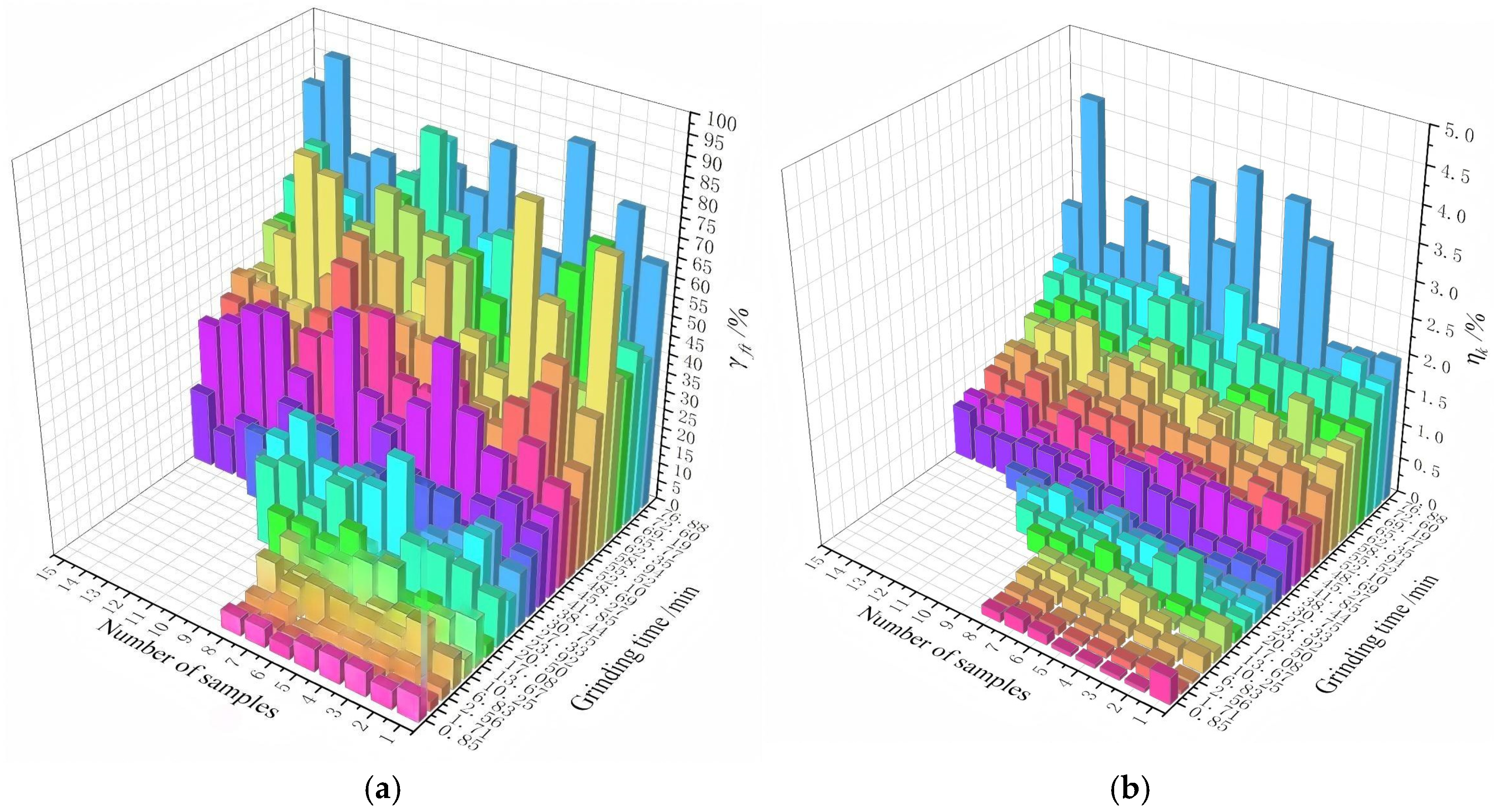

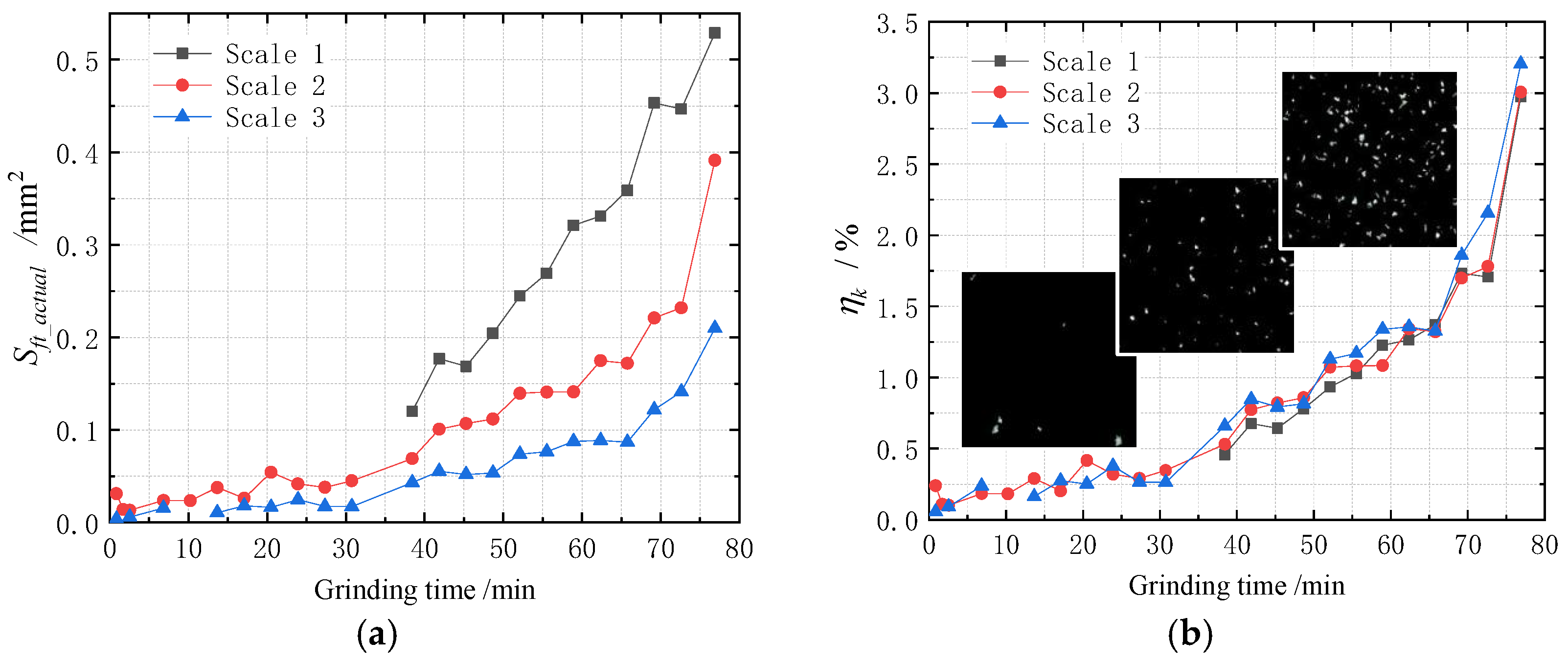

5.2. Wear Quantification and Performance Evaluation

6. Conclusions

- The trained TransUNet model is capable of pixel-level segmentation of the top surface of blunt abrasive grits with irregular and multiscale shapes. Its mIoU of prediction reaches 0.8408, which is much higher than those of the other three U-net-based networks. The number and top area of the abrasive particles participating in grinding can be accurately quantified by relying on the accurate segmentation results.

- The number of blunted abrasive grains is to some extent equal to the number of abrasive grains actually involved in grinding. As the grinding time increases, the number of blunted abrasive grits gradually increases. By the time the abrasive belt is exhausted, the percentage of the number of blunted abrasive grains is approximately 74.29%.

- Blunted wear occurs throughout the life cycle of the abrasive belt. And with the increase in grinding time, the wear rate of the blunted wear area is gradually increased in three stages. By the end of the belt’s life, the abrasive belt wear area rate is about 3.06%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, G.; Liu, X.; Song, K.; Zhang, T.; Huang, Y. Research on robotic belt grinding method of blisk for obtaining high surface integrity features with variable inclination angle force control. Robot. Comput. Manuf. 2024, 86, 102680. [Google Scholar] [CrossRef]

- Zhang, B.; Wu, S.; Wang, D.; Yang, S.; Jiang, F.; Li, C. A review of surface quality control technology for robotic abrasive belt grinding of aero-engine blades. Measurement 2023, 220, 113381. [Google Scholar] [CrossRef]

- Li, H.; Zou, L.; Gui, L.; Li, Y.; Zhang, X.; Wang, W. Effects of feed direction on material removal behavior in belt grinding of titanium alloys. J. Manuf. Process. 2023, 102, 756–764. [Google Scholar] [CrossRef]

- Chen, H.; Yang, J.; Ding, H. Robotic compliant grinding of curved parts based on a designed active force-controlled end-effector with optimized series elastic component. Robot. Comput. Manuf. 2024, 86, 102646. [Google Scholar] [CrossRef]

- Chu, Y.; Yan, S.; Yang, Z.; Xu, X.; Wang, H.; Ding, H. Grain shape-protrusion-based modeling and analysis of material removal in robotic belt grinding. J. Manuf. Process. 2024, 110, 211–223. [Google Scholar] [CrossRef]

- Ren, L.; Wang, N.; Wang, X.; Li, X.; Li, Y.; Zhang, G.; Lei, X. Modeling and analysis of material removal depth contour for curved-surfaces abrasive belt grinding. J. Mech. Work. Technol. 2023, 316, 117945. [Google Scholar] [CrossRef]

- Wang, N.; Zhang, G.; Ren, L.; Yang, Z. Analysis of abrasive grain size effect of abrasive belt on material removal performance of GCr15 bearing steel. Tribol. Int. 2022, 171, 107536. [Google Scholar] [CrossRef]

- Zhou, K.; Xiao, G.; Xu, J.; Huang, Y. Wear evolution of electroplated diamond abrasive belt and corresponding surface integrity of Inconel 718 during grinding. Tribol. Int. 2023, 177, 107972. [Google Scholar] [CrossRef]

- Xiao, G.; Zhang, Y.; Zhu, B.; Gao, H.; Huang, Y.; Zhou, K. Wear behavior of alumina abrasive belt and its effect on surface integrity of titanium alloy during conventional and creep-feed grinding. Wear 2023, 514–515, 204581. [Google Scholar] [CrossRef]

- Cheng, C.; Li, J.; Liu, Y.; Nie, M.; Wang, W. An online belt wear monitoring method for abrasive belt grinding under varying grinding parameters. J. Manuf. Process. 2020, 50, 80–89. [Google Scholar] [CrossRef]

- Li, Z.; Tang, Q.; Wang, S.; Zhang, P. A deep transfer learning method for monitoring the wear of abrasive belts with a small sample dataset. J. Manuf. Process. 2022, 74, 374–382. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Xu, J.; Song, X.; Wang, J.; Chen, X. A novel sound-based belt condition monitoring method for robotic grinding using optimally pruned extreme learning machine. J. Mech. Work. Technol. 2018, 260, 9–19. [Google Scholar] [CrossRef]

- Chen, J.; Chen, H.; Xu, J.; Wang, J.; Zhang, X.; Chen, X. Acoustic signal-based tool condition monitoring in belt grinding of nickel-based superalloys using RF classifier and MLR algorithm. Int. J. Adv. Manuf. Technol. 2018, 98, 859–872. [Google Scholar] [CrossRef]

- Pandiyan, V.; Caesarendra, W.; Tjahjowidodo, T.; Tan, H.H. In-process tool condition monitoring in compliant abrasive belt grinding process using support vector machine and genetic algorithm. J. Manuf. Process. 2018, 31, 199–213. [Google Scholar] [CrossRef]

- Khellouki, A.; Rech, J.; Zahouani, H. The effect of abrasive grain’s wear and contact conditions on surface texture in belt finishing. Wear 2007, 263, 81–87. [Google Scholar] [CrossRef]

- Wang, W.; Salvatore, F.; Rech, J.; Li, J. Comprehensive investigation on mechanisms of dry belt grinding on AISI52100 hardened steel. Tribol. Int. 2018, 121, 310–320. [Google Scholar] [CrossRef]

- Mezghani, S.; El Mansori, M. Abrasiveness properties assessment of coated abrasives for precision belt grinding. Surf. Coat. Technol. 2008, 203, 786–789. [Google Scholar] [CrossRef]

- He, Z.; Li, J.; Liu, Y.; Wang, W. Investigation of conditions leading to critical transitions between abrasive belt wear modes for rail grinding. Wear 2021, 484–485, 204048. [Google Scholar] [CrossRef]

- Wan, Q.; Zou, L.; Liu, S.; Wang, T.; Chen, S.; Huang, Y. Investigation on abrasive wear mechanism of single diamond grain in flexible scribing titanium alloy. Diam. Relat. Mater. 2021, 120, 108631. [Google Scholar] [CrossRef]

- Yu, J.B.; Xun, C.; Liang, L.; Wu, B. A machine vision method for measurement of machining tool wear. Measurement 2021, 182, 109683. [Google Scholar] [CrossRef]

- Wang, N.; Zhang, G.; Pang, W.; Ren, L.; Wang, Y. Novel monitoring method for material removal rate considering quantitative wear of abrasive belts based on LightGBM learning algorithm. Int. J. Adv. Manuf. Technol. 2021, 114, 3241–3253. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Çelik, E.; Ross, N.S.; Günay, M. Tool wear and its mechanism in turning aluminum alloys with image processing and machine learning methods. Tribol. Int. 2024, 191, 109207. [Google Scholar] [CrossRef]

- Wan, Q.; Zou, L.; Han, C.; Wang, W.; Qian, K.; Ou, J. A U-Net-based intelligent approach for belt morphology quantification and wear monitoring. J. Mech. Work. Technol. 2022, 306, 117652. [Google Scholar]

- Zhou, X.; Zhang, Y.; Ren, Z.; Mi, T.; Jiang, Z.; Yu, T.; Zhou, S. A Unet-inspired spatial-attention transformer model for segmenting gear tooth surface defects. Adv. Eng. Inform. 2024, 62, 102933. [Google Scholar]

- Ronneberger, O.; Fischer, P.; Brox, T. U-Net: Convolutional Networks for Biomedical Image Segmentation. Med. Image Comput. Comput. Assist. Interv. 2015, 9351, 234–241. [Google Scholar]

- Zhang, Q.; Zhu, H.; Lv, Y.; Jiang, D.; Li, Z.; Chauhan, S.; Vashishtha, G. An improved u-net for image segmentation of iron roughnecks on offshore oil drilling platforms. Measurement 2025, 253, 117689. [Google Scholar] [CrossRef]

- Chen, J.N.; Lu, Y.Y.; Yu, Q.H.; Luo, X.D.; Adeli, E.; Wang, Y.; Lu, L.; Yuille, A.L.; Zhou, Y.Y. TransUNet: Transformers Make Strong Encoders for Medical Image Segmentation. arXiv 2021, arXiv:2102.04306. [Google Scholar] [CrossRef]

| Items | Related Parameters |

|---|---|

| Workpiece | Material: GCr15; Hardness: 58 HRC; Size: 41 mm × 100 mm; Roughness: 1.6 Ra |

| Abrasive belt | Material: brown corundum; Type: 60 #; Length: 1.44 m; Width: 20 mm; Manufacturing process: electrostatic sand planting; |

| Contact wheel | Material: rubber; Diameter: 60 mm; Hardness: 85 Shore A; |

| Grinding parameters | Feed rate: 4 mm/s; Velocity: 32 m/s; Theoretical grinding depth: 0.3 mm; |

| Camera | Camera sensor: CMOS; Resolution: 21 million pixels; Optical dimensions: 1/2.33 inch; Image size: 4608 pixels × 3456 pixels |

| Magnifications | ×0.5 | ×1 | ×1.5 | ×2 | ×2.5 | ×3 | ×3.5 | ×4 | ×4.5 |

|---|---|---|---|---|---|---|---|---|---|

| γ (mm/pixel) | 1/458 | 1/785 | 1/1100 | 1/1540 | 1/1835 | 1/2160 | 1/2530 | 1/2930 | 1/3215 |

| Items | CPU | GPU | Memory | CUDA |

|---|---|---|---|---|

| Parameters | Inter(R) Xeon(R) Gold 6130 CPU @ 2.10 GHz | NVIDIA RTX A4000 | 30.9 G | 11.8 |

| Input Image | Activation Function | Batch-Size | Epochs | Initial Learning Rate | Optimizer | |

|---|---|---|---|---|---|---|

| UNet | 512 × 512 | ReLU | 10 | 300 | 0.01 | Adam |

| SAM2-UNet | 352 × 352 | GeLU | 12 | 300 | 0.01 | SGD |

| Swin-UNet | 224 × 224 | GeLU | 10 | 100 | 0.01 | SGD |

| TransUNet | 512 × 512 | ReLU | 2 | 100 | 0.01 | SGD |

| Evaluation Index | Sample No. | U-Net | SAM2-UNet | Swin-UNet | TransUNet |

|---|---|---|---|---|---|

| mIoU | 1 | 0.4995 | 0.8172 | 0.7529 | 0.8187 |

| 2 | 0.4180 | 0.7607 | 0.7398 | 0.8528 | |

| 3 | 0.7406 | 0.8475 | 0.7638 | 0.8874 | |

| 4 | 0.5384 | 0.8410 | 0.8231 | 0.8875 | |

| Precision | 1 | 0.5261 | 0.8187 | 0.9407 | 0.9720 |

| 2 | 0.4184 | 0.7622 | 0.7828 | 0.9325 | |

| 3 | 0.7659 | 0.8485 | 0.7866 | 0.9624 | |

| 4 | 0.5417 | 0.8443 | 0.9301 | 0.9591 | |

| Recall | 1 | 0.9081 | 0.9979 | 0.7904 | 0.8375 |

| 2 | 0.9982 | 0.9974 | 0.9309 | 0.9089 | |

| 3 | 0.9574 | 0.9986 | 0.9635 | 0.9193 | |

| 4 | 0.9885 | 0.9953 | 0.8774 | 0.9224 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, L.; Yan, W.; Wang, N.; Pang, W.; Zhang, G. A Vision-Based Approach for Precise Wear Evaluation of Abrasive Belts with Irregular Morphology in Flexible Grinding. Coatings 2025, 15, 1257. https://doi.org/10.3390/coatings15111257

Ren L, Yan W, Wang N, Pang W, Zhang G. A Vision-Based Approach for Precise Wear Evaluation of Abrasive Belts with Irregular Morphology in Flexible Grinding. Coatings. 2025; 15(11):1257. https://doi.org/10.3390/coatings15111257

Chicago/Turabian StyleRen, Lijuan, Weijian Yan, Nina Wang, Wanjing Pang, and Guangpeng Zhang. 2025. "A Vision-Based Approach for Precise Wear Evaluation of Abrasive Belts with Irregular Morphology in Flexible Grinding" Coatings 15, no. 11: 1257. https://doi.org/10.3390/coatings15111257

APA StyleRen, L., Yan, W., Wang, N., Pang, W., & Zhang, G. (2025). A Vision-Based Approach for Precise Wear Evaluation of Abrasive Belts with Irregular Morphology in Flexible Grinding. Coatings, 15(11), 1257. https://doi.org/10.3390/coatings15111257