Nearly Perfect Crystal Orientation of Nanocrystalline Bismuth Telluride Thin Films Deposited by Pressure-Gradient Sputtering and Their Thermal Transport Properties

Abstract

1. Introduction

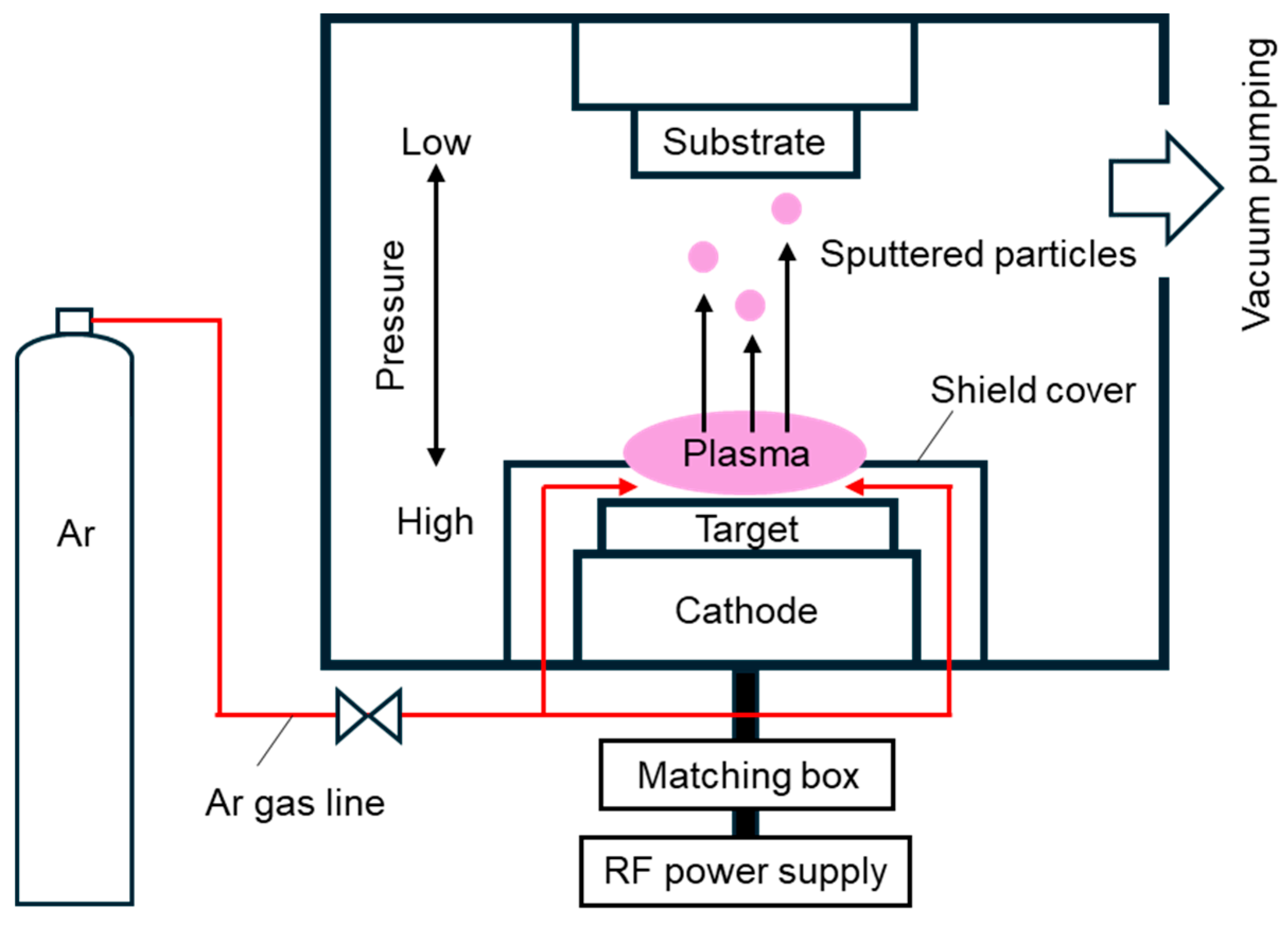

2. Experimental Procedure

3. Results and Discussion

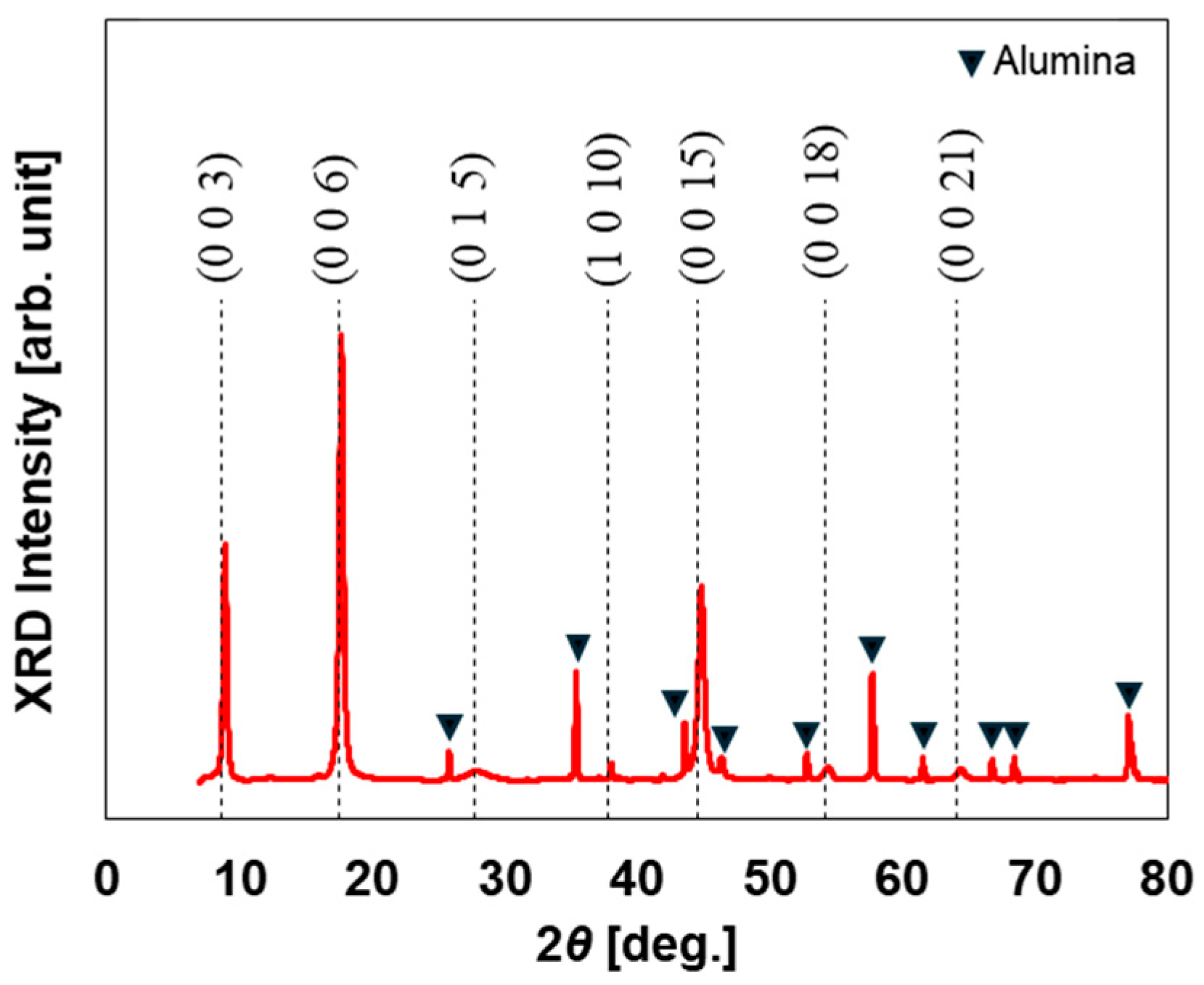

3.1. Structural Properties of Bi2Te3 Thin Films

3.2. Thermal Transport Properties of Bi2Te3 Thin Films

3.3. Thermoelectric Properties of Bi2Te3 Thin Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qin, Y.; Qin, B.; Wang, D.; Cheng, C.; Zhao, L.D. Solid-state cooling: Thermoelectrics. Energy Environ. Sci. 2022, 15, 4527–4541. [Google Scholar] [CrossRef]

- Zheng, X.F.; Liu, C.X.; Yan, Y.Y.; Wang, Q. A review of thermoelectrics research—Recent developments and potentials for sustainable and renewable energy applications. Renew. Sustain. Energy Rev. 2014, 32, 486–503. [Google Scholar] [CrossRef]

- Jia, Y.; Jiang, Q.; Sun, H.; Liu, P.; Hu, D.; Pei, Y.; Liu, W.; Crispin, X.; Fabiano, S.; Ma, U.; et al. Wearable Thermoelectric materials and devices for self-powered electronic systems. Adv. Mater. 2021, 33, 42. [Google Scholar] [CrossRef] [PubMed]

- Chiba, T.; Amma, Y.; Takashiri, M. Heat source free water floating carbon nanotube thermoelectric generators. Sci. Rep. 2021, 11, 14707. [Google Scholar] [CrossRef]

- Norimasa, O.; Tamai, R.; Nakayama, H.; Shinozaki, Y.; Takashiri, M. Self-generated temperature gradient under uniform heating in p–i–n junction carbon nanotube thermoelectric generators. Sci. Rep. 2025, 15, 15956. [Google Scholar] [CrossRef]

- Harman, T.C.; Paris, B.; Miller, S.E.; Goering, H.L. Preparation and some physical properties of Bi2Te3, Sb2Te3, and As2Te3. J. Phys. Chem. Solids 1957, 2, 181–190. [Google Scholar] [CrossRef]

- Satterthwaite, C.B.; Ure, R.W., Jr. Electrical and thermal properties of Bi2Te3. Phys. Rev. 1957, 108, 1164. [Google Scholar] [CrossRef]

- Wright, D.A. Thermoelectric properties of bismuth telluride and its alloys. Nature 1958, 181, 834. [Google Scholar] [CrossRef]

- Lachance, M.H.; Gardner, E.E. Thermoelectric properties of the Bi2Te3-Bi2Se3 isomorphic compound system. Adv. Energy Convers. 1961, 1, 133–138. [Google Scholar] [CrossRef]

- Testardi, L.R.; Bierly, J.N., Jr.; Donahoe, F.J. Transport properties of p-type Bi2Te3-Sb2Te3 alloys in the temperature range 80–370°K. J. Phys. Chem. Solids. 1962, 23, 1209–1217. [Google Scholar] [CrossRef]

- Venkatasubramanian, R.; Siivola, E.; Colpitts, T.; O’Quinn, B. Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 2001, 413, 597–602. [Google Scholar] [CrossRef]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 2008, 320, 634–638. [Google Scholar] [CrossRef]

- Wei, J.; Yang, L.; Ma, Z.; Song, P.; Zhang, M.; Ma, J.; Yang, F.; Wang, X. Review of current high-ZT thermoelectric materials. Asian J. Mater. Sci. 2020, 55, 12642–12704. [Google Scholar] [CrossRef]

- Kato, K.; Hagino, H.; Miyazaki, K. Fabrication of bismuth telluride thermoelectric films containing conductive polymers using a printing method. J. Electron. Mater. 2013, 42, 1313–1318. [Google Scholar] [CrossRef]

- Chiba, T.; Yabuki, H.; Takashiri, M. High thermoelectric performance of flexible nanocomposite films based on Bi2Te3 nanoplates and carbon nanotubes selected using ultracentrifugation. Sci. Rep. 2023, 13, 3010. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, X.; Pei, Y. Manipulation of phonon transport in thermoelectrics. Adv. Mater. 2018, 30, 1705617. [Google Scholar] [CrossRef] [PubMed]

- Kim, W. Strategies for engineering phonon transport in thermoelectrics. J. Mater. Chem. C. 2015, 3, 10336–10348. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Z.G.; Hong, M.; Han, G.; Zou, J. Enhanced thermoelectric performance of nanostructured Bi2Te3 through significant phonon scattering. ACS Appl. Mater. Interfaces 2015, 7, 23694–23699. [Google Scholar] [CrossRef]

- Li, J.F.; Liu, W.S.; Zhao, L.D.; Zhou, M. High-performance nanostructured thermoelectric materials. NPG Asia Mater. 2010, 2, 152–158. [Google Scholar] [CrossRef]

- Liu, Z.; Mao, J.; Liu, T.H.; Chen, G.; Ren, Z. Nano-microstructural control of phonon engineering for thermoelectric energy harvesting. MRS Bull. 2018, 43, 181–186. [Google Scholar] [CrossRef]

- Zeng, T.; Chen, G. Phonon heat conduction in thin films: Impacts of thermal boundary resistance and internal heat generation. ASME J. Heat Transfer. 2001, 123, 340–347. [Google Scholar] [CrossRef]

- Kashiwagi, M.; Hirata, S.; Harada, K.; Zheng, Y.; Miyazaki, K.; Yahiro, M.; Adachi, C. Enhanced figure of merit of a porous thin film of bismuth antimony telluride. Appl. Phys. Lett. 2011, 98, 023114. [Google Scholar] [CrossRef]

- Choi, H.; Jeong, K.; Chae, J.; Park, H.; Baeck, J.; Kim, T.H.; Song, J.Y.; Park, J.; Jeong, K.H.; Cho, M.H. Enhancement in thermoelectric properties of Te-embedded Bi2Te3 by preferential phonon scattering in heterostructure interface. Nano Energy 2018, 47, 374–384. [Google Scholar] [CrossRef]

- Kato, K.; Hatasako, Y.; Kashiwagi, M.; Hagino, H.; Adachi, C.; Miyazaki, K. Fabrication of a flexible bismuth telluride power generation module using microporous polyimide films as substrates. J. Electron. Mater. 2014, 6, 1733–1739. [Google Scholar] [CrossRef]

- Amma, Y.; Miura, K.; Nagata, S.; Nishi, T.; Miyake, S.; Miyazaki, K.; Takashiri, M. Ultra-long air-stability of n-type carbon nanotube films with low thermal conductivity and all-carbon thermoelectric generators. Sci. Rep. 2022, 12, 21603. [Google Scholar] [CrossRef]

- Yamamoto, H.; Amezawa, T.; Okano, Y.; Hoshino, K.; Ochiai, S.; Sunaga, K.; Miyake, S.; Takashiri, M. High thermal durability and thermoelectric performance with ultra-low thermal conductivity in n-type single-walled carbon nanotube films by controlling dopant concentration with cationic surfactant. Appl. Phys. Lett. 2025, 126, 063902. [Google Scholar] [CrossRef]

- Minnich, A.J. Advances in the measurement and computation of thermal phonon transport properties. J. Phys. Condens. Matter. 2015, 27, 5. [Google Scholar] [CrossRef]

- Gerboth, M.D.; Walker, D.G. Effects of acoustic softening on thermal conductivity beyond group velocity. J. Appl. Phys. 2020, 127, 204302. [Google Scholar] [CrossRef]

- Taheri, A.; Singh, C.V. Anisotropic phonon thermal transport in nitrophosphorene monolayer. Phys. Rev. Mater. 2021, 5, 034009. [Google Scholar] [CrossRef]

- Minnich, A.J.; Johnson, J.A.; Schmidt, A.J.; Esfarjani, K.; Dresselhaus, M.S.; Nelson, K.A.; Chen, G. Thermal conductivity spectroscopy technique to measure phonon mean free paths. Phys. Rev. Lett. 2011, 107, 095901. [Google Scholar] [CrossRef]

- Anufriev, R.; Ordonez-Miranda, J.; Nomura, M. Measurement of the phonon mean free path spectrum in silicon membranes at different temperatures using arrays of nanoslits. Phys. Rev. B 2020, 101, 115301. [Google Scholar] [CrossRef]

- Cahill, D.G.; Fischer, H.E.; Klitsner, T.; Swartz, E.T.; Pohl, R.O. Thermal conductivity of thin films: Measurements and understanding. J. Vac. Sci. Technol. 1989, 7, 1259–1266. [Google Scholar] [CrossRef]

- Khumtong, T.; Theekhasuk, N.; Somdock, N.; Pluengphon, P.; Inceesungvorn, B.; Sakulkalavek, A.; Sakdanuphab, R. Enhancing thermoelectric properties of Bi2Te3 film via CuI doping: Sputtering and solid iodination methods verified by ab initio calculation. Ceram. Int. 2024, 50, 10355–10362. [Google Scholar] [CrossRef]

- Nagata, S.; Nishi, T.; Miyake, S.; Azuma, N.; Hatori, K.; Awano, T.; Ohta, H. Development of novel thermal diffusivity analysis by spot periodic heating and infrared radiation thermometer method. Materials 2020, 13, 4848. [Google Scholar] [CrossRef] [PubMed]

- Shen, B.; Zeng, Z.; Lin, C.; Hu, Z. Thermal conductivity measurement of amorphous Si/SiGe multilayer films by 3 omega method. Int. J. Therm. Sci. 2013, 66, 19–23. [Google Scholar] [CrossRef]

- Lamuta, C.; Campi, D.; Cupolillo, A.; Aliev, Z.S.; Babanly, M.B.; Chulkov, E.V.; Politano, A.; Pagnotta, L. Mechanical properties of Bi2Te3 topological insulator investigated by density functional theory and nanoindentation. Scr. Mater. 2016, 121, 50–55. [Google Scholar] [CrossRef]

- Jian, S.R.; Tasi, C.-H.; Huang, S.-Y.; Luo, C.-W. Nanoindentation pop-in effects of Bi2Te3 thermoelectric thin films. J. Alloys Compd. 2015, 622, 601–605. [Google Scholar] [CrossRef]

- Tasi, C.H.; Tseng, Y.C.; Jian, S.R.; Liao, Y.-Y.; Lin, C.-M.; Yang, P.-F.; Chen, D.-L.; Chen, H.-J.; Luo, C.-W.; Juang, J.-Y. Nanomechanical properties of Bi2Te3 thin films by nanoindentation. J. Alloys Compd. 2015, 619, 834–838. [Google Scholar] [CrossRef]

- Bourgault, D.; Garampon, C.G.; Caillault, N.; Carbone, L.; Aymami, J.A. Thermoelectric properties of n-type Bi2Te2.7Se0.3 and p-type Bi0.5Sb1.5Te3 thin films deposited by direct current magnetron sputtering. Thin Solid Film. 2008, 516, 8579–8583. [Google Scholar] [CrossRef]

- Norimasa, O.; Chiba, T.; Hase, M.; Komori, T.; Takashiri, M. Improvement of thermoelectric properties of flexible Bi2Te3 thin films in bent states during sputtering deposition and post-thermal annealing. J. Alloys Compd. 2022, 898, 162889. [Google Scholar] [CrossRef]

- Somdock, N.; Kianwimol, S.; Harnwunggmoung, A.; Sakulkalavek, A.; Sakdanuphab, R. Simultaneous stoichiometric composition and highly (00l) orientation of flexible Bi2Te3thin films via optimising the DC magnetron sputter-deposition process. J. Alloys Compd. 2018, 773, 78–85. [Google Scholar] [CrossRef]

- Uchino, M.; Kato, K.; Hagino, H.; Miyazaki, K. Fabrication by coaxial-type vacuum arc evaporation method and characterization of bismuth telluride thin films. J. Electron. Mater. 2012, 42, 1814–1819. [Google Scholar] [CrossRef]

- Singh, S.; Singh, J.; Kaushal, J.; Tripathi, S.K. Effects of annealing on the thermoelectric properties of nanocrystalline Bi1.2Sb0.8Te3 thin films prepared by thermal evaporation. Appl. Phys. A 2019, 125, 144. [Google Scholar] [CrossRef]

- Kuleshova, J.; Koukharenko, E.; Li, X.; Frety, N.; Nandhakumar, I.S.; Tudor, J.; Beeby, S.P.; White, N.M. Optimization of the electrodeposition process of high-performance bismuth antimony telluride compounds for thermoelectric applications. Langmuir 2010, 26, 16980–16985. [Google Scholar] [CrossRef] [PubMed]

- Su, N.; Guo, S.; Li, F.; Li, B. Electrodeposition of Bi-Te thin films on silicon wafer and micro-column arrays on microporous glass template. Nanomaterials 2020, 10, 431. [Google Scholar] [CrossRef]

- Terai, Y.; Haraguchi, K.; Ichinose, R.; Oota, R.; Yonezawa, K. Structural and piezoelectric properties of AlN thin films grown by pressure gradient sputtering. Jpn. J. Appl. Phys. 2023, 62, SA1003. [Google Scholar] [CrossRef]

- Aono, M.; Terauchi, M.; Sato, Y.K.; Morita, K.; Inoue, T.; Kanda, K.; Yonezawa, K. Deposition of amorphous carbon nitride thin films using pressure-gradient RF magnetron sputtering and their chemical bonding structures. Appl. Surf. Sci. 2023, 635, 157677. [Google Scholar] [CrossRef]

- Abe, Y.; Nishimura, T.; Yamada, A. Impacts of O2/(O2+Ar) flow ratio on the properties of Li-doped NiO thin films fabricated by pressure-gradient radiofrequency magnetron sputtering. Phys. Status Solidi A 2025, 222, 2400497. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Hase, M.; Tanisawa, D.; Kohashi, K.; Kamemura, R.; Miyake, S.; Takashiri, M. Determination of Seebeck coefficient originating from phonon drag effect using Si single crystals at different carrier densities. Sci. Rep. 2023, 13, 13463. [Google Scholar] [CrossRef] [PubMed]

- Hase, M.; Kato, H.; Murotani, H.; Takashiri, M. Determining phonon transport properties of bismuth telluride thin films with extremely small grain size using nanoindentation and 3ω method. Appl. Phys. Express 2023, 16, 015004. [Google Scholar] [CrossRef]

- Seki, Y.; Nagata, K.; Takashiri, T. Facile preparation of air-stable n-type thermoelectric single-wall carbon nanotube films with anionic surfactants. Sci. Rep. 2020, 10, 8104. [Google Scholar] [CrossRef]

- Kudo, S.; Tanaka, S.; Miyazaki, K.; Nishi, Y.; Takashiri, M. Anisotropic analysis of nanocrystalline bismuth telluride thin films treated by homogeneous electron beam irradiation. Mater. Trans. 2017, 58, 513–519. [Google Scholar] [CrossRef]

- Carel, R.; Thompson, C.V.; Frost, H.J. Computer simulation of strain energy effects vs surface and interface energy effects on grain growth in thin films. Acta Mater 1996, 44, 2479–2494. [Google Scholar] [CrossRef]

- Vincent, G. Experiments and kinetic modeling of the ion energy distribution function at the substrate surface during magnetron sputtering of silver targets in radio frequency argon plasmas. J. Vac. Sci. Technol. 2019, 37, 021301. [Google Scholar]

- JCPDS File No. 15-0863; Joint Committee on Powder Diffraction Standards. ASTM: West Conshohocken, PA, USA, 2021.

- He, K.; Chen, N.; Wang, C.; Wei, L.; Chen, J. Method for determining crystal grain size by x-ray diffraction. Cryst. Res. Technol. 2018, 53, 1700157. [Google Scholar] [CrossRef]

- Lotgering, F.K. Topotactical reactions with ferrimagnetic oxides having hexagonal crystal structures—I. J. Inorg. Nucl. Chem. 1959, 9, 113–123. [Google Scholar] [CrossRef]

- Furushima, R.; Tanaka, S.; Kato, Z.; Uematsu, K. Orientation distribution–Lotgering factor relationship in a polycrystalline material—As an example of bismuth titanate prepared by a magnetic field. J. Ceram. Soc. Jpn. 2010, 118, 921–926. [Google Scholar] [CrossRef]

- Chernov, A.A. Modern Crystallography III; Springer: Berlin, Germany, 1984; pp. 104–158. [Google Scholar]

- Fu, J.; Huang, J.; Bernard, F. Electronic structure, elastic and optical properties of Bi2Te3/Sb2Te3 thermoelectric composites in the periodic-superlattice thin films. Compos. Commun. 2021, 28, 100917. [Google Scholar] [CrossRef]

- Nolas, G.S.; Morelli, D.T.; Tritt, T.M. Skutterudites: A phonon glass-electron crystal approach to advanced thermoelectric energy conversion applications. Annu. Rev. Mater. Sci. 1999, 29, 89. [Google Scholar] [CrossRef]

- Haynes, W.M. CRC Handbook of Chemistry and Physics, 95th ed.; CRC Press: Boca Raton, FL, USA, 2014; pp. 4–52. [Google Scholar]

- Borca-Tasciuc, T.; Kumar, A.R.; Chen, G. Data reduction in 3ω method for thin-film thermal conductivity determination. Rev. Sci. Instrum. 2001, 72, 2139. [Google Scholar] [CrossRef]

- Jaffe, G.R.; Smith, K.J.; Watanabe, K.; Taniguchi, T.; Lagally, M.G.; Eriksson, M.A.; Brar, V.W. Thickness-dependent cross-plane thermal conductivity measurements of exfoliated hexagonal boron nitride. ACS Appl. Mater. Interfaces 2023, 15, 12545–12550. [Google Scholar] [CrossRef] [PubMed]

- Wilson, R.B.; Cahill, D.G. Experimental validation of the interfacial form of the Wiedemann-Franz law. Phys. Rev. Lett. 2021, 108, 255901. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-S.; Zachary, M.G.; Tang, Y.; Wang, H.; Snyder, G.S. Characterization of Lorenz number with Seebeck coefficient measurement. APL Mater. 2015, 3, 041506. [Google Scholar] [CrossRef]

- Putatunda, A.; Singh, D.J. Lorenz number in relation to estimates based on the Seebeck coefficient. Mater. Today Phys. 2019, 8, 49–55. [Google Scholar] [CrossRef]

- Stordeur, M.; Kühnberger, W. Nichtparabolizität des valenzbandes von Bi2Te3 gefolgert aus transporteigenschaften. Phys. Status Solidi 1975, 69, 377. [Google Scholar] [CrossRef]

- Nolas, G.S.; Sharp, J.; Goldsmid, H.J. Thermoelectrics; Springer: New York, NY, USA, 2001; pp. 111–131. [Google Scholar]

- Arisaka, T.; Otsuka, M.; Hasegawa, Y. Measurement of thermal conductivity and specific heat by impedance spectroscopy of Bi2Te3 thermoelectric element. Rev. Sci. Instrum. 2019, 90, 046104. [Google Scholar] [CrossRef] [PubMed]

- Scherrer, H.; Scherrer, S. Thermoelectric materials. In CRC Handbook of Thermoelectrics; Rowe, D.M., Ed.; CRC Press: Boca Raton, FL, USA, 1995; Section D; pp. 211–440. [Google Scholar]

| Thickness [μm] | Atomic Composition | ||

|---|---|---|---|

| Bismuth [at.%] | Tellurium [at.%] | ||

| Bi2Te3 thin film | 0.6 | 37.8 | 62.2 |

| Crystallite Size [nm] | F Value | |

|---|---|---|

| Bi2Te3 thin film | 23.0 | 0.97 |

| Elastic Modulus [GPa] | Sound Velocity [m/s] | ||||

|---|---|---|---|---|---|

| Young’s | Shear | Longitudinal | Transverse | Average | |

| Bi2Te3 thin film | 67.0 | 27.0 | 2920 | 1862 | 2046 |

| Thermal Conductivity [W/(m·K)] | ||||||

|---|---|---|---|---|---|---|

| κtot (⊥) | κtot (//) | κele (⊥) | κele (//) | κlat (⊥) | κlat (//) | |

| Bi2Te3 thin film | 0.31 | 0.66 | 7.4 × 10−4 | 2.0 × 10−3 | 0.31 | 0.66 |

| vave [m/s] | κlat (//) [W/(m·K)] | Λ [nm] | |

|---|---|---|---|

| Bi2Te3 thin film | 2046 | 0.66 | 0.37 |

| Direction | S [μV/K] | σ [S/cm] | κtot [W/(m·K)] | ZT at 300 K | |

|---|---|---|---|---|---|

| Bi2Te3 thin film | In-plane | −106 | 254 | 0.66 | 1.3 × 10−1 |

| Cross-plane | −106 * | 94 | 0.31 | 1.0 × 10−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takizawa, T.; Kaneko, K.; Shinozaki, Y.; Kaneko, T.; Murotani, H.; Takashiri, M. Nearly Perfect Crystal Orientation of Nanocrystalline Bismuth Telluride Thin Films Deposited by Pressure-Gradient Sputtering and Their Thermal Transport Properties. Coatings 2025, 15, 1234. https://doi.org/10.3390/coatings15111234

Takizawa T, Kaneko K, Shinozaki Y, Kaneko T, Murotani H, Takashiri M. Nearly Perfect Crystal Orientation of Nanocrystalline Bismuth Telluride Thin Films Deposited by Pressure-Gradient Sputtering and Their Thermal Transport Properties. Coatings. 2025; 15(11):1234. https://doi.org/10.3390/coatings15111234

Chicago/Turabian StyleTakizawa, Tetsuya, Keisuke Kaneko, Yoshiyuki Shinozaki, Takumi Kaneko, Hiroshi Murotani, and Masayuki Takashiri. 2025. "Nearly Perfect Crystal Orientation of Nanocrystalline Bismuth Telluride Thin Films Deposited by Pressure-Gradient Sputtering and Their Thermal Transport Properties" Coatings 15, no. 11: 1234. https://doi.org/10.3390/coatings15111234

APA StyleTakizawa, T., Kaneko, K., Shinozaki, Y., Kaneko, T., Murotani, H., & Takashiri, M. (2025). Nearly Perfect Crystal Orientation of Nanocrystalline Bismuth Telluride Thin Films Deposited by Pressure-Gradient Sputtering and Their Thermal Transport Properties. Coatings, 15(11), 1234. https://doi.org/10.3390/coatings15111234