Cutting Performance of TiN/DLC-Coated Cemented Carbide Tool in Dry Cutting of Laser-Clad Cr-Ni-Based Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of Coating

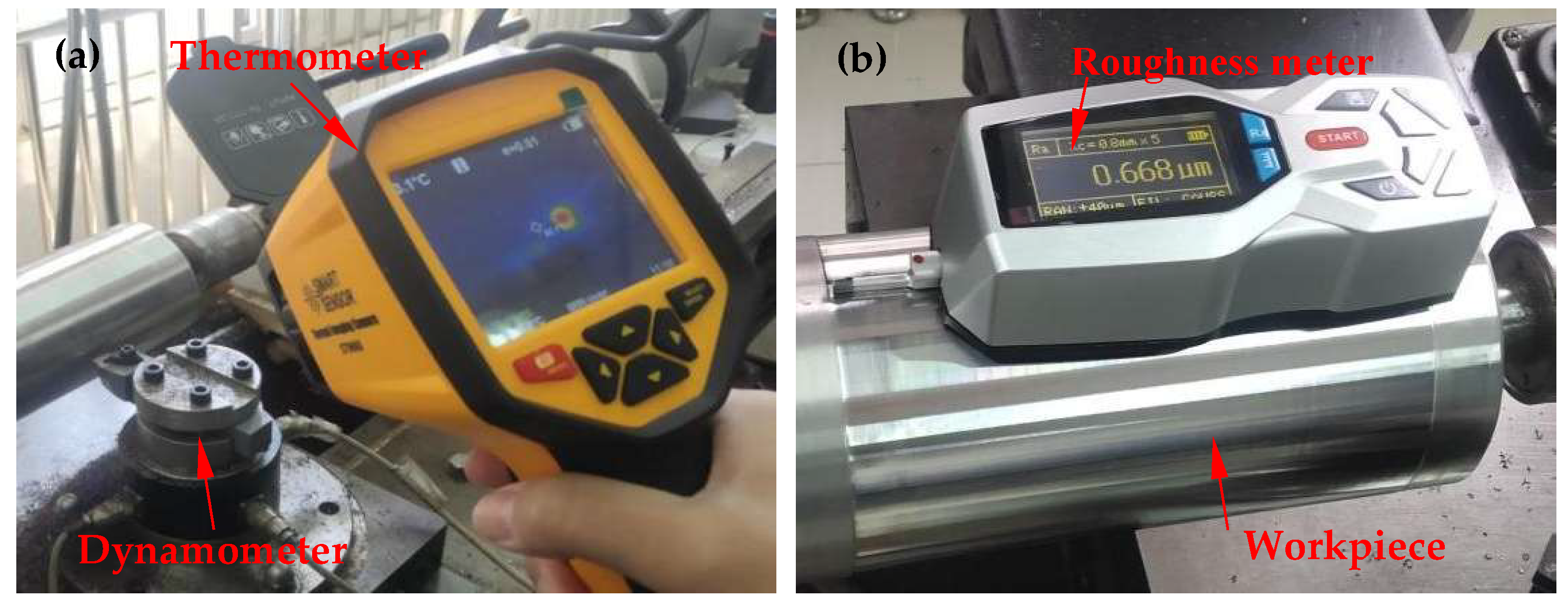

2.2. Testing and Characterization

3. Results and Discussion

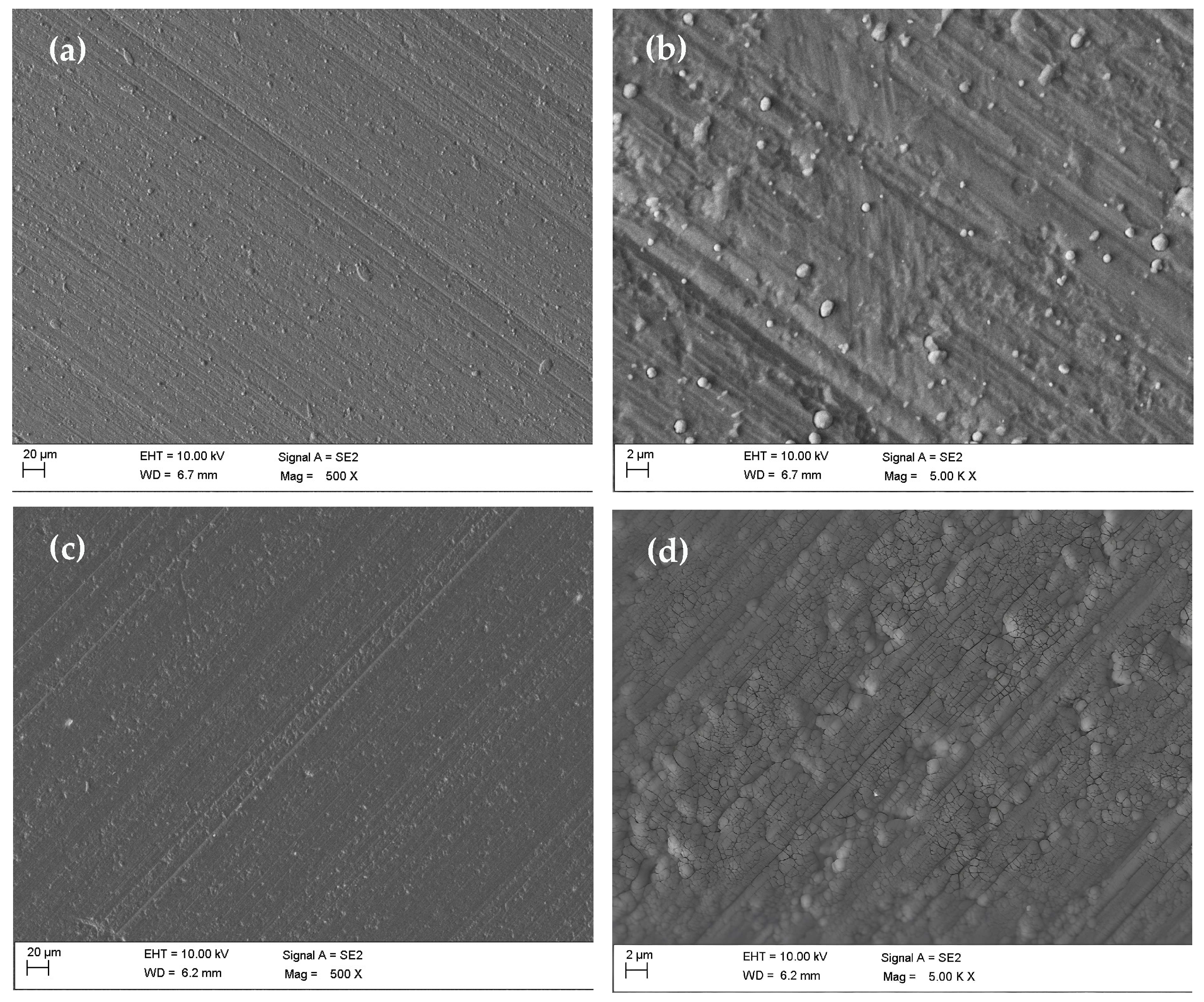

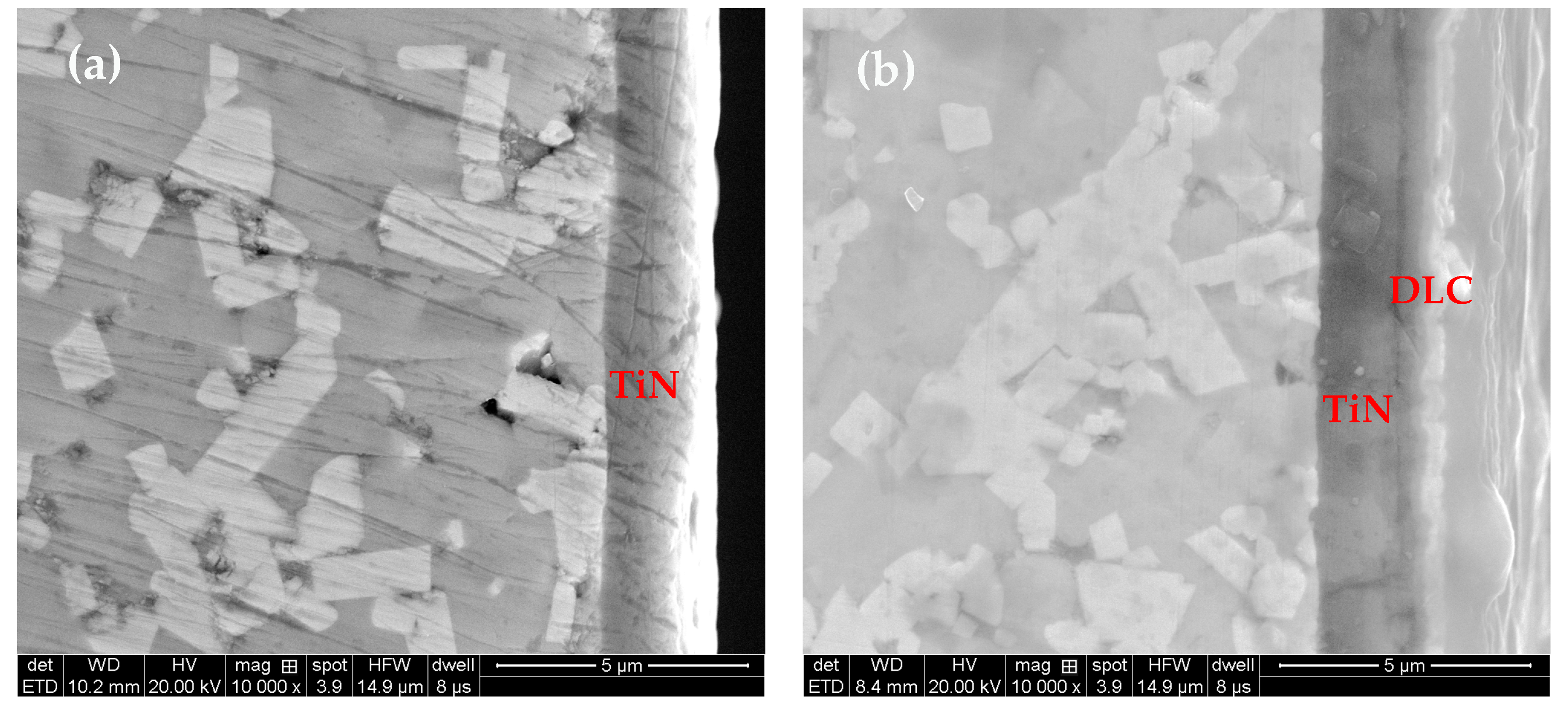

3.1. Properties of Coating

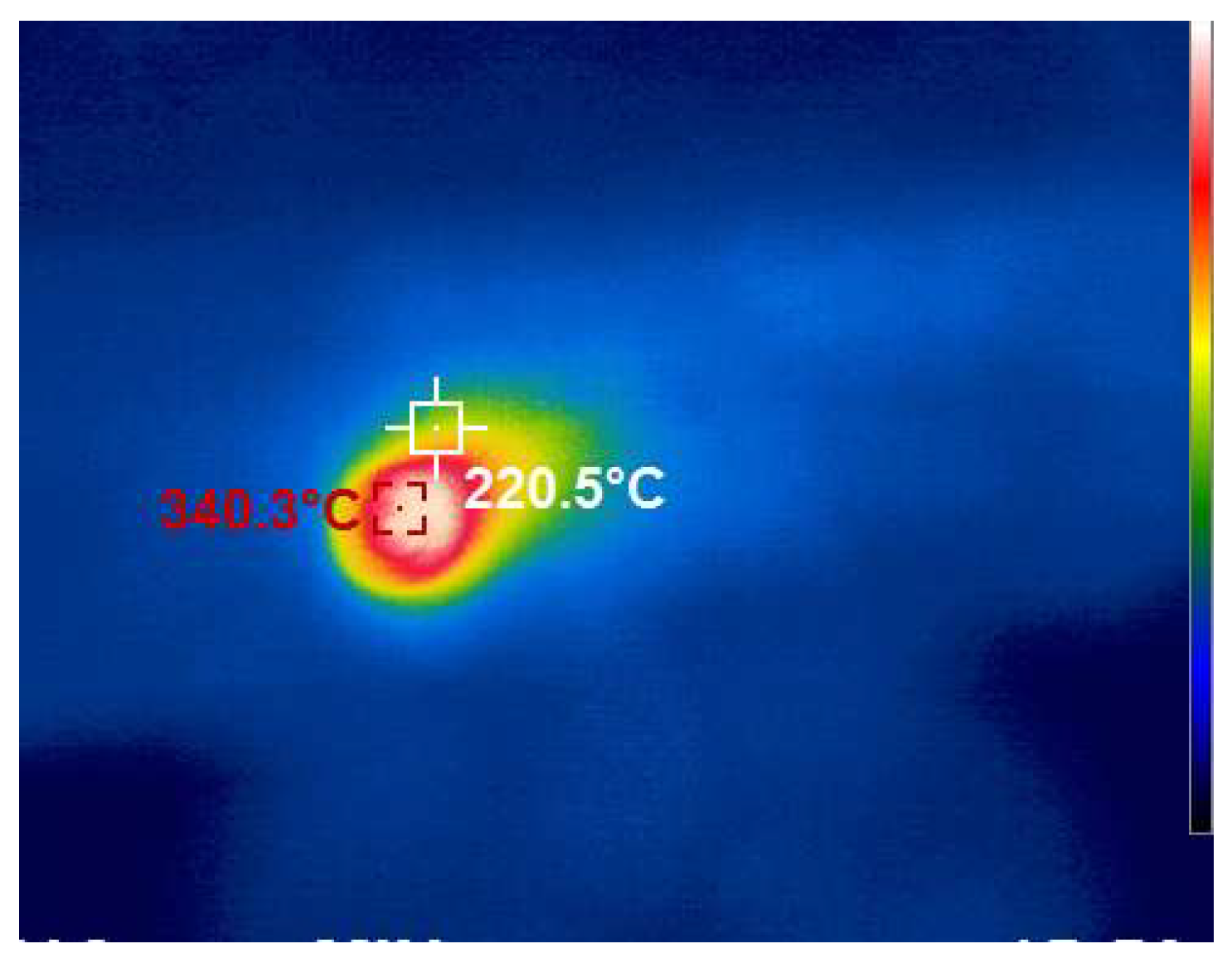

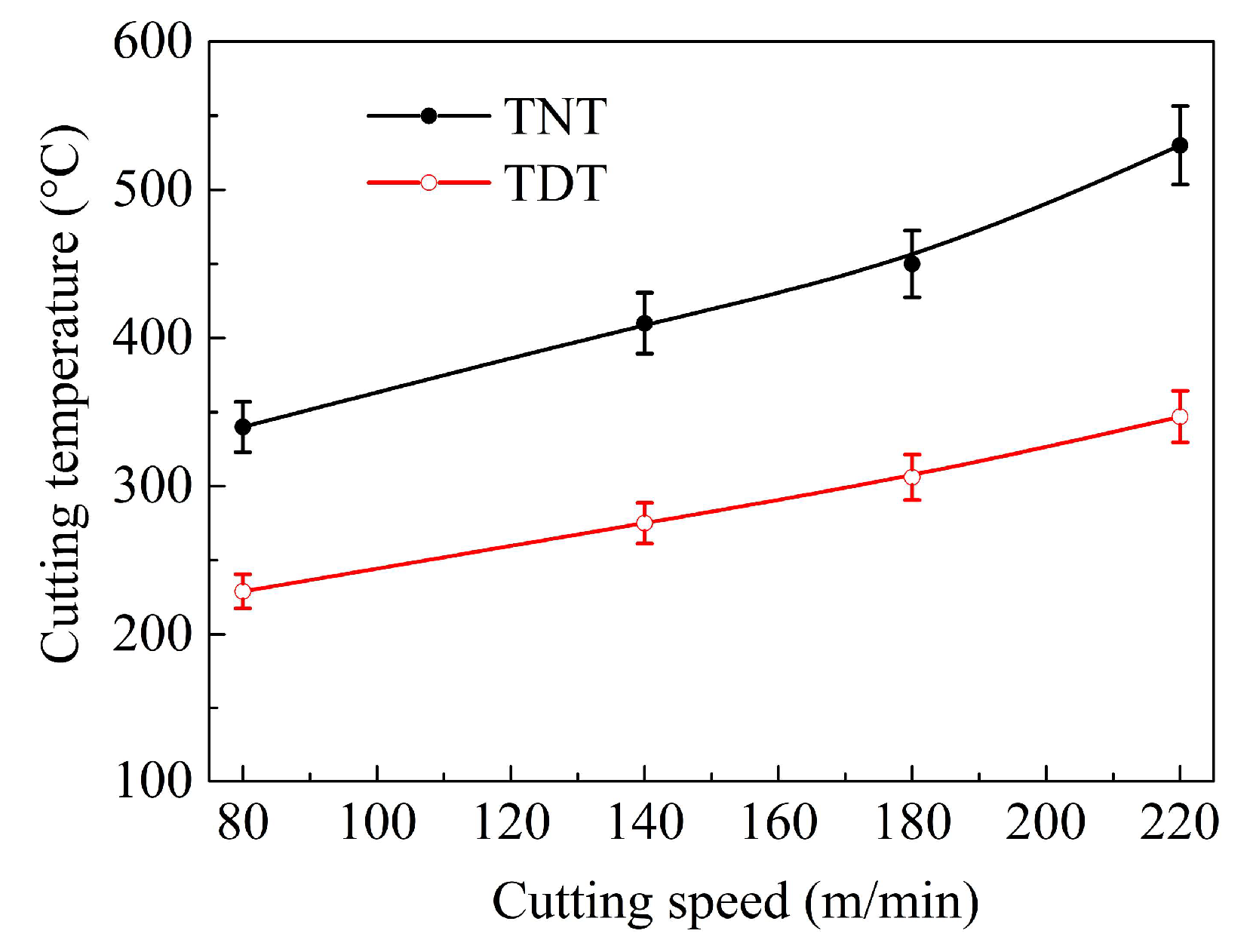

3.2. Cutting Temperature

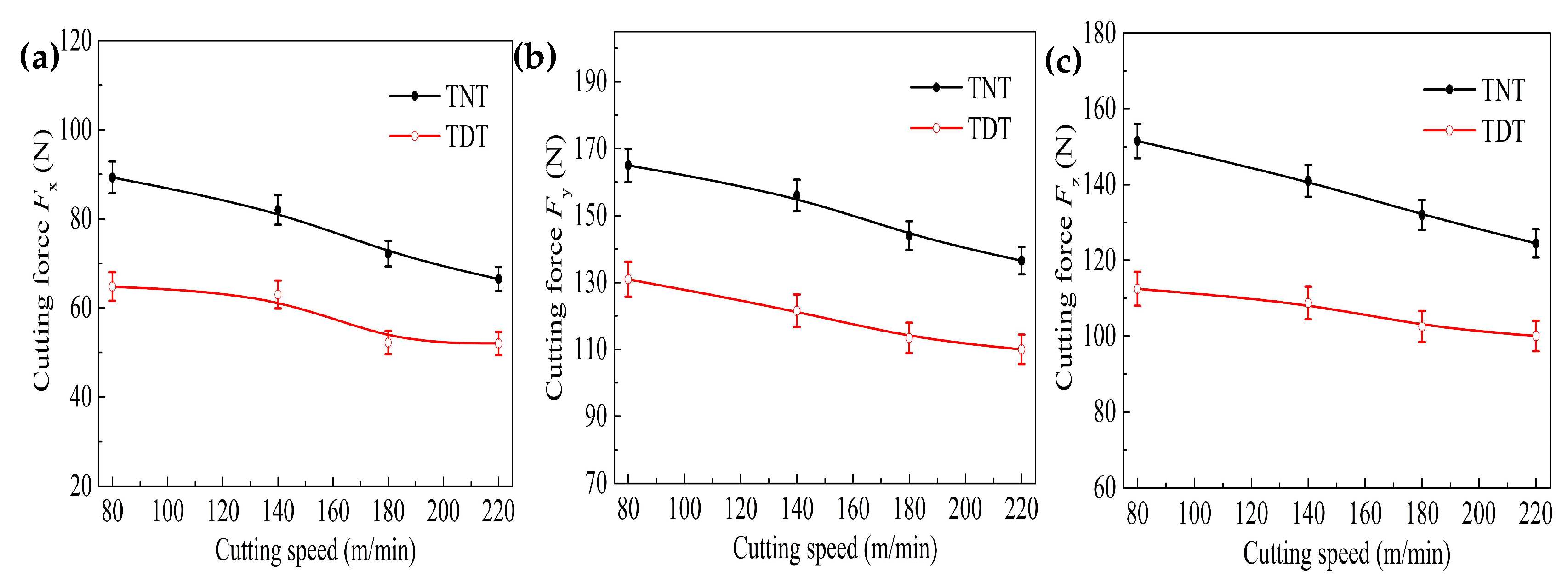

3.3. Cutting Forces

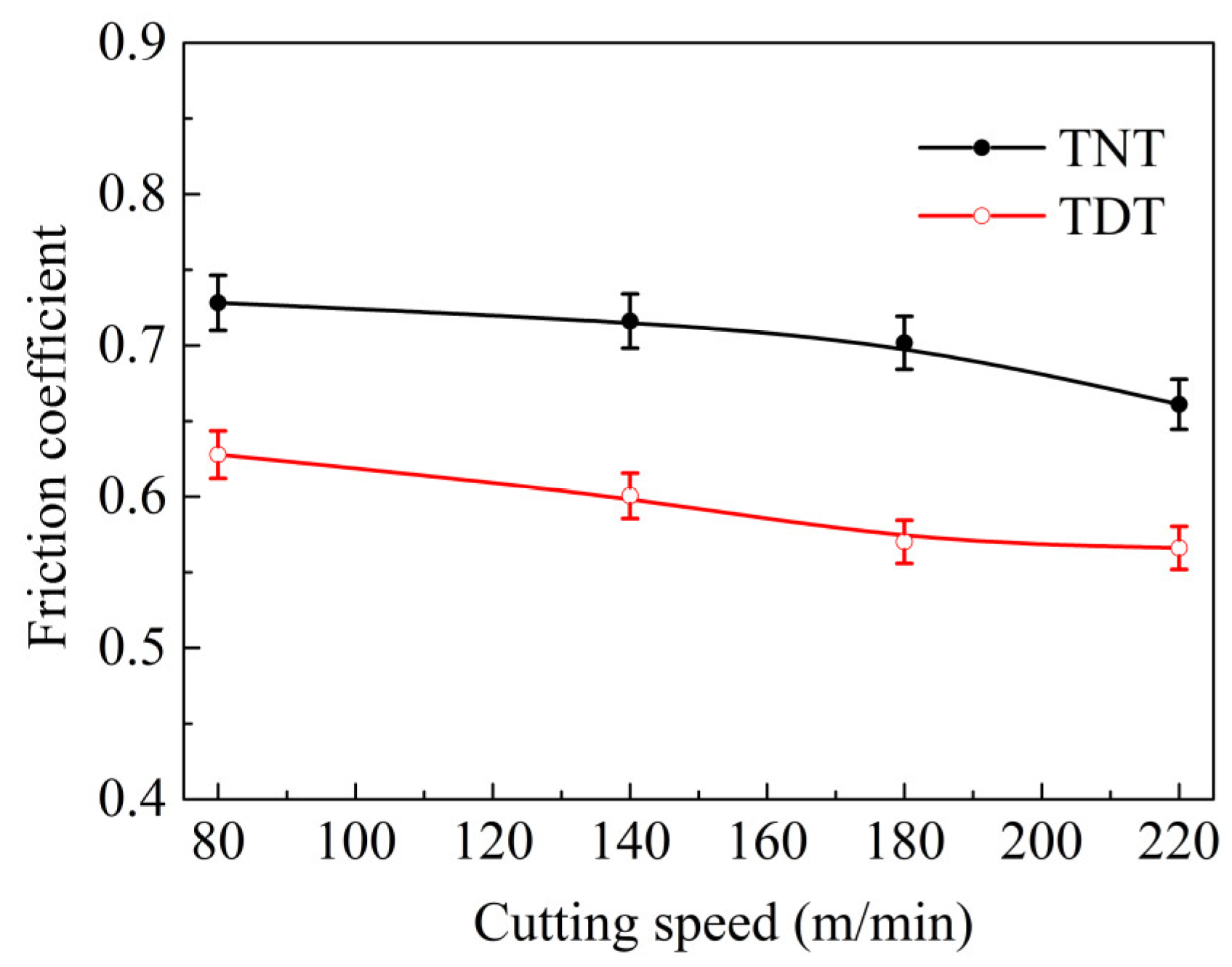

3.4. Average Coefficient of Friction on Tool Face

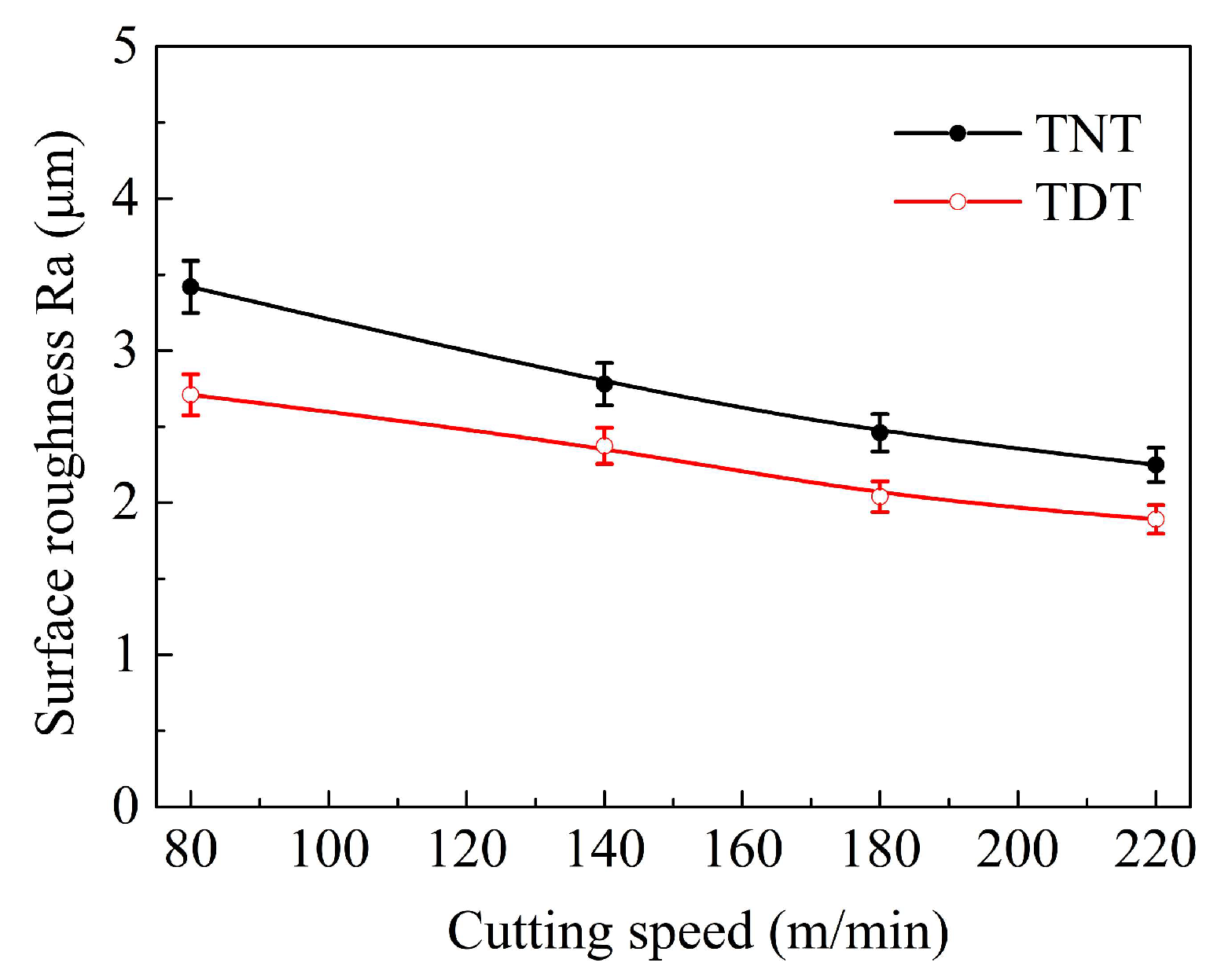

3.5. Machined Workpiece Surface Roughness

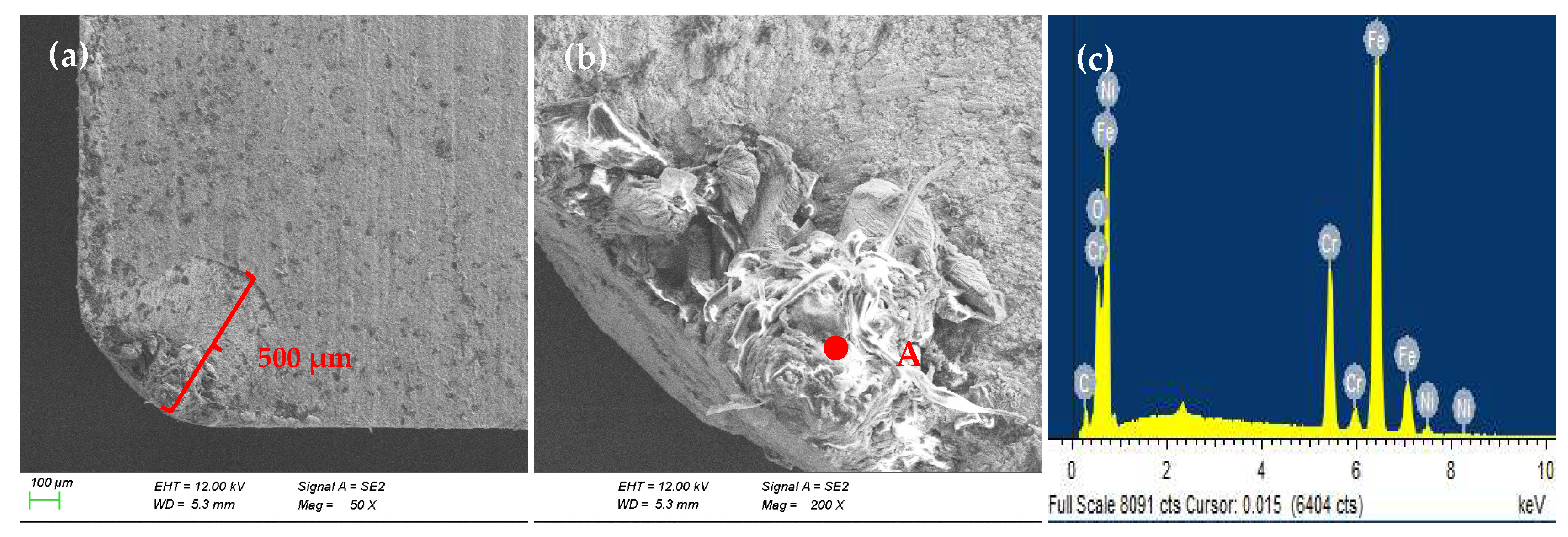

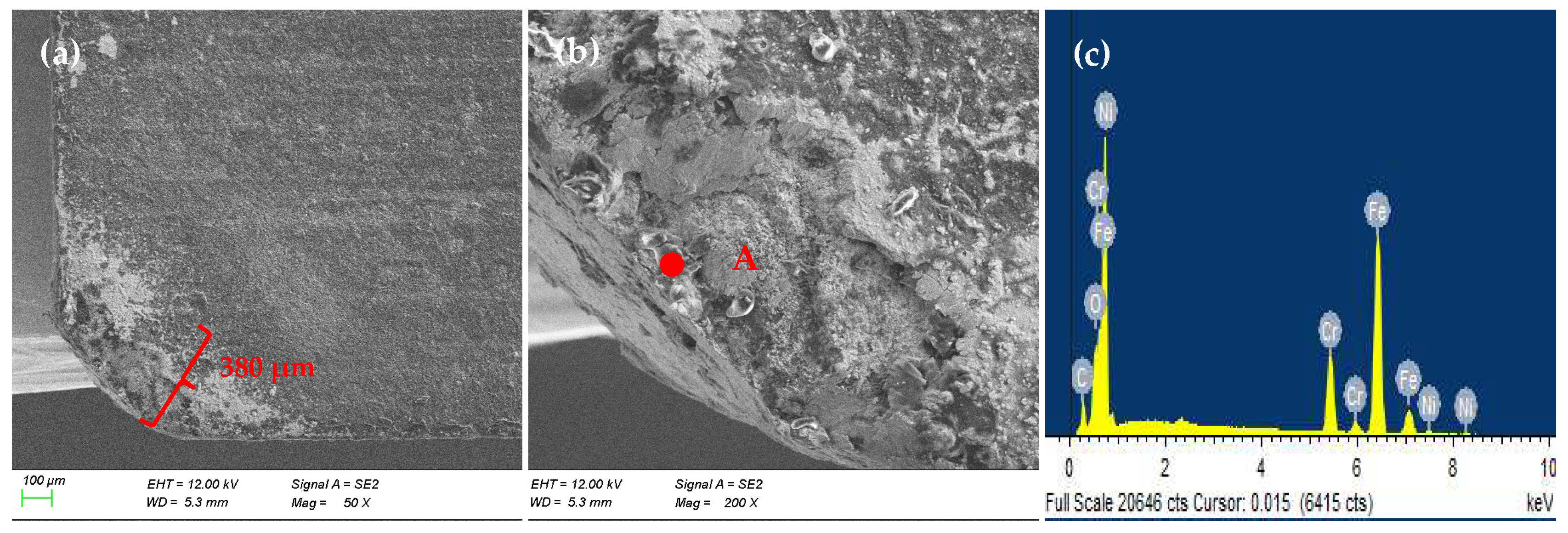

3.6. Wear Morphology

4. Conclusions

- The TiN/DLC composite coatings exhibit a homogeneous and compact morphological structure, devoid of any discernible cracks or voids. The coating thickness is approximately 2.11 μm, the surface hardness reaches 20.1 GPa, and the surface roughness (Ra) is about 0.21 μm.

- The TDT tool demonstrates a superior performance in the reduction in cutting force and friction at the tool–chip interface. Compared to that of TNT, the cutting temperature of TDT decreases by about 30%–35%, the three force components of TDT are reduced by 20% to 25%, and the average friction coefficient at the rake face is decreased by 14%–18%.

- The TiN/DLC composite coatings are effective in reducing the tool wear and improving the machined workpiece surface finish. As the cutting speed increased, the surface roughness of the workpiece machined by TDT showed a consistent improvement by about 15%–20% compared to that of TNT. In addition, the tool rake face wear was reduced by about 32%–35%.

- The superior performance of TDT can be explained by the unique properties and synergistic effects of its composite coating structure. This combination effectively balances the need for low friction with the mechanical demands of dry machining, which can extend the service life of a coating and improve the machining efficiency. The TDT composite coating tool can improve the dry-machining performance of a traditional-coated cemented carbide tool when cutting laser-clad Cr-Ni-based steel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sandoval, J.; Ali, A.; Kwon, P.; Stephenson, D.; Yang, G. Wear reduction mechanisms in modulated turning of compacted graphite iron with coated carbide tool. Tribol. Int. 2023, 178, 108062. [Google Scholar] [CrossRef]

- Chen, Y.H.; Wang, J.; Chen, M. Enhancing the machining performance by cutting tool surface modifications: A focused review. Mach. Sci. Technol. 2019, 23, 477–509. [Google Scholar] [CrossRef]

- Bjerke, A.; Lenrick, F.; Hrechuk, A.; Slipchenko, K.; M’Saoubi, R.; Andersson, J.M.; Bushlya, V. On chemical interactions between an inclusion engineered stainless steel (316L) and (Ti,Al)N coated tools during turning. Wear 2023, 532–533, 205093. [Google Scholar] [CrossRef]

- Boyle, H.; Norgren, S.; Crawforth, P.; Christofidou, K.; Boing, D.; Jackson, M. Insights in α-Al2O3 degradation in multilayer CVD coated carbide tools when turning IN718. Wear 2023, 523, 204786. [Google Scholar]

- Koricherla, M.V.; Torgerson, T.B.; Alidokht, S.A.; Munagala, V.N.V.; Scharf, T.W. High temperature sliding wear behavior and mechanisms of cold-sprayed Ti and Ti-TiC composite coatings. Wear 2021, 476, 203746. [Google Scholar] [CrossRef]

- Kumar, C.S.; Urbikain, G.; Fernandes, F.; Rjoub, A.A.; Lacalle, L.N.L.D. Influence of V concentration in TiAlSiVN coating on self-lubrication, friction and tool wear during two-pass dry turning of austenitic steel 316L. Tribol. Int. 2024, 193, 109355. [Google Scholar] [CrossRef]

- Roushan, A.; Rao, U.S.; Sahoo, P.; Patra, K.; Rawat, S.S. Wear behavior of AlTiN coated WC tools in micromilling of Ti6Al4V alloy using vegetable oil-based nanofluids. Tribol. Int. 2023, 188, 108825. [Google Scholar] [CrossRef]

- Olsson, M.; Bushlya, V.; Lenrick, F.; Ståhl, J.E. Evaluation of tool wear mechanisms and tool performance in machining single-phase tungsten. Int. J. Refract. Met. Hard Mater. 2021, 94, 105379. [Google Scholar] [CrossRef]

- Jackson, M.J.; Robinson, G.M.; Whitt, M.D.; Silva, R.B.; Silva, M.B.; Machado, A.R. Achieving clean production with nanostructured coated milling tools dry machining low carbon steel. J. Clean. Prod. 2023, 422, 138523. [Google Scholar] [CrossRef]

- Farid, M.A.; Abdollah-Zadeh, A.; Aghababaei, R. Effects of B and C elements on microstructure, mechanical and tribological properties of TiN coating deposited by PACVD. Mater. Charact. 2025, 225, 115178. [Google Scholar] [CrossRef]

- Li, Y.T.; Xie, M.L.; Sun, Q.; Xu, X.J.; Fan, X.Q.; Zhang, G.A.; Li, H.; Zhu, M.H. The effect of atmosphere on the tribological behavior of magnetron sputtered MoS2 coatings. Surf. Coat. Technol. 2020, 378, 125081. [Google Scholar]

- Sun, J.; Deng, J.X.; Li, X.M.; Meng, Y.; Zhang, Y.; Zhang, L.L.; Lu, Y. Preparation and tribological properties of MoS2-based multiple-layer structured films fabricated by electrohydrodynamic jet deposition. Surf. Coat. Technol. 2020, 384, 125334. [Google Scholar] [CrossRef]

- Mukhtar, S.H.; Wani, M.F.; Sehgal, R.; Sharma, M.D. Nano-mechanical and nano-tribological characterisation of self-lubricating MoS2 nano-structured coating for space applications. Tribol. Int. 2023, 178, 108017. [Google Scholar] [CrossRef]

- Lian, Y.S.; Long, Y.Y.; Zhao, G.L.; Mu, C.L.; Li, X.M.; Deng, J.X.; Xie, C.P. Performance of CrCN-WS2 hard/soft composite coated tools in dry cutting of titanium alloys. J. Manuf. Process 2020, 54, 201–209. [Google Scholar] [CrossRef]

- Abdelrazek, A.H.; Choudhury, I.A.; Nukman, Y.; Kazi, S.N. Metal cutting lubricants and cutting tools: A review on the performance improvement and sustainability assessment. Int. J. Adv. Manuf. Technol. 2020, 106, 4221–4245. [Google Scholar] [CrossRef]

- Li, X.M.; Deng, J.X.; Yue, H.Z.; Ge, D.L.; Zou, X.Q. Wear performance of electrohydrodynamically atomized WS2 coatings deposited on biomimetic shark-skin textured surfaces. Tribol. Int. 2019, 134, 240–251. [Google Scholar] [CrossRef]

- Yi, J.; Li, M.L.; Zhou, H.X.; Rosenkranz, A.; Jiang, N. Enhanced tribological properties of Y/MoS2 composite coatings prepared by chemical vapor deposition. Ceram. Int. 2020, 46, 23813–23819. [Google Scholar]

- Mukhtar, S.H.; Gulzar, A.; Saleem, S. Advances in development of solid lubricating MoS2 coatings for space applications: A review of modeling and experimental approaches. Tribol. Int. 2024, 192, 109194. [Google Scholar] [CrossRef]

- Bashandeh, K.; Lan, P.X.; Meyer, J.L.; Polycarpou, A.A. Tribological performance of graphene and PTFE solid lubricants for polymer coatings at elevated temperatures. Tribol. Lett. 2019, 67, 99. [Google Scholar] [CrossRef]

- Lu, Y.; Deng, J.X.; Song, W.L.; Li, X.M.; Zhang, L.L.; Sun, J. Tribological performance of AlCrN-MoS2/PTFE hard-lubricant composite coatings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 234, 1355–1367. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Zabinski, J.S. Nanocomposite and nanostructured tribological materials for space applications. Compos. Sci. Technol. 2005, 65, 741–748. [Google Scholar]

- Song, W.L.; Wang, S.J.; Lu, Y.; An, L.; Zhang, Q.G. Tribological performance of DLC-coated ceramics against cemented carbide under dry sliding conditions. Ceram. Int. 2021, 47, 16926–16934. [Google Scholar] [CrossRef]

- Zhu, W.; Xu, Z.; Su, Z.; Li, Y.; Yi, A.; Zheng, J.; Zhu, J.; Li, K.; Chen, K.; Liao, Z. Mechanical property and biocompatibility of multilayer Ti-DLC films with different Ti target power by hybrid PVD/PECVD on 316L stainless steel. Surf. Coat. Technol. 2025, 496, 131672. [Google Scholar]

- Ziberov, M.; Oliveira, D.D.; Silva, M.B.D.; Hung, W.N.P. Wear of TiAlN and DLC coated microtools in micromilling of Ti-6Al-4V alloy. J. Manuf. Process. 2020, 56, 337–349. [Google Scholar] [CrossRef]

- Jatti, V.S.; Sefene, E.M.; Jatti, A.V.; Akshansh, M.; Dhabale, R.D. Synthesis and characterization of diamond-like carbon coatings for drill bits using plasma-enhanced chemical vapor deposition. Int. J. Adv. Manuf. Technol. 2023, 127, 4081–4096. [Google Scholar]

- Kogovšek, J.; Kalin, M. Lubrication performance of graphene-containing oil on steel and DLC-coated surfaces. Tribol. Int. 2019, 138, 59–67. [Google Scholar] [CrossRef]

- Zhang, P.R.; Liu, Z.Q. Plastic deformation and critical condition for orthogonal machining two-layered materials with laser cladded Cr-Ni-based stainless steel onto AISI 1045. J. Clean. Prod. 2017, 149, 1033–1044. [Google Scholar]

- Masoumi, H.; Safavi, S.M.; Salehi, M. Grinding force, specific energy and material removal mechanism in grinding of HVOF-sprayed WC-Co-Cr coating. Mater. Manuf. Processes 2014, 29, 321–330. [Google Scholar]

- Masoumi, H.; Safavi, S.M.; Salehi, M.; Nahvi, S.M. Effect of grinding on the residual stress and adhesion strength of HVOF thermally sprayed WC-10Co-4Cr coating. Mater. Manuf. Processes 2014, 29, 1139–1151. [Google Scholar]

- Liu, X.B.; Zhang, B. Effects of grinding process on residual stresses in nanostructured ceramic coatings. J. Mater. Sci. 2002, 37, 3229–3239. [Google Scholar] [CrossRef]

- Zhang, P.R.; Liu, Z.Q. Effect of sequential turning and burnishing on the surface integrity of Cr–Ni-based stainless steel formed by laser cladding process. Surf. Coat. Technol. 2015, 276, 327–335. [Google Scholar] [CrossRef]

- Liu, X.B.; Zhang, B. Grinding of nanostructural ceramic coatings: Damage evaluation. Int. J. Mach. Tools Manuf. 2003, 43, 161–167. [Google Scholar] [CrossRef]

- Kopac, J.; Krajnik, P. High-performance grinding-a review. J. Mater. Process Technol. 2006, 175, 278–284. [Google Scholar] [CrossRef]

- Song, Z.; Liu, Y.; Jiang, X.; Pilipstou, D.G.; Rogachev, A.V. Improving the protective properties of an artificial joint friction couple by using tin and DLC films. Surf. Coat. Technol. 2023, 472, 129944. [Google Scholar] [CrossRef]

- Su, Z.; Jie, X.; Li, W.; Liao, Z.; Li, Y.; Zhu, W. Effect of C2H2 flow rate and a Ti/TiN/TiCN interlayer on the structure, mechanical and tribological properties of a-C:H films deposited using a hybrid PVD/PECVD process with an anode-layer ion source. Vacuum 2023, 209, 111753. [Google Scholar] [CrossRef]

- Wen, S.Z. Principle of Tribology; Tinghua University Press: Beijing, China, 2017. [Google Scholar]

| Composition (wt. %) | Density (g/cm3) | Flexural Strength (MPa) | Young′s Modulus (GPa) | Hardness (GPa) |

|---|---|---|---|---|

| WC + 15%TiC + 6%Co | 11.65 ± 0.1 | 1245 ± 5 | 498 ± 2 | 16.2 ± 0.1 |

| Composition (wt. %) | Hardness (GPa) | Surface Roughness (μm) | Diameter (mm) | Length (mm) |

|---|---|---|---|---|

| Fe + 10.5%Cr + 2.2%Ni | 540 ± 10 | 25 | 110 | 400 |

| Coating | Surface Hardness (HRC) | Surface Roughness (μm) | Thickness (μm) |

|---|---|---|---|

| TiN | 22.2 ± 0.1 | 0.32 ± 0.1 | 1.52 |

| TiN/DLC | 20.1 ± 0.1 | 0.21 ± 0.1 | 2.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, Z.; Song, W.; Yu, H.; Li, X.; Yin, Y.; Xie, W. Cutting Performance of TiN/DLC-Coated Cemented Carbide Tool in Dry Cutting of Laser-Clad Cr-Ni-Based Steel. Coatings 2025, 15, 1150. https://doi.org/10.3390/coatings15101150

Xia Z, Song W, Yu H, Li X, Yin Y, Xie W. Cutting Performance of TiN/DLC-Coated Cemented Carbide Tool in Dry Cutting of Laser-Clad Cr-Ni-Based Steel. Coatings. 2025; 15(10):1150. https://doi.org/10.3390/coatings15101150

Chicago/Turabian StyleXia, Zixiang, Wenlong Song, Hongjin Yu, Xing Li, Yijia Yin, and Weidong Xie. 2025. "Cutting Performance of TiN/DLC-Coated Cemented Carbide Tool in Dry Cutting of Laser-Clad Cr-Ni-Based Steel" Coatings 15, no. 10: 1150. https://doi.org/10.3390/coatings15101150

APA StyleXia, Z., Song, W., Yu, H., Li, X., Yin, Y., & Xie, W. (2025). Cutting Performance of TiN/DLC-Coated Cemented Carbide Tool in Dry Cutting of Laser-Clad Cr-Ni-Based Steel. Coatings, 15(10), 1150. https://doi.org/10.3390/coatings15101150