Abstract

There are many factors that determine the performance parameters of piezoelectric ceramics, but the process of preparing ceramics plays a decisive role in their properties. By improving the preparation process, significant improvements in ceramic properties can be achieved. In order to meet the growing demand for improvement in the performance of piezoelectric ceramics, various crystal preparation methods such as Template Crystal Growth (TGG), Reflected Template Growth (RTGG), and Oriented Curding (OCAP) techniques have been used for the preparation of piezoelectric ceramics. This article first introduces the performance parameters of piezoelectric ceramics, then summarizes the influence of various preparation processes on the performance of piezoelectric ceramics, and finally summarizes the parameters of high-tech ceramics reported this year, and predicts the future of the preparation of high-tech ceramic materials.

1. Introduction

The demands on the performance of piezoelectric materials are increasing, particularly in the fields of electronics, sensors, and medical devices, and traditional piezoelectric ceramics often fail to meet the requirements of high-performance materials due to the limitations of grain arrangement [1]. In this context, textured ceramics have emerged as a solution. Textured piezoelectric ceramics are ceramics in which the grains or crystals are oriented in a specific direction through certain processing techniques, thus achieving superior electromechanical properties [2,3]. Compared to traditional ceramics with random grain arrangements, textured piezoelectric ceramics can significantly improve the material’s piezoelectric performance, mechanical strength, and other physical properties [4,5]. The fabrication of textured ceramics not only addresses the performance bottlenecks of traditional materials under high-frequency, high-voltage, and high-temperature conditions but also provides higher efficiency and broader application prospects [6,7,8,9].

In the past, lead-based ceramics such as PZT [10,11,12], PMN-PT [13,14,15], and PLZT [16,17] were widely used. Common lead-free ceramics, such as BNT-BT [18,19,20,21], BKT [22,23], and KNN [24,25], generally cannot match the performance of lead-based ceramics, which is why lead-based ceramics remain the mainstream material for most commercial MLA. However, environmental awareness is growing; thus, the environmental impact of lead-based ceramics has become increasingly apparent, and the development of lead-free ceramics has become a hot topic in the current research on functional ceramics [26,27,28,29,30,31].

Currently, the most common methods used for the development of high-performance piezoelectric ceramics include ion doping modification [32,33,34,35,36,37], group element optimization [38,39], and texturing techniques [40,41,42,43,44,45,46,47,48]. Ion doping refers to the doping of different valence ions in ceramics to replace the A-site or B-site ions in the original crystal lattice [33,49], which can effectively regulate the physical structure and electrical properties of the ceramics [32,50]. The group element optimization involves optimizing the crystal structure and properties of piezoelectric ceramics by adjusting their chemical compositions and ratios.

Techniques such as introducing appropriate doping elements, adjusting the lattice structure, optimizing crystal defects, etc., improve the piezoelectric properties. The texturing technique controls the orientation and arrangement of the grains of the ceramic material, allowing the optimal orientation of the grains to be achieved, thus improving the piezoelectric properties of the material; this is mainly achieved using methods such as hot pressing texturing, tensile texturing, and electric field polarization [40,44]. Although there are many methods that can be used to improve the properties of piezoelectric ceramics, using texturing techniques to prepare textured ceramics with optimal grain orientation is still an effective way to improve the properties of piezoelectric ceramics [38,51].

In this paper, we will provide a detailed introduction of the process flow of the texturing technique and the development of the application of the texturing process in the field of high-performance piezoelectric ceramics in recent years.

2. Piezoelectric Material Texturing Process and Main Parameters

2.1. Main Parameters Characterizing the Properties of Piezoelectric Materials

- (1)

- Curie temperature (Tc): When it comes to piezoelectric materials, the Curie temperature (Tc) refers to the temperature at which the ferroelectric phase transforms into the cis-phase. It is generally believed that the higher the Tc, the higher its use or working temperature.

- (2)

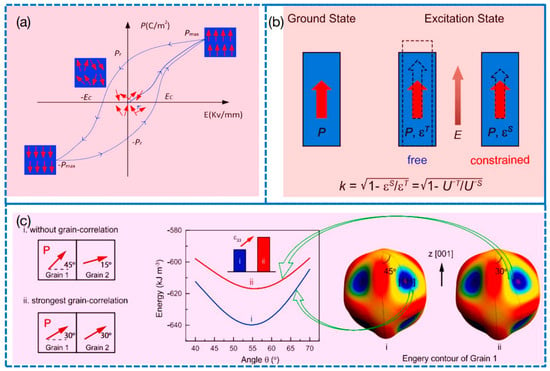

- Saturation polarization (Ps): Saturation polarization refers to the maximum polarization intensity that a piezoelectric material can achieve under the maximum electric field. A higher-saturation polarization means that the material has a higher output charge and greater displacement capacity [52]. When the electric field is raised to a certain value, the spontaneous polarization vectors of all the cells rotate in the direction closest to the external electric field, and the interior of the material approximates the state of a single domain. The voltage continues to increase at this point, and the increase in the polarization vector can be entirely attributed to the contribution of the non-ferroelectric part, so that the segment of the electric hysteresis loop in Figure 1a that is close to the maximum polarization vector (Pmax) is linear. Extrapolating this segment to E = 0, the intersection with the y-axis then represents the saturation polarization strength (Ps) [53].

Figure 1. (a) Typical hysteresis loop of ferroelectric materials. (b) Definition of electromechanical coupling factor, k. Reprinted with permission from Ref. [54] Copyright 2022, Nature Communications. (c) Illustration of the grain correlation effect on the permittivity based on the Landau theory: grain−correlation will make the polarization rotation path deviate from its equilibrium point and hence flattens the energy profile, which increases the permittivity εT and eventually enhances k33. Reprinted with permission from Ref. [54] Copyright 2022, Nature Communications.

Figure 1. (a) Typical hysteresis loop of ferroelectric materials. (b) Definition of electromechanical coupling factor, k. Reprinted with permission from Ref. [54] Copyright 2022, Nature Communications. (c) Illustration of the grain correlation effect on the permittivity based on the Landau theory: grain−correlation will make the polarization rotation path deviate from its equilibrium point and hence flattens the energy profile, which increases the permittivity εT and eventually enhances k33. Reprinted with permission from Ref. [54] Copyright 2022, Nature Communications. - (3)

- Piezoelectric coefficient (d): The piezoelectric coefficient is the proportionality between the amount of charge generated by a piezoelectric material when it is subjected to a mechanical stress or an electric field excitation and the intensity of the stress or electric field. Usually, d33, d31, d15, etc., are used to indicate the piezoelectric coefficient under different orientations. A higher piezoelectric coefficient indicates that the material is capable of generating a greater charge output or displacement. When pressure T3 is applied along the polarization direction of a piezoelectric material, a surface charge is generated through the inverse piezoelectric effect, where the surface charge density δ3 satisfies the relation.

And in the MKS system of units, the potential shift D3 is equal to the surface density of the surface charge δ3 and therefore satisfies the following relation:

In the formula, d33 is the piezoelectric constant in pC/N, T is the stress, and S is the strain produced by the inverse piezoelectric effect of the piezoelectric material. In the positive/inverse piezoelectric effect, d33 embodies the piezoelectric material’s ability to generate charge under applied pressure and the ratio of S to E under the action of E, respectively.

- (4)

- Electromechanical coupling coefficient (k): As shown in Figure 1b, the electromechanical coupling coefficient is a parameter used to respond to the conversion efficiency of the piezoelectric material in the conversion of mechanical and electrical energy. k’s anisotropic behavior is mainly determined by εT [54], which can be defined as follows:

- (5)

- Dielectric constant (ε): as shown in Figure 1c, the dielectric constant is the degree of polarization of a piezoelectric material under an applied electric field [54]. It reflects the ability of a material to store and release energy in response to an electric field. The dielectric constant usually includes the electrostatic dielectric constant (ε0) and dielectric loss (tanδ). The dielectric properties of ferroelectric materials are directly related to the temperature, and the curve of its dielectric constant ε with the temperature T initially exhibits a rise and then a fall with a peak, and the temperature corresponding to this peak is the value of Tc. At temperatures higher than the Curie temperature Tc, the dielectric constant of ordinary ferroelectric materials generally follows the Curie–Weiss rule:

However, for relaxing ferroelectrics, the temperature dependence of the dielectric constant follows the modified Curie–Weiss law in the temperature Tm interval above the temperature corresponding to the maximum value of the dielectric constant:

where ε is the sample dielectric constant; εm is the maximum value of the dielectric constant; Tm is the temperature corresponding to the maximum value of the dielectric constant; T is the temperature; C1 is the Curie constant; and γ is a constant indicating the degree of dispersion, with a range of 1~2. The larger the value, the larger the degree of dispersion.

2.2. Definition, Classification, and Main Processes of Texturing Processes

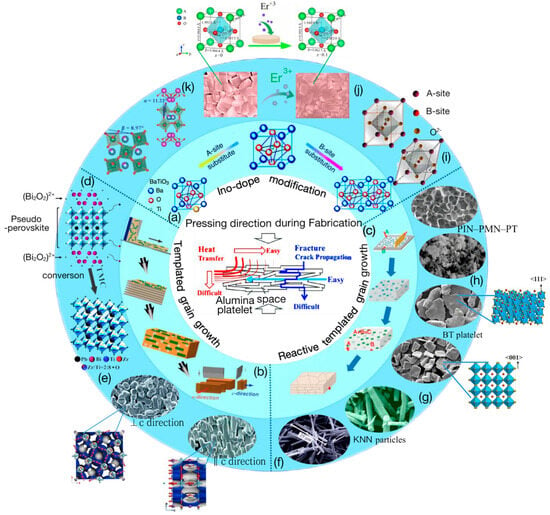

The enhanced piezoelectricity should be attributed to several combined effects, mainly including the R-O-T phase boundary that promotes polarization rotation, crystal orientation-induced intrinsic piezoelectric anisotropy, electric field-induced lattice distortion, and phase transition [55]. The strain output of randomly oriented ceramics can be suppressed due to limited polarization reversal induced by grain confinement [56]. Strongly anisotropic ferroelectric single crystals have a much higher piezoelectric response compared to polycrystals, and the texturing technique is a technique that is used to control the orientation and alignment of grains in ceramic materials, which essentially takes advantage of the anisotropy of piezoelectric properties [57]. The process comparison of the texturing technique with ion doping modification and group element optimization techniques is shown in Figure 2. In contrast to both, woven ceramics tend to exhibit single-crystal-like properties in the direction of grain orientation growth, which provides an opportunity to achieve superior strain output [56]. The optimal grain orientation is achieved by tuning the preparation parameters to allow such materials to grow optimally along the crystallographic direction with greater piezoelectric properties [40,58,59]. Compared with unoriented polycrystalline materials, after texturing, the highly optimal grains enhance the piezoelectric coefficient, d33, by a factor of 1.4 to 2.1 [44]. The following methods are used to prepare textured ceramic materials: thermal processing [60,61], template grain growth (TGG) [62,63,64], reactive template grain growth (RTGG) [47,48,65], and electroscopes and strong magnetic field-assisted method [66], oriented curing (OCAP) technique [67], and Rolling-assisted Biaxially Textured Substrates [68]. Figure 2 illustrates the main process flows of these techniques, and in this paper, we will focus on the template grain growth (TGG) and reactive template grain growth (RTGG) methods.

Figure 2.

(a) Schematic showing A−site or B−site substitution in BaTiO3 (BT) unit cell. Reprinted with permission from Ref. [32], Copyright 2020, Info−mat. (b) Templates’ grain growth. Reprinted with permission from Ref. [41], Copyright 2023, Ceramics International. (c) Reactive templates’ grain growth. Reprinted with permission from Ref. [46], Copyright 2020, Ceramics International. (d) Morphological evolution of Pb(ZrxTi1−x)O3 microcrystals fabricated by TMSS. Reprinted with permission from Ref. [42], Copyright 2023, Ceramics International. (e) SEM images of KSN textured ceramics of the surface:⊥c direction and ‖c direction. Reprinted with permission from Ref. [43], Copyright 2023, Journal of Physics and Chemistry of Solids. (f) SEM micrographs of the KNN particles. Reprinted with permission from Ref. [48], Copyright 2023, Journal of Wuhan University of Technology−Mater. (g) (001)c− and (111)c− oriented BT platelet templates. Reprinted with permission from Ref. [47], Copyright 2022, Journal of Materiomics. (h) SEM image of the 36PIN−30PMN−34PT matrix powders. Reprinted with permission from Ref. [69], Copyright 2015, Journal of Materials Research. (i) Schematic diagram of lattice distortion and phase transformation process caused by doping ions. Reprinted with permission from Ref. [50], Copyright 2023, Journal of Alloys and Compounds. (j) Diagrammatic sketch of the atomic displacements in the tetragonal cell for the x = 0 and 0.1 ceramics. Reprinted with permission from Ref. [33], Copyright 2023, Journal of Materiomics. (k) Visualized crystal structure of Bi3+ self−doped CBN ceramics viewed along two directions. Reprinted with permission from Ref. [35], Copyright 2022, Journal of the European Ceramic Society.

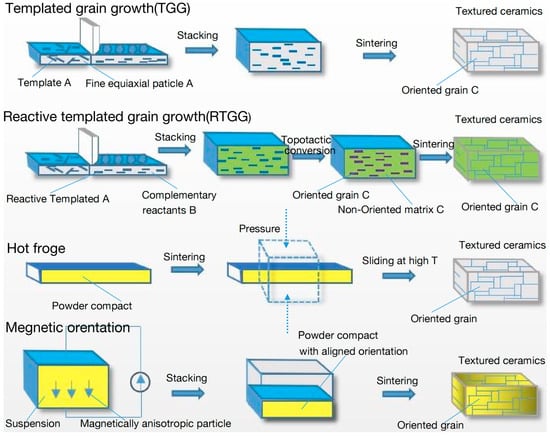

As shown in Figure 3, heat treatment texturing techniques include hot pressing, hot forging, and hot rolling [70], which are used to achieve texturing by applying an external force under high-temperature conditions to produce dislocation motion and grain boundary slip, etc., within the grains, which results in the directional arrangement of the grains [60]. Template grain growth (TGG) is a method that involves guiding the growth of other crystals through the use of a stationary crystal template [71]. This usually involves preparing a template crystal with the desired crystal structure, contacting the template crystal with a suitable solution or melt so that substances in the solution are deposited on the surface of the template crystal, controlling the growth conditions of the deposits (e.g., temperature, pressure, etc.) so that new crystals are formed on top of the template crystal, and, ultimately, removing the template crystal, leaving behind a new template-based crystal [36,69]. Reactive template growth (RTGG) is a method that utilizes a chemical reaction process to generate new crystals in a template. The steps of the method are as follows: prepare an appropriate template, e.g., porous material, nanoparticles, etc. Place the template in a suitable reactant solution or gas phase. When the chemical reaction occurs, the reactant reacts with the template to generate new crystals. Reaction conditions, such as temperature, concentration, and reaction time, are regulated to control the growth process of the new crystals. The reaction template growth method can be used to synthesize a wide variety of crystalline materials and can be used to control the shape, size, and structure of the crystals by adjusting the reaction conditions. The advantage of this method is that the structure, shape, and orientation of the new crystals can be controlled by the choice of template crystals. Therefore, it is widely used in materials science to synthesize materials with specific crystal structures, such as nanomaterials and polycrystalline materials [72,73].

Figure 3.

The schematic diagram of several methods used to prepare textured ceramics.

The TGG (template grain growth) technique improves upon the original OCAP (oriented curing) technique by introducing a template material as a guiding agent for grain growth to facilitate the formation and control of crystal orientation. This innovation is important for improving the crystal orientation and properties of ceramic materials and lays the foundation for subsequent research and applications [39]. The reactive template grain growth technique RTGG is a texturing ceramic preparation technique developed based on TGG, and based on the idea of preparing texturing ceramics by template grain growth (TGG), the piezoelectric ceramic properties have been substantially improved [69,71,72,73].

Important structural properties of textile ceramics include the degree of orientation as well as the sintering density and grain size [45]. There are many methods for evaluating the degree of preferred orientation of ceramics, such as the Lotgering method and the backscattered electron diffraction (EBSD) technique [74,75,76]. Among them, the Lotgering method is used to establish the relationship between the relative intensities of X-ray diffraction peaks and grain orientation and calculate the ceramic degree of texturing (Fhkl) by measuring the relative intensities of X-diffraction peaks, which has the advantages of being fast, simple, and convenient, and it is the most commonly used method. Taking 001 orientation as an example, the specific method is as follows:

where P and P0 correspond to the ratio of the (00l) diffraction peak intensity to the sum of all diffraction peak intensities for woven and randomly oriented ceramics, respectively, and I and I0 are the X-ray diffraction intensities for woven and random ceramic samples, respectively.

3. Development and Application of Texturing Processes

3.1. Hot-Pressing Method

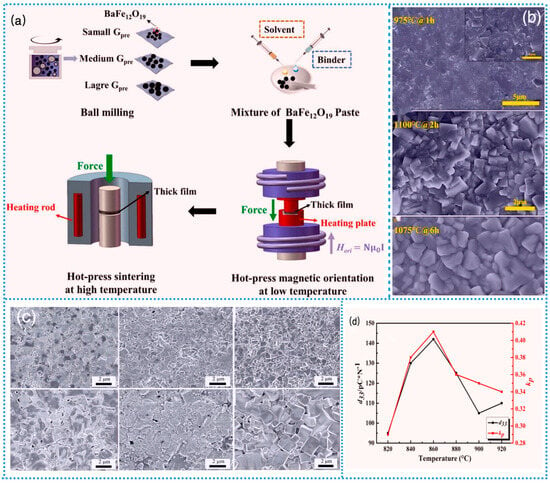

The detailed process of the hot-pressing method is shown in Figure 4a. Back in the 1960s, Jaeger [77] et al. developed a method for preparing potassium sodium niobate (KNN) piezoelectric ceramics by hot pressing, which showed that the density of piezoelectric ceramics could be significantly increased by hot pressing, thus enhancing their piezoelectric and dielectric properties. As shown in Figure 4b, Liu [60,78] et al. prepared dense lead-free ceramics K0.5Na0.5NbO3 (KNN) via a hot-pressing sintering method in a wide temperature range. The microstructure, dielectric, ferroelectric and piezoelectric properties of the ceramics were systematically investigated. The experimental results show that all ceramics exhibit a single orthorhombic phase and a dense microstructure with high relative density (>96.8%). The grain size is positively correlated with the domain size. Ceramics with average grain sizes of 490 and 720 nm showed submicron domain sizes of 100 and 150 nm, respectively; while ceramics with an average grain size of 160 nm had nanoscale host crystals, and fine-grained ceramics with nanoscale domains exhibited excellent electrical properties. Yu et al. [79] significantly enhanced the piezoelectric properties of the resulting ceramics by hot press sintering and by adding 0.5 mol% Al2O3 to K0.5Na0.5NbO3. The ceramics exhibit good temperature stability, with ceramic d33 reaching 137 pC/N and d33 remaining as high as 97 pC/N with increasing annealing temperature. As shown in Figure 4c, Li et al. [80] applied the OPAHP technique to the sintering process of KNN piezoelectric ceramics. KNN ceramics with fine and uniform grain distribution were prepared by OPAHP technology. The specimens sintered at the lowest temperature of 860 °C exhibited the highest relative density of 99.6%, with d33 reaching 142 pC/N. Compared with ceramics prepared by other methods, the OPAHP-prepared samples possessed enhanced dielectric and piezoelectric properties, as well as ultra-high hardness and bending strength due to the presence of oscillating pressure.

Figure 4.

(a) Hot−press magnetic orientation at low temperature and hot−press sintering at high temperature. Reprinted with permission from Ref. [61], Copyright 2023, Elsevier. (b) SEM images of the ceramics sintered at different temperatures for various dwelling hours. Reprinted with permission from Ref. [60], Copyright 2022, Ceramics International. (c) Surface morphologies of the ceramics sintered under the following conditions: T1 = 820 °C, T2 = 840 °C, T3 = 860 °C, T4 = 880 °C, T5 = 900 °C, T6 = 920 °C. Reprinted with permission from Ref. [80]. 2019, Ceramics International. (d) d33 and kp of the Na0.5K0.5NbO3 ceramics under various sintering temperature. Reprinted with permission from Ref. [80], Copyright 2019, Ceramics International.

3.2. Template Method

Thermal processing methods are unable to amend the texture of isotropic materials [1]. Template grain growth (TGG) and reaction template grain growth (RTGG) solve this problem. Both TGG and RTGG utilize the shape and structure of the template to control the growth process of the ceramic material to obtain the desired shape and microstructure [81,82]. Therefore, they can both be categorized as template methods. The use of piezoceramic template methods for the preparation of materials with specific texture configurations can introduce an orderly arrangement of crystal orientations into the microstructure of the material, which can significantly improve the properties of the material. The texture structure can affect the piezoelectric properties, thermo-mechanical stability, and piezoelectric coupling properties of piezoelectric ceramic materials [83].

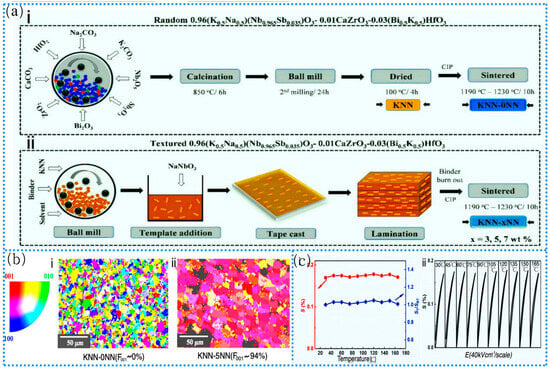

One of the most important techniques for the preparation of ceramics with a high degree of texturing is the preparation of template particles, which have morphologies categorizes as plate-like or fibrous. Examples include BaTiO3 (BT) and NaNbO3 (NN). To date, BT and NN templates have been preferentially used for the fabrication of highly doped PbTiO3 and BaTiO3 as well as (K, Na)NbO3 texturing ceramics, respectively [84]. Saito [1] et al. developed a new technique for synthesizing template particles which allowed them to completely transform BiNN5 particles into NaNbO3 particles with a plate-like, regular chalcocite structure, and successfully synthesized them via the RTGG method. High-performance KNN-based piezoelectric ceramic with a d33 of 416 pC/N and a kp of 0.61 was successfully synthesized by RTGG with a textured <001> orientation, and this discovery was like opening the door to lead-free piezoelectric ceramic systems. However, poor temperature stability is the main drawback of KNN-based ceramics [85]. Zheng et al. [86] proposed to design a new ceramic system (1−x)(K1−yNay)(Nb1−zSbz)O3−xBi0.5(Na1−wKw)0.5HfO3(KNNS-BNKH), where the R-T phase boundary can be constructed by optimizing x, y, z, and w. The piezoelectric properties can be improved by controlling the phase boundary. TC decreases rapidly with as Xandz increases. In addition, their TR-O and TO-T increase and decrease, respectively, with the increase in both. By changing the composition of the ceramics, high piezoelectric constants can be obtained in the ceramics. Using this method, the piezoelectricity and fatigue resistance properties of the material were enhanced simultaneously, further promoting the development of lead-free ceramics. Priya et al. [87] prepared (K, Na) NbO3-based piezoelectric ceramics with a high degree of texturing along the (001) direction using a NaNbO3 (NN) stencil in the process flow shown in Figure 5a. As shown in Figure 5b, the degree of texturing reached 94%, and experiments showed that the textured assemblage (KNN-5NN) with 5 wt% NN template showed a significant improvement in the electromechanical coefficients at room temperature, with d33 up to 590 pC/N, k31 up to 0.46 and d31 up to 215 × 10−12 C/N. Gao et al. [86] used a template grain growth (TGG) method to prepare Ba2+ doped 0.97 (K0.48Na0.52)(Nb0.96Sb0.04)O3−0.03Bax(Bi0.5Ag0.5)1−xZrO3(KNNS-BxBAZ) woven ceramics. As shown in Figure 5c, the monopole strain of the x¼0.2 sample reached about 0.17% at 40 kV/cm and is insensitive to temperature changes. The strain value ratios between the strain values at different temperatures and room temperature were calculated from the variation in the sample’s monopole strain, as shown in Figure 5c, the strain value of the x = 0.2 sample fluctuated around 0.17% as the temperature increased, and the variation in the strain was less than 5% in the temperature range from room temperature to 165 °C. The temperature stability of KNN-based crystals was effectively improved by the texturing technique [86,87,88].

Figure 5.

(a) Schematic illustration of synthesis procedures used to develop (i) random and (ii) textured KNN−xNN piezoceramics. Reprinted with permission from Ref. [87], Copyright 2023, ACS. (b) EBSD micrographs of (i) random ceramic, KNN−0NN. (ii) textured, KNN−5NN ceramic. Schematic illustration of synthesis procedures used to develop (i) random and (ii) textured KNN−xNN piezoceramics. Reprinted with permission from Ref. [87], Copyright 2023, ACS. (c) Unipolar strain curves (i) and ST/SRT (ii) of KNNS−BxBAZ (x = 0.2) textured ceramics as a function of temperature. Reprinted with permission from Ref. [85] Copyright 2023, Journal of Materiomics.

4. The Effect of Stencils on the Properties of Textured Ceramics

4.1. BT/ST Stencil Texture Ceramics

The template content, the size of the template particle morphology, and the sintering temperature can directly affect the growth of crystals, etc. [89,90], and BaTiO3 (BT) or SrTiO3 (ST) templates can greatly reduce the sintering temperature [63]. Zhao [90] et al. used the reaction template growth method (RTGG), which used Bi4Ti3O12 (BT) as a crystalline species based on the reaction depicted in formula (5). This method produced woven ceramics with ternary BNT-BKT-BT in <001> orientation, which resulted in a texturing degree of 81%, and the piezoelectric properties were improved by a factor of 1.4 compared with random orientation.

0.12Bi4Ti3O12 + 0.2125Na2CO3 + 0.0275K2CO3 + 0.6TiO2+ +0.04BaTiO3→0.85BNT + 0.11BKT + 0.04BT + 0.24CO2

Yang [63] used a BT template in combination with the TGG method to prepare <001> texture-structured 0.19Pb(In0.5Nb0.5)O3-xPb(Sc0.5Nb0.5)O3-(0.81−x)PbTiO3(PIN-PSN-PT) ceramics (x = 0.44~0.49) with <001> orientation via two-step topological chemical reaction synthesis with the following reaction equation:

2Bi2O3 + 3TiO2→Bi4Ti3O12

Bi4Ti3O12 + 3BaCO3→3BaTiO3 + 2Bi2O3 + 3CO2

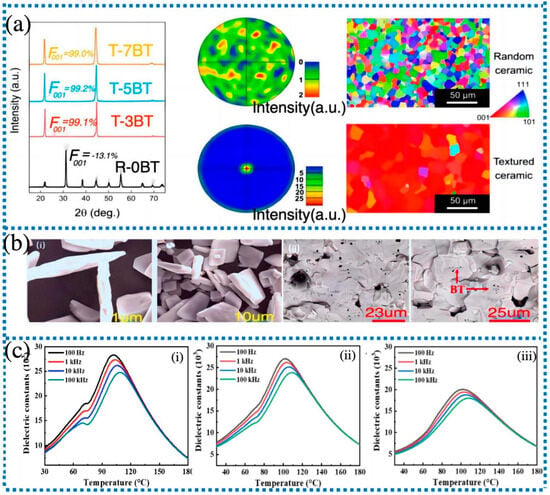

As shown in Figure 6a, due to its high melting point, the template-induced PIN-PSN-PT grains are very small at high temperatures, but the temperature leads to the volatilization of PbO, thus greatly reducing the densification and properties of the final samples. To solve this problem, experiments were carried out that involved adding small amounts of CuO and B2O3 (0.2~0.5 wt%). The results show that this method can effectively promote the growth of PIN-PSN-PT single crystals on BT templates. The performance parameters of all the woven ceramics created using varying BT templates are shown in Table 1. Compared with the nonwoven samples, Figure 6b shows that all the samples have a pure chalcogenide structure, whereas the intensity of the peaks of the woven ceramics at <001> is enhanced, and most of the grains are well orientated along the <001> direction in the woven PIN-PSN-PT ceramics [63,91]. The problem of the low-ferroelectric phase transition temperature in the relaxation phase of lead titanate bismuth niobate lead titanite ferroelectric materials, which has an impact on the design freedom of high-performance piezoelectric devices, was solved. Bian et al. [92] used a BaTiO3 template as in Figure 6c(i) to prepare a woven 0.42PNN-0.21PZ-0.37PT ceramic using the TGG method. The total capacitance of the material was equal to the substrate and the fillers in series and parallel connections [34]. Therefore, the curve of dielectric constant versus temperature can be flattened effectively by introducing stencils with appropriate dielectric constants as fillers. Moreover, the texturing volume fraction increases as the BT template concentration increases because a high concentration of BT templates introduces more grain orientation growth [93]. As shown in Figure 6c, the peak corresponding to the R-T phase transition diminishes with the increase in BT template volume fraction and disappears at 3% of BT template volume. On the other hand, the T-C phase transition temperature T exhibits very few changes due to the addition of the BT template [92]. In summary, the temperature stability of piezoelectric ceramics was significantly improved by ceramic texturing [94,95].

Figure 6.

(a) XRD patterns of the random ceramic and the textured ceramics with 3, 5, and 7 vol.% BT templates. The F001 of the random ceramic and textured ceramics was calculated based on the XRD pattern of the PIN–PSN–PT powders. The <001> pole figures of the non−textured ceramic (top) and the 3 vol.% BT−textured ceramic (bottom), where the color bar indicates the intensity in arbitrary units. Grain orientation images measured by the SEM−EBSD technique on the sample surface of the random ceramic and the 3 vol.% BT−textured ceramic, where the colors indicate the orientation of the grains. Reprinted with permission from Ref. [63], Copyright 2021, Nature Communications. (b) SEM micrograph of BaTiO3 templates. Reprinted with permission from Ref. [92], Copyright 2022, ACS. (c) Dielectric permittivity as a function of temperature for PNN−PZT−xBT ceramics: (i) random ceramic, (ii) PNN−PZT−3%BT, and (iii) PNN−PZT−5%BT. Reprinted with permission from Ref. [93], Copyright 2022, ACS.

Table 1.

Electromechanical properties of textured 0.19PIN–0.445PSN–0.365PT ceramics.

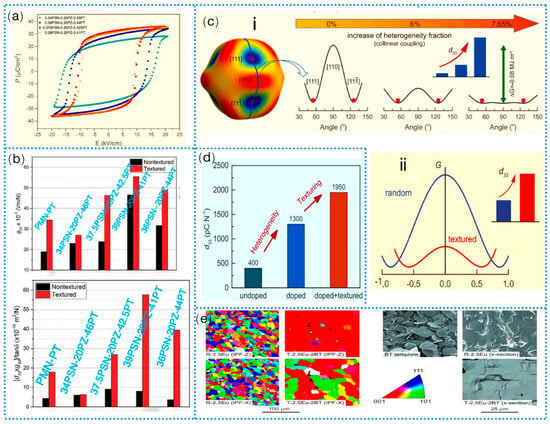

4.2. Texturing Ceramics Using PT Stencils

The piezoelectric properties of Pb-based ceramics can be improved by two methods, namely the formation of metamorphic phase boundaries (MPBs) and the doping of rare earth elements [96,97,98,99]. Moriana et al. [100] developed chalcogenide Pb(Sc1/2Nb1/2)O3-PbZrO3-PbTiO3(PSN-PZ-PT) systems with different compositions using the TGG method, and the ferroelectric properties are shown in Figure 7a. Comparing the degree of texturing of the templates with different contents reveals that the PT content is positively correlated with the degree of texturing, which is due to the suppression of TGG due to, for example, the higher melting points of Sc2O3 and ZrO2. As shown in Figure 7b, PSN-PZ-PT has a high Curie temperature and polarization stability while maintaining comparable piezoelectric properties to binary Pb(Mg1/3Nb2/3)O3-PbTiO3 (PMN-PT); achieving synergistic effects using the two mechanisms in the same material has been difficult because the microstructural design is affected by the compositionally induced local structural inhomogeneities. As shown in Figure 7c, Yan [101] et al. successfully addressed this challenge for the first time by proposing a synergistic design of local structural heterogeneity and grain texturing under image-only modeling and phase-field simulation, where local structural heterogeneity is introduced by doping rare earth elements (including relaxation ferroelectrics), and the d33 of the PMN-PTs is enhanced with the increase in the volume fraction of heterogeneity [101], and then PMN-PT piezoelectric ceramics are prepared using the TGG process. Figure 7d,e show that the Eu3+-doped woven PMN-PT piezoelectric ceramics are highly [001] oriented compared to the others. Li et al. [102] found that Eu3+ doping has a great influence on the morphology of the domains and the size of the domains of the PMN-0.25PT ceramics due to the fact that a high Eu3+ doping level helps to enhance the local structural inhomogeneity, disrupting the long-range ordered ferroelectric states and producing more disordered and smaller domain microstructures [102,103,104]. However, PMN-PT and PZN-PT single crystals show very low phase transition temperatures and low Curie temperatures (Tc~130–170 °C), resulting in poor temperature stability and a relatively low mechanical quality factor (Qm), both of which limit their applications [105].

Figure 7.

(a) Polarization–electric field loops of xPSN−20PZ−xPT, with 3 vol% BT−textured ceramics, and (b) left: piezoelectric voltage coefficient g33. Right: Figure of merit (FOM) comparison of both non-textured and textured PMN−PT and PSN−PZ−PT ceramics. Reprinted with permission from Ref. [100], Copyright 2023, Advanced Electronic Materials. (c) Comparison of piezoelectric coefficient d33 between undoped (R), doped (R−2.5Eu), and doped textured (T−2.5Eu−2BT) ceramics. Reprinted with permission from Ref. [101], Copyright 2022, Adv. (d) Phenomenological illustration and phase−field simulation of enhanced piezoelectricity via local structural heterogeneity and texture engineering. (i) Landau free energy of ferroelectrics with different volume fraction of the local structural heterogeneity. (ii) Landau free energy profiles with respect to the polarization component Pz along poling direction z for random and textured polycrystals, where the inset shows the corresponding d33 increment. Reprinted with permission from Ref. [101], Copyright 2022, Adv. (e) Inverse pole Figure (IPF) maps of R−2.5Eu andT−2.5Eu−2BT ceramics, measured by the SEM−EBSD technique. The IPF components in Z and X directions reveal the sample’s out−of−plane (normal) and in−plane spatial grain orientation distributions. SEM images of [001] BaTiO3 templates and cross-sections (x−section) of R−2.5Eu and T−2.5Eu−2BTceramics. Reprinted with permission from Ref. [101], Copyright 2022, Adv.

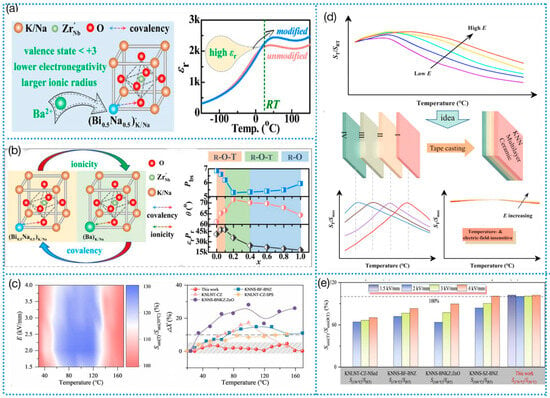

4.3. Textured Ceramics Using NN Templates

For KNN-based ceramics, it is very difficult to improve their thermal stability while maintaining good piezoelectric properties [106]. Both phase boundaries and engineered domain structures have an impact on the piezoelectricity of woven KNN-based ceramics [55]. Although a multiphase coexistence (MPC) strategy at room temperature improves the piezoelectric coefficient (d33) of potassium sodium niobate ((K, Na) NbO3, KNN) ceramics, it is still affected by the compositional and temperature dependence [107]. Polycrystalline phase transition (PPT) in KNN ceramics is considered to have the intrinsic drawback of poor temperature stability, and apart from the ionic substitution method shown in Figure 8a,b, which could improve the temperature stability, adjusting the crystal orientation can also lead to effective but improved temperature-stabilized strain characteristics of KNN-based piezoelectric ceramics [108,109]. Wang et al. [110] introduced V′K/Na-VO... defect dipole and constructed grain orientation to improve the strain performance and temperature stability of KNN-based piezoelectric ceramics. To prepare the woven ceramics, NN plate templates were synthesized by a two-step molten salt method, and the reaction equation for the template synthesis is as follows:

1.25Bi2O3 + 1.75Na2CO3 + 2.5Nb2O5 → BiNN5 +1.75CO2

BiNN5+ 0.75Na2CO3 → 5NaNbO3 + 1.25Bi2O3+ 0.75CO2

This KNN-based ceramic exhibits predominantly orthorhombic symmetry at RT, with four equivalent domains at 45° angles in the [001] direction. Due to the V′K/Na-VO defect dipole synergies and good grain orientation, normalized monopolar and bipolar strains are higher than most lead-free piezoelectric ceramics and even some single crystals [111,112]. Extensive experimental characterization has shown that more equivalent domains and smaller angles improve the longitudinal piezoelectric response [113]. As shown in Figure 8d, Yu et al. [114] proposed a strategy that involved building multilayer composites by band casting to achieve temperature stability where the strain is insensitive to temperature and electric field. As shown in Figure 8c, by selecting components with different strain responses under electric field and temperature and utilizing the strain coupling and complementary effects of each component, superior temperature stability with almost no electric field dependence of strain can be achieved [114,115].

Figure 8.

(a) Appropriately replace (Bi0.5Na0.5) 2+ MPC with Ba2+ at room temperature. Reprinted with permission from Ref. [107], Copyright 2020, ACS. (b) Schematic diagram showing the effects of the interreplacement between (Bi0.5Na0.5)2+ and Ba2+ on the ionicity and covalency of the A−O bond; variations of Pbs, εrPr, and θ with x. Reprinted with permission from Ref. [107], Copyright 2020, ACS. (c) Temperature−dependent strain of the multilayer composite ceramic (I−II−III−IV) under different electric fields. ΔX of the multilayer composite ceramic (I−II−III−IV) and other KNN−based ceramics. Reprinted with permission from Ref. [112], Copyright 2020, ACS. (d) Design schematic diagrams of a multilayer composite ceramic. Reprinted with permission from Ref. [112], Copyright 2020, ACS. (e) Suni(T)/Suni(RT) of different ceramics under different electric fields at a high temperature. Reprinted with permission from Ref. [112], Copyright 2020, ACS.

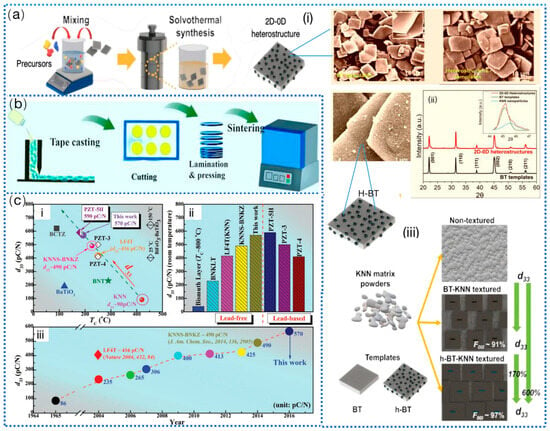

Template grain growth techniques have been successfully used to improve piezoelectric properties, and the development of heterostructured templates and the construction of novel piezoelectric composites are also helpful for enhancing piezoelectric properties [48,84,115]. Heterostructured BT (h−BT) templates are prepared by nucleating and growing undoped KNN nanoparticles on bare BT. h−BT can reduce the mechanical stress at the interface of the woven ceramics (h−BT−KNN), leading to larger grain growth and a higher degree of weaving than that of the woven ceramics (BT−KNN) prepared using bare BT. As shown in Figure 9a, Park et al. [84] used a BaTiO3 (BT) template and Ba, Mn, and Bi-doped (K, Na) NbO3 (BMBKNN) matrix powder to prepare heterostructured BT templates during the solvothermal reaction by heterogeneous nucleation growth of (K, Na) NbO3 (KNN) nanoparticles deposited onto BT templates by heterogeneous nucleation (h-) BT, as shown in Figure 9a. The process flow is shown in Figure 9b, and three different samples—nonwoven random ceramics, BT-KNN, and h-BT-KNN woven ceramics—were prepared using h-BT, BT template, and the same KNN substrate powders as shown in Figure 9(aiii). h-BT-KNN ceramics, compared to the BT-KNN ceramics prepared using the BT template via the conventional TGG process, showed that the dielectric and piezoelectric properties of BT-KNN ceramics were further improved. In particular, the piezoelectric constant (d33) in the woven h-BT-KNN ceramics was improved by about 170% compared to BT-KNN. Lin et al. [116] used a combination of the template grain growth (TGG) technique and composite design strategy to develop novel KNNTa- BNN piezoelectric composites. As shown in Figure 9c, Xu et al. [117] prepared 0.96(K0.44Na0.56) (Nb0.95Sb0.05) O3-0.04Bi0.5(Na0.18K0.82)0.5ZrO3 ceramics, with d33 ≈ 420–490 pC/N, in 2014, using a conventional solid-state method. Higher piezoelectricity was subsequently achieved by constructing ternary ceramics in KNN-based (1−x−y) K1−wNawNb1−zSbzO3-yBaZrO3-xBi0.5K0.5HfO3 (KNNS-BZ-BKH) ternary ceramics using a combination of Sb5+, BaZrO3, and Bi0.5K0.5HfO3 as additives to transfer their TR-O and TO-T to room temperature or near room temperature. By adjusting the x, y, z and w values to design the composition of the materials, an R-T phase boundary can be constructed, which can realize the multiphase coexistence in ternary ceramics [118], and the experimental results show that d33 reaches 570 ± 10 pC/N, which surpasses the results from the previous reports, and the piezoelectric properties are close to those of Pb-based ceramics.

Figure 9.

(a) Schematic of the preparation of 2D–0D BT-KNN heterostructure templates. (i) Typical scanning electron micrographs (SEM) of BT templates and 2D–0D BT-KNN heterostructure templates. (The inset in panel b depicts the surface of bare BT templates. (ii) X-ray diffractograms (XRD) of bare BT templates (black) and KNN nanoparticle-decorated BT templates (red). (iii) Schematic of the heterostructure strategy for improving grain orientation and piezoelectric properties through templated grain growth using KNN nanoparticle-decorated BT templates (h-BT). Reprinted with permission from Ref. [84], Copyright 2023, Journal of the European Ceramic Society. (b) Process diagram of the preparation of the PCD vibration energy harvester. Reprinted with permission from Ref. [84], Copyright 2023, Journal of the European Ceramic Society. (c) (i) Comparison of d33 versus TC values of piezoceramic materials; (ii) comparison of d33 among KNNS-BZ-BKH, other lead-free piezoelectric materials and PZT materials; and (iii) historical evolution in d33 of KNN-based ceramics as a function of time measured in years. All d33 values were recorded at room temperature. Reprinted with permission from Ref. [117] Copyright 2014, Adv.

5. Template Method and Ion Doping

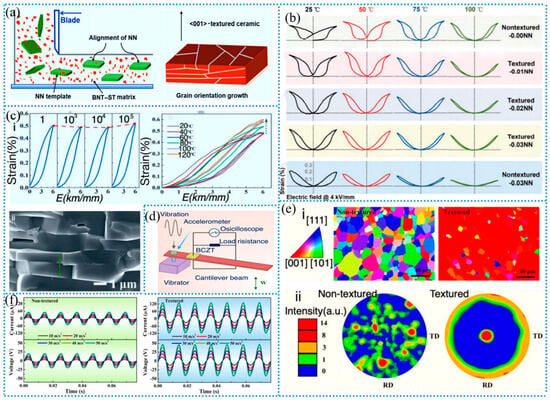

(Bi0.5Na0.5) TiO3 (BNT)-based lead-free piezoelectric ceramics have excellent electric field-induced strain (electrical strain) properties but tend to suffer from large hysteresis and poor fatigue resistance, which severely limits their applications. Zhou et al. [56] successfully used a combination of compositional and structural modulation using a slab NaNbO3 (NN) template-induced grain orientation growth to synthesize the woven (1-x) (0.76Bi0.5Na0.5TiO3-0.24SrTiO3)-xNaNbO3 (BNT-ST-xNN, x = 0.00–0.03). Doping Na+ at the A-site and Nb5+ at the B-site increases chemical disorder and enhances the random field, realizing BNT-based ceramics with a highly <001> woven configuration in the pure ER state. Plate-like NN templates were prepared by applying shear stress through strip casting, and a schematic of the strip casting process is shown in Figure 10a. The reaction equation for the synthesis of NN templates by the two-step lava method is as follows:

5Bi2O3 + 7Na2CO3 +10Nb2O5→4Bi2.5Na3.5Nb5O18 + 7CO2↑

4Bi2.5Na3.5Nb5O18 + 3Na2CO3→ 20NaNbO3 + 5Bi2O3 + 3CO2↑

Figure 10b shows that the woven BNT-ST-0.03NN ceramics exhibit the best strain stability in the temperature range studied. This is mainly because the constituent BNT-ST-0.03NN deviates from the NR/ER phase boundary (located around the constituent BNT-ST-0.01NN), and temperature changes do not lead to significant changes in the phase structure. Second, despite the presence of ER states, the highly <001> crystal structure and more ferroelectric R−3cPNR can provide an additional driving force for the relaxation-ferroelectric transition and resist the effect of temperature [56]. As shown in Figure 10(cii), Lai et al. [119] used Bi4Ti3O12 as a template and prepared Nb5+-doped 0.8(Bi0.5Na0.5) TiO3-0.2(Bi0.5K0.5) TiO3 with a high degree of weaving (~80%) using the reaction template grain growth (RTGG) method (0.8BNT-0.2BKT) ceramics. Using a combination of B-site donor doping and the RTGG method, the electrical strain performance was significantly improved and an ultra-high strain of 0.65% was obtained at 6 kV/mm, which was attributed to the fact that adding Nb5+ to the B-site not only reduces the concentration of the oxygen vacancies, but also forms a defective dipole with A-site vacancies, which would be favorable for the electrical strain response [120]. As shown in Figure 10(ci), after 105 cycles of unipolar electric field loading, the shape of the S-E curve did not change and the electrical strain performance did not decrease significantly, showing excellent fatigue resistance. Liu et al. [121] used a low-εT33/ε0 (~168) BT template to develop a weave with ultra-high power generation performance based on the TGG technology and excellent fatigue resistance of woven BCTZ ceramic piezoelectric energy harvester, as shown in Figure 10e, where the electron backscatter diffraction (EBSD) mapping image confirms the strong [001] optimal crystal orientation of the grains in the woven ceramic. The piezoelectric cantilever test system is shown in Figure 10d, where the BCTZ ceramic piezoelectric energy harvester maintains high robustness for up to 106.5 vibration cycles. This excellent mechanical durability is attributed to the use of grain-oriented ceramics, whose fatigue resistance is significantly improved. Figure 10f shows the output voltage and current of the randomly oriented and woven BCTZ energy harvester over time. The output voltage and current of the woven energy harvester are significantly improved.

Figure 10.

(a) Schematic diagram of tape−casting process for preparation of textured ceramics. Reprinted with permission from Ref. [56], Copyright 2022, Journal of Advanced Ceramics. (b) S–E curves of the non-textured BNT–ST, non-textured BNT–ST–0.03NN, and textured BNT–ST–xNN(x = 0.01–0.03) ceramics measured within the temperature range of 25~100 °C. Reprinted with permission from Ref. [56], Copyright 2022, Journal of Advanced Ceramics. (c) (i) Unipolar S–E curves recorded at 1 Hz after 105 electric cycles, and unipolar S−E curves for temperatures in the range of 20–120 for textured ceramics. (ii) Cross−section SEM image of textured BNKT15Nb ceramics. Reprinted with permission from Ref. [119], Copyright 2023, ACS. (d) Schematic illustration of the test system of a piezoelectric cantilever. Reprinted with permission from Ref. [121], Copyright 2018, ACS. (e) EBSD inverse pole figure maps and (001) pole figures of randomly oriented and textured BCTZ ceramics. Reprinted with permission from Ref. [121], Copyright 2018, ACS. (f) The variations in output voltage and current with time for randomly oriented and textured BCTZ energy harvesters under cyclic sine−wave loading at different accelerations. Reprinted with permission from Ref. [121], Copyright 2018, ACS.

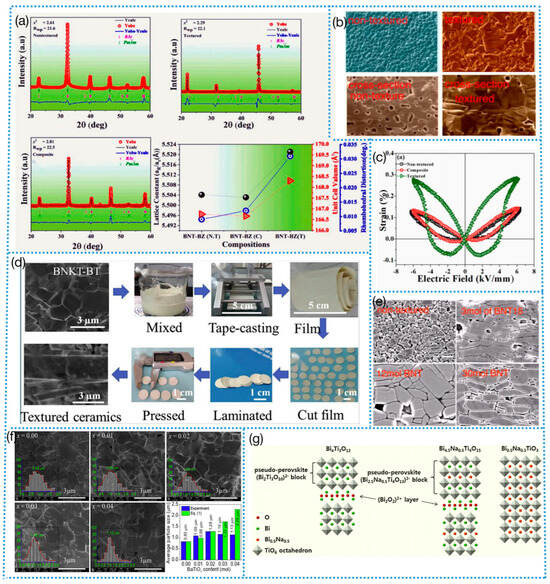

Specific amounts of BaZrO3 (BZ) modification also led to a significant improvement in the electromechanical properties of BNT ceramics [122,123]. As shown in Figure 11b, Hussain et al. [124] used plate templates with a single-phase chalcogenide structure synthesized by a conventional solid-state reaction (CSSR) method, and then used the RTGG method to prepare the woven 0.94Bi1/2Na1/2TiO3−0.06BaZrO3(BNT−BZ) ceramics, as shown in Figure 11a, where the woven samples exhibit a high level of lattice anisotropy/aberration compared to the nonwoven and composite BNT−BZ samples. This slight distortion (90o-αR = 0.031o) may originate from the lattice mismatch between cubic and rhombic symmetry, with an increase in the phase fraction (%) of the rhombic phase, which improves the piezoelectric properties of the woven ceramics [124]. The effect of plate-like BNT template particles on the structural phases and electromechanical properties of nonwoven and woven BNT−BZ ceramics is shown. Figure 11c shows the field-induced bipolar and unipolar strain responses of nonwoven, composite, and woven samples of BNT−BZ ceramics under an applied electric field of 6.0 kV/mm. The development of weaving plays an important role in improving the electromechanical properties of BNT−BZ ceramics compared to composites. Since BNT has a highly symmetric chalcogenide structure and usually grows isospinally, it is difficult to prepare BNT slabs by one-step molten salt synthesis. In this case, as shown in Figure 11g, Cha et al. [125] found that using plate-like BNT15 or BiT precursors and incorporating the TMC method is an effective way to obtain BNT slabs, and the reaction equation is shown below:

Bi4Ti3O12 + 3/4Na2CO3 → 3Bi0.5Na0.5TiO3 + 5/4Bi2O3 + 3/4CO2

5/4Bi2O3 + 5/4Na2CO3 + 5TiO2 → 5Bi0.5Na0.5TiO3 + 5/4CO2

Texturized Bi0.5(Na0.8K0.2)0.5TiO3 (BNKT) ceramics were prepared using plain BNT templates and BNT15, respectively, as shown in Figure 11e. The best texturization effect was achieved by the addition of the 3 mol BNT15 template as compared to the non-texturized and plain BNT templates, and the experiments revealed that the texturized BNT ceramics were synthesized by using the TMC method via RTGG. The lack of plate-like BNT particles in the texturized BNKT ceramics prepared by the process is due to the unavoidable presence of equiaxed BNT particles. Therefore, more BNT templates need to be added to the matrix to achieve better texturization. These results can be applied to the preparation of other BNT-based textured piezoelectric ceramics prepared by the RTGG process, such as BNT−BT, BNT−BZ, and BNKT−BT. As shown in Figure 11d, Gio et al. [126] used the conventional solid-phase reaction method and the template grain growth method to synthesize (1−x) [Bi0.5 (Na0.4 K0.1)TiO3]−xBaTiO3 (BNKT−BT) lead-free woven ceramics. Figure 11f shows the SEM and grain size distribution of BNKT−BT ceramics with different BaTiO3 contents. It is easy to see that the addition of BaTiO3 can improve the microstructure and the grain size increases with the increase in BaTiO3 content. When the amount of BaTiO3 added is greater than 0.02 moles, a large discrepancy between the experimental data and the theoretical calculations occurs. This is due to the fact that the diffusivity of solute atoms is usually different from that of most atoms, so the addition of BaTiO3 beyond the solubility limit in BNKT ceramics leads to a solute drag effect and inhibits grain growth. In summary, the increase in BaTiO3 content in BNKT ceramics may contribute to the improvement of ferroelectric properties, leading to a significant improvement in the energy storage performance of the materials used for dielectric capacitor applications.

Figure 11.

(a) XRD peaks fitted with Retvield refinement for space group of R3c and Pm3 m for non−textured, textured BNT−BZ, composite ceramics, and lattice constants (aC, and aR), unit cell volume, and Rhombohedral distortions (90°–αo). Reprinted with permission from Ref. [124], Copyright 2023, Ceramics International. (b) Scanning electron micrographs showing cross−sections of the non−textured and textured BNT−BZ ceramics measured at room temperature. Reprinted with permission from Ref. [124], Copyright 2023, Ceramics International. (c) Room temperature field−induced strain curves of the non−textured, composite, and textured BNT−BZ ceramics’ bipolar field−induced strain; Reprinted with permission from Ref. [124], Copyright 2023, Ceramics International. (d) The process of fabrication technology for textured ceramics. Reprinted with permission from Ref. [126], Copyright 2021, Journal of Alloys and Compounds. (e) SEM of non−textured BNKT and BNKT textured using 3 mol of BNT15, 12 mol of BNT, and 32 mol of BNT templates. Reprinted with permission from Ref. [125], Copyright 2018, Journal of the European Ceramic Society. (f) Typical SEM images of the BNKT−BT ceramics with different amounts of BaTiO3 content. Reprinted with permission from Ref. [126], Copyright 2021, Journal of the European Ceramic Society. Journal of Alloys and Compounds. (g) Crystal structures of BT, BNT15, and BNT. Reprinted with permission from Ref. [125], Copyright 2018, Journal of the European Ceramic Society.

6. Challenges and Prospects of Ceramic Fabrication Processes

This paper summarizes the progress of research on the piezoelectric ceramic-based weaving process and the factors that affect the performance of weaving ceramics. As more in-depth research has become available, researchers have gained a comprehensive understanding of woven high-performance piezoelectric ceramics and have rationalized the reaction mechanisms used to prepare woven ceramics through various characterization methods, and various high-performance piezoelectric ceramics have been prepared by the texture process. However, in the field of lead-free piezoelectric ceramics, including the existing KNN system, the piezoelectric performance has never been able to catch up with lead-based ceramics. The development of environmentally friendly piezoelectric ceramics with excellent performance remains an ongoing challenge.

Table 2 summarizes data from the literature pertaining to the performance parameters of piezoelectric ceramics prepared by the weaving process, from which we can easily ascertain that the performance of lead-free ceramics has never been able to exceed that of lead-based ceramics, especially with regard to piezoelectricity. Compared with the high-performance lead-free ceramics that have been developed previously, the performance of lead-based ceramics is up to three to four times higher. Regarding the degree of texture, most of the lead-based ceramics exhibit performance improvements of more than 95%, and there is a clear discrepancy between the performances of lead-free ceramics and lead-based ceramics. The performance of the lead-free ceramics is not as good as that of the lead-based ceramics. Regarding the Curie temperature of lead-free ceramics and lead-based ceramics, their performances are fairly equal, and in a few cases, the Curie temperature of lead-free ceramics has exceeded that of lead-based ceramics. When it comes to woven ceramics, follow-up research can consider the following topics:

Material improvement: Continue to improve the performance of lead-free piezoelectric ceramics, including their piezoelectric properties, stability and reliability. This may involve the study of new ceramic material synthesis and processing methods.

Preparation process optimization: Optimize the preparation process to improve efficiency and reduce the cost of material preparation. This may include optimization of the sintering temperature and time, and the material formulation.

Expansion of application areas: Study the potential applications of lead-free piezoelectric ceramics in different fields, such as sensor technology, medical devices, acoustic devices, and communication devices.

Environmental impact assessment: Evaluating the environmental impact of the production and use of lead-free piezoelectric ceramics to ensure that they are truly environmentally friendly.

Table 2.

Piezoelectric ceramic texturing process and performance parameters.

Table 2.

Piezoelectric ceramic texturing process and performance parameters.

| Textured Materials | Lotgering Factor | Tc (°C) | d33 (pC/N) | kp | Refs. | |

|---|---|---|---|---|---|---|

| KNN KNLN-BZ-BNT | - | - | 319 | 42% | [27] | |

| TGG | BCZT | 94% | 120 | - | - | [47] |

| TGG | KNN-CZ-xBKH | - | 256 | 550 | 72% | [55] |

| HPS | KNN | - | 396 | 151 | - | [60] |

| RTGG | NK(NS)— 0.02BZ—0.02BAZ | 97% | 178 | 805 | 0.68 | [62] |

| TGG | 0.19PIN–0.445PSN–0.365PT | 99% | 247 | 1090 | 0.83 | [63] |

| TGG | 0. 16PYN-0.52PMN-0.32 PT | 99% | 205 | 1087 | 0.9 | [64] |

| RTGG | KNN | 96% | 162 | 535 | 0.57 | [65] |

| TGG | PIN–PMN–PT | 95% | 225 | 780 | 0.59 | [69] |

| RTGG | BT | 84.6% | 126 | 788 | - | [72] |

| PIN-PHT-xSb | - | 300 | 706 | 0.68 | [74] | |

| PIN-PHT | - | 360 | 490 | 0.56 | ||

| PIN-PHT-CuF2 | - | 348 | 488 | 0.60 | ||

| PIN-PMN-PT-Mn | - | 209 | 347 | 0.57 | ||

| TGG | KNN-BCZT | 74% | 388 | 190 | 0.54 | [82] |

| TGG | BT-KNN | 91% | 390 | 180 | - | [84] |

| TGG | PMN-PT | 95% | 158 | 770 | - | [85] |

| TGG | KNNS-BxBAZ | 274 | 406 | 0.63 | [86] | |

| TGG | KNN-XNN | 94% | 240 | 590 | 0.8 | [87] |

| TGG | KNN | - | 276 | 380 | 0.54 | [88] |

| TGG | BNT–BKT–BT | 73% | - | - | - | [89] |

| TGG | 0.42PNN-0.21PZ-0.37PT | - | 167 | 910 | 0.74 | [92] |

| TGG | PNN-PZT | 93% | 103 | 1210 | [93] | |

| LKNNS-EuNZ-0.03BZ | 98% | - | 331 | 0.53 | [94] | |

| NBT-SBT | 91% | - | - | - | [95] | |

| PMN-PT | 97% | - | 800 | - | [99] | |

| PMN-PT | - | - | 1950 | - | [101] | |

| 0.42PMN–0.26PIN–0.32PT | - | 180 | 426 | - | [105] | |

| RTGG | KNLN-BZ-BNT | 90% | 247 | 319 | 0.48 | [106] |

| KNNS-BNBZ | - | - | 505 | - | [107] | |

| TGG | KNN-CZ | 89.7% | 192 | 330 | 0.46 | [112] |

| KNNTa–BNN | 94% | 360 | 435 | 0.71 | [116] | |

| RTGG | KNLN-BZ-BNT-Mn | - | 205 | 292 | 0.47 | [117] |

| RTGG | KNLN-BZ-BNT-Mn | 66% | - | 320 | - | [118] |

| RTGG | 0.8BNT–0.2BKT | 80% | - | - | - | [119] |

| TGG | BCTZ | 99% | - | 728 | - | [121] |

7. Conclusions

This paper summarizes various approaches for achieving high-performance piezoelectric ceramics based on the piezoelectric ceramic weaving process, preparation methods, and conditions. The main points are as follows:

Preparation consistency: Ensuring that the properties and quality of mass-produced woven ceramics remain consistent is challenging. Small variations in process parameters can lead to instability in terms of product performance.

Control of material composition: The composition of woven ceramics may affect their properties, including their mechanical strength, thermal stability, and electrical characteristics. Achieving precise control of material composition is an important issue.

Molding method: Choosing the appropriate molding method to obtain the desired textile structure is critical. Different molding methods may require different process parameters and equipment.

Sintering conditions: The sintering process is critical to the final properties of the woven ceramics. Controlling the sintering temperature and time and the atmosphere is key to the preparation process.

Interfacial treatments: Woven ceramics often contain multiple materials or layers, so interfacial treatments need to be precisely controlled to ensure good bonding and performance.

Author Contributions

N.S.: methodology, software, validation, form analysis, writing—original draft preparation, visualization; L.Q. and Q.L.: investigation, resources, data curation, writing—review and editing, supervision, project administration, funding acquisition; Y.L.: form analysis, software. R.L., Y.Z., S.S., Y.S. and C.Z.: form analysis. All authors have read and agreed to the published version of the manuscript.

Funding

This research received funding from the following sources: Beijing Natural Science Foundation (L243022), 2024 University Student Innovation and Entrepreneurship Training Program (S202411232814), the National Natural Science Foundation of China (U2006218), and the Project of Construction and Support for High-Level Innovative Teams of Beijing Municipal Institutions (BPHR20220124).

Acknowledgments

This work was supported by Beijing Natural Science Foundation (L243022), 2024 University Student Innovation and Entrepreneurship Training Program (S202411232814), the National Natural Science Foundation of China (U2006218), and the Project of Construction and Support for High-Level Innovative Teams of Beijing Municipal Institutions (BPHR20220124).

Conflicts of Interest

The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Gao, T.; Liao, Q.; Si, W.; Chu, Y.; Dong, H.; Li, Y.; Liao, Y.; Qin, L. From fundamentals to future challenges for flexible piezoelectric actuators. Cell Rep. Phys. Sci. 2024, 5, 101789. [Google Scholar] [CrossRef]

- Saito, Y.; Takao, H.; Tani, T.; Nonoyama, T.; Takatori, K.; Homma, T.; Nagaya, T.; Nakamura, M. Lead-free piezoceramics. Nature 2004, 432, 84–87. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Qu, W.; Daniels, J.; Wu, H.; Liu, L.; Wu, J.; Wang, M.; Checchia, S.; Yang, S.; Lei, H.; et al. Lead zirconate titanate ceramics with aligned crystallite grains. Science 2023, 380, 87–93. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Tao, Y.; Wang, Z.; Zeng, H.; Yang, J.; Li, Y.; Zhao, S.; Tang, P.; Zhang, J.; Yan, M.; et al. Highly–flexible, high–performance and stretchable piezoelectric sensor based on a hierarchical droplet-shaped ceramics with enhanced damage tolerance. Adv. Mater. 2024, 36, 2311624. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Wang, Z.; Zhong, J.; Yan, M.; Zhao, S.; Gong, J.; Feng, K.; Zhang, J.; Zhou, K.; Xie, J.; et al. Construction of flexible piezoceramic array with ultrahigh piezoelectricity via a hierarchical design strategy. Adv. Funct. Mater. 2023, 33, 2304402. [Google Scholar] [CrossRef]

- Wang, Q.; Bian, L.; Li, K.; Liu, Y.; Yang, Y.; Yang, B.; Cao, W. Achieving ultrahigh electromechanical properties with high TC in PNN-PZT textured ceramics. J. Mater. Sci. Technol. 2023, 175, 258–265. [Google Scholar] [CrossRef]

- Lu, G.; Zhao, Y.; Zhao, R.; Hao, J.; Bai, W.; Li, P.; Li, W.; Zhai, J. High performance (K, Na) NbO3-based textured ceramics for piezoelectric energy harvesting. Ceram. Int. 2024, 50, 54869–54877. [Google Scholar] [CrossRef]

- Tian, F.; Liu, Y.; Tian, W.; Wang, L.; Hao, B.; Yang, S. Research on the Characteristics of High-Performance Textured Ceramic Materials and Their Application in Composite Rod Transducers. Actuators 2024, 13, 437. [Google Scholar] [CrossRef]

- Zhao, L.; Yuan, X.; Zhou, X.; Wang, Q.; Li, J.; Xiong, X.; Zhang, Q.; Chen, C.; Chen, S.; Ju, D.; et al. Three-dimensional honeycomb structured BaTiO3-based piezoelectric ceramics via texturing and vat photopolymerization. Addit. Manuf. 2024, 95, 104542. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, H.; Zhu, Z.; Zeng, J.; Zhang, D.; Eriksson, M.; Viola, G.; Yan, H. Deciphering the peculiar hysteresis loops of 0.05Pb(Mn1/3Sb2/3)O3–0.95Pb(Zr0.52Ti0.48)O3 piezoelectric ceramics. Acta Mater. 2023, 244, 118563. [Google Scholar] [CrossRef]

- van der Veer, E.; Noheda, B.; Acuautla, M. Piezoelectric properties of PZT by an ethylene glycol-based chemical solution synthesis. J. Sol-Gel Sci. Technol. 2021, 100, 517–525. [Google Scholar] [CrossRef]

- Chen, J.X.; Li, J.W.; Cheng, C.C.; Chiu, C.W. Piezoelectric property enhancement of PZT/Poly (vinylidenefluoride-co-trifluoroethylene) hybrid films for flexible piezoelectric energy harvesters. ACS Omega 2021, 7, 793–803. [Google Scholar] [CrossRef] [PubMed]

- Erturk, O.; Shambaugh, K.; Park, H.-S.; Lee, S.-G.; Bhave, S.A. Self-aligned single-electrode actuation of tangential and wineglass modes using PMN-PT. Microsyst. Nanoeng. 2023, 9, 52. [Google Scholar] [CrossRef]

- Tian, F.; Liu, Y.; Ma, R.; Li, F.; Xu, Z.; Yang, Y. Properties of PMN-PT single crystal piezoelectric material and its application in underwater acoustic transducer. Appl. Acoust. 2021, 175, 107827. [Google Scholar] [CrossRef]

- Lv, P.; Qian, J.; Yang, C.; Liu, T.; Wang, Y.; Wang, D.; Huang, S.; Cheng, X.; Cheng, Z. Flexible all-inorganic Sm-doped PMN-PT film with ultrahigh piezoelectric coefficient for mechanical energy harvesting, motion sensing, and human-machine interaction. Nano Energy 2022, 97, 107182. [Google Scholar] [CrossRef]

- Zu, D.; Zhang, Y.; Li, H.; Wu, N.; OuYang, S. Sintering pressure of SPS-inducing lattice deformation enhances ferroelectric and photoluminescence properties of PLZT ceramics. J. Mater. Res. 2023, 38, 2894–2907. [Google Scholar] [CrossRef]

- Shcheglova, A.I.; Kislova, I.L.; Ilina, T.S.; Kiselev, D.A.; Barabanova, E.V.; Ivanova, A.I. Dielectric and Piezoelectric Properties of PLZT x/40/60 (x = 5; 12) Ceramics. Russ Microelectron 2021, 50, 673–678. [Google Scholar] [CrossRef]

- Luo, W.Q.; Li, D.X.; Li, Z.P.; Shen, Z.Y. Structure and Dielectric Energy Storage Properties of Secondary Phase CaCu3Ti4O12 Modified BSBNT Relaxor Ferroelectric Ceramics. Adv. Ceram. 2023, 44, 28–225. [Google Scholar]

- Wang, Y.; Wang, P.; Liu, L.; Wang, Y.; Zhao, Y.; Tian, W.; Liu, X.; Zhu, F.; Shi, J. Defect Dipole Behaviors on the Strain Performances of Bismuth Sodium Titanate-Based Lead-Free Piezoceramics. Materials 2023, 16, 4008. [Google Scholar] [CrossRef] [PubMed]

- Viola, G.; Tian, Y.; Yu, C.; Tan, Y.; Koval, V.; Wei, X.; Choy, K.L.; Yan, H. Electric field-induced transformations in bismuth sodium titanate-based materials. Prog. Mater. Sci. 2021, 122, 100837. [Google Scholar] [CrossRef]

- Zhou, X.; Xue, G.; Luo, H.; Bowen, C.R.; Zhang, D. Phase Structure and Properties of Sodium Bismuth Titanate Lead-free Piezoelectric Ceramics. Prog. Mater. Sci. 2021, 122, 100836. [Google Scholar] [CrossRef]

- Dinh, T.H.; Han, H.S.; Tran, V.D.N.; Le Van, V.; Lee, J.S. Thermally-Stable High EFIS Properties of Ternary Lead-Free BNT-BKT-BZ Piezoelectric Ceramics. J. Electron. Mater. 2023, 52, 2977–2985. [Google Scholar] [CrossRef]

- Liu, Y.; Khanbareh, H.; Halim, M.A.; Feeney, A.; Zhang, X.; Heidari, H.; Ghannam, R. Piezoelectric energy harvesting for self-powered wearable upper limb applications. Nano Sel. 2021, 2, 1459–1479. [Google Scholar] [CrossRef]

- Gao, X.; Cheng, Z.; Chen, Z.; Liu, Y.; Meng, X.; Zhang, X.; Wang, J.; Guo, Q.; Li, B.; Sun, H.; et al. The mechanism for the enhanced piezoelectricity in multi-elements doped (K,Na) NbO3 ceramics. Nat. Commun. 2021, 12, 881. [Google Scholar] [CrossRef]

- Xu, L.; Lin, J.; Yang, Y.; Zhao, Z.; Shi, X.; Ge, G.; Qian, J.; Shi, C.; Li, G.; Wang, S.; et al. Ultrahigh thermal stability and piezoelectricity of lead-free KNN-based texture piezoceramics. Nat. Commun. 2024, 15, 9018. [Google Scholar] [CrossRef]

- Wang, C.; Hou, L.; Xun, Y. Study on the Structure and Properties of (1−x)KNNS―xBFANZ Lead-free Piezoelectric Ceramics. Adv. Ceram. 2023, 44, 490–496. [Google Scholar]

- Liu, B.; Wang, Y.; Fan, N.; He, Y.; Yang, H.; Liu, S. Piezoelectric generator based on centrosymmetric CdO film with (111) orientation and its atomic mechanism. Cell Rep. Phys. Sci. 2023, 4, 101360. [Google Scholar] [CrossRef]

- Yin, J.; Shi, X.; Tao, H.; Tan, Z.; Lv, X.; Ding, X.; Sun, J.; Zhang, Y.; Zhang, X.; Yao, K.; et al. Deciphering the atomic-scale structural origin for large dynamic electromechanical response in lead-free Bi0.5Na0.5TiO3-based relaxor ferroelectrics. Nat. Commun. 2022, 13, 6333. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Yu, X.; Jiao, J.; Song, X.; Cheng, X.; Liu, M.; Wang, L.L.; Zheng, J.; Lv, W.; Zhong, G.; et al. Building cross-phase ion transport channels between ceramic and polymer for highly conductive composite solid-state electrolyte. Cell Rep. Phys. Sci. 2023, 4, 101382. [Google Scholar] [CrossRef]

- Liu, K.; He, J.; Li, T.; Hu, J.; Du, Y.; Shi, Y.; Yan, C.; Chen, Z.; Huang, S.; Sun, H. Fabrication of Ceramic-polymer Piezo-composites with Triply Periodic Minimal Interfaces via Digital Light Processing. Chin. J. Mech. Eng. Addit. Manuf. Front. 2023, 2, 100104. [Google Scholar] [CrossRef]

- Wang, B.; Wang, J.; Li, J.; Yang, M.; Huang, M.; Ma, T.; Tian, Y.; Wu, F. Structure and electrical properties of La2O3-doped (K,Na,Li)(Nb,Ta)O3-(Bi,Na)TiO3 ceramics. J. Adv. Dielectr. 2023, 13, 2350010. [Google Scholar] [CrossRef]

- Zhao, C.; Huang, Y.; Wu, J. Multifunctional barium titanate ceramics via chemical modification tuning phase structure. InfoMat 2020, 2, 1163–1190. [Google Scholar] [CrossRef]

- Gao, L.; Liu, Z.; Ren, P.; Liang, R.; Li, T.; Guo, K.; Xie, B.; Lu, J.; Mao, P.; Tian, J.; et al. Inhibiting oxygen vacancies and twisting NbO6 octahedron in erbium modified KNN-based multifunctional ceramics. J. Mater. 2023, 10, 179–189. [Google Scholar] [CrossRef]

- Mi, L.; Wu, D.; Zhou, H.; Chen, Y. Study on Sintering Characteristics of Ce-doped PZN-PZT Ternary Piezoelectric Ceramics. Adv. Ceram. 2023, 44, 57–66. [Google Scholar]

- Li, Y.; Zhou, Z.; Liang, R.; Gao, B.; Zhou, Z.; Dong, X. A simple Bi3+ self-doping strategy constructing pseudo-tetragonal phase boundary to enhance electrical properties in CaBi2Nb2O9 high-temperature piezoceramics. J. Eur. Ceram. Soc. 2022, 42, 2772–2780. [Google Scholar] [CrossRef]

- Zhai, Y.; Qi, X.; Tian, G.; Wang, J.; Yu, F.; Gai, Z.; Du, J.; Su, W.; Guo, S.; Zheng, L. Improved energy-harvesting performance of (k, na)nbo3-based ceramics through the synergistic effect of texture and defect engineering. J. Eur. Ceram. Soc. 2025, 45, 116984. [Google Scholar] [CrossRef]

- Zhan, L.; Xia, Y.; Zhang, X.; Liu, Y.; Liu, S. Effects of Stereolithography Process Parameters on the Curing Properties of Si3N4 Ceramic Slurries. Chin. J. Mech. Eng. Addit. Manuf. Front. 2023, 2, 100095. [Google Scholar] [CrossRef]

- Peng, G.; Chen, C.; Zhang, J.; Zheng, D.; Hu, S.; Zhang, H. Effects of PNN/PZT ratios on phase structure, electric properties and relaxation behavior of PZN–PNN–PZT ceramics. J. Mater. Sci. Mater. Electron. 2016, 27, 3145–3151. [Google Scholar] [CrossRef]

- Cheng, M.; Zhao, M.; Zhang, S.; Yan, Y.; Li, Z.; Wang, P.; Murakami, R.-I.; Zhang, D. Improved piezoelectricity of lead-based PNN-PIN-PT ternary ceramics via polymorphic nanodomain modulation. J. Eur. Ceram. Soc. 2023, 43, 5231–5240. [Google Scholar] [CrossRef]

- Hou, W.; Liao, Q.; Xie, S.; Song, Y.; Qin, L. Prospects and Challenges of Flexible Stretchable Electrodes for Electronics. Coatings 2022, 12, 558. [Google Scholar] [CrossRef]

- Cao, S.; Zou, Q.; Wang, Q.; Wang, W.; Chen, L.; Liu, T.; Xu, J.; Zhang, Q.; Gao, F. KSr2Nb5O15-based composite ceramics: The atomic-scale anisotropic origin of photochromism and influences of second phase concentrations on optical properties. Ceram. Int. 2023, 49, 18470–18482. [Google Scholar] [CrossRef]

- Li, X.; Yao, M.; Lin, W.; Lin, J.; Yao, X. Morphological evolution of plate-like B-site complex perovskite Pb(ZrxTi1−x)O3 microcrystals. J. Solid State Chem. 2023, 326, 124236. [Google Scholar] [CrossRef]

- Chen, Q.; Cao, S.; Song, W.; Xie, Y.; Yan, Z.; Xu, J.; Gao, F. Comparing investigation of the anisotropic thermoelectric properties of textured KSr2Nb5O15 ceramics. J. Phys. Chem. Solids 2023, 175, 111204. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S.; Li, X.; Li, L.; Liu, Z.; Zhang, J.; Wang, Y. High piezoelectricity and low strain hysteresis in PMN–PT-based piezoelectric ceramics. J. Adv. Ceram. 2023, 12, 792–802. [Google Scholar] [CrossRef]

- Haugen, A.B.; Ringgaard, E.; Levassort, F. Textured, lead-free piezoelectric ceramics with high figure of merit for energy harvesting. J. Phys. Mater. 2021, 4, 044002. [Google Scholar] [CrossRef]

- Fan, P.; Liu, K.; Ma, W.; Tan, H.; Zhang, Q.; Zhang, L.; Zhou, C.; Salamon, D.; Zhang, S.-T.; Zhang, Y.; et al. Progress and perspective of high strain NBT-based lead-free piezoceramics and multilayer actuators. J. Mater. 2021, 7, 508–544. [Google Scholar] [CrossRef]

- Kou, Q.; Yang, B.; Sun, Y.; Yang, S.; Liu, L.; Xie, H.; Chang, Y.; Zhang, S.; Li, F. Tetragonal (Ba, Ca) (Zr, Ti)O3 textured ceramics with enhanced piezoelectric response and superior temperature stability. J. Mater. 2022, 8, 366–374. [Google Scholar] [CrossRef]

- Liu, L.; Jiang, X.; Rui, L.; Guo, Z.; Hou, Z. A Duplex Grain Structure of Dense (K, Na) NbO3 Ceramics Constructed by Using Microcrystalline as Seed. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2022, 37, 385–392. [Google Scholar] [CrossRef]

- Yu, F.; Lu, Q.; Zhou, P.; Zhao, C.; Wu, X.; Lin, C.; Gao, M.; Lin, T. Microstructure and photoluminescence properties of Er3+/LaBiO3 co-modified (K0.5Na0.5) NbO3 transparent textured ceramics via tape-casting method. Mater. Sci. Eng. B 2022, 286, 116073. [Google Scholar] [CrossRef]

- Jia, P.; Zheng, Z.; Li, Y.; Li, Z.; Liu, T.; Wang, Y. The achieving enhanced piezoelectric performance of KNN-based ceramics: Decisive role of multi-phase coexistence induced by lattice distortion. J. Alloy. Compd. 2023, 930, 167416. [Google Scholar] [CrossRef]

- Leng, H.; Yan, Y.; Li, X.; Karan, S.K.; Fanton, M.; Priya, S. High-power piezoelectric behavior of acceptor-doped <001> and<111> textured piezoelectric ceramics. J. Mater. Chem. C 2023, 11, 2229–2240. [Google Scholar]

- Liao, Q.; Hou, W.; Liao, K.; Chen, L.; Song, Y.; Gao, G.; Qin, L. Solid-phase sintering and vapor-liquid-solid growth of BP@MgO quantum dot crystals with a high piezoelectric response. J. Adv. Ceram. 2022, 11, 1725–1734. [Google Scholar] [CrossRef]

- Smolenskii, G.; Agranovskaya, A. Dielectric polarization and losses of some complex compounds. Zhur. Tekh. Fiz. 1958, 28, 4294595. [Google Scholar]

- Yan, Y.; Geng, L.D.; Liu, H.; Leng, H.; Li, X.; Wang, Y.U.; Priya, S. Near-ideal electromechanical coupling in textured piezoelectric ceramics. Nat. Commun. 2022, 13, 3565. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Huan, Y.; Yang, W.; Zhu, F.; Li, X.; Zhang, X.; Shen, B.; Zhai, J. High-performance potassium-sodium niobate lead-free piezoelectric ceramics based on polymorphic phase boundary and crystallographic texture. Acta Mater. 2019, 165, 486–495. [Google Scholar] [CrossRef]

- Zhou, X.; Yang, H.; Xue, G.; Luo, H.; Zhang, D. Optimized strain performance in <001>-textured Bi0.5Na0.5TiO3-based ceramics with ergodic relaxor state and core-shell microstructure. J. Adv. Ceram. 2022, 11, 17. [Google Scholar] [CrossRef]

- Li, Y.; Liao, Q.; Hou, W.; Qin, L. Silver-Based Surface Plasmon Sensors: Fabrication and Applications. Int. J. Mol. Sci. 2023, 24, 4142. [Google Scholar] [CrossRef]

- Jia, Y.; Fan, H.; Zhang, A.; Wang, H.; Lei, L.; Quan, Q.; Dong, G.; Wang, W.; Li, Q. Giant electro-induced strain in lead-free relaxor ferroelectrics via defect engineering. Eur. Ceram. Soc. 2023, 43, 947. [Google Scholar] [CrossRef]

- Feng, W.; Luo, B.; Bian, S.; Tian, E.; Zhang, Z.; Kursumovic, A.; MacManus-Driscoll, J.L.; Wang, X.; Li, L. Heterostrain-enabled ultrahigh electrostrain in lead-free piezoelectric. Nat. Commun. 2022, 13, 5086. [Google Scholar] [CrossRef]

- Liu, X.; Chen, X.M.; Liu, M.D.; Lan, J.J.; Zhan, X.; Lu, J.B.; Jing, H.M. Improved dielectric and ferroelectric properties of fine-grained K0.5Na0.5NbO3 ceramics via hot-press sintering. Ceram. Int. 2022, 48, 11615–11622. [Google Scholar] [CrossRef]

- Dong, A.; Liu, R.; Tian, Z.; Peng, F.; Zhao, R.; Su, X.; Tang, R. Effect of pre-sintering particle size on the microstructure and magnetic properties of two-step hot-press prepared BaFe12O19 thick films. J. Alloy. Compd. 2023, 967, 171683. [Google Scholar] [CrossRef]

- Go, S.H.; Kim, H.; Kim, D.S.; Eum, J.M.; Chae, S.J.; Kim, E.J.; Nahm, S. Improvement of piezoelectricity of (Na, K) Nb-based lead-free piezoceramics using [001]-texturing for piezoelectric energy harvesters and actuators. J. Eur. Ceram. Soc. 2022, 42, 6478–6492. [Google Scholar] [CrossRef]

- Yang, S.; Li, J.; Liu, Y.; Wang, M.; Qiao, L.; Gao, X.; Chang, Y.; Du, H.; Xu, Z.; Zhang, S.; et al. Textured ferroelectric ceramics with high electromechanical coupling factors over a broad temperature range. Nat. Commun. 2021, 12, 1414. [Google Scholar] [CrossRef]

- Chang, Y.; Wu, J.; Liu, Z.; Sun, E.; Liu, L.; Kou, Q.; Li, F.; Yang, B.; Cao, W. Grain-oriented ferroelectric ceramics with single-crystal- ike piezoelectric properties and low texture temperature. ACS Appl. Mater. Inter. 2020, 12, 38415–38424. [Google Scholar] [CrossRef]

- Chae, S.J.; Na, J.W.; Kim, D.S.; Kim, S.W.; Go, S.H.; Kim, H.; Kim, E.J.; Eum, J.M.; Nahm, S. Application of [001]-textured (K, Na)(Nb, Sb)O3-CaZrO3 thick films to piezoelectric energy harvesters. Ceram. Int. 2022, 48, 18401–18414. [Google Scholar] [CrossRef]

- Makiya, A.; Kusano, D.; Tanaka, S. Particle Oriented bismuth titanate ceramics made in hugh magnetic field. J. Ceram. Soc. Jpn. 2003, 111, 702–704. [Google Scholar] [CrossRef]

- Kimuratyamaguchi, T. Fused salt synthesis of Bi4Ti312. Ceramint 1983, 9, 13–17. [Google Scholar]

- Goyal, A.; Feenstra, R.; List, F.A.; Paranthaman, M.; Lee, D.F.; Kroeger, D.M.; Beach, D.B.; Morrell, J.S.; Chirayil, T.G.; Verebelyi, D.T.; et al. Using RABiTS to fabricate high-temperature superconducting wire. JOM 1999, 51, 19–23. [Google Scholar] [CrossRef]

- Wei, D.-D.; Yuan, Q.-B.; Zhang, G.-Q.; Wang, H. Templated grain growth and piezoelectric properties of <001>-textured PIN–PMN–PT ceramics. J. Mater. Res. 2015, 30, 2144–2150. [Google Scholar]

- Chen, H.B.; Xu, J.B.; Zhai, J.W. Fabrication and Piezoelectric Property of Textured Bismuth Layered Structure Ceramics by Hot Pressing Technique. Key Eng. Mater. 2013, 547, 11–18. [Google Scholar] [CrossRef]

- Moriana, A.D.; Zhang, S. Lead-free textured piezoceramics using tape casting: A review. J. Mater. 2018, 4, 277–303. [Google Scholar] [CrossRef]

- Khanal, G.P.; Fujii, I.; Ueno, S.; Wada, S. Phase evolution and, rientation mechanism in RTGG-processed BaTiO3 ceramics with electrical properties. J. Am. Ceram. Soc. 2021, 104, 4649–4658. [Google Scholar] [CrossRef]

- Li, T.; Liu, C.; Shi, P.; Liu, X.; Kang, R.; Long, C.; Wu, M.; Cheng, S.; Mi, S.; Xia, Y.; et al. High-Performance Strain of Lead-Free Relaxor-Ferroelectric Piezoceramics by the Morphotropic Phase Boundary Modification. Adv. Funct. Mater. 2022, 32, 2202307. [Google Scholar] [CrossRef]

- Shi, H.; Zhao, M.; Zhang, D.; Li, Z.; Zhang, M.; Wang, J.; Jin, L.; Yan, Y. Effect of Sb-induced oxygen octahedral distortion on piezoelectric performance and thermal stability of Pb(In,Nb)O3-Pb(Hf,Ti) O3 ceramics. J. Mater. Sci. Technol. 2023, 161, 101–110. [Google Scholar] [CrossRef]

- Koblischka-Veneva, A.; Koblischka, M.R.; Simon, P.; Mücklich, F.; Murakami, M. Electron backscatter diffraction study of polycrystalline YBa2Cu3O7−δ ceramics. Phys. C 2002, 382, 311–322. [Google Scholar] [CrossRef]

- Zhao, Z.H.; Li, X.L.; Dai, Y.J.; Ye, M.Y.; Ji, H.M. Texture development in Ba0.85Ca0.15Ti0.90Zr0.10O3 lead-free ceramics prepared by reactive template grain growth with different Ba and Ca sources. Ceram. Int. 2016, 42, 18756–18763. [Google Scholar] [CrossRef]

- Jaeger, R.E.; Egerton, L. Hot Pressing of Potassium-Sodium Niobates. J. Am. Ceram. Soc. 1962, 45, 209–213. [Google Scholar] [CrossRef]

- Liu, Y.X.; Thong, H.C.; Cheng, Y.Y.S.; Li, J.W.; Wang, K. Defect-mediated domain-wall motion and enhanced electric-field-induced strain in hot-pressed K0.5Na0.5NbO3 lead-free piezoelectric ceramics. J. Appl. Phys. 2021, 129, 024102. [Google Scholar] [CrossRef]

- Yu, Z.D.; Chen, X.M.; Su, Y.L.; Lian, H.L.; Lu, J.B.; Zhou, J.P.; Liu, P. Hot-press sintering K0.5Na0.5NbO3–0.5 mol% Al2O3 ceramics with enhanced ferroelectric and piezoelectric properties. J. Mater. Sci. 2019, 54, 13457–13466. [Google Scholar] [CrossRef]

- Li, Z.; Sun, H.; Liu, X.; Sui, H.; Guo, H. High performance lead-free Na0.5K0.5NbO3 piezoelectric ceramics obtained via oscillatory hot-pressing. Ceram. Int. 2020, 46, 11617–11621. [Google Scholar] [CrossRef]

- Liu, K.; Ma, W.; Liu, F.; Tan, H.; Dou, Z.; Samart, C.; Kongparakul, S.; Zhang, G.; Jiang, S.; Fan, P.; et al. Boosting electric-field-induced strain of dual templates-textured (Na1/2Bi1/2)TiO3-based lead-free piezoceramics by polarization coupling. J. Eur. Ceram. Soc. 2022, 42, 6466–6477. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, Q.; Cai, W.; Chen, G.; Li, X.; Gao, R.; Deng, X.; Fu, C. Achieving enhanced ferroelectricity and piezoelectric responses in <0 0 1>-textured KNN-BCZT ceramics with BaTiO3 microplates as template. Mater. Lett. 2023, 351, 135098. [Google Scholar]

- Shi, W.; Zhang, H.; Liu, Y.; Bian, L.; Bi, W.; Deng, Y.; Yang, B. Improvement on Qm in high-power piezoelectric ceramics through [111] c texture engineering. J. Mater. Sci. Technol. 2025, 216, 260–268. [Google Scholar] [CrossRef]