Enhanced Fracture Toughness of WC-CoCr Thermally Sprayed Coatings by the Addition of NiCrFeSiBC and Mo and Its Influence on Sliding Wear Behavior

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Coatings Fabrication

2.2. Coatings Characterization

2.3. Sliding Wear Tests

2.4. Characterization of Worn Surfaces

3. Results and Discussion

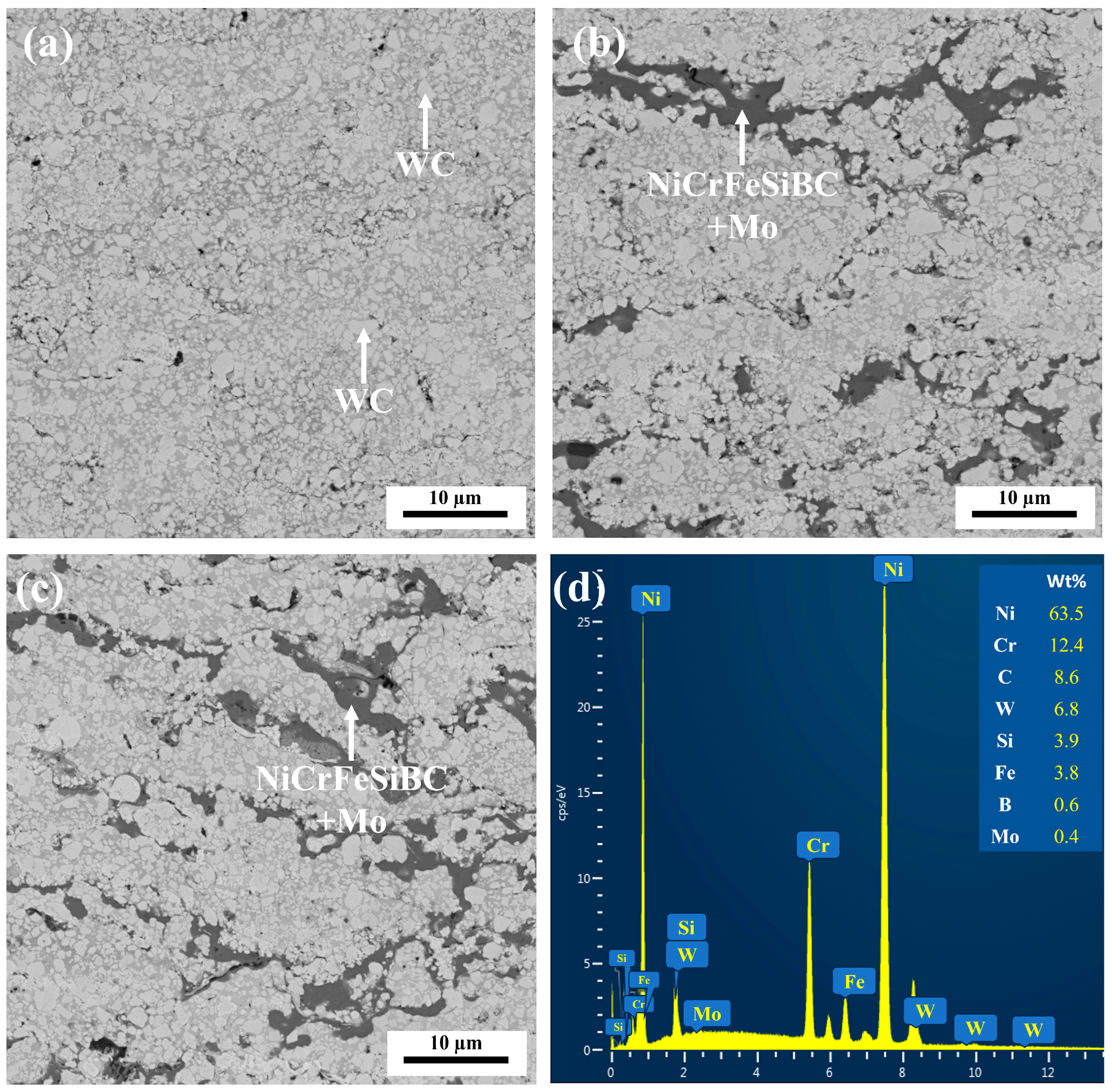

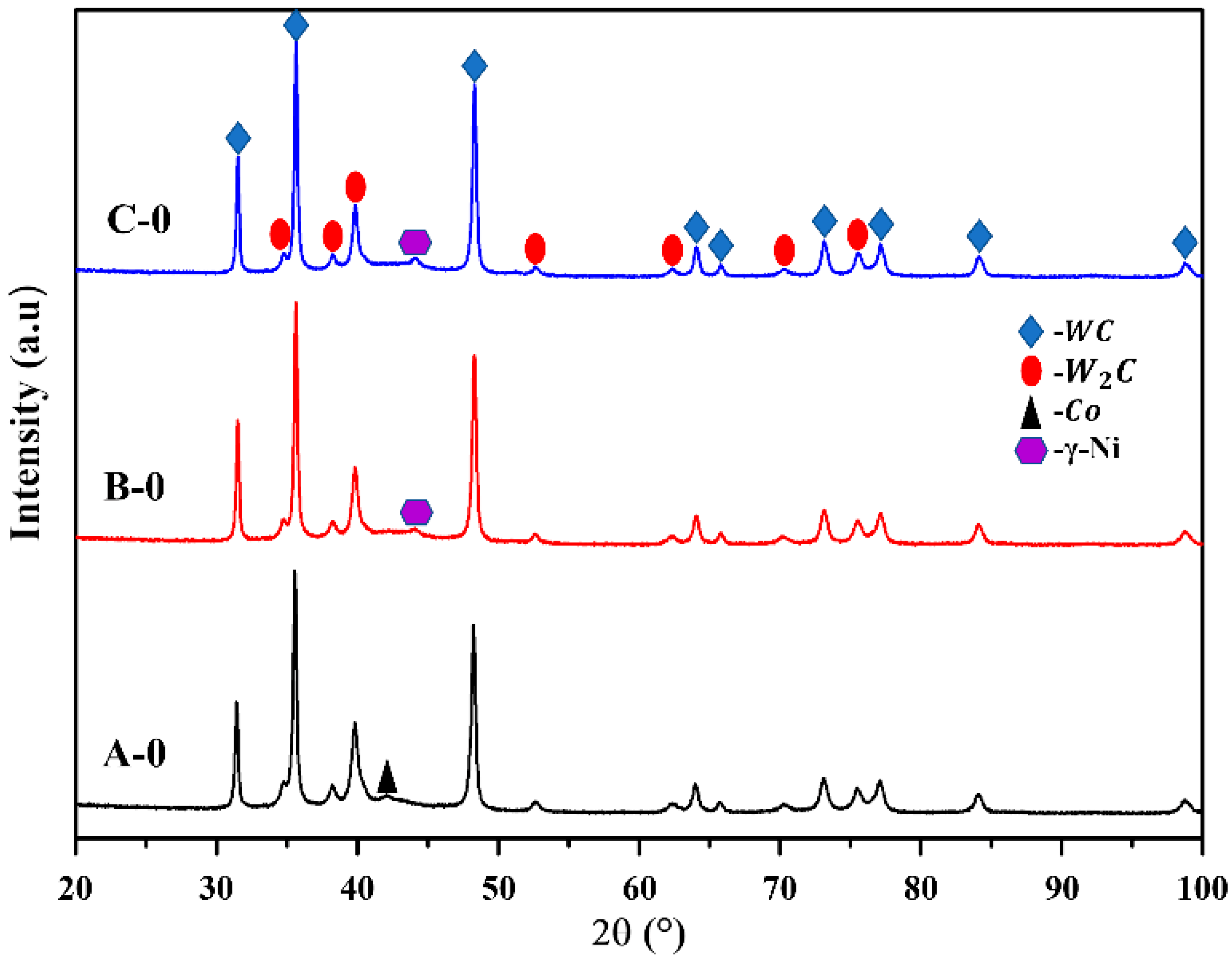

3.1. Microstructure Characterization

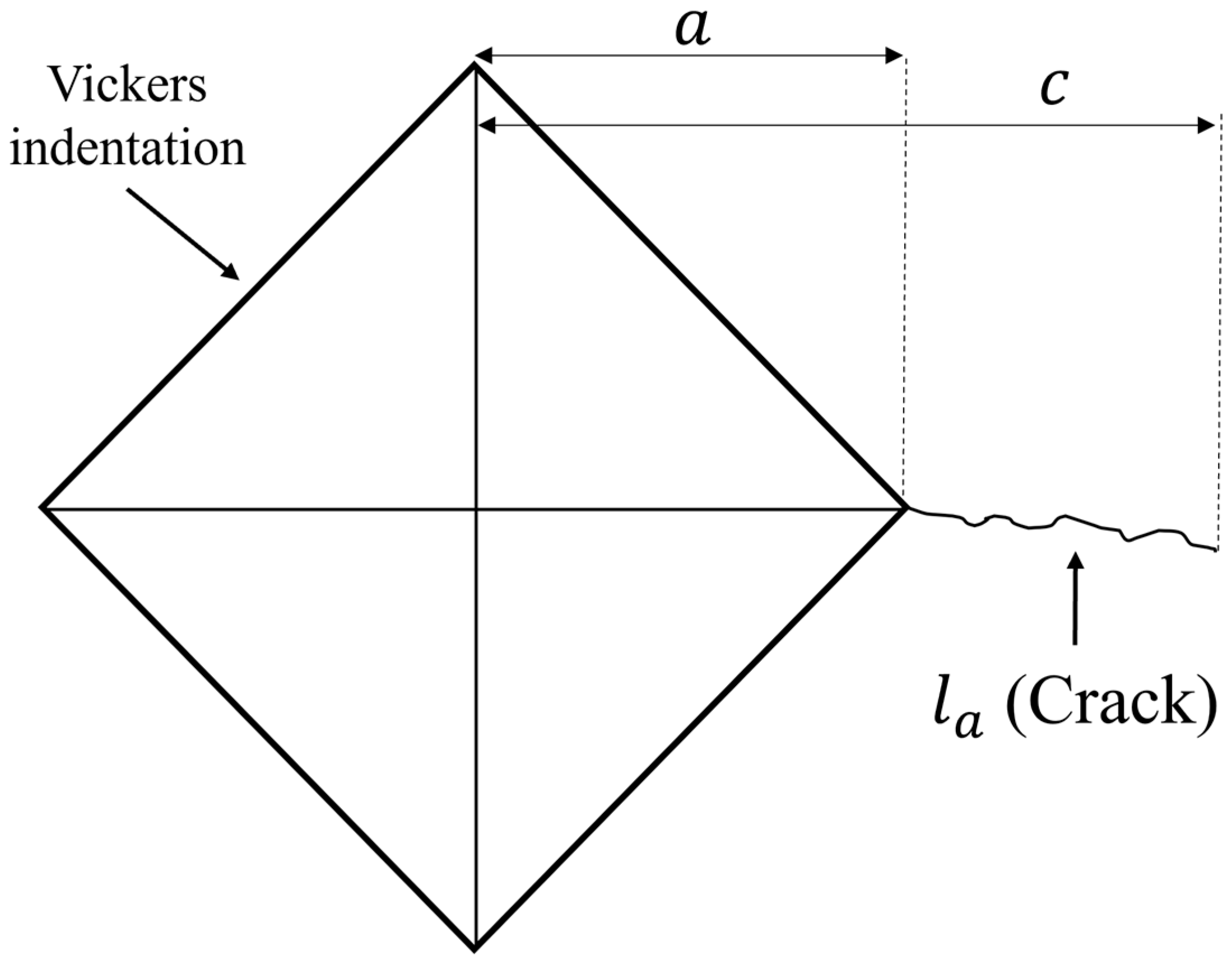

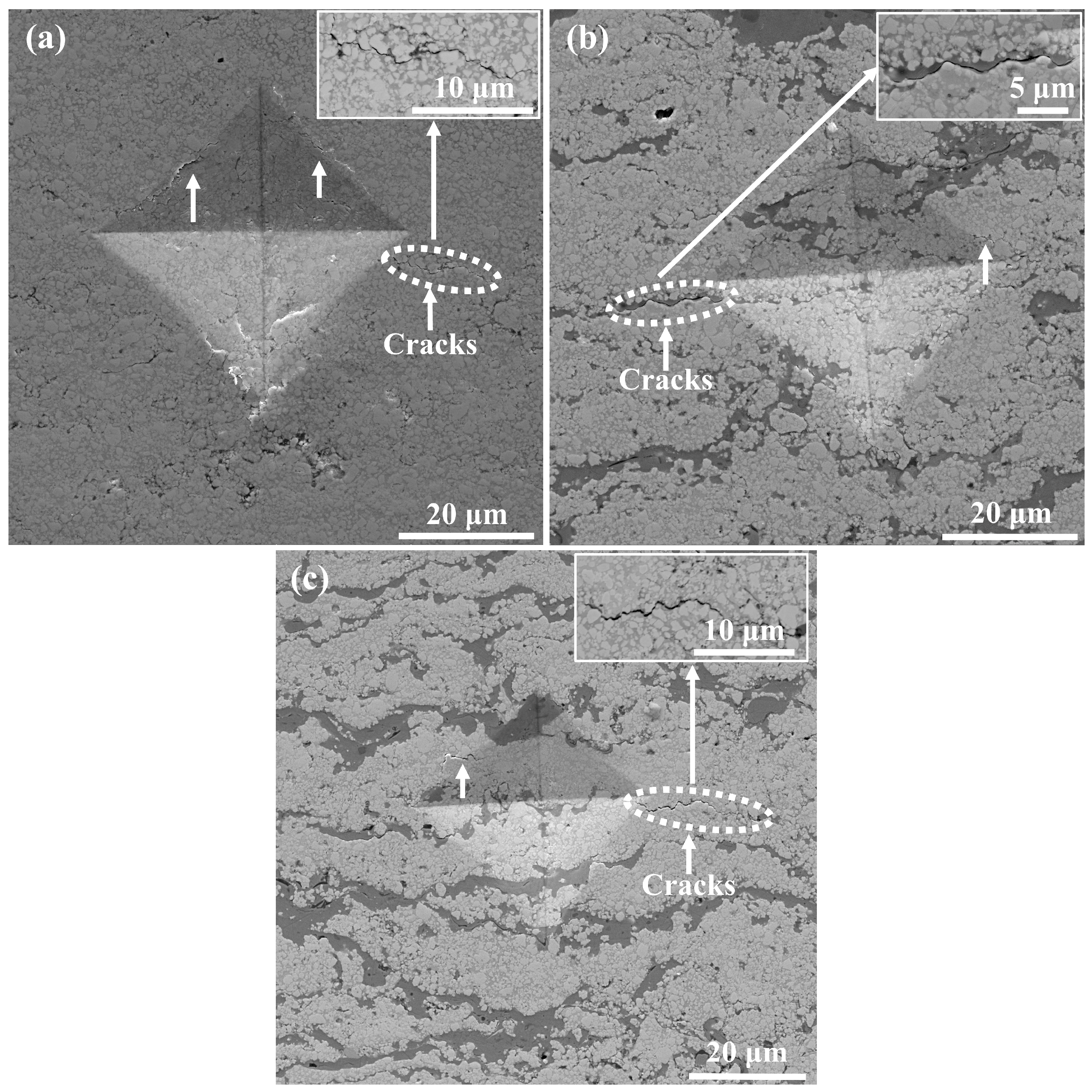

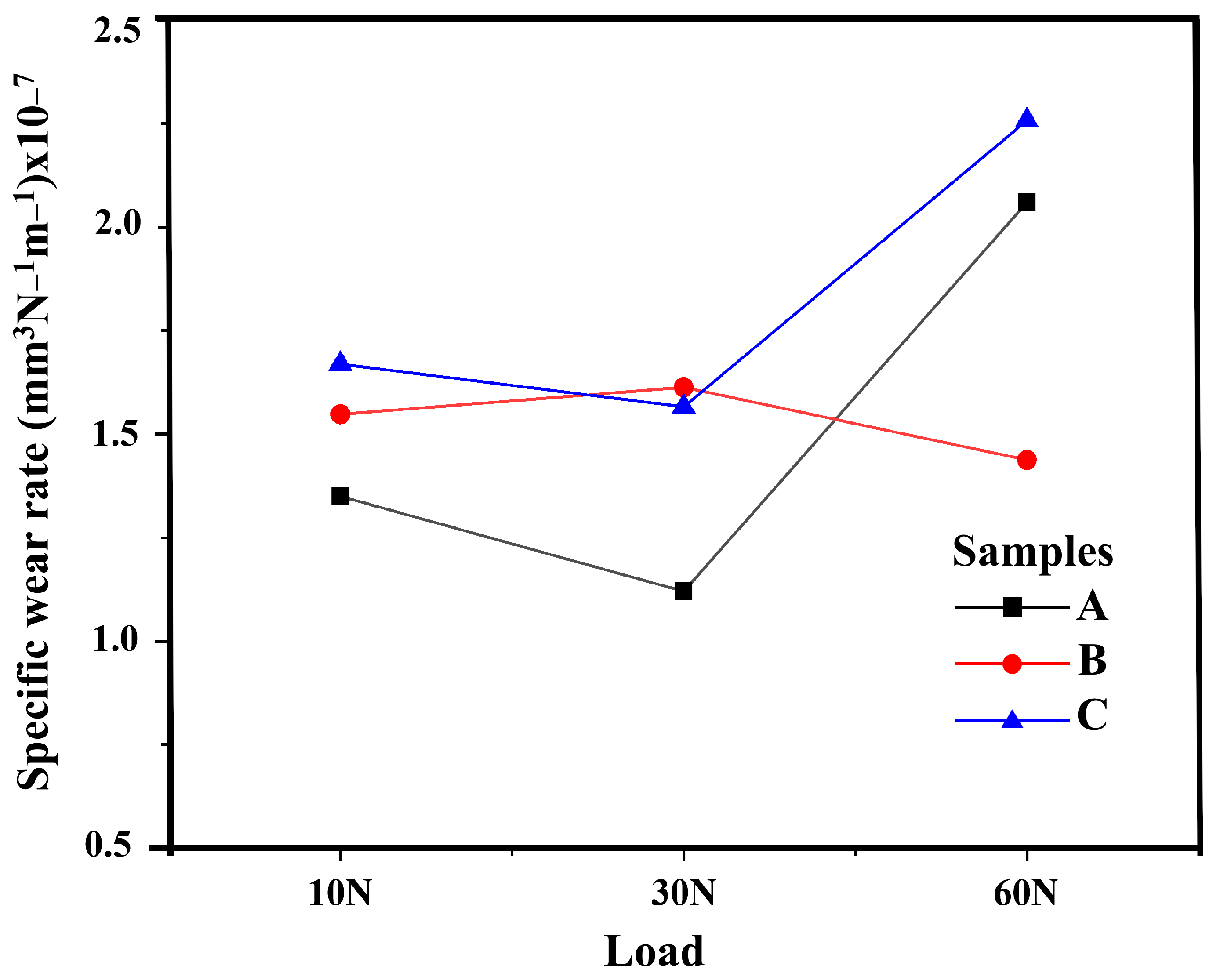

3.2. Microhardness Fracture Toughness and Sliding Wear

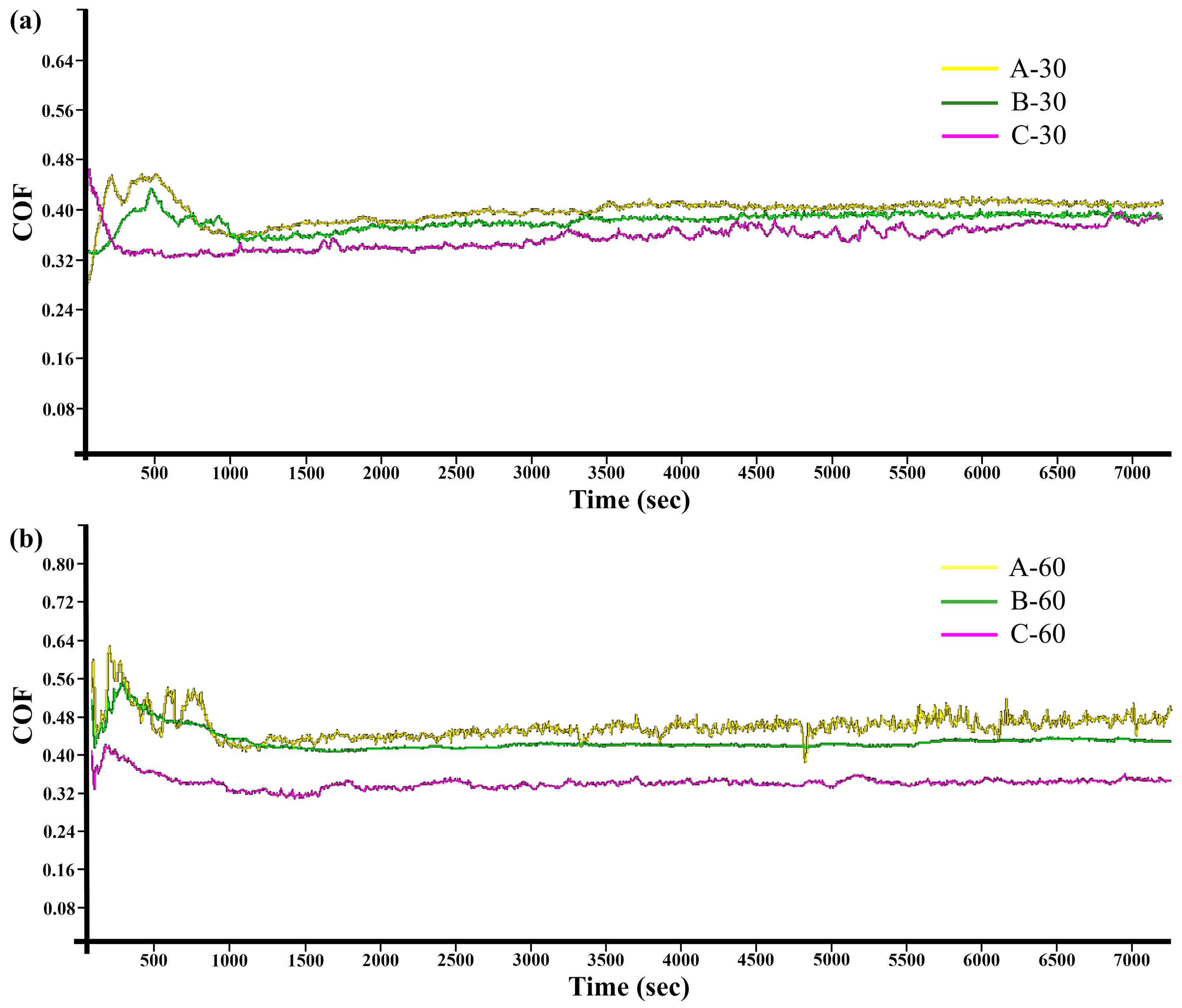

3.3. Coefficient of Friction and Wear Mechanisms

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ibarra, J.; Rodríguez, E.; González, M.A.; Cuenca, S.L.; Medina, A.; Vásquez, G.I. Erosion Behavior of 440C Stainless Steel Cryogenically Treated. Rev. Mex. Ing. Quim. 2020, 19, 1255–1264. [Google Scholar] [CrossRef]

- Plucknett, K.P.; Jin, C.; Onuoha, C.C.; Stewart, T.L.; Memarrashidi, Z. The Sliding Wear Response of High-Performance Cermets. In Handbook of Mechanics of Materials; Springer: Singapore, 2018; pp. 1–42. [Google Scholar]

- Zhang, S. Titanium Carbonitride-Based Cermets: Processes and Properties. Mater. Sci. Eng. 1993, 163, 141–148. [Google Scholar] [CrossRef]

- González, M.A.; Rodríguez, E.; Mojardín, E.; Jiménez, O.; Guillen, H.; Ibarra, J. Study of the Erosive Wear Behaviour of Cryogenically and Tempered WC-CoCr Coating Deposited by HVOF. Wear 2017, 376–377, 595–607. [Google Scholar] [CrossRef]

- Katranidis, V.; Kamnis, S.; Allcock, B.; Gu, S. Effects and Interplays of Spray Angle and Stand-off Distance on the Sliding Wear Behavior of HVOF WC-17Co Coatings. J. Therm. Spray Technol. 2019, 28, 514–534. [Google Scholar] [CrossRef]

- Bolleddu, V.; Racherla, V.; Bandyopadhyay, P.P. Comparative Study of Air Plasma Sprayed and High Velocity Oxy-Fuel Sprayed Nanostructured WC-17wt%Co Coatings. Int. J. Adv. Manuf. Technol. 2016, 84, 1601–1613. [Google Scholar] [CrossRef]

- Bravo, S.; Torres-González, J.; Morales-Hernández, J.; Martínez-Franco, E.; González-Olvera, J.C.; Mercader-Trejo, F.E.; Rodríguez-López, A.; Manzano-Ramírez, A.; Esparza, A.; Herrera-Basurto, R. Effect of the Manufacturing Parameters on the Quality of the Ceramic Thermal Barrier Coating after Ageing by Thermal Treatment. Rev. Mex. Ing. Quim. 2021, 20, 227–237. [Google Scholar] [CrossRef]

- Zhou, Y.K.; Kang, J.J.; Yue, W.; Fu, Z.Q.; Zhu, L.N.; She, D.S. Wet Sliding Wear of HVOF-Sprayed WC-10Co4Cr Coatings in Simulated Seawater Drilling Fluid. J. Therm. Spray Technol. 2021, 30, 2174–2186. [Google Scholar] [CrossRef]

- Gerner, D.; Azarmi, F.; McDonnell, M.; Okeke, U. Application of Machine Learning for Optimization of HVOF Process Parameters. J. Therm. Spray Technol. 2024, 33, 504–514. [Google Scholar] [CrossRef]

- Federici, M.; Straffelini, G.; Gialanella, S. Pin-on-Disc Testing of Low-Metallic Friction Material Sliding Against HVOF Coated Cast Iron: Modelling of the Contact Temperature Evolution. Tribol. Lett. 2017, 65, 1–12. [Google Scholar] [CrossRef]

- Yuan, J.; Zhan, Q.; Huang, J.; Ding, S.; Li, H. Decarburization Mechanisms of WC-Co during Thermal Spraying: Insights from Controlled Carbon Loss and Microstructure Characterization. Mater. Chem. Phys. 2013, 142, 165–171. [Google Scholar] [CrossRef]

- Mazaheri, Y.; Khodaveysi, E.; Roknian, M.; Sheikhi, M.; Heidarpour, A. 75Cr3C2-25NiCr and 86WC-10Co-4Cr High Wear- and Corrosion-Resistant Cermet Coatings Deposited on A356 Substrate by High-Velocity Oxy-Fuel Technique. Coatings 2022, 12, 1408. [Google Scholar] [CrossRef]

- Wang, X.; Xing, Z. Preparation and Properties of Composite Nanoceramic NiCrBSi-TiO2/WC(Co) Coatings. Coatings 2020, 10, 868. [Google Scholar] [CrossRef]

- García, J.; Collado Ciprés, V.; Blomqvist, A.; Kaplan, B. Cemented Carbide Microstructures: A Review. Int. J. Refract. Met. Hard. Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Ahmed, R.; Vourlias, G.; Algoburi, A.; Vogiatzis, C.; Chaliampalias, D.; Skolianos, S.; Berger, L.M.; Paul, S.; Faisal, N.H.; Toma, F.L.; et al. Comparative Study of Corrosion Performance of HVOF-Sprayed Coatings Produced Using Conventional and Suspension WC-Co Feedstock. J. Therm. Spray Technol. 2018, 27, 1579–1593. [Google Scholar] [CrossRef]

- Uzun, A.; Altuncu, E.; Ustel, F.; Turk, A.; Ozturk, S. Investigation of Wear Behaviour of HVOF Sprayed WC-Co Coatings for Automotive Parts in Different Working Conditions. Int. J. Surf. Sci. Eng. 2011, 5, 180–192. [Google Scholar] [CrossRef]

- Stoica, V.; Ahmed, R.; Golshan, M.; Tobe, S. Sliding Wear Evaluation of Hot Isostatically Pressed Thermal Spray Cermet Coatings. J. Therm. Spray Technol. 2004, 13, 93–107. [Google Scholar] [CrossRef]

- Pasha, M.; Kaleemulla, M. Erosive Wear Behavior of Sprayed Metal Matrix Composites: An Overview. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 1063–1075. [Google Scholar] [CrossRef]

- Sharma, M.; Goyal, K.; Kaushal, G.; Goyal, D.K.; Scholar, R. Erosive Behaviour of HVOF Sprayed Coatings: A Review 1. Int. J. Eng. Sci. 2017, 63019, 219–243. [Google Scholar]

- Rachidi, R.; Kihel, B.E.; Delaunois, F.; Vitry, V.; Deschuyteneer, D. Wear Performance of Thermally Sprayed NiCrBSi and NiCrBSi-WC Coatings under Two Different Wear Modes. J. Mater. Environ. Sci. 2017, 8, 4550–4559. [Google Scholar] [CrossRef]

- Spiegler, R.; Schmauder, S.; Sigl, L.S. Fracture Toughness Evaluation of WC Co Alloys by Indentation Testing. J. Hard Mater. 1990, 1, 147–158. [Google Scholar]

- ASTM G133-22; Standar Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear. ASTM International: West Conshohocken, PA, USA, 2022; pp. 1–6.

- Shu, W.; Deng, X.; Guo, W.; Shi, W.; Li, S.; Zhang, B.; Bai, J.; Cui, Q. Microstructure and Wear Resistance of HVOF Sprayed WC-10Co-4Cr Coating on Ti-6Al-4V. Heat Treat. Surf. Eng. 2022, 4, 70–75. [Google Scholar] [CrossRef]

- Xie, Z.; Zhang, C.; Wang, R.; Li, D.; Zhang, Y.; Li, G.; Lu, X. Microstructure and Wear Resistance of WC/Co-Based Coating on Copper by Plasma Cladding. J. Mater. Res. Technol. 2021, 15, 821–833. [Google Scholar] [CrossRef]

- Pulsford, J.; Venturi, F.; Pala, Z.; Kamnis, S.; Hussain, T. Application of HVOF WC-Co-Cr Coatings on the Internal Surface of Small Cylinders: Effect of Internal Diameter on the Wear Resistance. Wear 2019, 432–433, 202965. [Google Scholar] [CrossRef]

- Buytoz, S.; Ulutan, M.; Islak, S.; Kurt, B.; Nuri Çelik, O. Microstructural and Wear Characteristics of High Velocity Oxygen Fuel (HVOF) Sprayed NiCrBSi-SiC Composite Coating on SAE 1030 Steel. Arab. J. Sci. Eng. 2013, 38, 1481–1491. [Google Scholar] [CrossRef]

- Psyllaki, P.; Vardavoulias, M.; Kekes, D.; Psyllaki, P.; Vardavoulias, M. Wear Micro-Mechanisms of Composite WC- Co/Cr-NiCrFeBSiC Coatings. Part I: Dry Sliding. Tribol. Ind. 2014, 36, 361–374. [Google Scholar]

- Ahmed, R.; Ali, O.; Berndt, C.C.; Fardan, A. Sliding Wear of Conventional and Suspension Sprayed Nanocomposite WC-Co Coatings: An Invited Review. J. Therm. Spray Technol. 2021, 30, 800–861. [Google Scholar] [CrossRef]

- Bergant, Z.; Batič, B.Š.; Felde, I.; Šturm, R.; Sedlaček, M. Tribological Properties of Solid Solution Strengthened Laser Cladded NiCrBSi/WC-12Co Metal Matrix Composite Coatings. Materials 2022, 15, 342. [Google Scholar] [CrossRef]

- Pulsford, J.; Venturi, F.; Kamnis, S.; Hussain, T. Sliding Wear Behaviour of WC-Co Reinforced NiCrFeSiB HVOAF Thermal Spray Coatings against WC-Co and Al2O3 Counterbodies. Surf. Coat. Technol. 2020, 386, 125468. [Google Scholar] [CrossRef]

- Nahvi, S.M.; Jafari, M. Microstructural and Mechanical Properties of Advanced HVOF-Sprayed WC-Based Cermet Coatings. Surf. Coat. Technol. 2016, 286, 95–102. [Google Scholar] [CrossRef]

- Sun, L.; Pan, J.; Lin, C. Wear Behavior of TiC-MoSi2 Composites. Mater. Lett. 2003, 57, 1239–1243. [Google Scholar] [CrossRef]

- García-León, R.A.; Martínez-Trinidad, J.; Campos-Silva, I.; Figueroa-López, U.; Guevara-Morales, A. Wear Maps of Borided AISI 316L Steel under Ball-on-Flat Dry Sliding Conditions. Mater. Lett. 2021, 282, 128842. [Google Scholar] [CrossRef]

- Yang, Q.; Senda, T.; Hirose, A. Sliding Wear Behavior of WC-12% Co Coatings at Elevated Temperatures. Surf. Coat. Technol. 2006, 200, 4208–4212. [Google Scholar] [CrossRef]

- Guilemany, J.M.; Miguel, J.M.; Vizcaino, S.; Climent, F. Role of Three-Body Abrasion Wear in the Sliding Wear Behaviour of WCCo Coatings Obtained by Thermal Spraying. Surf. Coat. Technol. 2001, 140, 141–146. [Google Scholar] [CrossRef]

| Hydrogen Pressure (psi) | Oxygen Pressure (psi) | Argon Pressure (psi) | Oxygen Flow (%) | Hydrogen Flow (%) | Spray Distance (mm) | Feed Rate (rpm) | |

|---|---|---|---|---|---|---|---|

| HVOF | 110 | 118 | 105 | 60 | 80 | 190 | 3 |

| Specimens | Identification | Load (N) | Porosity | Microhardness, HV500 | KIC (MPa·m1/2) |

|---|---|---|---|---|---|

| WC-CoCr | A-0 | 0 | 0.43 ± 0.17 | 1052.06 ± 40.12 | 12.48 ± 2.52 |

| WC-CoCr and 12% NiCrFeSiBC+Mo | B-0 | 0.4 ± 0.04 | 887.04 ± 15.96 | 15.90 ± 2.83 | |

| WC-CoCr and 17% NiCrFeSiBC+Mo | C-0 | 0.23 ± 0.05 | 812.82 ± 41.25 | 13.61 ± 1.34 | |

| WC-CoCr | A-10 | 10 | |||

| WC-CoCr and 12% NiCrFeSiBC+Mo | B-10 | ||||

| WC-CoCr and 17% NiCrFeSiBC+Mo | C-10 | ||||

| WC-CoCr | A-30 | 30 | |||

| WC-CoCr and 12% NiCrFeSiBC+Mo | B-30 | ||||

| WC-CoCr and 17% NiCrFeSiBC+Mo | C-30 | ||||

| WC-CoCr | A-60 | 60 | |||

| WC-CoCr and 12% NiCrFeSiBC+Mo | B-60 | ||||

| WC-CoCr and 17% NiCrFeSiBC+Mo | C-60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibarra, J.d.J.; González, M.A.; Rodríguez, E.; Vásquez, G.I.; Medina, A.; Bernal, J.; Aguilar, C.; Velez, E.E. Enhanced Fracture Toughness of WC-CoCr Thermally Sprayed Coatings by the Addition of NiCrFeSiBC and Mo and Its Influence on Sliding Wear Behavior. Coatings 2024, 14, 1207. https://doi.org/10.3390/coatings14091207

Ibarra JdJ, González MA, Rodríguez E, Vásquez GI, Medina A, Bernal J, Aguilar C, Velez EE. Enhanced Fracture Toughness of WC-CoCr Thermally Sprayed Coatings by the Addition of NiCrFeSiBC and Mo and Its Influence on Sliding Wear Behavior. Coatings. 2024; 14(9):1207. https://doi.org/10.3390/coatings14091207

Chicago/Turabian StyleIbarra, José de Jesús, Marco Aurelio González, Eduardo Rodríguez, Gabriel Israel Vásquez, Ariosto Medina, José Bernal, Claudio Aguilar, and Eduardo Enrique Velez. 2024. "Enhanced Fracture Toughness of WC-CoCr Thermally Sprayed Coatings by the Addition of NiCrFeSiBC and Mo and Its Influence on Sliding Wear Behavior" Coatings 14, no. 9: 1207. https://doi.org/10.3390/coatings14091207

APA StyleIbarra, J. d. J., González, M. A., Rodríguez, E., Vásquez, G. I., Medina, A., Bernal, J., Aguilar, C., & Velez, E. E. (2024). Enhanced Fracture Toughness of WC-CoCr Thermally Sprayed Coatings by the Addition of NiCrFeSiBC and Mo and Its Influence on Sliding Wear Behavior. Coatings, 14(9), 1207. https://doi.org/10.3390/coatings14091207