Abstract

For a wide range of applications, paper materials require effective protection against the destructive effect of water, which is most effectively realized by superhydrophobic coatings. In recent years, a considerable amount of scientific research has been carried out in this area, focusing particularly on biogenic resources. With this contribution, we go one step further and examine how biogenic materials can be transferred into aqueous dispersions and coated onto paper via existing technologies. With this paper coating, based on a hydrophobic cellulose derivative in combination with a structurally similar wax, thermally regenerable flower-like surface morphologies are obtained via self-assembly, where the hydrophobic cellulose polymer acts as a structural template for the co-crystallization of the wax component. Such hydrophobic structures in the low micrometer range ensure perfectly water-repellent paper surfaces with contact angles > 150° starting from coating weights of 5 g/m2. The dispersion can be successfully applied to a variety of commercially available paper substrates, whereby the effects of different roughness, porosity, and hydrophobicity were investigated. In this context, a certain roughness of the base paper (Sa ~ 1.5–3 µm) was found to be beneficial for achieving the highest possible contact angles. Furthermore, the approach proved to be paper process-compatible, recyclable, and regenerable, whereby the processing temperatures allow the coating properties to be thermally generated in situ. With this work, we demonstrate how biogenic waxes are very well suited for superhydrophobic, regenerative coatings and, importantly, how they can be applied from aqueous coatings, enabling simple transfer into the paper industry.

1. Introduction

As a renewable, biodegradable, and highly recyclable raw material, paper offers great potential for a wide range of applications, including its use as construction material. Such lightweight constructions include furniture, interior design, outdoor billboards, automotive applications, temporary installations for festivals, exhibitions, and, more importantly, emergency shelters [1,2]. A quality feature of paper products for such novel construction applications but likewise for packaging applications is the highest possible water resistance, as moisture is often the cause of serious damage, such as the loss of mechanical properties, which is fatal for the mentioned applications [2,3,4]. The hydrophilic nature of cellulose, the main building block of paper fibers, is caused by the presence of an abundant number of hydroxyl groups, which makes paper fibers sensitive to water adsorption and affects the moisture-dependent mechanical properties and durability of neat papers [4,5,6,7]. The hydrophobization of cellulose by surface sizing, a technology well-developed and used in the paper industry, however, is insufficient to meet all requirements for water resistance of packaging materials and even more for construction applications [5]. The highest possible water resistance is generally offered by superhydrophobic, i.e., completely non-wettable surfaces [4], whereas in recent years, scientific research has been carried out in this area, focusing in particular on eco-friendly materials [8]. Very well known as the “Lotus effect” from the surface of natural plants [9,10,11,12,13], superhydrophobicity of artificial surfaces is obtained by a combination of hydrophobic material and micro- or nanosized surface structures [14,15,16,17]. By these small structures, the water may contact only a few bits of the surface, while a fine cushion of air is formed beneath a water droplet, thus minimizing contact with the surface. Such wetting properties result in static contact angles (θ) greater than 150° and roll-off angles of less than 10° [17]. As described by Feng et al., the roughness of the surface in the form of combined micro- and nanoscale structures further minimizes the contact between the water droplet and the surface (also found on plants such as the lotus leaf). Surfaces with such multiscale hierarchy structures increase the contact angle and can even be approaching static contact angles of approximately up to 180° [18]. For paper substrates, the surface already provides an inherent microscale roughness due to exposure of cellulose fibers, fibrils, and cavities. The nature of paper fibers and processing steps (e.g., refining and calendering) influence the surface morphology; therefore, different types of paper materials provide different levels of roughness [5]. In addition to effective protection against the destructive effects of water, particularly against loss of strength or deformation, superhydrophobic coatings further prevent contamination and microbial colonization [19].

One approach for a nano/micro structuring of surfaces as the basis for superhydrophobic properties is flower-like particles, with structures in the nano or low microscale that resemble the morphology of flowers. Various surfaces, such as wood [20], copper [21], cotton [22], aluminum [23,24], or steel [25], have already been superhydrophobized by means of such structures. In general, there is a wide variety of methods and substance classes for producing flower-like particles. One approach is the direct synthesis into the final flower-like structure [26,27]. An opposing and more straightforward way is the supramolecular assembly of a material in the form of flower-like structures. Here, weak molecular non-covalent forces such as hydrogen bonds, π-π interactions, electrostatic interactions, or van der Waals forces play a key role in the controlled formation of regular flower-like structures. For this, a wide range of molecule classes and applications are covered [28,29,30,31]. Also, the formation of flower-like cellulose-based polymer structures in organic solution is established via precipitation of cellulose stearoyl ester (CSE) [32,33,34]. CSE has a bottlebrush-like structure with a semi-flexible backbone, which is particularly rigid as all hydroxy functionalities are esterified with stearic acid functionalities, which corresponds to a degree of substitution (DS) of three (referred to as CSE3 henceforth) [35]. Like other polymers [36,37,38,39], CSE has the ability to precipitate into the form of spheric nano- or microparticles [40,41]. Due to the special structure of fully substituted CSE, the particle formation of CSE3 may (strongly depending on the process parameters, e.g., time scale) occur exceptionally in the form of flower-like particles. The formation mechanism of flower-like particles is more extensive than the precipitation of smooth particles; hence, for this (although the phase behavior of CSE additionally depends on the degree of substitution), a high DS and, thus, the ability for side-chain crystallization has proven to be decisive. By immersing surfaces in an organic CSE3 solution, these can be covered with flower-like structures and thus superhydrophobized, which is, however, not regenerative, meaning that this process is not repeatable and the flower-like structures, thus superhydrophobicity, is lost after, for example, defects [34].

For superhydrophobization of paper materials, the use of common superhydrophobization techniques is often unsuitable thorough the complex structure of paper materials and, for example, inhomogeneity, pore volume, low thermal stability, absorbance, or swelling. However, specifically designed for paper materials, too, a great number of scientific approaches for superhydrophobization have been researched as reviewed in the literature [4,5,6,7,19]. Thus, the question arises as to why there is no corresponding strategy on the market despite the wide range of possibilities [42]. Ultimately, the transfer to actual applications has yet to materialize [7]. Key criteria are that the processes required to produce superhydrophobic paper coatings are still complicated and usually cannot be transferred to a large scale. Additionally, changes that occur within coatings, for example, under thermal or mechanical stress and resulting from this, long-term durability is often not sufficiently investigated or inadequate [6,7,43]. For high-value-added special applications, such as diagnostics or flexible electronic devices, highly complex superhydrophobization processes may be feasible [7]. However, when it comes to large-scale applications (e.g., construction) and likewise applications that only consider low material costs (e.g., straws or packaging), it is essential that the superhydrophobization strategy is as simple as possible and thus can be applied on a large scale using existing paper processing technologies [7]. Furthermore, important factors are the material harmlessness (e.g., avoiding fluorinated compounds) combined with the use of eco-friendly bio-materials but also maintaining paper recyclability and, as mentioned above, the ability to regenerate superhydrophobic properties, for example, after damage [7,42]. The latter poses a particular problem with regard to further processing steps of coated papers, as the prevailing process conditions may irrevocably destroy or damage the structure of conventional superhydrophobic coatings, resulting in a loss of water-repellent surface properties. Additionally, the possibility of regenerating the coating after the paper shaping process would enable superhydrophobic properties at inaccessible surfaces, such as inner winding cores, honeycomb panels, or corrugated boards. With addressing the aspects of material harmlessness, the capability of regeneration (even in inaccessible areas), and paper compatibility, we previously developed a self-structuring superhydrophobic coating material based on fully substituted CSE3 combined with structurally similar but low molecular ethylene glycol distearate (EGDS) wax. In contrast to the flower-like shaping of CSE via nanoprecipitation processes out of organic solvent, this specific combination, interestingly, has the ability to self-structure via cooling down from the molten state. After the application of EGDS and subsequent CSE via spray coating of a toluene solution, flower-like structures occur on a paper surface, providing superhydrophobic properties through a simple and fast (within seconds) thermal regeneration process at low temperatures. Furthermore, this step can be repeated for regeneration, e.g., after mechanical or thermal damage, whereby the usability of the superhydrophobic coating significantly increases [44]. While for the scientific approach described, a coating of toluene solution is convenient, it is, however, not suitable for an industrial application.

This publication focuses on converting organic solvent-based paper coatings into aqueous dispersion coatings, with approximately 20% solids by weight and less than 5% additives by weight. These coatings can be easily applied using common paper industry technologies, such as doctor blades or roll-to-roll processes, thereby enabling large-scale applications on various paper types. The goal is to ensure compatibility with papers exhibiting a broad range of properties, including wettability (θ ranging from 70° to 120°), surface roughness (Sa ranging from 1.0 to 3.5 μm), and pore volume (Vp ranging from 0 to 550 mL∙m2). Additionally, the aim is to achieve superhydrophobic properties with static contact angles (θ > 150°) while maintaining low coat weights of 5–10 g∙m2.

2. Materials and Methods

Materials: Demineralized water, ethylene glycol distearate >85% (Carbosynth Ltd., Compton, UK), microcrystalline cellulose Avicel, 50 μm particle size (Sigma-Aldrich, St. Louis, Missourim, USA), stearoyl chloride >97% (TCI Europe N.V., Zwijndrecht, Belgium), toluene 99.85% (Thermo Scientific, Waltham, USA), pyridine >99% (Carl Roth, Karlsruhe, Germany), ethanol 99.8% (Carl Roth, Karlsruhe, Germany), cationic starch HI-CAT 21 370 (Roquette, Lestrem, France), Sorbitanmonooctadecanoat Span® 60, synthesis grade (Sigma-Aldrich, St. Louis, Missouri, USA), lignosulfonic acid (LISA), glue 46325 VL (Eukalin Spezial-Klebstoff Fabrik GmbH, Eschweiler, Germany)

Synthesis of Cellulose Stearoyl Ester: CSE with a Degree of substitution of DS = 3 is prepared according to literature with a few modifications. An amount of 1 g of dried cellulose is suspended in 30 mL pyridine and heated up to 100 °C. Nitrogen gas is purged through the stirring suspension before 13.83 mL (6 mol/anhydroglucose units (AGU) of cellulose) stearoyl chloride are added to the suspension. The reaction is stirred at 100 °C for 1 h and poured into 200 mL ethanol. The crude CSE is separated by centrifugation and purified through repeated boiling in ethanol. The slightly yellow product is dissolved in toluene and dried under vacuum. Yield: 5.60 g. Complete substitution (DS = 3) is confirmed by IR spectroscopy (Supplementary Materials S1).

Dispersion of coating materials: A 5:95 wt% mixture of cellulose stearoyl ester (CSE) and ethylene glycol distearate (EGDS) is dispersed in water. To produce the aqueous dispersion with a CSE3/EGDS content of 22 wt%, 1.25 g of CSE and 23.75 g of EGDS are premixed by stirring the molten substances at 85 °C for 4 h. The additives (cationic starch and surfactant) are dissolved in 100 mL of water for 1 h at 100 °C. The CSE/EGDS waxes are poured into the hot additive solution and emulsified while mixing with an IKA T25 digital Ultra-Turrax® at 20,000 rpm for 10 min (IKA-Werke GmbH, Staufen, Germany). The hot emulsion is poured into an ice-cooled beaker and filtered over a nylon sieve with 125 μm mesh size.

Laboratory paper sheets: Laboratory paper sheets are prepared according to DIN 54358 and ISO 5269/2 [45] (Rapid-Köthen process) with 100 g∙m−2 basis weight using unrefined, pure, unbleached kraft pulp (UKP) made from softwood without additives.

Coating of Paper Substrates: Dispersion coating is performed via doctor blade using a K Control Coater 623 from Erichsen, whereas different coating weights are applied via a variation of wands. The coatings are dried and initially thermally generated by placing the samples in an oven at 90 °C for 4 min. After removal, the samples were allowed to cool to room temperature without active cooling. The coating weight is determined in comparison to an oven-dry substrate. Each subsequent treatment in the oven (4 min at 90 °C) followed by cooling to room temperature, reconstitutes the surface structures, which is referred to as a regeneration cycle.

Water contact angle and surface free energy: Contact angle measurements are performed in normal climate conditions (23 °C, 50% RH) after storing the papers for 24 h. Static contact angles are measured with device OCA35 or OCA 200 from Dataphysics (Filderstadt, Germany) with a 10 μL ultrapure water droplet (Milli-Q®, Advantage A10, Millipak Express 20, Merck Millipore, Billerica, MA, USA) and fitted with Young−Laplace model via Dataphysics SCA20 software. The evaluation of the contact angle is conducted immediately after the drop has settled. At least five droplets were measured for each surface. The outliers of the measurement are eliminated by means of a boxplot and 1-fold interquartile range, and an average value is determined, whereby the error represents the standard error of the mean, which is the standard deviation divided by the square root of the number of samples. For dynamic contact angle measurements, the tilt unit TBU 90E from Dataphysics (Filderstadt, Germany) is used, and the analysis of drop shape is performed by elliptical fit. Via these measurements, contact angle hysteresis is obtained by calculation using the advancing and receding contact angle of the drop immediately before roll-off. The surface free energy (SFE) of the paper substrates is determined using the contact angles of three test liquids: water, ethylene glycol, and formamide.

Differential scanning calorimetry (DSC) analysis: Calorimetric studies are carried out with a DSC 3 from Mettler Toledo (Columbus, Ohio, USA) using the STARe software (Version 16.30a) for evaluation. The measurements are performed in 10 µL aluminum crucible with a heating rate of 5 K/min. The second heating cycle is used for evaluation. Homogeneous sample mixtures of CSE and EGDS are prepared by treating the melt of both compounds in a CellMedia (Zeitz, Germany) thermomixer at 90 °C for one day.

Viscosity measurement: Viscosity measurements are performed using an Anton Paar MCR 302 rotational rheometer (Anton Paar, Graz, Austria) with increasing and subsequent decreasing of shear rate from 0 to 50,000 s−1.

Scanning Electron Microscopy SEM: Paper samples are cut into small pieces and adhered to an SEM carrier using a carbon foil. The bulk substances are investigated after the corresponding temperature treatment using a DSC oven for examination. The aluminum pan containing the mixture is opened and adhered to an SEM plate. The samples were sputtered with 10 nm Pt/Pd (80/20) in argon plasma using a Sputter Coater 208 HR from Cressington (Cressington Scientific Instruments, Watford, UK). An SEM Type XL 30 from Philips (Amsterdam, Netherlands) equipped with a field emission gun and a secondary electron detector with an acceleration voltage of 5 or 10 keV is used.

Basis weight of paper is determined gravimetrically according to DIN EN ISO 536 [46].

Thickness of paper is determined according to DIN EN ISO 534 [47] using a thickness gauge (micrometer) SE 250 from Lorentzen & Wettre.

Surface Roughness parameters of raw paper are determined with an Alicona IFM G3 from Bruker (Bruker Alicona, Graz, Austria) at 10× magnification and a vertical resolution of 0.110 µm. The calculation of surface roughness parameters was carried out using a cut-off wavelength (λc) of 200 µm. The surface roughness of coated papers is analyzed with a Keyence VK-X1100 3D laser scanning microscope (Keyence GmbH, Neu-Isenburg, Germany) with 20× and 150× magnification. The measured surface had an extension of 17 × 284 microns.

Pore volume Vp and overall porosity Φ of the paper substrates are determined by mercury intrusion porosimetry using a PoreMaster 60 GT mercury porosimeter from Anton Paar (Graz, Austria). All measurements are carried out in duplicate, whereby the result corresponds to the mean value of the individual measurements.

Water vapor transmission rate (WVTR) is examined analogously to DIN 53122-1 [48].

Water Absorbency by Cobb60 test is examined according to DIN EN ISO 535 [49]. Therefore, a defined sample area (100 cm2) is exposed to contact with deionized water for a defined period of time (here: 60 s) and weighed before and after. The water absorption is expressed accordingly in g∙m−2. Five individual measurements were carried out on each side; the values given represent the mean value of the individual measurements with errors expressed as standard deviation.

Dynamic Vapor Sorption (DVS) is measured with a DVS Resolution device from Surface Measurement Systems. Measurement is performed at 25 °C starting with 0% humidity, enhancing the relative humidity in 10%-steps up to 90%, and desorption is measured by decreasing the humidity in 10% steps subsequently.

Paper Recyclability tests are conducted according to the Confederation of European Paper Industries (CEPI) recyclability laboratory test method (Version 2).

3. Results and Discussion

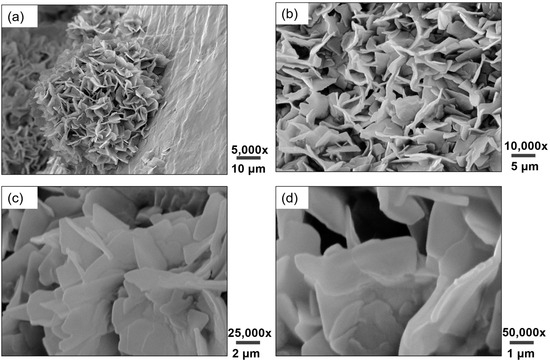

Any successful and sustainable coating on paper has to meet important criteria. First, the coating should not interfere with the recyclability of paper, retaining paper as one of the best recyclable materials. Second, the coating should be applied from an aqueous phase to meet well-established paper coatings technology, such as curtain-coating, size-press, or blade-coating technology. Finally, the coating must be functional on a variety of commercial paper substrates to encourage widespread use. The functionality of exhibiting excellent water barriers on paper using CSE3/EGDS relies on the formation of flower-like sub-micron scale structures through co-crystallization of the biopolymer and the wax, respectively. Detailed information for this structure formation on the surface of paper fibers can be inferred from preliminary work [44] as well as additional experimental results shown in Supplementary S2. The morphology of an EGDS/CSE3 co-crystals with a composition of 95/5 that are formed during cooling from the molten state is visible in Figure 1 for different magnifications. The plate-like structure with a low microscale can be clearly seen here, which contracts into flower-like spheres when the molten compounds are crystallized.

Figure 1.

Sanning electron micrographs of ethylene glycol distearate/cellulose stearoyl ester (EGDS)/CSE3 (95/5) co-crystals at different magnifications (a–d). The plate-like structure can be seen in the low microscale, which contracts into flower-like spheres when the molten compounds are crystallized.

Our current understanding is that the macromolecule CSE3 arranges into ordered configurations when cooled in a liquid EGDS melt. A key aspect is the formation of CSE3 nuclei, which serve as templates for EGDS co-crystallization before EGDS solidifies. Due to overlapping crystallization regions of EGDS and CSE3, side-chain co-crystallization occurs, driven by van der Waals interactions between the aliphatic side chains of EGDS and CSE3. Crucially, since the ordered arrangement of CSE3 chains must occur at temperatures above EGDS crystallization, the molecular weight of CSE3 is critical. As the DSC analyses in Supplementary Materials S2 show, chain alignment occurs preferentially for high molecular weights. This is advantageous for our coating approach, as no fractionation of CSE3 by molecular weight needs to be carried out; instead, CSE3 with a broad molecular weight distribution proves functional. Based on these investigations, it has additionally been revealed that the proportions between CSE3 and EGDS are critical for functionality. The material only crystallizes in the form of flower-like structures with very low CSE3 contents ranging from 2 to 7 wt%.

3.1. Water-Based Dispersions for Superhydrophobic Coatings on Model Papers

Following the beforementioned criteria, we are first interested in answering the following questions to successfully develop an aqueous dispersion:

- Is it possible to disperse both substances with the determined composition (e.g., 5% CSE/95% EGDS) in a single aqueous dispersion at high consistency (ideally on or about 20 wt% solid) to enable a one-step coating process?

- If necessary, could natural additives with a focus on keeping additive quantities to a minimum be used to stabilize the dispersion and ensure their ability to run with common coating techniques (e.g., doctor-blading)? And to what extent is the coating effectiveness influenced by such additives:

- i.

- The dispersion must be capable of being applied to the paper with standard equipment, whereby viscosity plays a particularly important role as the coating should spread homogenously without penetrating directly into the paper.

- ii.

- It must be ensured that the dispersion additives do not prevent thermal regeneration by inhibiting the melting of the waxy substances.

- iii.

- The used surfactants should not increase wettability in a manner that suspends superhydrophobicity.

- iv.

- For the regeneration capability, the influence of the cationic starch component on the penetration of the coating waxes into the paper structure during several regeneration cycles is investigated.

- Does the dried coating gained from deposition of the aqueous dispersion on model paper substrates result in superhydrophobic paper properties with static contact angles above 150°, similar to those coatings of pure substances derived from organic solutions [44] or from melt (Supplementary Materials S2)?

- Is it finally possible to upscale the dispersion in the lab with regard to potential applications in the paper industry?

- Identification of suitable dispersion parameters and additives

The aqueous dispersion is prepared via melt dispersion, where waxes, which are solid at room temperature, are emulsified above melting and subsequently cooled down to room temperature to gain solidified spherical particles. For melt dispersions, we applied a previously determined (Supplementary Materials S2) ratio of 5% CSE/95% EGDS, which has been proven to reproducibly produce the above-mentioned flower-like surface morphology after at least one heating-cooling cycle.

In order to examine process parameters and dispersion composition, an aqueous formulation was adapted from a common alkyl ketene dimer dispersion approach that is commonly used to hydrophobize the surfaces of paper fibers [50]. Alkyl ketene dimer is a sizing agent with a similar structure to EGDS frequently used in the paper industry with aqueous dispersions providing solids contents of approx. 20%. Common stabilizing systems for alkyl ketene dimer are net cationic but with an amphoteric character, as they are based on classical lignosulfonic acid (LISA)/cationic starch formulations or similar, whereas the lignosulfonic acid acts as surfactant and cationic starch as protective colloid [50].

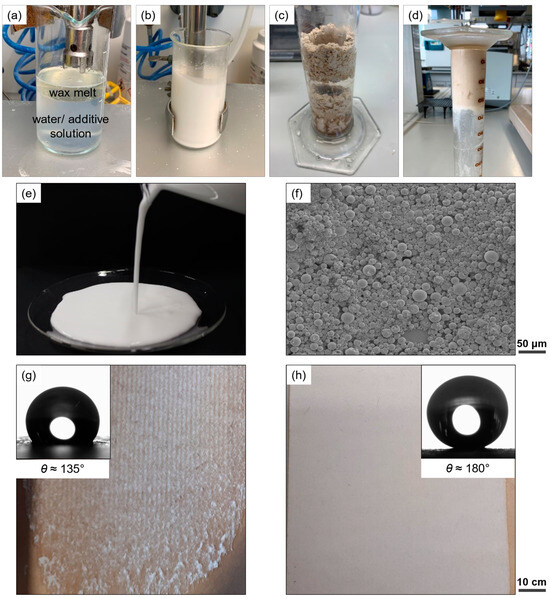

For preparing the dispersion, the molten waxes are emulsified with a solid polymer/wax solid content of 20 wt% and additional additives in water (Figure 2a) using an Ultra-Turrax® (Figure 2b). Inspired by the above-mentioned alkyl ketene dimer dispersions, we selected lignosulfonic acid and cationic starch as additives, which are derived from natural sources, as well as the surfactant Sorbitanmonooctadecanoat (Span® 60) as an alternative to lignosulfonic acid. It turned out that the optimum energy was introduced into the selected system after 10 min and stirring at 20,000 rpm at 95 °C. In addition to the selection of additives and process parameters, a critical point of emulsifying process is the cooling process after emulsification. The emulsified, melted wax droplets solidify during cooling as the temperature passes through the melting point of the waxes. To preserve the emulsified spherical droplets of the melted waxes in this form, it was found that rapid cooling was required, excluding further stirring. If this is not ensured, the warm liquid emulsion (Figure 2b) solidifies completely during cooling due to the wax particles sticking together as a result of stirring during cooling (experiment Figure 2c). The same occurs when the mixture is cooled too slowly (experiment Figure 2d). If cooled rapidly via active cooling and without any stirring, a stable liquid dispersion is obtained (Figure 2e), in which the waxes are present in separate spherical particles (Figure 2f).

Figure 2.

Emulsification of molten waxes with water and additives (a) using an Ultra-Turrax® (b) with 20,000 rpm for 10 min. The importance of the subsequent cooling process visualized by experiment (c), where dispersion solidifies completely during cooling while stirring and (d) when the mixture is cooled too slowly. Only rapid cooling without stirring results in a liquid dispersion (e) of separate spherical wax particles (f). The coating containing lignosulfonic acid (LISA) as surfactant applied by doctor blade is not homogeneous (g) because of rapid penetration into the paper matrix, resulting in contact angles (θ) of 135°, using the alternative surfactant Span® 60 results in homogeneous superhydrophobic coating (h) after a regeneration cycle.

In addition to process parameters (temperature, stirring rate, time), we next investigated different formulation compositions, with a focus on using different additives. In our first set of trials, lignosulfonic acid was characterized as a suitable additive for stabilizing an aqueous dispersion. We, therefore, used this dispersion in the first dispersion coating trials on model paper substrates. As can be inferred from Figure 2g, the dispersion coating with lignosulfonic acid additive applied by the doctor blade is not homogeneous. We assign this finding to the rapid penetration of the dispersion into the paper matrix. In addition, the coated paper is placed in an oven at 90 °C for 4 min to melt the coating substances and subsequently taken out of the oven to allow the coating to cool down to ambient temperature. During this cooling from the molten state, the co-crystallization process can take place, resulting in flower-like structures. The measured temperature profile of the coated paper surfaces during the described cooling is shown in (Supplementary Materials S4). It reveals that the passive cooling to ambient temperatures occurs in less than a minute, whereby the cooling below the melting point is achieved after approx. 20 s, thereby enabling the structure to be formed instantaneously (which is consistent with our previous studies [44]). Despite the temperature program described, inadequate dispersion and the resulting inhomogeneous coating resulted in static contact angles of as low as 135° (Figure 2g); thus, no superhydrophobic surface properties were observed. As a result, Lignosulfonic acid is insufficient to be used as an additive for coating of CSE/EGDS dispersions onto model paper substrates. Similar to the lignosulfonic acid, the surfactant Span® 60 was characterized as a suitable additive for dispersion stabilization (Figure 2e). An example of the used formulation is given in Table 1. Applying this formulation onto paper resulted in a homogeneous paper coating, as can be seen in Figure 2h. The coatings have static water contact angles close to 180° after the regeneration process (melting at 90 °C for 4 min).

Table 1.

Composition example of an aqueous dispersion formulation of EGDS, CSE, and additional dispersion-stabilizing additives, respectively.

As expected, the solids content of the dispersion shown in Table 1 is around 22 wt%, which is in the range of commercial wax dispersions. As the DSC curves (Supplementary Materials S3) clearly reveal, the CSE/EGDS dispersion exhibits identical melting behavior to the pure mixed CSE/EGDS substances despite the presence of dispersion additives. This is an important finding, as the melting/recrystallization process is essential for the formation of microstructures and, thus, for the development of superhydrophobicity as well as the regeneration capability of the coatings.

In summary, it can be said that the investigation of the process parameters and the choice of dispersion additives made it possible to develop the first stable aqueous formulation that produces superhydrophobic papers when applied with a doctor blade. To understand the effect of the additives used on the dispersion and coating properties, systematic investigations of the respective property profiles were conducted. The stable and functional dispersion described above was used as the starting point for these studies.

- Influence of dispersion formulation on dispersion properties

All experiments with variation of surfactant and amount of cationic starch added, are performed by retaining the identical process parameters and are outlined in Supplementary Materials S4. It was possible to produce aqueous dispersions with all tested compositions having surfactant contents between 0 g/L and 13 g/L, and additional starch quantities between 7.5 g/L and 20 g/L. The latter corresponds to 0–0.52 g surfactant per gram of wax and 0.3–0.8 g cationic starch per gram of wax, respectively. However, even though a stable dispersion is achieved, the formulations without surfactant additives do not result in even paper coatings and, therefore, fail to achieve superhydrophobic coatings. Thus, overall, a very low total additive quantity of 1.3–3.0 wt% proved to be functional for both a stable dispersion and the resulting superhydrophobic paper coating.

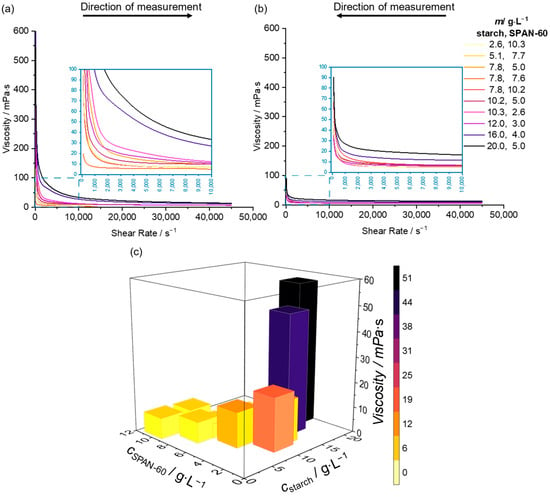

Following this, we investigated the dispersions with regard to viscosity using a rotational rheometer and particle size using SEM imaging. The viscosity profiles are shown as a function of shear rate in Figure 3a,b, where a typical behavior for wax/polymer dispersions is evident. The profiles show that the viscosity is shear-dependent and decreases as the shear rate increases; thus, the dispersions behave structure-viscous. At the same time, a thixotropic behavior is observed since the dispersions are less viscous with decreasing shear rate (a) than with increasing shear rate (b). The viscosities at 4500 s−1 are shown in Figure 3c for the different compositions. Here, it can be observed that the amount of surfactant (Span® 60) has only a minor influence on the viscosity. Moreover, the amount of polymeric protective colloid (cationic starch) is the decisive factor in increasing the viscosity. This behavior can be explained by dissolved starch inherently increasing the viscosity due to the presence of entangled large polymer chains. With this, we demonstrated how the dispersion additive cationic starch is able to tune the viscosity, which can be applied to adjust the required viscosity for specific coating equipment, including the equipment configuration used.

Figure 3.

Viscosity measurements via rotational rheometer reveal typical behavior for water-based dispersions as they are structure-viscous (viscosity decreases with increasing shear rate) (a) as well as thixotropic reduced viscosity with increasing (a) compared to decreasing sheer rate (b). Resulting viscosity (at a shear rate of 4550 s−1) by variation of additives (cationic starch, Span® 60) amounts (c) demonstrates a strong dependence of the viscosity on the starch content.

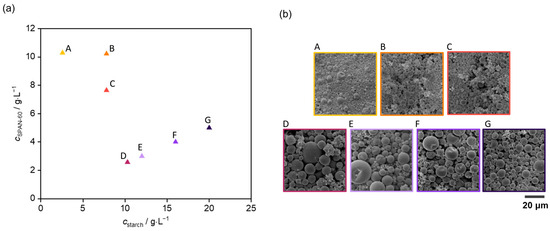

In Figure 4, the additive composition of functional dispersions with a variation of cationic starch concentration (c) (x-axis) and surfactant (Span® 60) concentration y-axis are demonstrated (a). In addition, REM images are shown for each experiment (b) to confirm the presence of separated spherical particles. Furthermore, it clearly visualizes the changes in particle size as the two additive quantities are varied: As can be inferred, the starch content exhibits only a minor effect; thus, a higher surfactant concentration results in the formation of smaller micelles containing the molten wax, and therefore, smaller particle sizes are obtained. This is to be expected as a higher surfactant amount leads to a higher number but smaller micelles surrounding the molten wax droplets.

Figure 4.

The additive composition of functional dispersions with a variation of cationic starch concentration (x-axis) and surfactant (Span® 60) concentration (c) y-axis (a). Resulting in separated spherical particles (SEM images (b)) with changes in particle size as a function of two additive concentrations.

- Influence of dispersion formulation on coating properties

Next, we investigate how the additive composition influences the coating properties. Again, we consider coatings on model paper substrates. The coating weight is adjusted to 25 g∙m−2 on a 100 g∙m−2 laboratory paper, and the coatings are thermally regenerated by melting at 90 °C, for 4 min (refer to experimental section) and cooled down at ambient temperature by eliminating the heat source (see Supplementary Materials S4 for cooling profile). Regarding the melting behavior of the applied coating, it has already been demonstrated above that the coating remains meltable onto paper, despite the use of additives.

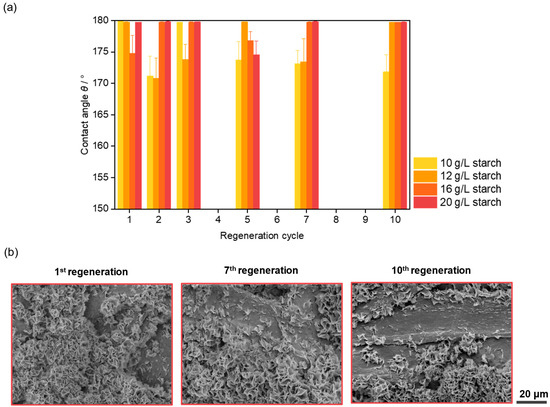

To understand the influence of the starch-based polymer (which itself has no melting point in the relevant temperature range; Supplementary Materials S3) on the melting/recrystallization regeneration process, static contact angles are investigated after consecutive regeneration steps. Figure 5a shows the static water contact angle as a function of cationic starch concentration and regeneration cycle, respectively. When coating from dispersion using a doctor blade (with a coating weight of approx. 25 g∙m−2 on 100 g∙m−2 laboratory paper), the aqueous, slightly viscous dispersion is retained well on the paper surface. It, therefore, provides a homogeneous yet structured coating at the wetting interface after 1st regeneration cycle), as can be inferred from SEM data Figure 5b). For the consecutive regeneration cycles, it is observed that the water contact angles decrease slightly with a lower cationic starch content. After 10 regeneration cycles, the contact angles of the dispersions with the highest cationic starch contents (16 and 20 g∙L−1) are slightly higher (almost 180°) compared to the less starch-containing dispersions (10 and 12 g∙L−1). The lowest water contact angles of about 170° are observed with 10 g∙L−1 cationic starch additive in the formulation. Note, if CSE3/EGDS is applied onto paper without starch and from organic solution, in preliminary work, we have observed water contact angles between 150° and 165°, respectively [44]. The latter suggests that polymeric additives, such as starch, can act by film formation at the interface, thus reducing possible pore volume and subsequent imbibition of the waxes into the paper sheet. At the same time, soluble starch derivatives increase the viscosity of the dispersion, which again limits the imbibition of the dispersion during doctor-blading. In particular, starch-based coatings can form a barrier that prevents the molten coating waxes (CSE3/EGDS) from migrating into the paper structure during regeneration cycles, which explains why contact angles remain stable, even after multiple heating/cooling regeneration cycles. However, as shown in Figure 5b in more detail, after multiple regeneration cycles, we observe a decrease in the coating amount on the outer surface of the paper that suggests a partial migration of the molten wax into the paper. Nevertheless, it is observed that all coated papers remain superhydrophobic (θ ≥ 150°) for up to ten regeneration cycles, regardless of the coating formulation (e.g., cationic starch content used).

Figure 5.

Static contact angles (a) after several regeneration steps (90 °C, 4 min) of laboratory paper coated with dispersions with varying cationic starch content (25 g∙m−2, 100 g∙m−2). Resulting waxy structures on paper surface via SEM imaging (b).

- Up-scaling of functional aqueous dispersion

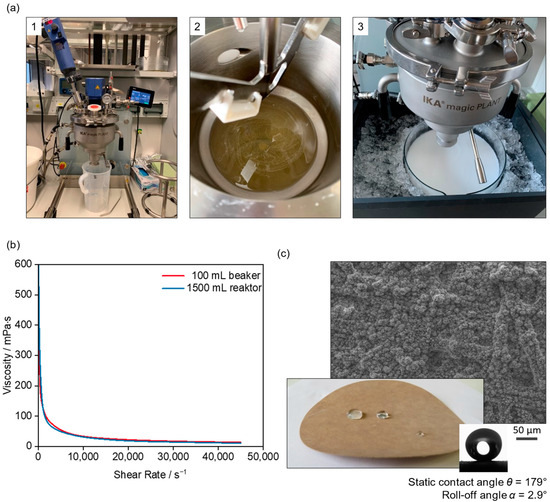

Because technological paper grades may behave differently with respect to the successful transfer of functional coatings and as typical sizes of technical paper grade samples are much larger than typical lab-made model paper sheets, we next investigated a scale-up of dispersion formulation from the laboratory 100 mL beaker setup to a laboratory reactor on a 1.5 L (i.e., kilogram scale). As a higher starch additive content demonstrated a positive effect on rheological properties and coating performance, the formulation with the highest cationic starch content (20 g∙L−1) is selected and scaled up by a factor of fifteen compared to laboratory scales before. Figure 6a shows photos of the dispersion process with the plant (IKA magic plant) (1); the inner reactor with hot (i.e., molten) CSE3/EGDS prior to cooling (2); and the ready-to-use dispersion with all additives after cooling using an ice bath (3). The comparison of the dispersion viscosities (Figure 6b) produced on a 100 or 1500 mL scale reveals practically no difference. Furthermore, the scaled-up dispersion can be successfully applied onto paper as previously described for smaller scale (laboratory paper, 25 g∙m−2, 100 g∙m−2). After regeneration, structures in the lower micrometer scale again appear on the paper surface. The contact angle measurements of the paper coated with this final dispersion show static water contact angles of almost 180° and roll-off angles of α = 2.9°, thus proving that the surface is completely non-wettable for water (Figure 6c). These results demonstrate a very easy scaling of the before-developed dispersion and blade-coating on lab papers. Finally, the use of the dispersion prepared at higher scales does not interfere with the structure formation of the CSE3/EGDS coating on the surface, which is important to gain reproducible wetting properties.

Figure 6.

Up-scaling of dispersion using a laboratory reactor (a), resulting in dispersion properties similar to the 100 mL beaker approach with regard to viscosity (b), surface structure (SEM image), and water repellency (c). This final dispersion coated onto laboratory paper (25 g∙m−2, 100 g∙m−2) results in highly superhydrophobic paper surfaces after thermal regeneration with static contact angles of θ = 179° as well as the roll-off angle of as low as α = 2.9° (c).

3.2. Transfer and Investigation of Commercial Paper Applications

Following the successful scaling of the dispersion, we turned our interest toward commercial paper grades from different paper producers. It is important to understand how different types of commercial paper materials with different intrinsic properties, such as roughness or porosity due to the heterogeneous fiber types as well as additives and processing steps, interact with the coating. Furthermore, the influences of paper intrinsic characteristics on the coating process and final paper properties are investigated by addressing the following research questions:

- Which types of industrial papers are suited to generate a superhydrophobic surface (contact angles above 150°) with low coating weight?

- Are the paper’s intrinsic properties, such as surface roughness and porosity, affecting the coating performance?

- Is it possible to apply the coating using continuous paper finishing techniques?

- Does the coating affect the recyclability of the paper materials according to “CEPI recyclability laboratory test method version 2—Standard mill”?

- Is it possible to process the coated paper further (e.g., print or glue it)? Is it possible to use the heat of processing (e.g., corrugation) in situ to regenerate the superhydrophobic properties?

- Selection and characterization of commercial paper grades

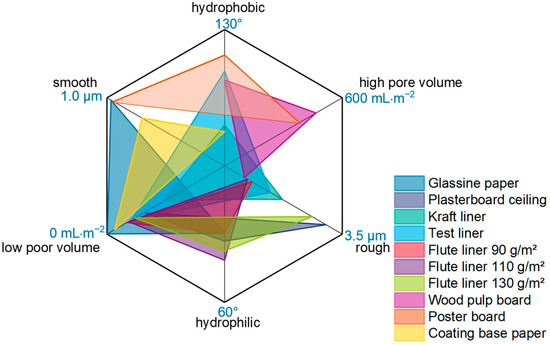

While the selected commercial papers vary in a wide number of parameters, ranging from, for example, the fiber source and paper processing to additives, the resulting surface properties relevant for the coating performance are described by a function of three parameters: hydrophobicity (expressed as contact angle of uncoated paper θraw paper), porosity (expressed as pore volume Vp) and surface roughness Sa. Since the coated papers are intended to be tested for use as lightweight materials in construction and parts of furniture, as well as functional papers for packaging applications, corrugated and honeycomb-based paper is selected for these investigations. Paper materials with particularly smooth or porous characteristics are additionally included to examine the effectiveness and limitations of the coating presented. As an overview, the radar chart in Figure 7 illustrates the combination spectrum covered by the selected papers in terms of roughness, hydrophilicity, and pore volume.

Figure 7.

Radar chart illustrates the wide range of paper properties of the selected industrial paper materials in terms of wettability (hydrophilic/hydrophobic axis 60°–130°), surface roughness (rough/smooth axis in a range of 1.0–3.5 μm), and pore volume (low poor volume/ high pore volume axis in a range of 0–600 mL∙m−2).

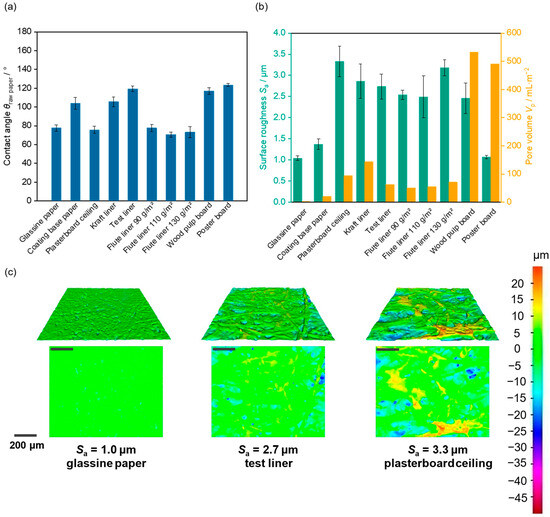

Figure 8 summarizes the paper property profiles of the samples investigated with respect to wetting behavior, surface roughness, and pore volume, respectively. The wetting behavior of the raw paper surface is analyzed via static contact angle measurements. (In addition to the static contact angles, the calculation of surface free energy is shown in Supplementary Materials S6). The contact angles of paper substrates θraw paper (determined directly after droplet deposition) vary between approx. 70° and 120° indicating a selection of hydrophilic (contact angle θ < 90°; e.g., flute liner, plasterboard ceiling, glassine paper) and hydrophobic (contact angle θ > 90°; e.g., coating base paper, kraft liner, test liner, paper board materials) papers. Furthermore, no contact angles below 70° are determined, which indicates that the selected papers have already been functionalized with hydrophobic additives typical for the application, e.g., with internal or surface sizing agents.

Figure 8.

Wetting behavior of selected paper substates expressed as static contact angle θraw paper in the range between 70° and 120° reveals a selection of hydrophilic as well as hydrophobic papers (a). Pore volumes ((b), right y-axis) and surface roughness expressed as average arithmetic height Sa ((b), left y-axis) of selected paper materials. The 3D and 2D images (c) of smooth (left, Sa = 1.0 μm) glassine paper, a slightly rough (middle, Sa = 2.7 μm) test liner, and rough (right, Sa = 3.3 μm) plasterboard ceiling paper reveal different roughness characteristics caused by the different types of paper fibers.

Additionally, the substrates exhibit a wide range of porosity Φ, expressed as pore volume Vp in Figure 8b (right y-axis). The variables are related via the equation (), where Vb represents the bulk volume. The board materials (wood pulp board, poster board), both containing stone groundwood (SGW) pulp fibers, clearly distinguish from the other substrates by their extremely high porosity and corresponding pore volumes (530 and 490 mL∙m−2, respectively). Both wood pulp board and poster board differ significantly from the other substrates additionally in terms of their basis weight (380 g∙m−2; 640 g∙m−2) and thickness (1080 μm; 870 μm) (see Supplementary Materials S7), alongside the different types of fiber. The paper substrates with basis weights from 60 g∙m−2 to 140 g∙m−2 and thicknesses between 55 µm and 240 µm as well as the kraft liner (280 g∙m−2, 400 µm) show lower pore volumes in general. The corrugated and honeycomb board base papers (except for the kraft liner) have pore volumes in the same range (60–70 mL∙m−2), while slightly higher pore volumes occur for plasterboard ceiling and kraft liner. The glassine paper examined is a distinctive material with almost no pores.

The surface roughness Sa of the selected paper substrates, determined via microscopy imaging and focus variation, differs between approx. 1 μm for glassine paper and 3.3 μm for plasterboard ceiling (Figure 8b, left y-axis). The technique allows the determination of various roughness parameters. In the figure, the arithmetic average of the height (Sa) is shown as it is the most used roughness parameter for comparison. Not surprisingly, the calendered glassine paper and the papers designed for coating or printing applications (coating base paper, poster board) exhibit lower surface roughness than corrugated-based paper or liner, respectively. Figure 8c shows the 3D and 2D images of an extremely smooth calendered glassine paper (Sa = 1.0 μm, left image), a medium rough test liner surface (Sa = 2.7 μm, middle image), and a plasterboard ceiling as rough paper substate (Sa = 3.3 μm, right image). The images reveal the different types of surface roughness that appear through different fiber types. The following chapter will investigate whether the paper’s own structure improves the water-repellent effect of the coating by creating an additional hierarchical roughness level, as described as essential for the natural lotus leaf, for example [18].

- Correlation of coating properties with paper intrinsic properties

The selected paper substrates were coated with the CSE3/EGDS dispersion using a doctor blade with coating weights of 5, 10, and 15 g∙m−2 (±1 g∙m−2). After the generation of flower-like structures via drying of the dispersion in an oven (i.e., in situ temperature treatment; 90 °C, 4 min), the wetting behavior of the coated papers is determined by water contact angle measurements to establish a relationship between the paper properties and the effectiveness of the coating as a function of coat weight. Measured static contact angles for all paper substrates, each with a variation of the coating thickness, are plotted in Supplementary Materials S8, as a function of the base contact angle (θraw paper) (a), the pore volume (b) or the surface roughness (c). Additionally, in Supplementary Materials S8 an exemplary SEM image shows the successful formation of flower-like structures in the nano- to low micrometer scale on the fiber surfaces and fiber cavities, as well as examples of contact angle measurements demonstrating how the droplet wets the surface less and less as the contact angle increases from 110° to 178°.

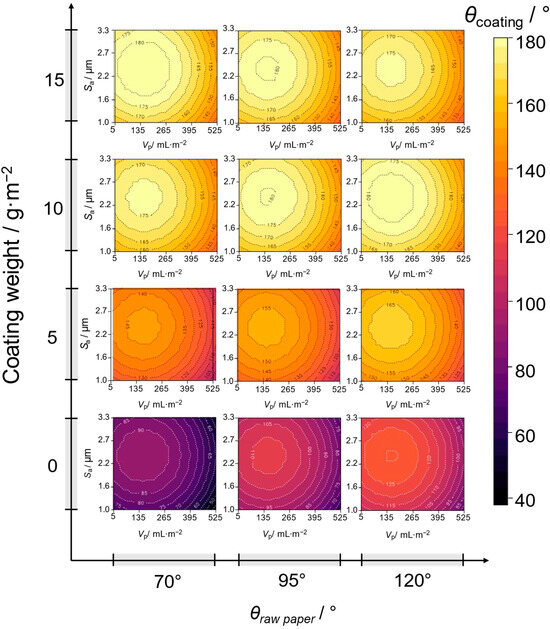

By means of a multiple regression analysis (Figure 9) of the measured data (Supplementary Materials S8), a correlation of the contact angle of the coated papers (θcoating) is predicted in dependence of papers surface roughness Sa, pore volume Vp, the contact angle of uncoated paper (θraw paper) (divided into three regions: hydrophilic 70°, hydrophobic 95°, highly hydrophobic 120°). The modeled data is represented for the threshold value of uncoated paper (0 g·m−2), or 5, 10, 15 g·m−2, respectively. The correlation of the model described by adjusted R2 is 0,84, and an RPD value of 2.18 provides a suitable description of the relationship. Further information on modeling can be found in Supplementary Materials S9.

Figure 9.

Modulation of the static contact angle θcoating of coated paper substrates as a function of the paper intrinsic properties, i.e., the uncoated paper contact angle (θraw paper, regimes of 70°, 95° or 120°), surface roughness Sa and pore volume Vp, for threshold value of uncoated paper (0 g·m−2), or coating weight of 5, 10, 15 g∙m−2 respectively.

Based on this model, the following prediction (i.e., model) can be derived: A superhydrophobic surface (θ ≥ 150°) will in no case be achieved with uncoated paper (0 g·m−2), which naturally meets the expectations. In general, the contact angle rises by applying the developed coating in increasing quantities, starting at 5 g·m−2 through 10 and up to 15 g·m−2. The statistical significance of the coating weight onto the θcoating is determined as very high and explains 63% of the variance. Thus, the coating weight is well suited to adjust the contact angle (i.e., with sufficient coating weight), superhydrophobic contact angles can be obtained easily. In addition, the paper surface roughness has a significant quadratic influence, as does the wettability of the substrate θraw paper, while the pore volume exerts almost no influence on the coating contact angle θcoating. Depending on the intrinsic properties of the paper, superhydrophobic properties (θ > 150°) can be achieved for a wide range of papers with coating weights of just 5 g∙m−2. While an increase to 10 g∙m−2 considerably raises this range of papers that exhibit this wetting profile, and a further increase to about 15 g∙m−2 results in minor improvements, i.e., a leveling-off of the static contact angle and, as such, a reproducible wetting behavior. Therefore, it is predicted that a maximum contact angle is reached at approximately 10 g∙m−2 for a wide range of paper materials. This is caused by the fact that the entire paper surface is, at this point, already homogeneously covered with a layer of the waxy structures (see Supplementary Materials S7) and thicker coatings do not further improve chemical or morphological changes of this interface. In the context of these observations, it is important to consider the interaction of the free surface energy and the surface morphology in terms of the respective wetting scenario. The hydrophobic coating materials applied (CSE and EGDS) basically reduce the surface energy of the rather hydrophilic cellulose substrate and thus cause increased water contact angles. At the same time, the crystallization of these materials results in the formation of fine structural elements in addition to the already existing paper roughness, which prevents the surface from being wetted uniformly. It is no longer possible to interpret the effects using Young’s formula alone, as this assumes a planar phase interface. In the case of the superhydrophobicity targeted here (with contact angles close to 180° and roll-off angles < 5°), a heterogeneous Cassie-Baxter wetting state can clearly be assumed, in which the air trapped between the fine surface structures is no longer displaced by the fluid.

To examine the influence of the paper materials themselves besides the coating weight, a closer look is given to the respective paper properties wetting behavior (θraw paper), pore volume or surface roughness, and their influence on the contact angles of the coating. Here, the main influence of the paper’s intrinsic properties is visible for the lowest coating thickness of 5 g∙m−2, as it would otherwise be lost in the effects of more influential coating wight. For the raw paper’s wetting behavior, a dependence of the raw paper’s contact angle on the coating contact angle is significant. A higher contact angle of the raw paper contributes to an increase in the coating contact angle. Thus, in the range of hydrophilic substrates (θraw paper = 70°), a superhydrophobic contact angle cannot be achieved with as low as 5 g∙m−2, unlike hydrophobic substrates θraw paper = 95° or 120°.

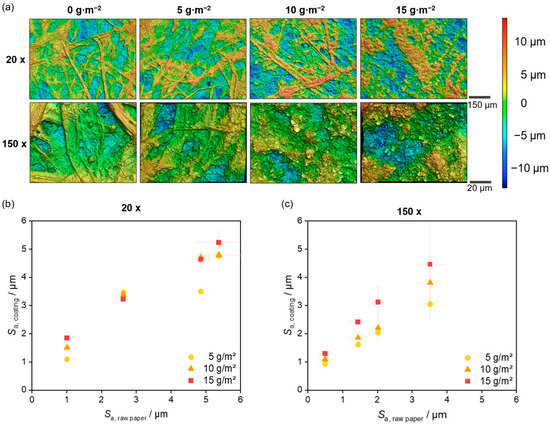

For the pore volume, almost no influence on the coating contact angle θcoating is evident. Only with paper substrates having extremely high pore volumes (such as poster board or wood pulp board; Supplementary Materials S7) is it more difficult to establish superhydrophobic surface properties. Here, the large pores may cause a migration of the coating into the inner volume of the paper material; therefore, the coating material does not fully contribute to the structuring of the surface. This can be compensated, for example, by applying higher coat weights; however, if the pore volume is too high (exceeding approx. 500 mL∙m−2), no superhydrophobic surfaces can be achieved at all. It should be mentioned that larger pore volumes often contribute to higher paper roughness, so an increased but not extremely high pore volume may be beneficial. This is because, as the multiple regression analysis (Supplementary Materials S8) reveals, the paper roughness contributes significantly to an increase in the contact angle. This trend can be assessed on the basis of four paper substrates, for which the roughness values for uncoated (0 g∙m−2) and coated (respectively 5, 10, 15 g∙m−2) paper were recorded and determined using 3D laser scanning microscopy at 20× and 150× magnification (Figure 10a). It can be clearly seen in Figure 10b,c (especially at a high magnification of 150× in Figure 10c) that the individual increase in roughness of the coated papers rises with the basic roughness of the respective substrates. As in the theory of the lotus leaf, the surface structure of the paper, therefore, provides an additional hierarchical level of roughness, which ultimately has a positive effect on the water-repellent properties. Additionally, the roughness of the coating increases with the coating weight, which confirms the increasing contact angle with the coating thickness.

Figure 10.

3D laser scanning images (a) show increasing amounts of rough micro-wax structures on the paper fibers obtained by increasing coating weight. Roughness values for coated paper (Sa, coating) with, respectively, 5 g∙m−² (blue square), 10 g∙m−² (orange circle), and 15 g∙m−² (green triangle) independent of uncoated papers roughness (Sa, raw paper) analyzed via 3D laser scanning microscopy at 20× (b) and 150× magnification (c).

Overall, it can be concluded that the contact angles of coated papers can be adjusted primarily by the coating weight. For paper applications, however, low coating quantities are more interesting due to economic reasons. With low coat weights, however, the paper’s intrinsic properties take on relevance. Since the surface roughness is a significant parameter influencing the contact angle of the coating, the developed coating is extremely well suited as paper coating, as it provides intrinsic roughness. Liner paper materials and plasterboard ceilings, which have a higher surface roughness, are particularly suitable for superhydrophobic coatings using the developed approach. Extremely smooth papers, such as glassine, thus represent the limitation of the applicability of the coating, at least with economically viable coat weights. Furthermore, as the raw paper wetting behavior is significant, an enhanced uncoated paper hydrophobicity provides an advantage, at least in the case of very low coating weights. Finally, the surface roughness and the paper contact angle can be used to predict whether superhydrophobic contact angles can be achieved for a defined coating weight. In contrast, it has been determined that the pore volume is not a relevant factor and, therefore, not necessary to determine.

- Application-related paper characterization, coating, and processing

Since corrugated papers are the most promising substrates regarding an application in construction applications, kraft liner and flute liner were selected for further characterization steps. With a flute liner, another coating experiment was carried out to investigate the minimum coating weight necessary for a superhydrophobic surface (requirement: θ ≥ 150°). It was found that 1 g∙m−2 is already sufficient to fulfill this requirement for this substrate. However, thicker films may be beneficial for stability through different heating cycles or mechanical impact.

Furthermore, the interaction of liquid water and water vapor with the coated papers was investigated, as well as the recycling ability of the coated papers. The detailed results can be found in the supplementary materials. In summary, it is demonstrated that the coating has very good water absorbency properties (Cobb60 test, Supplementary Materials S10). In contrast, uncoated substrates are soaked completely (accordingly, no Cobb value determinable), and coated samples showed very low values (between 4.5 and 10 g∙m−2), especially the coated flute liner exhibits a Cobb60 value of as low as 4.5 ± 1.4 g∙m−2. The coating therefore drastically increases the resistance to liquid water compared to uncoated papers. Additionally, the values of these papers functionalized with the superhydrophobic coating are significantly lower than values that can be achieved with conventional hydrophobization approaches (e.g., Cobb60 of highly internal sized papers approx. 25 g∙m−2 [51,52] or nanostructured polymer coating 26 g∙m−2 [53]) and even lower than Cobb60 values of superhydrophobic papers known from the literature [19,54,55,56,57,58,59].

In terms of interaction with water vapor, no barrier properties can be determined based on the WVTR values (water vapor transmission rate; Supplementary Materials S11). This is assumed to be the result of the coating’s structure, which, unlike a polymer film, does not form a closed surface. However, depending on the application, this can be an advantage, especially with regard to applications in the construction sector. The interaction with water vapor is further studied by Dynamic Vapor Sorption (DVS). The results (Supplementary Materials S12) show that the coated substrates not only have no barrier against water vapor but also have almost the same sorption/desorption behavior as the raw paper substrate. Despite this finding not being beneficial for an application as a barrier coating, it is highly preferable for indoor applications where the gas barrier is not necessary or even not desired in most cases.

The recyclability of the coated papers was tested according to CEPI recyclability laboratory test method (Version 2), whereby no abnormalities could be identified, therefore classified as “recyclable” (see Supplementary Materials S13 for details). However, we are aware that investigations using upcoming methods and adapted evaluation procedures are necessary in order to be able to make reliable statements about the fate and behavior of the coating material in the recycling process.

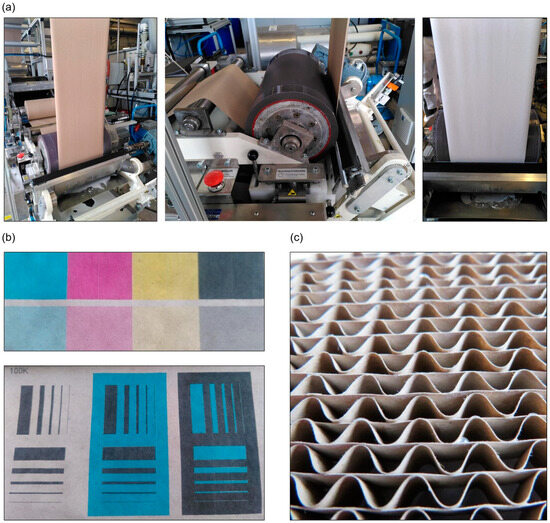

In addition, a roll-to-roll pilot plant trial was carried out in which the paper was coated by means of roll application and doctor blade (Figure 11a). This preliminary trial proved that it is possible to apply the coating using continuous paper finishing techniques. Despite, as described above, the dispersion properties, such as the water retention capacity, need to be specifically adapted to the specific machine used, which is not the subject of this publication.

Figure 11.

Coating of paper web on a pilot coating machine using a doctor blade (a), successful test prints of coated papers (b), superhydrophobization of the inner of corrugated cardboards prove regeneration is possible by applied heat of laboratory corrugator, gluing with synthetic resin dispersion proves effective (c).

Additionally, the processability of the coated papers was examined by carrying out test prints, corrugation, and gluing. Coated papers were successfully printed (test prints in Figure 11b). To check if it is possible to superhydrophobize the inner of corrugated cardboards, corrugations were formed using a laboratory corrugator. The subsequent measurement of the water contact angle revealed contact angles of a flute liner, for both before and after corrugation, of approx. 160°. Here, it is demonstrated that due to the increased temperature during corrugation, the regeneration of the superhydrophobic properties occurs in situ due to temperature-induced formation of microstructures. Consequently, no extra heating step is required to generate the superhydrophobicity, as it is part of the process anyway. Following corrugation, the liner is glued with a commercially available dispersion adhesive (Eukalin 46325 VL) to produce a corrugated cardboard demonstrator (Figure 11c).

4. Conclusions

In this work, we have transferred biogenic self-structuring materials into an aqueous dispersion for paper coatings, making them suitable for conventional paper-converting methods. Additionally, we studied the feasibility of a variety of commercial paper materials. The use of structurally similar substances, the low-molecular EGDS and hydrophobic cellulose-based polymer CSE3 with a composition of 2–7 wt% CSE3 and 98–93 wt% EGDS enables the formation of flower-like structures immediately upon cooling from the molten state (at low temperatures of approx. 90 °C) through co-crystallization. As this thermal regeneration process is repeatable, the structures and, therefore, superhydrophobicity can be regenerated frequently and easily (e.g., after destruction). Furthermore, it allows for in-situ superhydrophobization during paper finishing as part of the drying process. During the transformation into an aqueous dispersion, we discovered a homogeneous dispersion of the two components in a functional ratio of 5% CSE3 to 95% EGDS with a solid content of approx. 20 wt%. The dispersions containing cationic starch and the surfactant Span® 60 as additives are highly stable with low additive contents of 1.3–3.0 wt% and show no negative impact on the wettability as well as regeneration properties of the coated papers. Starch is also suitable for adjusting the viscosity of the dispersion and, furthermore, acts as a film-forming polymer, which prevents the waxes from penetrating into the paper matrix (thus reducing the surface structures and static contact angles) even after repeated regeneration. We proved that the CSE3/EGDS materials form flower-like structures equally from dispersion as applied as pure substances from organic solvents [44], and the approach is therefore suitable for a real transfer into technological applications. An investigation of commercial paper materials with a broad property profile in terms of wettability (θ in a range of 70°–120°), surface roughness (Sa in a range of 1.0–3.5 μm), and porosity (expressed as pore volume Vp) in a range of 0–550 mL∙m−2), additionally, proved a wide opportunity for paper applications. Thus, paper intrinsic parameters (e.g., roughness) are decisive for the coating weight required to achieve superhydrophobic properties, While a coating weight of 5 g∙m−2 is sufficient to obtain superhydrophobicity on a number of substrates (particularly papers relevant for construction applications), 10 g∙m−2 proved as adequate for an extensive spectrum of paper materials. Limitations are imposed by extremely smooth (Sa = 1.0 μm) calendered specialty papers, at least for practical coating weights (for 5–20 g∙m−2 θ = 110°–135°), as it is evident that the paper’s intrinsic roughness provides a second hierarchical level to the flower-like structures and therefore reduces water wetting even further. The integration into the processing was demonstrated on a pilot scale, as the dispersion is easy to apply precisely in a roll-to-roll process while the structures can be regenerated within the converting process within the drying zone. Furthermore, and highly important, the functionalized paper proves to be suitable for recycling according to the CEPI recyclability laboratory test method.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/coatings14081028/s1. Supplementary Materials S1: Synthesis and characterization of CSE3 and EGDS; Supplementary Materials S2: Investigation of CSE3/EGDS flower-like formation; Supplementary Materials S3: DSC measurement of dispersion and dispersion additives cationic starch and Span® 60; Supplementary Materials S4: Investigation of the cooling behavior of dispersion-coated papers; Supplementary Materials S5: Series of experiments to vary surfactant and cationic starch contents in the dispersion; Supplementary Materials S6: Calculation of surface free Energy; Supplementary Materials S7: Basis weight and thickness of selected commercial paper substrates; Supplementary Materials S8: Coating of paper substrates with different base properties; Supplementary Materials S9: Multiple Regression Analysis; Supplementary Materials S10: Water Absorbency by Cobb60 test; Supplementary Materials S11: Water vapor transmission rate; Supplementary Materials S12: Dynamic Vapor Sorption; Supplementary Materials S13: Recyclability test of coated paper. References [34,35,40,44,60,61,62,63] are cited in the supplementary materials.

Author Contributions

Conceptualization, C.C., J.D., A.G. and M.B.; investigation, C.C. and J.D.; writing—original draft preparation, C.C. and J.D.; Formal analysis O.E. and C.C.; writing—review and editing, all authors, visualization, C.C.; supervision, A.G. and M.B.; funding acquisition, A.G. and M.B. All authors have read and agreed to the published version of the manuscript.

Funding

The research project was carried out in the framework of the industrial collective research program (IGF no. 21373 BG “Regenerate”). It was supported by the Federal Ministry for Economic Affairs and Climate Action (BMWK) through the former AiF (German Federation of Industrial Research Associations eV) based on a decision taken by the German Bundestag.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding authors.

Acknowledgments

The authors thank the members of the project support committee for their consultation as well as the providing of materials (paper materials, waxes, 3D laser scanning microscope.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kanli, E.; Bach, R.; Götzinger, R.; Kiziltoprak, N.; Knaack, U.; Schabel, S.; Schneider, J. Case study: Development and Evaluation methods for bio-based construction realized with paper-based building materials. AJCE 2019, 37, 664–671. [Google Scholar]

- Knaack, U.; Bach, R.; Schabel, S. (Eds.) Bauen mit Papier: Architektur und Konstruktion; Birkhäuser: Basel, Switzerland, 2023; ISBN 9783035621402. [Google Scholar]

- Samyn, P. Active Barrier Coating for Packaging Paper with Controlled Release of Sunflower Oils. Molecules 2021, 26, 3561. [Google Scholar] [CrossRef] [PubMed]

- Asim, N.; Badiei, M.; Mohammad, M. Recent advances in cellulose-based hydrophobic food packaging. Emergent Mater. 2022, 5, 703–718. [Google Scholar] [CrossRef]

- Samyn, P. Wetting and hydrophobic modification of cellulose surfaces for paper applications. J. Mater. Sci. 2013, 48, 6455–6498. [Google Scholar] [CrossRef]

- Li, A.; Wang, G.; Zhang, Y.; Zhang, J.; He, W.; Ren, S.; Xu, Z.; Wang, J.; Ma, Y. Preparation methods and research progress of superhydrophobic paper. Coord. Chem. Rev. 2021, 449, 214207. [Google Scholar] [CrossRef]

- Yun, T.; Tao, Y.; Li, Q.; Cheng, Y.; Lu, J.; Lv, Y.; Du, J.; Wang, H. Superhydrophobic modification of cellulosic paper-based materials: Fabrication, properties, and versatile applications. Carbohydr. Polym. 2023, 305, 120570. [Google Scholar] [CrossRef]

- Bayer, I.S. Superhydrophobic Coatings from Ecofriendly Materials and Processes: A Review. Adv. Mater. Interfaces 2020, 7, 2000095. [Google Scholar] [CrossRef]

- Darmanin, T.; Guittard, F. Superhydrophobic and superoleophobic properties in nature. Mater. Today 2015, 18, 273–285. [Google Scholar] [CrossRef]

- Barthlott, W.; Neinhuis, C. Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta 1997, 202, 1–8. [Google Scholar] [CrossRef]

- Koch, K.; Barthlott, W. Superhydrophobic and superhydrophilic plant surfaces: An inspiration for biomimetic materials. Phil. Trans. R. Soc. A 2009, 367, 1487–1509. [Google Scholar] [CrossRef]

- Ensikat, H.J.; Ditsche-Kuru, P.; Neinhuis, C.; Barthlott, W. Superhydrophobicity in perfection: The outstanding properties of the lotus leaf. Beilstein J. Nanotechnol. 2011, 2, 152–161. [Google Scholar] [CrossRef] [PubMed]

- Koch, K.; Ensikat, H.-J. The hydrophobic coatings of plant surfaces: Epicuticular wax crystals and their morphologies, crystallinity and molecular self-assembly. Micron 2008, 39, 759–772. [Google Scholar] [CrossRef]

- Getaneh, S.A.; Temam, A.G.; Nwanya, A.C.; Ejikeme, P.M.; Ezema, F.I. Advances in bioinspired superhydrophobic surface materials: A review on preparation, characterization and applications. Hybrid Adv. 2023, 3, 100077. [Google Scholar] [CrossRef]

- Sotoudeh, F.; Mousavi, S.M.; Karimi, N.; Lee, B.J.; Abolfazli-Esfahani, J.; Manshadi, M.K. Natural and synthetic superhydrophobic surfaces: A review of the fundamentals, structures, and applications. Alex. Eng. J. 2023, 68, 587–609. [Google Scholar] [CrossRef]

- Shirtcliffe, N.J.; McHale, G.; Atherton, S.; Newton, M.I. An introduction to superhydrophobicity. Adv. Colloid Interface Sci. 2010, 161, 124–138. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.Y.; Gao, N.; Barthlott, W. Mimicking natural superhydrophobic surfaces and grasping the wetting process: A review on recent progress in preparing superhydrophobic surfaces. Adv. Colloid Interface Sci. 2011, 169, 80–105. [Google Scholar] [CrossRef]

- Feng, L.; Li, S.; Li, Y.; Li, H.; Zhang, L.; Zhai, J.; Song, Y.; Liu, B.; Jiang, L.; Zhu, D. Super-Hydrophobic Surfaces: From Natural to Artificial. Adv. Mater. 2002, 14, 1857–1860. [Google Scholar] [CrossRef]

- Li, P.; Zhou, M.; Jian, B.; Lei, H.; Liu, R.; Zhou, X.; Li, X.; Wang, Y.; Zhou, B. Paper material coated with soybean residue nanocellulose waterproof agent and its application in food packaging. Ind. Crops Prod. 2023, 199, 116749. [Google Scholar] [CrossRef]

- Wu, X.; Yang, F.; Gan, J.; Zhao, W.; Wu, Y. A flower-like waterborne coating with self-cleaning, self-repairing properties for superhydrophobic applications. J. Mater. Res. Technol. 2021, 14, 1820–1829. [Google Scholar] [CrossRef]

- Khorsand, S.; Raeissi, K.; Ashrafizadeh, F.; Arenas, M.A. Super-hydrophobic nickel–cobalt alloy coating with micro-nano flower-like structure. Chem. Eng. J. 2015, 273, 638–646. [Google Scholar] [CrossRef]

- Pakdel, E.; Zhao, H.; Wang, J.; Tang, B.; Varley, R.J.; Wang, X. Superhydrophobic and photocatalytic self-cleaning cotton fabric using flower-like N-doped TiO2/PDMS coating. Cellulose 2021, 28, 8807–8820. [Google Scholar] [CrossRef]

- Peng, H.; Yang, H.; Ma, X.; Shi, T.; Li, Z.; Xue, S.; Wang, Q. In situ fabrication of flower-like ZnO on aluminum alloy surface with superhydrophobicity. Colloids Surf. A Physicochem. Eng. Asp. 2022, 643, 128800. [Google Scholar] [CrossRef]

- Rius-Ayra, O.; Fiestas-Paradela, S.; Llorca-Isern, N. Non-Fluorinated, Sustainable, and Durable Superhydrophobic Microarrayed Surface for Water-Harvesting. Coatings 2020, 10, 314. [Google Scholar] [CrossRef]

- Weng, R.; Zhang, H.; Yin, L.; Rong, W.; Wu, Z.; Liu, X. Fabrication of superhydrophobic surface by oxidation growth of flower-like nanostructure on a steel foil. RSC Adv. 2017, 7, 25341–25346. [Google Scholar] [CrossRef]

- Wang, X.; He, Y.; Liu, X.; Zhu, J. Synthesis of hierarchical flower-like particles and its application as super-hydrophobic coating. Powder Technol. 2017, 319, 408–414. [Google Scholar] [CrossRef]

- Yang, C.; Yang, X.; Li, F.; Li, T.; Cao, W. Controlled synthesis of hierarchical flower-like Sb 2 WO 6 microspheres: Photocatalytic and superhydrophobic property. J. Ind. Eng. Chem. 2016, 39, 93–100. [Google Scholar] [CrossRef]

- Bhosale, R.S.; Al Kobaisi, M.; Bhosale, S.V.; Bhargava, S.; Bhosale, S.V. Flower-like supramolecular self-assembly of phosphonic acid appended naphthalene diimide and melamine. Sci. Rep. 2015, 5, 14609. [Google Scholar] [CrossRef]

- Zhou, Y.; Yan, D. Supramolecular self-assembly of amphiphilic hyperbranched polymers at all scales and dimensions: Progress, characteristics and perspectives. Chem. Commun. 2009, 10, 1172–1188. [Google Scholar] [CrossRef] [PubMed]

- Bhosale, S.V.; Al Kobaisi, M.; Jadhav, R.W.; Jones, L.A. Flower-Like Superstructures: Structural Features, Applications and Future Perspectives. Chem. Rec. 2021, 21, 257–283. [Google Scholar] [CrossRef]

- Boccalon, E.; Gorrasi, G.; Nocchetti, M. Layered double hydroxides are still out in the bloom: Syntheses, applications and advantages of three-dimensional flower-like structures. Adv. Colloid Interface Sci. 2020, 285, 102284. [Google Scholar] [CrossRef]

- Zhang, K.; Geissler, A.; Chen, X.; Rosenfeldt, S.; Yang, Y.; Förster, S.; Müller-Plathe, F. Polymeric Flower-Like Microparticles from Self-Assembled Cellulose Stearoyl Esters. ACS Macro Lett. 2015, 4, 214–219. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, C.; Tian, J.; Xie, Y.; Zhang, K. A Comparative Study of Self-Assembled Superstructures from Cellulose Stearoyl Ester and Poly(Vinyl Stearate). Macromol. Chem. Phys. 2018, 219, 1800229. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, J.; Deng, X.; Chen, L.; Rosenfeldt, S.; Förster, S.; Vana, P.; Zhang, K. Polymeric Flaky Nanostructures from Cellulose Stearoyl Esters for Functional Surfaces. Adv. Mater. Interfaces 2016, 3, 1600636. [Google Scholar] [CrossRef]

- Vierheller, T.R.; Foster, M.D.; Schmidt, A.; Mathauer, K.; Knoll, W.; Wegner, G.; Satija, S.; Majkrzak, C.F. Structure and Thermal Stability of Langmuir-Blodgett-Kuhn Layers of Hairy-Rod Polymers Probed with Neutron and X-ray Reflectometry. Macromolecules 1994, 1994, 6893–6902. [Google Scholar] [CrossRef]

- Vitale, S.A.; Katz, J.L. Liquid Droplet Dispersions Formed by Homogeneous Liquid−Liquid Nucleation: “The Ouzo Effect”. Langmuir 2003, 19, 4105–4110. [Google Scholar] [CrossRef]

- Gericke, M.; Schulze, P.; Heinze, T. Nanoparticles Based on Hydrophobic Polysaccharide Derivatives-Formation Principles, Characterization Techniques, and Biomedical Applications. Macromol. Biosci. 2020, 20, e1900415. [Google Scholar] [CrossRef] [PubMed]

- Schubert, S.; Delaney, J.J.T.; Schubert, U.S. Nanoprecipitation and nanoformulation of polymers: From history to powerful possibilities beyond poly(lactic acid). Soft Matter 2011, 7, 1581–1588. [Google Scholar] [CrossRef]

- Gavory, C.; Durand, A.; Six, J.-L.; Nouvel, C.; Marie, E.; Leonard, M. Polysaccharide-covered nanoparticles prepared by nanoprecipitation. Carbohydr. Polym. 2011, 84, 133–140. [Google Scholar] [CrossRef]

- Geissler, A.; Biesalski, M.; Heinze, T.; Zhang, K. Formation of nanostructured cellulose stearoyl esters via nanoprecipitation. J. Mater. Chem. A 2014, 2, 1107–1116. [Google Scholar] [CrossRef]

- Geissler, A.; Chen, L.; Zhang, K.; Bonaccurso, E.; Biesalski, M. Superhydrophobic surfaces fabricated from nano- and microstructured cellulose stearoyl esters. Chem. Commun. 2013, 49, 4962–4964. [Google Scholar] [CrossRef]

- Li, L.; Wei, J.; Zhang, J.; Li, B.; Yang, Y.; Zhang, J. Challenges and strategies for commercialization and widespread practical applications of superhydrophobic surfaces. Sci. Adv. 2023, 2023, 1554. [Google Scholar] [CrossRef] [PubMed]

- Loesch-Zhang, A.; Meckel, T.; Biesalski, M.; Geissler, A. Enhancing Hydrophobic Properties in Olive Oil-Coated Papers through Thermal Treatment. Coatings 2024, 14, 364. [Google Scholar] [CrossRef]

- Cordt, C.; Geissler, A.; Biesalski, M. Regenerative Superhydrophobic Paper Coatings by In Situ Formation of Waxy Nanostructures. Adv. Mater. Interfaces 2020, 8, 2001265. [Google Scholar] [CrossRef]

- ISO 5269-2:2004(E); Pulps–Preparation of Laboratory Sheets for Physical Testing–Part 2: Rapid-Köthen Method. International Organization for Standardization: Geneva, Switzerland, 2004.

- ISO 536:2019; Paper and Board–Determination of Grammage. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 534:2011; Paper and Board–Determination of Thickness, Density and Specific Volume. International Organization for Standardization: Geneva, Switzerland, 2011.

- DIN 53122-1:2001-08; Testing of Plastics and Elastomer Films, Paper, Board and Other Sheet Materials–Determination of Water Vapour Transmission–Part 1: Gravimetric Method. Deutsches Institut für Normung e.V.: Berlin, Germany, 2001.

- ISO 535:2023; Paper and Board–Determination of Water Absorptiveness–Cobb Method. International Organization for Standardization: Geneva, Switzerland, 2023.

- Johansson, J.; Lindström, T. A study on AKD-size retention, reaction and sizing efficiency Part 1: The effects of pulp bleaching on AKD-sizing. Nord. Pulp Pap. Res. J. 2004, 19, 330–335. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, L.; An, X.; Liu, H.; Nie, S.; Cao, H.; Xu, Q.; Lu, B. Improving sizing performance of middle layer of liquid packaging board containing high-yield pulp. Cellulose 2020, 27, 4707–4719. [Google Scholar] [CrossRef]

- Kumar, A.; Shaveta, K. Efficacy of ASA Sizinh with Agro-Residue and Recycled Pulps Using Different Fillers. Ippta 2012, 2012, 92–98. [Google Scholar]

- Samyn, P.; Deconinck, M.; Schoukens, G.; Stanssens, D.; Vonck, L.; van den Abbeele, H. Modifications of paper and paperboard surfaces with a nanostructured polymer coating. Prog. Org. Coat. 2010, 69, 442–454. [Google Scholar] [CrossRef]