Abstract

Using chitosan as the shell material and Toddalia asiatica (L.) Lam extract as the core material, microcapsules of chitosan-coated Toddalia asiatica (L.) Lam extracts were prepared. The microcapsules were added to waterborne topcoats to investigate the effects of different content and MToddalia asiatica (L.) Lam extracts:Mchitosan (MT:MC) on the performance of waterborne coatings on poplar surfaces. Under different MT:MC of microcapsules, the content of microcapsules in the coating was negatively correlated with the glossiness, reflectivity, and adhesion of the coating. The addition of microcapsules reduced the liquid resistance of the coating to citric acid and improved the ethanol and cleaning agent resistance of the coating. The hardness, impact resistance, and roughness of the coatings increased gradually with the increase in microcapsule content. The content of microcapsules was positively correlated with the Escherichia coli and Staphylococcus aureus antibacterial performance of coatings, and the coatings had a slightly higher antibacterial rate against Staphylococcus aureus than Escherichia coli overall. The poplar surface coating with 5.0% microcapsules and MT:MC of 4.0:1 was excellent: the gloss was 5.30 GU, the light loss rate was 62.22%, the color difference ΔE was 22.93, the hardness was HB, the impact resistance was grade 3, the adhesion was grade 2, the roughness was 2.022 µm, the resistance to ethanol and cleaning agent was grade 2, and the resistances to Escherichia coli and Staphylococcus aureus were 74.21% and 82.01%, respectively. The results of the study provide a technical reference for the application of antibacterial waterborne coatings on wood surfaces.

1. Introduction

Wood is a renewable biomass material mainly composed of three components: lignin, cellulose, and hemicellulose. These components make wood susceptible to pests and diseases, as well as bacterial and fungal erosion [1,2,3], leading to a sharp reduction in the service life and utilization value of wood products [4,5,6]. Poplar is a fast-growing wood with strong toughness and stability, but its loose fiber structure and difficulty drying can lead to bacterial growth [7,8,9]. Therefore, an antibacterial treatment of poplar is an important way and means to extend its service life, improve its utilization level, and save poplar resources [10,11,12]. Using painting technology to treat poplar can effectively block the invasion of bacteria and microorganisms into the poplar [13,14,15]. Compared to traditional coatings, waterborne coatings are green and are becoming increasingly widely used. However, their antibacterial properties still need to be improved [16,17,18]. Waterborne acrylic acid has a higher release rate of fungicides due to a faster hydrolysis rate [19,20,21]. Coatings with antibacterial properties can achieve the goal of protecting coatings and substrates by inhibiting the growth of bacteria on the surface of wooden products in practical applications [22,23]. Microcapsules are small particles made by wrapping solid, liquid, or gas materials as the core and using natural or artificial polymer materials as the capsule shell [24]. They have the functions of enhancing core stability, reducing volatility, and prolonging shelf life, as well as targeting, sustained release, and controlled release [25]. On the basis of retaining the green and environmentally friendly properties of waterborne coatings, it is important to use antibacterial microcapsules to prepare antibacterial coatings, achieving the purpose of protecting the substrate and expanding the application range of functional coatings [26,27,28].

Toddalia asiatica (L.) Lam belongs to the Rutaceae family and is a traditional Chinese medicinal herb used in traditional medicine [29]. Its roots, skin, leaves, and other parts have extremely high medicinal value [30]. Raj et al. used different materials to sequentially extract the active ingredients from the leaves of Toddalia asiatica (L.) Lam. The results showed that the extract exhibited antibacterial activity against selected bacteria (Staphylococcus epidermidis, Enterobacter aerogenes, Shigella flexneri, Klebsiella pneumoniae, Escherichia coli) and fungi (Aspergillus flavus, Candida krusei, and Botrytis cinerea) [31]. Wang et al. [32] used a urea formaldehyde resin as a shell material. Although the preparation was simple and the cost was low, the use of formaldehyde in the preparation process caused pollution to the environment, which was not conducive to environmental protection. In addition, the coverage rate of urea formaldehyde resin on the microcapsules of Toddalia asiatica (L.) Lam extract was low, and the antibacterial activity needed to be improved. Chitosan is a green and environmentally friendly material with a good biocompatibility, degradability, film-forming properties, antibacterial properties, etc. Therefore, chitosan as the shell material and Toddalia asiatica (L.) Lam extract as the core material were used in order to further improve the encapsulation efficiency and antibacterial properties of the microcapsules while ensuring the green and environmentally friendly properties.

In this paper, three different microcapsule samples of MToddalia asiatica (L.) Lam extracts:Mchitosan (MT:MC) were prepared. They were sample 1# with 3.0:1 MT:MC, sample 2# with 3.5:1 MT:MC, and sample 3# with 4.0:1 MT:MC. The three types of microcapsules were added to waterborne topcoat coatings at concentrations of 1.0%, 2.0%, 3.0%, 5.0%, and 6.0%, respectively, and coated on the surface of poplar wood using a coating process of two bottoms and two sides. By testing and analyzing the microstructure, chemical composition, optical properties, mechanical properties, cold liquid resistance, and antibacterial properties of the surface coating of poplar wood, the influence of different MT:MC and contents on the comprehensive performance of the surface coating on poplar wood was explored, providing a reference for the coating process of antibacterial coatings.

2. Test Materials and Methods

2.1. Materials

Toddalia asiatica (L.) Lam leaves were from Lingshan County, Qinzhou, Guangxi Province, China. The leaves were placed in a 40 °C oven (Shanghai Jinghong Experimental Equipment Co., Ltd., Shanghai, China) and dried to a constant weight. They were ground into powder using a crusher. The coating was a waterborne acrylic topcoat (Jiangsu Haitian Technology Co., Ltd., Yangzhong, China). The size of the poplar wood was 50 mm × 50 mm × 8 mm, which was smoothed using 800# and 1000# sandpaper. Table 1 shows the list of experimental materials. Among them, a cleaning agent consisted of non-ionic surfactant, anionic surfactant, phosphoric acid and other complex acids, pine oil, essence, etc.

Table 1.

List of experimental materials.

2.2. Preparation Method of Microcapsules

2.2.1. Preparation Method of Toddalia asiatica (L.) Lam Extracts

First, 30 g of leaf powder and 450 g of anhydrous ethanol were mixed in a 1:15 mass ratio and poured into a beaker for extraction for 70 min at a temperature of 50 °C and a speed of 600 rpm, according to the previous preparation method [33].

2.2.2. Preparation Method of Microcapsules

First, 0.20 g of acetic acid was diluted in 19.8 g of deionized water to prepare a 1% concentration acetic acid solution. Then, 0.20 g of chitosan powder was weighed and added to the acetic acid solution, then a magnetic stirrer (Yancheng Xieying Machinery Manufacturing Co., Ltd., Yancheng, China) was added into the beaker. The beaker was placed in a water bath pot (Shanghai Yiheng Technology Co., Ltd., Shanghai, China) with a set speed of 600 rpm and a temperature of 60 °C until the chitosan powder was completely dissolved to form a chitosan shell material solution. Tween 80 and X-100 were weighed according to Table 2 to prepare an emulsifier solution with a mass fraction of about 3.0%, and the solution was added dropwise to the Toddalia asiatica (L.) Lam extract. The beaker was placed in the water bath with a speed of 600 rpm and a temperature of 50 °C. After 45 min, a uniformly dispersed core material solution was obtained. Then the temperature of the water bath was adjusted to 60 °C and the rotational speed was 600 rpm. A dropper was used to absorb the shell material solution. The solution was added dropwise to the core material solution, and the core material and shell material solution were mixed fully for 1 h. Then, 0.5 mol/mL of NaOH solution was added to adjust the pH value of the solution to around 7. The TPP solution was added with a concentration of 5.0%, which was placed in the water bath for cross-linking reaction and microencapsulation for 3 h at the temperature of 60 °C and the speed of 600 rpm. Then, the resulting solution was cooled to room temperature. The obtained mixture was centrifuged at 7000 rpm and for 10 min, and the upper clear liquid was poured out. The solid material was put into a freeze-drying machine (BoyiKang (Beijing) Instrument Co., Ltd., Beijing, China) for 24 h, then it was taken out and ground. The final product obtained was microcapsules of chitosan-coated Toddalia asiatica (L.) Lam extract [34].

Table 2.

The proportion of microcapsule raw materials.

2.3. Painting Method for Poplar Board

According to the “Technical Specification for Application of Waterborne Wood Coatings on Furniture Surface”, a uniform layer of coating was manually applied, with a one-time application amount of 60 g/m2 to 80 g/m2. The painting method for the poplar board was brush painting. A coating method of two layers of primer and two layers of topcoat was adopted. The selected coating amount for each layer was 80 g/m2, and the total coating amount for the primer and topcoat was 320 g/m2. Taking into account the loss error during the coating process, the actual consumption of the coating was 1.8 times the theoretical application amount. Therefore, the total mass of the coating applied on the surface of poplar wood was 1.44 g. During the coating process, it was found that when the content of microcapsules of chitosan-coated Toddalia asiatica (L.) Lam extract exceeded 7.0%, the microcapsules agglomerated severely in the coating and covered the original wood grain, which was not suitable for practical applications. Therefore, the content of microcapsules of chitosan-coated Toddalia asiatica (L.) Lam extract was adjusted to 1.0%, 2.0%, 3.0%, 5.0%, and 6.0%, respectively. Table 3 shows the materials used for waterborne coatings.

Table 3.

List of materials used for waterborne coatings.

The specific coating process for the surface coating of poplar wood: a 360# sandpaper was used to treat the rough edges of the poplar board, an 800# sandpaper was used to remove the surface of the poplar board and polished smooth. The first layer of primer was applied. After painting, it was kept level at room temperature for 20 min before transferring to an oven (Shanghai Jinghong Experimental Equipment Co., Ltd., Shanghai, China) to dry the coating. After the coating was completely cured, it was taken out and polished with 800# sandpaper. The brushing, leveling, and curing were repeated. The total mass of the topcoat was kept constant, and the three microcapsule samples 1#, 2#, and 3# prepared were added to the topcoat in different contents of 1.0%, 2.0%, 3.0%, 5.0%, and 6.0%, respectively, and were mixed evenly. The first layer of topcoat was brushed. The brushing, leveling, and curing operations of the primer were repeated. Then the 1000# sandpaper was used to polish the coating. The second layer of topcoat was applied. The poplar board was leveled at room temperature for 20 min before transferring to the oven for coating curing. In addition, pure primer and pure topcoat were applied to the poplar board as a control group specimen for future use.

2.4. Testing and Characterization

2.4.1. Performance Characterization of Microcapsules

- (1)

- Coverage rate (C): The microcapsules with a mass of M1 were weighed. M2 was the weight of the weighing filter paper. The microcapsules were soaked in ethanol and filtered and dried after 24 h. The total mass of the dried filter paper and shell material was M3. The calculation of coverage rate is shown in Formula (1) [35].

- (2)

- Yield rate (Y): The total mass of the core material, shell material, and emulsifier used for preparing microcapsule samples was denoted as M1. The mass of microcapsule powder after drying was recorded as M2. The calculation of yield rate is shown in Formula (2) [36].

- (3)

- Analysis of microstructure and chemical composition: The morphology of microcapsules was observed using a Zeiss optical microscope (OM, Carl Zeiss AG, Oberkochen, Germany). The microstructure of microcapsules and coatings was analyzed using scanning electron microscopy (SEM, Tescan, Brno, the Czech Republic). The chemical composition of microcapsules and coatings was analyzed using Fourier transform infrared spectroscopy (FTIR, Brucker AG, Karlsruhe, Germany).

2.4.2. Color Difference Testing of Coating

In the light of GB/T 11186.3-1989 [37], the chromaticity value of the coating was measured and recorded using a colorimeter (Shenzhen San’enshi Technology Co., Ltd., Shenzhen, China) and the color difference was calculated. The color difference ΔE between the coating with microcapsules added and the pure coating was calculated using Formula (3), where ΔL = L1 − L2, Δa = a1 − a2, and Δb = b1 − b2. ΔL represents the difference in brightness of the coating; Δa represents the red–green difference of the coating; Δb represents the yellow–blue difference in the coating [38].

2.4.3. Glossiness and Reflectivity of Coating

The sample was treated according to the requirements of GB/T 4893.6-2013 [39]. The glossiness values of the coating at three incidence angles of 20°, 60°, and 85° were tested and recorded using a glossmeter (Shenzhen Linshang Technology Co., Ltd., Shenzhen, China), with the unit being GU.

The reflection curve of the coating in the visible light wavelength range (380–780 nm) was tested and recorded using a Hitachi UV spectrophotometer (Zhuhai Tianchuang Instrument Co., Ltd., Zhuhai, China). The reflectance R value was calculated using Formula (4) [40].

where i(λ) is standard radiation intensity for sunlight, and its unit is W∙m−2∙nm−1. r(λ) is reflectance values obtained through testing.

2.4.4. Roughness Testing of Coating

The roughness value was tested and recorded using a J8-4C roughness tester (Cangzhou Oupu Testing Instrument Co., Ltd., Cangzhou, China). The macro knob was rotated to fine tune the probe position until the red display point was at the zero scale line. Test button was clicked and data were recorded. The unit of roughness value is µm.

2.4.5. Cold Liquid Resistance Test of Coating

According to GB/T 4893.1-2021 [41], citric acid solution with a mass fraction of 10%, undescended ethanol with a volume fraction of 96%, and cleaning agent prepared with deionized water were chosen as the experimental liquids. The damage of the surface was inspected under specified lighting conditions. The test results were evaluated using numerical levels.

2.4.6. Antibacterial Performance Testing of Coating

According to GB/T 21866-2008 [42], test operations were carried out. Firstly, Escherichia coli (ATCC25922) and Staphylococcus aureus (ACTT6538) were subjected to live bacterial manipulation. Briefly, 24 g of agar medium and 1000 mL of distilled water were weighed to prepare agar plate medium, and sterilization treatment was performed. The slanted preserved bacterial strains were inoculated onto agar plates and placed in a constant temperature and humidity incubator (Shanghai Zhetu Scientific Instrument Co., Ltd., Shanghai, China) with a relative temperature of 38 °C for cultivation for 18–20 h. Then, 9 g of nutrient broth (Qingdao Haibo Biotechnology Co., Ltd., Qingdao, China) and 500 mL of distilled water were weighed and sterilized. Then, 1–2 rings of fresh bacteria were scraped from the agar medium (Shandong Top Pharmaceutical Technology Co., Ltd., Jinan, China) of live bacteria and added to the broth culture medium using an inoculation ring (Taizhou Kangzhida Experimental Equipment Co., Ltd., Taizhou, China). The sterilized nutrient broth culture medium was diluted to a test bacterial suspension with a concentration of 106 CFU/mL for later use. Approximately 0.5 mL of test bacterial suspension was weighed and dropped onto the surface of the test coating and control group, respectively. The sterilized plastic film was placed on the surface of the specimen using sterilized tweezers. The processed specimen was placed in a sterilized culture dish and transferred to a constant temperature and humidity incubator for cultivation for 24 h. The temperature of the constant temperature and humidity incubator was set to 38 °C, and the relative humidity was >90%. After 24 h of cultivation, the sample was taken out and 20 mL of eluent was added. The thin film was clamped with tweezers and the sample was repeatedly rinsed. The rinse solution was inoculated into nutrient agar culture medium and was placed in the constant temperature and humidity incubator with a relative temperature of 38 °C for 48 h. According to GB/T 4789.2-2022 [43], the number of colonies in the culture medium was measured and recorded using a colony counter (Guansen Biotechnology (Shanghai) Co., Ltd., Shanghai, China). The actual number of colonies recovered after 48 h of cultivation for each sample was multiplied by 1000. The formula for calculating the antibacterial rate is shown in Formula (5), where R represents the antibacterial rate and the unit is %. B represents the average number of recovered colonies of pure coating samples after 48 h, in CFU/piece [44]. C represents the average number of recovered bacteria of the antibacterial coating sample after 48 h, in CFU/piece.

2.4.7. Hardness, Impact Resistance, and Adhesion Testing of Coatings

- (1)

- Hardness: according to GB/T 6739-2022 [45], a pencil with a hardness of 9B-9H was used and tested by a QHQ-A portable pencil hardness tester (Quzhou Aipu Measuring Instrument Co., Ltd., Quzhou, China). The pencil was inserted diagonally at a 45° angle into the pencil hardness tester with a load of 750 g for hardness testing. The pencil hardness was the coating hardness.

- (2)

- Impact resistance: according the content of GB/T 4893.9-2013 “Physical and chemical properties testing of furniture surface coating—Part 9: determination of impact resistance” [46], the impact resistance of wood surface coatings was tested with a coating impactor (Dongguan Jiaxin Measuring Instrument Co., Ltd., Dongguan, China). A magnifying glass was used to observe the number of cycles of surface rupture of the coating to evaluate its impact resistance level. Each sample was subjected to 5 impacts. The nearest integer to the arithmetic mean of an evaluation level was taken as the result of the level evaluation. The impact resistance level increased sequentially from level 5 to level 1. The evaluation for the coating impact level is shown in Table 4.

Table 4. Evaluation table of coating impact position grade.

Table 4. Evaluation table of coating impact position grade. - (3)

- Adhesion: according to GB/T 4893.4-2013 [47], the adhesion of the coating was tested using a coating adhesion tester (Quzhou Aipu Measuring Instrument Co., Ltd., Quzhou, China). The coating was cross-cut with the blade at a vertical angle of 90 degrees. A 3 M adhesive tape was applied on the grid surface and quickly and smoothly peeled off at an angle close to 60°. The adhesion level decreased from level 0 to level 5.

3. Results and Discussion

3.1. Morphology and Chemical Composition Analysis of Microcapsules

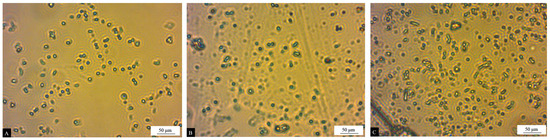

3.1.1. Microscopic Morphology Analysis of Microcapsules

Figure 1 shows the microscopic images of microcapsules 1#–3#. Microcapsule samples 1#–3# were relatively dispersed. The shell–core structure of microcapsules can be observed, where the bright spots inside the microcapsules were the core material and the black circles outside were the shell material. With the continuous increase in MT:MC, the morphology of the obtained microcapsules became better.

Figure 1.

Microscopic diagram of microcapsules with different MT:MC: (A) Sample 1#, (B) Sample 2#, (C) Sample 3#.

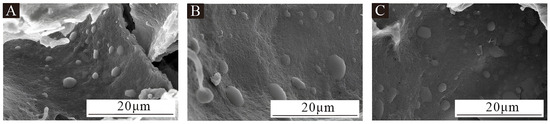

SEM images of three groups of microcapsules are shown in Figure 2. When the MT:MC was 3.0:1, the prepared microcapsules exhibited adhesion and uneven size. When the MT:MC was 3.5:1 and 4.0:1, there were many microcapsule microspheres, but the microcapsules exhibited uneven dispersion and local adhesion. This is because the core material content is too high and not completely emulsified and dispersed, resulting in an increase in the viscosity of the formed core material emulsion. During the microencapsulation process, the core material exists between the already coated microcapsules, causing them to form adhesion with each other and resulting in the formation of microcapsules that is slightly sticky and relatively rough [48].

Figure 2.

SEM images of microcapsules with different MT:MC: (A) Sample 1#, (B) Sample 2#, (C) Sample 3#.

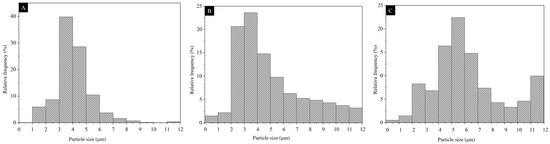

The particle size distribution of microcapsules is shown in Figure 3. The particle size distribution of 1# microcapsules was mainly between 3.0 μm and 5.0 μm, while the particle size distribution of 2# microcapsules was concentrated between 2.0 μm and 7.0 μm. The particle size distribution of 3# microcapsules was relatively uniform compared to the first two groups of samples, with a distribution between 2.0 μm and 12.0 μm.

Figure 3.

Particle size distribution: (A) 1#, (B) 2#, (C) 3#.

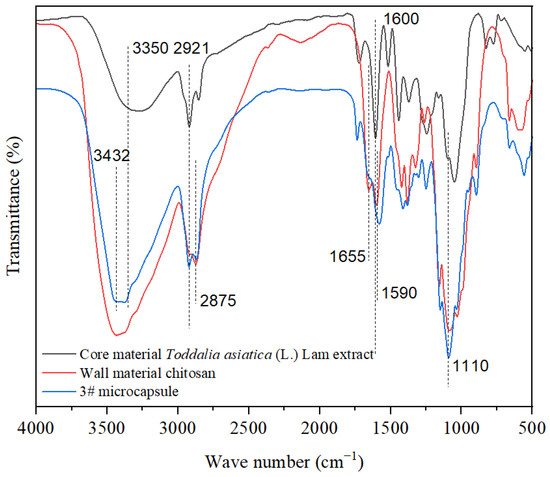

3.1.2. Chemical Composition Analysis of Microcapsules

Figure 4 shows the infrared spectra of the core material, shell material, and microcapsules. An absorption peak at 3350 cm−1 was the stretching vibration peak of C-O in the core material. The stretching absorption peak of C=O in chitosan was located at 1655 cm−1, and the deformation vibration peak of NH2 in chitosan was located at 1590 cm−1 [49]. The two stretching vibration absorption peaks generated at 2921 cm−1 and 2875 cm−1 were the absorption peaks of C-H in chitosan, and the absorption peak of -OH in chitosan was at 3432 cm−1, indicating the presence of shell material of chitosan in microcapsules [50]. The absorption peaks at 1600 cm−1 and 1110 cm−1 were characteristic peaks of C=N and C-O in coumarin compounds in the core material, which existed on the absorption curve of microcapsules, proving the presence of core material Toddalia asiatica (L.) Lam extract in microcapsules as well. The characteristic peaks of both core and shell materials were included in the microcapsules, indicating that the microcapsules were successfully prepared.

Figure 4.

Infrared spectra of core materials, shell materials, and microcapsules.

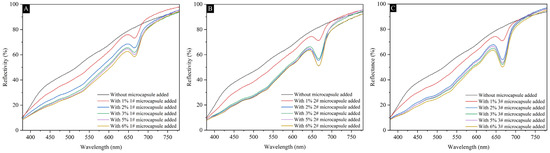

3.2. Optical Performance Analysis of Coatings

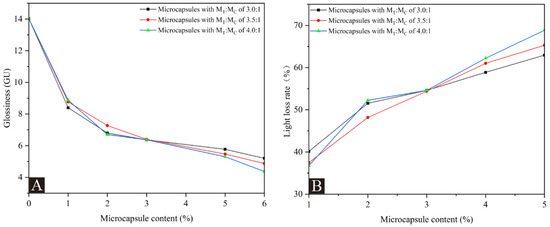

Table 5 shows the effect of the content of microcapsules with different MT:MC on the glossiness and light loss rate of the coating. The data of glossiness and light loss rate at a 60° incidence angle were analyzed. The glossiness corresponding to the surface coating of poplar without microcapsules was 14.03 GU. From Figure 5A, it can be seen that there was a small difference in the glossiness of coating of three different MT:MC, and the content of microcapsules in the coating was negatively correlated with the surface glossiness of the coating. Comparing the changes in surface glossiness of three types of coatings, the glossiness values decreased rapidly when the microcapsule content was 1.0%–3.0% and tended to stabilize at 3.0%. When the microcapsule content was greater than 3.0%, the glossiness of the coating surface decreased again. This is because the microcapsule powder is relatively rough and has poor dispersibility in waterborne coatings, and the solid powder of microcapsules in waterborne coatings weakens the mirror reflection of light, resulting in a decrease in the glossiness of the coating surface [51,52]. Under different MT:MC of the microcapsules, the light loss rate of the coating was positively correlated with the amounts of microcapsules added. Regarding comprehensive glossiness and light loss rate, when the MT:MC of microcapsules was 3.0:1 and 3.5:1, the optical performance of the coating was slightly better.

Table 5.

Glossiness and light loss rate of poplar surface coating with different MT:MC and different content.

Figure 5.

Effects of microcapsules with different MT:MC and different content on glossiness and light loss rate of poplar surface coatings: (A) glossiness, (B) light loss rate.

Table 6 and Figure 6 show the chromaticity values and color difference of coatings with different MT:MC and different contents, as well as their changing trends. The addition of microcapsules had a significant impact on the chromaticity values and color difference of the coatings. The L value of the surface coating on poplar without microcapsules was 80.35, the a value was 5.30, and the b value was 29.95. As shown in Figure 6A, as the amount of microcapsules added increased, the brightness value of the coating gradually decreased. This is because the dispersion uniformity of microcapsule powder in the coating is poor in the base material, resulting in a rough coating that reduces the brightness value of the wood surface coating. In Figure 6B,C, the red green value, yellow blue value, and microcapsule contents of the coating are generally positively correlated, with a significant increase in the red–green value. This is because the coating with microcapsules is reddish brown, and the higher the microcapsule content, the darker the coating color. In Figure 6D, the color difference value of the coating shows an overall upward trend with the increase in microcapsule content, and the increase was significant. The color difference values between the surface coatings of three types of MT:MC of microcapsules on wood were relatively small. For microcapsule coatings with MT:MC added at 3.0:1, 3.5:1, and 4.0:1, the color difference values all reached their minimum values at microcapsule content of 1.0%, which were 8.81, 9.53, and 6.86, respectively. The increase in color difference value is due to the inability to evenly disperse the microcapsules in the waterborne coating during the mixing process, which can affect the covering power of the coating. In addition, the manual brushing process may lead to uneven coating thickness, which can also affect the color difference value of the coating surface. The overall color difference of the coating with 3.5:1 MT:MC was small, and when the microcapsule content was 3.0%, the color difference value of the coating was 15.45.

Table 6.

The chromaticity values and color difference of poplar surface coating with different MT:MC and different contents.

Figure 6.

The trend graphs of chromaticity and color difference about surface coatings on poplar wood: (A) L value, (B) a value, (C) b value, (D) ΔE value.

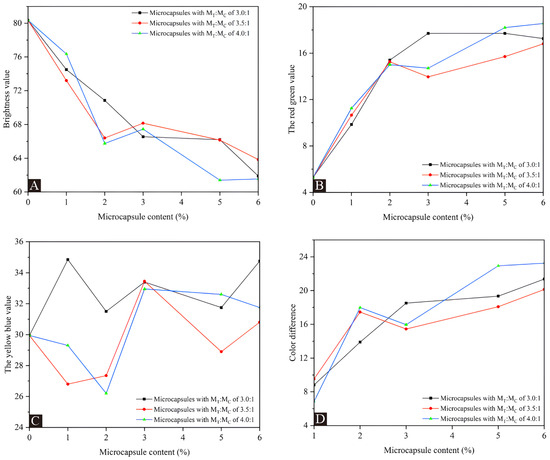

Figure 7 shows the effect of microcapsules with different MT:MC on the coating reflectivity for the poplar wood. The coating reflectivity reflects the strength of the light absorption ability, which is related to the ability to absorb solar infrared and ultraviolet rays. An increase in reflectivity can improve the heat resistance of the coating and extend the service life of the coating. The reflectivity curves of the coatings on poplar prepared with the three types of the microcapsules had extremely high similarity and minimal difference. Compared with the reflectivity of the surface coating on poplar without microcapsules added, the addition of microcapsules did not have a significant effect on the reflectivity of the surface coating on poplar. When the content of microcapsules was greater than 1.0%, the reflectivity of the coating changed less. Table 7 shows the effect of microcapsule content and MT:MC on the coating reflectivity R value. The surface coating reflectivity R value without microcapsules added was 0.6193. As the content of microcapsules increased, the coating reflectivity R values of three different MT:MC microcapsules showed a decreasing trend. When the content was 1.0%, the reflectivity R values of the coating all reached their maximum values, which were 0.5821, 0.5703, and 0.5715, respectively. Among them, the coating reflectivity R values with MT:MC of 3.0:1 were larger.

Figure 7.

Effects of microcapsules with different MT:MC on the reflectivity of poplar surface coating: (A) 1# microcapsule, (B) 2# microcapsule, (C) 3# microcapsule.

Table 7.

Effects of microcapsules with different MT:MC and different contents on coating reflectance R value.

3.3. Cold Liquid Resistance of Coatings

Table 8 shows the cold liquid resistance levels of surface coatings on poplar wood with different MT:MC and contents. The cold liquid resistance of coatings is used to characterize the resistance of substrate surface coatings to common liquids. Excellent cold liquid resistance coatings can extend the service life of wood materials. When microcapsules were not added to the coating, the cold resistance levels for citric acid, ethanol, and cleaning agents were level 2, level 3, and level 3, respectively. Under different MT:MC of microcapsules, as the content of microcapsules increased, the citric acid resistance level of the coating decreased from level 2 to level 3 or 4, the ethanol resistance level increased to level 2, and the cleaning agent resistance level increased from level 3 to level 1 or 2. The change in the MT:MC of microcapsules had no significant effect on the cold liquid resistance of the coating. As the content of microcapsules increased, the cold resistance level of the coating to citric acid gradually decreased, the cold resistance level to ethanol tended to stabilize, and the cold resistance level to cleaning agents gradually increased. This is because shell material chitosan dissolves in weak acid solutions, and adding microcapsule powder as a filler to waterborne coatings can reduce the cold resistance of the coating to citric acid. When the MT:MC was 3.0:1 and 3.5:1, and the microcapsule content was 3.0%, the comprehensive cold liquid resistance performance of the coating was relatively excellent.

Table 8.

Cold liquid resistance grade of poplar surface coating with different MT:MC and different contents.

3.4. Mechanical Properties of Surface Coatings

3.4.1. Hardness of Surface Coating on Poplar Wood

Table 9 shows the hardness test results of the surface coating on poplar wood. When the MT:MC of microcapsules was 3.0:1 and 3.5:1, the hardness of the coating increased from 2B to HB with the increase in microcapsule contents. When adding microcapsules with a MT:MC of 3.5:1, the hardness of the coating increased from B to H with the increase in microcapsule contents. The larger the MT:MC of microcapsules, the higher the hardness of the surface coating of the prepared poplar wood. This is because microcapsules added as additives to waterborne coatings can enhance the mechanical properties of the coating and reduce the external forces acting on the coating [53].

Table 9.

Hardness of coating with different MT:MC and different contents.

3.4.2. Impact Resistance of Surface Coating on Poplar Wood

Table 10 shows the changes in the impact resistance level of the surface coating of poplar wood. The impact resistance level of the wood surface coating was evaluated at a height of 50 mm. The impact resistance level of the wood surface coating without microcapsules was level 5, and the performance was poor. For the coatings prepared with three different MT:MC microcapsules, when the content of microcapsules in the coating was 1.0%–3.0%, the impact resistance level of the coating was improved to level 4, resulting in poor performance. When the content of microcapsules exceeded 3.0%, the impact resistance level of the coating was further increased to level 3, reaching the qualified standard for surface coating on wooden furniture. The content of microcapsules in the coating had a relatively small impact on the impact resistance of the coating [54].

Table 10.

Impact resistance grade of poplar surface coating with different MT:MC and different contents.

3.4.3. Adhesion of Surface Coating on Poplar Wood

The adhesion of the surface coating on wooden furniture refers to the ability of the coating to firmly bond with the surface of the wooden furniture substrate or between the coatings [55]. Table 11 shows the changes in the adhesion level of the surface coating on poplar wood. The adhesion level of the surface coating on wood without the addition of microcapsules was 0, indicating excellent performance. Under different MT:MC, the content of microcapsules was negatively correlated with the adhesion of the coating. For the coating with MT:MC of 3.0:1, as the content of microcapsules increased, the adhesion of the coating remained at level 1. For microcapsules with MT:MC of 3.5:1 and 4.0:1, the adhesion of the coating was level 1 when the microcapsule content was 1.0%–3.0%. When the microcapsule content was between 5.0% and 6.0%, the adhesion of the coating decreased to level 2. The adhesion performance of the coating with MT:MC of 3.0:1 was superior. The addition of microcapsules reduced the mechanical adhesion of the coating, enhanced the viscosity, and reduced the wettability of waterborne coatings on wood surfaces, thereby reducing the adhesion of the coating.

Table 11.

Adhesion grade of coating with different MT:MC and different contents.

3.4.4. Roughness of Surface Coating on Poplar Wood

Table 12 shows the variation of surface coating roughness of poplar wood. The roughness value of the wood surface coating without microcapsules added was 0.260 μm, and the coating surface was uniform and smooth. Under different MT:MC, the content of microcapsules was positively correlated with the roughness value of the coating. The waterborne coating with 3.5:1 of MT:MC exhibited excellent roughness performance. For the waterborne coating with 3.0:1 of MT:MC, as the microcapsule content increased, the roughness value of the coating increased from 0.369 μm to 2.713 μm. When adding microcapsules with MT:MC of 3.5:1 to the coating, the roughness value of the coating increased from 0.743 μm to 1.959 μm. When the added microcapsule MT:MC was 4.0:1, as the microcapsule content gradually increased, the coating roughness value increased from 0.439 μm to 2.825 μm. This is because the addition of microcapsule samples in waterborne coatings increases the viscosity of the coating, weakens its leveling ability, and thus increases the surface roughness of the coating.

Table 12.

Surface coating roughness of poplar with different MT:MC and different contents.

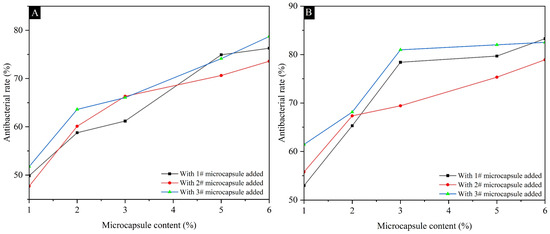

3.5. Antibacterial Properties of Surface Coatings on Poplar Wood

Table 13 shows the average number of recovered colonies and antibacterial rates of surface coatings on poplar against Escherichia coli and Staphylococcus aureus. The content of microcapsules in the coating was positively correlated with the antibacterial rate of the coating. From Figure 8, for Escherichia coli, when the content of microcapsules in the coating was less than 5.0%, the antibacterial rate of the coating increased significantly. When the content of microcapsules was greater than 5.0%, the increase in antibacterial rate of the coating tended to be gradual. For Staphylococcus aureus, when the content of microcapsules in the coating was 1.0%–3.0%, the antibacterial rate of the coating increased significantly. When the content of microcapsules was greater than 3.0%, the antibacterial rate of the coating gradually stabilized. The antibacterial rate of the coating with three types of microcapsules on poplar wood against Staphylococcus aureus was generally slightly higher than that of Escherichia coli. The comprehensive antibacterial performance of the coating with microcapsules of 4.0:1 MT:MC and 6.0% content was the best. With this coating, the maximum antibacterial rate against Escherichia coli was 78.71%, and the maximum antibacterial rate against Staphylococcus aureus was 82.52%. This is because the core antibacterial agent contains coumarin compounds, which can inhibit the growth of biofilms of Staphylococcus aureus and Escherichia coli [56], thus improving the antibacterial rate of wood surface coatings.

Table 13.

Average number of recovered colonies and antibacterial rate of poplar surface coating.

Figure 8.

Effect of microcapsules with different MT:MC and different contents on antibacterial rate of coating: (A) Escherichia coli, (B) Staphylococcus aureus.

3.6. Microscopic Morphology and Chemical Composition of Surface Coating on Poplar Wood

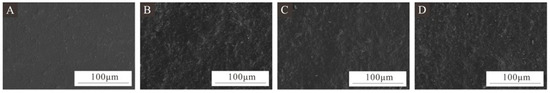

The coating with chitosan-coated Toddalia asiatica (L.) Lam extract microcapsules at a 5.0% content had better comprehensive performance. Therefore, the coating prepared with microcapsules with different MT:MC at 5.0% content was selected for SEM analysis (Figure 9). The surface coating of poplar wood without microcapsules was flat and smooth. The microcapsule coating with 3.0:1 and 4.0:1 MT:MC had poor flatness, and there were a large amount of aggregation and protrusion on the coating. Meanwhile, the coating with 3.5:1 MT:MC had fewer protrusions and wrinkles, and the surface was relatively flat. At 5.0% content, the roughness values of the coating with MT:MC of 3.0:1, 3.5:1, and 4.0:1 for microcapsules were 2.073 μm, 1.610 μm, and 2.022 μm, respectively. The microstructure of the coating was consistent with the roughness analysis results (Table 12).

Figure 9.

SEM images of wood surface coatings prepared by adding 5.0% microcapsules with different MT:MC: (A) coatings without microcapsules, coatings with (B) 1#, (C) 2#, (D) 3# microcapsules.

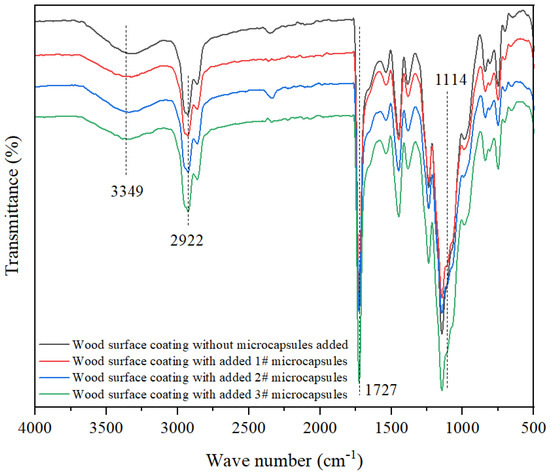

Figure 10 shows the infrared spectrum of waterborne coating containing microcapsules. The absorption peak at 1727 cm−1 was the absorption peak of C=O in waterborne coatings. In the infrared spectrum of the surface coating of poplar wood with microcapsules added, the absorption peak of chitosan in the shell material appeared at 3349 cm−1, due to the stretching vibration of N-H and O-H, while the stretching vibration absorption peak of C-H appeared at 2922 cm−1. The absorption peak of C-O in the microcapsule core material appeared at 1114 cm−1. This proved that after mixing with microcapsules, the shell and core components belonging to microcapsules still existed in waterborne coatings, and there was no chemical reaction between microcapsules and waterborne topcoat. These results were consistent with the infrared analysis results of chitosan-coated Toddalia asiatica (L.) Lam extract microcapsules.

Figure 10.

Infrared spectra of different MT:MC microcapsule coatings on poplar wood with 5.0% content.

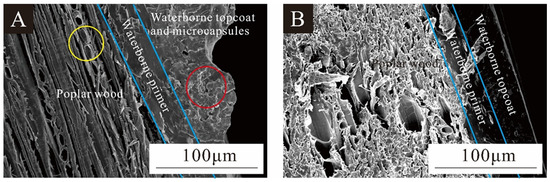

3.7. Interface Bonding and Antibacterial Mechanism Analysis between Poplar Wood and Coating

3.7.1. Interface Bonding between Poplar Wood and Coating

Figure 11 shows views of poplar wood coated with microcapsule coating and waterborne coating. The yellow circle in Figure 9A shows a small amount of primer filling in the conduit holes of poplar wood. The red circle also shows microcapsules distributed in the waterborne topcoat, which inhibited the growth of Staphylococcus aureus and Escherichia coli. The blue area shows that the waterborne primer penetrated into the poplar wood to a certain extent, and the application of the primer had a certain sealing and isolation effect on the wood surface, without a large number of obvious microcapsules penetrating into the wood. The cross-section of the waterborne coating in Figure 9B is flat, while the waterborne topcoat containing microcapsules in Figure 9A is relatively rough. According to the transport mechanism of waterborne coatings with microcapsules in wood, utilizing the porous structure of the wood capillary system and cell walls, the waterborne coatings with microcapsules can form a highly permeable continuous layer in wood, forming “glue nails” and meshing structures between the waterborne coatings and wood.

Figure 11.

View of coated poplar wood: (A) with microcapsules, (B) without microcapsules.

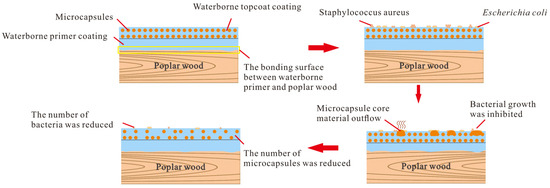

3.7.2. Analysis of Antibacterial Principle of Surface Coating on Poplar Wood

Figure 12 shows a schematic diagram of the antibacterial principle of microcapsules. The microcapsules of chitosan-coated Toddalia asiatica (L.) Lam extract were dispersed in waterborne coatings to form an antibacterial layer. When the coating surface was corroded by Escherichia coli and Staphylococcus aureus, the antibacterial components released by the core antibacterial agent inhibited the growth of biofilms of Staphylococcus aureus and Escherichia coli, thereby achieving the effect of inhibiting bacterial growth and improving the antibacterial performance of waterborne coatings.

Figure 12.

Antimicrobial principle of wood surface coatings.

4. Conclusions

Under different MT:MC, the content of microcapsules was negatively correlated with the glossiness and reflectivity of the coating surface and positively correlated with the light loss of the coating. The addition of microcapsules reduced the liquid resistance of the coating to citric acid and improved the ethanol and cleaning agent resistance of the coating. With the increase in microcapsule content, the hardness of the coating gradually increased, and the impact resistance of the coating was also improved. While the adhesion of the coating was weakened, the surface roughness value of the coating showed an upward trend. The overall antibacterial rate of the coating against Staphylococcus aureus was slightly higher than that of Escherichia coli, and the content of microcapsules was positively correlated with the antibacterial rate of the coating against Escherichia coli and Staphylococcus aureus. The antibacterial coating on the surface of poplar wood with 5.0% microcapsules and 4.0:1 MT:MC had better comprehensive performance. The glossiness of the superior coating was 5.30 GU, the light loss rate was 62.22%, the reflectivity was 0.4975, the color difference ΔE was 22.93, the hardness was HB, and the impact resistance level at an impact height of 50 mm was level 3, meeting the qualified standards for surface coatings on wooden furniture. The adhesion level was level 2, and the roughness was 2.022 μm. Cold liquid resistance was excellent, with resistance to ethanol and cleaning agents of grade 2. The antibacterial rates against Escherichia coli and Staphylococcus aureus were 74.12% and 82.01%, respectively. Compared with the performance of waterborne coating on a poplar surface with urea formaldehyde resin as the microcapsule shell material [32], the change in shell material improved the glossiness, color difference, and antibacterial rate against Escherichia coli and Staphylococcus aureus on the surface coating of poplar wood. The increase in color difference value was more significant, while the reflectivity, impact resistance level, roughness value, and liquid cold resistance to citric acid, ethanol, and cleaning agents, as well as the adhesion of the coating were slightly reduced, but the degree of reduction was relatively small. These findings provide technical references for the application of Toddalia asiatica (L.) Lam extract microcapsules in antibacterial coatings on poplar surfaces and expand their potential application prospects in industries such as coatings. But the obtained microcapsule powder was relatively rough and adhesive, with a low encapsulation rate. Therefore, it is necessary to prepare antibacterial microcapsules with better performance. The physical state and encapsulation rate of the microcapsules should be optimized to enhance the antibacterial performance of the coating. This paper only investigated the antibacterial performance of waterborne coatings on a poplar wood surface after 48 h, without testing and analyzing the durability of microcapsules and the maximum antibacterial time of waterborne coatings containing microcapsules. Further exploration and research are needed. Only microcapsules were added to waterborne topcoats, without exploring the effects of different ways of adding microcapsules and different types of wood on the surface coatings. In the future, deeper exploration is needed on the comprehensive performance of the interface regulation of waterborne coatings, microcapsules, and wood.

Author Contributions

Conceptualization and methodology, writing—review and editing, Y.Z.; validation, resources, data management, Y.W.; formal analysis, investigation, and supervision, X.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This project was partly supported by the Natural Science Foundation of Jiangsu Province (BK20201386).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare that there are no conflicts of interest.

References

- Mai, C.; Schmitt, U.; Niemz, P. A brief overview on the development of wood research. Holzforschung 2022, 75, 102–119. [Google Scholar] [CrossRef]

- Zhang, N.; Xu, W.; Tan, Y. Multi-attribute hierarchical clustering for product family division of customized wooden doors. BioResources 2023, 18, 7889–7904. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Wang, J.X.; Xu, W. Study of selective modification effect of constructed structural color layers on European beech wood surfaces. Forests 2024, 15, 261. [Google Scholar] [CrossRef]

- Yang, L.C.; Wu, Y.; Yang, F.; Wang, W.H. The effect of antibacterial and waterproof coating prepared from hexadecyltrimethoxysilane and nano-titanium dioxide on wood properties. Front. Mater. 2021, 8, 699579. [Google Scholar] [CrossRef]

- Arif, S.; Nawab, Y.; Shaker, K.; Umair, M. Mechanical performance of flame retardant and antibacterial glass-carbon/epoxy hybrid composites for furniture applications. J. Ind. Text. 2022, 51, 5822S–5846S. [Google Scholar] [CrossRef]

- Hu, W.G.; Liu, M.; Xu, L.; Guan, H.Y. Study on cold/warm sensation of materials used in desktop of furniture. Wood Res. 2020, 65, 497–506. [Google Scholar] [CrossRef]

- Qi, Y.Q.; Sun, Y.; Zhou, Z.W.; Huang, Y.; Li, J.X.; Liu, G.Y. Response surface optimization based on freeze-thaw cycle pretreatment of poplar wood dyeing effect. Wood Res. 2023, 68, 293–305. [Google Scholar] [CrossRef]

- Hu, W.G.; Liu, N.; Guan, H.Y. Experimental and numerical study on methods of testing withdrawal resistance of mortise-and-tenon joint for Wood products. Forests 2020, 11, 280. [Google Scholar] [CrossRef]

- Hu, W.G.; Li, S.; Liu, Y. Vibrational characteristics of four wood species commonly used in wood products. BioResources 2021, 16, 7100–7110. [Google Scholar] [CrossRef]

- Jian, H.; Liang, Y.Q.; Deng, C.; Xu, J.X.; Liu, Y.; Shi, J.Y.; Wen, M.Y.; Park, H.J. Research progress on the improvement of flame retardancy, hydrophobicity, and antibacterial properties of wood surfaces. Polymers 2023, 15, 951. [Google Scholar] [CrossRef]

- Gu, Y.T.; Zhang, J.L. Tensile properties of natural and synthetic rattan strips used as furniture woven materials. Forests 2020, 11, 129. [Google Scholar] [CrossRef]

- Wu, S.S.; Zhou, L.C.; Xu, W. A convenient approach to manufacturing lightweight and high-sound-insulation plywood using furfuryl alcohol/multilayer graphene oxide as a shielding layer. Wood Mater. Sci. Eng. 2024, 1–8. [Google Scholar] [CrossRef]

- Qi, Y.Q.; Zhou, Z.W.; Xu, R.; Dong, Y.T.; Liu, M.J.; Shen, L.M.; Han, J.L. Research on the dyeing properties of Chinese fir using ultrasonic-assisted mulberry pigment dyeing. Forests 2023, 14, 1832. [Google Scholar] [CrossRef]

- Qi, Y.R.; Wen, L.X.; Dong, Y.Y.; Gong, R.Z.; Wang, X.W.; Yao, F.B.; Liu, Y.L.; Kong, L.L.; Dong, X.Y.; Li, Y.F. AgCu nanoparticles as an antibacterial coating for wood. ACS Appl. Nano Mater. 2024, 7, 5339–5347. [Google Scholar] [CrossRef]

- Hu, W.G.; Wan, H. Comparative study on weathering durability properties of phenol formaldehyde resin modified sweetgum and southern pine specimens. Maderas-Cienc. Tecol. 2022, 24. [Google Scholar] [CrossRef]

- Sang, R.J.; Yang, F. Effect of TiO2@CaCO3 waterborne primer on the coloring performance of inkjet-printed wood product coatings. Coatings 2023, 13, 2071. [Google Scholar] [CrossRef]

- Sang, R.J.; Yang, F.; Fan, Z.X. The effect of water-based primer pretreatment on the performance of water-based inkjet coatings on wood surfaces. Coatings 2023, 13, 1649. [Google Scholar] [CrossRef]

- Qi, Y.Q.; Zhou, Z.W.; Li, J.X.; Shen, L.M.; Han, J.L. Study on the dyeing properties of Chinese fir with Cinnamomum camphor pigment by premordant dyeing. Wood Mater. Sci. Eng. 2024, 1–11. [Google Scholar] [CrossRef]

- Jalaie, A.; Afshaar, A.; Mousavi, S.B.; Heidari, M. Investigation of the release rate of biocide and corrosion resistance of Vinyl-, Acrylic-, and Epoxy-Based antifouling paints on steel in marine infrastructures. Polymers 2023, 15, 3948. [Google Scholar] [CrossRef]

- Hu, W.G.; Zhang, J.L. Bolt-bearing yield strength of three-layered cross-laminated timber treated with phenol formaldehyde resin. Forests 2020, 11, 551. [Google Scholar] [CrossRef]

- Sang, R.J.; Yang, S.Q.; Fan, Z.X. Effects of MDF substrate surface coating process on UV inkjet print quality. Coatings 2023, 13, 970. [Google Scholar] [CrossRef]

- Cheng, L.S.; Ren, S.B.; Lu, X.N. Application of eco-Friendly waterborne polyurethane composite coating incorporated with nano cellulose crystalline and silver nano particles on wood antibacterial board. Polymers 2020, 12, 407. [Google Scholar] [CrossRef] [PubMed]

- Egghe, T.; Morent, R.; Hoogenboom, R.; De Geyter, N. Substrate-independent and widely applicable deposition of antibacterial coatings. Trends Biotechnol. 2023, 41, 63–76. [Google Scholar] [CrossRef] [PubMed]

- Zigon, J.; Moghaddam, M.S.; Walinder, M.E.P. Wettability and surface interactions of natural and thermally modified beech wood with water and water-based coatings: The effect of surface pre-treatment type. Eur. J. Wood Wood Prod. 2023, 81, 73–88. [Google Scholar] [CrossRef]

- Veeramani, N.; Samikannu, R.; Deshpande, A.P.; Varghese, S.; Moses, V. Effects of polymeric microcapsules on self-healing composites reinforced with carbon fibers: A comparative study. Int. Polym. Proc. 2023, 38, 483–495. [Google Scholar] [CrossRef]

- Zhao, B.Q.; Ni, Y.Z.; Chen, K.L.; Lin, Z.H.; Jia, Z.H.; Qiu, H. Double-shell lignin microcapsules were prepared by one- step method for fabric coatings with UV resistance and durable antibacterial activity. Prog. Org. Coat. 2023, 179, 107518. [Google Scholar] [CrossRef]

- Hu, W.G.; Zhang, J.L. Effect of growth rings on acoustic emission characteristic signals of southern yellow pine wood cracked in mode Ⅰ. Constr. Build. Mater. 2022, 329, 127092. [Google Scholar] [CrossRef]

- Qi, Y.Q.; Zhang, Z.Q.; Sun, Y.; Shen, L.M.; Han, J.L. Study on the Process Optimization of Peanut Coat Pigment Staining of Poplar Wood. Forests 2024, 15, 504. [Google Scholar] [CrossRef]

- Cao, C.X.; Du, P.X.; Zhu, X.M.; Yan, H.J.; Song, X.Y.; Zhu, H.; Geng, Y.L.; Wang, D.J. Rapid screening and purification of potential alkaloid neuraminidase inhibitors from Toddalia asiatica (Linn.) Lam. roots via ultrafiltration liquid chromatography combined with stepwise flow rate counter-current chromatography. J. Sep. Sci. 2019, 42, 2621–2627. [Google Scholar] [CrossRef]

- Li, X.; Qiu, Z.D.; Jin, Q.H.; Chen, G.L.; Guo, M.Q. Cell cycle arrest and apoptosis in HT-29 cells induced by dichloromethane fraction from Toddalia asiatica (L.) Lam. Front. Pharmacol. 2018, 9, 629. [Google Scholar] [CrossRef]

- Raj, M.K.; Balachandran, C.; Duraipandiyan, V.; Agastian, P.; Ignacimuthu, S. Antimicrobial activity of Ulopterol isolated from Toddalia asiatica (L.) Lam.: A traditional medicinal plant. J. Ethnopharmacol. 2012, 140, 161–165. [Google Scholar]

- Wang, Y.; Yan, X.X. Preparation of Toddalia asiatica (L.) Lam. Extract Microcapsules and Their Effect on Optical, Mechanical and Antibacterial Performance of Waterborne Topcoat Paint Films. Coatings 2024, 14, 655. [Google Scholar] [CrossRef]

- Qin, H.G.; Zhou, K.; Song, H.H.; Fang, G.; Chen, Q.; Pang, Y.Z. Toddalia asiatica extract attenuates adjuvant-induced arthritis by modulating colon Th17/Treg balance and colony homeostasis. J. Ethnopharmacol. 2023, 313, 116542. [Google Scholar] [CrossRef]

- Meng, Q.Y.; Zhong, S.L.; Wang, J.; Gao, Y.; Cui, X.J. Advances in chitosan-based microcapsules and their applications. Carbohydr. Polym. 2023, 300, 120265. [Google Scholar] [CrossRef]

- Chang, Y.J.; Yan, X.X. Preparation and self-repairing properties of MF-coated shellac water-based microcapsules. Coatings 2020, 10, 778. [Google Scholar] [CrossRef]

- Beglarigale, A.; Eyice, D.; Seki, Y.; Yalcinkaya, C.; Çopuroglu, O.; Yazici, H. Sodium silicate/polyurethane microcapsules synthesized for enhancing self-healing ability of cementitious materials: Optimization of stirring speeds and evaluation of self-healing efficiency. J. Build. 2021, 39, 102279. [Google Scholar] [CrossRef]

- GB/T 11186.3-1989; Methods for Measuring the Color of Coatings—Part 3: Calculation of Color Difference. Standardization Administration of the People’s Republic of China: Beijing, China, 1989.

- Azamatov, M.K.; Gainutdinov, I.S.; Sabirov, R.S.; Safin, R.G.; Mikhailov, A.V. Determining the color difference of interference coatings. J. Opt. Techol. 2007, 74, 205–207. [Google Scholar] [CrossRef]

- GB/T 4893.6-2013; Testing of Physical and Chemical Properties of Furniture Surface Paint Films—Part 6: Gloss Determination Method. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- Takebayashi, H.; Tanabe, J.; Aoyama, T.; Sonoda, T.; Nakanishi, Y. Using field measurements to assess aging of self-cleaning high-reflectance paint. Int. J. Thermophys. 2017, 38, 119. [Google Scholar] [CrossRef]

- GB/T 4893.1-2021; Test of Surface Coatings of Furniture—Part 1: Determination of Surface Resistance to Cold Liquids. Standardization Administration of the People’s Republic of China: Beijing, China, 2021.

- GB/T 21866-2008; Test Method and Effect for Antibacterial Capability of Paints Film. Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- GB/T 4789.2-2022; Microbiological Examination of Food Hygiene—Aerobic Plate Count. Standardization Administration of the People’s Republic of China: Beijing, China, 2022.

- Shen, Y.; Shan, X.F.; Etim, I.P.; Siddiqui, M.A.; Yang, Y.; Shi, Z.W.; Su, X.P.; Chen, J.X. Comparative study of the effects of nano ZnO and CuO on the biodegradation, biocompatibility, and antibacterial properties of micro-arc oxidation coating of magnesium alloy. Acta Metall. Sin.-Engl. Lett. 2024, 37, 242–254. [Google Scholar] [CrossRef]

- GB/T 6739-2022; Paints and Varnishes—Determination of Film Hardness by Pencil Test. Standardization Administration of the People’s Republic of China: Beijing, China, 2022.

- GB/T 4893.9-2013; Test of Surface Coatings of Furniture—Part 9: Determination of Resistance to Impact. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- GB/T 4893.4-2023; Test of Surface Coatings of Furniture—Part 4: Determination of Adhesion—Cross Cut. Standardization Administration of the People’s Republic of China: Beijing, China, 2023.

- Han, Y.; Yan, X.X.; Tao, Y. Effect of number of impregnations of Microberlinla sp. with microcapsule emulsion on the performance of self-repairing coatings on wood surfaces. Coatings 2022, 12, 989. [Google Scholar] [CrossRef]

- Varankovich, N.; Martinez, M.F.; Nickerson, M.T.; Korber, D.R. Survival of probiotics in pea protein-alginate microcapsules with or without chitosan coating during storage and in a simulated gastrointestinal environment. Food Sci. Biotechnol. 2017, 26, 189–194. [Google Scholar] [CrossRef] [PubMed]

- Ciftci, N.; Sargin, I.; Arslan, G.; Arslan, U.; Okudan, A. Ascorbic Acid Adsorption-Release Performance and Antibacterial Activity of Chitosan-ter(GMA-MA-NTBA) Polymer Microcapsules. J. Polym. Environ. 2020, 28, 2277–2288. [Google Scholar] [CrossRef]

- Zhou, J.C.; Xu, W. A fast method to prepare highly isotropic and optically adjustable transparent wood-based composites based on interface optimization. Ind. Crops Prod. 2024, 218, 118898. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, Z.Y. Optical properties and lampshade design applications of PLA 3D printing materials. BioResources 2023, 18, 1545–1553. [Google Scholar] [CrossRef]

- Hu, W.G.; Chen, B.R.; Zhang, T.X. Experimental and numerical studies on mechanical behaviors of beech wood under compressive and tensile states. Wood Res. 2021, 66, 27–37. [Google Scholar] [CrossRef]

- Wang, Y.; Gala, S.; Huang, J.T. Fabrication of Flexible Thin Veneer for Electromagnetic Interference Shielding and Decoration through Simple Electroless Plating. Bioresources 2020, 15, 5737–5748. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gao, D.; Xu, W. Effect of Paint Process on the Performance of Modified Poplar Wood Antique. Coatings 2021, 11, 1174. [Google Scholar] [CrossRef]

- Feng, D.X.; Zhang, A.H.; Yang, Y.; Yang, P. Coumarin-containing hybrids and their antibacterial activities. Arch. Pharm. 2020, 353, e1900380. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).