Fabrication and Tribological Properties of Diamond-like Carbon Film with Cr Doping by High-Power Impulse Magnetron Sputtering

Abstract

1. Introduction

2. Experiment Details

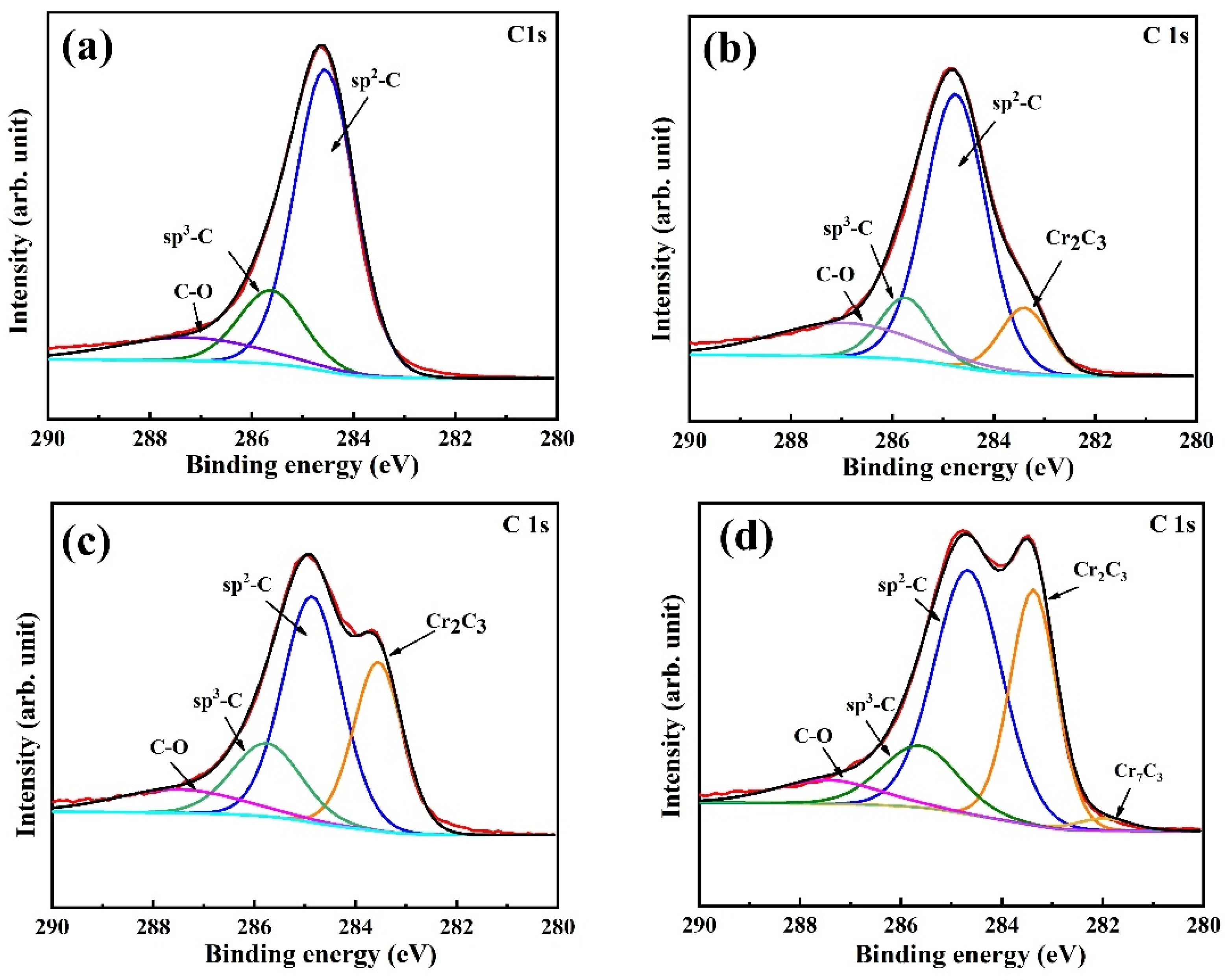

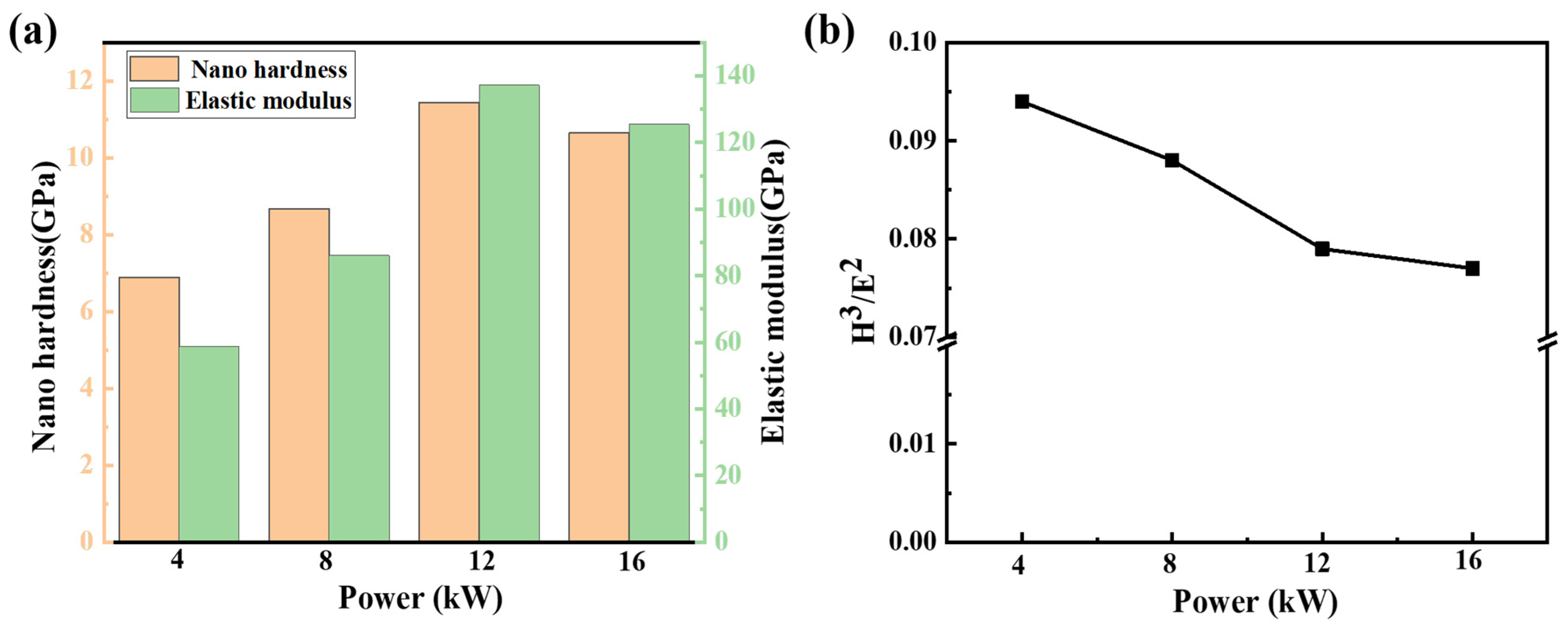

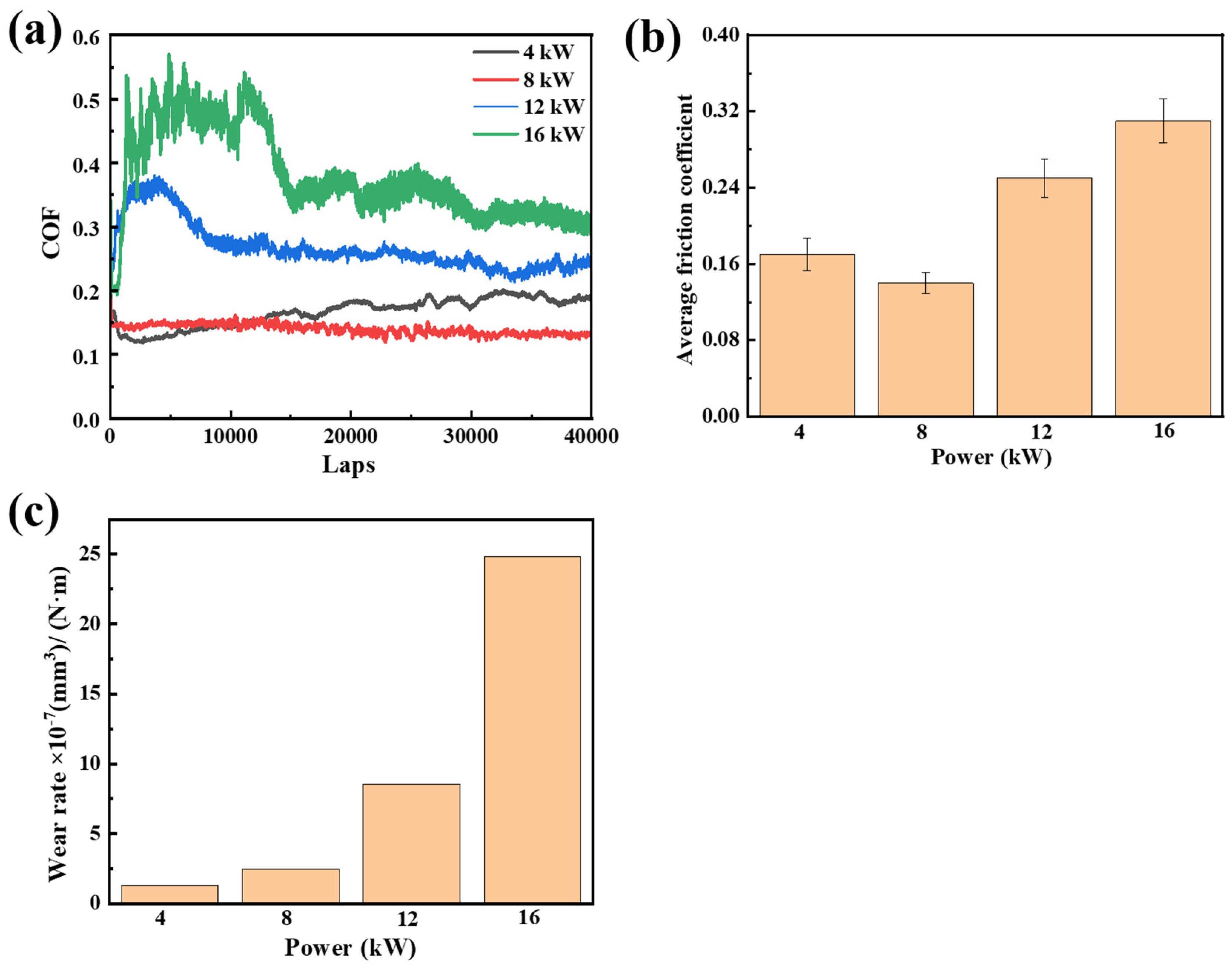

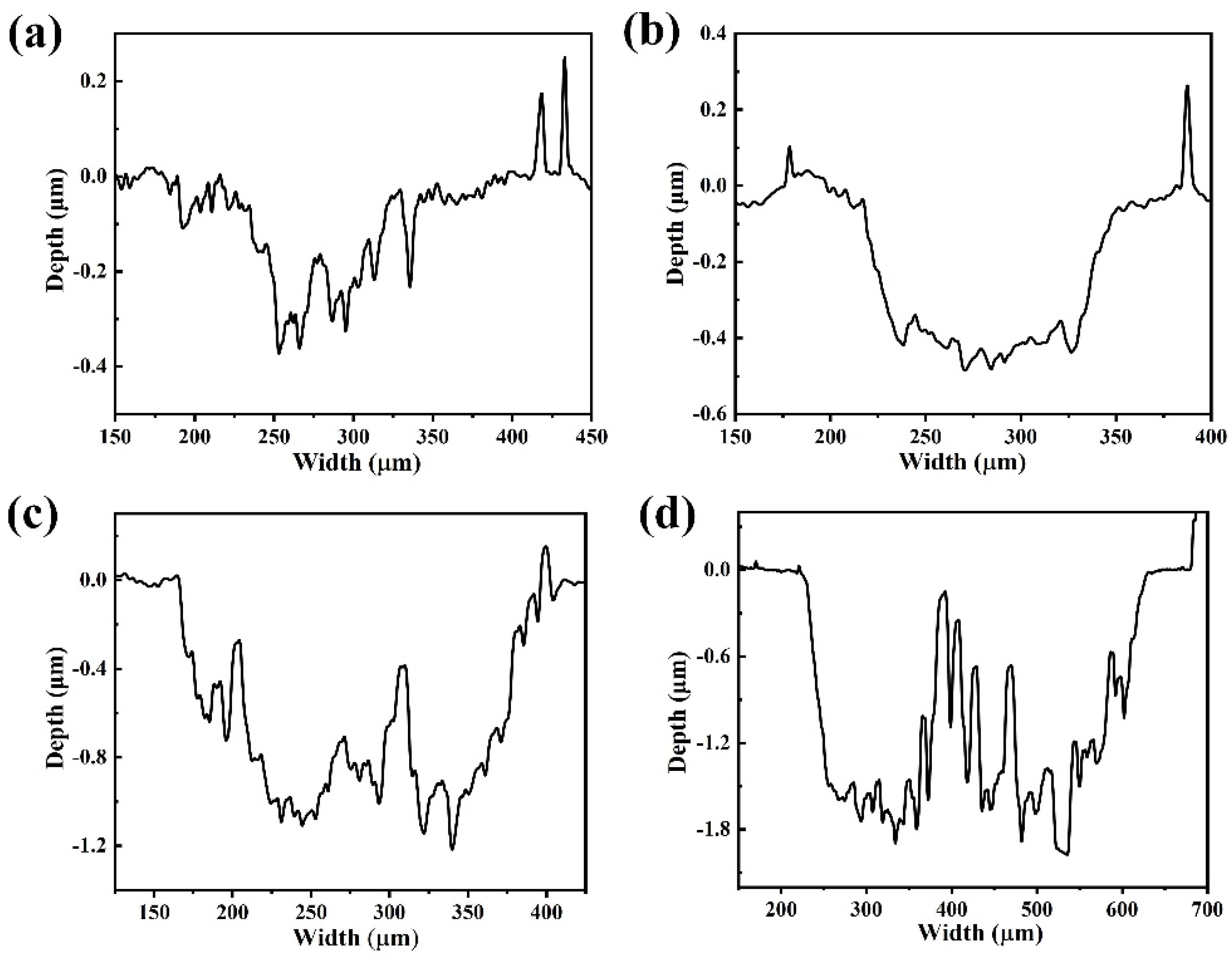

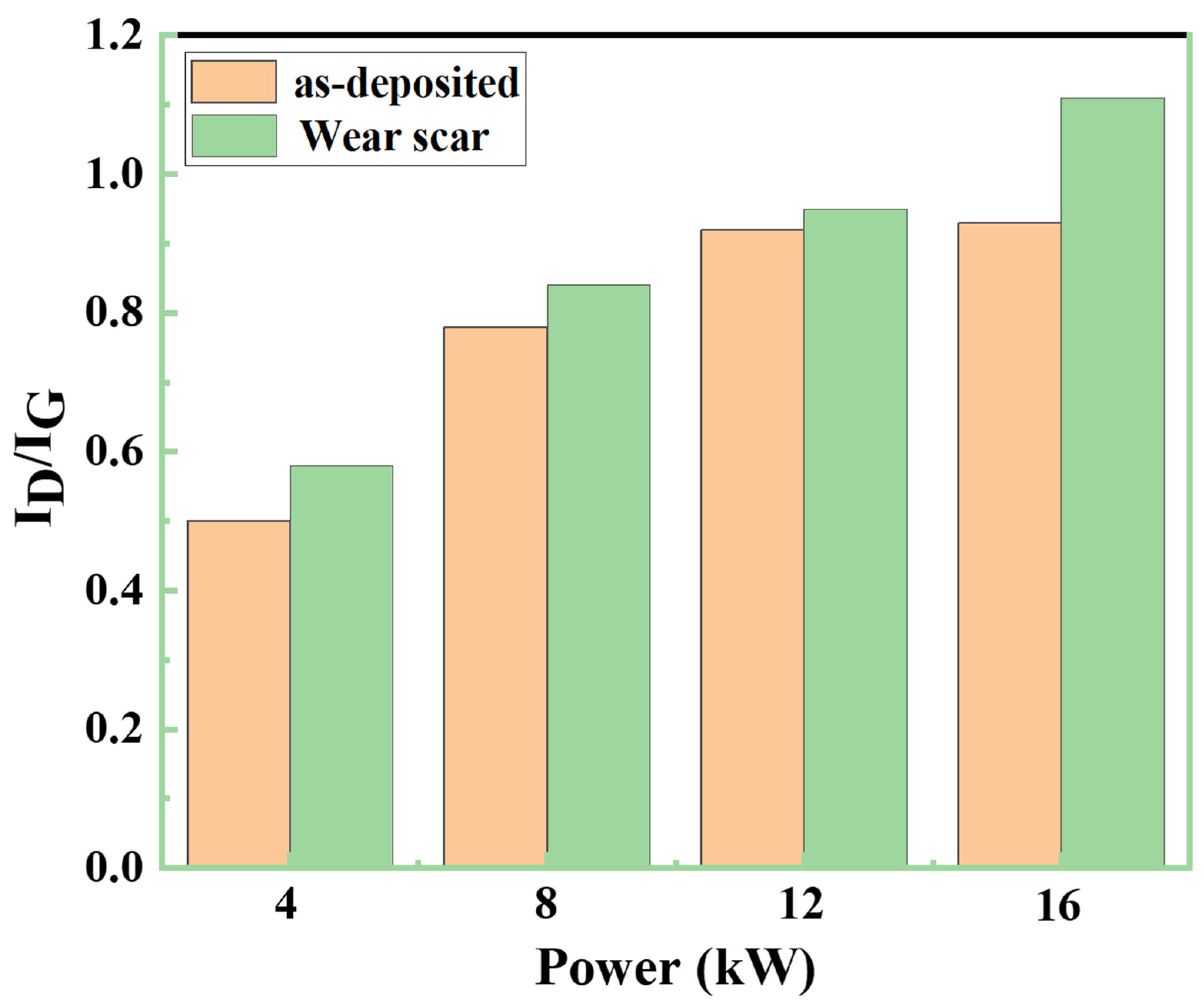

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sadeghpour, S.; Javaheri, V.; Bruschi, S.; Kömi, J.; Karjalainen, P. Strain rate and mechanical stability in determining deformation behavior of beta Ti alloys. Mater. Sci. Eng. A 2020, 798, 140274. [Google Scholar] [CrossRef]

- Ren, L.; Xiao, W.; Kent, D.; Wan, M.; Ma, C.; Zhou, L. Simultaneously enhanced strength and ductility in a metastable β-Ti alloy by stress-induced hierarchical twin structure. Scr. Mater. 2020, 184, 6–11. [Google Scholar] [CrossRef]

- Shao, L.; Li, W.; Li, D.; Xie, G.; Zhang, C.; Zhang, C.; Huang, J. A review on combustion behavior and mechanism of Ti alloys for advanced aero-engine. J. Alloys Compd. 2023, 960, 170584. [Google Scholar] [CrossRef]

- Jain, S.; Parashar, V. Comparison of priori and posteriori approach of multi-objective optimization for wedm on Ti6Al4V alloy. Mater. Res. Express 2022, 9, 076504. [Google Scholar] [CrossRef]

- Zhang, B.; Cai, Z.; Gan, X.; Zhu, M.; Yu, H. Dual motion fretting wear behaviors of titanium and its alloy in artificial saliva. Trans. Nonferr. Met. Soc. China 2014, 24, 100–107. [Google Scholar] [CrossRef]

- Kashyap, V.; Ramkumar, P. DLC coating over pre-oxidized and textured Ti6Al4V for superior adhesion and tribo-performance of hip implant. Surf. Coat. Technol. 2022, 440, 128492. [Google Scholar] [CrossRef]

- Ghahramanzadeh Asl, H. Investigation of friction and wear performance on oxidized Ti6Al4V alloy at different temperatures by plasma oxidation method under ambient air and vacuum conditions. Vacuum 2020, 180, 109578. [Google Scholar] [CrossRef]

- Zhou, Z.-Y.; Liu, X.-B.; Zhuang, S.-G.; Yang, X.-H.; Wang, M.; Sun, C.-F. Preparation and high temperature tribological properties of laser in-situ synthesized self-lubricating composite coatings containing metal sulfides on Ti6Al4V alloy. Appl. Surf. Sci. 2019, 481, 209–218. [Google Scholar] [CrossRef]

- Kümmel, D.; Schneider, J.; Gumbsch, P. Influence of interstitial oxygen on the tribology of ti6al4v. Tribol. Lett. 2020, 68, 96. [Google Scholar] [CrossRef]

- Wang, J.; Ma, J.; Huang, W.; Wang, L.; He, H.; Liu, C. The investigation of the structures and tribological properties of f-dlc coatings deposited on Ti-6Al-4V alloys. Surf. Coat. Technol. 2017, 316, 22–29. [Google Scholar] [CrossRef]

- Zhang, S.; Huang, T.; Sun, S.; Wu, S.; Yang, X.; Guo, F.; Zhang, B.; Dai, L. Effects of bias voltages on the tribological behaviors of DLC Coatings. Coatings 2024, 14, 176. [Google Scholar] [CrossRef]

- Wang, J.; Wang, L.; Chen, H.; Wang, H. Molecular dynamics simulation of friction in dlc films with different sp3 contents. Tribol. Int. 2023, 190, 109050. [Google Scholar] [CrossRef]

- Tillmann, W.; Wittig, A.; Dias, N.F.L.; Stangier, D.; Thomann, C.A.; Moldenhauer, H.; Debus, J. Silicon- and tungsten-containing hydrogen-free and hydrogenated amorphous carbon films for friction-reducing applications. Diam. Relat. Mater. 2022, 123, 108866. [Google Scholar] [CrossRef]

- Sha, B.; Lukianov, A.N.; Dusheiko, M.G.; Lozinskii, V.B.; Klyui, A.N.; Korbutyak, D.V.; Pritchin, S.E.; Klyui Nickolai, I. Carbon-rich amorphous silicon carbide and silicon carbonitride films for silicon-based photoelectric devices and optical elements: Application from uv to mid-ir spectral range. Opt. Mater. 2020, 106, 109959. [Google Scholar] [CrossRef]

- Li, X.; Hou, K.; Qiu, D.; Yi, P.; Lai, X. A first principles and experimental study on the influence of nitrogen doping on the performance of amorphous carbon films for proton exchange membrane fuel cells. Carbon 2020, 167, 219–229. [Google Scholar] [CrossRef]

- Alotaibi, S.; Nama Manjunatha, K.; Paul, S. Stability of hydrogenated amorphous carbon thin films for application in electronic devices. Diam. Relat. Mater. 2018, 90, 172–180. [Google Scholar] [CrossRef]

- Wu, J.; Wei, P.; Liu, G.; Chen, D.; Zhang, X.; Chen, T.; Liu, H. A comprehensive evaluation of DLC coating on gear bending fatigue, contact fatigue, and scuffing performance. Wear 2024, 536–537, 205177. [Google Scholar] [CrossRef]

- Ding, J.C.; Cheng, Y.; Zhang, S.; Wang, Q.; Zhang, T.F. Microstructure, mechanical and tribological properties of ti doped ta-c films deposited by a hybrid coating system. Diam. Relat. Mater. 2023, 131, 109565. [Google Scholar] [CrossRef]

- Ding, J.C.; Dai, W.; Zhang, T.F.; Zhao, P.; Yun, J.M.; Kim, K.H.; Wang, Q.M. Microstructure and properties of nb-doped diamond-like carbon films deposited by high power impulse magnetron sputtering. Thin Solid Films 2018, 663, 159–167. [Google Scholar] [CrossRef]

- Guo, C.-Q.; Li, H.-Q.; Peng, Y.-L.; Dai, M.-J.; Lin, S.-S.; Shi, Q.; Wei, C.-B. Residual stress and tribological behavior of hydrogen-free al-dlc films prepared by hipims under different bias voltages. Surf. Coat. Technol. 2022, 445, 128713. [Google Scholar] [CrossRef]

- Santiago, J.A.; Fernández-Martínez, I.; Sánchez-López, J.C.; Rojas, T.C.; Wennberg, A.; Bellido-González, V.; Molina-Aldareguia, J.M.; Monclús, M.A.; González-Arrabal, R. Tribomechanical properties of hard cr-doped dlc coatings deposited by low-frequency hipims. Surf. Coat. Technol. 2020, 382, 124899. [Google Scholar] [CrossRef]

- Jain, V.; Roychowdhury, T.; Kuimelis, R.G.; Linford, M.R. Differences in surface reactivity in two synthetic routes between hipims and dc magnetron sputtered carbon. Surf. Coat. Technol. 2019, 378, 125003. [Google Scholar] [CrossRef]

- Ma, D.; Harvey, T.J.; Wellman, R.G.; Ehiasarian, A.P.; Hovsepian, P.E.; Sugumaran, A.A.; Purandare, Y.P.; Wood, R.J.K. Cavitation erosion performance of cralyn/crn nanoscale multilayer coatings deposited on Ti6Al4V by hipims. J. Alloys Compd. 2019, 788, 719–728. [Google Scholar] [CrossRef]

- Costa, A.; Ferreira, F.; Colaux, J.L.; Vahidi, A.; Serra, R.; Oliveira, J. Effect of hydrogen incorporation on the mechanical properties of dlc films deposited by hipims in doms mode. Surf. Coat. Technol. 2023, 473, 129980. [Google Scholar] [CrossRef]

- Solomon, I.; Bhatnagar, M.; Shukla, K.; Sarma, B.; Ranjan, M.; Sarma, A. Correlation of structural and optical properties of pvd grown amorphous carbon thin films. Diam. Relat. Mater. 2017, 75, 69–77. [Google Scholar] [CrossRef]

- Kouznetsov, V.; Macák, K.; Schneider, J.M.; Helmersson, U.; Petrov, I. A novel pulsed magnetron sputter technique utilizing very high target power densities. Surf. Coat. Technol. 1999, 122, 290–293. [Google Scholar] [CrossRef]

- Ganesan, R.; Fernandez-Martinez, I.; Akhavan, B.; Matthews, D.T.A.; Sergachev, D.; Stueber, M.; McKenzie, D.R.; Bilek, M.M.M. Pulse length selection in bipolar hipims for high deposition rate of smooth, hard amorphous carbon films. Surf. Coat. Technol. 2023, 454, 129199. [Google Scholar] [CrossRef]

- Brenning, N.; Hajihoseini, H.; Rudolph, M.; Raadu, M.A.; Gudmundsson, J.T.; Minea, T.M.; Lundin, D. HiPIMS optimization by using mixed high-power and low-power pulsing. Plasma Sources Sci. Technol. 2021, 30, 015015. [Google Scholar] [CrossRef]

- Huo, C.; Lundin, D.; Raadu, M.A.; Anders, A.; Gudmundsson, J.T.; Brenning, N. On the road to self-sputtering in high power impulse magnetron sputtering: Particle balance and discharge characteristics. Plasma Sources Sci. Technol. 2014, 23, 025017. [Google Scholar] [CrossRef]

- Fernandes, F.; Calderon, V.S.; Ferreira, P.J.; Cavaleiro, A.; Oliveira, J.C. Low peak power deposition regime in hipims: Deposition of hard and dense nanocomposite Ti-Si-n films by doms without the need of energetic bombardment. Surf. Coat. Technol. 2020, 397, 125996. [Google Scholar] [CrossRef]

- Adelhelm, C.; Balden, M.; Rinke, M.; Stueber, M. Influence of doping (Ti, V, Zr, W) and annealing on the sp2 carbon structure of amorphous carbon films. J. Appl. Phys. 2009, 105, 033522. [Google Scholar] [CrossRef]

- Peng, Y.-L.; Guo, C.-Q.; Lin, S.-S.; Shi, Q.; Wei, C.-B.; Su, Y.-F.; Wu, Y.-Q.; Tang, P.; Zhu, X.-G.; Dai, M.-J. Effects of working pressure on structure and properties of al-containing amorphous carbon films prepared by high-power impulse magnetron sputtering. J. Alloys Compd. 2020, 816, 152587. [Google Scholar] [CrossRef]

- NIST X-ray Photoelectron Spectroscopy Database (SRD 20), Version 5.0. Available online: https://srdata.nist.gov/xps/EnergyTypeElement (accessed on 25 June 2024).

- Zhu, L.; Li, J.; Kang, J.; Tang, L.; Ma, G.; Han, C.; Shi, J.; Wang, H. Different cr contents on the microstructure and tribomechanical properties of multi-layered diamond-like carbon films prepared by unbalanced magnetron sputtering. J. Mater. Eng. Perform. 2020, 29, 7131–7140. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Y.; Xu, Z.; Toshiaki, N.; Xi, Y.; Ni, Q. Effect of heat treatment on mechanical property of amorphous carbon films by magnetron sputtering. Diam. Relat. Mater. 2022, 129, 109328. [Google Scholar] [CrossRef]

- Tao, H.; Tsai, M.T.; Chen, H.-W.; Huang, J.C.; Duh, J.-G. Improving high-temperature tribological characteristics on nanocomposite cralsin coating by mo doping. Surf. Coat. Technol. 2018, 349, 752–756. [Google Scholar] [CrossRef]

- Dai, W.; Ke, P.; Wang, A. Microstructure and property evolution of cr-dlc films with different Cr content deposited by a hybrid beam technique. Vacuum 2011, 85, 792–797. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, Z.; Zhang, T.; Zhang, S.; Xing, X.; Yang, Q.; Li, D. Metastable hybridized structure transformation in amorphous carbon films during friction—A study combining experiments and MD simulation. Friction 2023, 11, 1708–1723. [Google Scholar] [CrossRef]

| Parameters | Cr | CrN | Cr-DLC |

|---|---|---|---|

| Base pressure (Pa) | 5.0 × 10−5 | 5.0 × 10−5 | 5.0 × 10−5 |

| Working pressure (Pa) | 0.5 | 0.5 | 0.5 |

| Bias voltage (V) | −50 | −50 | −100 |

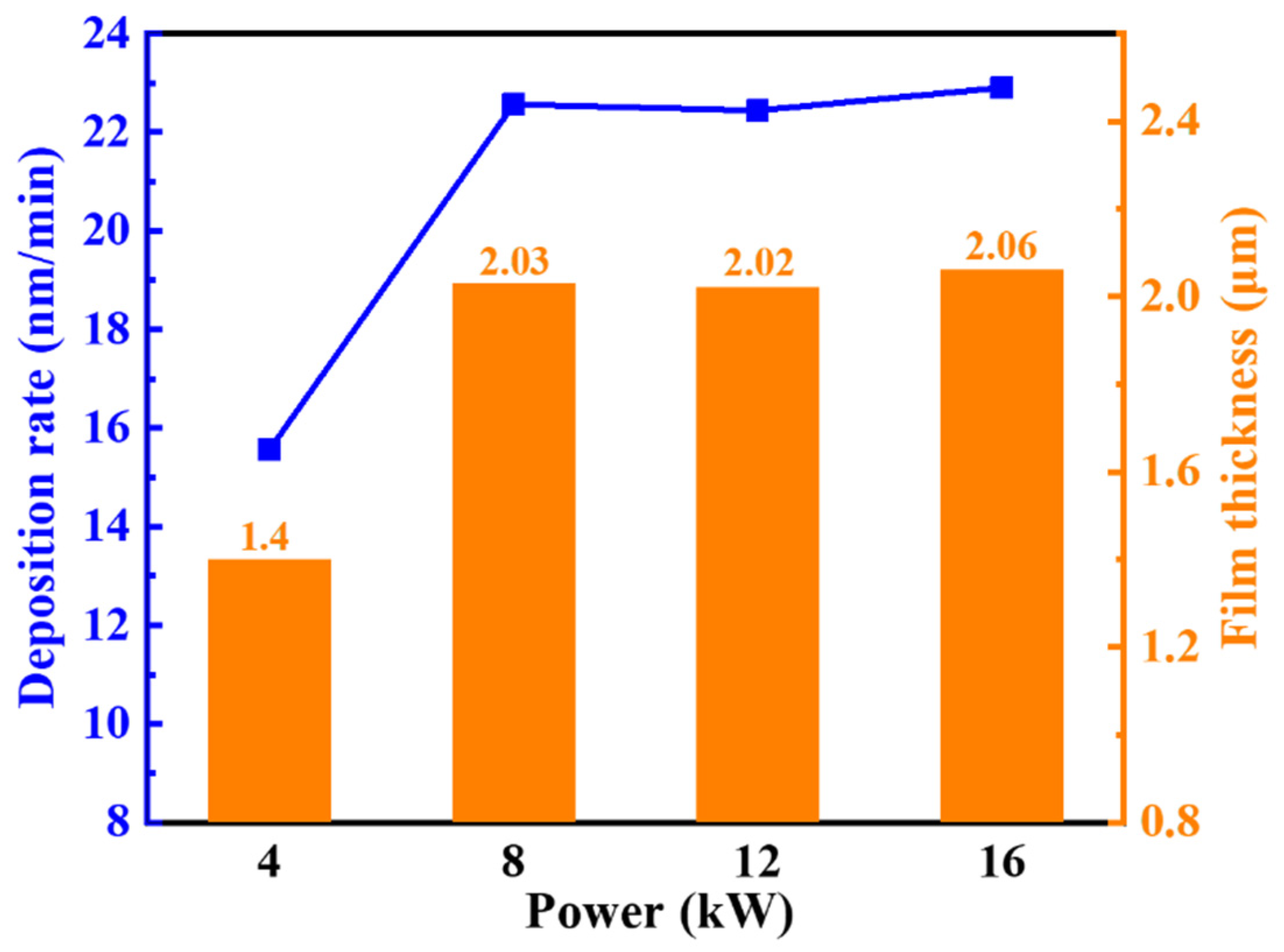

| HiPIMS power (kW) | 15 | 15 | 4, 8, 12, 16 |

| Pulse length (μs) | 100 | 100 | 70 |

| Flow rate (sccm) | Ar: 300 | Ar/N2: 200/100 | Ar/C2H2: 150/300 |

| Deposition time (min) | 15 | 60 | 90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Zhuang, W.; Ding, J.; Liu, Y.; Yu, W.; Yang, Y.; Liu, X.; Yuan, J.; Zheng, J. Fabrication and Tribological Properties of Diamond-like Carbon Film with Cr Doping by High-Power Impulse Magnetron Sputtering. Coatings 2024, 14, 916. https://doi.org/10.3390/coatings14070916

Liu S, Zhuang W, Ding J, Liu Y, Yu W, Yang Y, Liu X, Yuan J, Zheng J. Fabrication and Tribological Properties of Diamond-like Carbon Film with Cr Doping by High-Power Impulse Magnetron Sputtering. Coatings. 2024; 14(7):916. https://doi.org/10.3390/coatings14070916

Chicago/Turabian StyleLiu, Shuai, Wenjian Zhuang, Jicheng Ding, Yuan Liu, Weibo Yu, Ying Yang, Xingguang Liu, Jing Yuan, and Jun Zheng. 2024. "Fabrication and Tribological Properties of Diamond-like Carbon Film with Cr Doping by High-Power Impulse Magnetron Sputtering" Coatings 14, no. 7: 916. https://doi.org/10.3390/coatings14070916

APA StyleLiu, S., Zhuang, W., Ding, J., Liu, Y., Yu, W., Yang, Y., Liu, X., Yuan, J., & Zheng, J. (2024). Fabrication and Tribological Properties of Diamond-like Carbon Film with Cr Doping by High-Power Impulse Magnetron Sputtering. Coatings, 14(7), 916. https://doi.org/10.3390/coatings14070916