Research on Layered Steel Fiber Reinforced Concrete Mix Ratio Design Based on Orthogonal Test

Abstract

1. Introduction

2. Experimental Raw Materials and Methods

2.1. Experimental Raw Materials

2.2. Orthogonal Experimental Design

2.3. The Methods of Specimen Fabrication and Testing

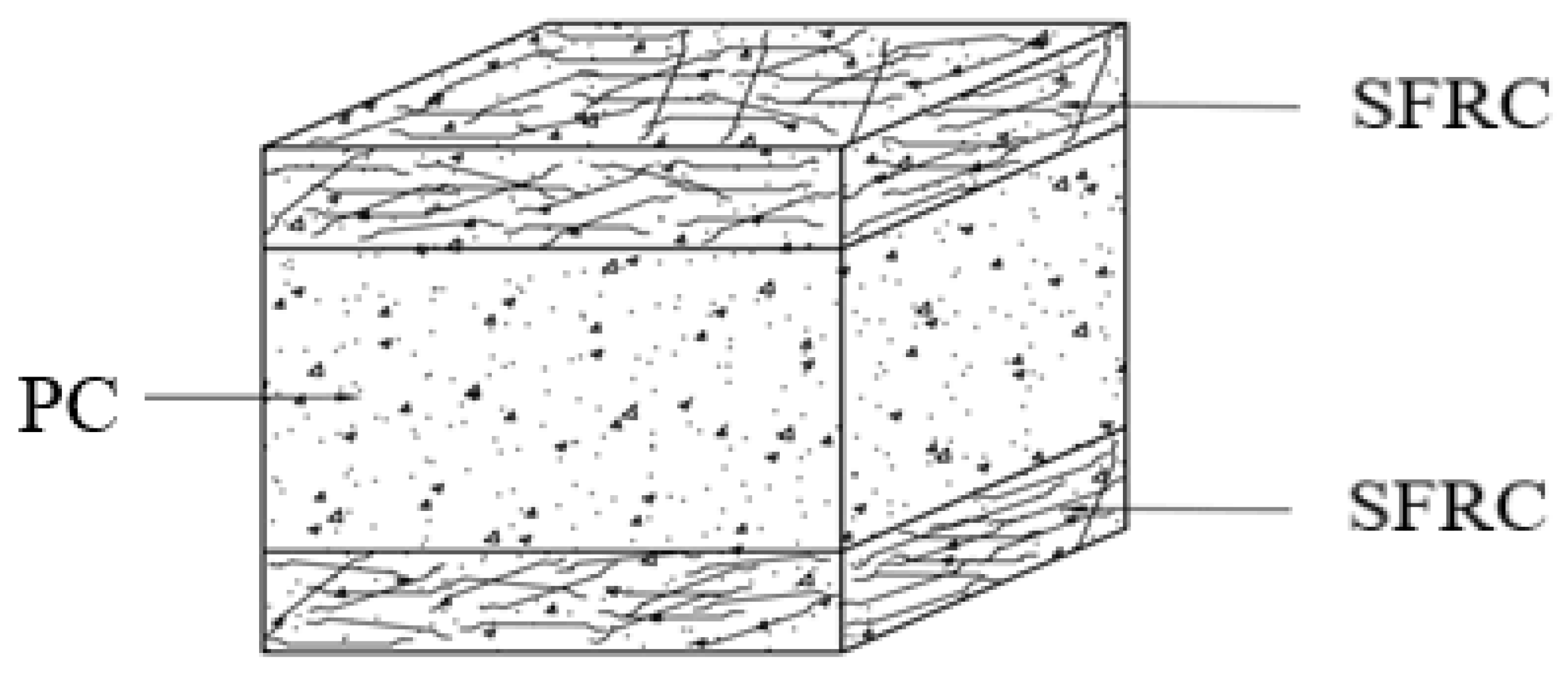

- (1)

- Specimen Fabrication

- (2)

- Mixing Procedure

- (3)

- Layered Structure Formation

- (4)

- Conservation conditions and processes

- (5)

- Testing Methods

3. Analysis of the Influence of Testing Factors on the Performance of Concrete

3.1. Analysis of the Influence of Testing Factors on the Workability of Concrete

- (1)

- Test Results of Slump Test for Steel Fiber Concrete

3.2. Analysis of the Influence of Testing Factors on the Mechanical Properties of Concrete

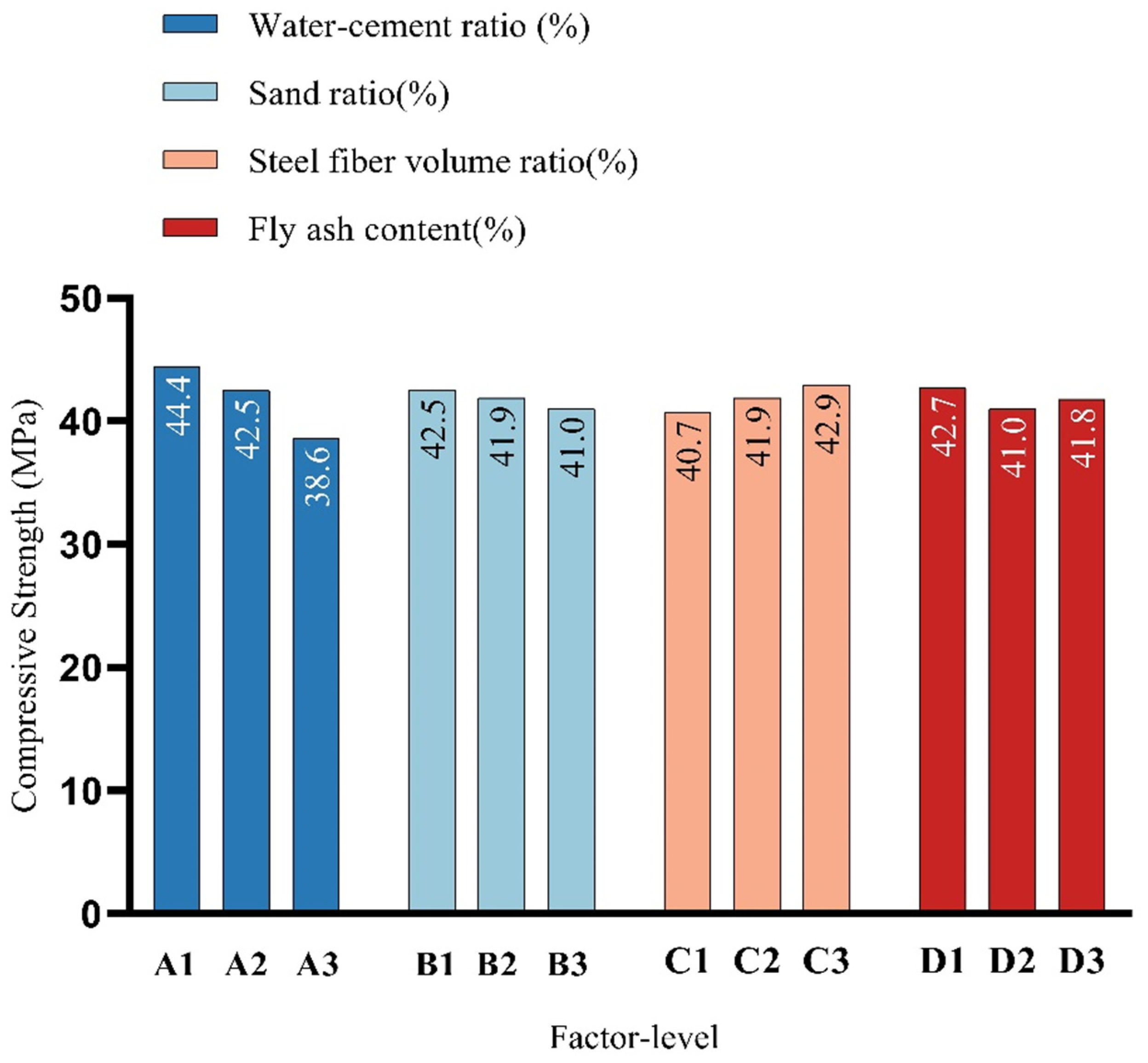

3.2.1. Range Analysis

- (1)

- Range Analysis of Compressive Strength

- (2)

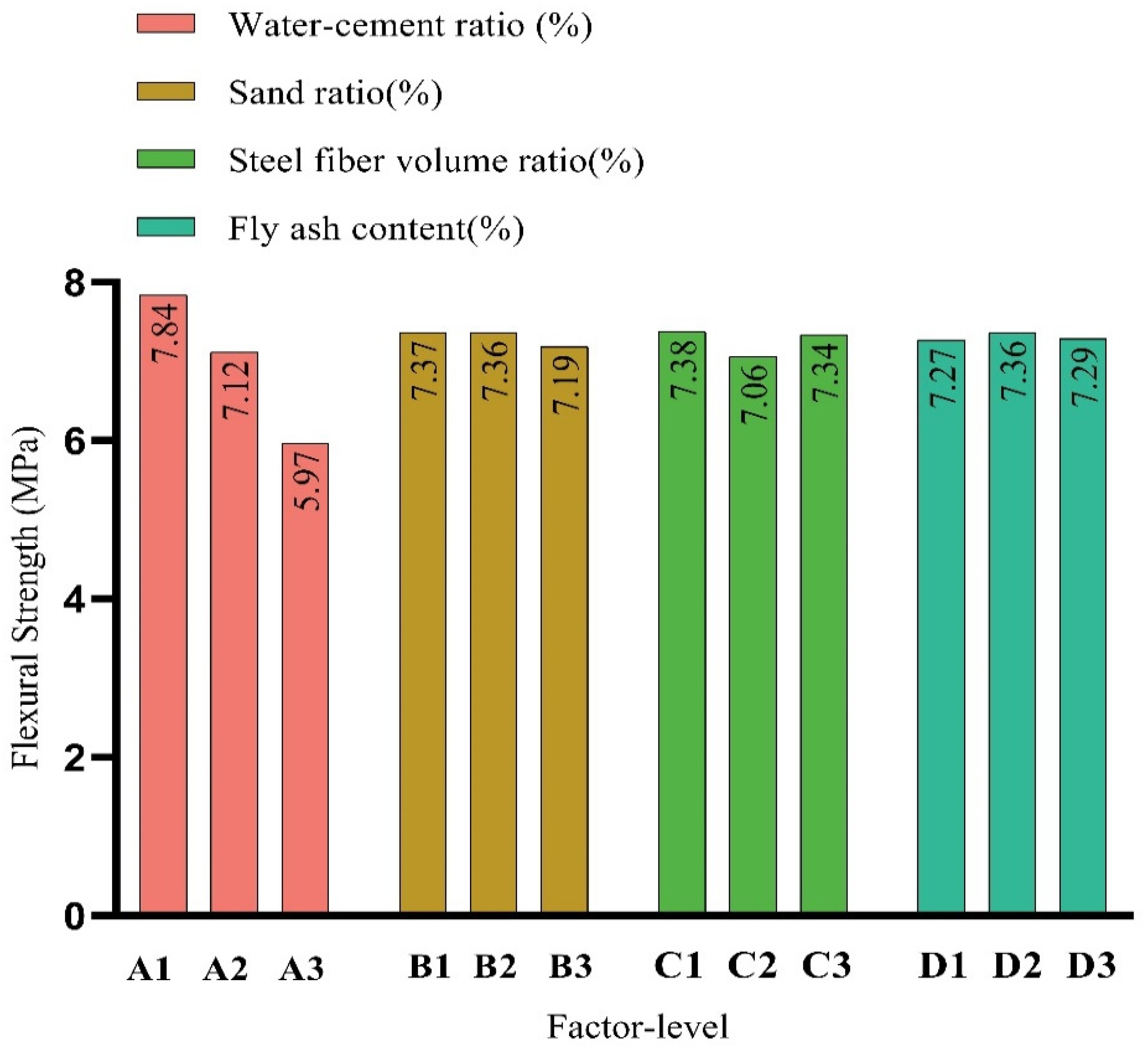

- Range Analysis of Flexural Performance

- (3)

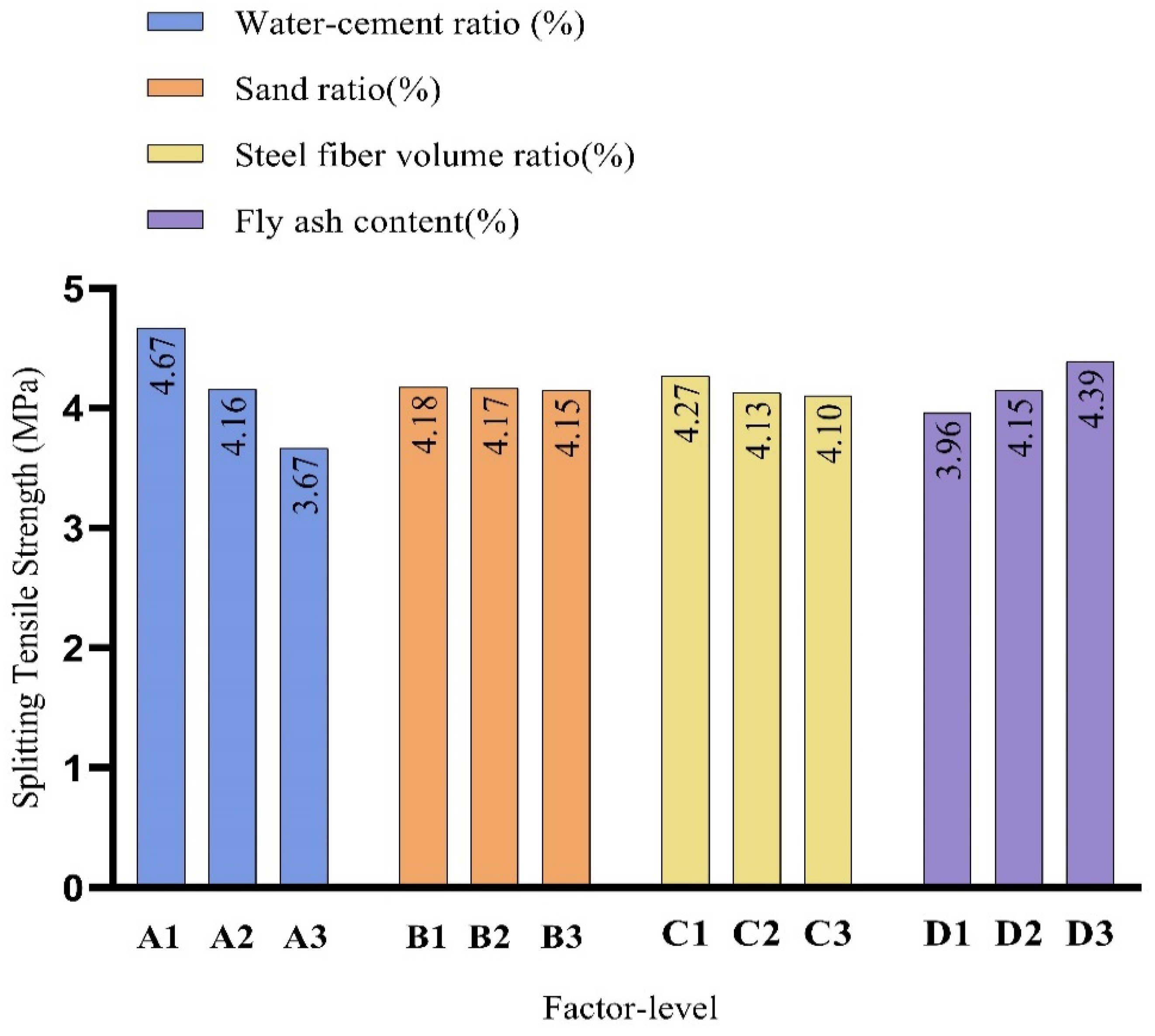

- Range Analysis of Splitting Tensile Performance

3.2.2. Analysis of Factor Indicators

- (1)

- Analysis of Factor Indicators for Compressive Performance

- (2)

- Analysis of Factors Indicators for Flexural Strength

- (3)

- Analysis of Splitting Tensile Strength Factors

3.2.3. Response Surface Analysis of Significant Influencing Factors

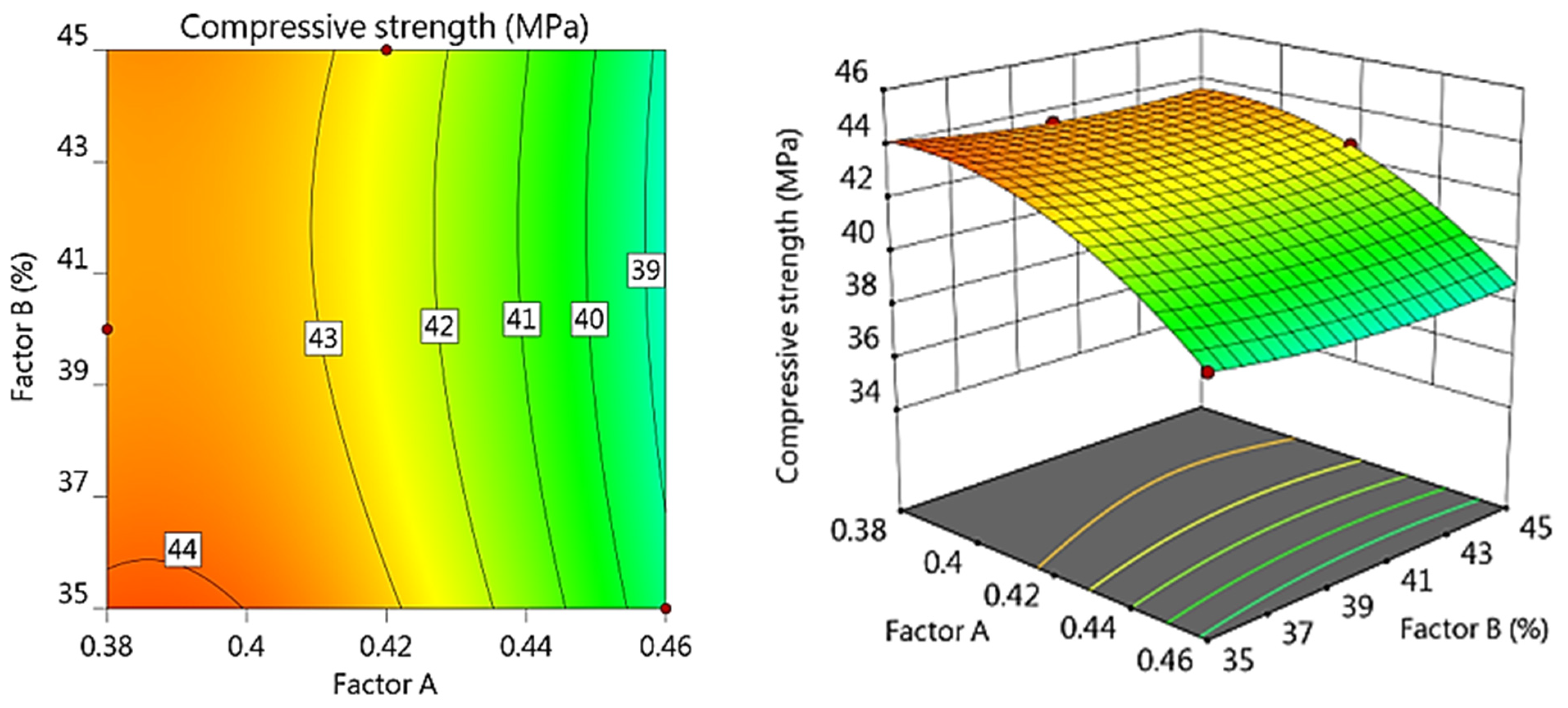

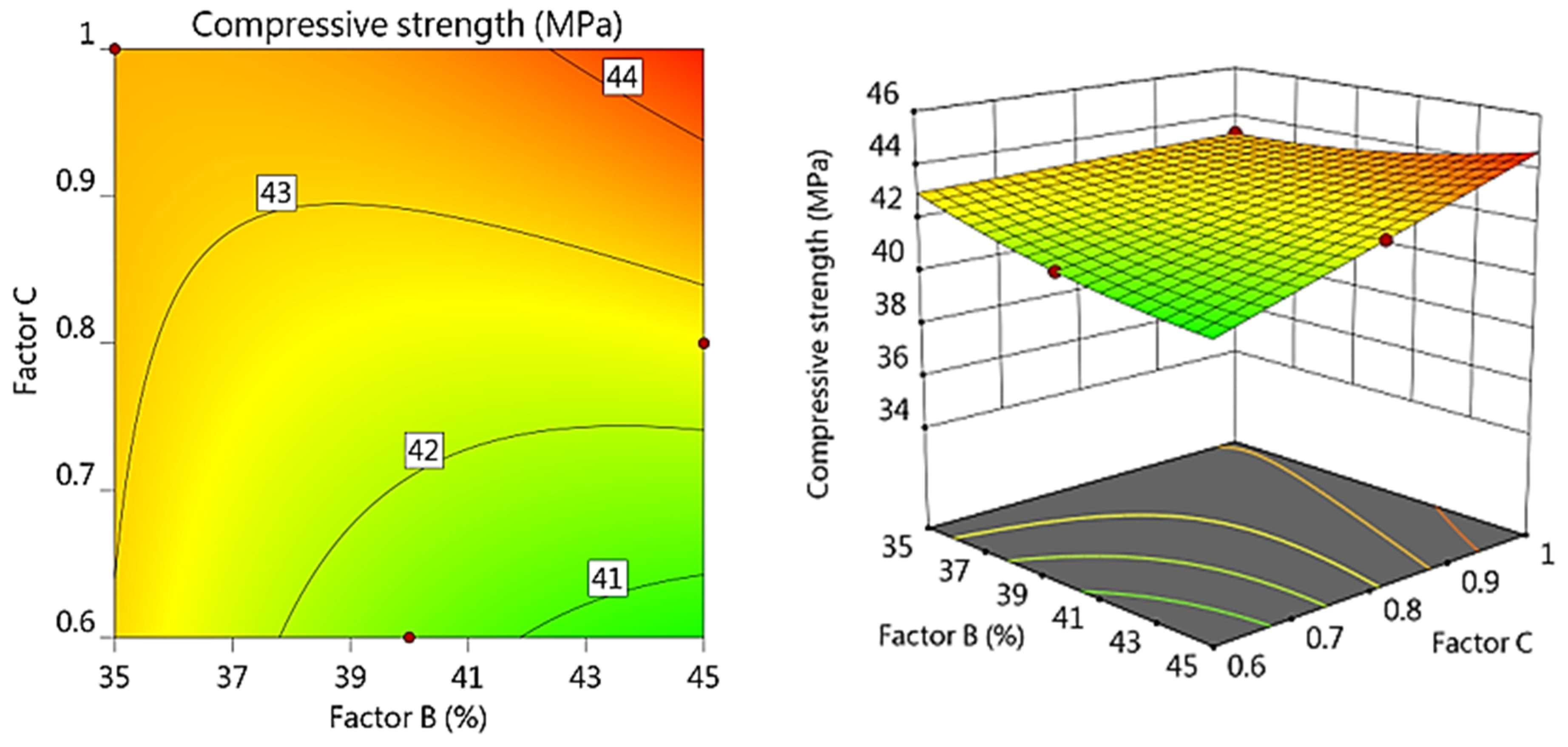

- (1)

- Response surface analysis of factors influencing compressive strength.

- (2)

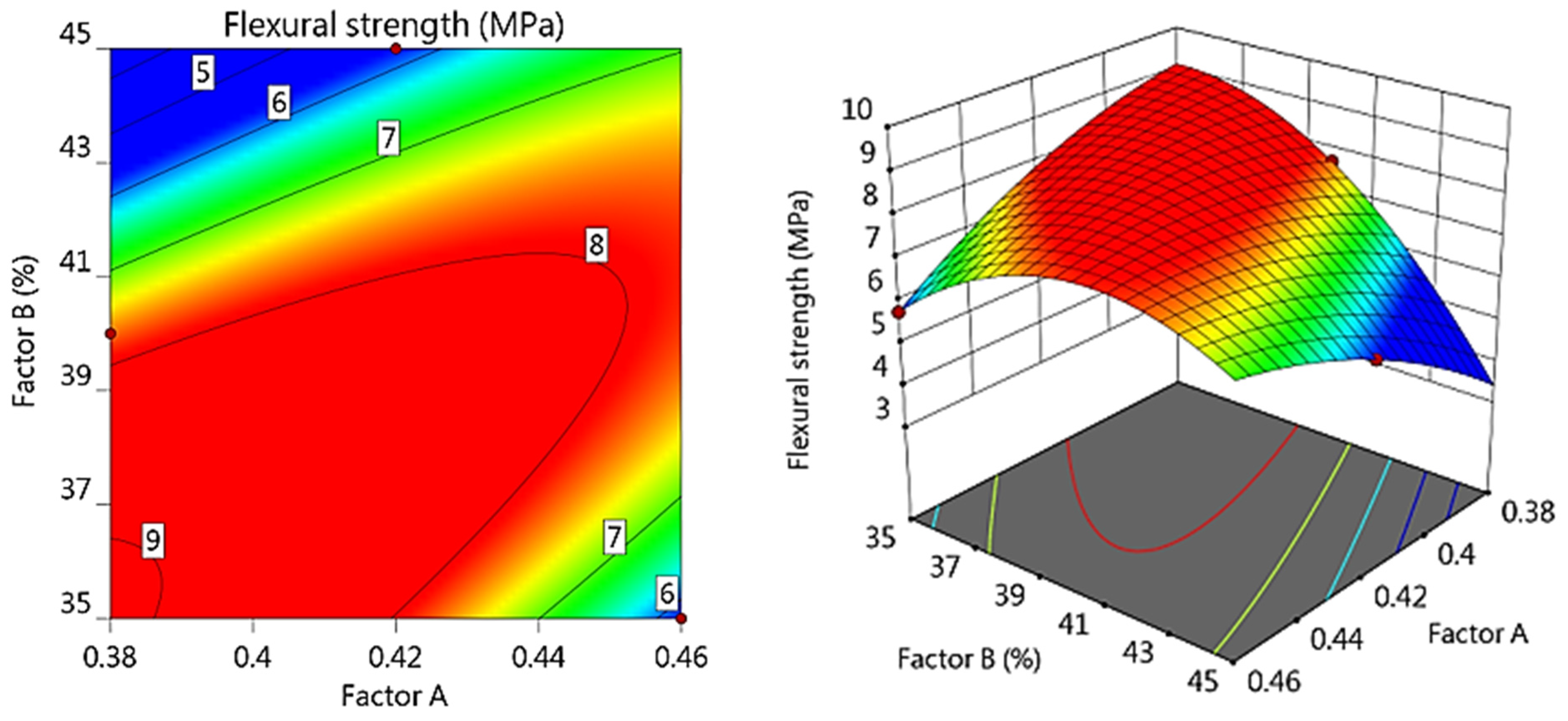

- Response surface analysis of factors influencing flexural strength.

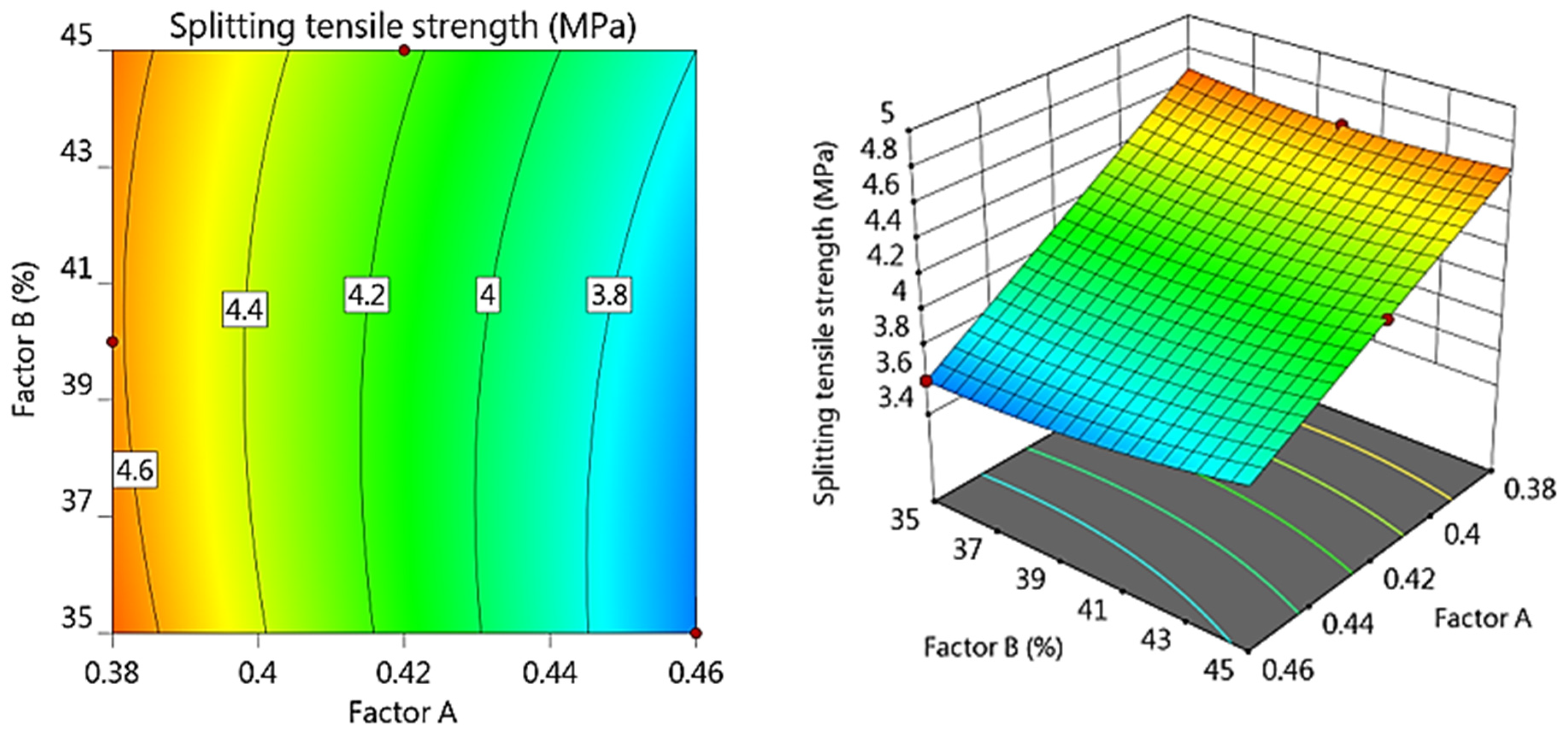

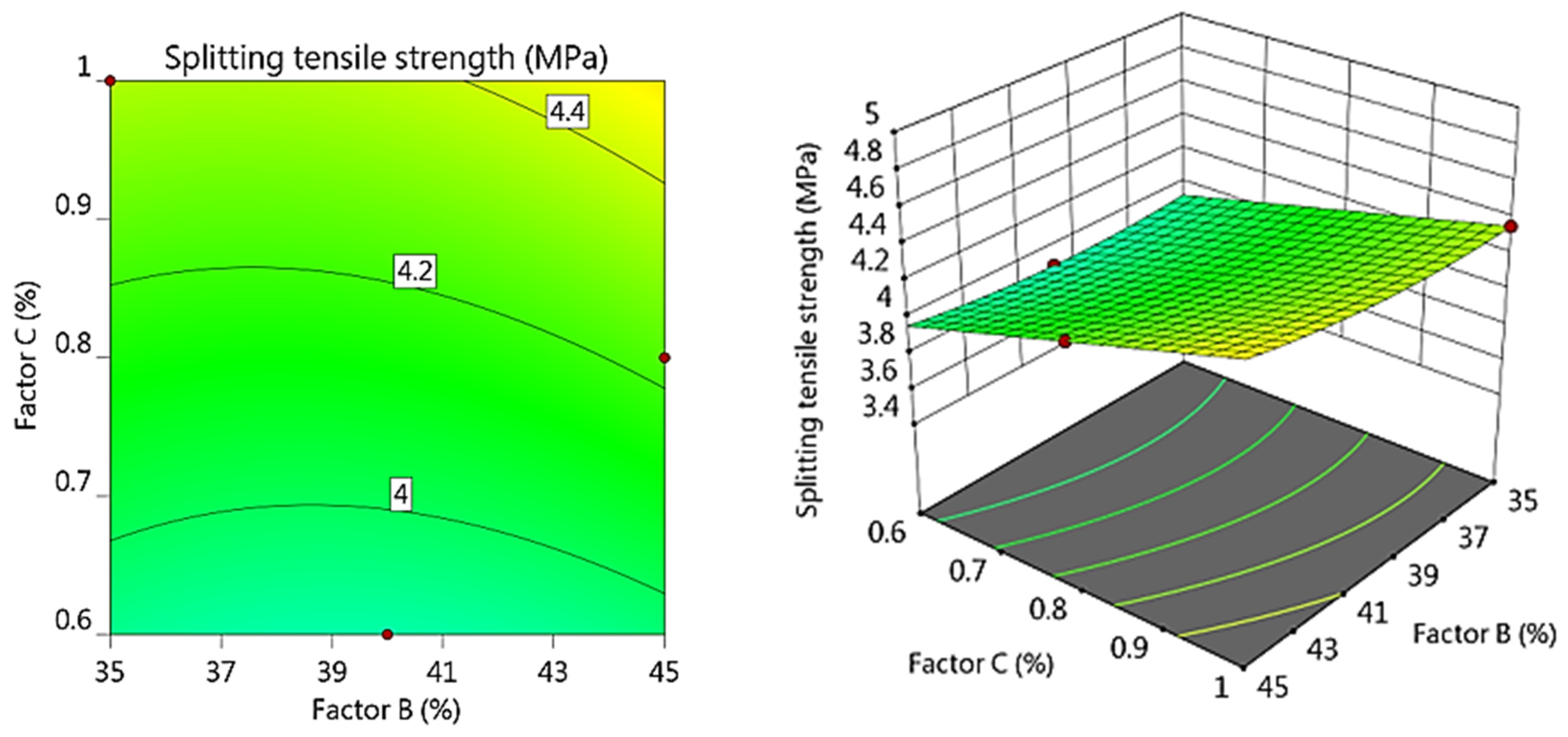

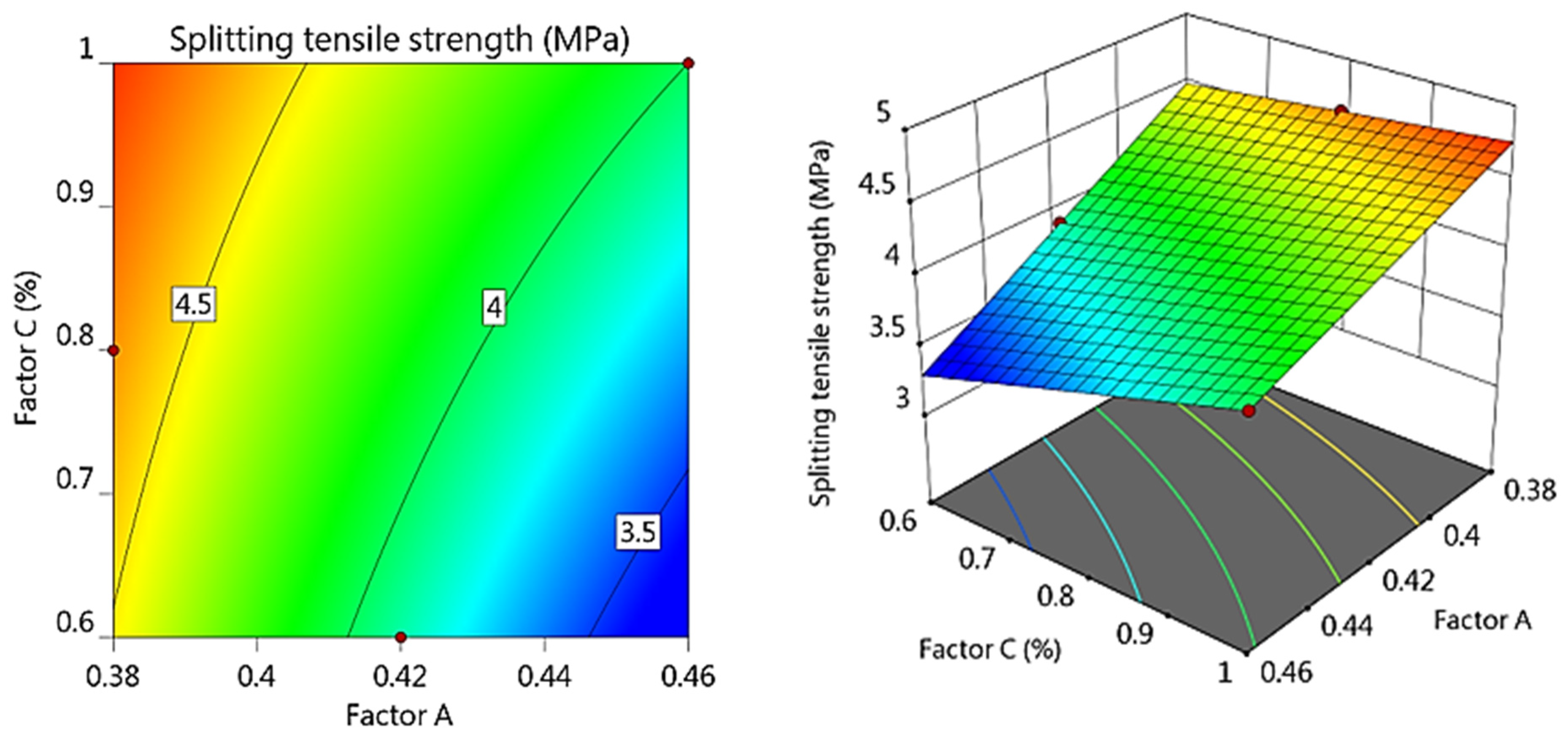

- (3)

- Response surface analysis of factors influencing splitting tensile strength.

3.2.4. Analysis of Factor Indicators

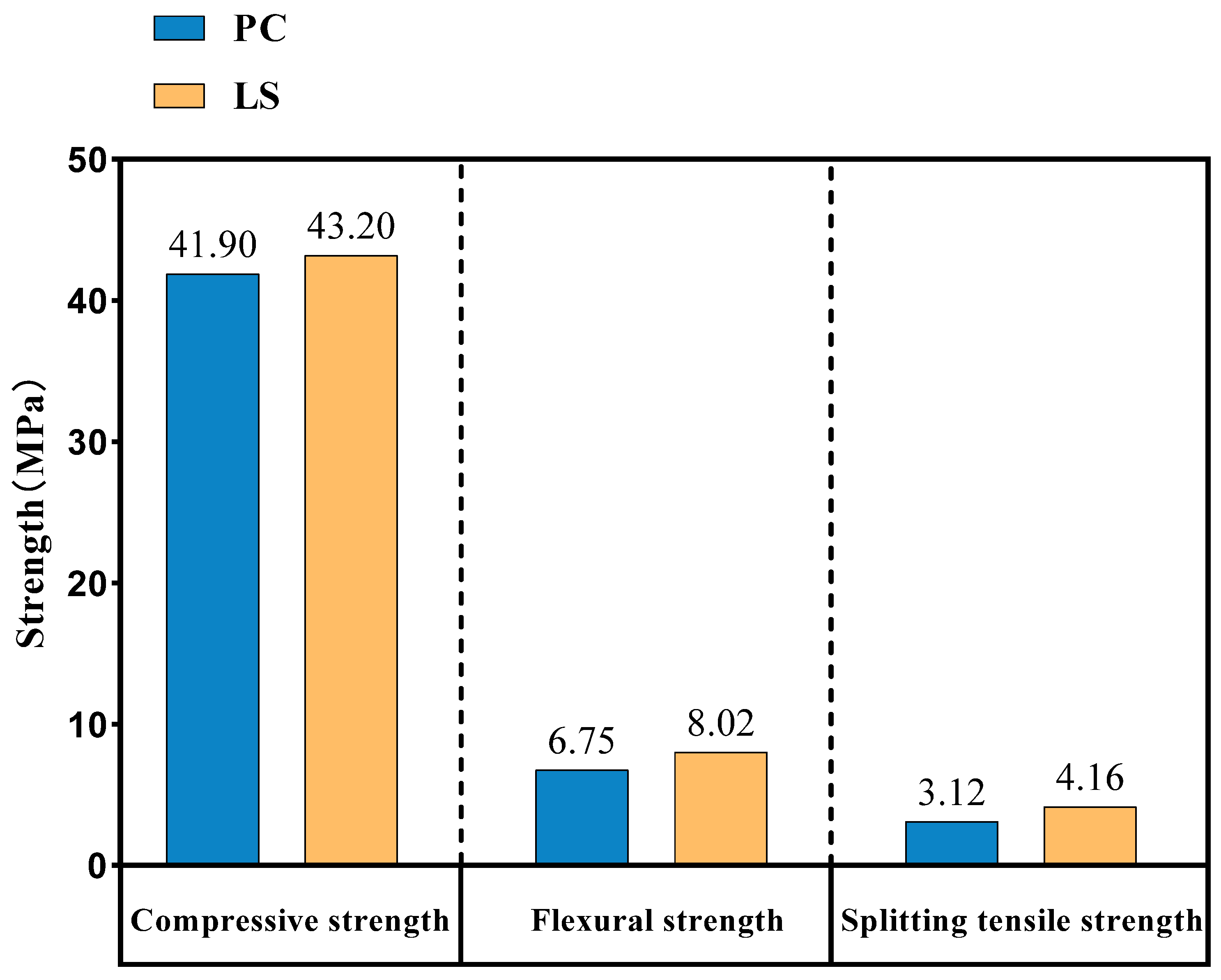

4. Optimal Mix Proportion Selection and Experimental Verification

4.1. Mix Proportion Selection

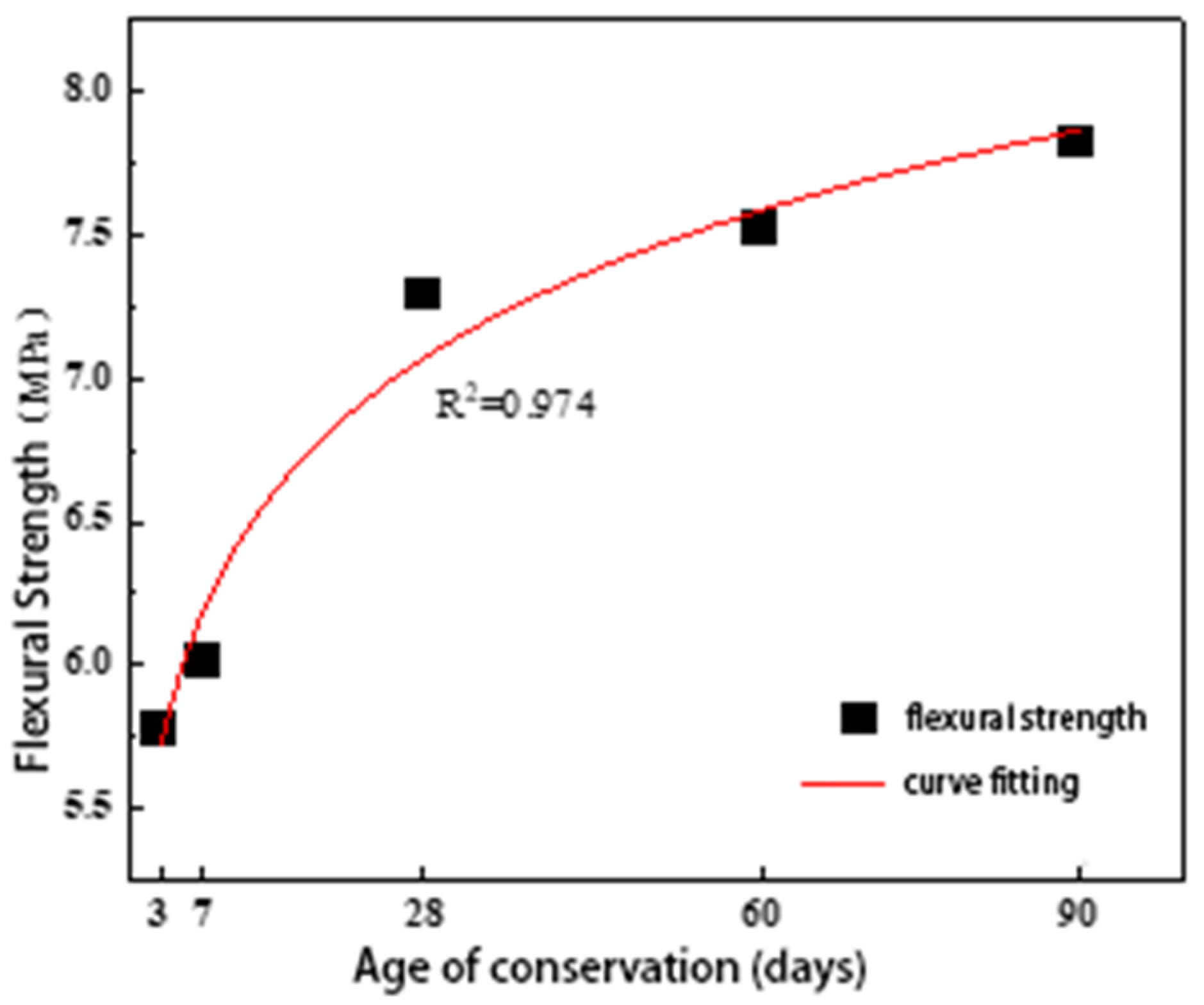

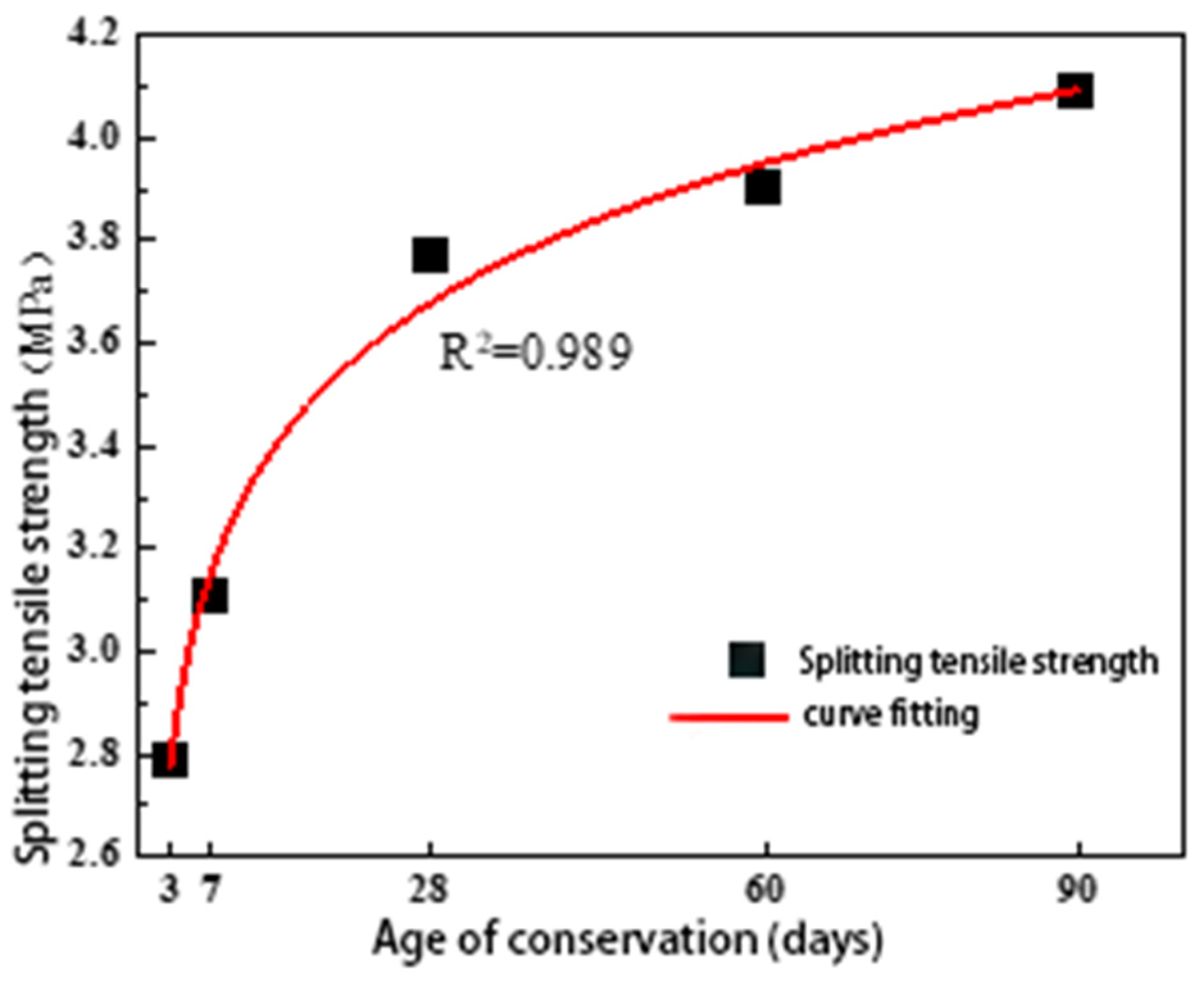

4.2. Analysis of Optimal Proportioning Strength at Different Ages

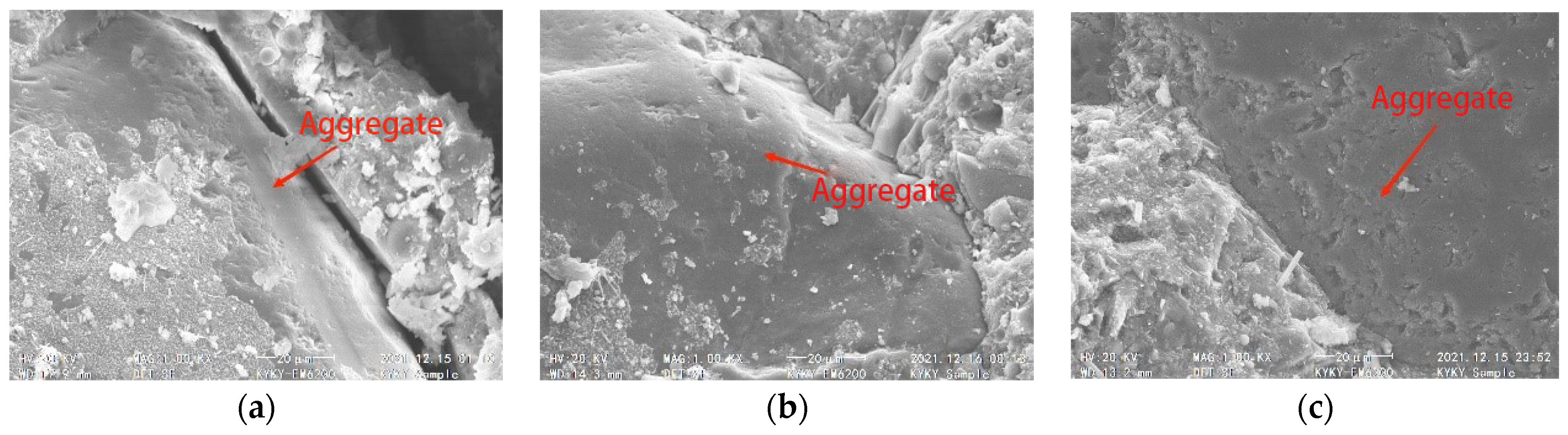

4.3. Microscopic Analysis

5. Conclusions

- (1)

- The strength of steel fiber-reinforced concrete is significantly affected not only by the water–cement ratio but also by the steel fiber and fly ash content. When the steel fiber content was between 0.6% and 1%, the fluctuation range of the compressive, flexural, and splitting tensile strength of the concrete was 5% (38 MPa to 42 MPa), 5% (6 MPa to 10 MPa), and 10%(3.5 MPa to 4.5 MPa), respectively. Among them, the optimal steel fiber content for the flexural strength of concrete was 0.6%, and the influence of fly ash and sand ratio on the strength of concrete at 28 d age was relatively small.

- (2)

- Taking into account the comprehensive factors of mechanical performance, workability, and economic applicability, an optimal mix ratio was ultimately obtained: a water–cement ratio of 0.42, a steel fiber content of 0.6%, a sand ratio of 40%, and a fly ash content of 20%. Compared with ordinary concrete of the same age, the compressive, flexural, and splitting tensile performance of the concrete was improved by 3%, 19%, and 33%, respectively.

- (3)

- In conjunction with the effect of age on the mechanical properties of LSFRC, the longer the curing period, the better mechanical properties LSFRC will have. In particular, after reaching a curing duration of 28 days, LSFRC is fully capable of being applied directly to the project. Therefore, more than 28 days in advance, through the factory prefabrication of steel fiber concrete components and the use of the assembly construction process during construction, may be able to significantly shorten the construction cycle.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fan, C. Research on Mechanical Properties of Mixed Steel Fiber Concrete. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2017. [Google Scholar]

- Hussain, A.; Wankhade, R.L.; Singh, H. Enhancing the Properties of Self-Compacting Concrete by Using Steel and Polypropylene Fibers. Pract. Period. Struct. Des. Constr. 2024, 29, 04024037. [Google Scholar] [CrossRef]

- Shen, D.; Wen, C.; Kang, J.; Shi, H.; Xu, Z. Early-age stress relaxation and cracking potential of High-strength concrete reinforced with Bar chip fiber. Constr. Build. Mater. 2020, 258, 119538. [Google Scholar] [CrossRef]

- Ramadoss, P.; Li, L.; Fatima, S.; Sofi, M. Mechanical performance and numerical simulation of high-performance steel fiber reinforced concrete. J. Build. Eng. 2023, 64, 105424. [Google Scholar] [CrossRef]

- Nath, A.D.; Hoque, M.I.; Datta, S.D.; Shahriar, F. Various recycled steel fiber effect on mechanical properties of recycled aggregate concrete. Int. J. Build. Pathol. Adapt. 2024, 42, 448–468. [Google Scholar] [CrossRef]

- Zhang, W.; Bao, C.; Kong, X. Study on the effect of mixed fiber content on mechanical properties of recycled concrete. Sci. Technol. Eng. 2016, 16, 106–112+123. [Google Scholar]

- Yu, A.; Qin, Q.; Shi, M. Analysis of the influence of steel fiber on the mechanical properties of concrete. In Proceedings of the 25th Annual Conference of Beijing Institute of Mechanics, Beijing, China, 25–27 March 2019; Beijing Institute of Mechanics, Beijing Society of Mechanics: Beijing, China, 2019; pp. 635–636. [Google Scholar]

- Zhang, Y.; Chen, B.; Wang, Y. Experimental study on basic mechanical properties of steel fiber concrete. Concrete 2020, 4, 74–77. [Google Scholar]

- Hao, Y.; Hao, H. Impact test analysis of spiral steel fiber concrete. J. Tianjin Univ. (Nat. Sci. Eng. Technol. Ed.) 2016, 49, 355–360. [Google Scholar]

- Ye, Y.; Wang, Z.; Xie, F. Mechanical properties of steel fiber reinforced high-strength light aggregate concrete. J. Build. Mater. 2021, 24, 63–70. [Google Scholar]

- Xue, G.; Wang, C.; Zhang, J.; Liu, Z.; Zhang, T.; Zhang, Y. Effect of steel fiber shape on properties of high-performance concrete. AMCS 2021, 38, 4313–4324. [Google Scholar]

- Sun, J.; Xu, J.; Luo, G. Research on compacted composite steel fiber concrete pavement. In Proceedings of the 4th National Conference on Fiber Cement and Fiber Concrete (I), Nanjing, China, 9–12 November 1992; pp. 196–199. [Google Scholar]

- Huang, W.; Xu, G. Analysis of mechanical properties and failure characteristics of padded steel fiber concrete. Highway 2015, 60, 22–26. [Google Scholar]

- Yang, J.; Dong, Y. Effect of fiber gradient distribution on mechanical properties of concrete. Henan Sci. 2002, 645–648. [Google Scholar] [CrossRef]

- Lu, H.; He, X. Study on bending performance of local steel fiber-reinforced concrete composite beam. J. Highw. Transp. Sci. Technol. (Appl. Technol. Ed.) 2016, 12, 223–225. [Google Scholar]

- Guo, Z. Study on Reinforcement Mechanism of Laminated Steel Fiber and Hybrid Fiber Concrete. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2006. [Google Scholar]

- Peng, O. Study on Mechanical Properties of Composite and Layered Steel Fiber High-Strength Concrete. Master’s Thesis, Guangzhou University, Guangzhou, China, 2019. [Google Scholar]

- Martínez-Pérez, I.; Valivonis, J.; Šalna, R.; Cobo-Escamilla, A. Experimental study of flexural behaviour of layered steel fibre reinforced concrete beams. J. Civ. Eng. Manag. 2017, 23, 806–813. [Google Scholar] [CrossRef]

- Suddeepong, A.; Buritatum, A.; Hoy, M.; Horpibulsuk, S.; Takaikaew, T.; Horpibulsuk, J.; Arulrajah, A. Natural Rubber Latex–Modified Concrete Pavements: Evaluation and Design Approach. J. Mater. Civ. Eng. 2022, 34, 04022215. [Google Scholar] [CrossRef]

- GB/T50081-2019; Standard for Test Methods for Physical and Mechanical Properties of Concrete. National Standard of the People’s Republic of China: Beijing, China, 2019.

- JTG E30-2005; Technical Code for Construction of Highway Cement Concrete Pavement. Ministry of Transport Scientific Research Institute: Beijing, China, 2005.

- Abubakar, A.; Idongesit, U.R.; Konitufe, C.; Mohammed, A. Prediction of Strength Properties of Concrete Containing Calcined Black Cotton Soil Using Response Surface Methodology. Am. J. Mater. Synth. Process. 2020, 5, 17–25. [Google Scholar] [CrossRef]

- Busari, A. Response Surface Analysis of the Compressive Strength of Metakoalin Self-Compacting Concrete. Adv. Sci. Technol. Res. J. 2019, 13, 7–13. [Google Scholar] [CrossRef] [PubMed]

- Sridhar, J.; Balaji, S.; Jegatheeswaran, D.; Awoyera, P. Prediction of the Mechanical Properties of Fibre-Reinforced Quarry Dust Concrete Using Response Surface and Artificial Neural Network Techniques. Adv. Civ. Eng. 2023, 2023, 8267639. [Google Scholar] [CrossRef]

- Muthukumar, M.; Mohan, D. Optimization of Mechanical Properties of Polymer Concrete and Mix Design Recommendation Based on Design of Experiments. J. Appl. Polym. Sci. 2004, 94, 1107–1116. [Google Scholar] [CrossRef]

- Shi, X.; Schillings, P.; Boyd, D. Applying artificial neural networks and virtual experimental design to quality improvement of two industrial processes. Int. J. Prod. Res. 2004, 42, 101–118. [Google Scholar] [CrossRef]

- Luo, W. Mechanical Properties of Prefabricated LSFRC Road Panels. Master’s Thesis, Chongqing University of Science & Technology, Chongqing, China, 2022. [Google Scholar]

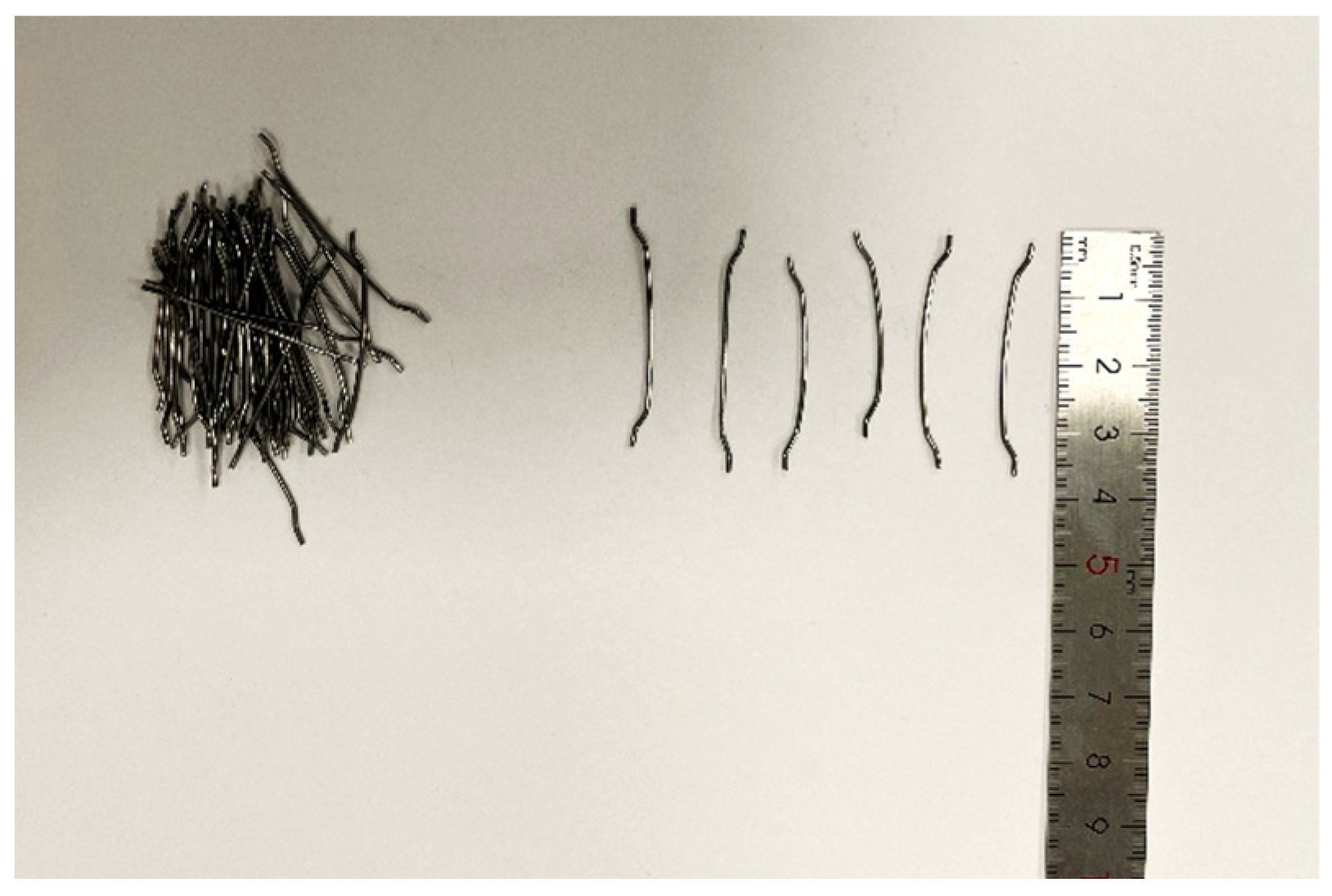

| Experimental Items | Length (mm) | Diameter (mm) | Tensile Strength (MPa) | Shape Qualification Rate (%) |

|---|---|---|---|---|

| Measured results | 35 | 0.7 | 1120 | 100 |

| Factor | Water–Cement Ratio (A) | Sand Ratio (B) | Steel Fiber Volume Ratio (C) | Fly Ash Content (D) | |

|---|---|---|---|---|---|

| Level | |||||

| 1 | 0.38 | 35% | 0.6% | 0% | |

| 2 | 0.42 | 40% | 0.8% | 10% | |

| 3 | 0.46 | 45% | 1.0% | 20% | |

| The Number | The Orthogonal Design | Water–Cement Ratio (A) | Sand Ratio (B) | The Volume Fraction of Steel Fibers (C) | The Substitution Rate of Fly Ash (D) | |

|---|---|---|---|---|---|---|

| Factor | ||||||

| LS-1 | A1B1C1D1 | 0.38 | 35% | 0.6% | 0% | |

| LS-2 | A1B2C2D2 | 0.38 | 40% | 0.8% | 10% | |

| LS-3 | A1B3C3D3 | 0.38 | 45% | 1.0% | 20% | |

| LS-4 | A2B1C2D3 | 0.42 | 35% | 1.0% | 10% | |

| LS-5 | A2B2C3D1 | 0.42 | 40% | 0.6% | 20% | |

| LS-6 | A2B3C1D2 | 0.42 | 45% | 0.8% | 0% | |

| LS-7 | A3B1C3D2 | 0.46 | 35% | 0.8% | 20% | |

| LS-8 | A3B2C1D3 | 0.46 | 40% | 1.0% | 0% | |

| LS-9 | A3B3C2D1 | 0.46 | 45% | 0.6% | 10% | |

| The Experimental Code | LS-1 | LS-2 | LS-3 | LS-4 | LS-5 | LS-6 | LS-7 | LS-8 | LS-9 |

|---|---|---|---|---|---|---|---|---|---|

| The slump value (mm) | 27 | 35 | 30 | 33 | 40 | 39 | 38 | 37 | 46 |

| Factor | The Slump Value (mm) | |||

|---|---|---|---|---|

| A | B | C | D | |

| 31.00 | 34.00 | 35.67 | 39.00 | |

| 37.00 | 37.00 | 35.33 | 37.33 | |

| 40.67 | 37.67 | 35.67 | 32.33 | |

| The range value R | 9.67 | 3.67 | 1.00 | 5.67 |

| The Number | LS-1 | LS-2 | LS-3 | LS-4 | LS-5 | LS-6 | LS-7 | LS-8 | LS-9 |

|---|---|---|---|---|---|---|---|---|---|

| The compressive strength (Mpa) | 44.9 | 43.5 | 44.7 | 43.3 | 41.4 | 42.6 | 39.3 | 40.7 | 35.8 |

| Factor | The Compressive Strength (MPa) | |||

|---|---|---|---|---|

| A | B | C | D | |

| 44.4 | 42.5 | 40.7 | 42.7 | |

| 42.5 | 41.9 | 41.9 | 41.0 | |

| 38.6 | 41.0 | 42.9 | 41.8 | |

| The range R | 5.9 | 1.5 | 2.3 | 1.8 |

| The Number | LS-1 | LS-2 | LS-3 | LS-4 | LS-5 | LS-6 | LS-7 | LS-8 | LS-9 |

|---|---|---|---|---|---|---|---|---|---|

| The flexural strength (MPa) | 44.9 | 43.5 | 44.7 | 43.3 | 41.4 | 42.6 | 39.3 | 40.7 | 35.8 |

| Factor | The Flexural Strength (MPa) | |||

|---|---|---|---|---|

| A | B | C | D | |

| 7.84 | 7.37 | 7.38 | 7.27 | |

| 7.12 | 7.36 | 7.06 | 7.36 | |

| 7.97 | 7.19 | 7.34 | 7.29 | |

| The range R | 0.85 | 0.18 | 0.32 | 0.09 |

| The Number | LS-1 | LS-2 | LS-3 | LS-4 | LS-5 | LS-6 | LS-7 | LS-8 | LS-9 |

|---|---|---|---|---|---|---|---|---|---|

| The splitting tensile strength (MPa) | 4.58 | 4.62 | 4.82 | 4.36 | 3.89 | 4.23 | 3.60 | 4.00 | 3.42 |

| Factor | The Splitting Tensile Strength | |||

|---|---|---|---|---|

| A | B | C | D | |

| 4.67 | 4.18 | 4.27 | 3.96 | |

| 4.16 | 4.17 | 4.13 | 4.15 | |

| 3.67 | 4.15 | 4.10 | 4.39 | |

| The range R | 1.00 | 0.03 | 0.17 | 0.43 |

| Factor | A | B | C | D |

|---|---|---|---|---|

| R (total) | 8.3 | 2.32 | 3.7 | 2.13 |

| Factor | Factor 28 d-Collapse | ||

|---|---|---|---|

| Factor-Level | Factor-Weight | Intra-Layer Weights | |

| Water–cement ratio | 0.38 | 0.4833 | 0.1379 |

| 0.42 | 0.1645 | ||

| 0.46 | 0.1809 | ||

| Sand ratio (%) | 35 | 0.1834 | 0.0574 |

| 40 | 0.0624 | ||

| 45 | 0.0636 | ||

| Steel fiber volumetric rate (%) | 0.6 | 0.2834 | 0.1017 |

| 0.8 | 0.0973 | ||

| 1.0 | 0.0843 | ||

| Fly ash content (%) | 0 | 0.0500 | 0.0167 |

| 10 | 0.0166 | ||

| 20 | 0.0167 | ||

| Factor | Factor 28 d-Compressive Strength | ||

|---|---|---|---|

| Factor-Level | Factor-Weight | Intra-Layer Weights | |

| Water–cement ratio | 0.38 | 0.5179 | 0.1832 |

| 0.42 | 0.1754 | ||

| 0.46 | 0.1593 | ||

| Sand ratio (%) | 35 | 0.1339 | 0.0454 |

| 40 | 0.0447 | ||

| 45 | 0.0438 | ||

| Steel fiber volumetric rate (%) | 0.6 | 0.1964 | 0.0637 |

| 0.8 | 0.0656 | ||

| 1.0 | 0.0671 | ||

| Fly ash content (%) | 0 | 0.1518 | 0.0516 |

| 10 | 0.0496 | ||

| 20 | 0.0506 | ||

| Factor | Factor 28 d-Flexural Strength | ||

|---|---|---|---|

| Factor-Level | Factor-Weight | Intra-Layer Weights | |

| Water–cement ratio | 0.38 | 0.4462 | 0.1512 |

| 0.42 | 0.1447 | ||

| 0.46 | 0.1504 | ||

| Sand ratio (%) | 35 | 0.0365 | 0.0123 |

| 40 | 0.0124 | ||

| 45 | 0.0120 | ||

| Steel fiber volumetric rate (%) | 0.6 | 0.3448 | 0.1144 |

| 0.8 | 0.1158 | ||

| 1.0 | 0.1147 | ||

| Fly ash content (%) | 0 | 0.1724 | 0.0590 |

| 10 | 0.0535 | ||

| 20 | 0.0599 | ||

| Factor | Factor 28 d-Split Tensile Strength | ||

|---|---|---|---|

| Factor-Level | Factor-Weight | Intra-Layer Weights | |

| Water–cement ratio | 0.38 | 0.6135 | 0.2292 |

| 0.42 | 0.2042 | ||

| 0.46 | 0.1801 | ||

| Sand ratio (%) | 35 | 0.0184 | 0.0062 |

| 40 | 0.0061 | ||

| 45 | 0.0060 | ||

| Steel fiber volumetric rate (%) | 0.6 | 0.2638 | 0.0836 |

| 0.8 | 0.0876 | ||

| 1.0 | 0.0926 | ||

| Fly ash content (%) | 0 | 0.1043 | 0.0356 |

| 10 | 0.0345 | ||

| 20 | 0.0342 | ||

| Factor | A | B | C | D |

|---|---|---|---|---|

| LS-5 | 0.42 | 40% | 0.6% | 20% |

| Number | Age Period (day) | Compressive Strength (MPa) | Flexural Strength (MPa) | Splitting Tensile Strength (MPa) |

|---|---|---|---|---|

| LS5-3 d | 3 | 35.9 | 5.78 | 2.79 |

| LS5-7 d | 7 | 37.5 | 5.01 | 3.11 |

| LS5-28 d | 28 | 41.7 | 7.29 | 3.83 |

| LS5-60 d | 60 | 45.1 | 7.52 | 3.96 |

| LS5-90 d | 90 | 47.9 | 7.82 | 4.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Li, H.; Ye, X.; Luo, W.; Zhang, B.; Hu, A.; Wu, L. Research on Layered Steel Fiber Reinforced Concrete Mix Ratio Design Based on Orthogonal Test. Coatings 2024, 14, 697. https://doi.org/10.3390/coatings14060697

Wang Z, Li H, Ye X, Luo W, Zhang B, Hu A, Wu L. Research on Layered Steel Fiber Reinforced Concrete Mix Ratio Design Based on Orthogonal Test. Coatings. 2024; 14(6):697. https://doi.org/10.3390/coatings14060697

Chicago/Turabian StyleWang, Zijian, Hongkun Li, Xiangyang Ye, Wenyu Luo, Bin Zhang, Anlin Hu, and Liming Wu. 2024. "Research on Layered Steel Fiber Reinforced Concrete Mix Ratio Design Based on Orthogonal Test" Coatings 14, no. 6: 697. https://doi.org/10.3390/coatings14060697

APA StyleWang, Z., Li, H., Ye, X., Luo, W., Zhang, B., Hu, A., & Wu, L. (2024). Research on Layered Steel Fiber Reinforced Concrete Mix Ratio Design Based on Orthogonal Test. Coatings, 14(6), 697. https://doi.org/10.3390/coatings14060697