Predicting New Single/Multiphase-Structure High-Entropy Alloys Using a Pattern Recognition Network

Abstract

1. Introduction

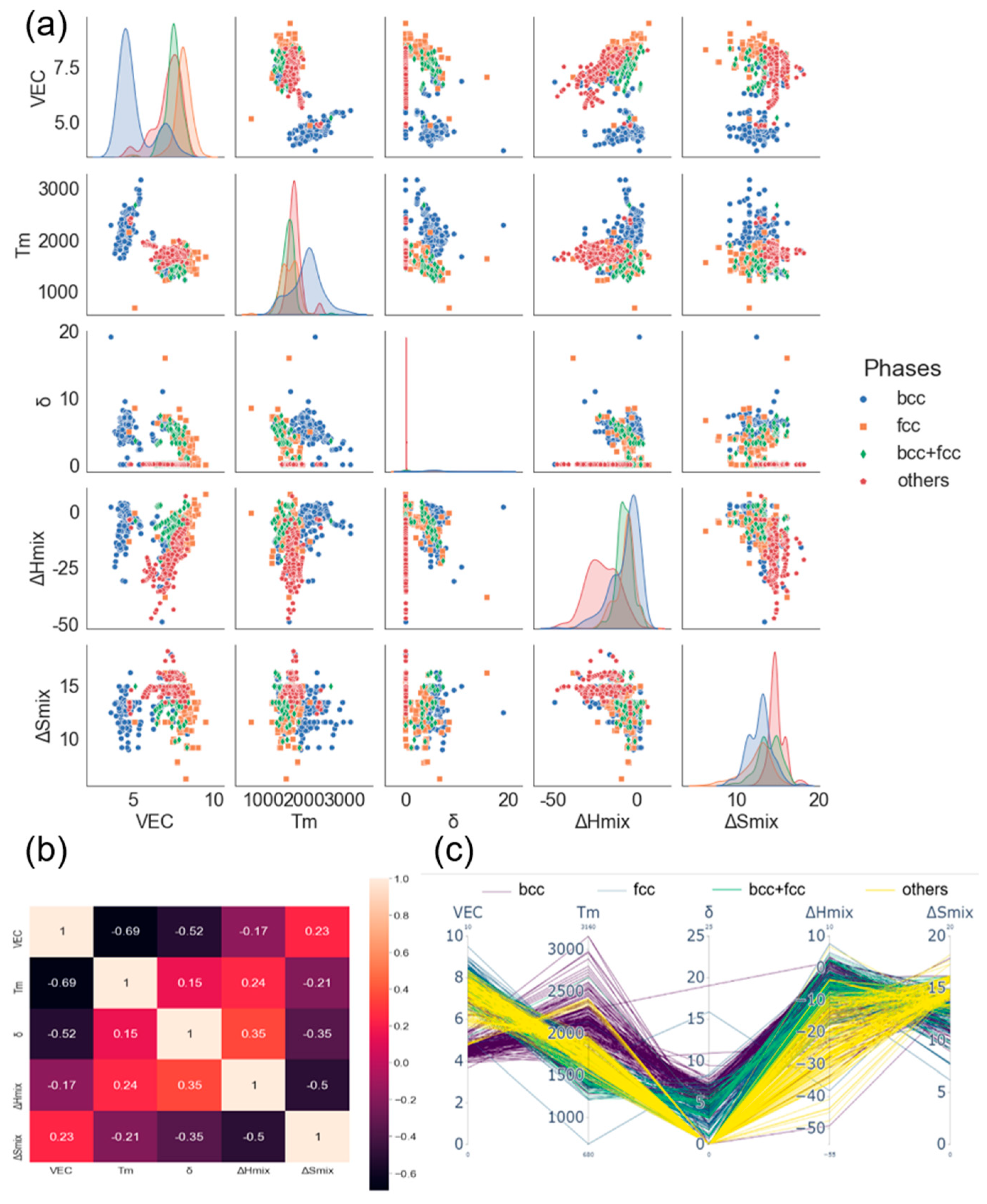

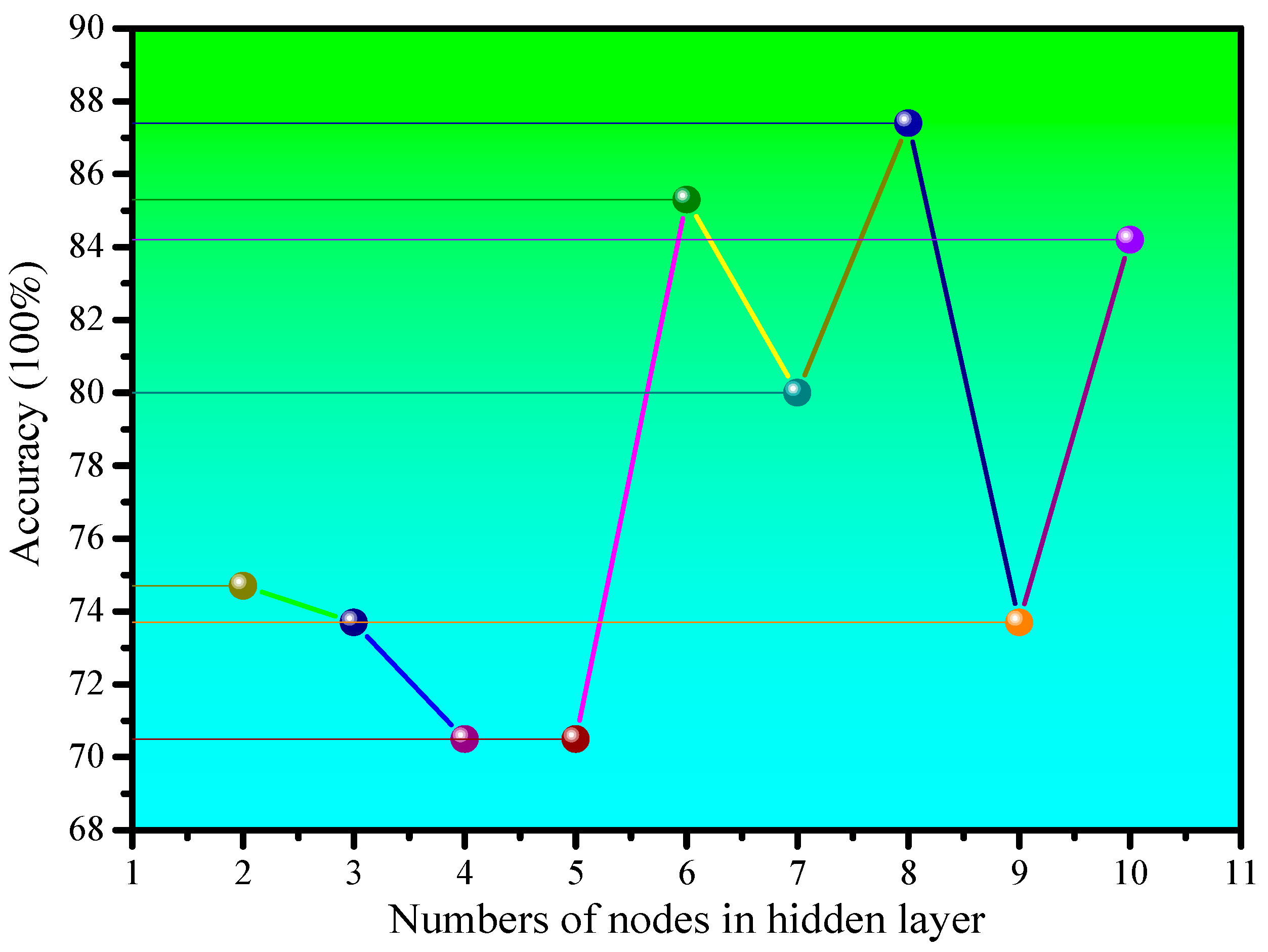

2. Materials and Methods

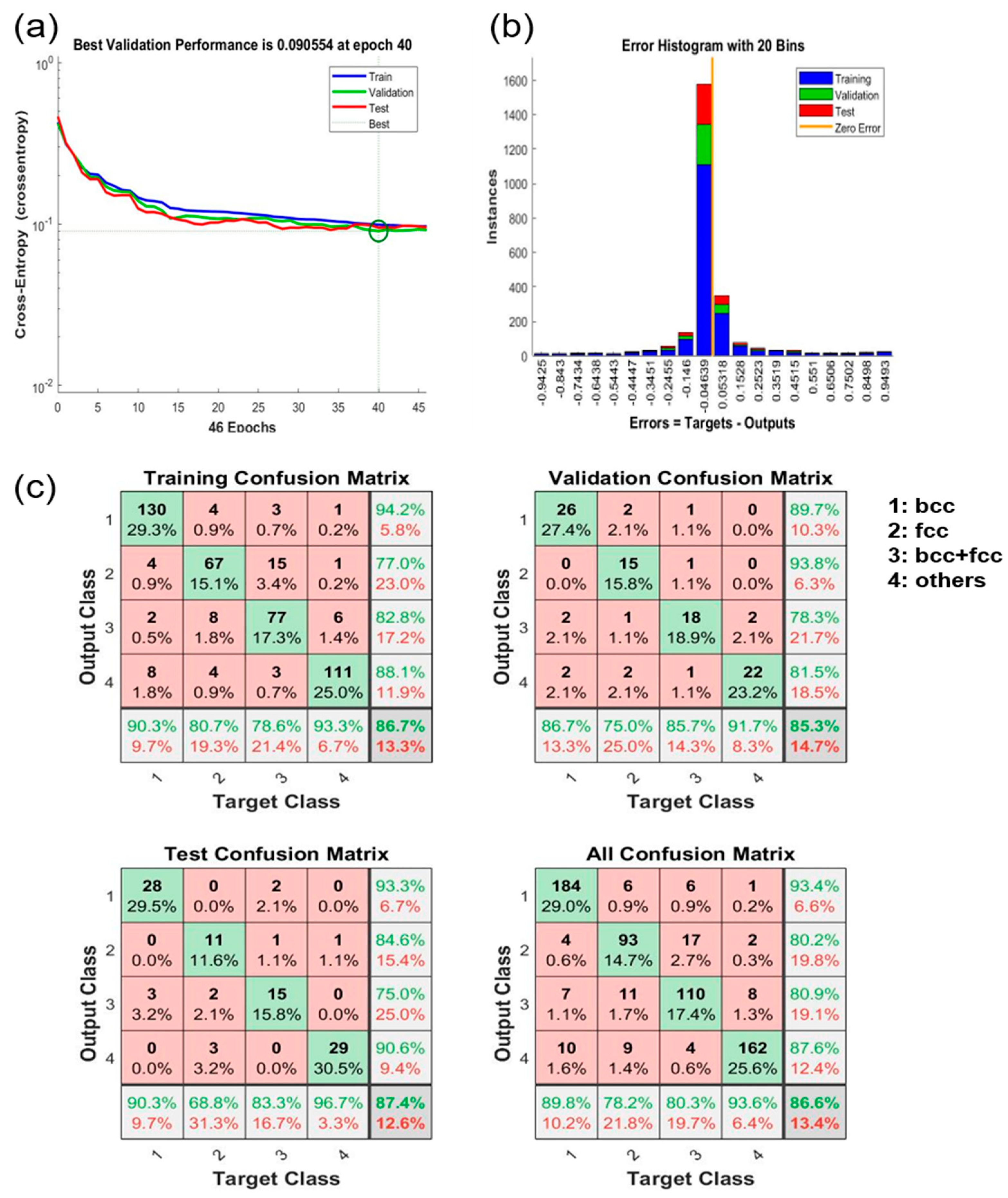

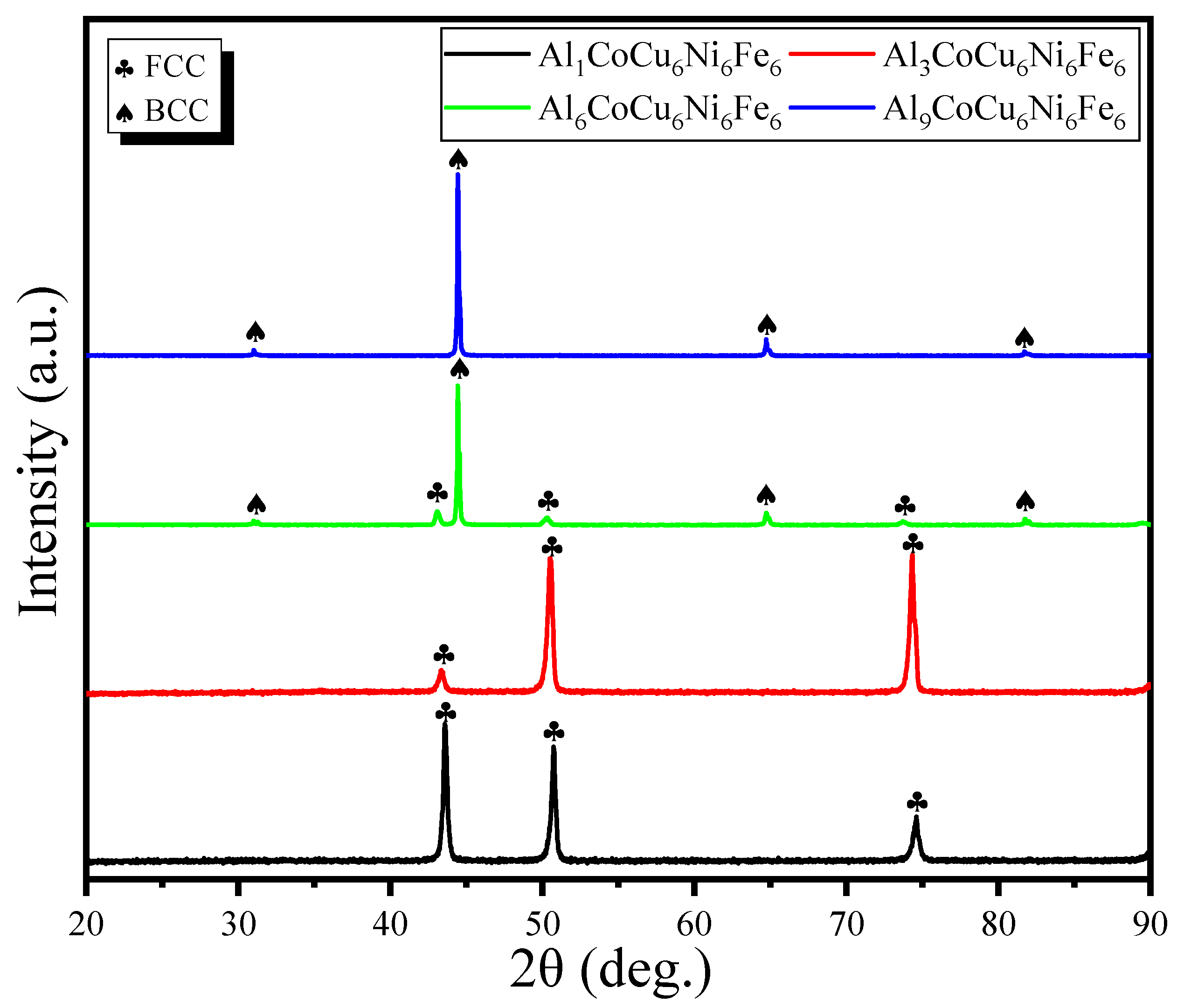

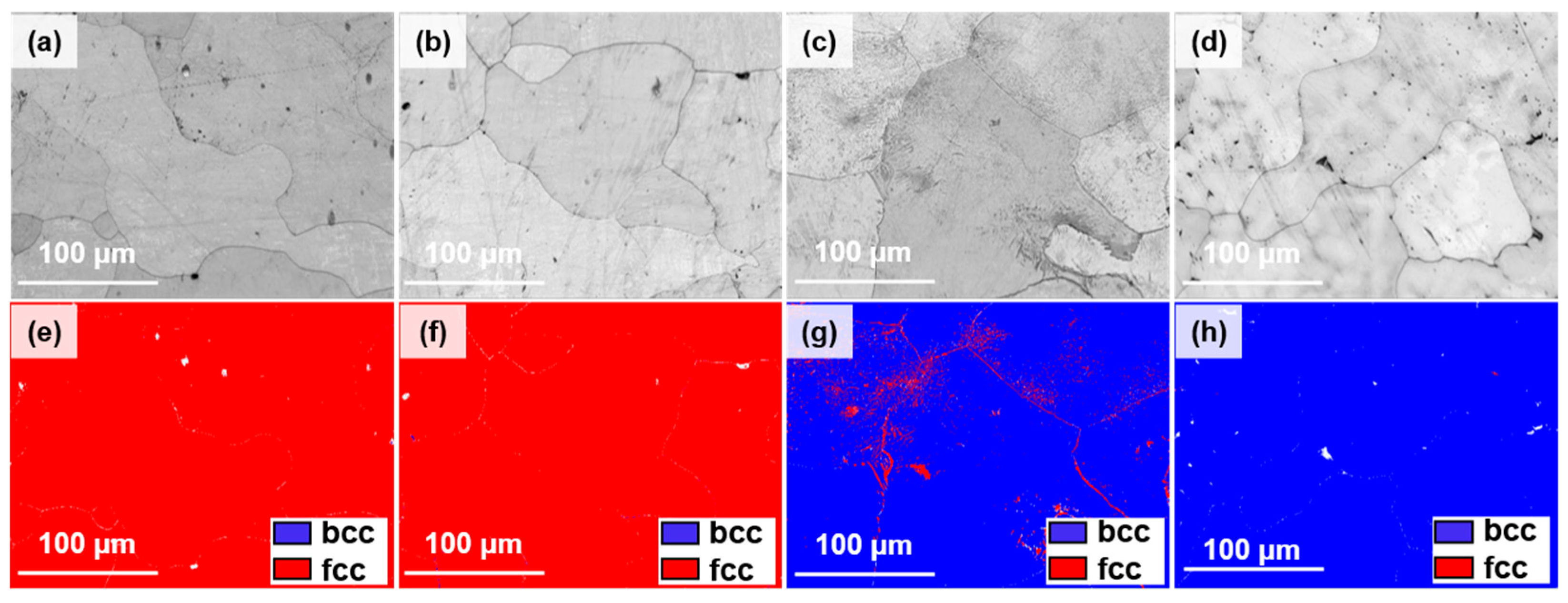

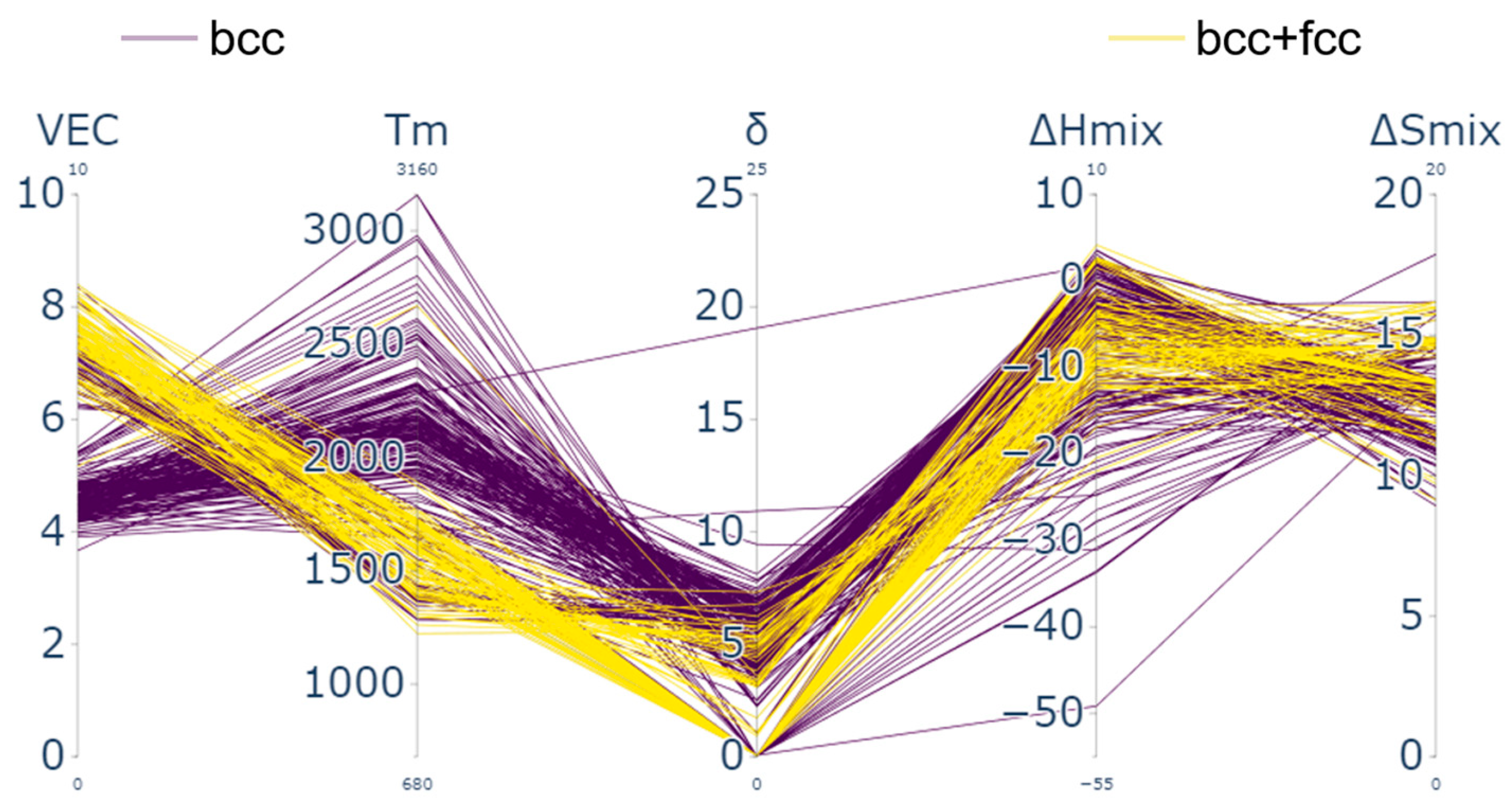

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Senkov, O.N.; Miller, J.D.; Miracle, D.B.; Woodward, C. Accelerated exploration of multi-principal element alloys with solid solution phases. Nat. Commun. 2015, 6, 6529. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical properties of nbmotaw and vnbmotaw refractory high entropy alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Wani, I.S.; Bhattacharjee, T.; Sheikh, S.; Lu, Y.P.; Chatterjee, S.; Bhattacharjee, P.P.; Guo, S.; Tsuji, N. Ultrafine-grained alcocrfeni2.1 eutectic high-entropy alloy. Mater. Res. Lett. 2016, 4, 174–179. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef]

- Liu, K.; Wang, J.Y.; Li, X.; Qin, Q.; Wu, S.J.; Yu, H.C. A new lightweight Al2.7TiVCrCu high entropy alloy with excellent strength and toughness after homogenization treatment. Mater. Sci. Eng. A 2023, 869, 144779. [Google Scholar] [CrossRef]

- Todai, M.; Nagase, T.; Hori, T.; Matsugaki, A.; Sekita, A.; Nakano, T. Novel tinbtazrmo high-entropy alloys for metallic biomaterials. Scr. Mater. 2017, 129, 65–68. [Google Scholar] [CrossRef]

- Hori, T.; Nagase, T.; Todai, M.; Matsugaki, A.; Nakano, T. Development of non-equiatomic Ti-Nb-Ta-Zr-Mo high-entropy alloys for metallic biomaterials. Scr. Mater. 2019, 172, 83–87. [Google Scholar] [CrossRef]

- Liu, K.; Li, X.; Wang, J.Y.; Zhang, Y.; Guo, X.; Wu, S.J.; Yu, H.C. Investigation of mechanical and corrosion properties of light and high hardness cast AlTiVCrCu0.4 high entropy alloy. Mater. Charact. 2023, 200, 112878. [Google Scholar] [CrossRef]

- Jiang, H.; Han, K.; Gao, X.; Lu, Y.; Cao, Z.; Gao, M.C.; Hawk, J.A.; Li, T.J. A new strategy to design eutectic high-entropy alloys using simple mixture method. Mater. Des. 2018, 142, 101–105. [Google Scholar] [CrossRef]

- Jin, X.; Zhou, Y.; Zhang, L.; Du, X.; Li, B.S. A new pseudo binary strategy to design eutectic high entropy alloys using mixing enthalpy and valence electron concentration. Mater. Des. 2018, 143, 49–55. [Google Scholar] [CrossRef]

- Saboktakin, R.M.; Minouei, H.; Lee, B.J.; Toroghinejad, M.R.; Hong, S.I. Effects of carbon and molybdenum on the nanostructural evolution and strength/ductility trade-off in Fe40Mn40Co10Cr10 high-entropy alloys. J. Alloys Compd. 2022, 911, 165108. [Google Scholar] [CrossRef]

- Rahul, M.R.; Phanikumar, G. Design of a Seven-Component Eutectic High-Entropy Alloy. Metall. Mater. Trans. A 2019, 50, 2594–2598. [Google Scholar] [CrossRef]

- Zhang, L.; Cai, H.; Liu, J.; Ouyang, Y.F.; Peng, Q.; Du, Y. Machine learning reveals the importance of the formation enthalpy and atom-size difference in forming phases of high entropy alloys. Mater. Des. 2020, 193, 108835. [Google Scholar] [CrossRef]

- Jaiswal, U.K.; Krishna, Y.V.; Rahul, M.R.; Phanikumar, G. Machine learning-enabled identification of new medium to high entropy alloys with solid solution phases. Comput. Mater. Sci. 2021, 197, 110623. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, C.S.; Fu, H.D.; Shen, J.; Zhang, Z.H.; Xie, J.X. Discovery of aluminum alloys with ultra-strength and high-toughness via a property-oriented design strategy. J. Mater. Sci. Technol. 2022, 98, 33–43. [Google Scholar] [CrossRef]

- Yegi, V.K.; Ujjawal, K.J.; Rahul, M.R. Machine learning approach to predict new multiphase high entropy alloys. Scr. Mater. 2021, 197, 113804. [Google Scholar]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-Solution Phase Formation Rules for Multi-component Alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Guo, S.; Ng, C.; Lu, J.; Liu, C.T. Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J. Appl. Phys. 2011, 109, 103505. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y. Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 2012, 132, 233–238. [Google Scholar] [CrossRef]

- Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. Design of high entropy alloys: A single-parameter thermodynamic rule. Scr. Mater. 2015, 104, 53–55. [Google Scholar] [CrossRef]

- Li, Y.; Guo, W.L. Machine-learning model for predicting phase formations of high-entropy alloys. Phys. Rev. Mater. 2019, 3, 095005. [Google Scholar] [CrossRef]

- Machaka, R. Machine Learning Based Prediction of Phases in High-Entropy Alloys. Comput. Mater. Sci. 2020, 188, 110244. [Google Scholar] [CrossRef]

- Gorsse, S.; Nguyen, M.H.; Senkov, O.N.; Miracle, D.B. Database on the mechanical properties of high entropy alloys and complex concentrated alloys. Data Brief 2018, 21, 2664–2678. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.Y.; Byeon, S.; Kim, H.S.; Jin, H.; Lee, S. Deep learning-based phase prediction of high-entropy alloys: Optimization, generation, and explanation. Mater. Des. 2021, 197, 109260. [Google Scholar] [CrossRef]

- Zheng, T.; Hu, X.B.; He, F.; Wu, Q.F.; Han, B.; Da, C.; Li, J.J.; Wang, Z.J.; Wang, J.C.; Kai, J.; et al. Tailoring nanoprecipitates for ultra-strong high-entropy alloys via machine learning and prestrain aging. J. Mater. Sci. Technol. 2021, 69, 156–167. [Google Scholar] [CrossRef]

- Dixit, S.; Singhal, V.; Agarwal, A.; Rao, A.K.P. Multi-label phase-prediction in high-entropy-alloys using Artificial-Neural-Network. Mater. Lett. 2020, 268, 127606. [Google Scholar] [CrossRef]

- Mi, X.X.; Tian, L.J.; Tang, A.; Kang, J.; Peng, P.; She, J.; Wang, H.L.; Chen, X.H.; Pan, F.S. A reverse design model for high-performance and low-cost magnesium alloys by machine learning. Comput. Mater. Sci. 2022, 201, 110881. [Google Scholar] [CrossRef]

- Wu, C.T.; Chang, H.T.; Wu, C.Y.; Chen, S.W.; Huang, S.Y.; Huang, M.M.; Pan, Y.T.; Bradbury, P.; Chou, J.; Yen, H.W. Machine learning recommends affordable new Ti alloy with bone-like modulus. Mater. Today 2020, 34, 41–50. [Google Scholar] [CrossRef]

- Prieto, A.; Prieto, B.; Ortigosa, E.M.; Ros, E.; Pelayo, F.; Ortega, J.; Rojas, I. Neural networks: An overview of early research, current frameworks and new challenges. Neurocomputing 2016, 214, 242–268. [Google Scholar] [CrossRef]

- Basheer, I.A.; Hajmeer, M.; Microbiol, J. Artificial neural networks: Fundamentals, computing, design, and application. J. Microbiol. Methods 2000, 43, 3–31. [Google Scholar] [CrossRef] [PubMed]

- Praveen, S.; Murty, B.S.; Kottada Ravi, S. Alloying behavior in multi-component AlCoCrCuFe and NiCoCrCuFe high entropy alloys. Mater. Sci. Eng. A 2012, 534, 83–89. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, Q.; Jiang, B.B.; Li, C.L.; Hao, J.M.; Li, X.N.; Dong, C.; Nieh, T.G. Controlled formation of coherent cuboidal nanoprecipitates in body-centered cubic high-entropy alloys based on Al2(Ni,Co,Fe,Cr)14 compositions. Acta Mater. 2018, 147, 213–225. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

| Composition | bcc | fcc | bcc+fcc | Others | Predict | Experiment | Reference |

|---|---|---|---|---|---|---|---|

| Al1CoCu6Ni6Fe6 | 0 | 0.96 | 0.04 | 0 | fcc | fcc | This work |

| Al3CoCu6Ni6Fe6 | 0 | 0.87 | 0.12 | 0.01 | fcc | fcc | This work |

| Al6CoCu6Ni6Fe6 | 0.01 | 0.42 | 0.56 | 0.01 | bcc+fcc | bcc+fcc | This Work |

| Al9CoCu6Ni6Fe6 | 0.01 | 0.13 | 0.86 | 0 | bcc+fcc | bcc | This Work |

| Al0CoCrCuNiFe | 0.01 | 0.89 | 0.08 | 0.02 | fcc | fcc | [35] |

| Al0.3CoCrCuNiFe | 0.02 | 0.58 | 0.33 | 0.07 | fcc | fcc | [35] |

| Al0.5CoCrCuNiFe | 0.02 | 0.33 | 0.54 | 0.11 | bcc+fcc | fcc | [35] |

| Al0.8CoCrCuNiFe | 0.02 | 0.11 | 0.73 | 0.13 | bcc+fcc | bcc+fcc | [35] |

| Al1CoCrCuNiFe | 0.02 | 0.06 | 0.80 | 0.12 | bcc+fcc | bcc+fcc | [35] |

| Al1.3CoCrCuNiFe | 0.02 | 0.02 | 0.86 | 0.10 | bcc+fcc | bcc+fcc | [35] |

| Al1.5CoCrCuNiFe | 0.02 | 0.01 | 0.89 | 0.08 | bcc+fcc | bcc+fcc | [35] |

| Al1.8CoCrCuNiFe | 0.02 | 0.01 | 0.91 | 0.06 | bcc+fcc | bcc+fcc | [35] |

| Al2CoCrCuNiFe | 0.01 | 0.01 | 0.93 | 0.05 | bcc+fcc | bcc+fcc | [35] |

| Al2.3CoCrCuNiFe | 0.01 | 0.01 | 0.94 | 0.04 | bcc+fcc | bcc+fcc | [35] |

| Al2.5CoCrCuNiFe | 0.01 | 0.01 | 0.95 | 0.03 | bcc+fcc | bcc+fcc | [35] |

| Al2.8CoCrCuNiFe | 0.01 | 0 | 0.96 | 0.03 | bcc+fcc | bcc | [35] |

| Al3CoCrCuNiFe | 0.01 | 0.01 | 0.96 | 0.02 | bcc+fcc | bcc | [35] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Wang, J.; Wang, J.; Wu, R.; Liu, K. Predicting New Single/Multiphase-Structure High-Entropy Alloys Using a Pattern Recognition Network. Coatings 2024, 14, 690. https://doi.org/10.3390/coatings14060690

Wang F, Wang J, Wang J, Wu R, Liu K. Predicting New Single/Multiphase-Structure High-Entropy Alloys Using a Pattern Recognition Network. Coatings. 2024; 14(6):690. https://doi.org/10.3390/coatings14060690

Chicago/Turabian StyleWang, Fang, Jiahao Wang, Jiayu Wang, Ruirui Wu, and Ke Liu. 2024. "Predicting New Single/Multiphase-Structure High-Entropy Alloys Using a Pattern Recognition Network" Coatings 14, no. 6: 690. https://doi.org/10.3390/coatings14060690

APA StyleWang, F., Wang, J., Wang, J., Wu, R., & Liu, K. (2024). Predicting New Single/Multiphase-Structure High-Entropy Alloys Using a Pattern Recognition Network. Coatings, 14(6), 690. https://doi.org/10.3390/coatings14060690