Impact of Magnetic Field Direction on Performance and Structure of Ni-Co-SiC Coatings Fabricated via Magnetic-Field-Induced Electrodeposition

Abstract

1. Introduction

2. Experimental Section

2.1. Fabrication of Material

2.2. Characterization

3. Results and Discussion

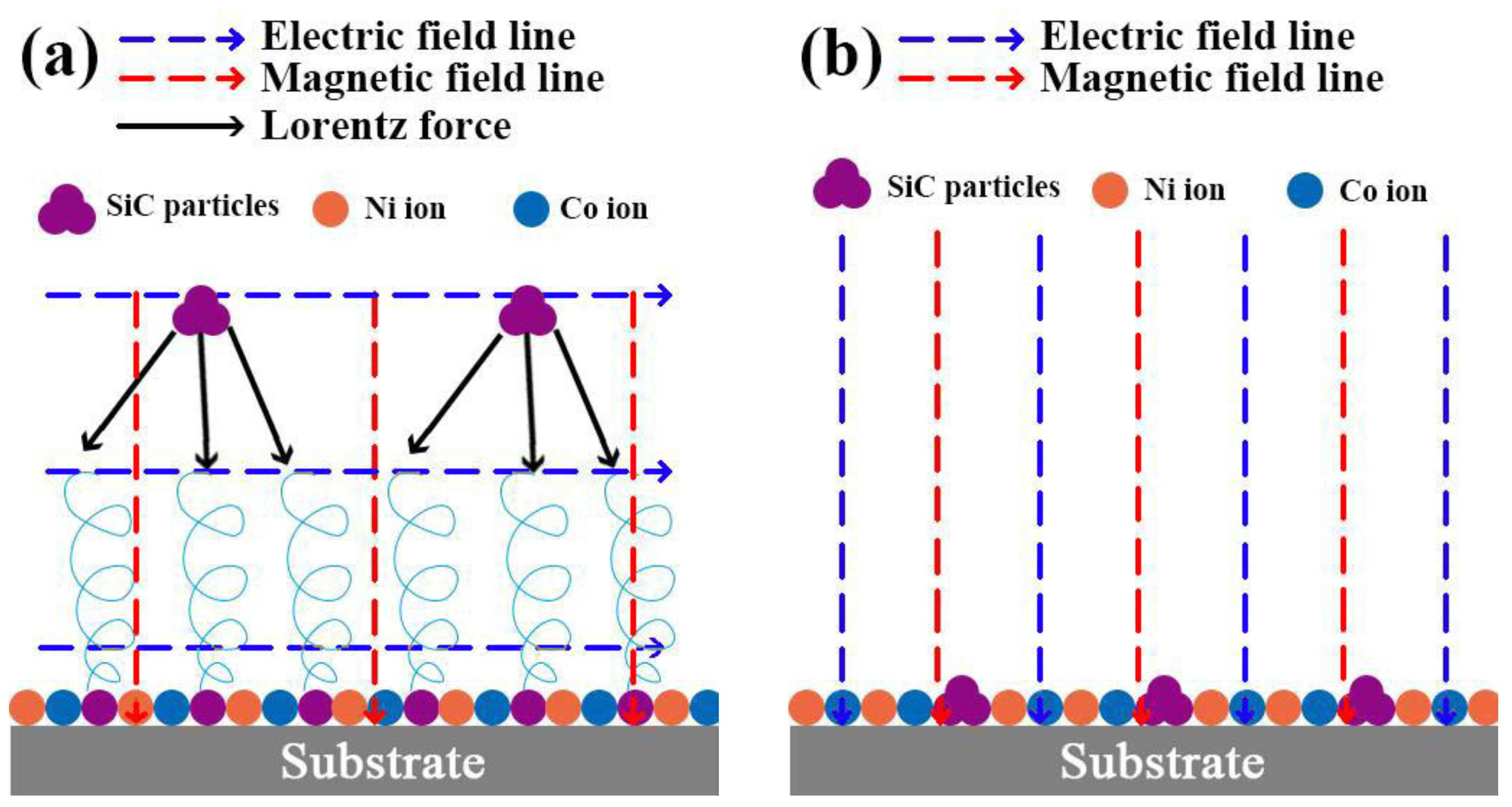

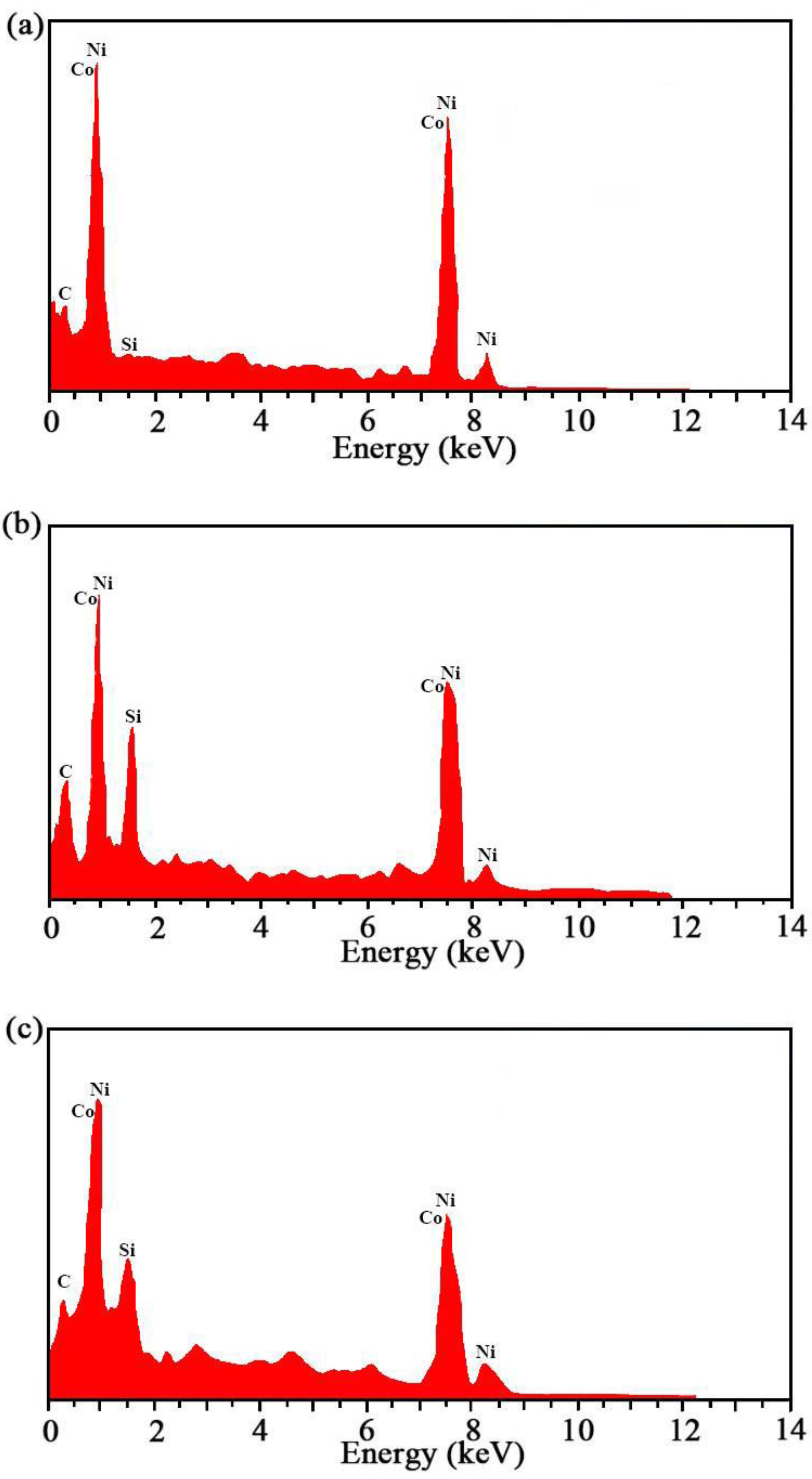

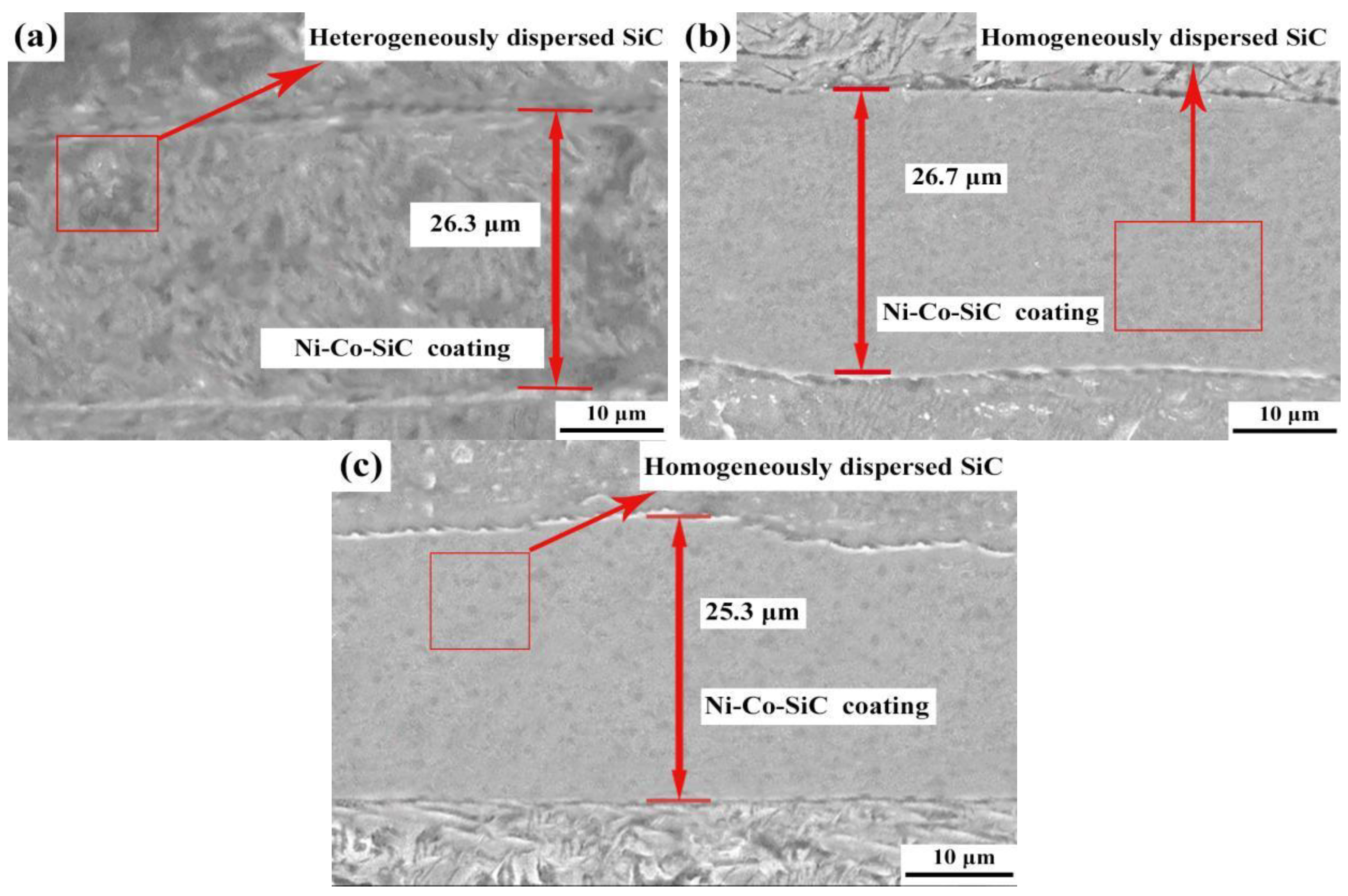

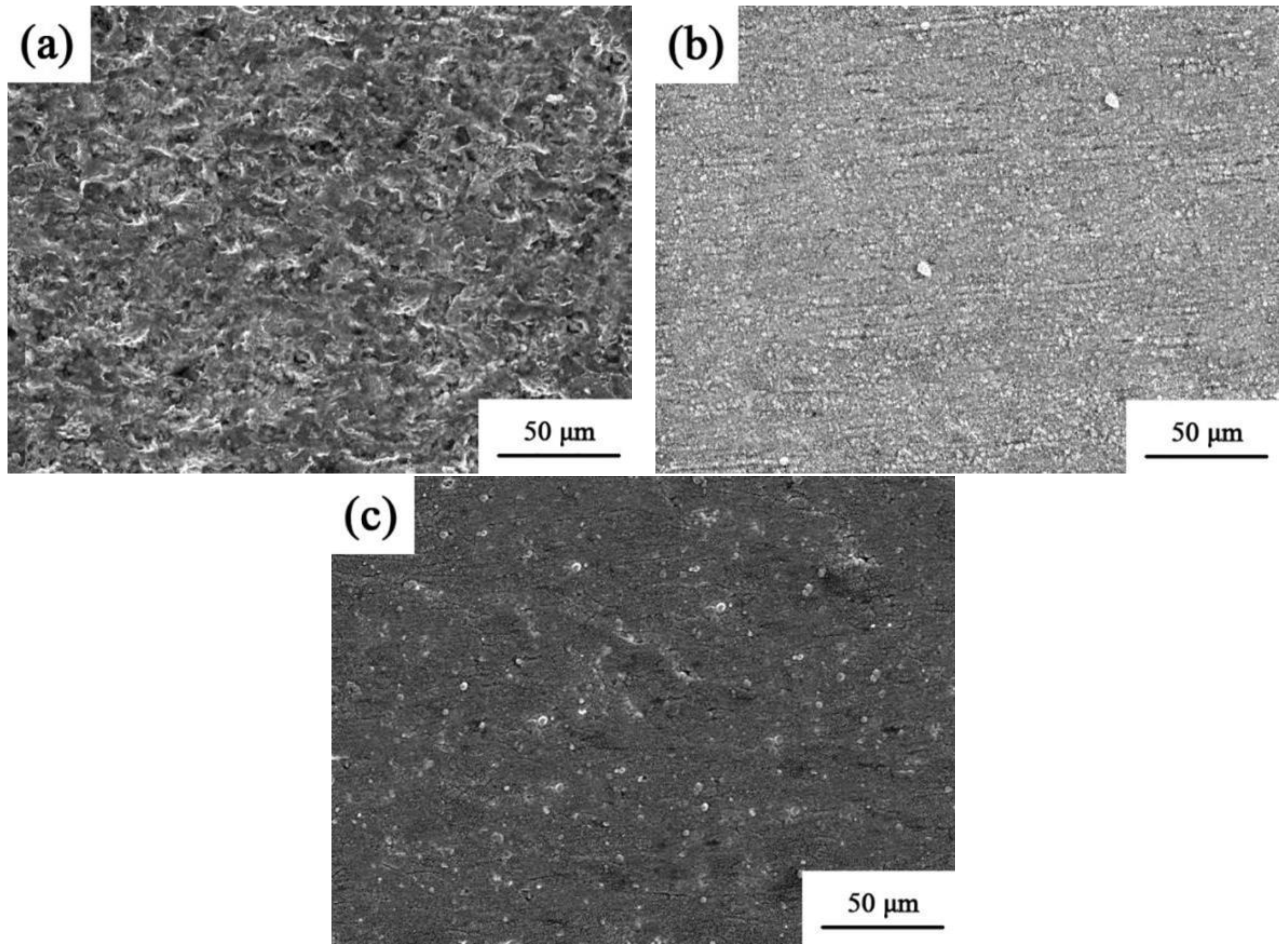

3.1. Microstructure and Surface Morphology

3.2. Surface Roughness

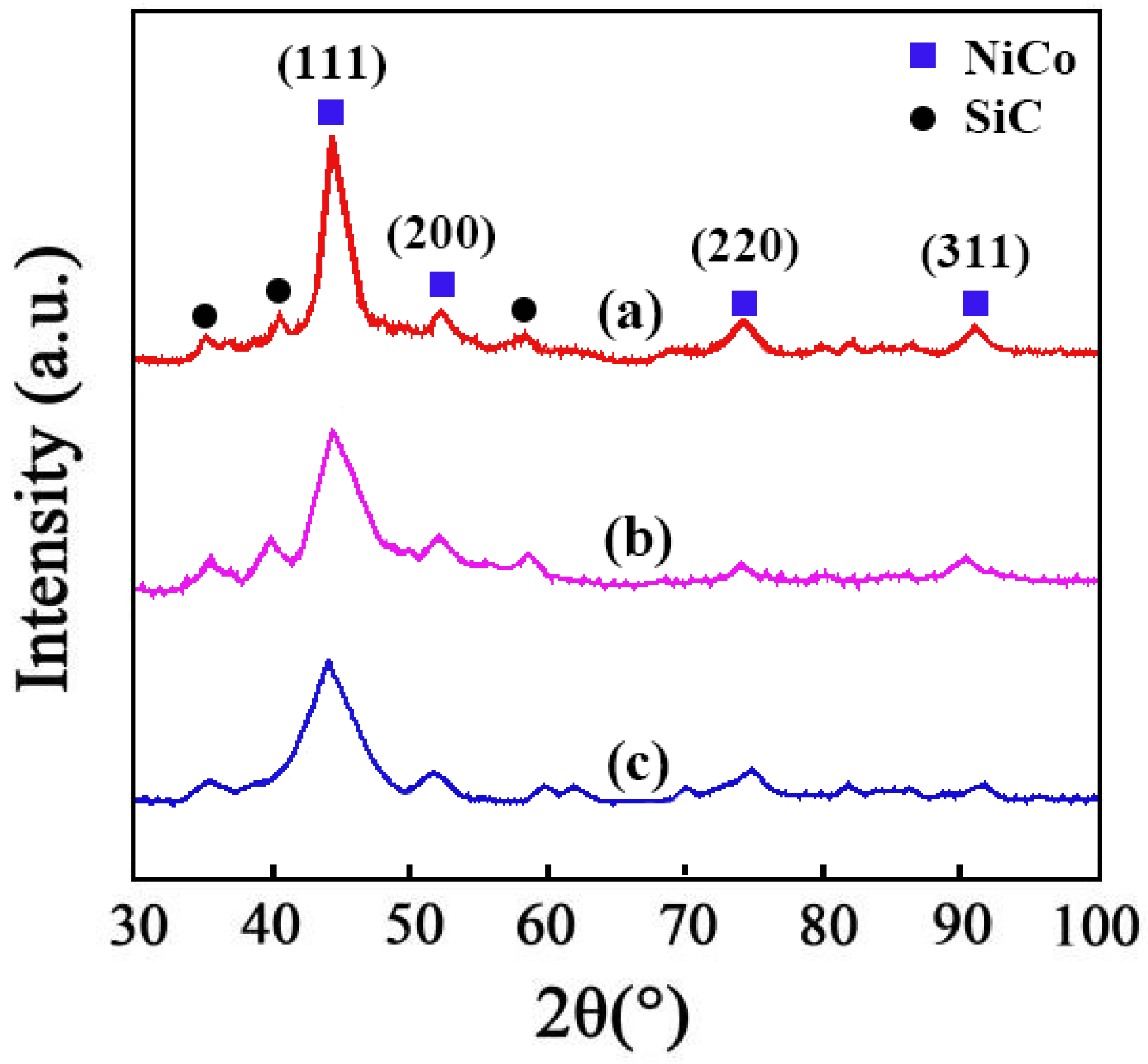

3.3. Crystallinity

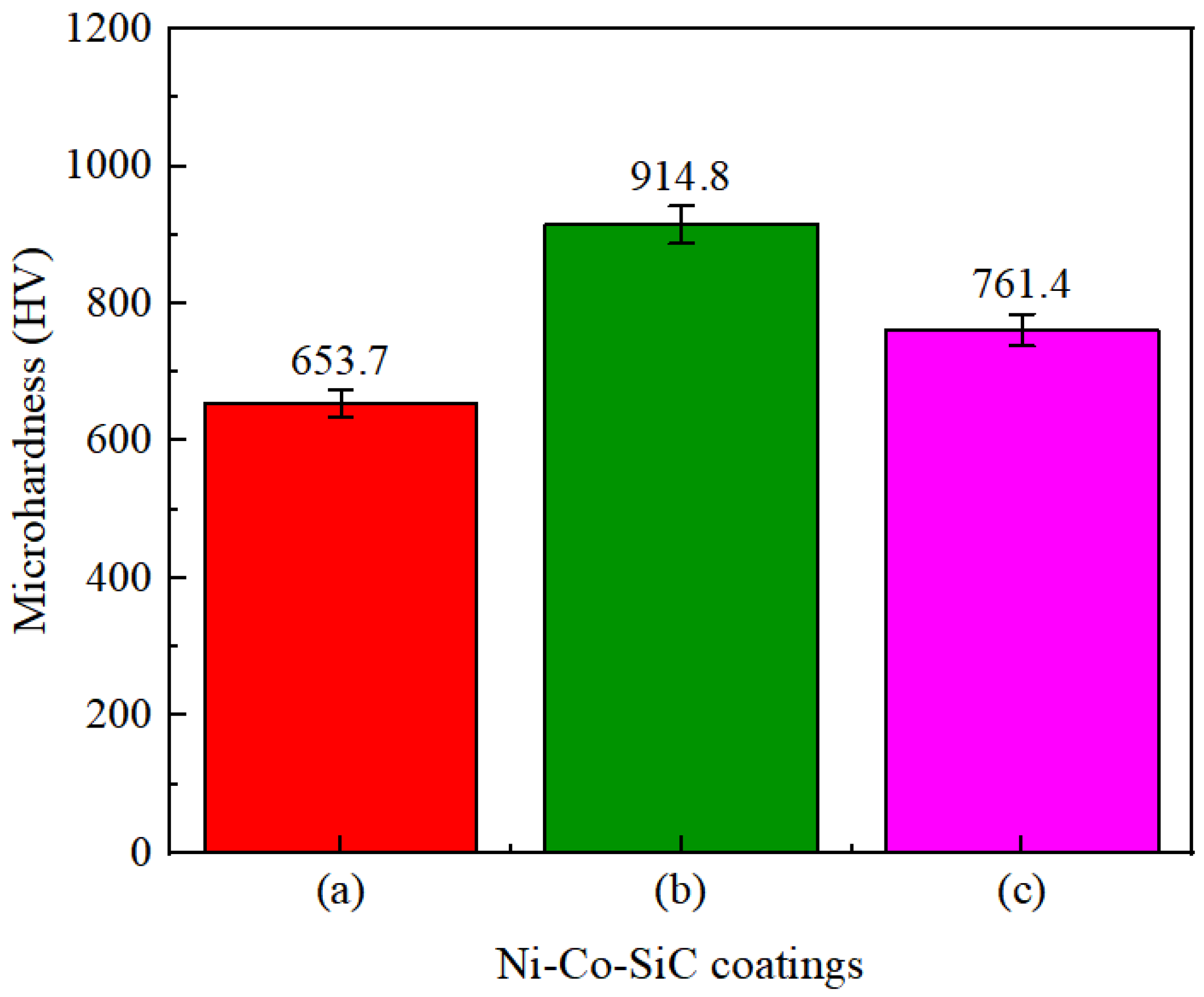

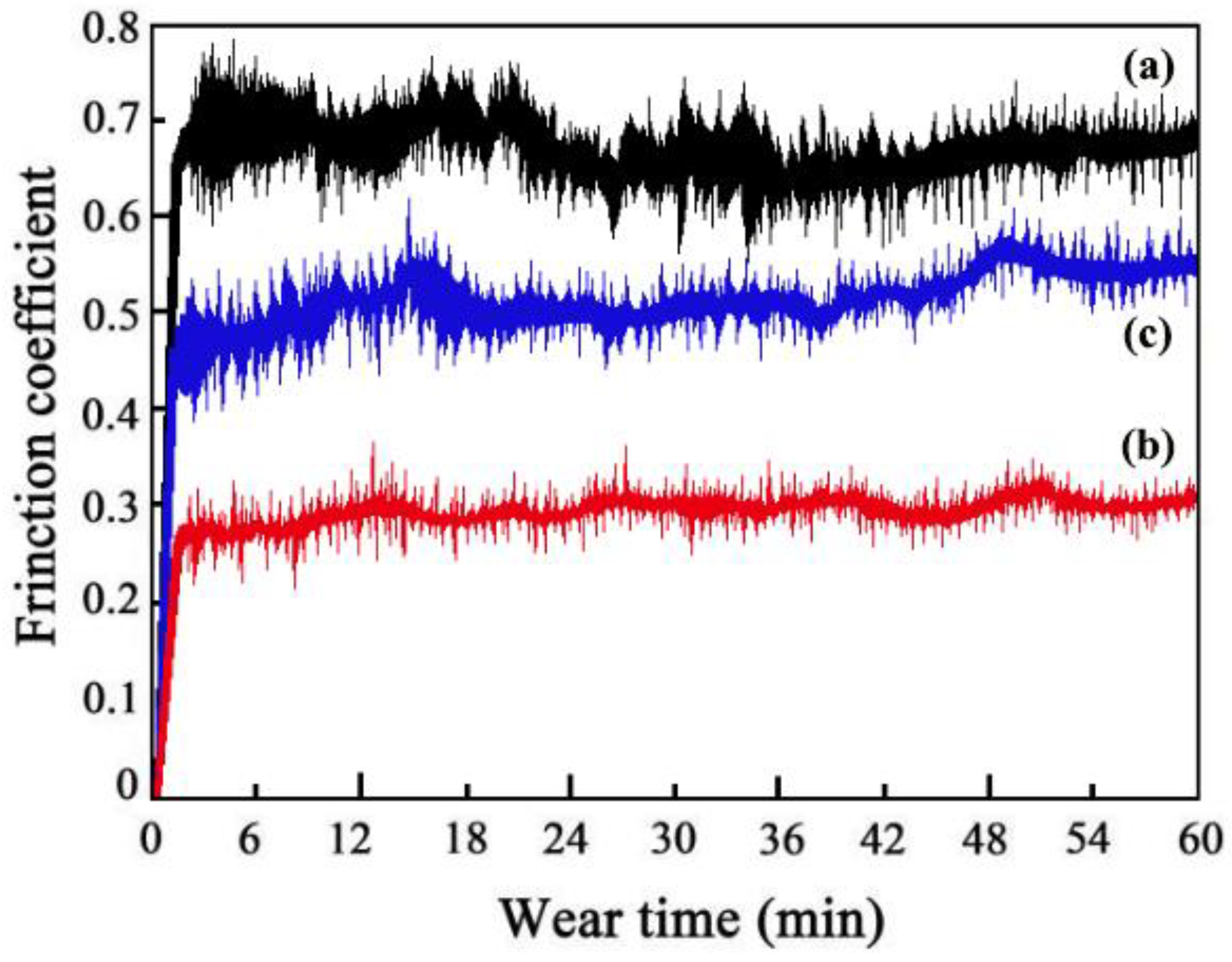

3.4. Abrasion Resistance

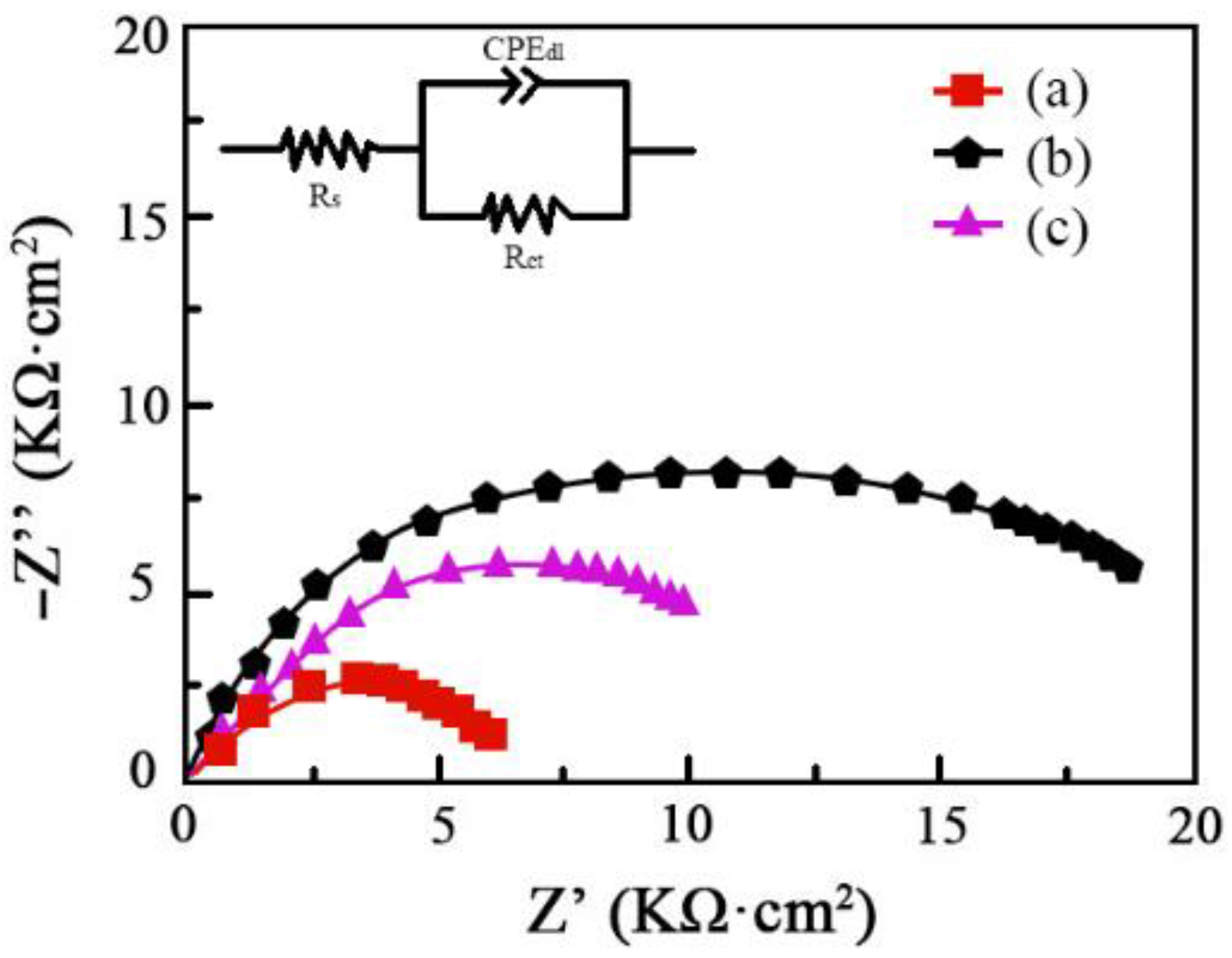

3.5. Corrosion Resistance

4. Conclusions

- (1)

- The patterns of influence of magnetic field strength (0 T-MS0, 0.4 T-MS1 magnetic field direction perpendicular, 0.4 T-MS2 magnetic field direction parallel) on the characteristics and structure of electrodeposited (ED) Ni-Co-SiC coatings were studied.

- (2)

- Employing a magnetic field during the ED led to a denser and smoother surface morphology. Furthermore, MS1 revealed the most SiC content of all coatings and the smallest NiCo grain size, measuring just 86.5 nm.

- (3)

- NiCo diffraction peaks observed at 92.4°, 76.8°, 52.4°, and 44.6° corresponded to the (311), (220), (200), and (111) crystal planes. The preferential growth direction of the Ni grains shifted from (200) to the (111) planar direction with the introduction of a magnetic field. Furthermore, the NiCo grain diffraction peak intensity was most influenced by the perpendicular magnetic field.

- (4)

- MS1 revealed the lowest friction coefficient and the highest microhardness among all prepared coatings, suggesting enhanced abrasion resistance. Furthermore, MS1 showed higher corrosion resistance than MS0 and MS2 coatings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, W.Q.; Lei, W.N.; Shen, Y.; Wang, C.Y.; Qian, H.F.; Lim, Q.L. Performance characterization and preparation of Ni-SiC nanocomposites based on SCF-CO2. Integr. Ferroelectr. 2017, 179, 45–55. [Google Scholar] [CrossRef]

- Jiménez-Solano, A.; Galisteo-López, J.F.; Míguez, H. Flexible and adaptable light-emitting coatings for arbitrary metal surfaces based on optical Tamm mode coupling. Adv. Opt. Mater. 2017, 6, 1700560. [Google Scholar] [CrossRef]

- Liu, Y.; Han, X.G.; Kang, L.; Li, Q. Process prediction of Ni-SiC coatings based on RBF-BP model. J. Indian Chem. Soc. 2022, 99, 100513. [Google Scholar] [CrossRef]

- Xia, F.; Yan, P.; Ma, C.; Zhang, Y.; Li, H. Pulse-electrodeposited Ni/W-Al2O3 nanocomposites at different current densities. J. Nanopart. Res. 2023, 25, 208. [Google Scholar] [CrossRef]

- Kumar, K.A.; Mohan, P.; Kalaignan, G.P.; Muralidharan, V.S. Electrodeposition and characterization of Ni-ZrO2 nanocomposites by direct and pulse current methods. J. Nanosci. Nanotechnol. 2013, 12, 8364–8371. [Google Scholar] [CrossRef] [PubMed]

- Khoran, E.; Zandrahimi, M.; Ebrahimifar, H. Microstructure and oxidation behavior of Ni-TiO2 composite coating at high temperature. Oxid. Met. 2019, 91, 177–189. [Google Scholar] [CrossRef]

- Sun, C.F.; Liu, X.Q.; Zhou, C.Y.; Wang, C.N.; Cao, H.W. Preparation and wear properties of magnetic assisted pulse electrodeposited Ni-SiC nanocoatings. Ceram. Int. 2019, 45, 1348–1355. [Google Scholar] [CrossRef]

- Azizi-Nour, J.; Nasirpouri, F. Exploiting magnetic sediment co-electrodeposition mechanism in Ni-Al2O3 nanocomposite coatings. J. Electroanal. Chem. 2022, 907, 116052. [Google Scholar] [CrossRef]

- Long, Q.; Zhong, Y.B.; Wu, J.M. Research progress of magnetic field techniques for electrodeposition of coating. Int. J. Electrochem. Sci. 2020, 15, 8026–8040. [Google Scholar] [CrossRef]

- Yang, X.Y.; Li, K.J.; Peng, X.; Wang, F.H. Beneficial effects of Co2+ on co-electrodeposited Ni-SiC nanocomposite coating. Trans. Nonferrous Met. Soc. China 2009, 19, 119–124. [Google Scholar] [CrossRef]

- Cai, C.; Yin, J.Y.; Zhang, Z.; Yang, J.F. The electrodeposition of nanostructured Ni-TiN composite films. Mater. Sci. Forum 2009, 620–622, 727–730. [Google Scholar] [CrossRef]

- Yang, G.R.; Song, W.M.; Sun, X.M.; Ma, Y.; Lu, J.J.; Hao, Y. The wear behavior of electroless Ni-P/SiC composite coating. Adv. Mater. Res. 2011, 239–242, 954–957. [Google Scholar] [CrossRef]

- Wang, X.Y.; Cui, H.X.; Zhou, Q.; Zhang, X.L.; Zhang, Y.R. Microhardness and corrosion resistance of electrodeposited Ni-SiC-BN composite coatings. Int. J. Electrochem. Sci. 2022, 17, 220677. [Google Scholar] [CrossRef]

- Wang, Q.W.; Huang, J.L.; Liu, J.N.; Yang, Y.F.; Han, G.F.; Li, W. Enhanced performance of electrodeposited Ni-SiC plating as an alternative to electroplated chromium deposits: The effect of pulse duty cycle. Surf. Topogr.-Metrol. Prop. 2022, 10, 15024. [Google Scholar] [CrossRef]

- Wasekar, N.; Latha, S.; Ramakrishna, M.; Rao, D.; Sundararajan, G. Pulsed electrodeposition and mechanical properties of Ni-W/SiC nano-composite coatings. Mater. Des. 2016, 112, 140–150. [Google Scholar] [CrossRef]

- Singh, J.P.; Pal, S.; SDharma, Y.K.; Nagm, A. Nd-doped CdS nano-particles: Optical band gap and urbach energy investigations. J. Opt. 2024, 1–8. [Google Scholar] [CrossRef]

- Waware, U.S.; Nazir, R.; Prasad, A.; Hamouda, A.M.S.; Pradhan, A.K.; Alshehri, M.; Syed, R.; Malik, A.; Alqahtan, M.S. Preparation and properties of electrodeposited Ni-B-V2O5 composite coatings. Surf. Coat. Technol. 2021, 409, 126888. [Google Scholar] [CrossRef]

- Rao, V.R.; Hegde, A.C. Magnetically induced codeposition of Ni-Cd alloy coatings for better corrosion protection. Ind. Eng. Chem. Res. 2014, 53, 5490–5497. [Google Scholar] [CrossRef]

- Liu, L.; Yu, X.; Zhang, W.W.; Lv, Q.Y.; Hou, L.; Fautrelle, Y.; Ren, Z.M.; Cao, G.H.; Lu, X.G.; Li, X. Strong magnetic-field-engineered porous template for fabricating hierarchical porous Ni-Co-Zn-P nanoplate arrays as battery-type electrodes of advanced all-solid-state supercapacitors. ACS Appl. Mater. Interfaces 2022, 14, 2782–2793. [Google Scholar] [CrossRef]

- Hu, F.; Chan, K.C.; Song, S.Z.; Yang, X.J. Enhancement of corrosion resistance of electrocodeposited Ni-SiC composites by magnetic field. J. Solid State Electrochem. 2007, 11, 745–750. [Google Scholar] [CrossRef]

- Bakhit, B.; Akbari, A. Synthesis and characterization of Ni-Co/SiC nanocomposite coatings using sediment co-deposition technique. J. Alloys Compd. 2013, 560, 92–104. [Google Scholar] [CrossRef]

- Ababsa, A.; Ben Temam, H.; Hasan, G.G.; Althamthami, M.; Malfi, A.N. Effect of sodium dodecyl sulfate and different SiC quantities on electrodeposited Ni-Co alloy coatings. Surf. Topogr.-Metrol. Prop. 2022, 10, 015038. [Google Scholar] [CrossRef]

- Liu, T.X.; Li, C.Y.; Li, Q.; Li, L.Z.; Xia, F.F.; Xing, H.Y.; Ma, C.Y. Synthesis and wear characterization of ultrasonic electrodeposited Ni-TiN thin coatings. Int. J. Electrochem. Sci. 2021, 16, 151028. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Jiang, C.H.; Fu, P.; Cai, F.; Ma, N.H. Microstructure and texture of electrodeposited Ni-ZrC composite coatings investigated by Rietveld XRD line profile analysis. J. Alloys Compd. 2015, 626, 118–123. [Google Scholar] [CrossRef]

- Huang, P.C.; Chou, C.C.; Wang, H.T.; Cheng, C.H.; Hou, K.H.; Ger, M.D. Tribocorrosion study of electrodeposited Ni-W alloy/BN(h) composited coatings for piston rings. Surf. Coat. Technol. 2022, 436, 128289. [Google Scholar] [CrossRef]

- Yang, Z.G.; Yi, S.J.; Cao, L.K.; Tang, S.H.; Li, Q. Process simulation and abrasion behavior of jet electrodeposited Ni-TiN nanocoatings. Coatings 2022, 12, 86. [Google Scholar] [CrossRef]

- Demir, M.; Kanca, E.; Karahan, I.S.H. Characterization of electrodeposited Ni-Cr/hBN composite coatings. J. Alloys Compd. 2020, 844, 155511. [Google Scholar] [CrossRef]

- Peng, X.S.; Xu, X.Y.; Wang, J. Characterization and performance prediction of jet pulse electrodeposited Ni-SiC nanocomposites by means of artificial neural networks. Ceram. Int. 2018, 44, 8599–8604. [Google Scholar] [CrossRef]

- Galicia-Aguilar, G.; Campo-Garcia, G.; Ramirez-Reyes, J.L.; Medina-Almazan, A.L. Study of the magnetic field effect on the electrochemical behavior of a Ni electrodeposit. Int. J. Electrochem. Sci. 2017, 12, 928–942. [Google Scholar] [CrossRef]

- Zhao, Y.T.; Wang, L.B.; Qin, Z.B.; Wang, C.X.; Xu, Z.; Jiang, C.H.; Ji, V. The roles of Ti particles in improving the corrosion resistance of electrochemically assembled Ni-Ti composite coatings. Corros. J. Sci. Eng. 2017, 73, 1107–1118. [Google Scholar] [CrossRef]

| Sample | MS0 | MS1 | MS2 |

|---|---|---|---|

| NiSO4·6H2O (g/L) | 260 | 260 | 260 |

| NiCl2·H2O (g/L) | 28 | 28 | 28 |

| SiC content of electrolyte (g/L) | 8 | 8 | 8 |

| H3BO3 (g/L) | 25 | 25 | 25 |

| Current density (A/dm2) | 5 | 5 | 5 |

| Duty cycle (%) | 60 | 60 | 60 |

| Impulse frequency (Hz) | 10 | 10 | 10 |

| ton (μs) | 60 | 60 | 60 |

| toff (μs) | 40 | 40 | 40 |

| Bath temperature (°C) | 48 | 48 | 48 |

| Cetyltrimethyl ammonium bromide (mg/L) | 65 | 65 | 65 |

| pH | 4.4 | 4.4 | 4.4 |

| Deposition time (min) | 45 | 45 | 45 |

| Magnetic direction | - | Perpendicular | Parallel |

| Magnetic field intensity (T) | 0 | 0.4 | 0.4 |

| Component | Concentration |

|---|---|

| NaOH (g/L) | 26 |

| Na2CO3 (g/L) | 20 |

| Na3PO4 (g/L) | 45 |

| NaCl (g/L) | 2.5 |

| Coating | NiCo Grain (nm) | SiC Nanoparticle (nm) |

|---|---|---|

| MS0 | 138.8 | 87.8 |

| MS1 | 86.5 | 44.2 |

| MS2 | 98.1 | 69.2 |

| Coating | Carbon (C) | Nickel (Ni) | Silicon (Si) | Cobalt (Co) |

|---|---|---|---|---|

| MS0 | 7.26% | 75.43% | 8.18% | 9.13% |

| MS1 | 10.83% | 70.29% | 11.74% | 7.14% |

| MS2 | 9.79% | 70.19% | 10.83% | 9.19% |

| Coating | Rs | Rct |

|---|---|---|

| MS0 | 10.25 Ω | 3.56 Ω |

| MS1 | 8.10 Ω | 15.93 Ω |

| MS2 | 9.71 Ω | 7.24 Ω |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C.; He, H.; Zhang, H.; Li, Z.; Wei, L.; Xia, F. Impact of Magnetic Field Direction on Performance and Structure of Ni-Co-SiC Coatings Fabricated via Magnetic-Field-Induced Electrodeposition. Coatings 2024, 14, 672. https://doi.org/10.3390/coatings14060672

Ma C, He H, Zhang H, Li Z, Wei L, Xia F. Impact of Magnetic Field Direction on Performance and Structure of Ni-Co-SiC Coatings Fabricated via Magnetic-Field-Induced Electrodeposition. Coatings. 2024; 14(6):672. https://doi.org/10.3390/coatings14060672

Chicago/Turabian StyleMa, Chunyang, Hongxin He, Hongbin Zhang, Zhiping Li, Lixin Wei, and Fafeng Xia. 2024. "Impact of Magnetic Field Direction on Performance and Structure of Ni-Co-SiC Coatings Fabricated via Magnetic-Field-Induced Electrodeposition" Coatings 14, no. 6: 672. https://doi.org/10.3390/coatings14060672

APA StyleMa, C., He, H., Zhang, H., Li, Z., Wei, L., & Xia, F. (2024). Impact of Magnetic Field Direction on Performance and Structure of Ni-Co-SiC Coatings Fabricated via Magnetic-Field-Induced Electrodeposition. Coatings, 14(6), 672. https://doi.org/10.3390/coatings14060672