A Novel Approach towards the Preparation of Silk-Fibroin-Modified Polyethylene Terephthalate with High Hydrophilicity and Stability

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Silk-Fibroin Solution

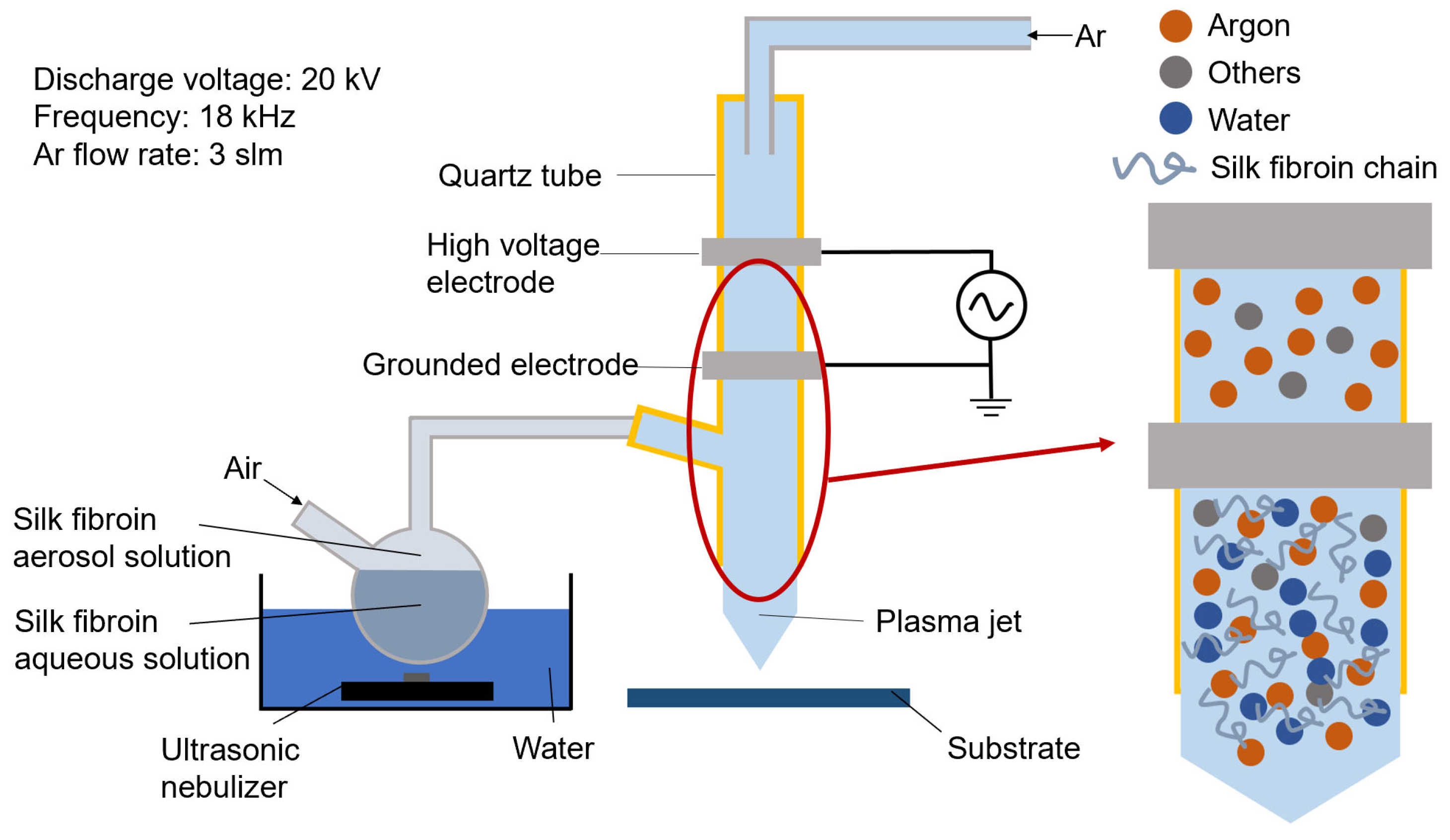

2.2. Silk Fibroin Immobilization

- (1)

- Solution dip-coating: The pretreated PET films were then immersed in an SF solution and reacted for 12 h at 4 °C [29], referred to as C-PET-SF;

- (2)

- Plasma-assisted deposition: The pretreated PET films were exposed to APPJ using SF aerosol as the feed gas for 10 min, referred to as P-PET-SF;

- (3)

- The two-step method: The pretreated PET films were immersed in an SF solution for 6 h at 4 °C and finally subjected to APPJ using SF aerosol as the feed gas for 3 min, referred to as PC-PET-SF.

2.3. Characterization

3. Results and Discussion

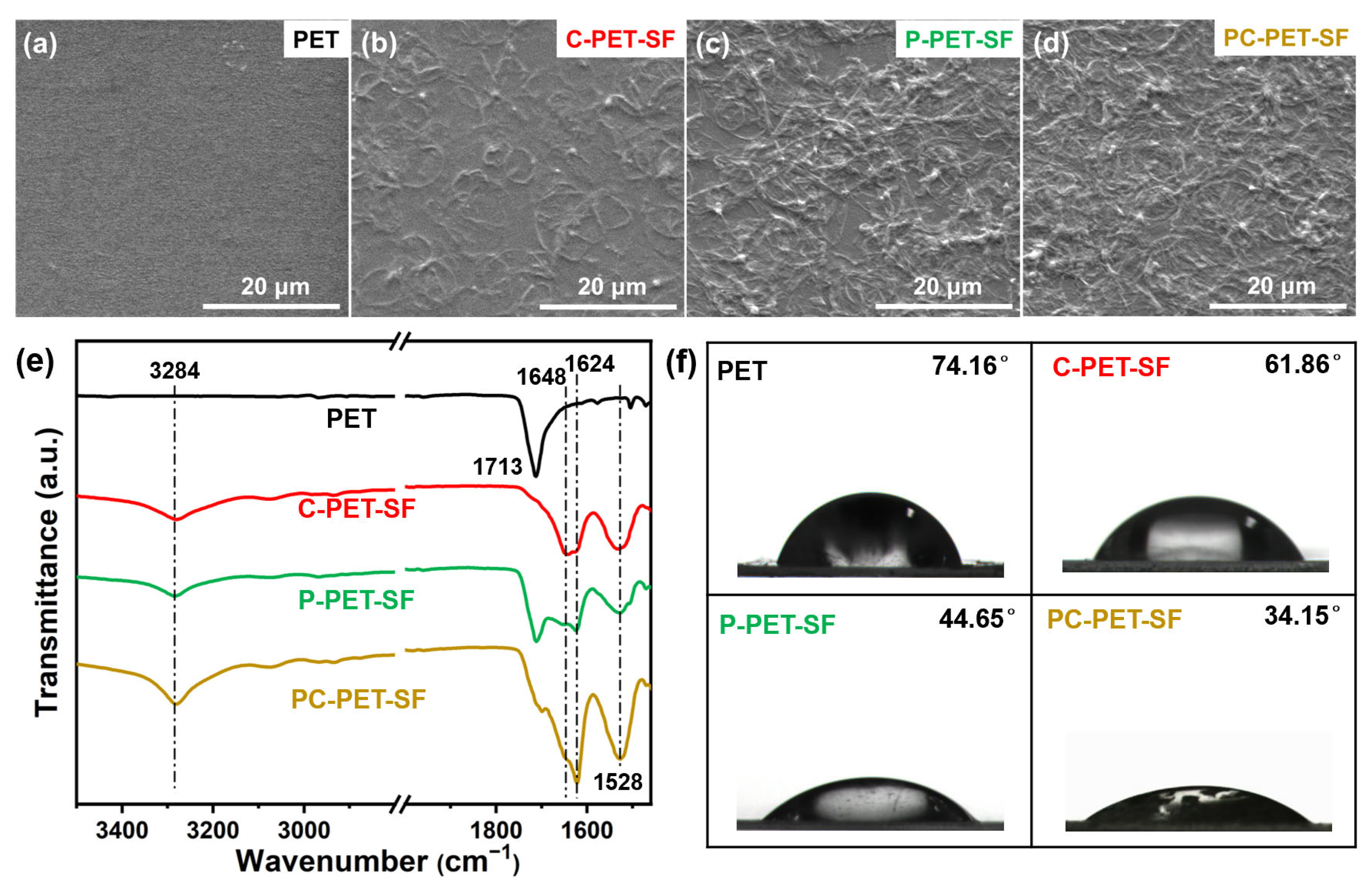

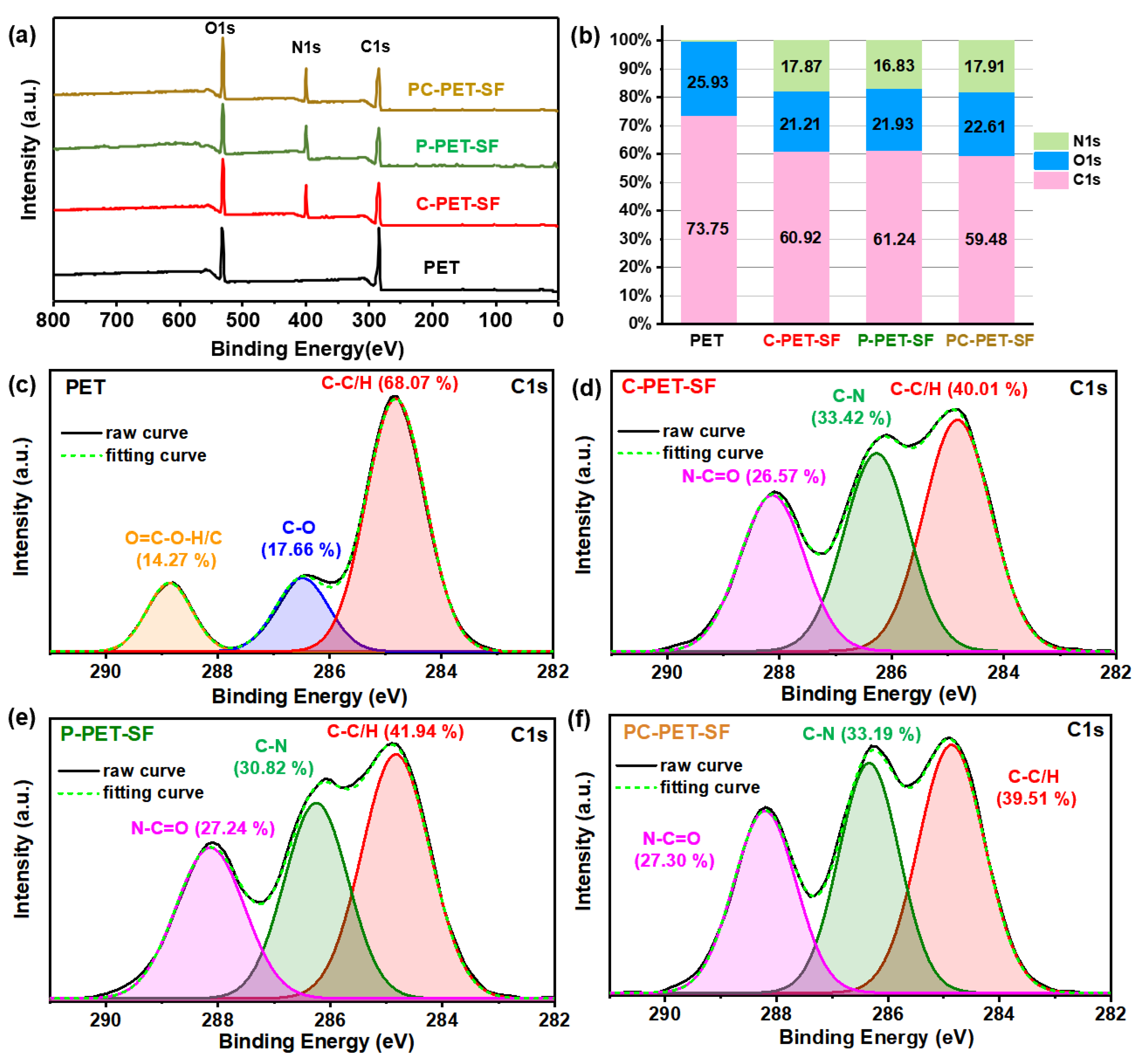

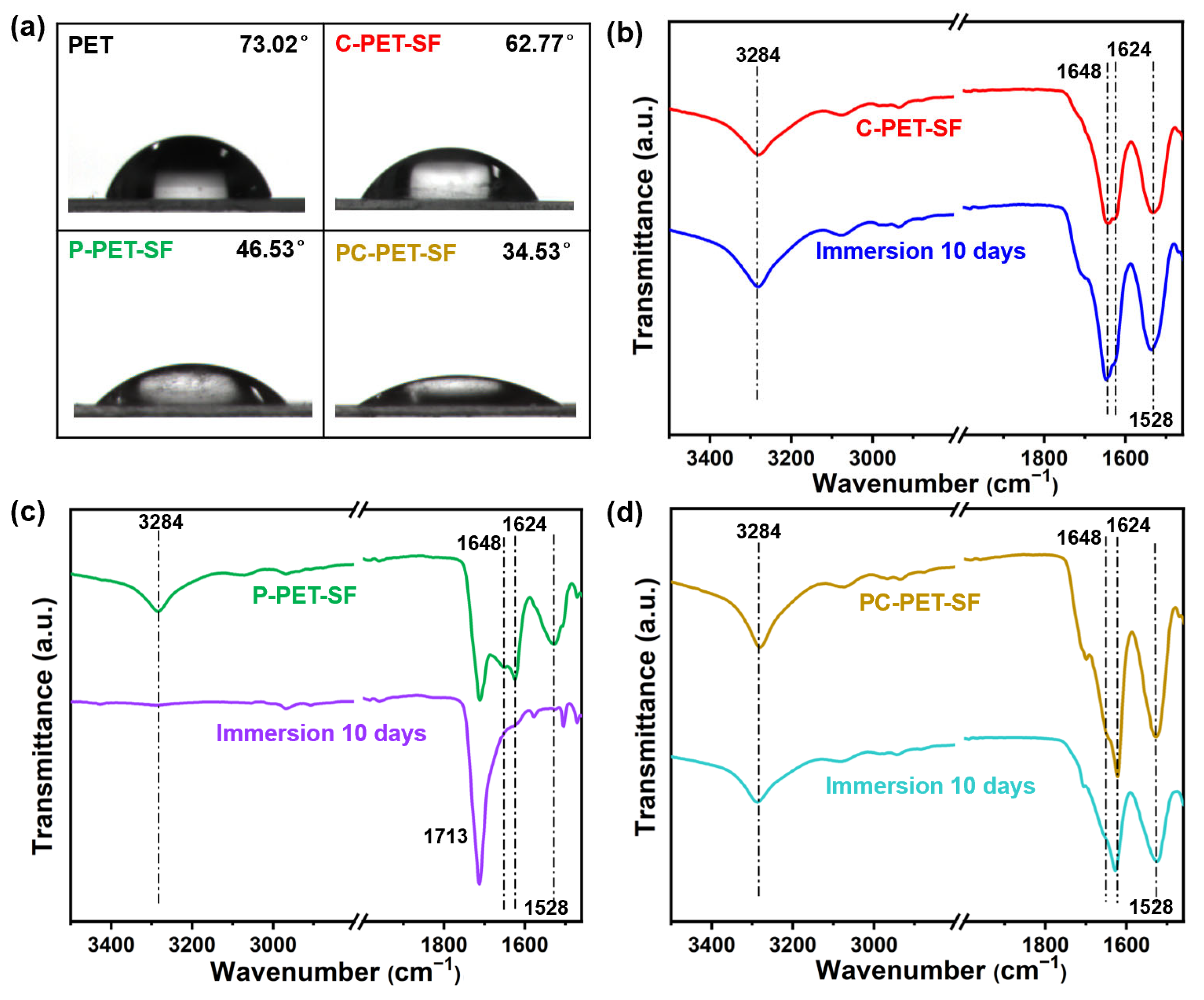

3.1. PET-SF Films Prepared Using Three Different Methods

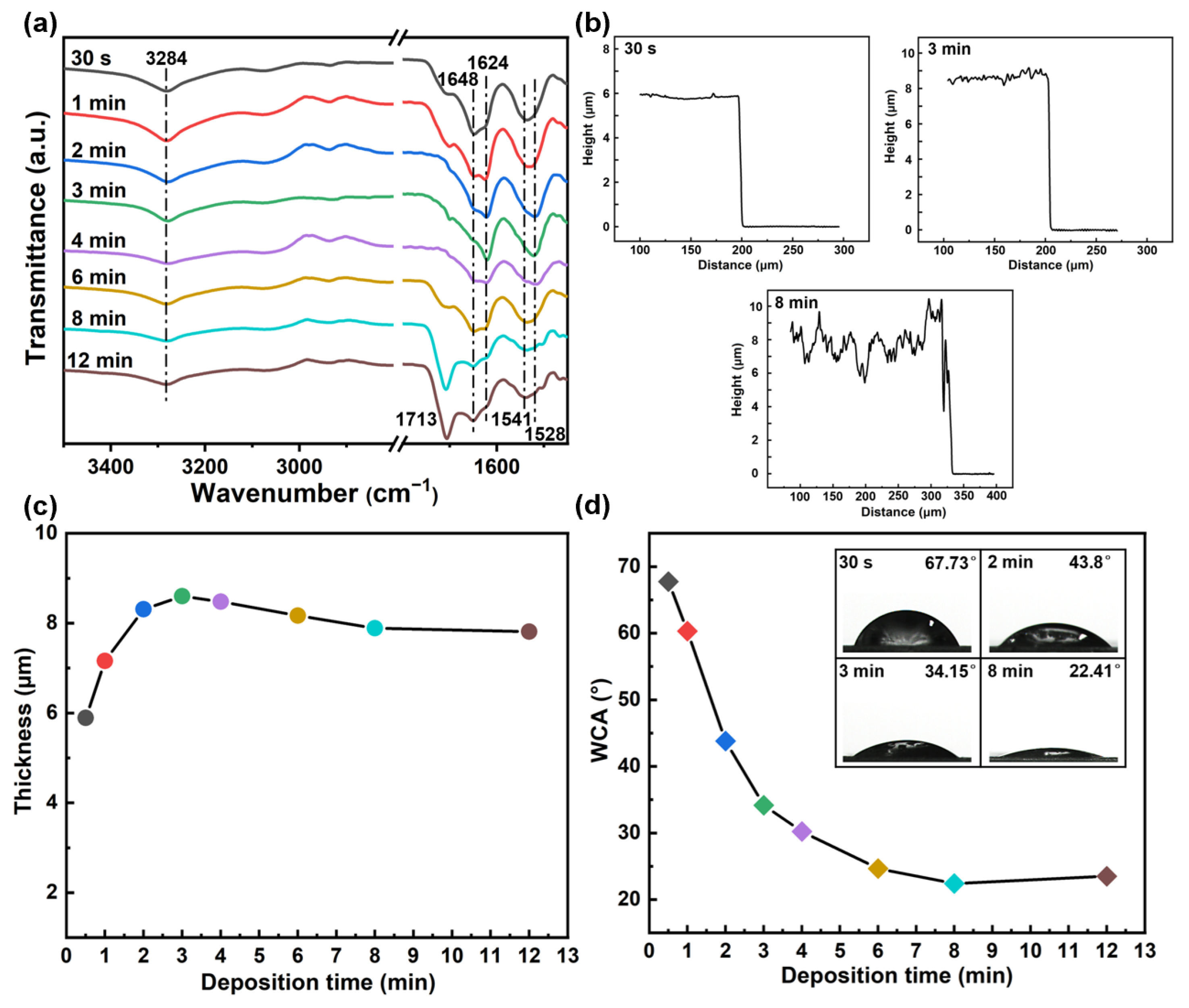

3.2. Influence of Treatment Time in the Two-Step Method

- Fixed plasma deposition time of 3 min while varying dipping times at 1 h, 2 h, 3 h, 4 h, 6 h, 8 h, 12 h, and 24 h;

- (4)

- Fixed dipping time of 6 h while varying plasma deposition times at intervals of 30 s, 1 min, 2 min, 3 min, 4 min, 6 min, 8 min, and 12 min.

4. Conclusions

- (1)

- The dipping process resulted in a strong adhesion strength between SF and the PET substrate. The plasma contributed to converting the SF secondary structure from a random coil to a more stable β-sheet structure and forming hydrophilic functional groups.

- (2)

- The dipping time for 6 h and the deposition time for 3 min resulted in a maximum SF grafting amount with a highly stable structure.

- (3)

- The modified PET exhibited satisfactory hydrophilicity when the deposition time was more than 3 min and showed the most hydrophilicity surface at 8 min.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Drobota, M.; Ursache, S.; Aflori, M. Surface functionalities of polymers for biomaterial applications. Polymers 2022, 14, 2307. [Google Scholar] [CrossRef] [PubMed]

- Hoque, M.E.; Rayhan, A.M.; Shaily, S.I. Natural fiber-based green composites: Processing, properties and biomedical applications. Appl. Sci. Eng. 2021, 14, 689. [Google Scholar] [CrossRef]

- Afonso, E.; Martinez-Gomez, A.; Huerta, A.; Tiemblo, P.; Garcia, N. Facile preparation of hydrophobic PET surfaces by solvent induced crystallization. Coatings 2022, 12, 137. [Google Scholar] [CrossRef]

- Wu, J.; Wu, K.; Chen, J.; Song, C.; Jia, P.; Li, X. Influence of air addition on surface modification of polyethylene terephthalate treated by an atmospheric pressure argon plasma brush. Plasma Sci. Technol. 2021, 23, 085504. [Google Scholar] [CrossRef]

- El-Saftawy, A.A.; Elfalaky, A.; Ragheb, M.S.; Zakhary, S.G. Electron beam induced surface modifications of PET film. Radiat. Phys. Chem. 2014, 102, 96–102. [Google Scholar] [CrossRef]

- Mui, T.S.M.; Mota, R.P.; Quade, A.; de Oliveira Hein, L.R.; Kostov, K.G. Uniform surface modification of polyethylene terephthalate (PET) by atmospheric pressure plasma jet with a horn-like nozzle. Surf. Coat. Technol. 2018, 352, 338–347. [Google Scholar] [CrossRef]

- Caykara, T.; Silva, J.; Fernandes, S.; Braga, A.; Rodrigues, J.; Rodrigues, L.R.; Silva, C. Modification of PET surfaces with gum Arabic towards its bacterial anti-adhesiveness using an experimental factorial design approach. Mater. Today Commun. 2021, 28, 102684. [Google Scholar] [CrossRef]

- Mao, Y.; Li, Q.; Wu, C. Surface modification of PET fiber with hybrid coating and its effect on the properties of PP composites. Polymers 2019, 11, 1726. [Google Scholar] [CrossRef]

- Lai, J.; Sunderland, B.; Xue, J.; Yan, S.; Zhao, W.; Folkard, M.; Michael, B.D.; Wang, Y. Study on hydrophilicity of polymer surfaces improved by plasma treatment. Appl. Surf. Sci. 2006, 252, 3375–3379. [Google Scholar] [CrossRef]

- Klein, M.O.; Bijelic, A.; Toyoshima, T.; Gotz, H.; von Koppenfels, R.L.; Al-Nawas, B.; Duschner, H. Long-term response of osteogenic cells on micron and submicron-scale-structured hydrophilic titanium surfaces: Sequence of cell proliferation and cell differentiation. Clin. Oral Implant. Res. 2010, 21, 642–649. [Google Scholar] [CrossRef]

- Ma, Z.; Mao, Z.; Gao, C. Surface modification and property analysis of biomedical polymers used for tissue engineering. Colloids Surf. B 2007, 60, 137–157. [Google Scholar] [CrossRef] [PubMed]

- Popescu, S.; Zarif, M.E.; Dumitriu, C.; Ungureanu, C.; Pirvu, C. Silk fibroin-based hybrid nanostructured coatings for titanium implantable surfaces modification. Coatings 2020, 10, 518. [Google Scholar] [CrossRef]

- Porter, D.; Vollrath, F. Silk as a biomimetic ideal for structural polymers. Adv. Mater. 2009, 21, 487–492. [Google Scholar] [CrossRef]

- Ma, D.; Wang, Y.; Dai, W. Silk fibroin-based biomaterials for musculoskeletal tissue engineering. Mater. Sci. Eng. C 2018, 89, 456–469. [Google Scholar] [CrossRef] [PubMed]

- Tomeh, M.A.; Hadianamrei, R.; Zhao, X. Silk fibroin as a functional biomaterial for drug and gene delivery. Pharmaceutics 2019, 11, 494. [Google Scholar] [CrossRef] [PubMed]

- Meinel, L.; Fajardo, R.; Hofmann, S.; Langer, R.; Chen, J.; Snyder, B. Silk implants for the healing of critical size bone defects. Bone 2005, 37, 688–698. [Google Scholar] [CrossRef] [PubMed]

- Altman, G.H.; Horan, R.L.; Lu, H.H.; Moreau, J.; Martin, I.; Richmond, J.C.; Kaplan, D.L. Silk matrix for tissue engineered anterior cruciate ligaments. Biomaterials 2002, 23, 4131–4141. [Google Scholar] [CrossRef]

- Unger, R.E.; Wolf, M.; Peters, K.; Motta, A.; Migliaresi, C.; Kirkpatrick, C.J. Growth of human cells on a non-woven silk fibroin net: A potential for use in tissue engineering. Biomaterials 2004, 25, 1069–1075. [Google Scholar] [CrossRef]

- Ming, J.; Liu, Z.; Bie, S.; Zhang, F.; Zuo, B. Novel silk fibroin films prepared by formic acid/hydroxyapatite dissolution method. Mater. Sci. Eng. C 2014, 37, 48–53. [Google Scholar] [CrossRef]

- Youn, Y.H.; Pradhan, S.; Da Silva, L.P.; Kwon, I.K.; Kundu, S.C.; Reis, R.L.; Yadavalli, V.K.; Correlo, V.M. Micropatterned silk-fibroin/eumelanin composite films for bioelectronic applications. ACS Biomater. Sci. Eng. 2021, 7, 2466–2474. [Google Scholar] [CrossRef]

- Liu, J.; Xie, X.; Wang, T.; Chen, H.; Fu, Y.; Cheng, X.; Wu, J.; Li, G.; Liu, C.; Liimatainen, H.; et al. Promotion of wound healing using nanoporous silk fibroin sponges. ACS Appl. Mater. Interfaces 2023, 15, 12696–12707. [Google Scholar] [CrossRef] [PubMed]

- Sionkowska, A.; Michalska, M.; Walczak, M. Preparation and characterization of silk fibroin/collagen sponge with nanohydroxyapatite. Mol. Cryst. Liq. Cryst. 2016, 640, 106–112. [Google Scholar] [CrossRef]

- Chouhan, D.; Lohe, T.; Samudrala, P.K.; Mandal, B.B. In Situ forming injectable silk fibroin hydrogel promotes skin regeneration in full thickness burn wounds. Adv. Healthc. Mater. 2018, 7, 1801092. [Google Scholar] [CrossRef]

- He, S.; Shi, D.; Han, Z.; Dong, Z.; Xie, Y.; Zhang, F.; Zeng, W.X.; Yi, Q. Heparinized silk fibroin hydrogels loading FGF1 promote the wound healing in rats with full-thickness skin excision. BioMed. Eng. OnLine 2019, 18, 97. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Ji, S.; Wang, Y.; Shen, X.; Liang, H. Silk fibroin-based scaffolds for tissue engineering. Front. Mater. Sci. 2013, 7, 237–247. [Google Scholar] [CrossRef] [PubMed]

- Kuboyama, N.; Kiba, H.; Arai, K.; Uchida, R.; Tanimoto, Y.; Bhawal, U.K.; Abiko, Y.; Miyamoto, S.; Knight, D.; Asakura, T.; et al. Silk fibroin-based scaffolds for bone regeneration. J. Biomed. Mater. Res. Part B 2013, 101B, 295–302. [Google Scholar] [CrossRef]

- Hu, J.; Jiang, Z.; Zhang, J.; Yang, G. Application of silk fibroin coatings for biomaterial surface modification: A silk road for biomedicine. J. Zhejiang Univ. Sci. B 2023, 24, 943–956. [Google Scholar] [CrossRef] [PubMed]

- Tkavc, T.; Petrinic, I.; Luxbacher, T.; Vesel, A.; Ristic, T.; Zemljic, L.F. Influence of O2 and CO2 plasma treatment on the deposition of chitosan onto polyethylene terephthalate (PET) surfaces. Int. J. Adhes. Adhes. 2014, 48, 168–176. [Google Scholar] [CrossRef]

- Liang, M.; Yao, J.; Chen, X.; Huang, L.; Shao, Z. Silk fibroin immobilization on poly(ethylene terephthalate) films: Comparison of two surface modification methods and their effect on mesenchymal stem cells culture. Mater. Sci. Eng. C 2013, 33, 1409–1416. [Google Scholar] [CrossRef]

- Poletti, G.; Orsini, F.; Raffaele-Addamo, A.; Riccardi, C.; Selli, E. Cold plasma treatment of PET fabrics: AFM surface morphology characterization. Appl. Surf. Sci. 2003, 219, 311–316. [Google Scholar] [CrossRef]

- Zhu, Z.; Kelley, M. Poly(ethylene terephthalate) surface modification by deep UV (172 nm) irradiation. Appl. Surf. Sci. 2004, 236, 416–425. [Google Scholar] [CrossRef]

- Eberl, A.; Heumann, S.; Brückner, T.; Araujo, R.; Cavaco-Paulo, A.; Kaufmann, F.; Kroutil, W.; Guebitz, G.M. Enzymatic surface hydrolysis of poly(ethylene terephthalate) and bis(benzoyloxyethyl) terephthalate by lipase and cutinase in the presence of surface active molecules. J. Biotechnol. 2009, 143, 207–212. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Gu, Z. A study of one-bath alkali-amine hydrolysis and silk fibroin finishing of polyester microfiber crepe fabric. J. Appl. Polym. Sci. 2001, 81, 1467–1473. [Google Scholar] [CrossRef]

- Gupta, B.; Plummer, C.; Bisson, I.; Frey, P.; Hilborn, J. Plasma-induced graft polymerization of acrylic acid onto poly(ethylene terephthalate) films: Characterization and human smooth muscle cell growth on grafted films. Biomaterials 2002, 23, 863–871. [Google Scholar] [CrossRef]

- Kim, Y.J.; Kang, I.K.; Huh, M.W.; Yoon, S.C. Surface characterization and in vitro blood compatibility of poly(ethylene terephthalate) immobilized with insulin and/or heparin using plasma glow discharge. Biomaterials 2000, 21, 121–130. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Zheng, D.; Zhang, F.; Zhang, G. Durable grafting of silkworm pupa protein onto the surface of polyethylene terephthalate fibers. Mater. Sci. Eng. C 2016, 69, 1290–1296. [Google Scholar] [CrossRef]

- Ai, C.; Cai, J.; Zhu, J.; Zhou, J.; Jiang, J.; Chen, S. Effect of PET graft coated with silk fibroin via EDC/NHS crosslink on graft-bone healing in ACL reconstruction. RSC Adv. 2017, 7, 51303–51312. [Google Scholar] [CrossRef]

- Carnide, G.; Cacot, L.; Champouret, Y.; Pozsgay, V.; Verdier, T.; Girardeau, A.; Cavarroc, M.; Sarkissian, A.; Mingotaud, A.F.; Vahlas, C.; et al. Direct liquid reactor-injector of nanoparticles: A safer-by-design aerosol injection for nanocomposite thin-film deposition adapted to various plasma-assisted processes. Coatings 2023, 13, 630. [Google Scholar] [CrossRef]

- Arkhangelskiy, A.; Maniglio, D.; Bucciarelli, A.; Yadavalli, V.K.; Quaranta, A. Plasma-assisted deposition of silk fibroin on different surfaces. Adv. Mater. Interfaces 2021, 8, 2100324. [Google Scholar] [CrossRef]

- Shi, P.; Zhang, L.; Tian, W.; Li, H.; Wang, Q.; Yi, H.; Yin, Y.; Wang, A.; Ning, P.; Dong, F.; et al. Preparation and anticoagulant activity of functionalised silk fibroin. Chem. Eng. Sci. 2019, 199, 240–248. [Google Scholar] [CrossRef]

- Jacobs, T.; Morent, R.; Geyter, N.D.; Dubruel, P.; Leys, C. Plasma surface modification of biomedical polymers: Influence on cell-material interaction. Plasma Chem. Plasma Process. 2012, 32, 1039–1073. [Google Scholar] [CrossRef]

- Kamalha, E.; Zheng, Y.S.; Zeng, Y.C.; Fredrick, M.N. FTIR and WAXD study of regenerated silk fibroin. Adv. Mater. Res. 2013, 677, 211–215. [Google Scholar] [CrossRef]

- Ling, S.; Qi, Z.; Knight, D.P.; Shao, Z.; Chen, X. Synchrotron FTIR microspectroscopy of single natural silk fibers. Biomacromolecules 2011, 12, 3344–3349. [Google Scholar] [CrossRef] [PubMed]

- Adamczyk, A. The influence of organically modified derivatives of silica on the structure and the wetting angle values of silica coatings. Coatings 2021, 11, 1058. [Google Scholar] [CrossRef]

- Amornsudthiwat, P.; Mongkolnavin, R.; Kanokpanont, S.; Panpranot, J.; Wong, C.S.; Damrongsakkul, S. Improvement of early cell adhesion on Thai silk fibroin surface by low energy plasma. Colloids Surf. B Biointerfaces 2013, 111, 579–586. [Google Scholar] [CrossRef]

- Arkhangelskiy, A.; Quaranta, A.; Motta, A.; Yang, Y.; Yadavalli, V.K.; Maniglio, D. Atmospheric plasma-assisted deposition and patterning of natural polymers. Adv. Mater. Interfaces 2022, 9, 2200454. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, J.; Zhang, Y.; Li, M.; Ji, P.; Tan, H.; Huang, T.; Zhuge, L.; Zhang, X.; Wu, X. A Novel Approach towards the Preparation of Silk-Fibroin-Modified Polyethylene Terephthalate with High Hydrophilicity and Stability. Coatings 2024, 14, 636. https://doi.org/10.3390/coatings14050636

Fan J, Zhang Y, Li M, Ji P, Tan H, Huang T, Zhuge L, Zhang X, Wu X. A Novel Approach towards the Preparation of Silk-Fibroin-Modified Polyethylene Terephthalate with High Hydrophilicity and Stability. Coatings. 2024; 14(5):636. https://doi.org/10.3390/coatings14050636

Chicago/Turabian StyleFan, Jingyi, Yiwen Zhang, Maoyang Li, Peiyu Ji, Haiyun Tan, Tianyuan Huang, Lanjian Zhuge, Xiaoman Zhang, and Xuemei Wu. 2024. "A Novel Approach towards the Preparation of Silk-Fibroin-Modified Polyethylene Terephthalate with High Hydrophilicity and Stability" Coatings 14, no. 5: 636. https://doi.org/10.3390/coatings14050636

APA StyleFan, J., Zhang, Y., Li, M., Ji, P., Tan, H., Huang, T., Zhuge, L., Zhang, X., & Wu, X. (2024). A Novel Approach towards the Preparation of Silk-Fibroin-Modified Polyethylene Terephthalate with High Hydrophilicity and Stability. Coatings, 14(5), 636. https://doi.org/10.3390/coatings14050636