Abstract

In this study, laser cladding of CoCrFeNiMnTix (x is the proportion of the mass of a material, x = 0.0, 0.2, 0.4, 0.6, 0.8) high-entropy alloy (HEA) composite powder coating on 45 steel substrate was studied by using the method of preplaced powder. The phase composition, morphology, microhardness, corrosion resistance and wear properties of CoCrFeNiMnTix high entropy alloy were analyzed by XRD, SEM, microhardness tester, electrochemical workstation and reciprocating friction wear tester, respectively. The influences of Ti concentration on structure and properties of CoCrFeNiMn HEA laser cladding coating were discussed. The macromorphology of CoCrFeNiMnTix HEA coating layer becomes worse with the increase in Ti quantity. The coating layer is a face-centered cubic solid solution phase. The microstructure of the coating layer is dominated by dendrites and equiaxed crystals. The average microhardness of the coating layer grows with the increases in Ti content, and CoCrFeNiMnTi0.8 can reach 823 HV. The friction coefficient of the cladding coating gradually reduces and the wear resistance adds as Ti content rises; the friction coefficients of CoCrFeNiMnTi0.6 and CoCrFeNiMnTi0.8 cladding coating are similar, at 0.835 and 0.828, respectively. Adhesive and abrasive wear are the two basic types of cladding coating wear. In 3.5 wt.% NaCl solution, the corrosion potential of cladding coating increases with increases in Ti content, the corrosion potential of CoCrFeNiMnTi0.8 is about 244 mV higher than that of CoCrFeNiMnTi0, and the density of corrosion current drops to 3.41 × 10−6 A/cm2 from 7.17 × 10−5 A/cm2.

1. Introduction

Wear and corrosion are identified as the primary causes of mechanical parts failures in the process of their working, and approximately 80% of mechanical parts failures are attributed to their surface wear and corrosion [1]. The 45 steel is a widely used material in the modern industry, with uses in machines (spindles, gears, shafts, connecting rods), vehicles (piston rings, transmission shafts, brake pads), aerospace (engines, crankshafts, rams), and chain sprocket wheels, because of its strong and resistant to deformation mechanical qualities [2,3]. Nevertheless, 45 steel’s application under wear, friction and corrosion conditions is seriously restricted due to its low surface hardness, low corrosion resistance and poor abrasion resistance performance [4]. Manufacturing mechanical parts with high-performance materials resistant to wear and corrosion entails higher costs. Thus, the preparation of a wear-resistant and corrosion-resistant cladding layer on conventional 45 steel surfaces with high-performance alloy powder presents an effective solution to this issue. The use of diverse surface alteration methods with different cladding alloy powders allows an economic material with a protective layer for improving surface properties and functionality [5]. The traditional cladding alloy powder materials typically involve nickel-based compositions with added reinforcing phases such as TiC [6], WC [7], Al2O3 [8], and SiC [9]. Yeh introduced HEA where the liquid or random solid solution states compared to traditional alloys, have noticeably greater mixing entropies [10]. An alloy comprising five to thirteen primary elements and a molar ratio of 5% to 35% for each element is known as HEA [11]. Compared to other alloys, HEAs offer a series of advantages including strong wear resistance [12,13,14], outstanding corrosion resistance [15], and superior resistance to high-temperature oxidation [16], which have garnered increasing attention from researchers. Rakesh et al. [17] fabricated two new mechanically alloyed AlCoCrFeMoW and AlCoCrFeMoV coatings. Low pores and a precise microstructure were displayed by HEA coatings. Microhardness results revealed that the maximum mean hardness of around 561 ± 63 HV was attained by AlCoCrFeMoV HEA coatings. Yang et al. [18] sintered the FeNiCrCoMoW coatings by plasma surface alloying technology with different holding temperatures (1150 °C, 1200 °C, 1250 °C, 1300 °C) and studied the microstructure morphology evolution of HEA coatings. All FeNiCrCoMoW coatings consist of two layers: one for deposition and the other for diffusion, creating a gradient structure HEA coating. The phase of FeNiCrCoMoW HEA coatings is entirely composed of FCC phase + HCP phase. The FeNiCrCoMoW HEA coating has good application prospects.

Laser cladding technology offers a method to form a high-performance cladding alloy layer, which utilizes high-density energy laser beams to melt cladding materials onto the surface of substrates. In comparison to other surface cladding techniques like flame spraying and plasma cladding, laser cladding technology presents several advantages such as a smaller heat-affected zone, lower coating dilution rate, formation of alloy bonding with the substrate, dense microstructure, and a wide range of applications [19,20,21], leading to its increasingly widespread use. Lv et al. [22] produced FeCoNiCrAl coatings on Q235 steel substrate by using the laser cladding process. The steel surface’s resistance to wear is enhanced. FeCoNiCrBSi coating on the surface of a stainless-steel exhibits exceptional resistance to corrosion [23]. Liu et al. [24] discussed the relationship between the frictional properties and alloy material element design, secondary phase doping, and process treatment. Meanwhile, Zhou et al. [25] have elaborated on the effects of elements, laser processing technology, post-treatment, and service temperature on the resistance to corrosion. Both studies suggest that the addition of specific elements to a certain HEA system can effectively enhance its wear resistance and corrosion resistance. The addition of small amounts of other elements in HEA systems can induce lattice distortion, thereby enhancing the comprehensive performance of the alloy [26,27,28,29]. Excellent metallurgical bonding surfaces between the substrates and the Al-modified FeCoNiTiAlx and FeCoCrNiAlx coatings were observed [30,31]. The microhardness of CoCrFeNINbx first grew remarkably with an increase in Nb concentration, and it thereafter remained high [32]. Nevertheless, there has been little research done to far on the impact of the Ti element on HEA coatings, and the underlying mechanisms remain unclear. It is essential to carry out methodical investigation and research.

Based on this, in this study, the new CoCrFeNiMnTix (x = 0, 0.2, 0.4, 0.6, 0.8) HEA was designed, and prepared on 45 steel substrates by using the pre-placed powder laser cladding process. The influence of Ti addition on the microstructure, friction resistance and corrosion properties of CoCrFeNiMnTix coatings were investigated systematically. Our objective is to produce HEA coatings and enhance the 45 steel’s resilience to corrosion and surface wear, hence increasing the material’s use in a variety of technical applications.

2. Materials and Procedures

2.1. Experiment Materials

The 45 steel with dimensions of 110 mm × 110 mm × 10 mm was chosen as an instance of the substrate. The substrate sample surface was prepared by sandblasting to remove rust and impurities, followed by polishing with 200#, 400#, 600#, 800#, and 1000# grit sandpaper to achieve a smooth surface. Subsequently, the surface was wiped clean with anhydrous ethanol and air-dried for further processing. CoCrFeNiMn alloy powder (purity 99.9%, particle size 250 mesh) and pure Ti powder (purity 99.9%, particle size 250 mesh) were mixed according to the molar ratios using a planetary ball mill to ensure uniform blending. The powder ratios are listed in Table 1.

Table 1.

Element ratio of CoCrFeNiMnTix HEA (at.%).

2.2. Experiment Method

The mixed powder of CoCrFeNiMnTix was prepared into a paste-like consistency by using a 5% polyvinyl alcohol solution. The paste mixed alloy powder was preplaced onto the surface of the substrate by using a 1 mm thick acrylic template. Then, the substrate samples with preplaced powder were dried at 60 °C for 24 h in preparation for laser cladding. The laser cladding process was carried out using a laser cladding system with the model of RFL—4000 manufactured by Raycus of China (Wuhan Raycus Fiber Laser Technologies Co., Ltd., Wuhan, China). The optimal laser cladding process parameters for the CoCrFeNiMnTix coating were determined based on the macroscopic quality of the cladding coating surface. The specific process parameters of laser cladding are listed in Table 2. After laser cladding, single and multi-pass cladding samples were cut into different sizes using an electrical discharge wire cutting machine (Model of EDM 450, Suzhou Baoma Numerical Control Equipment Co., Ltd., Suzhou, China) for various performance tests and characterizations. Then, the main tests and characterization were as follows:

Table 2.

Process parameters of laser cladding.

(1) The samples were ground using sandpaper, grinding started at 180#, and then proceeded at 400#, 800#, and 2000# sandpaper. Then they were polished using a 0.5 µm aluminum oxide suspension, and then etched by a 4% hydrofluoric acid solution. Then the microstructure of sample was observed by SEM (SEM, Model of SEM3200, CIQTEK Co., Ltd., Hefei, China), and composition analysis was performed using the energy spectrometer of Oxford Explorer 30 (Oxford Instruments, Oxford, UK).

(2) The phase of the HEA cladding coating was checked with an X-ray diffractometer produced by Bruker in the Oberkochen, Germany.

(3) Microhardness of the cladding coating was measured using the HXS-1000AY Vickers hardness tester (Shanghai Haowei Optoelectronics Technology Co., Shanghai, China). Ten seconds was the holding time, and the load weighed 0.2 kg. Measurements were taken at intervals of 0.1 mm. Four sets of measurement data were collected in the same direction of each sample, and the mean value of each set was calculated as the final values of corresponding sample’s microhardness.

(4) The GF-I reciprocating friction and wear tester, made by Lanzhou Zhongke Kaihua Technology Development Co., Ltd. (Lanzhou, China), was used to perform the friction and wear tests on the cladding coating. In this experiment, the friction pair was the 4 mm-diameter GCr15 steel ball, which was offered by Lanzhou Zhongke Kaihua Technology Development Co., Ltd. (Lanzhou, China). 100 mm/s was the sliding line speed, and 5 N was the test load.

(5) Electrochemical corrosion experiments were performed using the RST5000 electrochemical workstation made by Zhengzhou Shiruisi Instrument Technology Co., Ltd. (Zhengzhou, China). The non-test surface of the sample was uniformly coated with silicone gel to insulate it, leaving an exposed area of approximately 0.785 cm2 of cladding coating for testing. After being submerged in a 3.5 weight percent NaCl solution for an hour, the prepared samples were connected via copper wires to the electrochemical workstation’s working electrode. The scan rate was set to 5 × 10−4 V/s, the sampling interval was 1 × 10−4 V, and the rest time was 10 s. After immersing the various samples in a 3.5 weight percent NaCl solution for 72 h, the corrosion mechanism was examined.

3. Results and Discussion

3.1. Cladding Coating Morphology Analysis

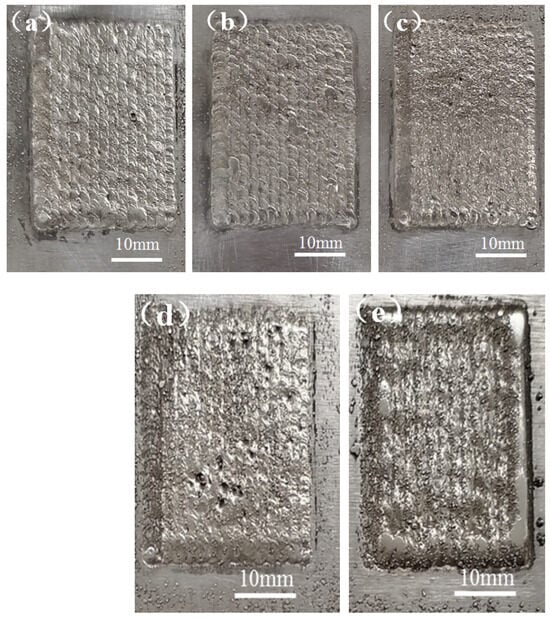

Figure 1 illustrates the macroscopic morphology of the multi-pass laser-cladded CoCrFeNiMnTix HEA coating. From the Figure 1, it is evident that the morphology of the alloy cladding coating without added Ti content appears comparatively bright and smooth, exhibiting better formability. However, with an increase in the Ti content, the formability of the cladding coating gradually deteriorates. The result is in accordance with Zuo et al. [33]. According to the authors of [33], the addition of Ti content leads to an increase in the contact angle between the CoCrFeNiMnTix high-entropy coating with the substrate. Consequently, as the Ti content increases, the wettability between the cladding coating with the substrate and both the substrate and adjacent cladding coatings diminishes. The increase in surface tension results in the formation of more ripples and unevenness on the cladding coating surface, leading to an overall decrease in formability.

Figure 1.

Surface morphology of CoCrFeNiMnTix HEA cladding coating: (a) x = 0; (b) x = 0.2; (c) x = 0.4; (d) x = 0.6; (e) x = 0.8.

3.2. Phase Analysis

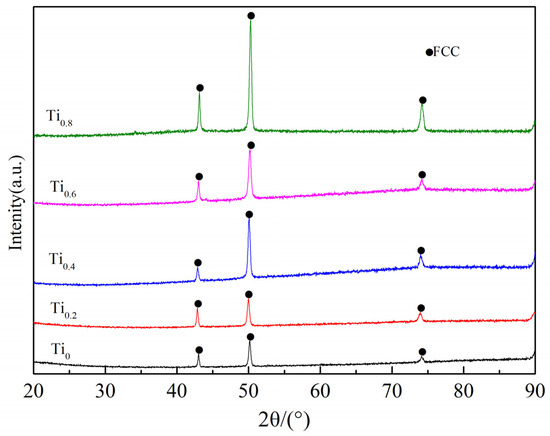

Figure 2 illustrates the XRD patterns of the CoCrFeNiMnTix (x = 0, 0.2, 0.4, 0.6, 0.8) HEA cladding coating. Notably, in the absence of Ti element, the phase composition of the CoCrFeNiMn cladding coating primarily comprises a single face-centered cubic (FCC) solid solution phase. The composition phase of the cladding coating still consists of a single FCC solid solution phase even after the Ti components are added and the Ti content is increased. The position of the FCC phase diffraction peaks in the cladding coating basically remains unchanged, but the intensity of the diffraction peaks gradually increases. This is because there are more constituent elements in the CoCrFeNiMnTix HEA, and the close atomic percentage of each element makes the mixing entropy in the system high, which promotes the generation of random disordered solid solution phases with a simple and stable structure. This result is in accordance with Wang et al. [34]. Meanwhile, it may be concluded that an increase in Ti content further promotes the formation of the FCC solid solution phase.

Figure 2.

X-ray diffraction pattern of CoCrFeNiMnTix HEA coating.

3.3. Microstructural Morphology and Structural Analysis

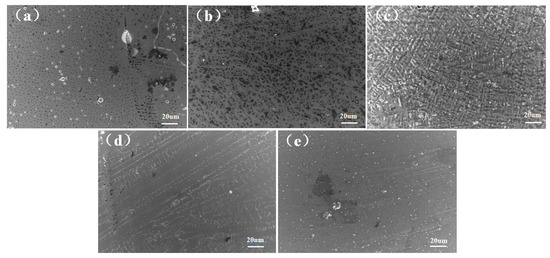

Figure 3 shows the microstructural morphology of the CoCrFeNiMnTix HEA coating. It can be seen from the Figure 3a–e that the grain structures of all CoCrFeNiMnTix cladding coatings are mostly dendrites and equiaxed crystals, and the amount of equiaxed crystal increases with the increase in Ti content. The rationale behind this phenomenon can be attributed to two primary factors. Firstly, laser cladding, characterized by its energy concentration and rapid cooling rate, facilitates swift crystallization of crystals, thereby exerting a moderating influence on the anisotropic growth of crystals. Secondly, the higher melting point of Ti element relative to other elements within the alloy system plays a pivotal role. As Ti content escalates, the alloy system’s capacity for heat absorption is augmented, subsequently amplifying the alloy’s solidification rate and refining the grain size. There are some small pores in the coating Figure 3a. This is primarily because the laser cladding technology’s quick heating and cooling cycles lead to inadequate dispersion during the solidification process. As a result, as the molten pool solidifies, fewer pores are created and a tiny amount of gas is prevented from escaping [35].

Figure 3.

Microstructure and morphology of CoCrFeNiMnTix HEA cladding coating (500×): (a) x = 0; (b) x = 0.2; (c) x = 0.4; (d) x = 0.6; (e) x = 0.8.

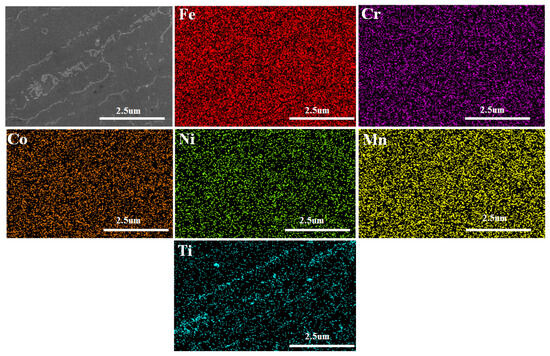

Figure 4 depicts the energy spectrum of the CoCrFeNiMnTi0.6 HEA cladding coating. Analysis of the graph reveals a relatively homogeneous distribution of each alloy element within the coating. Notably, the incorporation of Ti element exhibits uniform dispersion throughout the entirety of the cladding coating. It shows that the process of adding Ti element to the alloy system is feasible and can ensure the consistency of the whole performance of cladding coating.

Figure 4.

EDS mapping images of the CoCrFeNiMnTi0.6 HEA cladding layer (2000×).

3.4. Microhardness Analysis

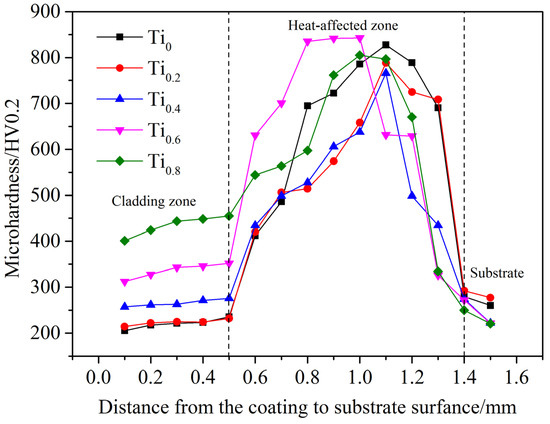

Figure 5 illustrates the microhardness distribution curves of laser-cladded CoCrFeNiMnTix HEA cladding coating with different Ti contents. Along the depth profile from top to bottom of cladding coating, the coating delineates into distinct zones: the cladding zone, the heat-affected zone, and the substrate. As can be seen from the Figure 5, with the increases in Ti content, the hardness of the cladding coating gradually increases, and the hardness of the cladding zone is greater than that of the substrate, the hardness of the heat-affected zone is greater than that of the cladding zone. With increasing Ti content, the average hardness value of the cladding zone ascends from 230.46 HV to 453.38 HV, reaching a peak of 823 HV in the heat-affected zone. This phenomenon primarily arises from two factors according to the previous microstructure and energy spectrum analysis. On the one hand, the evident grain refinement effect within the cladding coating as Ti content rises, synergizing with the inherent benefits of laser cladding itself, thus accentuate the refinement strengthening effect. On the other hand, the atomic radii of Co, Cr, Fe, Ni, Mn, and Ti are 125 pm, 124 pm, 124 pm, 121 pm, 124 pm, and 145 pm, respectively, the largest atomic radius of Ti element in contrast to other alloy element constituents accentuates lattice effects, bolstering solid solution strengthening and consequently enhancing the microhardness of the cladding coating. This result is accordance with Liang et al. [36], who used laser cladding to manufacture the CoCrFeNiMoTix coatings and discovered that when the Ti concentration hits 0.75 at.%, the coating’s average hardness peaks at 950 HV.

Figure 5.

Microhardness of CoCrFeNiMnTix HEA cladding coating.

3.5. Friction and Wear Performance

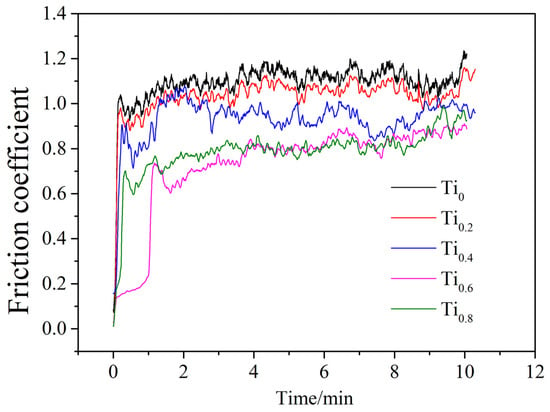

Figure 6 illustrates the friction coefficient curves of the CoCrFeNiMnTix HEA cladding coating. It is evident that during the initial phase of the friction test, all cladding coatings with different Ti contents undergo a running-in stage before gradually stabilizing over time. The friction coefficient curve of each sample has a sawtooth fluctuation, which is mainly due to the periodic accumulation and elimination of abrasive chips. After reaching the stable stage, the average friction coefficients of the coatings with Ti contents ranging from x = 0 to x = 0.8 are 1.123, 1.062, 0.941, 0.835, and 0.828, respectively. This shows that the average friction coefficient of the coating decreases with the increase in Ti content, and the wear resistance of the coating is significantly improved with the addition of Ti element. The friction coefficients at x = 0.6 and x = 0.8 are approximate, indicating that with the increase in Ti elements, the wear resistance of the coating approaches its limit.

Figure 6.

Friction coefficient curve of CoCrFeNiMnTix HEA cladding coating.

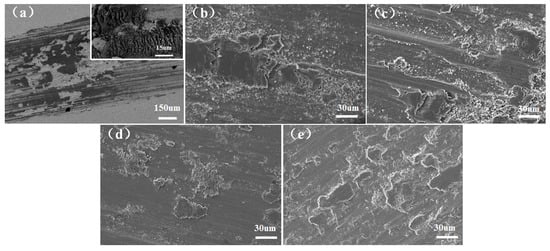

Figure 7 illustrates the wear morphology of laser-cladded CoCrFeNiMnTix HEA coatings. From the diagram, it is clear that abrasive and adhesive wear are the two main wear processes. At x = 0, the worn surface of the coating exhibits plow-shaped wear accompanied by partial pits. Upon magnification, numerous plow furrows are observed within the pits [Figure 7a]. This phenomenon primarily arises from the relatively low hardness of the coating, resulting in the formation of plow furrows on the surface due to the reciprocating sliding action of the steel balls against the coating. As the Ti content increases from x = 0.2 to x = 0.8, the number of pits and plow furrows on the worn surface of the coating decreases. However, abrasive wear and adhesive wear remain predominant, accompanied by the presence of peeled debris. Under the frictional heat generated during operation, these peeled debris adhere to the worn surface of the coating, acting as abrasives that continuously micro-cut the coating surface, leading to fluctuations in the friction coefficient. With the increases in Ti content, the hardness of the coating increases, resulting in smaller peeled debris and a weakening of the micro-cutting action of the abrasives on the coating surface, consequently reducing the friction coefficient. This result is in accordance with ref. [36] and ref. [37]. The wear scars on CoCrFeNiMoTix cladding samples consistently show an initial drop followed by a subsequent pattern as the Ti content increases. The wear scars on CoCrFeNiMoTi0.75 coating, on the other hand, are the lowest and most wear resistant [36]. Ti increases the FeCoCrNiAlTix coating’s resistance to wear; in the wear test, the grooves disappear and there is less debris on the coating surface as the concentration of Ti rises [37].

Figure 7.

Worn morphologies of CoCrFeNiMnTix HEA cladding coating: (a) x = 0; (b) x = 0.2; (c) x = 0.4; (d) x = 0.6; (e) x = 0.8.

3.6. Corrosion Resistance Analysis

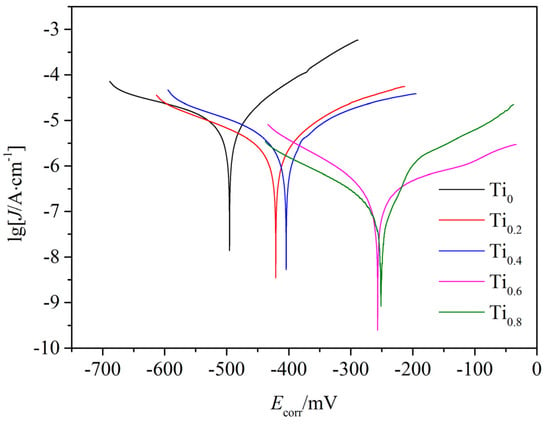

Figure 8 presents the potentiodynamic polarization curves of the CoCrFeNiMnTix HEA cladding coating in a 3.5 wt.% NaCl solution. By fitting the curves, the corrosion potentials and corrosion current densities of all cladding alloy samples are determined (Table 3). According to electrochemical corrosion principles, the corrosion potential and corrosion current density represent the corrosion tendency and corrosion rate of the alloy, respectively. Because the alloy material is less likely to experience corrosion reactions, a higher corrosion potential and a lower corrosion current density indicate greater resistance to corrosion. Titanium element exhibits excellent corrosion resistance, as its generated oxide film can protect the material surface from further oxidation. Therefore, with an increase in Ti content in cladding coating, the corrosion potential of the CoCrFeNiMnTix HEA cladding coatings gradually increases from −495 mV to −251 mV, and the corresponding corrosion current density gradually decreases. Particularly, at Ti molar ratios of x = 0.6 and 0.8, compared to x = 0, 0.2, and 0.4, the CoCrFeNiMnTix HEA coatings exhibit a reduction in corrosion current density of an order of magnitude. This indicates that the addition of Ti element in the cladding coating significantly improves the corrosion resistance of the CoCrFeNiMn alloy system.

Figure 8.

Potential polarization curve of CoCrFeNiMnTix HEA cladding coating.

Table 3.

Electrochemical parameters of CoCrFeNiMnTix HEA cladding coating.

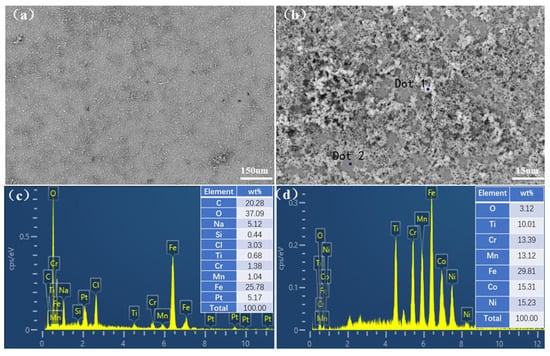

Figure 9, Figure 10 and Figure 11 show the corrosion morphology of the samples immersed in a 3.5 wt.% NaCl solution for 72 h. Chromium (Cr) elements in the high-entropy coating form an oxide layer to protect the substrate. This protective film is a thin and relatively porous metal oxide compound [38,39]. During prolonged immersion, chloride ions (Cl−) gradually permeate the alloy surface and interact with the metal, causing the alloy to dissolve. The Cl− migrates concurrently along the passive film’s grain boundaries. During this migration, it locally dissolves and thins the surface passive film up until it reaches the passive film/metal interface. This can result in cracking or detachment of the passive film, leading to the dissolution of the metal. Consequently, after prolonged immersion, Figure 9 indicates that the surface of sample (x = 0) is completely corroded, with obvious corrosion products. It is hypothesized that iron oxide (Fe2O3) and iron hydroxide (Fe(OH)3) make up the corrosion products when combined with the EDS data displayed in Figure 9c. The presence of residual Cr elements in the EDS results is attributed to residual Cr-containing passive film, as indicated by Kocks U. F.’s research [40]. Additionally, the presence of Cl elements in the EDS results, combined with analysis from ref. [41], suggests that as the passive film thins, Cl− migration through defects accelerates, with some Cl− preferentially reaching the alloy surface through membrane defects and reacting with the metal to form chlorine-containing particles. Stress is created between the metal and the passive film as these particles expand. Due to the weaker binding strength between passive film grains compared to the bond strength between metal atoms, passive film peels off. Many black corrosion pits are visible in Figure 9b, indicating pitting corrosion. It can be inferred that chloride ions (Cl−) penetrate longitudinally into the corrosion after damaging the surface oxide protective layer. The EDS results in Figure 9d indicate that some areas are not covered by corrosion products, revealing exposed high-entropy coatings.

Figure 9.

Corrosion morphology and EDS results of CoCrFeNiMnTi0 HEA cladding coating: (a) 100×; (b) 1000×; (c) EDS result of Dot1; (d) EDS result of Dot2.

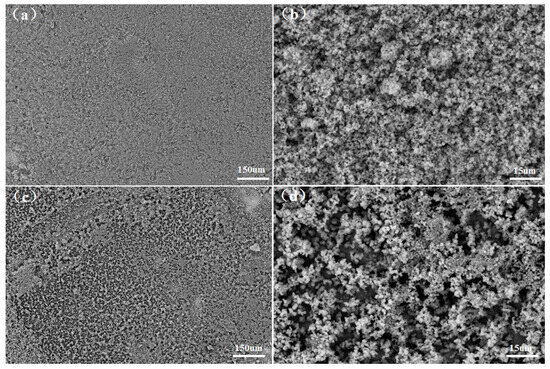

Figure 10.

Corrosion morphology and EDS results of CoCrFeNiMnTix HEA cladding coating: (a) x = 0.2, 100×; (b) x = 0.2, 1000×; (c) x = 0.4, 100× and (d) x = 0.4, 1000×.

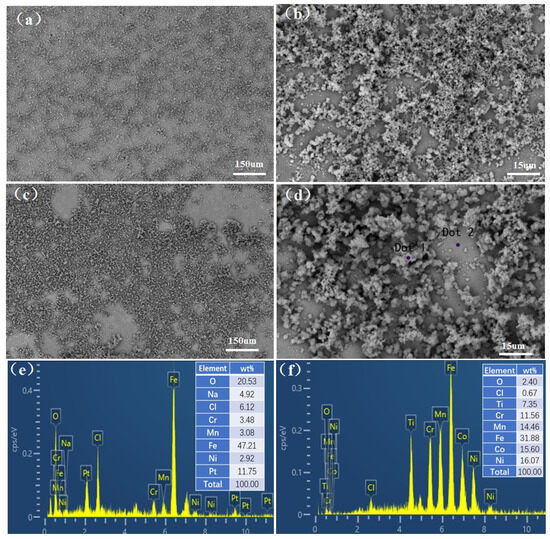

Figure 11.

Corrosion morphology and EDS results of CoCrFeNiMnTix HEA cladding coating: (a) x = 0.6, 100×; (b) x = 0.6, 1000×; (c) x = 0.6, 100×; (d) x = 0.6, 1000×; (e) EDS result of Dot1; (f) EDS result of Dot2.

Figure 10 illustrates that the corrosion products reduce with the addition of Ti content. This phenomenon arises due to the formation of compounds such as titanium dioxide (TiO2) facilitated by titanium, which subsequently yields a protective corrosion-resistant oxide layer. This oxide layer acts as a barrier to external media, slowing down the corrosion process. Notably, in samples with x = 0.2 and x = 0.4, the corrosion product layers appear relatively dense. The corrosion product layer is not uniform, indicating different corrosion rates across different regions, resulting in variations in the thickness of the corrosion product layers. It is inferred that during the corrosion process, corrosion products precipitate along grain boundaries, and the main corrosion mechanism is intergranular corrosion.

Figure 11a,b clearly depict that with further increases in Ti content, the corrosion layer in sample x = 0.6 appears incomplete, with some regions devoid of accumulated corrosion products. This phenomenon becomes more pronounced in sample x = 0.8. EDS analysis results indicate that Dot 1 represents the corrosion product layer, while Dot 2 represents the exposed high-entropy coating without apparent oxides. Combining this with electrochemical data analysis, the heightened corrosion resistance of the coating due to the addition of Ti elements is evident. This results in a reduced corrosion rate, accompanied by diminished corrosion product formation and thinner, more porous corrosion product layers. During experimental procedures, such corrosion product layers are highly susceptible to detachment. Notably, there are no apparent pitting corrosion signs in samples x = 0.6 and x = 0.8.

4. Conclusions

This study focuses on the preparation of novel CoCrFeNiMnTix HEA coatings on 45 steel using laser cladding. The investigation primarily examines the microstructure, hardness, wear resistance and corrosion resistance of these coating.

(1) The CoCrFeNiMnTix HEA cladding coating primarily consists of a face-centered cubic solid solution. Its microstructure mainly comprises dendritic and equiaxed grains, with an increase in equiaxed grain quantity as the Ti content rises. The added Ti element is uniformly distributed within the cladding coating.

(2) The hardness of the cladding coating gradually increases with the increase in Ti content, reaching a peak hardness of 823 HV at x = 0.8. The wear resistance of the cladding coating improves progressively with the Ti content increment, resulting in a gradual reduction in friction coefficient. Notably, at x = 0.6 and 0.8, the friction coefficients are relatively close, with the lowest average friction coefficient being 0.828.

(3) The predominant forms of wear in the cladding coating are adhesive and abrasive wear. When Ti content is low, the worn surface exhibits noticeable pits and furrows. However, as the Ti content increases, the occurrence of pits and furrows decreases, along with a reduction in the amount of detached debris.

(4) With an increase in Ti content in cladding coating, the corrosion potential of the CoCrFeNiMnTix HEA cladding coating gradually rises, while the current density gradually decreases, indicating a progressive enhancement in corrosion resistance.

Author Contributions

Conceptualization, S.M. and L.L.; methodology, S.M.; software, S.M. and C.Z.; validation, S.M., L.L. and C.Z.; formal analysis, L.L. and C.Z.; investigation, S.M. and C.Z.; Data curation, S.M. and C.Z.; writing—original draft preparation, S.M.; writing—review and editing, C.Z., L.L. and Y.Y.; visualization, S.M. and C.Z.; supervision, S.M.; project administration, S.M.; funding acquisition, S.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Key Research Project of Henan Province Department of Education (No. 22B460019).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jiang, W.; Zhang, C.Y.; Gu, Q.M.; Xu, K.; Zhu, H.; Cao, Z.H. Tribological properties of micro-pit texture generated by composite processing. Lubr. Eng. 2019, 44, 85–89. [Google Scholar]

- Liu, Q.S.; Liu, X.B.; Wang, G.; Liu, Y.F.; Meng, Y.; Zhang, S.H. Effect of Cu content on microstructure evolution and tribological behaviors of Ni60 composite coatings on 45# steel by laser cladding. Opt. Laser Technol. 2022, 156, 108549. [Google Scholar]

- Huang, G.K.; Qu, L.D.; Lu, Y.Z.; Wang, Y.Z.; Li, H.G. Corrosion resistance improvement of 45 steel by Fe-based amorphous coating. Vacuum 2018, 153, 39–42. [Google Scholar] [CrossRef]

- Liu, H.X.; Wang, C.Q.; Zhang, X.W.; Jiang, Y.H.; Cai, C.X.; Tang, S.J. Improving the corrosion resistance and mechanical property of 45 steel surface by laser cladding with Ni60CuMoW alloy powder. Surf. Coat. Technol. 2013, 228, S296–S300. [Google Scholar] [CrossRef]

- Chong, Z.Z.; Sun, Y.N.; Cheng, W.J.; Han, C.Y.; Huang, L.F.; Su, C.J. Enhanced wear and corrosion resistances of AlCoCrFeNi high-entropy alloy coatings via high-speed laser cladding. Mater. Today Commun. 2022, 33, 104417. [Google Scholar] [CrossRef]

- Ma, S.B.; Xia, Z.W.; Xu, Y.; Shi, H.R.; Wang, X.; Zheng, Y. Microstructure and abrasion resistance of In-situ TiC particles reinforced Ni-based composite coating by laser cladding. J. Mater. Eng. 2017, 45, 24–30. [Google Scholar]

- Li, Y.F.; Shi, Y. Effect of WC on microstructure, wear resistance and impact resistance of laser cladding layer. China Surf. Eng. 2021, 34, 104–113. [Google Scholar]

- Liu, H.F.; Su, H.J.; Shen, Z.L.; Zhao, D.; Liu, Y.; Guo, Y.N.; Guo, H.T.; Guo, M.; Xie, K.Y.; Zhang, J.; et al. One-step additive manufacturing and microstructure evolution of melt-grown Al2O3/GdAlO3/ZrO2 eutectic ceramics by laser directed energy deposition. J. Eur. Ceram. Soc. 2021, 41, 3547–3558. [Google Scholar] [CrossRef]

- Ning, J.S.; Lan, Q.; Zhu, L.D.; Xu, L.; Yang, Z.C.; Xu, P.H. Microstructure and mechanical properties of SiC-reinforced Inconel 718 composites fabricated by laser cladding. Surf. Coat. Technol. 2023, 463, 129514. [Google Scholar] [CrossRef]

- Yeh, J.W. High-entropy alloys: Overview. Encycl. Mater. Met. Alloys 2022, 2, 294–307. [Google Scholar]

- Han, C.Y.; Sun, Y.N.; Xu, Y.F.; Zhang, R.H.; Zhao, F.; Chen, L.N. Wear and corrosion properties of nano-TiC reinforced AlCoCrFeNi high entropy alloy prepared by laser cladding. Rare Met. Mater. Eng. 2022, 51, 607–614. [Google Scholar]

- Shen, Q.K.; Kong, X.D.; Chen, X.Z. Fabrication of bulk Al-Co-Cr-Fe-Ni high-entropy alloy using combined cable wire arc additive manufacturing (CCW-AAM): Microstructure and mechanical properties. J. Mater. Sci. Technol. 2021, 74, 136–142. [Google Scholar] [CrossRef]

- Zia, U.A.; Muhammad, Y.K.; Ehtsham, U.R.; Sibghat, U.; Muhammad, A.; Ali, T. A review on laser cladding of high-entropy alloys, their recent trends and potential applications. J. Manuf. Process. 2021, 68, 225–273. [Google Scholar]

- Jyoti, M.; Akash, V.; Pringal, P.; Harshad, N.; Satish, M. Wear, erosion and corrosion behavior of laser cladded high entropy alloy coatings—A review. Mater. Today Proc. 2021, 38, 2824–2829. [Google Scholar]

- Li, Y.Z.; Shi, Y. Microhardness, wear resistance, and corrosion resistance of AlxCrFeCoNiCu high-entropy alloy coatings on aluminum by laser cladding. Opt. Laser Technol. 2021, 134, 106632. [Google Scholar] [CrossRef]

- Cui, Y.; Shen, J.Q.; Sunusi, M.M.; Keping, G.; Hu, S.S. Wear resistance of FeCoCrNiMnAlx high-entropy alloy coatings at high temperature. Appl. Surf. Sci. 2020, 512, 145736. [Google Scholar] [CrossRef]

- Rakesh, B.N.; Sean, N.; Andre, M. Dry abrasive wear and solid particle erosion assessments of high entropy alloy coatings fabricated by cold spraying. Mater. Today Commun. 2023, 34, 105527. [Google Scholar]

- Yang, J.J.; Wang, C.L.; Zhang, L.C.; Wang, Z.J.; Liang, M.L.; Liu, C.; Liu, W.J.; Li, X.; Zhou, S.F.; Tan, H. Microstructure evolution and properties of Fe-Ni-Cr-Co-Mo-W high-entropy alloy coatings by plasma surface alloying technology. Surf. Coat. Technol. 2023, 467, 129732. [Google Scholar] [CrossRef]

- Jiang, M.M.; Sun, S.F.; Wang, J.; Wang, P.P.; Sun, X.Y.; Shao, J. Research progress in wear resistance of high entropy alloy coating prepared by laser cladding. J. Mater. Eng. 2022, 50, 18–32. [Google Scholar]

- Li, Z.; Morteza, T.; Pouria, T.; Isa, H.; Mohammad, J.T. Laser cladding of NiCrCoFeNbMox high-entropy alloy to increase resistance to corrosion of gas turbine blades. Vacuum 2024, 219, 112749. [Google Scholar] [CrossRef]

- Ma, S.B.; Su, B.B.; Wang, X.; Xia, Z.W.; Liu, J.; Xu, Y. Wear resistance of SiC/Ni composite coating based on laser cladding. J. Mater. Eng. 2016, 44, 77–82. [Google Scholar]

- Lv, T.Y.; Zou, W.K.; He, J.Q.; Ju, X.; Zheng, C.B. Study on the microstructure and properties of FeCoNiCrAl high-entropy alloy coating prepared by laser cladding-remelting. Coatings 2024, 14, 49. [Google Scholar] [CrossRef]

- Zhang, H.L.; Li, W.J.; Xu, H.H.; Chen, H.H.; Chen, L.; Zeng, J.S.; Ding, Z.B.; Guo, W.M.; Liu, B. Microstructure and corrosion behavior of laser cladding FeCoNiCrBSi based high-entropy alloy coatings. Coatings 2022, 12, 628. [Google Scholar] [CrossRef]

- Liu, Y.F.; Chang, T.; Liu, X.B.; Zhu, Y.; Wang, G.; Meng, Y.; Liang, J.; Xie, J.C. Research progress on tribological properties of high-entropy alloy coatings. Surf. Technol. 2021, 50, 156–169. [Google Scholar]

- Zhou, Z.J.; Jiang, F.L.; Song, P.F.; Yang, F.Z.; Wang, Y.L.; Yang, Y.; Liang, P. Advances in corrosion resistance of high entropy alloy coating prepared by laser cladding. Surf. Technol. 2021, 50, 257–270. [Google Scholar]

- Liu, J.; Liu, H.; Chen, P.J.; Hao, J.B. Microstructural characterization and corrosion behaviour of AlCoCrFeNiTix high-entropy alloy coatings fabricated by laser cladding. Surf. Coat. Technol. 2019, 361, 63–74. [Google Scholar] [CrossRef]

- Chen, B.; Li, X.M.; Tian, L.Y.; Jia, H.Y.; Li, H.; Li, Y. The CrFeNbTiMox refractory hihg-entropy alloy coating prepared on the 40Cr by laser cladding. J. Alloys Compd. 2023, 966, 171630. [Google Scholar] [CrossRef]

- Caner, B.; Fatih, Y.; Temel, V.; Tevfik, O.E. Effect of titanium on the structural, mechanical and surface properties of CoCrFeMnNiTix high entropy alloy fabricated by selective laser melting. Intermetallics 2024, 169, 108281. [Google Scholar]

- Zhang, Z.K.; Hua, K.; Cao, H.; Song, Y.Q.; Li, X.L.; Zhou, Q.; Wang, H.F. Microstructures and properties of FeCrAlMoSix high entropy alloy coatings prepared by laser cladding on a titanium alloy substrate. Surf. Coat. Technol. 2024, 478, 130437. [Google Scholar] [CrossRef]

- Sun, Z.L.; Zhang, M.Y.; Wang, G.Q.; Yang, X.F.; Wang, S.R. Wear and corrosion resistance analysis of FeCoNiTiAlx high-entropy alloy coating prepared by laser cladding. Coatings 2021, 11, 155. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, Z.X.; Xu, G.J.; Chen, H.Y. Influence of Al addition on the microstructure and wear behavior of laser cladding FeCoCrNiAlx high-entropy alloy coatings. Coatings 2023, 13, 426. [Google Scholar] [CrossRef]

- Liu, H.; Gao, Q.; Gao, W.P.; Liu, X.B.; Hao, J.B.; Yang, H.F. High temperature tribological properties of CoCrFeNINbx high-entropy alloy coatings by laser cladding. Tribology 2021, 42, 1–20. [Google Scholar]

- Zuo, R.Y.; Sun, R.L.; Niu, W.; Hao, W.J.; Gu, M.; Li, X.L. Microstructure and properties of CoCrFeNiTix high entropy alloy coated by laser cladding. Surf. Technol. 2022, 51, 363–370. [Google Scholar]

- Wang, X.Y.; Liu, Q.; Ren, H.T.; Li, Z.; Xu, Q.; Huang, Y.B.; Guo, Y.M. Effects of Ti content on hardness and wear resistance of CoCrFeNiTi high-entropy alloy coatings. Surf. Technol. 2023, 52, 47–55. [Google Scholar]

- Xu, Y.K.; Li, Z.Y.; Liu, J.R.; Chen, Y.N.; Zhang, F.Y.; Wu, L.; Hao, J.M.; Liu, L. Micrstructure evolution and properties of laser cladding CoCrFeNiTiAlx high-entropy alloy coatings. Coatings 2020, 10, 373. [Google Scholar] [CrossRef]

- Liang, H.; Hou, J.X.; Jiang, L.; Cao, Z.Q. Microstructure and dry-sliding wear resistance of CoCrFeNiMoTix high entropy alloy coating produced by laser cladding. Coating 2024, 14, 221. [Google Scholar] [CrossRef]

- He, B.; Zhang, N.N.; Lin, D.Y.; Zhang, Y.; Dong, F.Y.; Li, D.Y. The phase evolution and property of FeCoCrNiAlTix high-entropy alloying coatings on Q235 laser cladding. Coatings 2017, 7, 157. [Google Scholar] [CrossRef]

- Daniela, Z.; Beate, H.; Isabella, G. Corrosion resistance of Cu-Zr-Al-Y and Zr-Cu-Ni-Al-Nb bulk metallic glasses. J. Alloys Compd. 2007, 434–435, 234–236. [Google Scholar]

- Varshney, P.; Mishra, R.S.; Kumar, N. Understanding the nature of passivation film formed during corrosion of Fe39Mn20Co20Cr15Si5Al1 high entropy alloy in 3.5 wt% NaCl solution. J. Alloys Compd. 2022, 904, 164100. [Google Scholar] [CrossRef]

- Kocks, U.F.; Meching, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Xu, Z.L.; Zhang, H.; Du, X.J.; He, Y.Z.; Luo, H.; Song, G.S.; Mao, L.; Zhou, T.W.; Wang, L.L. Corrosion resistance enhancement of CoCrFeMnNi high-entropy alloy fabricated by additive manufacturing. Corros. Sci. 2020, 177, 108954. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).