Frictional Study on 30CrNi2MoVA Steel Based on Experiments and Finite Element Simulation: Wear Prediction

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Materials and Dry Friction Test

2.1.1. Specimen

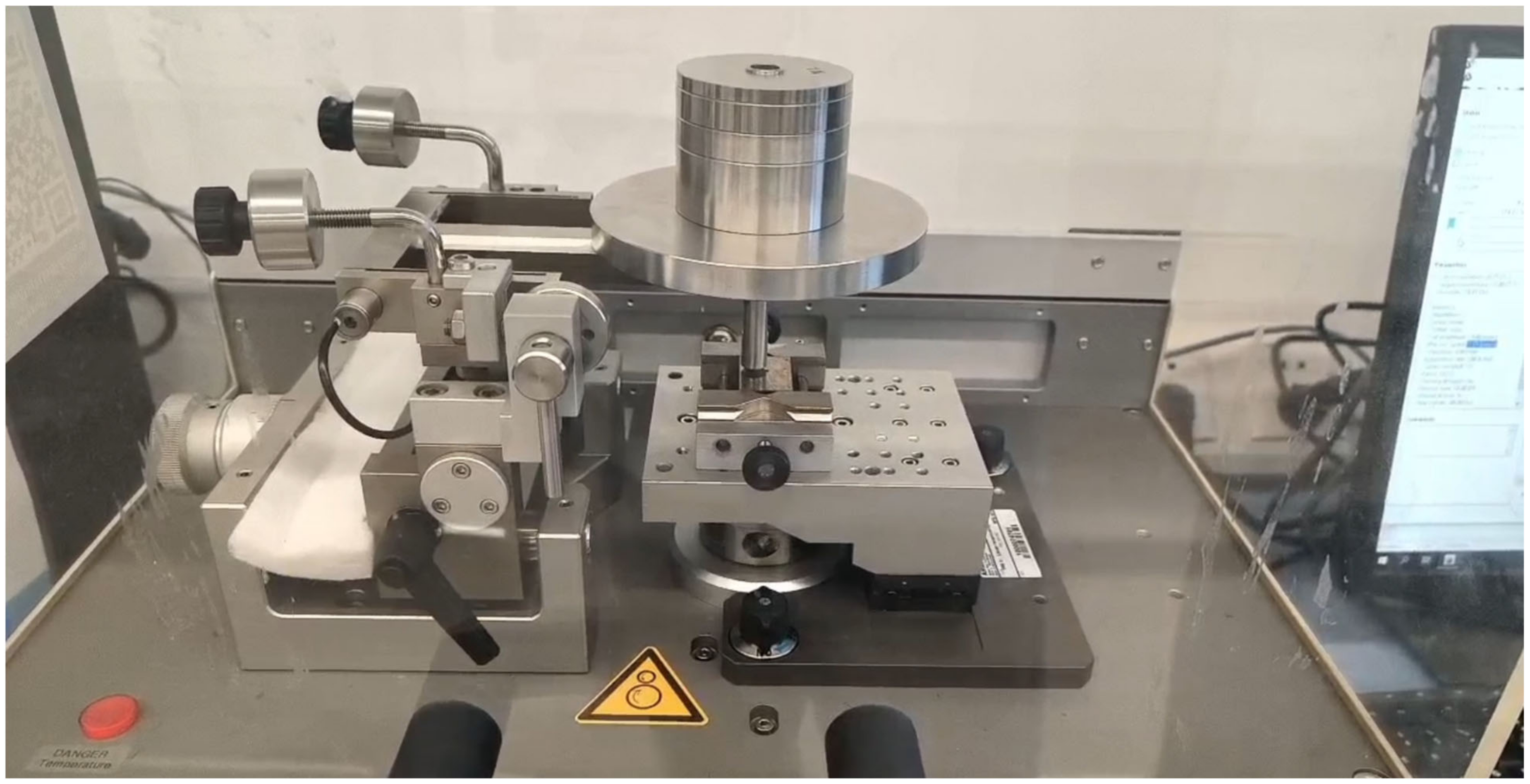

2.1.2. Dry Friction Test Equipment and Test Parameters

2.1.3. Acquisition and Characterization of Test Results

2.2. Finite Element Simulation

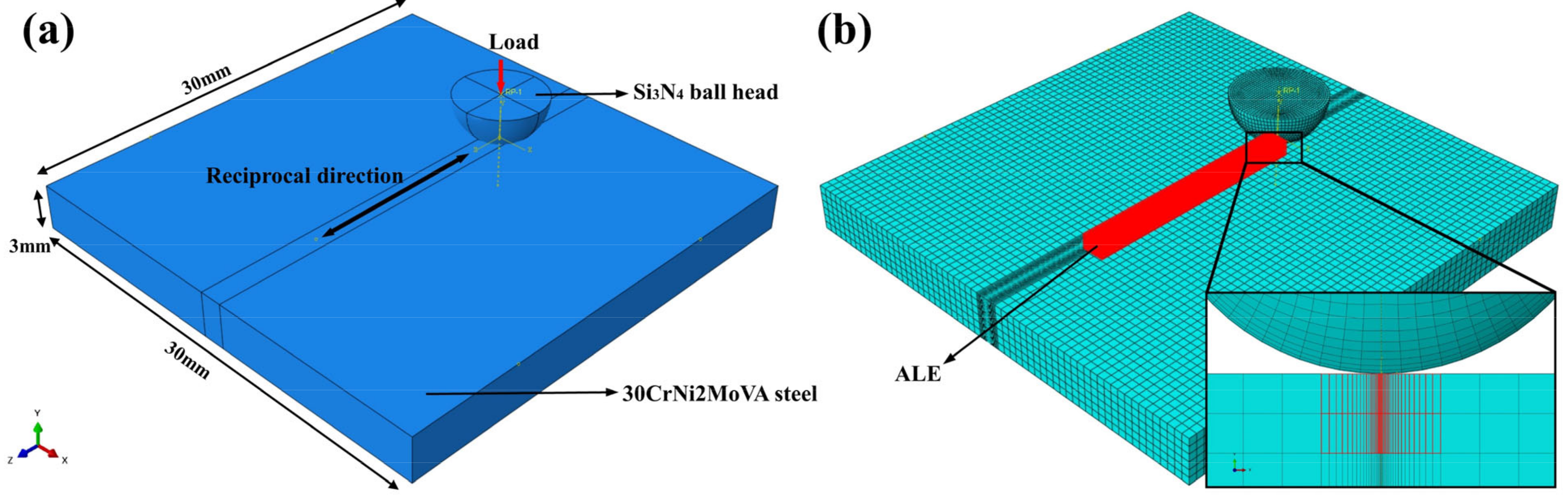

2.2.1. Finite Element Simulation Modeling

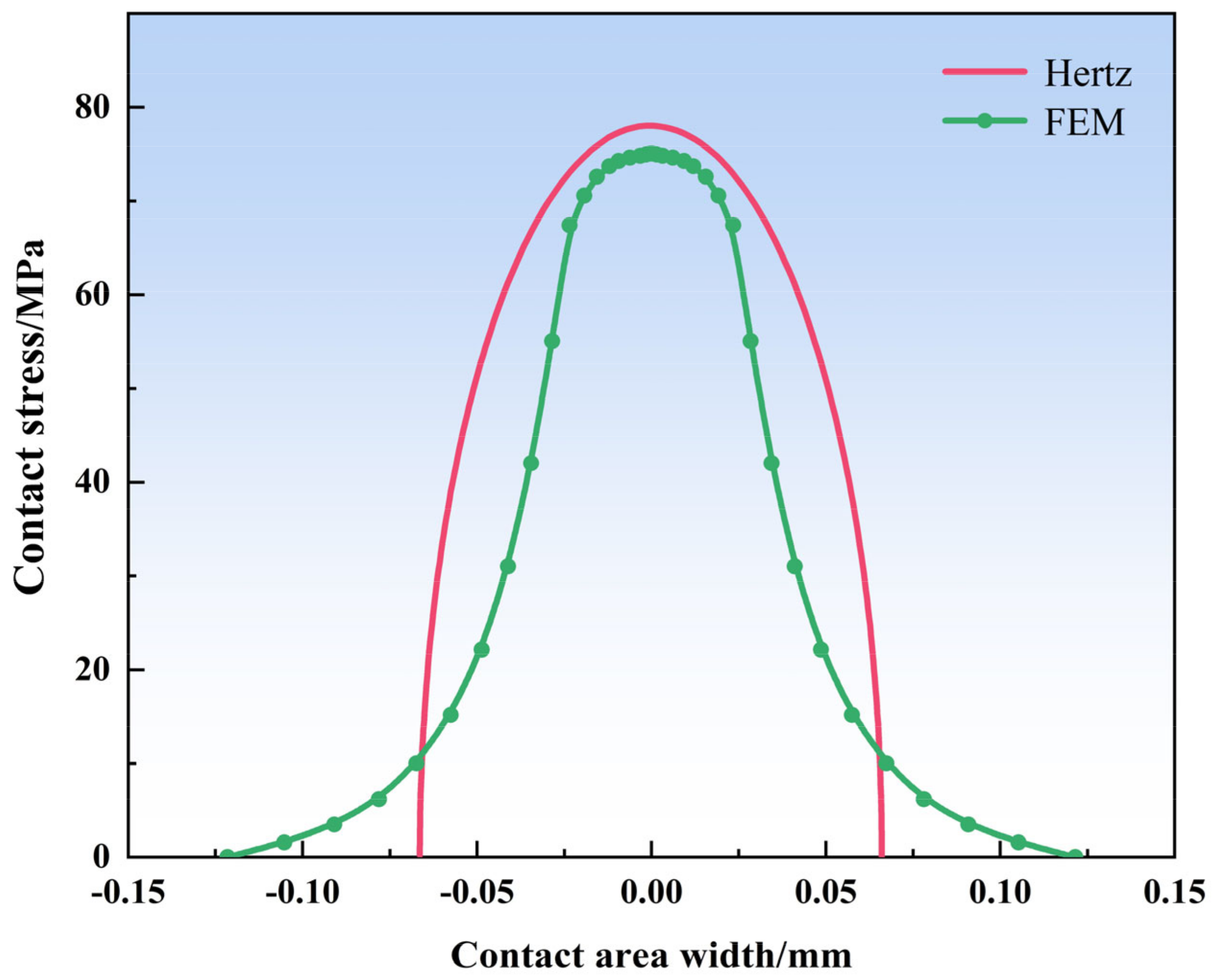

2.2.2. Verification of the Model

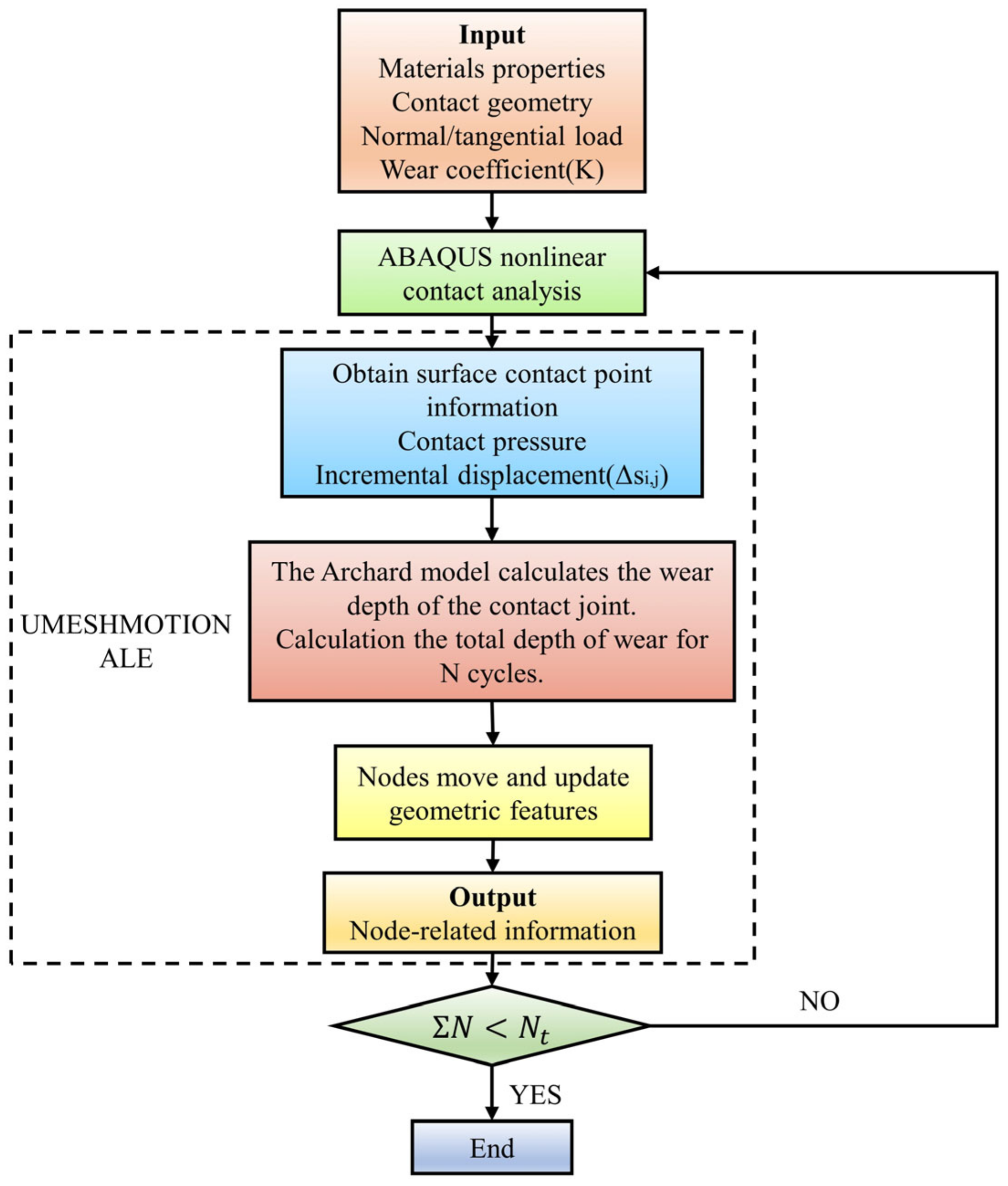

2.2.3. UMESHMOTION Subroutine and ALE Adaptive Mesh

2.2.4. Modified Archard Wear Model

3. Results and Discussion

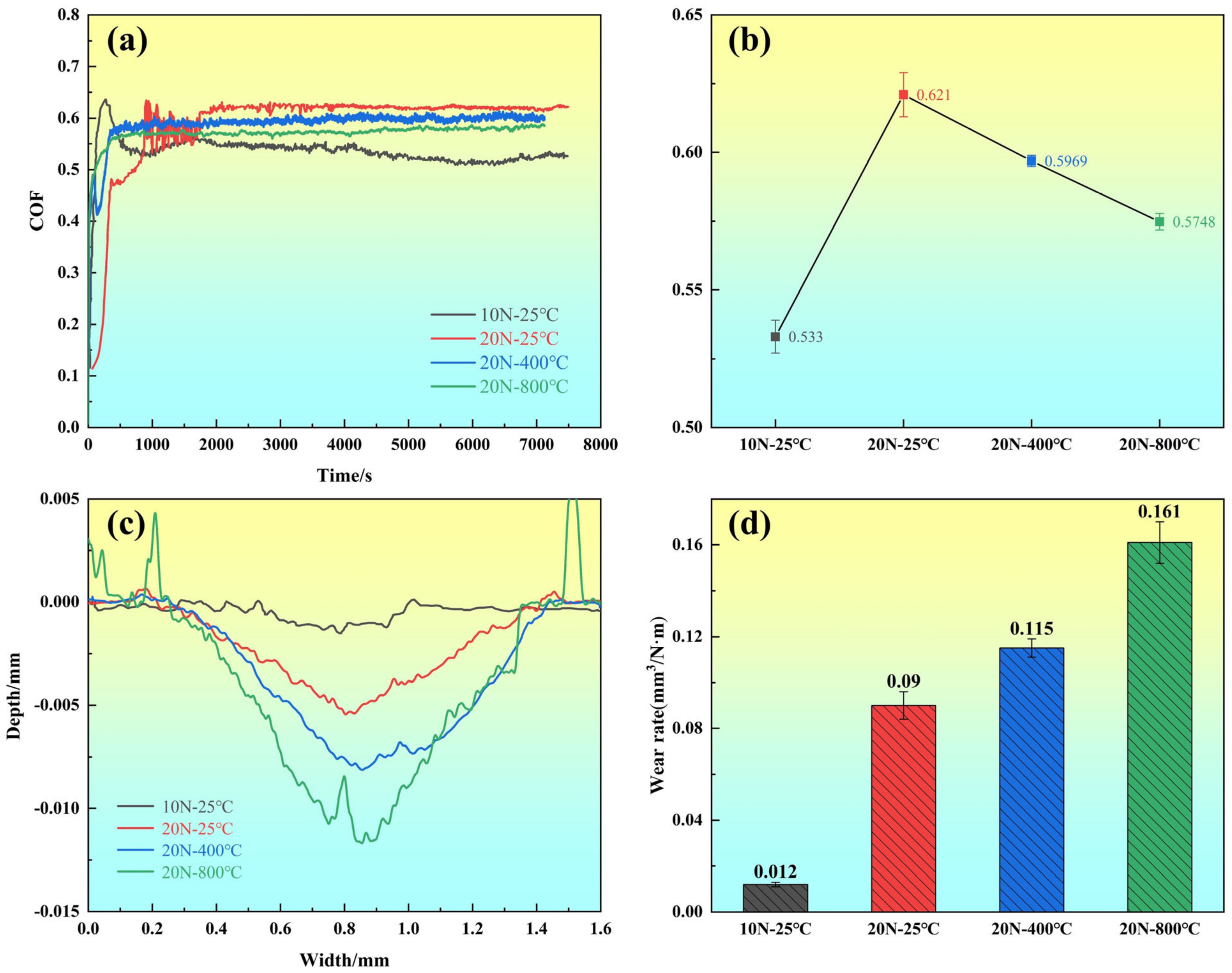

3.1. Dry Friction Characteristics

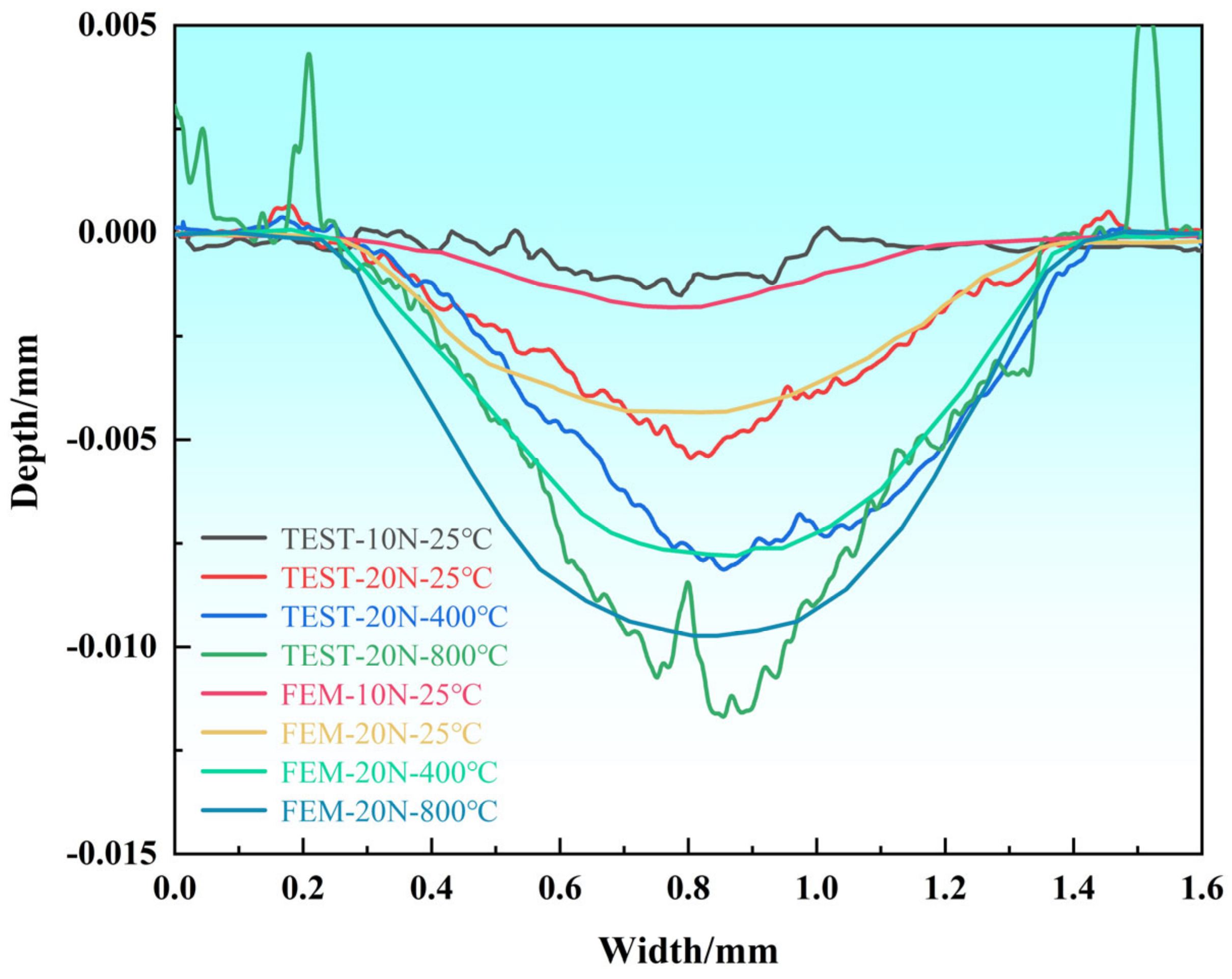

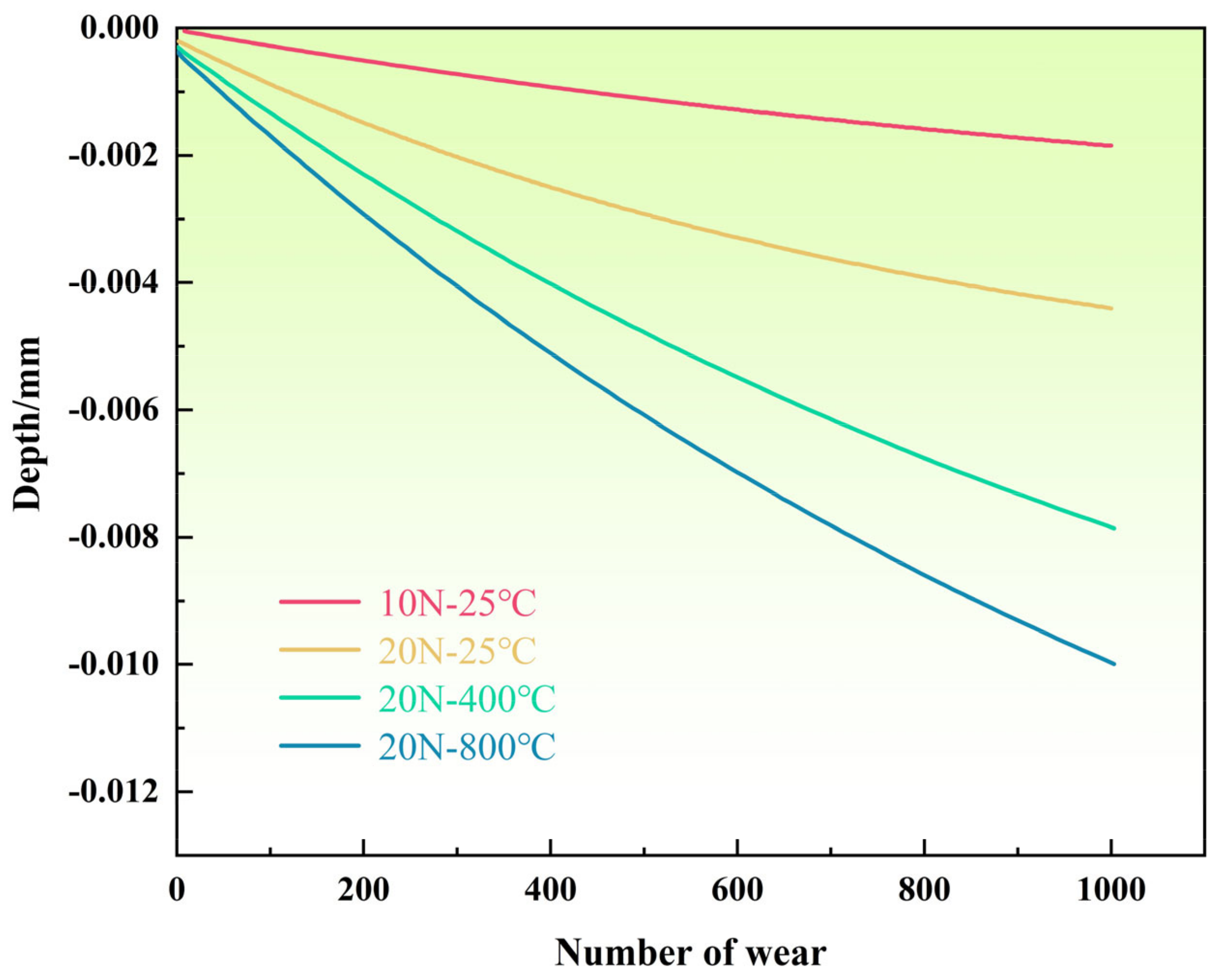

3.2. Wear Depth Simulation Prediction

4. Conclusions

- 1.

- Under dry friction conditions, an increase in load accelerates material loss, with the wear mechanism being abrasive wear. An increase in thermal cycling temperature reduces the friction coefficient but increases the wear depth, with the wear mechanisms being adhesive wear and abrasive wear. The increase in load and temperature will amplify the damage to the material.

- 2.

- Wear simulation is implemented using a modified Archard wear model, along with the UMESHMOTION subroutine in ABAQUS (version 2020) software and ALE adaptive mesh technology. A method and workflow for finite element simulation of ball–disc friction–wear are proposed.

- 3.

- A comparative study between simulated wear data and experimental wear data validates the feasibility of the simulation and provides support for predicting wear depth profiles.

- 4.

- A process function was derived from the simulation results to fit the relationship between wear depth and the number of cycles. This function can be utilized for predicting the wear depth and the resulting surface profile after wear for 30CrNi2MoVA. Wear is influenced by multiple factors, and this study also provides an approach for predicting the service life of this steel. Moreover, this research serves as a reference for more intricate models of frictional wear.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, D.; Shen, Y.; Wang, E.; Wang, H.; Liu, J.; Wang, K.; Sun, J. Improvement of the Mechanical Properties of 30CrNi2MoVA through Ultrasonic-Milling in Certain Key Components. Coatings 2023, 13, 1626. [Google Scholar] [CrossRef]

- Li, X.; Pan, C.; Fu, D.; Wang, M.; Zhang, Z.; Qu, S.; Yang, C. Fabrication of highly dissimilar TC4/steel joint with V/Cu composite transition layer by laser melting deposition. J. Alloys Compd. 2021, 862, 158319. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, S.; Li, M. Research on fatigue crack propagation process of fracturing pumphead. Eng. Fail. Anal. 2020, 116, 104726. [Google Scholar] [CrossRef]

- Wei, A.; Feng, Y.; Wu, L.; Li, Y.; Xie, Z. Corrosion wear behavior of 30CrNi2MoVA steel in simulated seawater. Mater. Lett. 2023, 349, 134750. [Google Scholar] [CrossRef]

- Liu, D.; Liu, D.; Zhang, X.; He, G.; Ma, A.; Wu, G. Plain fatigue and fretting fatigue behaviors of 17-4PH steel subjected to ultrasonic surface rolling process: A comparative study. Surf. Coat. Technol. 2020, 399, 126196. [Google Scholar] [CrossRef]

- Limmer, L.; Nowell, D.; Hills, D.A. A combined testing and modelling approach to the prediction of the fretting fatigue performance of splined shafts. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2001, 215, 105–112. [Google Scholar] [CrossRef]

- Bijwe, J.; Indumathi, J.; Rajesh, J.J.; Fahim, M. Friction and wear behavior of polyetherimide composites in various wear modes. Wear 2001, 249, 715–726. [Google Scholar] [CrossRef]

- Wei, M.X.; Chen, K.M.; Wang, S.Q.; Cui, X.H. Analysis for wear behaviors of oxidative wear. Tribol. Lett. 2011, 42, 1–7. [Google Scholar] [CrossRef]

- Huang, T.-C.; Tsai, J.-W.; Liao, K.-C. Wear and leakage assessments of canted coil Spring–Energized polytetrafluoroethylene seals under Ultra-High cycle operations. Eng. Fail. Anal. 2022, 135, 106110. [Google Scholar] [CrossRef]

- Attanasio, A.; Ceretti, E.; Rizzuti, S.; Umbrello, D.; Micari, F. 3D finite element analysis of tool wear in machining. CIRP Ann. 2008, 57, 61–64. [Google Scholar] [CrossRef]

- Xue, X.; Li, Y.; Sui, L.; Yu, W.; Lin, K.; Liu, J. Mechanism and prediction method of fretting damage in involute spline couplings of aero-engine. Eng. Fail. Anal. 2023, 148, 107200. [Google Scholar] [CrossRef]

- Donner, R.; Potirakis, S.; Balasis, G.; Eftaxias, K.; Kurths, J. Friction and wear of a piston ring/cylinder liner at the top dead centre: Experimental study and modelling. Tribol. Int. 2017, 106, 23–33. [Google Scholar] [CrossRef]

- Tang, L.; Ding, S.; Qian, H.; Xie, Y.; Huo, Y. Fretting fatigue tests and crack initiation analysis on zircaloy tube specimens. Int. J. Fatigue 2014, 63, 154–161. [Google Scholar] [CrossRef]

- Lee, R.; Jou, J. Application of numerical simulation for wear analysis of warm forging die. J. Mater. Process. Technol. 2003, 140, 43–48. [Google Scholar] [CrossRef]

- Shen, X.; Liu, Y.; Cao, L.; Chen, X. Numerical simulation of sliding wear for self-lubricating spherical plain bearings. J. Mater. Res. Technol. 2012, 1, 8–12. [Google Scholar] [CrossRef][Green Version]

- Molinari, J.; Ortiz, M.; Radovitzky, R.; Repetto, E. Finite-element modeling of dry sliding wear in metals. Eng. Comput. 2001, 18, 592–610. [Google Scholar] [CrossRef]

- Martínez-Londoño, J.C.; Martínez-Trinidad, J.; Hernández-Fernández, A.; García-León, R.A. Finite Element Analysis on AISI 316L Stainless Steel Exposed to Ball-on-Flat Dry Sliding Wear Test. Trans. Indian Inst. Met. 2023, 76, 97–106. [Google Scholar] [CrossRef]

- Xie, L.-J.; Schmidt, J.; Schmidt, C.; Biesinger, F. 2D FEM estimate of tool wear in turning operation. Wear 2005, 258, 1479–1490. [Google Scholar] [CrossRef]

- Bortoleto, E.; Rovani, A.; Seriacopi, V.; Profito, F.; Zachariadis, D.; Machado, I.; Sinatora, A.; Souza, R. Experimental and numerical analysis of dry contact in the pin on disc test. Wear 2013, 301, 19–26. [Google Scholar] [CrossRef]

- Li, C.; He, J.; Du, Y.; Xiao, W.; Wang, Z. Wear Model and Finite Element Analysis of Machine Tool Guide Based on Archard Model. J. Mech. Eng. 2016, 52, 106–113. [Google Scholar] [CrossRef]

- Bastola, A.; Stewart, D.; Dini, D. Three-dimensional finite element simulation and experimental validation of sliding wear. Wear 2022, 504, 204402. [Google Scholar] [CrossRef]

- Terashima, S. Determination of total carbon and sulfur in fifty-two geochemical reference samples by combustion and infrared absorption spectrometry. Geostand. Newsl. 1988, 12, 249–252. [Google Scholar] [CrossRef]

- Fan, W.; Gao, P. A review on erosion-reducing additive materials to extend the lifespan of gun barrels. J. Mater. Sci. 2021, 56, 19767–19790. [Google Scholar] [CrossRef]

- Susantez, C.; Caldeira, A.B. Heat Transfer Modelling and Simulation of a 120 mm Smoothbore Gun Barrel During Interior Ballistics. Def. Sci. J. 2022, 72, 30–39. [Google Scholar] [CrossRef]

- Wei, A.; Hu, J.; Li, Y.; Wang, S.; Feng, L.; Feng, Y.; Xie, Z. Friction behavior of 30CrNi2MoVA gun barrel steel after thermo-cyclic treatment: Air and simulated seawater. Eng. Fail. Anal. 2023, 157, 107948. [Google Scholar] [CrossRef]

- Lim, S.; Ashby, M.; Brunton, J. Wear-rate transitions and their relationship to wear mechanisms. Acta Metall. 1987, 35, 1343–1348. [Google Scholar] [CrossRef]

- Toupin, R.A. Saint-Venant’s principle. Arch. Ration. Mech. Anal. 1965, 18, 83–96. [Google Scholar] [CrossRef]

- Ma, L.; Eom, K.; Geringer, J.; Jun, T.-S.; Kim, K. Literature review on fretting wear and contact mechanics of tribological coatings. Coatings 2019, 9, 501. [Google Scholar] [CrossRef]

- McColl, I.R.; Ding, J.; Leen, S.B. Finite element simulation and experimental validation of fretting wear. Wear 2004, 256, 1114–1127. [Google Scholar] [CrossRef]

- Cai, M.; Zhang, P.; Xiong, Q.; Cai, Z.; Luo, S.; Gu, L.; Zeng, L. Finite element simulation of fretting wear behaviors under the ball-on-flat contact configuration. Tribol. Int. 2023, 177, 107930. [Google Scholar] [CrossRef]

- Bae, J.W.; Lee, C.Y.; Chai, Y.S. Three dimensional fretting wear analysis by finite element substructure method. Int. J. Precis. Eng. Manuf. 2009, 10, 63–69. [Google Scholar] [CrossRef]

- Wang, Y.; Pasiliao, C.L. Modeling ablation of laminated composites: A novel manual mesh moving finite element analysis procedure with ABAQUS. Int. J. Heat Mass Transf. 2018, 116, 306–313. [Google Scholar] [CrossRef]

- Jin, Y.; Zou, L.; Huang, J.; Jiang, X.; Guo, Z.; Xie, J.; Yuan, Z. Numerical research on ablation and wear of the artillery barrel based on UMESHMOTION user-defined subroutine. Eng. Rep. 2023, 5, e12575. [Google Scholar] [CrossRef]

- Zhang, C.-Z.; Shen, F.; Ke, L.-L. Electrical contact resistance endurance of AgNi10 alloys under fretting wear: Experiment and numerical prediction. Wear 2023, 530–531, 205009. [Google Scholar] [CrossRef]

- Wang, C.; Chen, J.; Xia, Z.C.; Ren, F. Die wear prediction by defining three-stage coefficient K for AHSS sheet metal forming process. Int. J. Adv. Manuf. Technol. 2013, 69, 797–803. [Google Scholar] [CrossRef]

- Donner, R.; Potirakis, S.; Balasis, G.; Eftaxias, K.; Kurths, J. Sliding wear analysis in borided AISI 316L steels. Mater. Lett. 2021, 285, 129138. [Google Scholar] [CrossRef]

- Yan, J.; Yan, Q.; Pan, J. Study on the electrochemical corrosion and surface friction-wear characteristics of GaN chips. Surf. Technol. 2023, 52, 208–222. [Google Scholar] [CrossRef]

- Li, W.; Kou, H.; Zhang, X.; Ma, J.; Li, Y.; Geng, P.; Wu, X.; Chen, L.; Fang, D. Temperature-dependent elastic modulus model for metallic bulk materials. Mech. Mater. 2019, 139, 103194. [Google Scholar] [CrossRef]

- Zheng, J.; Li, L.; Tian, L.; Fan, J. Influence of annealing temperature on fatigue damage evolution behavior of 304 stainless steel. Hot Work. Technol. 2024, 1–5. [Google Scholar] [CrossRef]

- Ding, H.; Yang, T.; Wang, W.; Zhu, Y.; Lin, Q.; Guo, J.; Xiao, Q.; Gan, L.; Liu, Q. Optimization and wear behaviors of 316L stainless steel laser cladding on rail material. Wear 2023, 523, 204830. [Google Scholar] [CrossRef]

- Shi, L.; Li, M.; Liu, Z.; Zhan, Z.; Yuan, Z.; Wang, X. Fabrication of yttria-stabilized zirconia/La2O3 composite coating by electrophoretic deposition to improve high-temperature oxidation resistance of stainless steel. Ceram. Int. 2023. [Google Scholar] [CrossRef]

- Wang, Y.-M.; Liang, Y.; Zhai, Y.-D.; Zhang, Y.-S.; Sun, H.; Liu, Z.-G.; Su, G.-Q. Study on the role of cryogenic treatment on corrosion and wear behaviors of high manganese austenitic steel. J. Mater. Res. Technol. 2023, 24, 5271–5285. [Google Scholar] [CrossRef]

- Xue, X.; Wang, S.; Yu, J.; Qin, L. Wear characteristics of the material specimen and method of predicting wear in floating spline couplings of aero-engine. Int. J. Aerosp. Eng. 2017, 2017, 1859167. [Google Scholar] [CrossRef]

- Huang, F.; He, W.; Xu, Y.; Xia, F.; Luo, X. Study on Wear of Polyurethane Bowl for Pipe Cleaner Based on Modified Archard Model. Plast. Ind. 2020, 48, 126–131. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Ni | Mo | V |

|---|---|---|---|---|---|---|

| 0.32 | 0.26 | 0.44 | 0.90 | 2.29 | 0.25 | 0.18 |

| Temp/°C | Elastic Modulus/MPa | Poisson Ratio/σ |

|---|---|---|

| 25 | 205,865.3 | 0.27 |

| 400 | 165,425.1 | 0.299 |

| 800 | 146,326.1 | 0.344 |

| Load–Temp | h0 | A0 | t |

|---|---|---|---|

| 10 N–25 °C | −0.00346 | 0.00343 | 1322.75 |

| 20 N–25 °C | −0.00616 | 0.00597 | 817.6 |

| 20 N–400 °C | −0.0144 | 0.0141 | 1306.1 |

| 20 N–800 °C | −0.0183 | 0.01794 | 1307.2 |

| Number of Wear | Load–Temp | Experiment Values | Fitting Values |

|---|---|---|---|

| 960 | 10 N–25 °C | −0.00151 mm | −0.00180 mm |

| 20 N–25 °C | −0.00538 mm | −0.004315 mm | |

| 20 N–400 °C | −0.00813 mm | −0.007639 mm | |

| 20 N–800 °C | −0.01160 mm | −0.009632 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, A.; Li, Y.; Feng, L.; Feng, Y.; Xie, Z. Frictional Study on 30CrNi2MoVA Steel Based on Experiments and Finite Element Simulation: Wear Prediction. Coatings 2024, 14, 265. https://doi.org/10.3390/coatings14030265

Wei A, Li Y, Feng L, Feng Y, Xie Z. Frictional Study on 30CrNi2MoVA Steel Based on Experiments and Finite Element Simulation: Wear Prediction. Coatings. 2024; 14(3):265. https://doi.org/10.3390/coatings14030265

Chicago/Turabian StyleWei, Ao, Yiyi Li, Lianghai Feng, Yongjun Feng, and Zhiwen Xie. 2024. "Frictional Study on 30CrNi2MoVA Steel Based on Experiments and Finite Element Simulation: Wear Prediction" Coatings 14, no. 3: 265. https://doi.org/10.3390/coatings14030265

APA StyleWei, A., Li, Y., Feng, L., Feng, Y., & Xie, Z. (2024). Frictional Study on 30CrNi2MoVA Steel Based on Experiments and Finite Element Simulation: Wear Prediction. Coatings, 14(3), 265. https://doi.org/10.3390/coatings14030265