A Comprehensive Review of Cathodic Arc Evaporation Physical Vapour Deposition (CAE-PVD) Coatings for Enhanced Tribological Performance

Abstract

1. Introduction

2. Substrate Preparation

Effect of Substrate Profiling on the Properties of CAE-PVD Coatings

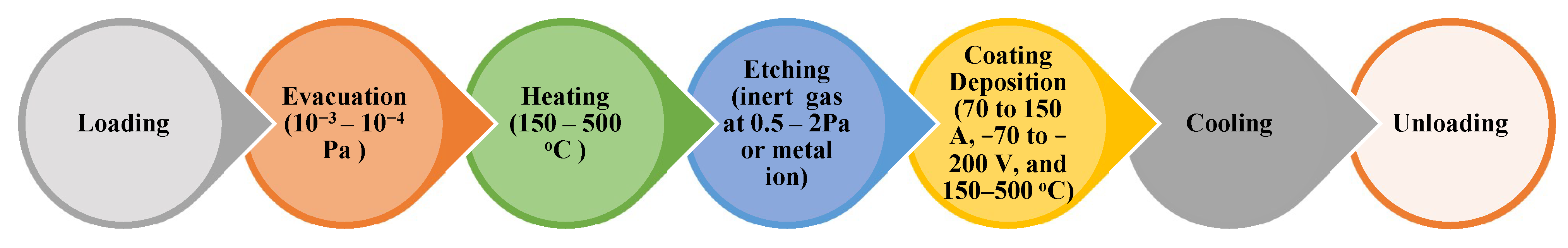

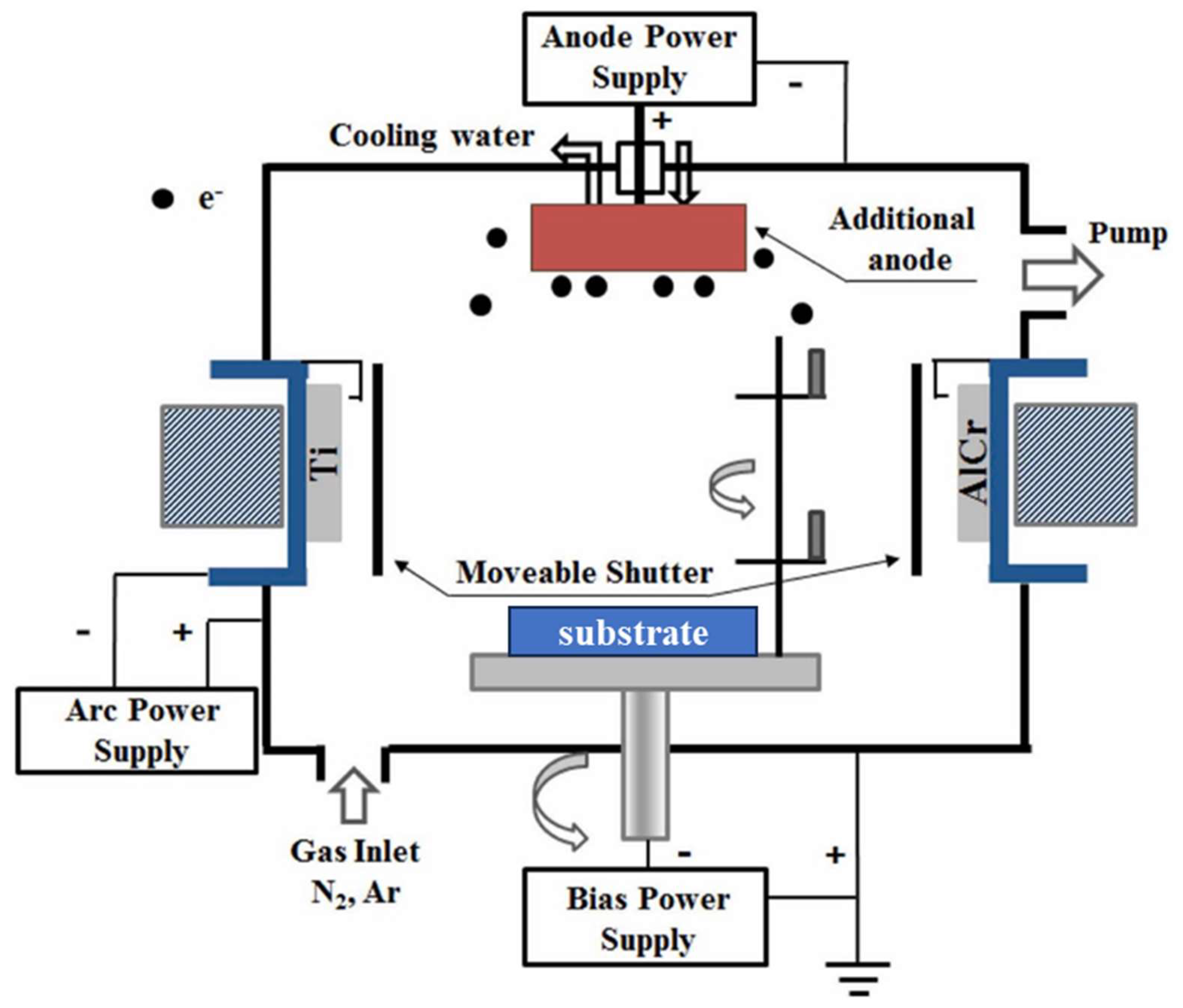

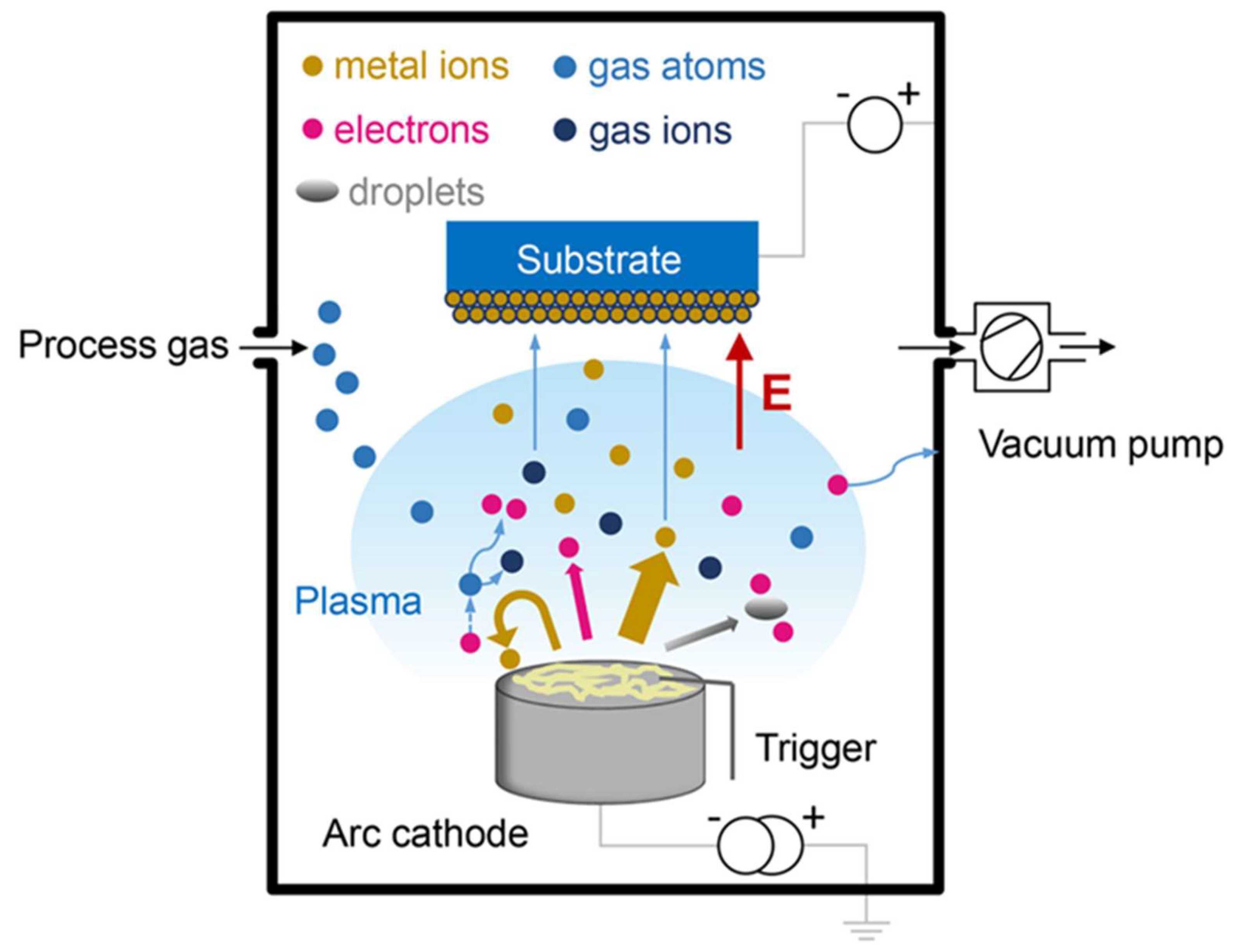

3. Process and Principles of CAE-PVD

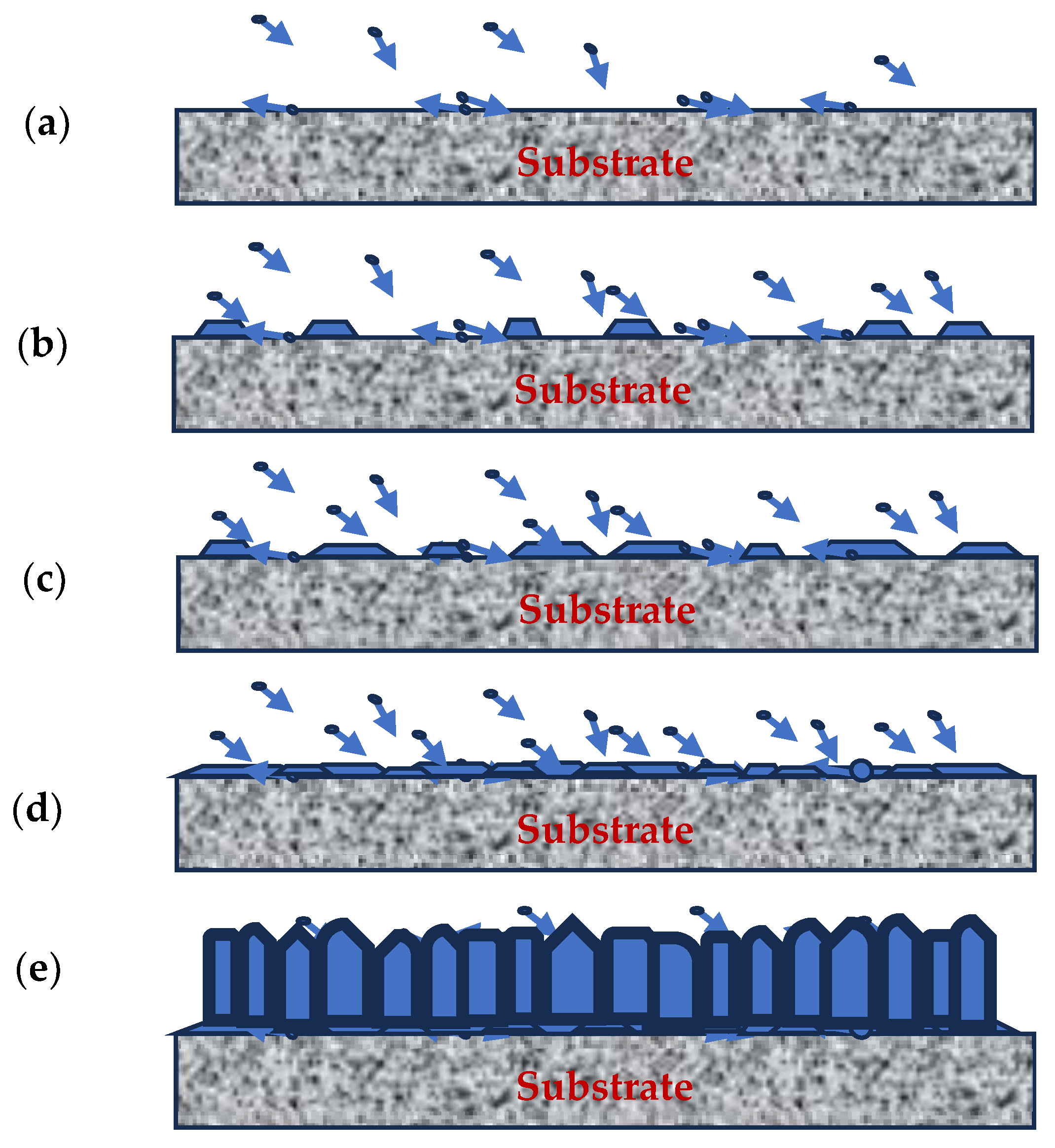

4. Microstructural Evolution of CAE-PVD Coating

4.1. Structural Zone Model (SZM)

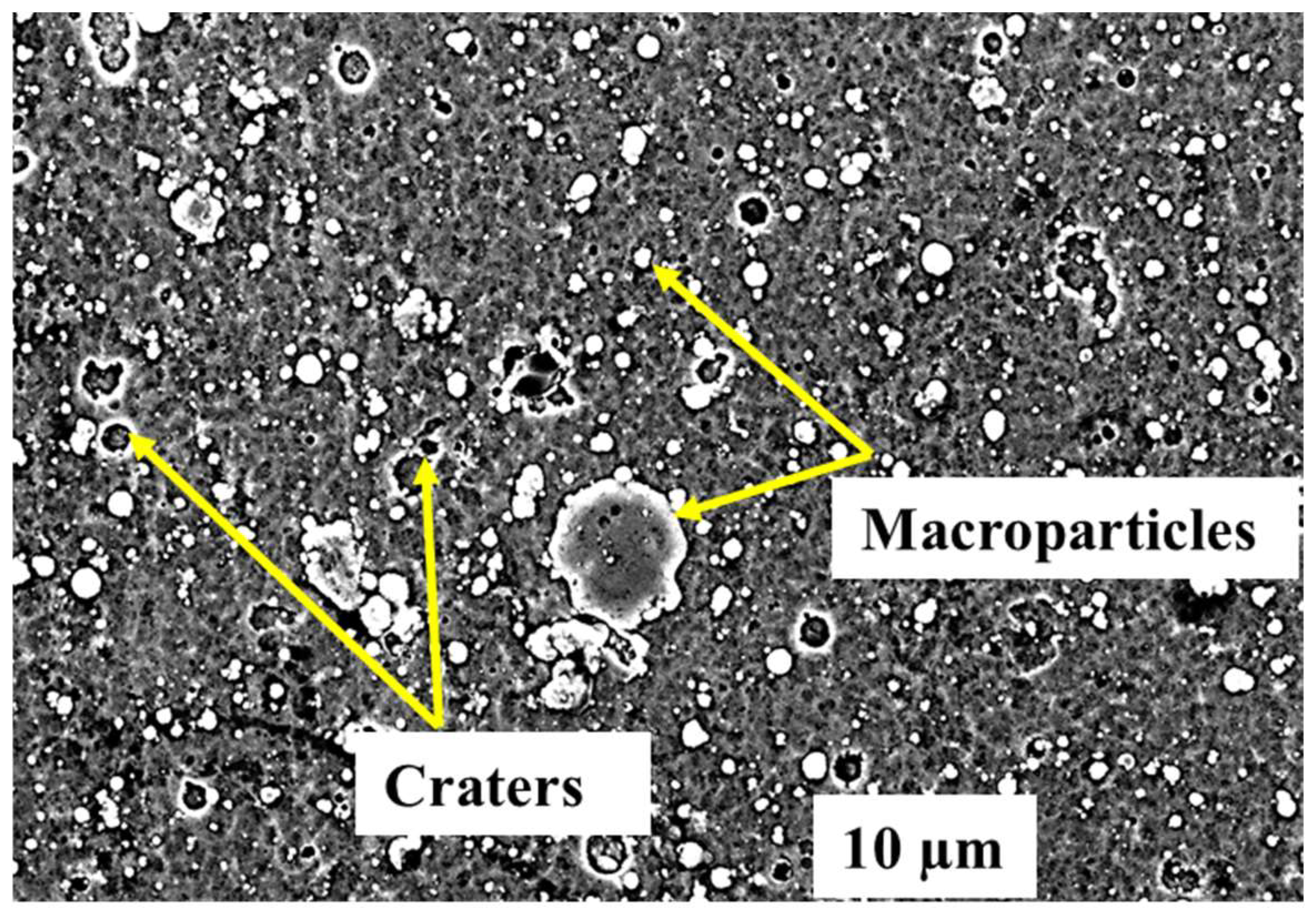

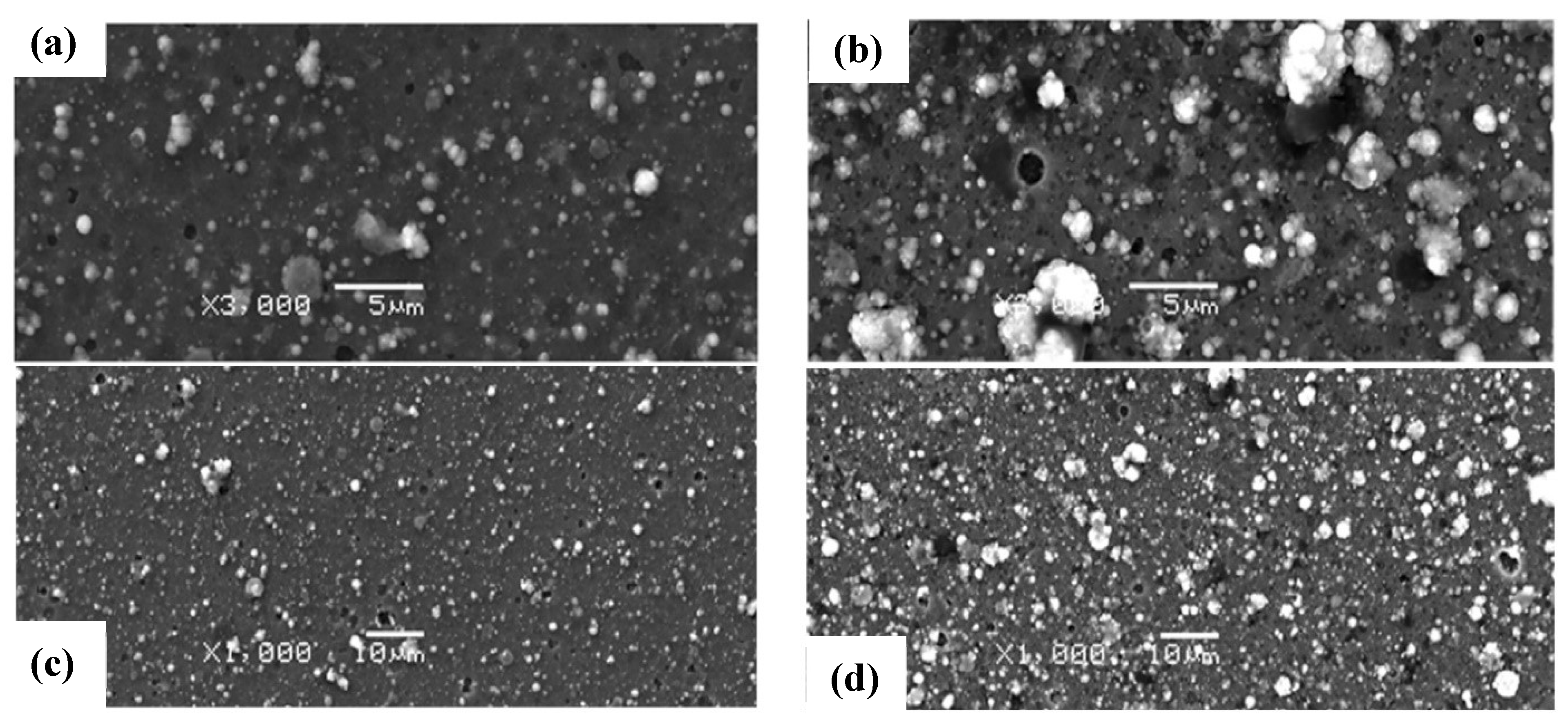

4.2. Macroparticles (MPs) in CAE-PVD Coatings

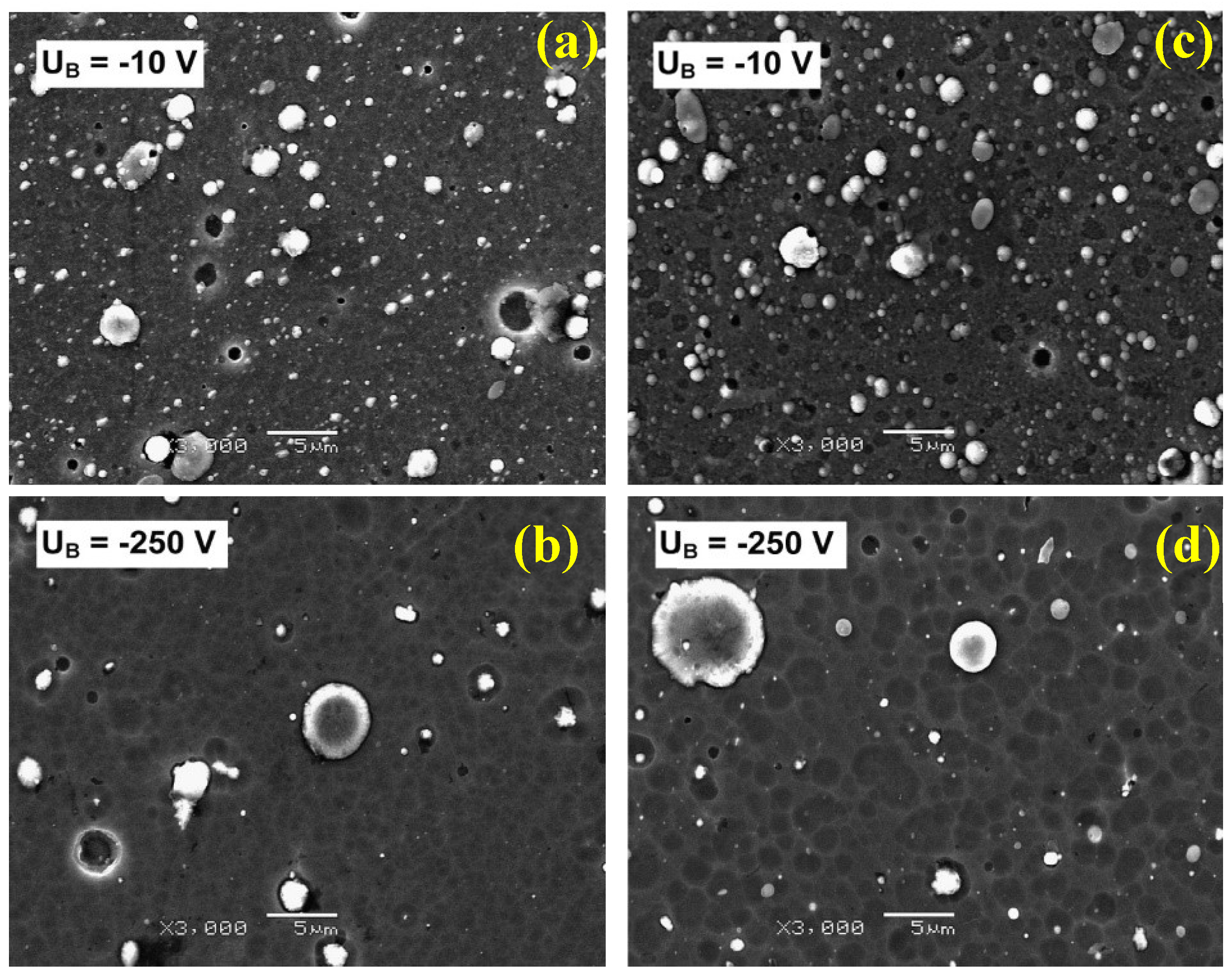

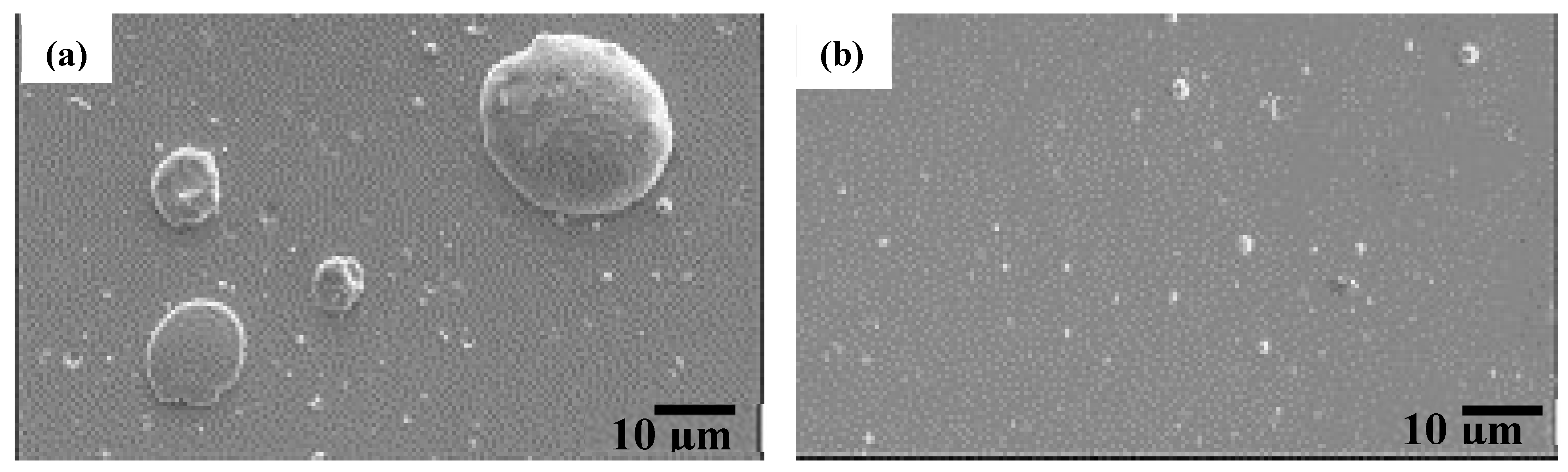

4.3. Research Advances in MP Reduction in CAE-PVD Coatings

4.4. Research Advances in CAE-PVD Microstructural Characterization

5. Characterization of Mechanical and Tribological-Related Properties of CAE-PVD Coating

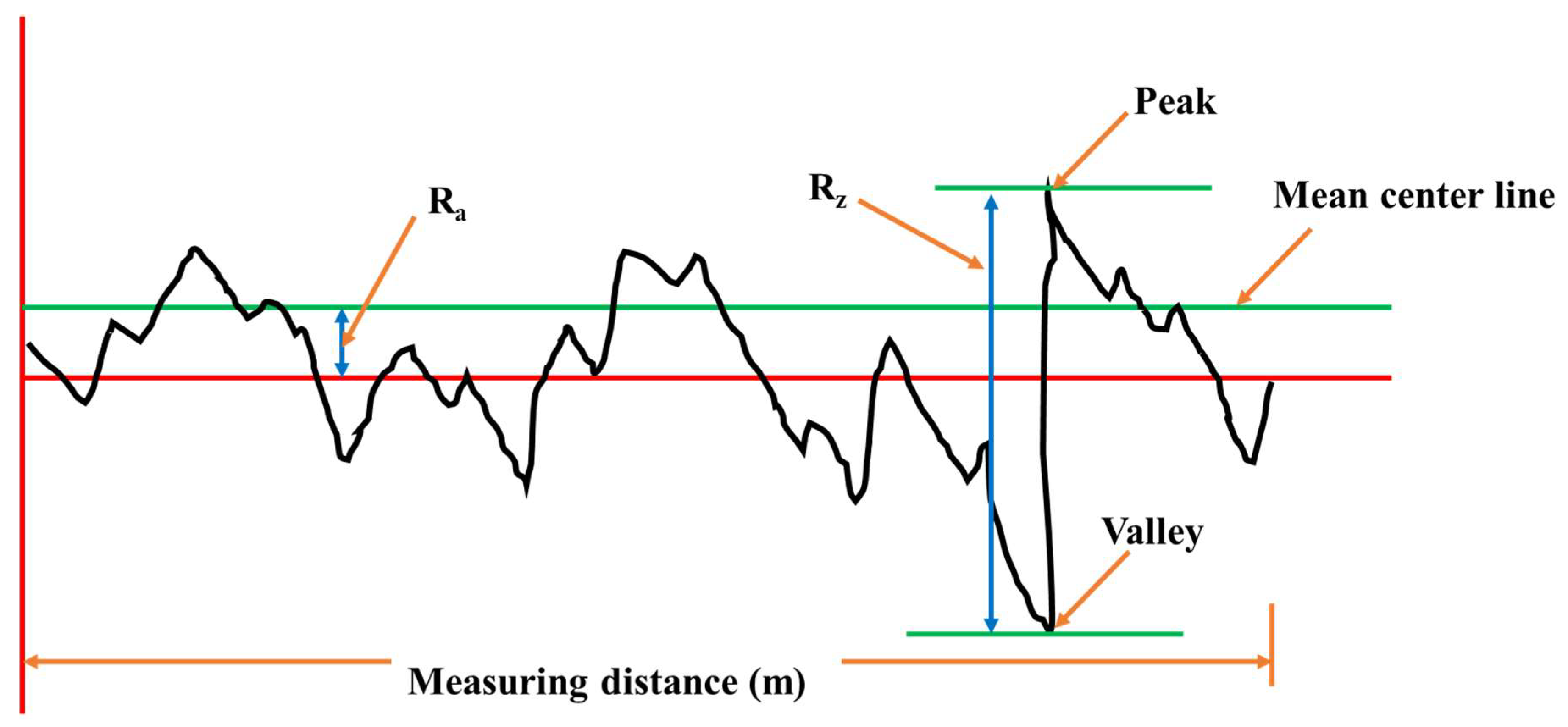

5.1. Hardness (H), Plasticity Index (H/E), and Resistance to Plastic Deformation (H3/E2) and Roughness

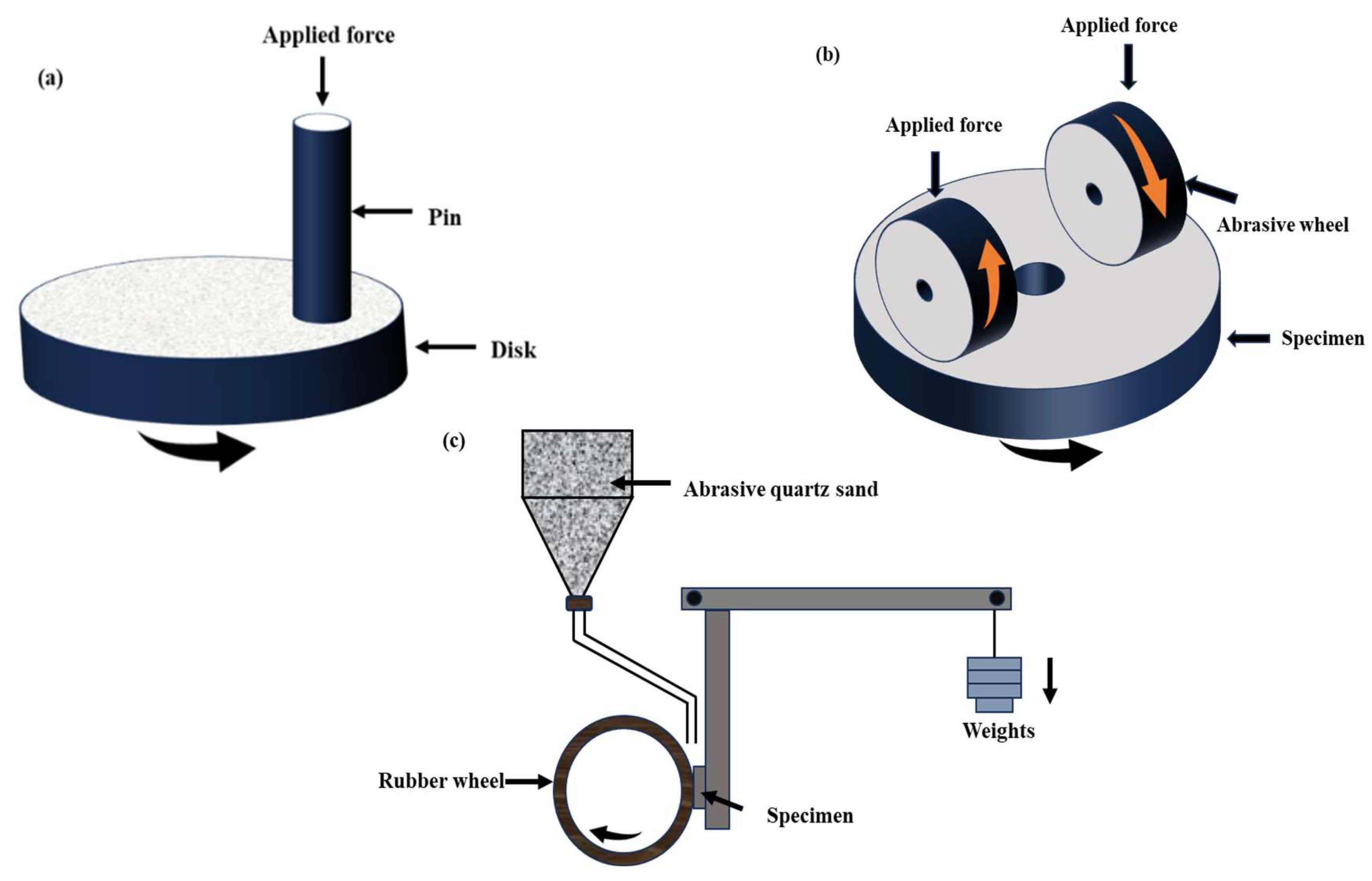

5.2. Wear Characterization

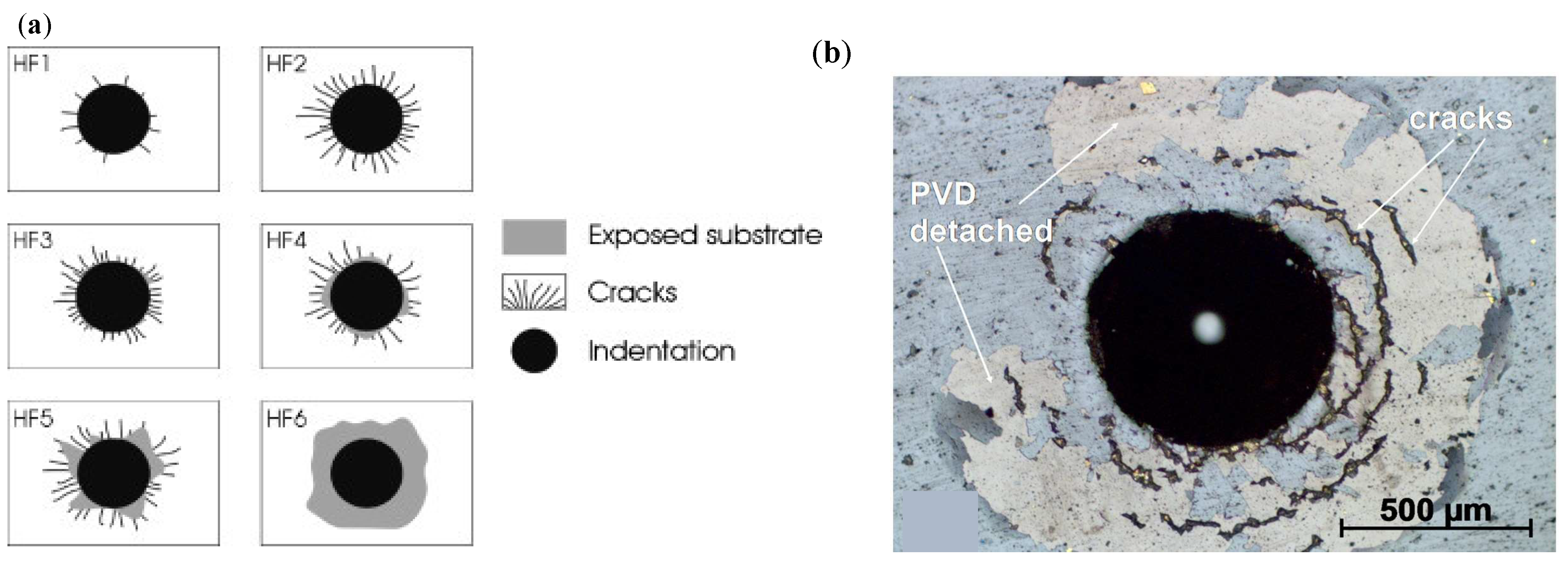

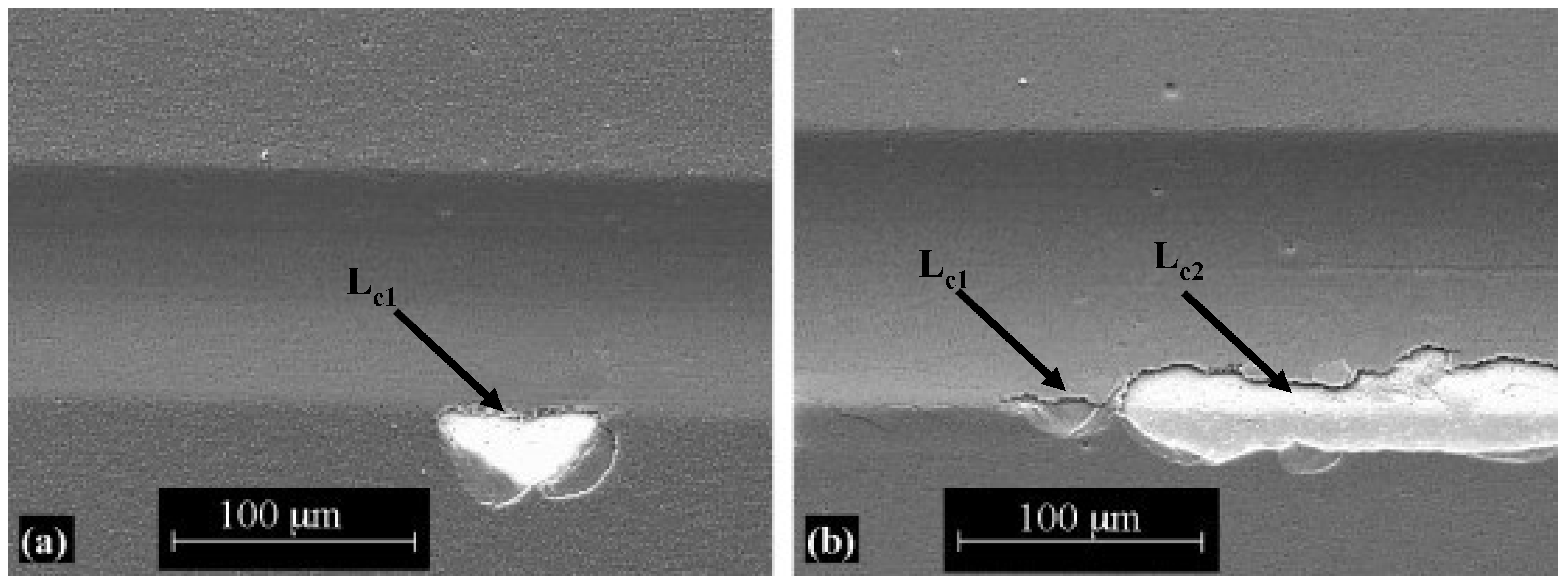

5.3. Coating Adhesion

6. Electrochemical Properties of CAE-PVD Coatings

7. Effect of Deposition Parameters on the Properties of CAE-PVD Coatings

7.1. Effect of Arc Current

7.2. Effect of Deposition Temperature

7.3. Effect of Substrate Bias

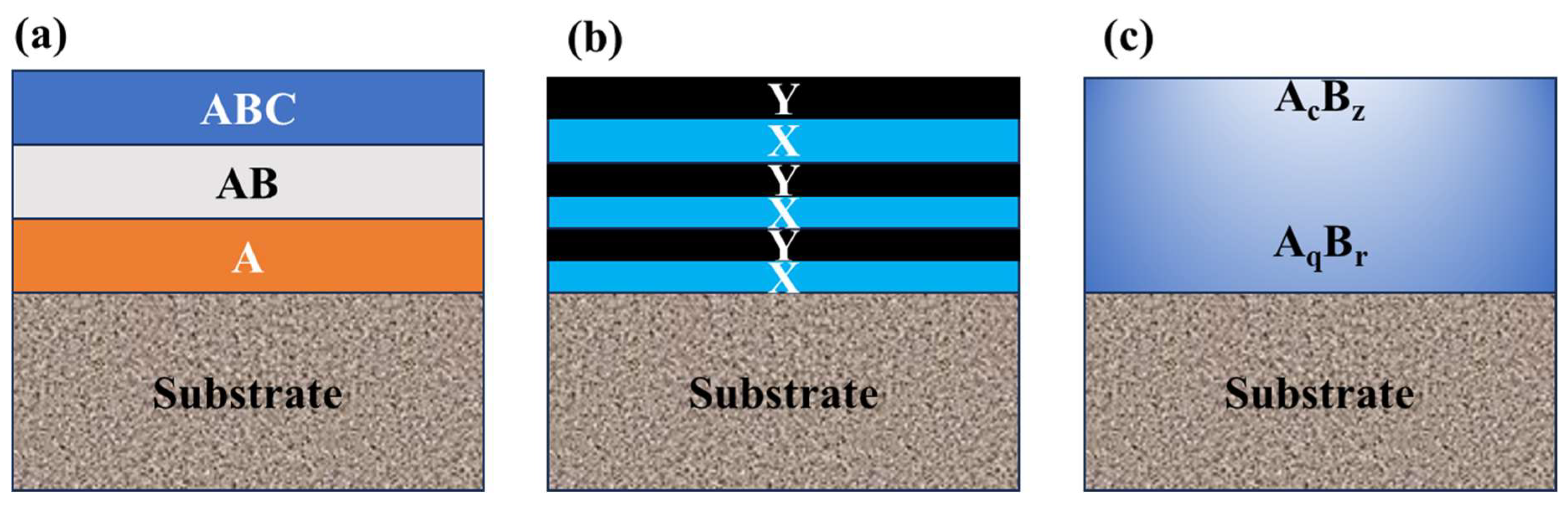

8. CAE-PVD Coating Architecture

8.1. Evolution of Monolayer CAE-PVD Coatings

8.2. Doping of Coatings

8.3. Multilayer Architecture

9. Summary and Future Directions

9.1. Summary

9.2. Future Directions

- (1)

- More systematic studies on the optimization and the effect of substrate profile with specific emphasis on the correlation with the resulting morphology, mechanical properties, the evolution of the coating–substrate interface, and the tribological performance should be conducted. Achieving this would reinforce the existing understanding of the parameter’s effect on the coatings’ service performance.

- (2)

- Researchers should explore the effect of the property mismatch between the coating and the substrate on the adhesion and tribological performances of CAE-PVD coatings. In this discourse, the focus can be directed towards the effect of the coating–substrate chemistry, hardness and elastic modulus differentials on the resulting residual stresses and bond strength. The results of such investigation can provide some valuable insight for making informed decisions during the coating–substrate selection for optimized tribological performance.

- (3)

- More systematic studies should be conducted on the effect of the deposition parameters on the coating properties, with more emphasis on process parameter optimization. Regarding the effect of process parameters, attention should be directed towards the evolution of the coating–substrate interface and the resulting impact on coating quality. In order to achieve the goal of parameter optimization, adopting a design of experiment (DOE), such as the response surface methodology (RSM) or Taguchi method, might come in very handy. The objective of such an optimization process should be targeted towards improving energy efficiency during coating deposition and maximizing the coating quality. This holds great potential benefits, particularly for industrial practitioners.

- (4)

- Researchers should also investigate the effects of substrate heating resulting from high deposition temperature, arc current heating, and substrate temperature rise due to energetic bombardment, on the properties of the substrate, particularly tool steels. This is of utmost importance as the substrate heating might influence the carbide characteristics, retained austenite composition, and the resulting mechanical and tribological performance of the coated substrate. To achieve this objective, an in situ temperature measurement device such as a thermocouple can be used to obtain information about the thermal cycle of the coated substrate during coating deposition. Such a cycle can then be replicated in an uncoated substrate in a furnace, followed by subsequent mechanical and tribological characterizations. The result of such an investigation would facilitate informed decision making in the selection of deposition parameters for optimal tribological performance of the coated substrate.

- (5)

- Further comparative studies on the tribological performance of the different optimized coating architectures should be conducted to ascertain which would provide superior tribological enhancement. If possible, such an investigation should be supported by field tests to further validate the suitability of the optimal architecture for the intended application.

Funding

Acknowledgments

Conflicts of Interest

References

- Muhammed, M.; Javidani, M.; Heidari, M.; Jahazi, M. Enhancing the Tribological Performance of Tool Steels for Wood-Processing Applications: A Comprehensive Review. Metals 2023, 13, 1460. [Google Scholar] [CrossRef]

- Chinnasamy, M.; Rathanasamy, R.; Samanta, B.; Pal, S.K.; Palaniappan, S.K.; Muthuswamy, P.; Korrayi, R.R.; Roy, S. Implications of cryogenic treatment on microstructure, phase formation, mechanical and tribological properties of tungsten carbide cutting bits with varying cobalt content for mining applications. Int. J. Refract. Met. Hard Mater. 2023, 117, 106421. [Google Scholar] [CrossRef]

- Bozkurt, F.; Çakir, F.H. Investigation of the Tribological and Mechanical Properties of Boron Steels in Terms of Potential Usage in Agricultural Applications. J. Polytech. 2021, 24, 431–438. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A. Multilayer coatings on tools for woodworking. Wear 2011, 271, 2812–2820. [Google Scholar] [CrossRef]

- Ratajski, J.; Gulbiński, W.; Staśkiewicz, J.; Walkowicz, J.; Myśliński, P.; Czyżniewski, A.; Suszko, T.; Gilewicz, A.; Warcholiński, B. Hard coatings for woodworking tools--a review. Manuf. Eng. 2009, 37, 668–674. [Google Scholar]

- Bendikiene, R.; Keturakis, G. The influence of technical characteristics of wood milling tools on its wear performance. J. Wood Sci. 2017, 63, 606–614. [Google Scholar] [CrossRef]

- Al-Asadi, M.M.; Al-Tameemi, H.A. A review of tribological properties and deposition methods for selected hard protective coatings. Tribol. Int. 2022, 176, 107919. [Google Scholar] [CrossRef]

- Holmberg, K.; Laukkanen, A.; Ronkainen, H.; Waudby, R.; Stachowiak, G.; Wolski, M.; Podsiadlo, P.; Gee, M.; Nunn, J.; Gachot, C.; et al. Topographical orientation effects on friction and wear in sliding DLC and steel contacts, part 1: Experimental. Wear 2015, 330, 3–22. [Google Scholar] [CrossRef]

- Erdogan, A. Boriding temperature effect on micro-abrasion wear resistance of borided tool steel. J. Tribol. 2019, 141, 121702. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A. Surface Engineering of Woodworking Tools, a Review. Appl. Sci. 2022, 12, 10389. [Google Scholar] [CrossRef]

- Salunkhe, S.; Fabijanic, D.; Nayak, J.; Hodgson, P. Effect of Single and Double Austenitization Treatments on the Microstructure and Hardness of AISI D2 Tool Steel. Mater. Today Proc. 2015, 2, 1901–1906. [Google Scholar] [CrossRef]

- Heidari, M. Improvement of the Cutting Tool Life for the Primary Transformation of Wood. Ph.D. Thesis, Laval University, Québec, QC, Canada, 2019. [Google Scholar]

- Cardoso, P.; Israel, C.; da Silva, M.; Klein, G.; Soccol, L. Effects of deep cryogenic treatment on microstructure, impact toughness and wear resistance of an AISI D6 tool steel. Wear 2020, 456, 203382. [Google Scholar] [CrossRef]

- da Silva, F.J.; Franco, S.D.; Machado, R.; Ezugwu, E.O.; Souza, A.M. Performance of cryogenically treated HSS tools. Wear 2006, 261, 674–685. [Google Scholar] [CrossRef]

- Sonar, T.; Lomte, S.; Gogte, C. Cryogenic Treatment of Metal—A Review. Mater. Today Proc. 2018, 5, 25219–25228. [Google Scholar] [CrossRef]

- Zambaldi, E.; Magalhães, R.R.; Barbosa, B.H.; da Silva, S.P.; Ferreira, D.D. Lowcost automated control for steel heat treatments. Appl. Therm. Eng. 2017, 114, 163–169. [Google Scholar] [CrossRef]

- Oppenkowski, A.; Weber, S.; Theisen, W. Evaluation of factors influencing deep cryogenic treatment that affect the properties of tool steels. J. Am. Acad. Dermatol. 2010, 210, 1949–1955. [Google Scholar] [CrossRef]

- Subbiah, R.; Kumar, V.V.; Prasanna, G.L. Wear analysis of treated Duplex Stainless Steel material by carburizing process—A review. Mater. Today Proc. 2019, 26, 2946–2952. [Google Scholar] [CrossRef]

- Faga, M.G.; Settineri, L. Innovative anti-wear coatings on cutting tools for wood machining. Surf. Coat. Technol. 2006, 201, 3002–3007. [Google Scholar] [CrossRef]

- Psyllaki, P.; Kefalonikas, G.; Pantazopoulos, G.; Antoniou, S.; Sideris, J. Microstructure and tribological behaviour of liquid nitrocarburised tool steels. Surf. Coat. Technol. 2003, 162, 67–78. [Google Scholar] [CrossRef]

- Marichamy, S.; Dhinakaran, V.; Stalin, B.; Ravichandran, M.; Balasubramanian, M.; Chairman, C.A. Taguchi Optimization and Flame Hardening Experimental Investigation on Eglin Steel. IOP Conf. Ser. Mater. Sci. Eng. 2020, 988, 012099. [Google Scholar] [CrossRef]

- Li, J.; Cao, Z.; Liu, L.; Liu, X.; Peng, J. Effect of Microstructure on Hardness and Wear Properties of 45 Steel after Induction Hardening. Steel Res. Int. 2021, 92, 2000540. [Google Scholar] [CrossRef]

- Ormanova, M.; Petrov, P.; Kovacheva, D. Electron beam surface treatment of tool steels. Vacuum 2017, 135, 7–12. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O. Optimization of Shot Peening Effective Parameters on Surface Hardness Improvement. Met. Mater. Int. 2021, 27, 3173–3185. [Google Scholar] [CrossRef]

- Prabhudev, K.H. Handbook of Heat Treatment of Steels; Tata McGraw_Hill Education: New York, NY, USA, 1988. [Google Scholar]

- Thomas, G.W.G.; Digges, G.; Rosenberg, S.J. Heat Treatment and Properties of Iron and Steel; US Government Printing Office: Washington, DC, USA, 1966.

- Harris, S.; Doyle, E.; Vlasveld, A.; Audy, J.; Long, J.; Quick, D. Influence of chromium content on the dry machining performance of cathodic arc evaporated TiAlN coatings. Wear 2003, 254, 185–194. [Google Scholar] [CrossRef]

- de Lacalle, L.N.L.; Fernández-Larrinoa, J.; Rodríguez-Ezquerro, A.; Fernández-Valdivielso, A.; López-Blanco, R.; Azkona-Villaverde, I. On the cutting of wood for joinery applications. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 940–952. [Google Scholar] [CrossRef]

- Kalincová, D.; Ťavodová, M.; Jakubéczyová, D. Quality Evaluation of the Coatings and Its Influence on the Wood Machining Tool Wear. Manuf. Technol. 2018, 18, 578–584. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Michailidis, N.; Skordaris, G.; Bouzakis, E.; Biermann, D.; M’Saoubi, R. Cutting with coated tools: Coating technologies, characterization methods and performance optimization. CIRP Ann. 2012, 61, 703–723. [Google Scholar] [CrossRef]

- Holmberg, K.; Mathews, A. Coatings Tribology—Properties, Mechanisms, Techniques and Application in Surface Engineering, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Kong, Y.; Tian, X.; Gong, C.; Chu, P.K. Enhancement of toughness and wear resistance by CrN/CrCN multilayered coatings for wood processing. Surf. Coat. Technol. 2018, 344, 204–213. [Google Scholar] [CrossRef]

- Kulkarni, A.P.; Joshi, G.G.; Sargade, V.G. Performance of PVD AlTiCrN coating during machining of austenitic stainless steel. Surf. Eng. 2013, 29, 402–407. [Google Scholar] [CrossRef]

- Lee, S.-C.; Ho, W.-Y.; Lai, F. Effect of substrate surface roughness on the characteristics of CrN hard film. Mater. Chem. Phys. 1996, 43, 266–273. [Google Scholar] [CrossRef]

- Mattox, D.M. Handbook of Physical Vapor Deposition (PVD) Processing; Elsevier Science & Technology Books: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Baptista, A.; Silva, F.J.G.; Porteiro, J.; Míguez, J.L.; Pinto, G. Sputtering Physical Vapour Deposition (PVD) Coatings: A Critical Review on Process Improvement and Market Trend Demands. Coatings 2018, 8, 402. [Google Scholar] [CrossRef]

- Deng, Y.; Chen, W.; Li, B.; Wang, C.; Kuang, T.; Li, Y. Physical vapor deposition technology for coated cutting tools: A review. Ceram. Int. 2020, 46, 18373–18390. [Google Scholar] [CrossRef]

- Sheikh-Ahmad, J.Y.; Morita, T. Tool coatings for wood machining: Problems and prospects. For. Prod. J. 2002, 52, 43–51. [Google Scholar]

- Pak, A.; Masoudi, M.; Elmkhah, H. Effect of ultrasonic peening on the surface properties of nano-layered CrN/CrAlN coating deposited by CAPVD method on D3 tool steel. Surf. Interfaces 2021, 28, 101618. [Google Scholar] [CrossRef]

- Jacob, A. Effect of Micro-blasting on Characteristics and Machining Performance of PVD AlTiN Coated Cutting Tools; Master of Technology; National Institute of Technology: Rourkela, India, 2015. [Google Scholar]

- Grundas, S. Advances in Induction and Microwave Heating of Mineral and Organic Materials; IntechOpen: Rijeka, Croatia, 2011; ISBN 9789533075228. [Google Scholar]

- Zhang, Q.; Wu, Z.; Xu, Y.X.; Wang, Q.; Chen, L.; Kim, K.H. Improving the mechanical and anti-wear properties of AlTiN coatings by the hybrid arc and sputtering deposition. Surf. Coat. Technol. 2019, 378, 125022. [Google Scholar] [CrossRef]

- Wu, S.; Zhao, Y.; Zhang, L.; Liu, S.; Qin, L.; Liao, B.; Zhang, X.; Chen, L.; Zhang, T. Effect of C doping on structure and properties of TiAlCrN coatings by filter cathode vacuum arc deposition. Vacuum 2022, 201, 111093. [Google Scholar] [CrossRef]

- Bull, S.; Jones, A. Multilayer coatings for improved performance. Surf. Coat. Technol. 1996, 78, 173–184. [Google Scholar] [CrossRef]

- Anders, A. Cathodic arc plasma deposition. Vac. Technol. Coat. 2002, 3, 49915. [Google Scholar]

- Sanders, D.M.; Anders, A. Review of cathodic arc deposition technology at the start of the new millennium. Surf. Coat. Technol. 2000, 133, 78–90. [Google Scholar] [CrossRef]

- Vereschaka, A.; Milovich, F.; Andreev, N.; Sotova, C.; Alexandrov, I.; Muranov, A.; Mikhailov, M.; Tatarkanov, A. Investigation of the structure and phase composition of the microdroplets formed during the deposition of PVD coatings. Surf. Coat. Technol. 2022, 441, 128574. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Myslinski, P.; Dobruchowska, E.; Murzynski, D. Structure and Properties of AlCrN Coatings Deposited Using Cathodic Arc Evaporation. Coatings 2020, 10, 793. [Google Scholar] [CrossRef]

- Mubarak, A.; Akhter, P.; Hamzah, E.; Radzi, M.; Toff, H.M.; Qazi, I.A. Effect of Coating Thickness on the Properties of TiN coatings Deposited on Tool Steels Using Cathodic Arc PVD Technique. Surf. Rev. Lett. 2008, 15, 401–410. [Google Scholar] [CrossRef]

- Steffens, H.-D.; Mack, M.; Moehwald, K.; Reichel, K. Reduction of droplet emission in random arc technology. Surf. Coat. Technol. 1991, 46, 65–74. [Google Scholar] [CrossRef]

- Harris, S.; Doyle, E.; Wong, Y.-C.; Munroe, P.; Cairney, J.; Long, J. Reducing the macroparticle content of cathodic arc evaporated TiN coatings. Surf. Coat. Technol. 2004, 183, 283–294. [Google Scholar] [CrossRef]

- Ovcharenko, V.; Kuprin, A.; Tolmachova, G.; Kolodiy, I.; Gilewicz, A.; Lupicka, O.; Rochowicz, J.; Warcholinski, B. Deposition of chromium nitride coatings using vacuum arc plasma in increased negative substrate bias voltage. Vacuum 2015, 117, 27–34. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Zelenkov, V.; Sitnikov, N.; Bublikov, J.; Milovich, F.; Andreev, N.; Mustafaev, E. Specific features of the structure and properties of arc-PVD coatings depending on the spatial arrangement of the sample in the chamber. Vacuum 2022, 200, 111047. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Zelenkov, V.; Sitnikov, N.; Bublikov, J.; Milovich, F.; Andreev, N.; Sotova, C. Investigation of the influence of the features of the deposition process on the structural features of microparticles in PVD coatings. Vacuum 2022, 202, 111144. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Ratajski, J.; Kuklinski, Z.; Rochowicz, J. An analysis of macroparticle-related defects on CrCN and CrN coatings in dependence of the substrate bias voltage. Vacuum 2012, 86, 1235–1239. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Kuprin, A. effect of arc current on mechanical properties of alcrn coatings deposited using cathodic arc evaporation. Probl. At. Sci. Technol. 2022, 140, 141–146. [Google Scholar] [CrossRef]

- Rother, B. Cathodic arc evaporation as a coating technique. Surf. Eng. 1988, 4, 335–342. [Google Scholar] [CrossRef]

- Gotman, I.; Gutmanas, E.Y. Titanium nitride-based coatings on implantable medical devices. Adv. Biomater. Devices Med. 2014, 53–73. [Google Scholar]

- Ferreira, A.A.; Silva, F.J.G.; Pinto, A.G.; Sousa, V.F.C. Characterization of thin chromium coatings produced by pvd sputtering for optical applications. Coatings 2021, 11, 215. [Google Scholar] [CrossRef]

- Śliwa, A.; Mikuła, J.; Gołombek, K.; Kwaśny, W.; Pakuła, D. Internal stresses in PVD coated tool composites. Arch. Met. Mater. 2016, 61, 1371–1378. [Google Scholar] [CrossRef]

- Petrov, I.; Barna, P.B.; Hultman, L.; Greene, J.E. Microstructural evolution during film growth. J. Vac. Sci. Technol. A 2003, 21, S117–S128. [Google Scholar] [CrossRef]

- Nouveau, C.; Labidi, C.; Collet, R.; Benlatreche, Y.; Djouadi, M.-A. Effect of surface finishing such as sand-blasting and CrAlN hard coatings on the cutting edge’s peeling tools’ wear resistance. Wear 2009, 267, 1062–1067. [Google Scholar] [CrossRef]

- Uddin, G.M.; Khan, A.A.; Ghufran, M.; Tahir, Z.-U.; Asim, M.; Sagheer, M.; Jawad, M.; Ahmad, J.; Irfan, M.; Waseem, B. Experimental study of tribological and mechanical properties of TiN coating on AISI 52100 bearing steel. Adv. Mech. Eng. 2018, 10, 1687814018802882. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A. Effect of substrate bias voltage on the properties of CrCN and CrN coatings deposited by cathodic arc evaporation. Vacuum 2013, 90, 145–150. [Google Scholar] [CrossRef]

- Abusuilik, S.B. Pre-, intermediate, and post-treatment of hard coatings to improve their performance for forming and cutting tools. Surf. Coat. Technol. 2015, 284, 384–395. [Google Scholar] [CrossRef]

- Huang, R.-X.; Qi, Z.-B.; Sun, P.; Wang, Z.-C.; Wu, C.-H. Influence of substrate roughness on structure and mechanical property of TiAlN coating fabricated by cathodic arc evaporation. Phys. Procedia 2011, 18, 160–167. [Google Scholar] [CrossRef]

- Ali, M.; Hamzah, E.; Qazi, I.; Toff, M. Effect of cathodic arc PVD parameters on roughness of TiN coating on steel substrate. Curr. Appl. Phys. 2010, 10, 471–474. [Google Scholar] [CrossRef]

- Ling, C.L.; Yajid, M.A.M.; Tamin, M.N.; Kamarudin, M.; Taib, M.A.A.; Nosbi, N.; Ali, W.F.F.W. Effect of substrate roughness and PVD deposition temperatures on hardness and wear performance of AlCrN-coated WC-Co. Surf. Coat. Technol. 2022, 436, 128304. [Google Scholar] [CrossRef]

- Bhushan, T.; Chandrashekhar, A.; Prasat, S.V.; Reddy, I.R. Effect of Substrate Surface Roughness On Adhesion Of Titanium Nitride Coatings Deposited By Physical Vapour Deposition Technique. IOP Conf. Ser. Mater. Sci. Eng. 2020, 981, 042022. [Google Scholar] [CrossRef]

- Ravi, N.; Markandeya, R.; Joshi, S.V. Effect of substrate roughness on adhesion and tribological properties of nc-TiAlN/a-Si3N4 nanocomposite coatings deposited by cathodic arc PVD process. Surf. Eng. 2017, 33, 7–19. [Google Scholar] [CrossRef]

- Tkadletz, M.; Mitterer, C.; Sartory, B.; Letofsky-Papst, I.; Czettl, C.; Michotte, C. The effect of droplets in arc evaporated TiAlTaN hard coatings on the wear behavior. Surf. Coat. Technol. 2014, 257, 95–101. [Google Scholar] [CrossRef]

- Lindholm, P.; Björklund, S.; Svahn, F. Method and surface roughness aspects for the design of DLC coatings. Wear 2006, 261, 107–111. [Google Scholar] [CrossRef]

- Lin, S.-S.; Zhou, K.-S.; Dai, M.-J.; Hu, F.; Shi, Q.; Hou, H.-J.; Wei, C.-B.; Li, F.-Q.; Tong, X. Effects of surface roughness of substrate on properties of Ti/TiN/Zr/ZrN multilayer coatings. Trans. Nonferrous Met. Soc. China 2015, 25, 451–456. [Google Scholar] [CrossRef]

- Naghashzadeh, A.R.; Shafyei, A.; Sourani, F. Nanoindentation and Tribological Behavior of TiN-TiCN-TiAlN Multilayer Coatings on AISI D3 Tool Steel. J. Mater. Eng. Perform. 2022, 31, 4335–4342. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Michailidis, N.; Hadjiyiannis, S.; Efstathiou, K.; Pavlidou, E.; Erkens, G.; Rambadt, S.; Wirth, I. Improvement of PVD coated inserts cutting performance, through appropriate mechanical treatments of substrate and coating surface. Surf. Coat. Technol. 2001, 146, 443–450. [Google Scholar] [CrossRef]

- Subramanian, C.; Strafford, K.; Wilks, T.; Ward, L.; McMillan, W. Influence of substrate roughness on the scratch adhesion of titanium nitride coatings. Surf. Coat. Technol. 1993, 62, 529–535. [Google Scholar] [CrossRef]

- Vengesa, Y.; Fattah-Alhosseini, A.; Elmkhah, H.; Imantalab, O. Influence of post-deposition annealing temperature on morphological, mechanical and electrochemical properties of CrN/CrAlN multilayer coating deposited by cathodic arc evaporation- physical vapor deposition process. Surf. Coat. Technol. 2022, 432, 128090. [Google Scholar] [CrossRef]

- Özkan, D.; Yılmaz, M.A.; Szala, M.; Türküz, C.; Chocyk, D.; Tunç, C.; Göz, O.; Walczak, M.; Pasierbiewicz, K.; Yağcı, M.B. Effects of ceramic-based CrN, TiN, and AlCrN interlayers on wear and friction behaviors of AlTiSiN + TiSiN PVD coatings. Ceram. Int. 2021, 47, 20077–20089. [Google Scholar] [CrossRef]

- Mattox, D. Surface effects on the growth, adhesion and properties of reactively deposited hard coatings. Surf. Coat. Technol. 1996, 81, 8–16. [Google Scholar] [CrossRef]

- Barshilia, H.C.; Ananth, A.; Khan, J.; Srinivas, G. Ar + H2 plasma etching for improved adhesion of PVD coatings on steel substrates. Vacuum 2012, 86, 1165–1173. [Google Scholar] [CrossRef]

- Sproul, W.; Rudnik, P.; Legg, K.; Münz, W.-D.; Petrov, I.; Greene, J. Reactive sputtering in the ABSTM system. Surf. Coat. Technol. 1993, 56, 179–182. [Google Scholar] [CrossRef]

- Kong, Y.; Tian, X.; Gong, C.; Tian, Q.; Yang, D.; Wu, M.; Li, M.; Golosov, D.A. Microstructure and mechanical properties of Ti-Al-Cr-N films: Effect of current of additional anode. Appl. Surf. Sci. 2019, 483, 1058–1068. [Google Scholar] [CrossRef]

- Sanchette, F.; Ducros, C.; Schmitt, T.; Steyer, P.; Billard, A. Nanostructured hard coatings deposited by cathodic arc deposition: From concepts to applications. Surf. Coat. Technol. 2011, 205, 5444–5453. [Google Scholar] [CrossRef]

- Boxman, R.; Goldsmith, S.; Greenwood, A. Twenty-five years of progress in vacuum arc research and utilization. IEEE Trans. Plasma Sci. 1997, 25, 1174–1186. [Google Scholar] [CrossRef]

- Grosfils, P.; Lutsko, J.F. Impact of Surface Roughness on Crystal Nucleation. Crystals 2021, 11, 4. [Google Scholar] [CrossRef]

- Movchan, B.A.; Demchishin, A.V. Study of The Structure and Properties of Thick Vacuum Condensates of Nickel, Tita-nium, Tungsten, Aluminium Oxide and Zirconium Dioxide. Phys. Met. Metallogr. 1969, 28, 653–660. [Google Scholar]

- Thornton, J.A. Influence of apparatus geometry and deposition conditions on the structure and topography of thick sputtered coatings. J. Vac. Sci. Technol. 1974, 11, 666–670. [Google Scholar] [CrossRef]

- Rickerby, D.; Bull, S. Engineering with surface coatings: The role of coating microstructure. Surf. Coat. Technol. 1989, 39, 315–328. [Google Scholar] [CrossRef]

- Anders, A. A structure zone diagram including plasma-based deposition and ion etching. Thin Solid Films 2010, 518, 4087–4090. [Google Scholar] [CrossRef]

- Romero, J.; Gómez, M.A.; Esteve, J.; Montalà, F.; Carreras, L.; Grifol, M.; Lousa, A. CrAlN coatings deposited by cathodic arc evaporation at different substrate bias. Thin Solid Films 2006, 515, 113–117. [Google Scholar] [CrossRef]

- Anders, A. Cathodic Arc Plasma Deposition: From Fractal Spots to Energetic Condensation; Springer: New York, NY, USA, 2008; Volume 50. [Google Scholar]

- Pohler, M.; Franz, R.; Ramm, J.; Polcik, P.; Mitterer, C. Cathodic arc deposition of (Al,Cr)2O3: Macroparticles and cathode surface modifications. Surf. Coat. Technol. 2011, 206, 1454–1460. [Google Scholar] [CrossRef]

- Creasey, S.; Lewis, D.; Smith, I.; Münz, W.-D. SEM image analysis of droplet formation during metal ion etching by a steered arc discharge. Surf. Coat. Technol. 1997, 97, 163–175. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, K.; Wang, S.; Pan, C.; Chen, S. Ti0·33Al0.67 cathode surface modifications and the effect on the mechanical and electrochemical properties of AlTiN coating. Vacuum 2016, 131, 97–105. [Google Scholar] [CrossRef]

- Vlasveld, A.; Harris, S.; Doyle, E.; Lewis, D.; Munz, W. Characterisation and performance of partially filtered arc TiAlN coatings. Surf. Coat. Technol. 2002, 149, 217–223. [Google Scholar] [CrossRef]

- Gautier, C.; Machet, J. Study of the growth mechanisms of chromium nitride films deposited by vacuum ARC evaporation. Thin Solid Films 1997, 295, 43–52. [Google Scholar] [CrossRef]

- Aksenov, I.I.; Belous, V.A.; Padalka, V.G.; Khoroshikh, V.M. Transport of plasma streams in a curvilinear plasma-optics system. Sov. J. Plasma Phys. 1978, 4, 425–428. [Google Scholar]

- Gautier, C.; Machet, J. Effects of deposition parameters on the texture of chromium films deposited by vacuum arc evaporation. Thin Solid Films 1996, 289, 34–38. [Google Scholar] [CrossRef]

- Li, M.; Wang, F. Effects of nitrogen partial pressure and pulse bias voltage on (Ti,Al)N coatings by arc ion plating. Surf. Coat. Technol. 2003, 167, 197–202. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, S.; Chen, Z.; Li, J.; Li, M. Influence of deposition parameters on hard Cr–Al–N coatings deposited by multi-arc ion plating. Appl. Surf. Sci. 2012, 258, 3629–3636. [Google Scholar] [CrossRef]

- Huang, M.; Lin, G.; Zhao, Y.; Sun, C.; Wen, L.; Dong, C. Macro-particle reduction mechanism in biased arc ion plating of TiN. Surf. Coat. Technol. 2003, 176, 109–114. [Google Scholar] [CrossRef]

- Anders, A. Approaches to rid cathodic arc plasmas of macro- and nanoparticles: A review. Surf. Coat. Technol. 1999, 120, 319–330. [Google Scholar] [CrossRef]

- Wan, X.; Zhao, S.; Yang, Y.; Gong, J.; Sun, C. Effects of nitrogen pressure and pulse bias voltage on the properties of Cr–N coatings deposited by arc ion plating. Surf. Coat. Technol. 2010, 204, 1800–1810. [Google Scholar] [CrossRef]

- Gilewicz, A.; Kuznetsova, T.; Aizikovich, S.; Lapitskaya, V.; Khabarava, A.; Nikolaev, A.; Warcholinski, B. Comparative investigations of alcrn coatings formed by cathodic arc evaporation under different nitrogen pressure or arc current. Materials 2021, 14, 304. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Li, L.; Dai, H.; Li, X.; Cai, X.; Chu, P.K. Effects of pulsing parameters on production and distribution of macroparticles in cathodic vacuum arc deposition. J. Vac. Sci. Technol. A 2006, 24, 957–961. [Google Scholar] [CrossRef]

- Takikawa, H.; Kawakami, N.; Sakakibara, T. N/sub 2/ gas absorption in cathodic arc apparatus with an Al cathode under medium vacuum. IEEE Trans. Plasma Sci. 1999, 27, 1034–1038. [Google Scholar] [CrossRef]

- Ali, M.; Hamzah, E.; Abbas, T.; Toff, M.R.H.M.; Qazi, I.A. Macrodroplet reduction and growth mechanisms in cathodic arc physical vapor deposition of tin films. Surf. Rev. Lett. 2008, 15, 653–659. [Google Scholar] [CrossRef]

- Wang, D.-Y.; Li, Y.-W.; Ho, W.-Y. Deposition of high quality (Ti,Al)N hard coatings by vacuum arc evaporation process. Surf. Coat. Technol. 1999, 114, 109–113. [Google Scholar] [CrossRef]

- Banerjee, P.P. Materials Characterization Techniques. In Encyclopedia of Modern Optics, Five-Volume Set; CRC Press: Boca Raton, FL, USA, 2008; pp. 25–33. [Google Scholar] [CrossRef]

- Khakzadian, J.; Hosseini, S.; Madar, K.Z. The effect of the substrate temperature on the microstructure properties of the NiCrAl coating in cathodic arc deposition. Surf. Coat. Technol. 2018, 337, 342–348. [Google Scholar] [CrossRef]

- Aihua, L.; Jianxin, D.; Haibing, C.; Yangyang, C.; Jun, Z. Friction and wear properties of TiN, TiAlN, AlTiN and CrAlN PVD nitride coatings. Int. J. Refract. Met. Hard Mater. 2012, 31, 82–88. [Google Scholar] [CrossRef]

- Mo, J.; Zhu, M.; Lei, B.; Leng, Y.; Huang, N. Comparison of tribological behaviours of AlCrN and TiAlN coatings—Deposited by physical vapor deposition. Wear 2007, 263, 1423–1429. [Google Scholar] [CrossRef]

- Chim, Y.C.; Ding, X.Z.; Zeng, X.T.; Zhang, S. Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc. Thin Solid Films 2009, 517, 4845–4849. [Google Scholar] [CrossRef]

- Bilgin, S.; Güler, O.; Alver, Ü.; Erdemir, F.; Aslan, M.; Çanakçı, A. Effect of TiN, TiAlCN, AlCrN, and AlTiN ceramic coatings on corrosion behavior of tungsten carbide tool. J. Aust. Ceram. Soc. 2021, 57, 263–273. [Google Scholar] [CrossRef]

- Sabitzer, C.; Steinkellner, C.; Koller, C.; Polcik, P.; Rachbauer, R.; Mayrhofer, P. Diffusion behavior of C, Cr, and Fe in arc evaporated TiN- and CrN-based coatings and their influence on thermal stability and hardness. Surf. Coat. Technol. 2015, 275, 185–192. [Google Scholar] [CrossRef]

- Gregorius, H.-R.; Hattemer, H. Characterization of mating systems. J. Theor. Biol. 2007, 8, 407–422. [Google Scholar] [CrossRef]

- Lattemann, M.; Ehiasarian, A.; Bohlmark, J.; Persson, P.; Helmersson, U. Investigation of high power impulse magnetron sputtering pretreated interfaces for adhesion enhancement of hard coatings on steel. Surf. Coat. Technol. 2006, 200, 6495–6499. [Google Scholar] [CrossRef]

- Dejun, K.; Guizhong, F.; Jinchun, W. Interfacial bonding mechanism and bonding strength of AlTiCrN coating by cathodic arc ion plating. Surf. Interface Anal. 2015, 47, 198–205. [Google Scholar] [CrossRef]

- Tian, L.-H.; Tang, B.; Liu, D.-X.; Zhu, X.-D.; He, J.-W. Interfacial reactions during IBAD and their effects on the adhesion of Cr–N coatings on steel. Surf. Coat. Technol. 2005, 191, 149–154. [Google Scholar] [CrossRef]

- Ruppi, S. Advances in chemically vapour deposited wear resistant coatings. J. Phys. 2001, 11, Pr3-847–Pr3-859. [Google Scholar] [CrossRef]

- Ribis, J.; Wu, A.; Brachet, J.-C.; Barcelo, F.; Arnal, B. Atomic-scale interface structure of a Cr-coated Zircaloy-4 material. J. Mater. Sci. 2018, 53, 9879–9895. [Google Scholar] [CrossRef]

- Brachet, J.-C.; Rouesne, E.; Ribis, J.; Guilbert, T.; Urvoy, S.; Nony, G.; Toffolon-Masclet, C.; Le Saux, M.; Chaabane, N.; Palancher, H.; et al. High temperature steam oxidation of chromium-coated zirconium-based alloys: Kinetics and process. Corros. Sci. 2020, 167, 108537. [Google Scholar] [CrossRef]

- Pang, X.; Gao, K.; Yang, H.; Qiao, L.; Wang, Y.; Volinsky, A.A. Interfacial Microstructure of Chromium Oxide Coatings. Adv. Eng. Mater. 2007, 9, 594–599. [Google Scholar] [CrossRef]

- Kathrein, M.; Michotte, C.; Penoy, M.; Polcik, P.; Mitterer, C. Multifunctional multi-component PVD coatings for cutting tools. Surf. Coat. Technol. 2005, 200, 1867–1871. [Google Scholar] [CrossRef]

- ASTM E384-05a; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2005.

- Durand-Drouhin, O.; Santana, A.; Karimi, A.; Derflinger, V.; Schütze, A. Mechanical properties and failure modes of TiAl(Si)N single and multilayer thin films. Surf. Coat. Technol. 2003, 163, 260–266. [Google Scholar] [CrossRef]

- Picas, J.; Forn, A.; Baile, M.; Martín, E. Substrate effect on the mechanical and tribological properties of arc plasma physical vapour deposition coatings. Int. J. Refract. Met. Hard Mater. 2005, 23, 330–334. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Musil, J.; Kunc, F.; Zeman, H.; Poláková, H. Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings. Surf. Coat. Technol. 2002, 154, 304–313. [Google Scholar] [CrossRef]

- Aninat, R.; Valle, N.; Chemin, J.-B.; Duday, D.; Michotte, C.; Penoy, M.; Bourgeois, L.; Choquet, P. Addition of Ta and Y in a hard Ti-Al-N PVD coating: Individual and conjugated effect on the oxidation and wear properties. Corros. Sci. 2019, 156, 171–180. [Google Scholar] [CrossRef]

- Ali, M.; Hamzah, E.; Toff, M.R. Friction coefficient and surface roughness of TiN-coated HSS deposited using cathodic arc evaporation PVD technique. Ind. Lubr. Tribol. 2008, 60, 121–130. [Google Scholar] [CrossRef]

- ASTM G99-95a; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2010.

- Rickerby, D.; Bull, S.; Robertson, T.; Hendry, A. The role of titanium in the abrasive wear resistance of physically vapour-deposited TiN. Surf. Coat. Technol. 1990, 41, 63–74. [Google Scholar] [CrossRef]

- Knotek, O.; Lugscheider, E.; Löffler, F.; Krämer, G.; Zimmermann, H. Abrasive wear resistance and cutting performance of complex PVD coatings. Surf. Coat. Technol. 1994, 68, 489–493. [Google Scholar] [CrossRef]

- ASTM G65-16; Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel. ASTM International: West Conshohocken, PA, USA, 2013.

- Scholl, M. Abrasive wear of titanium nitride coatings. Wear 1997, 203, 57–64. [Google Scholar] [CrossRef]

- Zeghni, A.E.; Hashmi, M.S.J. The effect of coating and nitriding on the wear behaviour of tool steels. J. Mater. Process. Technol. 2004, 155, 1918–1922. [Google Scholar] [CrossRef]

- Warcholiński, B.; Gilewicz, A.; Kukliński, Z.; Myśliński, P. Arc-evaporated CrN, CrN and CrCN coatings. Vacuum 2008, 83, 715–718. [Google Scholar] [CrossRef]

- Fazel, Z.A.; Elmkhah, H.; Fattah-Alhosseini, A.; Babaei, K.; Meghdari, M. Comparing electrochemical behavior of applied CrN/TiN nanoscale multilayer and TiN single-layer coatings deposited by CAE-PVD method. J. Asian Ceram. Soc. 2020, 8, 510–518. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Myslinski, P.; Dobruchowska, E.; Murzynski, D.; Kuznetsova, T.A. Effect of silicon concentration on the properties of Al-Cr-Si-N coatings deposited using cathodic arc evaporation. Materials 2020, 13, 4717. [Google Scholar] [CrossRef]

- VDI 3198; Guidelines for the Evaluation of Coating Adhesion Strength. Deutsches Institut fur Normung E.V. (DIN): Berlin, Germany, 1992.

- Gerth, J.; Wiklund, U. The influence of metallic interlayers on the adhesion of PVD TiN coatings on high-speed steel. Wear 2008, 264, 885–892. [Google Scholar] [CrossRef]

- Biava, G.; Siqueira, I.B.d.A.F.; Vaz, R.F.; de Souza, G.B.; Jambo, H.C.M.; Szogyenyi, A.; Pukasiewicz, A.G. Evaluation of high temperature corrosion resistance of CrN, AlCrN, and TiAlN arc evaporation PVD coatings deposited on Waspaloy. Surf. Coat. Technol. 2022, 438, 128398. [Google Scholar] [CrossRef]

- ASTM D4541-09; Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion. ASTM International: West Conshohocken, PA, USA, 2014.

- Ang, C.; Carpenter, D.; Terrani, K.; Katoh, Y. Preliminary Characterization and Projections of PVD Coatings On SiC Cladding for Light Water Reactors. In Proceedings of the 42nd International Conference on Advanced Ceramics and Composites: Ceramic Engineering and Science Proceedings; John Wiley & Sons: Hoboken, NJ, USA, 2019; pp. 117–134. [Google Scholar] [CrossRef]

- ASTM C1624-05; Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing. ASTM International: West Conshohocken, PA, USA, 2013.

- Kazlauskas, D.; Jankauskas, V.; Kreivaitis, R.; Tučkutė, S. Wear behaviour of PVD coating strengthened WC-Co cutters during milling of oak-wood. Wear 2022, 498, 204336. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, D.; Fu, Y.; Du, H. Effect of sputtering target power on microstructure and mechanical properties of nano-composite nc-TiNya-SiN thin films. Thin Solid Film. 2004, 447, 462–467. [Google Scholar] [CrossRef]

- Geffert, A.; Geffertova, J.; Dudiak, M. Direct Method of Measuring the pH Value of Wood. Forests 2019, 10, 852. [Google Scholar] [CrossRef]

- Gant, A.; Gee, M.; May, A. The evaluation of tribo-corrosion synergy for WC–Co hardmetals in low stress abrasion. Wear 2004, 256, 500–516. [Google Scholar] [CrossRef]

- Ismail, A.; Othman, N.H.; Mustapha, M.; Saheed, M.S.M.; Abdullah, Z.; Muhammed, M.; Saat, A.M.; Mustapha, F. Mechanical Performance and Corrosion Behaviour of Diffusion-Bonded A5083 Aluminium and A36 Mild Steel with Gallium Interlayer. Materials 2022, 15, 6331. [Google Scholar] [CrossRef]

- Merl, D.K.; Panjan, P.; Panjan, M.; Čekada, M. The role of surface defects density on corrosion resistance of PVD hard coatings. Plasma Process. Polym. 2007, 4, S613–S617. [Google Scholar] [CrossRef]

- Calderon, S.; Alves, C.F.A.; Manninen, N.K.; Cavaleiro, A.; Carvalho, S. Electrochemical corrosion of nano-structured magnetron-sputtered coatings. Coatings 2019, 9, 682. [Google Scholar] [CrossRef]

- da Silva, F.; Cinca, N.; Dosta, S.; Cano, I.; Couto, M.; Guilemany, J.; Benedetti, A. Corrosion behavior of WC-Co coatings deposited by cold gas spray onto AA 7075-T6. Corros. Sci. 2018, 136, 231–243. [Google Scholar] [CrossRef]

- Bayón, R.; Igartua, A.; Fernández, X.; Martínez, R.; Rodríguez, R.; García, J.; de Frutos, A.; Arenas, M.; de Damborenea, J. Corrosion-wear behaviour of PVD Cr/CrN multilayer coatings for gear applications. Tribol. Int. 2009, 42, 591–599. [Google Scholar] [CrossRef]

- Vetter, J.; Lugscheider, E.; Guerreiro, S. (Cr:Al)N coatings deposited by the cathodic vacuum are evaporation. Surf. Coat. Technol. 1998, 98, 1233–1239. [Google Scholar] [CrossRef]

- Brown, I.; Shiraishi, H. Cathode erosion rates in vacuum-arc discharges. IEEE Trans. Plasma Sci. 1990, 18, 170–171. [Google Scholar] [CrossRef]

- Lafferty, J.M. Cathode Processes. In Vacuum Arcs, Theory and Applications; Wiley: New York, NY, USA, 1980. [Google Scholar]

- Grantscharova, E. Texture transition in thin metal films vacuum condensed on glass: A general consideration. Thin Solid Films 1993, 224, 28–32. [Google Scholar] [CrossRef]

- Odén, M.; Almer, J.; Håkansson, G. The effects of bias voltage and annealing on the microstructure and residual stress of arc-evaporated Cr–N coatings. Surf. Coat. Technol. 1999, 120, 272–276. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Chao, L.-C. Effect of substrate bias voltage on the mechanical properties of AlTiN/CrTiSiN multilayer hard coatings. Vacuum 2021, 190, 110241. [Google Scholar] [CrossRef]

- Windischmann, H. Intrinsic stress in sputtered thin films. J. Vac. Sci. Technol. A 1991, 9, 2431–2436. [Google Scholar] [CrossRef]

- Prabakaran, V.; Chandrasekaran, K. Characterisation and Corrosion Resistance of TiCrN Composite Coating on Steel by Physical Vapour Deposition Method. J. Bio-Tribo-Corros. 2016, 2, 25. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A. The properties of multilayer CrCN/CrN coatings dependent on their architecture. Plasma Process. Polym. 2011, 8, 333–339. [Google Scholar] [CrossRef]

- Mo, J.L.; Zhu, M.H.; Leyland, A.; Matthews, A. Impact wear and abrasion resistance of CrN, AlCrN and AlTiN PVD coatings. Surf. Coat. Technol. 2013, 215, 170–177. [Google Scholar] [CrossRef]

- Reiter, A.; Derflinger, V.; Hanselmann, B.; Bachmann, T.; Sartory, B. Investigation of the properties of Al1−xCrxN coatings prepared by cathodic arc evaporation. Surf. Coat. Technol. 2005, 200, 2114–2122. [Google Scholar] [CrossRef]

- Sabitzer, C.; Paulitsch, J.; Kolozsvári, S.; Rachbauer, R.; Mayrhofer, P. Influence of bias potential and layer arrangement on structure and mechanical properties of arc evaporated Al–Cr–N coatings. Vacuum 2014, 106, 49–52. [Google Scholar] [CrossRef]

- Benlatreche, Y.; Nouveau, C.; Aknouche, H.; Imhoff, L.; Martin, N.; Gavoille, J.; Rousselot, C.; Rauch, J.-Y.; Pilloud, D. Physical and mechanical properties of CrAlN and CrSiN ternary systems for wood machining applications. Plasma Process. Polym. 2009, 6, S113–S117. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Yang, Y.-J.; Weng, S.-Y. Effect of interlayer design on the mechanical properties of AlTiCrN and multilayered AlTiCrN/TiSiN hard coatings. Surf. Coat. Technol. 2020, 389, 125637. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A. Mechanical properties of multilayer TiAlN/CrN coatings deposited by cathodic arc evaporation. Surf. Eng. 2011, 27, 491–497. [Google Scholar] [CrossRef]

- Zou, L.; Mei, F.; Zhang, H.; Lin, X.; Wang, Y.; Yuan, T.; Chen, Y.; Gao, J. Improvement of the mechanical, tribological properties and oxidation resistance of AlCrVN coatings by Nb alloying. Ceram. Int. 2022, 48, 2555–2565. [Google Scholar] [CrossRef]

- Kuo, Y.-C.; Wang, C.-J.; Lee, J.-W. The microstructure and mechanical properties evaluation of CrTiAlSiN coatings: Effects of silicon content. Thin Solid Films 2017, 638, 220–229. [Google Scholar] [CrossRef]

- Nadolny, K.; Kapłonek, W.; Sutowska, M.; Sutowski, P.; Myśliński, P.; Gilewicz, A.; Warcholiński, B. Moving towards sustainable manufacturing by extending the tool life of the pine wood planing process using the AlCrBN coating. Sustain. Mater. Technol. 2021, 28, e00259. [Google Scholar] [CrossRef]

- Mei, F.; Chen, Y.; Zhang, H.; Lin, X.; Gao, J.; Yuan, T.; Cao, X. Greater improvement of carbon and boron co-doping on the mechanical properties, wear resistance and cutting performance of AlTiN coating than that of doping alone. Surf. Coat. Technol. 2021, 406, 126738. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Z.; Yuan, T.; Mei, F.; Lin, X.; Gao, J.; Chen, W.; Xu, Y. The synergy of V and Si on the microstructure, tribological and oxidation properties of AlCrN based coatings. Surf. Coat. Technol. 2021, 412, 127082. [Google Scholar] [CrossRef]

- Le Bourhis, E.; Goudeau, P.; Staia, M.; Carrasquero, E.; Puchi-Cabrera, E. Mechanical properties of hard AlCrN-based coated substrates. Surf. Coat. Technol. 2009, 203, 2961–2968. [Google Scholar] [CrossRef]

- Fahrussiam, F.; Praja, I.A.; Darmawan, W.; Wahyudi, I.; Nandika, D.; Usuki, H.; Koseki, S. Wear characteristics of multilayer-coated cutting tools in milling wood and wood-based composites. Tribol. Ind. 2016, 38, 66–73. [Google Scholar]

- Harris, S.G.; Doyle, E.D.; Vlasveld, A.C.; Dolder, P.J. Dry cutting performance of partially filtered arc deposited titanium aluminium nitride coatings with various metal nitride base coatings. Surf. Coat. Technol. 2001, 146, 305–311. [Google Scholar] [CrossRef]

- Sousa, V.F.C.; Da Silva, F.J.G.; Pinto, G.F.; Baptista, A.; Alexandre, R. Characteristics and wear mechanisms of TiAlN-based coatings for machining applications: A comprehensive review. Metals 2021, 11, 260. [Google Scholar] [CrossRef]

- Dobrzański, L.; Żukowska, L.; Mikuła, J.; Gołombek, K.; Pakuła, D.; Pancielejko, M. Structure and mechanical properties of gradient PVD coatings. J. Am. Acad. Dermatol. 2008, 201, 310–314. [Google Scholar] [CrossRef]

| Profiling Method | Profiling Details | Average Roughness, Ra (µm) | Substrate | Coating | Thickness (µm) | Significant Findings | Ref. |

|---|---|---|---|---|---|---|---|

| Mechanical treatment | Mechanical grinding discs (600 and 1200 mesh sizes) and polishing with diamond powder. | 0.016–0.038 | Tungsten carbide | TiAlN | 3.5 | 1—Increase in coating’s Ra and COF with the substrate’s Ra. 2—No significant effect on the crystal structure, residual stresses, and coating thickness. 3—Increase in the adhesion strength and wear resistance at lower Ra. | [66] |

| Mechanical treatment | Mechanical grinding with emery paper (800 and 1000 grit sizes) and 1 µm diamond polishing. | 0.01–0.08 | AISI M2 HSS | TiN and nc-TiAlSiN | 2 | 1—Minimal wear rates at high substrate Ra. 2—Increase in the adhesion strength of TiN and a decrease for the nc-TiAlSiN coating with an increasing substrate Ra. | [70] |

| Chemical treatment | Etching with Murakami’s reagent and Caro’s solution. | 0.05–0.11 | Tungsten carbide | AlCrN | 1.24–2.78 | Increase in the coating thickness, homogeneity, and adhesion strength at higher substrate Ra. | [68] |

| Mechanical treatment | Mechanical grinding with emery paper (600–2500 mesh sizes) | 0.05 and 0.2 | AISI 52100 steel | TiN | 0.432 and 2.83 | 1—Increase in the MP density, COF, H/E, H3/E2, adhesion strength, and wear resistance with increased substrate Ra. 2—No significant changes in the coating thickness. | [63] |

| Mechanical treatment | Not provided | 0.1–0.31 | AISI M2 HSS | CrN | 2.36 | Reduced adhesion strength, corrosion, and high-temperature oxidation resistance at higher substrate Ra. | [34] |

| Not provided | Not provided | 0.037–1.348 | Cr17Ni2 stainless steel | Ti-TiN-Zr-ZrN | 11–15 | Reduction in the adhesion strength and coating homogeneity at higher substrate Ra. | [73] |

| Arc Current (A) | Temperature, Substrate Bias | Substrate | Coating | Thickness (µm) | Significant Findings | Ref. |

|---|---|---|---|---|---|---|

| 50–90 | 400 °C, −70 V | Stainless steel | Cr | 1.8 | 1—No effect on coating texture. 2—Increase in the deposition rate with the arc current. | [98] |

| 0–100 | 500 °C, −100 V | High-speed steel | CrN and AlN | 3.1–6.6 | 1—A positive correlation exists between the arc current and the coating’s metallic composition. | [156] |

| 75–175 | 300 °C, −150 V | M2 high-speed steel | TiAlN | 1 | 1—No significant effect on the coating’s hardness and residual stress. 2—A reduction in the adhesion strength with an increasing arc current. 3—An increase in the deposition rate and aluminium concentration with the arc current. | [95] |

| 50–100 | 350 °C, −100 V | Not provided | AlCrN | 3–4 | 1—No significant effect on the coating texture, crystallite size, composition, H, H/E and H3/E2. 2—An increase in the coating defects, surface roughness and deposition rate with the arc current. 3—A reduction in the COF with an increasing arc current. 4—A fluctuation in the adhesion strength and wear rate with the arc current, reaching an optimum at 80 A. | [104] |

| 50–120 | 350 °C, −100 V | 4H13 and HS6-5-2 steel | AlCrN | Not provided | 1—An increase in the crystallite size, deposition rate, surface roughness and residual stresses with the arc current. 2—The H, H/E and H3/E2 decreased with an increasing arc current. 3—The adhesion strength and wear rate followed a similar trend, reaching an optimum at 80 A. | [56] |

| Temperature (°C) | Arc Current, Substrate Bias | Substrate | Coating | Thickness (µm) | Significant Findings | Ref. |

|---|---|---|---|---|---|---|

| 250–450 | 80 A, −100 V | WC-Co | AlCrN | 1.24–2.78 | 1—Reductions in the crystallite size, compressive residual stresses and wear rate with an increasing temperature. 2—An increase in the hardness with the deposition temperature. | [68] |

| 250–500 | 80 A, −70 V | Stainless steel | Cr | 3 | A change in the coating texture from (110) to (200). | [98] |

| 350–450 | 80 A, −100 V | HS6-5-2 steel | AlCrN | 3.9–6 | 1—Reductions in the hardness, deposition rate and adhesion strength with an increasing temperature. 2—An increase in the crystallite size with the temperature. | [48] |

| 150–450 | 100 A, bias not provided | HSS | TiN | 6.3 | Increases in the COF and surface roughness with the deposition temperature. | [131] |

| 250–500 | 80 A, −100 V | Stainless steel | Cr | 2.35–4.35 | 1—The crystallite size increased with temperatures up to 400 °C and remained constant afterward. 2—The hardness, wear resistance, and lattice perfection increased with the temperature. | [96] |

| Negative Bias (V) | Arc Current, Temperature | Substrate | Coating | Thickness (µm) | Significant Findings | Ref. |

|---|---|---|---|---|---|---|

| 0–100 | 80 A, 400 °C | Stainless steel | Cr | 1.4 | 1—Increase in the crystallite size and enhancement of (110) texture with the increasing bias. 2—Reduction in MPs with increasing bias. | [98] |

| 0–300 | 80 A, 350 °C | HS6-5-2 steel | AlCrN | 4.5 | 1—Increases in the crystallite size and hardness with bias. 2—Reductions in the deposition rate and surface roughness with an increasing bias. | [48] |

| 50–400 | 80 A, 400–420 °C | Hardened steel | CrAlN | 1.9–3.6 | 1—Reductions in the wear rate, crystallite size, residual stresses and deposition rate with an increasing bias. 2—Increases in the Cr/Al ratio and hardness with bias. 3—A change in texture from (100) to (220) and a constant N composition with increasing bias. | [90] |

| 10–300 | 80 A, 300 °C | HS6-5-2 steel | CrN and CrCN | 2.2 | 1—Fluctuations in the hardness and residual stresses with bias (an increase up to 150 V followed by a decrease). 2—A reduction in substrate roughness and no effect on the Cr/N ratio with an increasing bias. 3—The adhesion strength of CrCN was unaffected while that of CrN reduced with an increasing bias. 4—Transformation of coating morphology from fine-grained to a polycrystalline dense structure with increasing bias. | [64] |

| 50–250 | 75 A, 300 °C | M2 High-speed steel | TiAlN | 1 | 1—Increase in residual stresses, hardness, and enhanced coating texture (111) with increasing bias. 2—Increase in adhesion strength with bias up to 150 V followed by a decrease. 3—Reduction in Al content with an increasing bias. | [95] |

| 20–400 | 135 A, 200–420 °C | High-speed steel | CrN | 8.6–9.7 | 1—A positive correlation between the substrate temperature and bias. 2—Fluctuation in residual stresses with the bias (an increase up to 100 V, followed by a decrease) with an increasing bias. 3—No changes in the coating’s composition. 4—Hexagonal Cr2N phases were formed at 400 V. | [160] |

| 70–300 | 80 A, 300 °C | HS6-5-2 steel | CrN | 9 | 1—Hardness, surface roughness, and defects were reduced with an increasing bias. 2—Deposition rate and coating composition remained fairly constant. 3—Crystallite size and density were positively correlated with the bias. 4—Hexagonal Cr2N phase was formed at a higher bias. | [52] |

| 20–180 | 280–320 °C, Arc current not provided. | SK H9 steel | AlTiN/CrTiSiN | 1.6–1.7 | 1—Hardness decreased with an increasing bias. 2—Residual stresses increased with the bias. 3—A less columnar morphology was observed with an increasing bias. 4—The coating thickness and composition were not affected by changes in the bias. | [161] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muhammed, M.; Javidani, M.; Ebrahimi Sadrabadi, T.; Heidari, M.; Levasseur, T.; Jahazi, M. A Comprehensive Review of Cathodic Arc Evaporation Physical Vapour Deposition (CAE-PVD) Coatings for Enhanced Tribological Performance. Coatings 2024, 14, 246. https://doi.org/10.3390/coatings14030246

Muhammed M, Javidani M, Ebrahimi Sadrabadi T, Heidari M, Levasseur T, Jahazi M. A Comprehensive Review of Cathodic Arc Evaporation Physical Vapour Deposition (CAE-PVD) Coatings for Enhanced Tribological Performance. Coatings. 2024; 14(3):246. https://doi.org/10.3390/coatings14030246

Chicago/Turabian StyleMuhammed, Musa, Mousa Javidani, Tahere Ebrahimi Sadrabadi, Majid Heidari, Tom Levasseur, and Mohammad Jahazi. 2024. "A Comprehensive Review of Cathodic Arc Evaporation Physical Vapour Deposition (CAE-PVD) Coatings for Enhanced Tribological Performance" Coatings 14, no. 3: 246. https://doi.org/10.3390/coatings14030246

APA StyleMuhammed, M., Javidani, M., Ebrahimi Sadrabadi, T., Heidari, M., Levasseur, T., & Jahazi, M. (2024). A Comprehensive Review of Cathodic Arc Evaporation Physical Vapour Deposition (CAE-PVD) Coatings for Enhanced Tribological Performance. Coatings, 14(3), 246. https://doi.org/10.3390/coatings14030246