An Experimental Study Based on the Surface Microstructure of Bionic Marine Animals

Abstract

1. Introduction

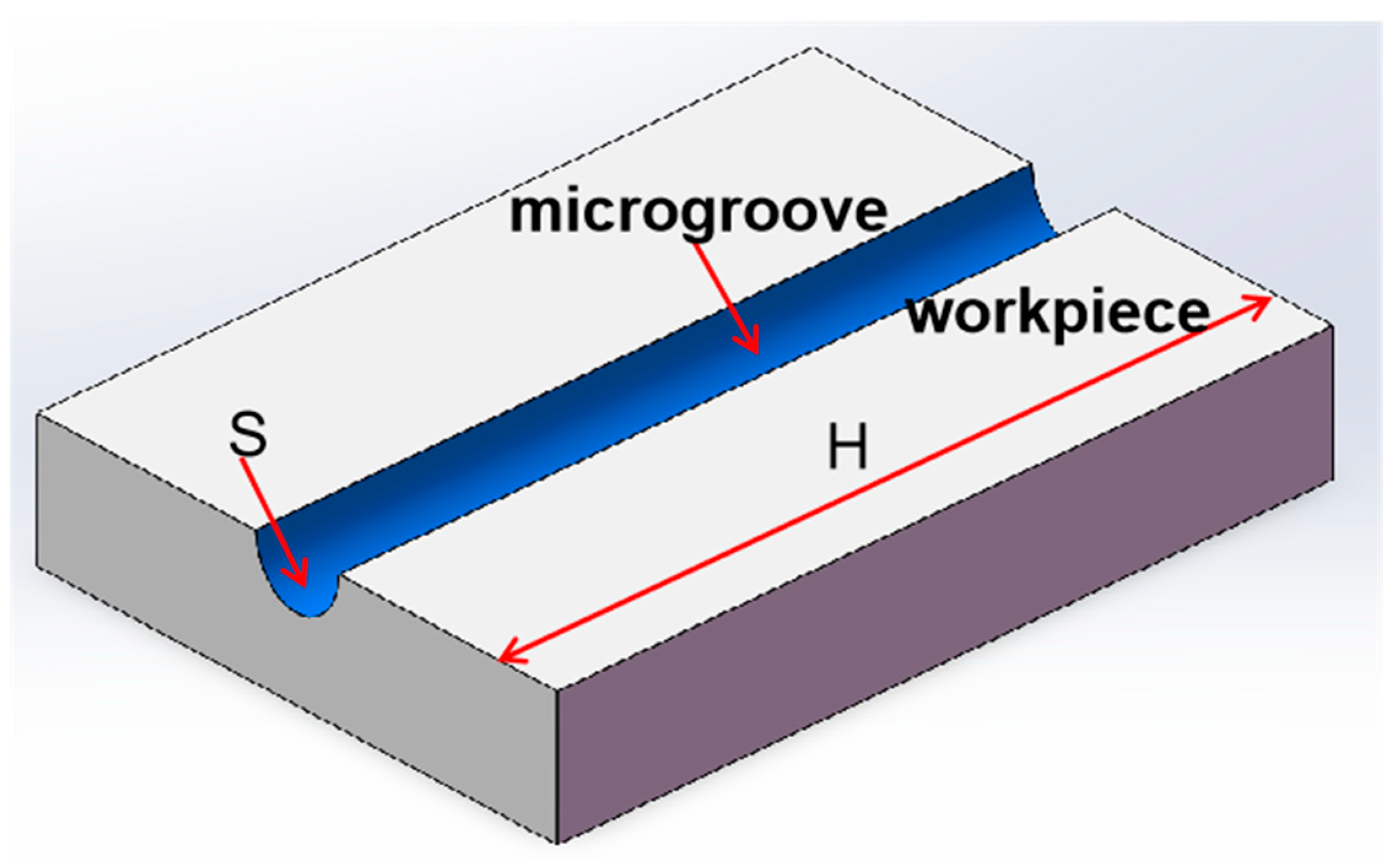

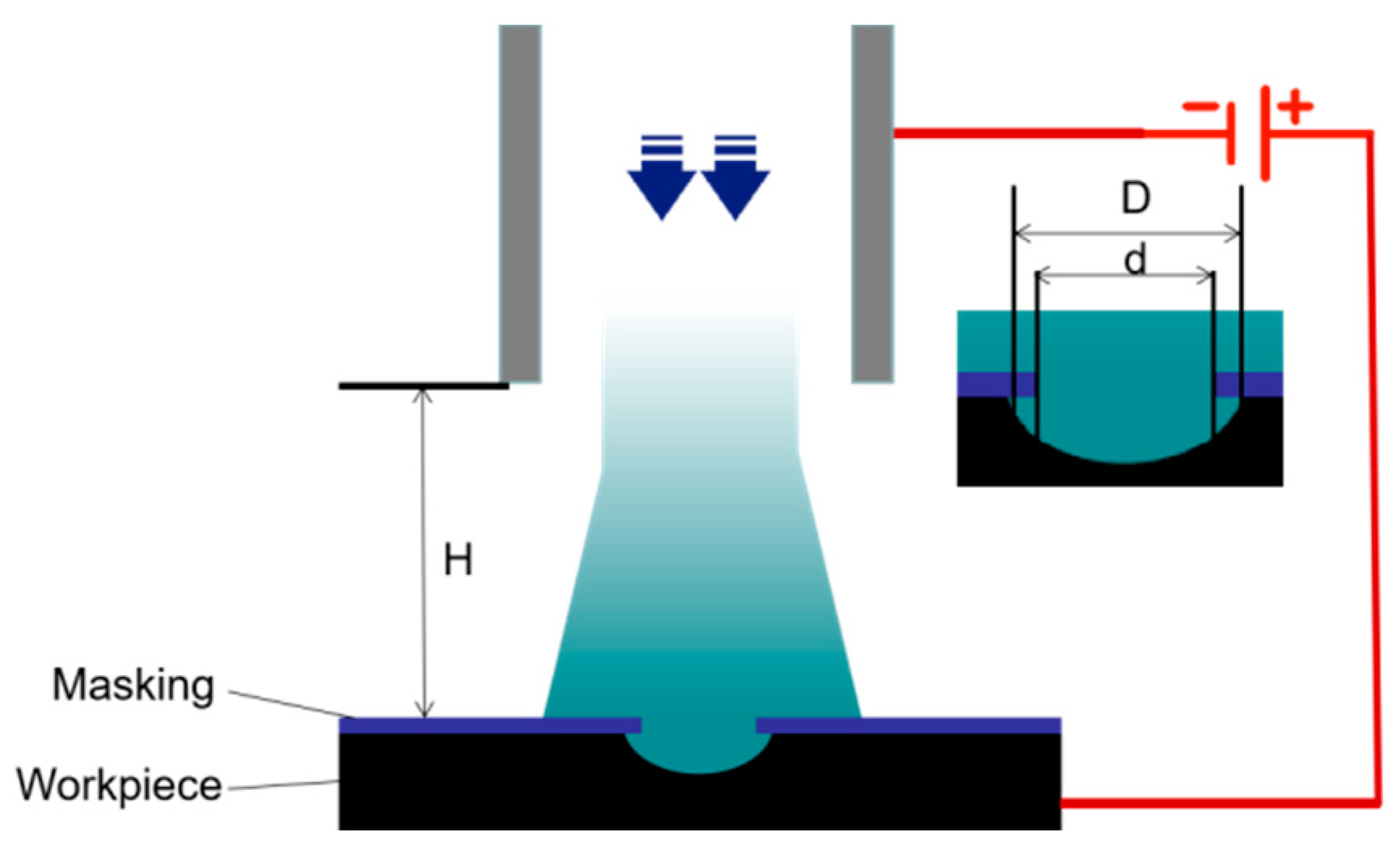

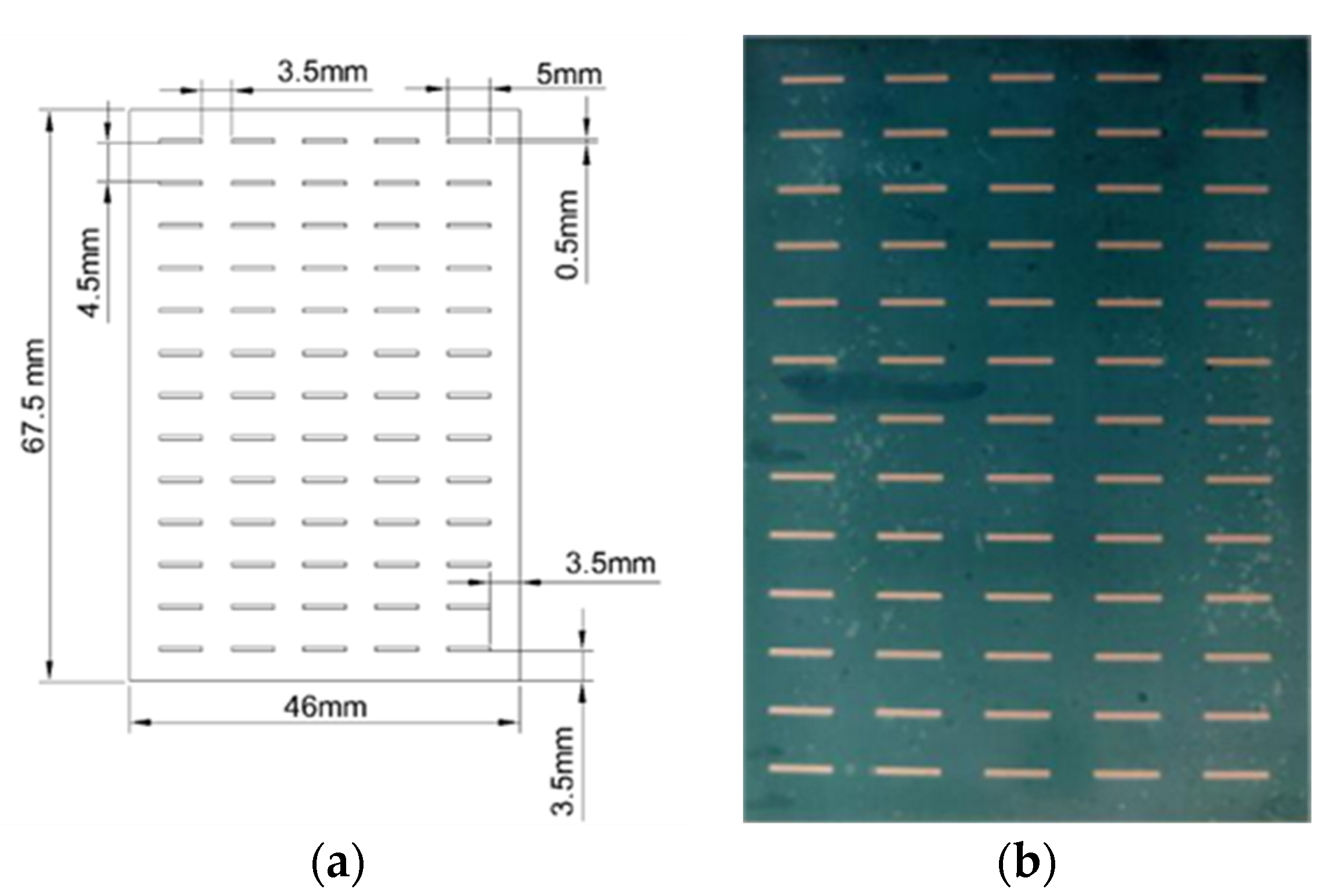

2. Experimental Design

2.1. Theoretical Analysis of Processing Efficiency

2.2. Experimental Design Scheme

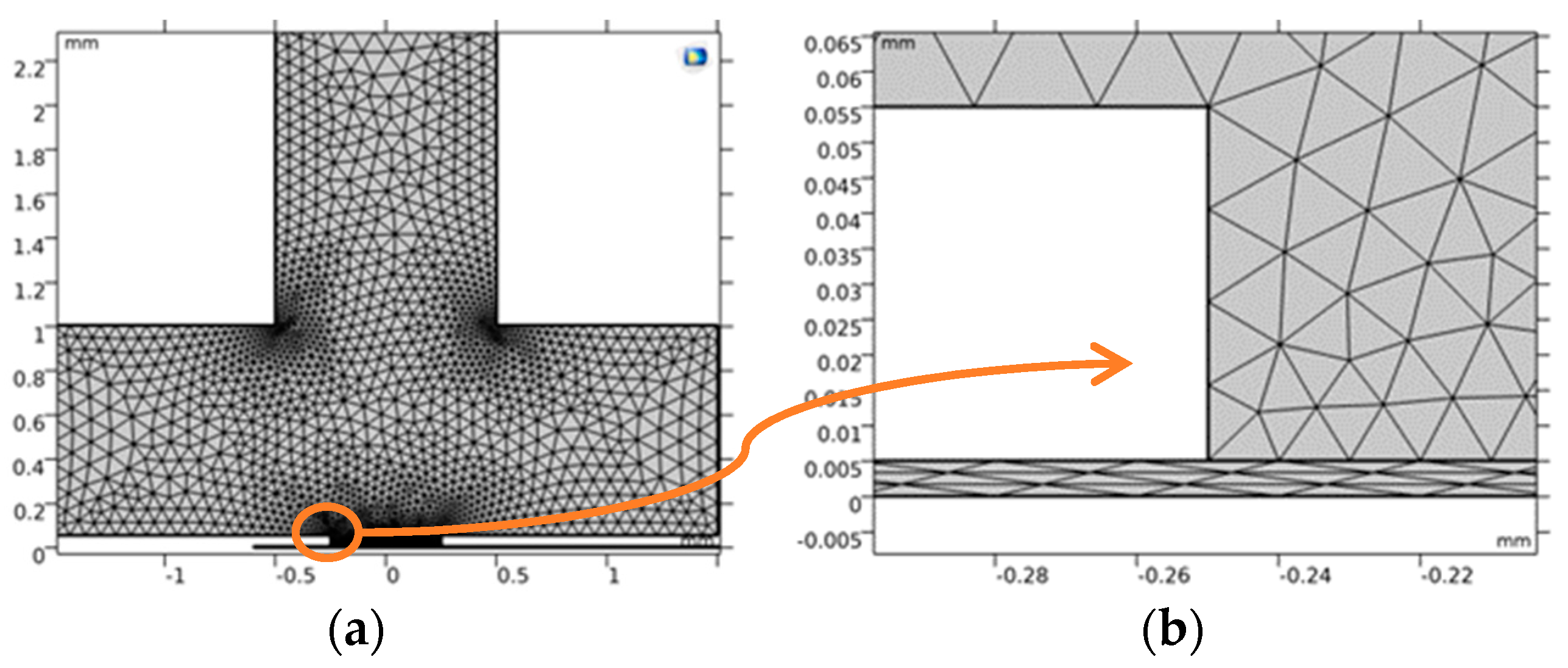

3. Modeling and Simulation Analysis

3.1. Multi-Physical Field Coupling

3.2. Microgroove Simulation Analysis

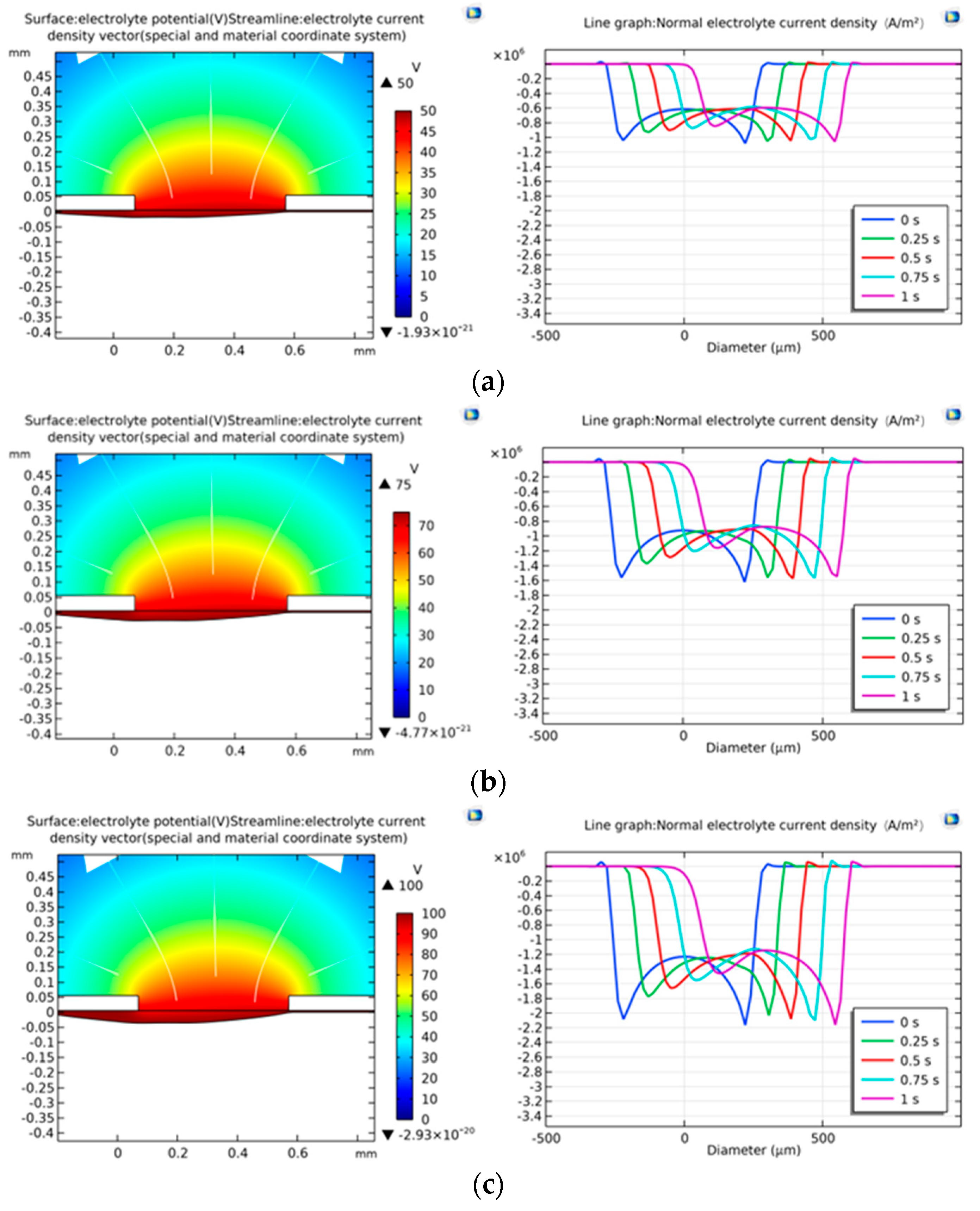

3.2.1. Simulation Analysis of Microgroove with Different Pulse Voltages

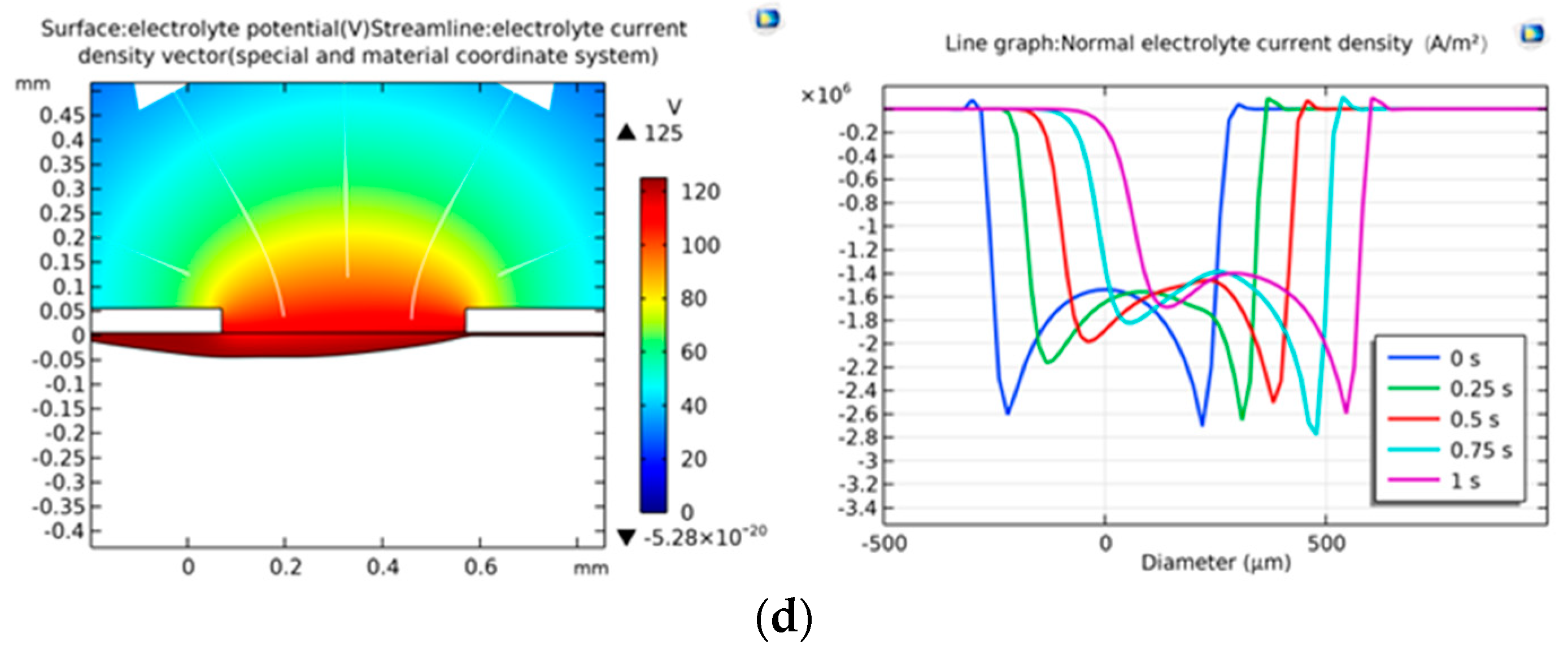

3.2.2. Simulation Analysis of Microgroove with Different Machining Gap

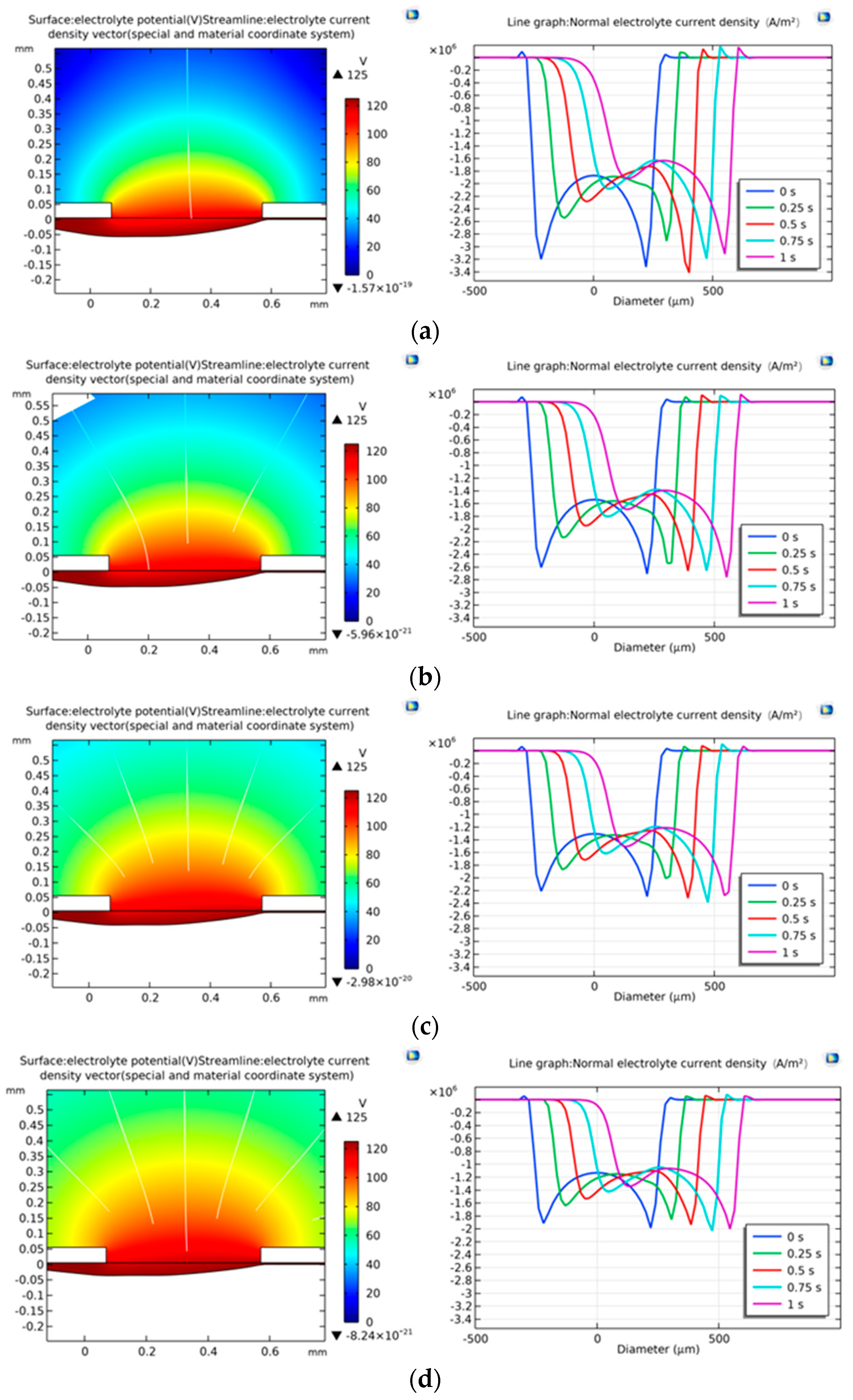

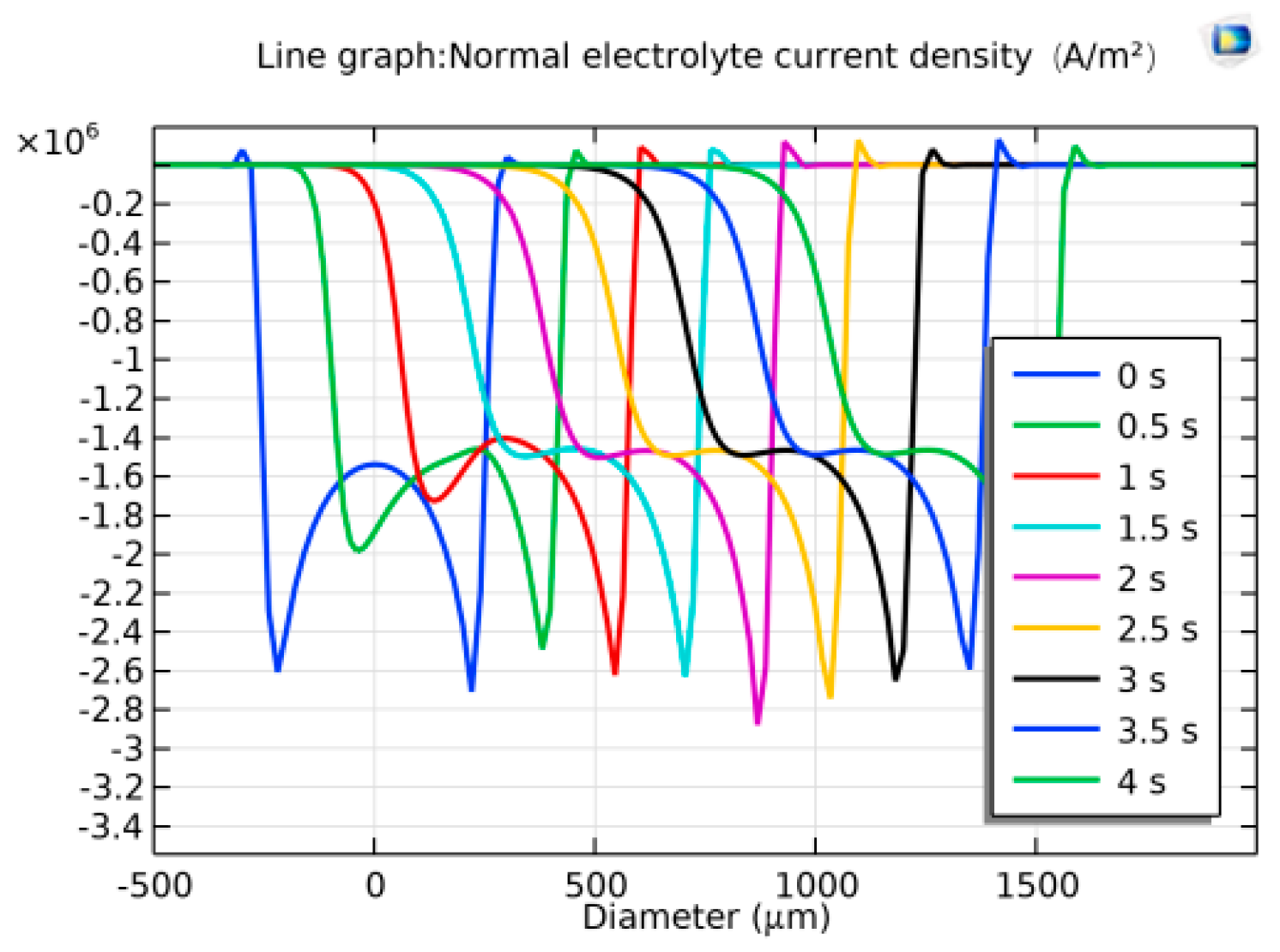

3.2.3. Simulation Analysis of Electric Field with Different Processing Times

4. Experimental Research

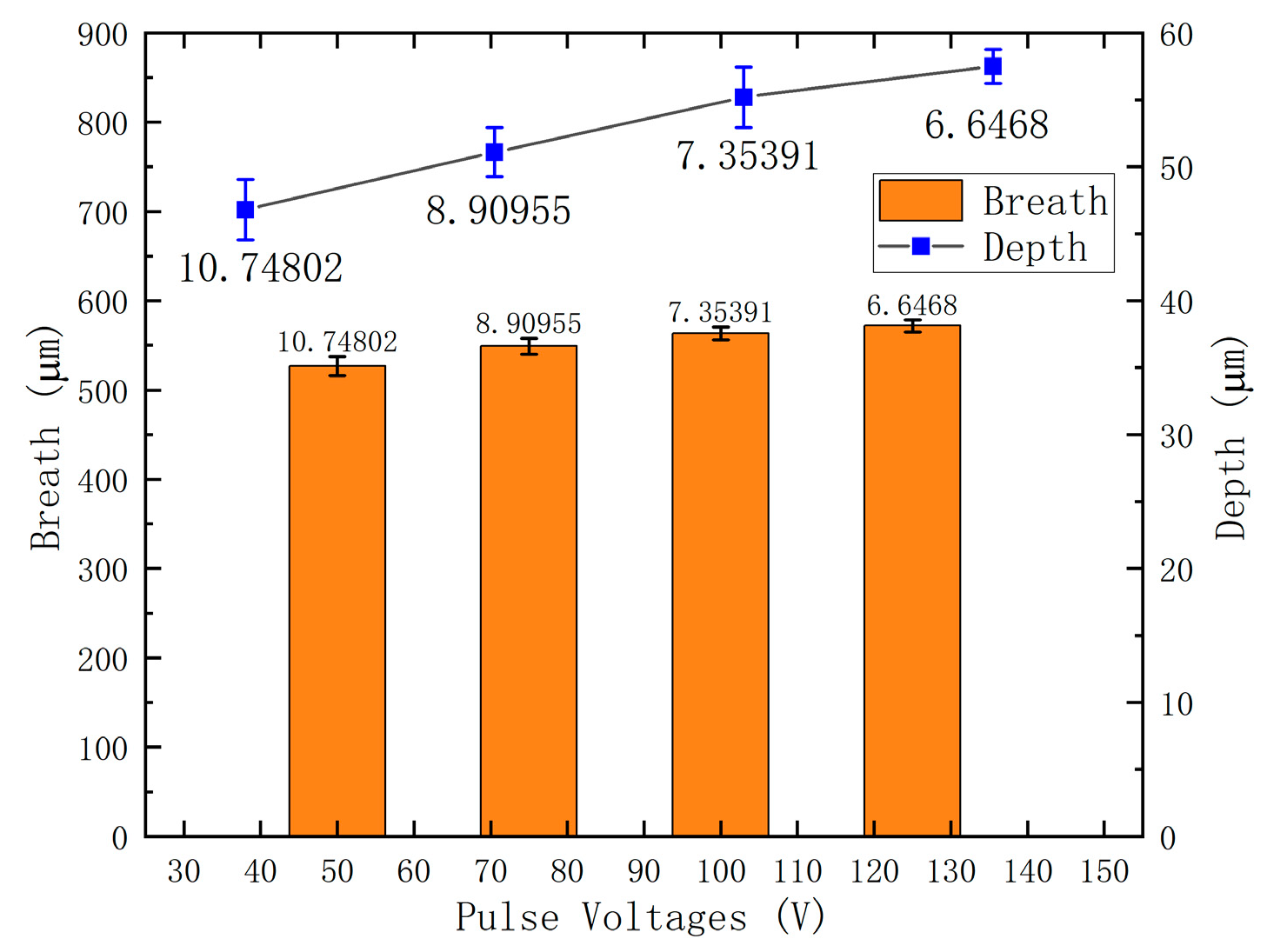

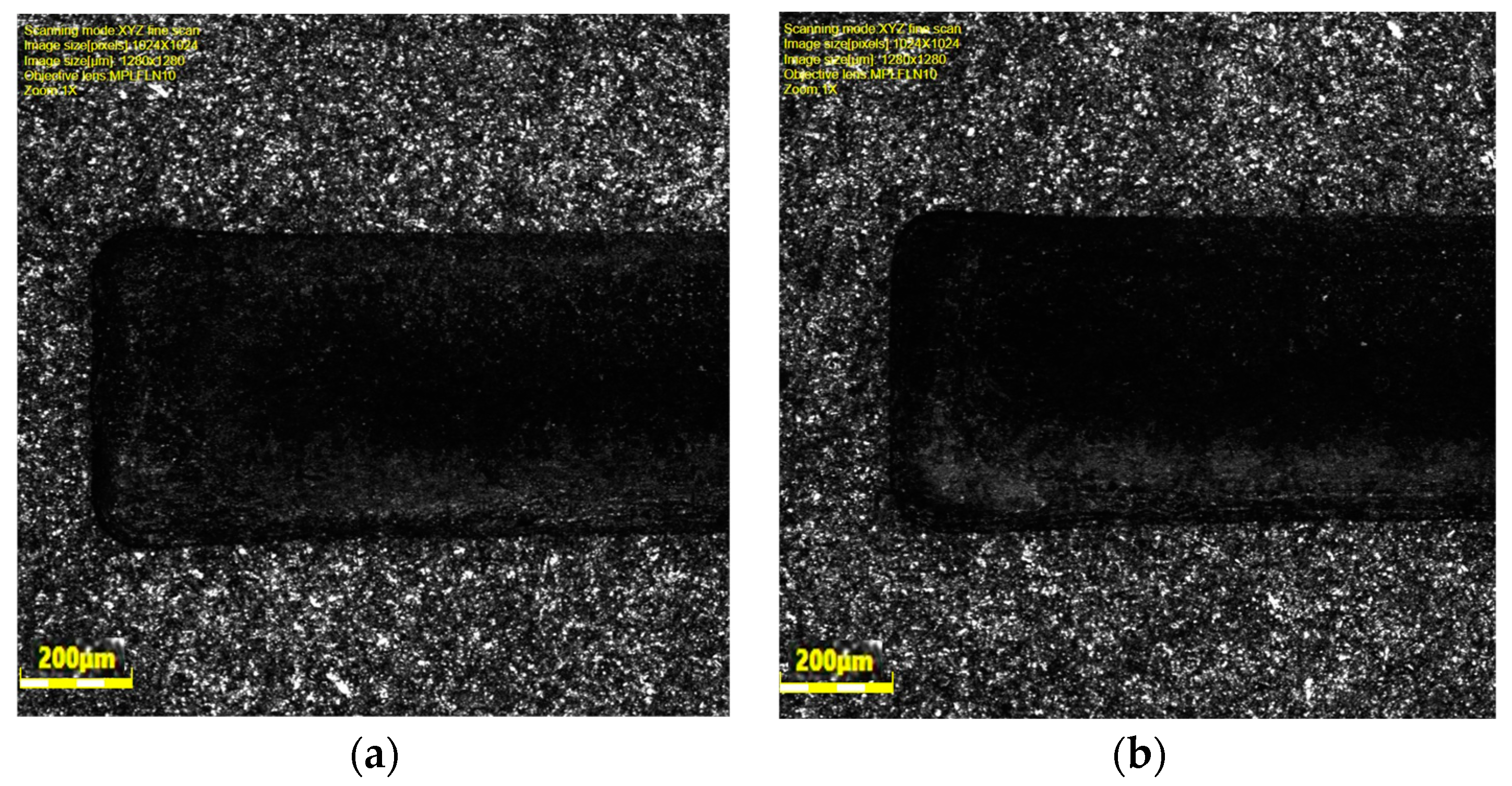

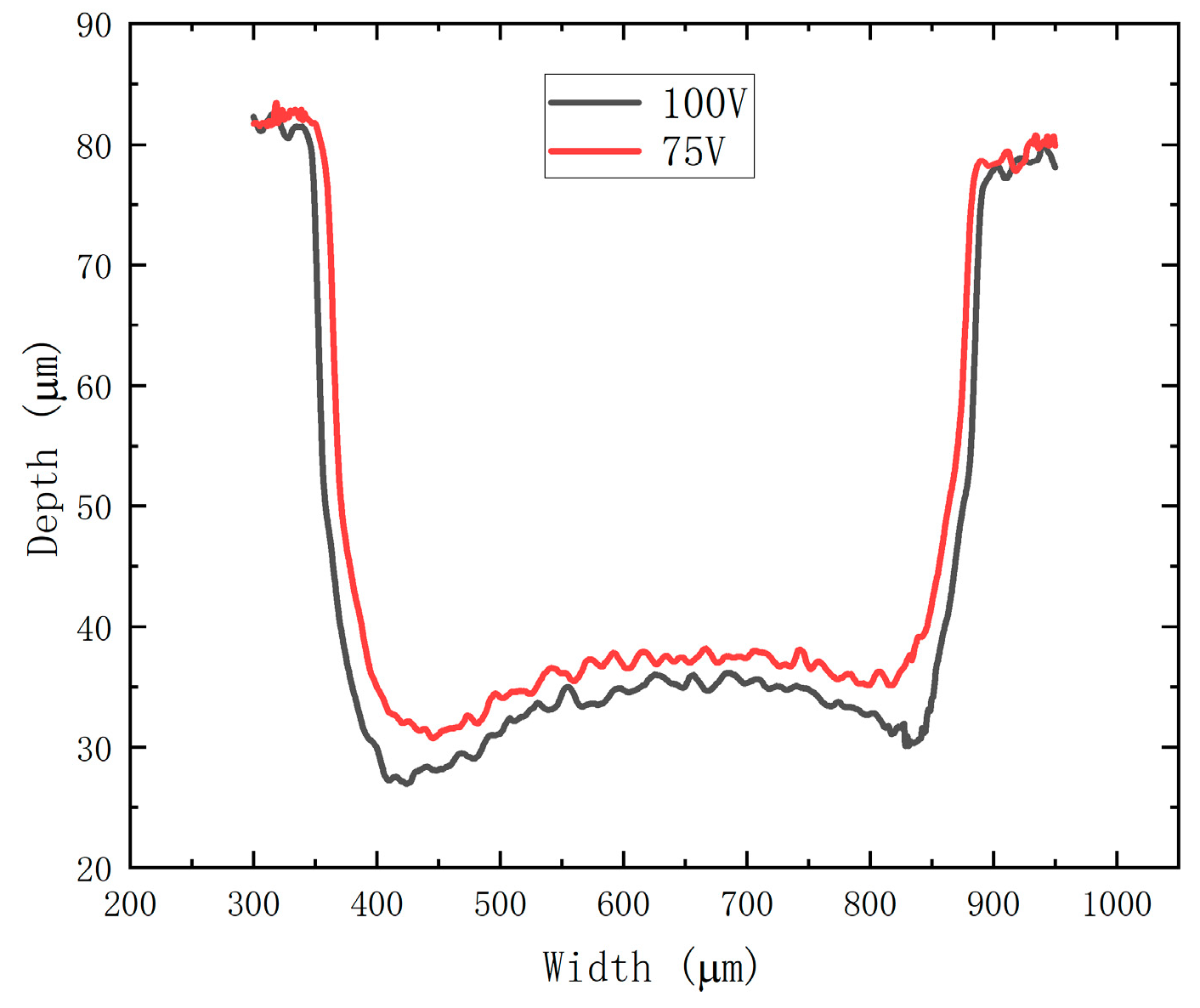

4.1. Impact of Pulse Voltage on Microgroove Structure

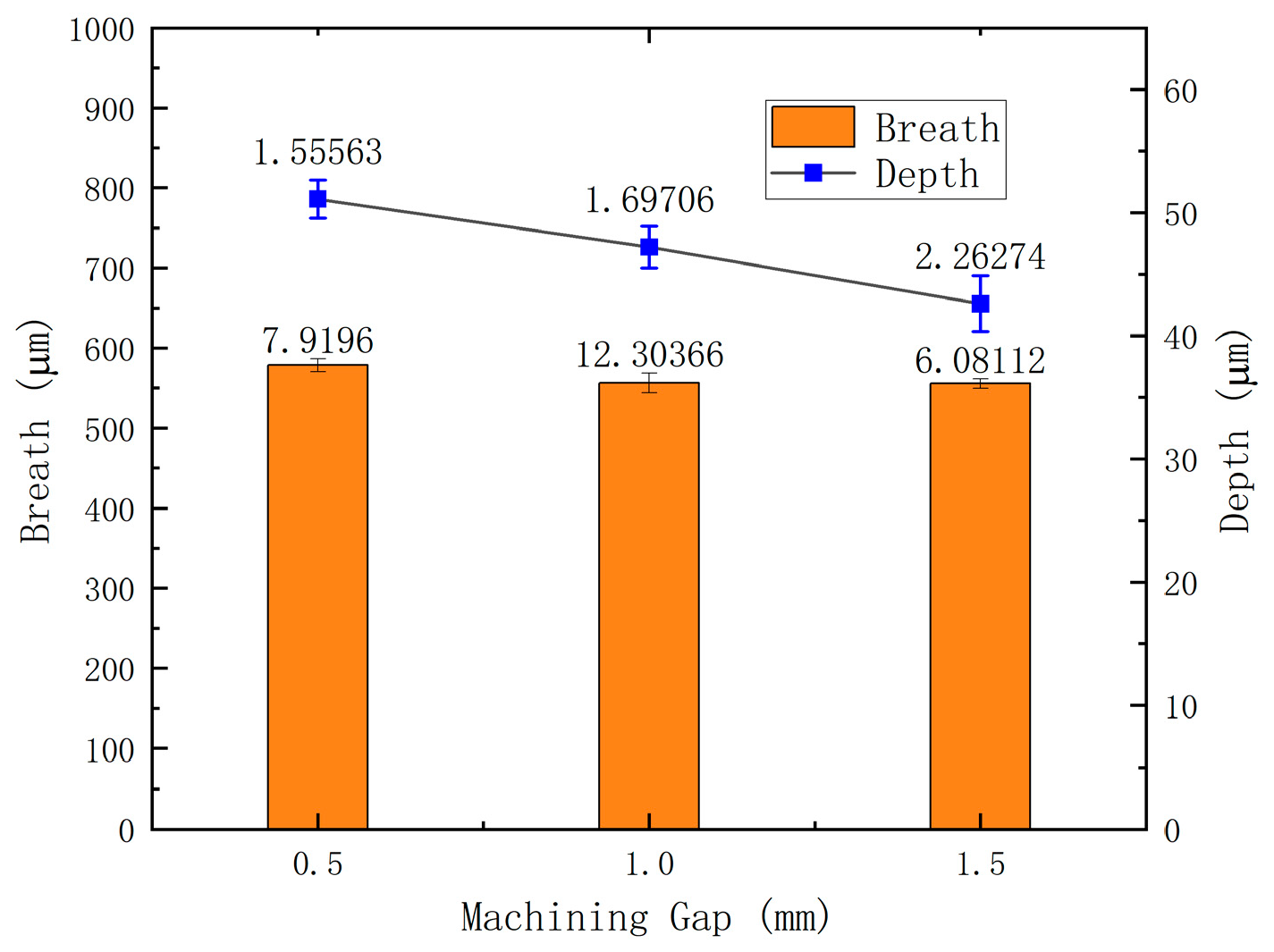

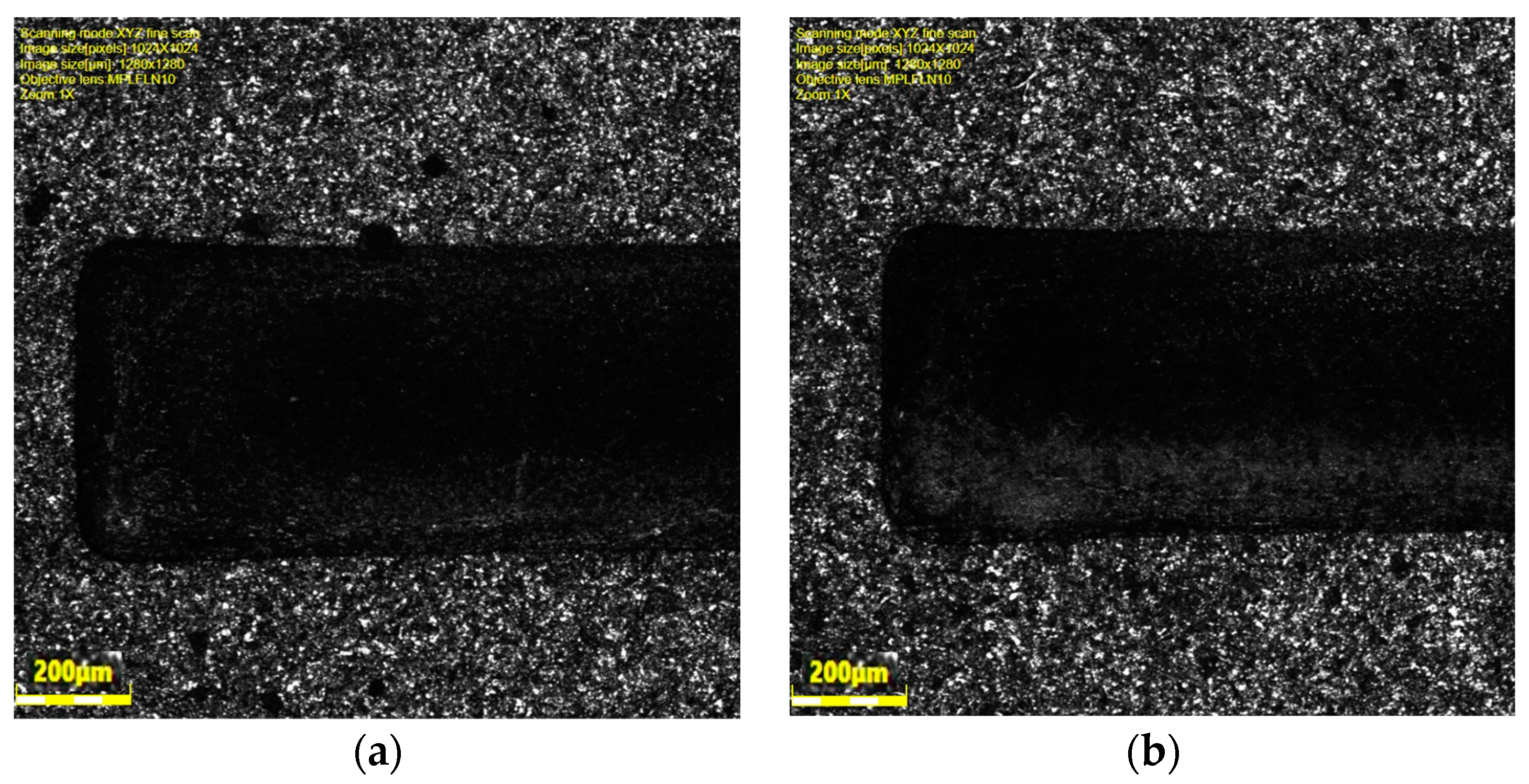

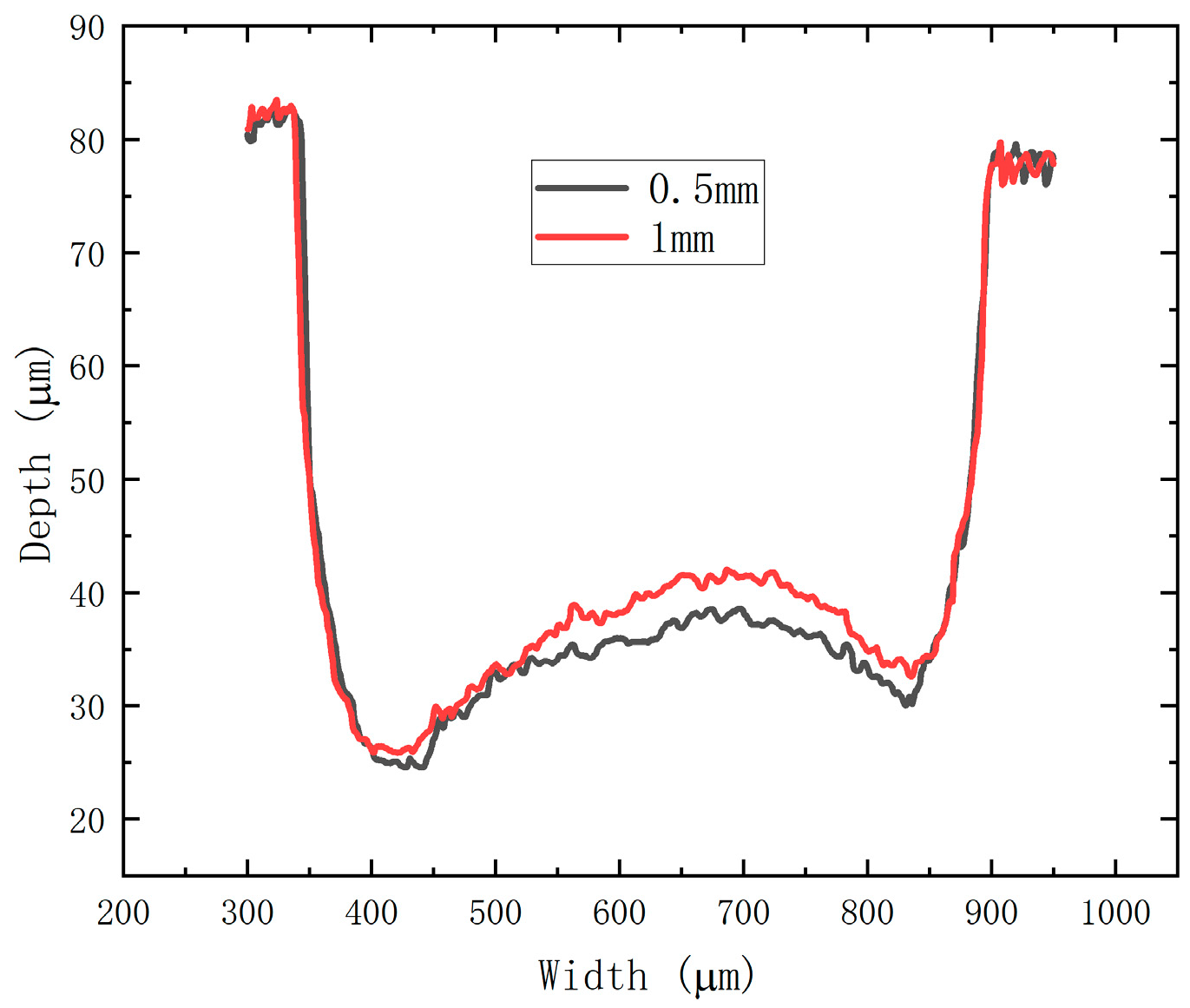

4.2. Effect of Machining Gap on Microgroove Structure

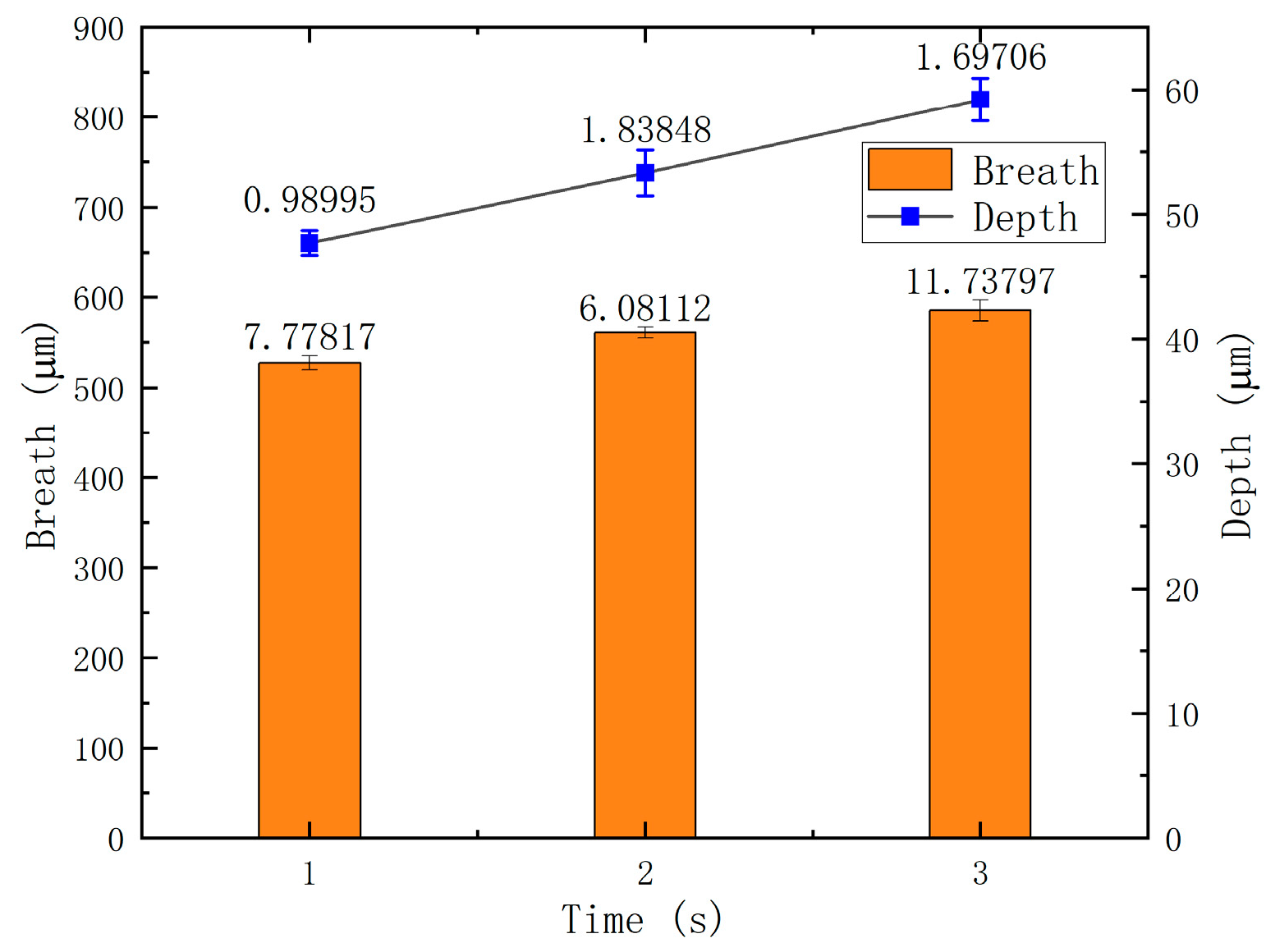

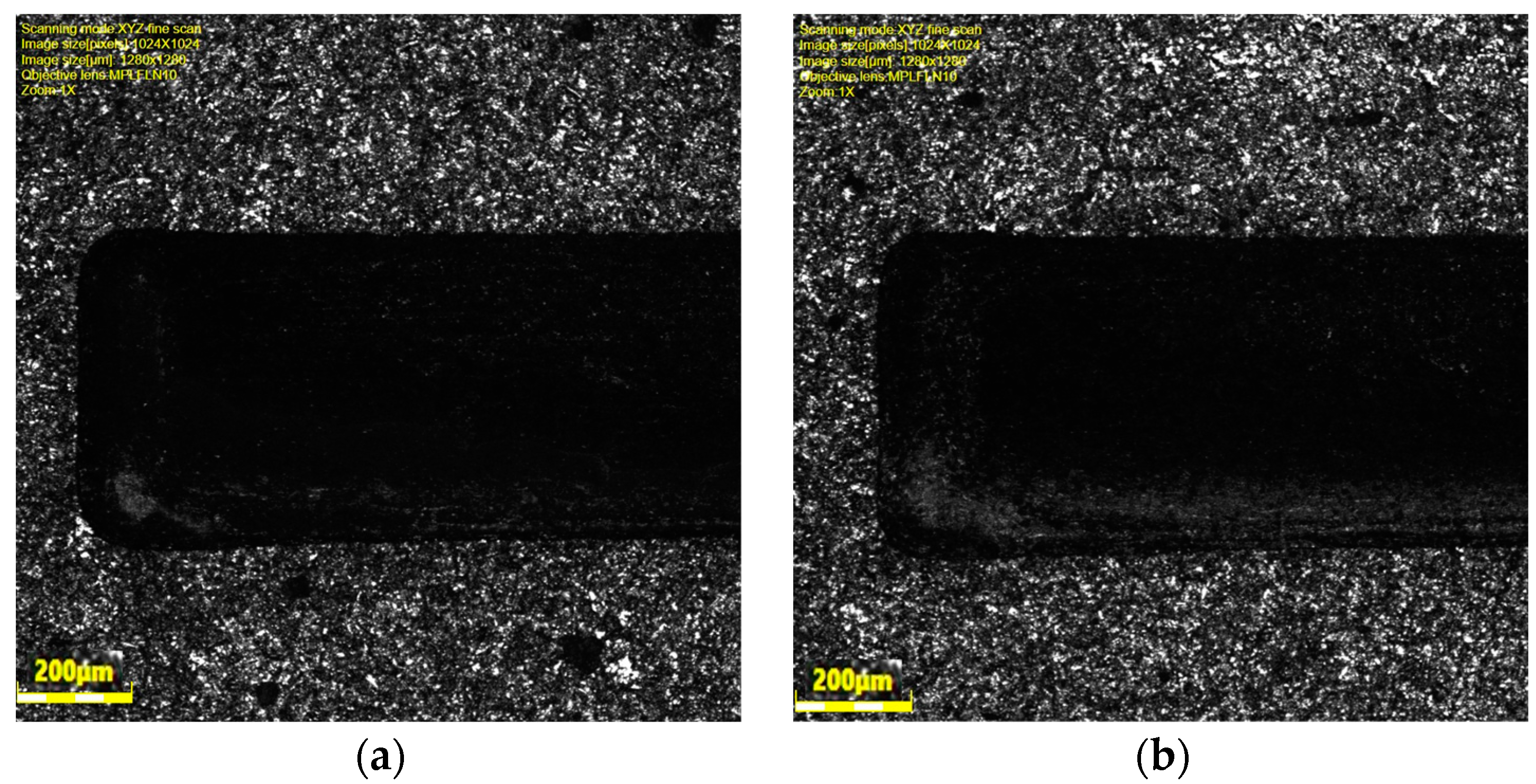

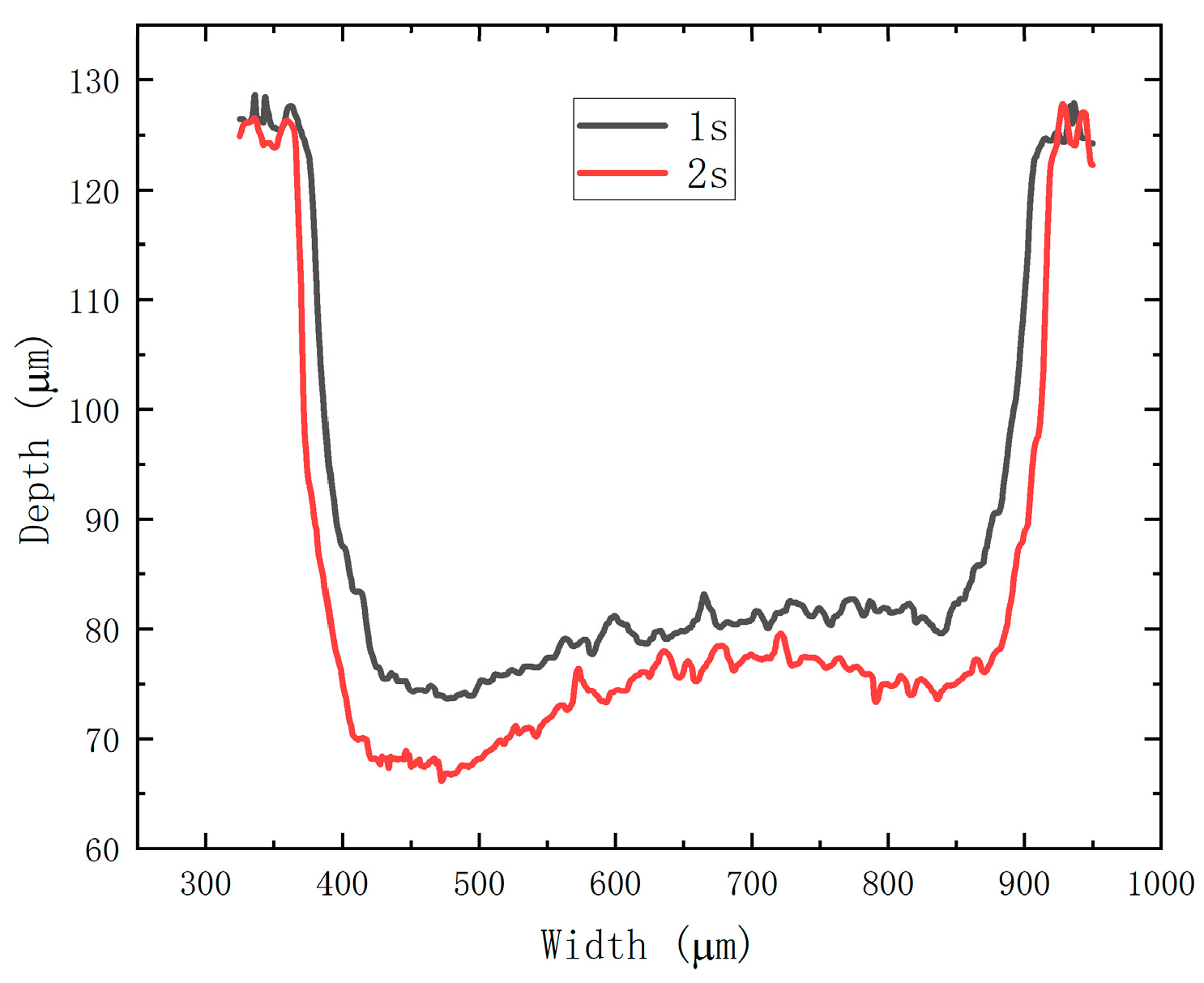

4.3. Effect of Machining Time on Microgroove Structure

5. Conclusions

- (1)

- Based on the COMSOL 6.2 software to construct the electric field simulation model of different processing parameters (pulse voltage, processing gap, and processing time), the results show that increasing the pulse voltage and reducing the processing gap can improve the electrolytic processing speed.

- (2)

- The contribution of 125 V pulse voltage to the depth of the microgroove is increased by 28.8%, and the contribution to the width is increased by 7.7% compared with that of 50 V. Reasonably increasing the pulse voltage can improve the microgroove replication accuracy and enhance the machining efficiency.

- (3)

- The contribution of the 1.5 mm machining gap to the microgroove depth decreases by 18.0%, and the contribution to the width decreases by 2.2% compared with 0.5 mm. It is concluded that by reducing the machining gap, the microgroove shape is well maintained, and the material removal rate is greatly improved.

- (4)

- The contribution of the 3 s machining time to the microgroove depth increased by 23.4%, and the contribution to the width increased by 13.6% compared with that of 1 s. By prolonging the processing time, the current efficiency can be effectively adjusted to achieve precise control of material removal, which is especially critical for fields such as the fabrication of microstructures on the surface of bionic marine animals.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yu, M.; Du, L.; Du, B.; Wang, F.; Zhang, C.; Li, D. Efficient evolution mechanism of electrolytic gas products from laser-assisted electrolyte jet machining. J. Mech. Work. Technol. 2024, 333. [Google Scholar] [CrossRef]

- Ding, H.; Chen, R.; Zhu, Y.; Shen, H.; Gao, Q. Effect of Frequency–Amplitude Parameter and Aspect Ratio on Propulsion Performance of Underwater Flapping-Foil. Biomimetics 2024, 9, 324. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Xu, H.; Zhang, Y.; Chen, S.; Zhao, Z.; Chen, J. Design of a Bio-Inspired Anti-Erosion Structure for a Water Hydraulic Valve Core: An Experimental Study. Biomimetics 2019, 4, 63. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.A. Research on Bionic Squid-inspired Robot for Underwater Monitorization and Preservation of Coral Reefs. In Proceedings of the 2023 IEEE International Conference on Sensors, Electronics and Computer Engineering (ICSECE), Jinzhou, China, 18–20 August 2023; pp. 844–851. [Google Scholar]

- Li, Y.; Xu, P.; Liu, B.; Liu, J.; Guo, L.; Meng, Z.; Xu, M. An Underwater Bionic Palm-Like Tactile Sensor Based on Triboelectric Nanogenerator. In Proceedings of the 2023 China Automation Congress (CAC), Chongqing, China, 17–19 November 2023; pp. 6241–6246. [Google Scholar]

- Li, A.; Guo, S.; Li, C. An Artificial Lateral Line-Based Active Obstacle Recognition Strategy and Performance Evaluation for Bionic Underwater Robots. IEEE Sensors J. 2024, 24, 26266–26277. [Google Scholar] [CrossRef]

- Wu, X.; Huang, J.; Wang, L. Pose Estimation-Based Visual Perception System for Analyzing Fish Swimming. IEEE Sensors J. 2024, 24, 13293–13303. [Google Scholar] [CrossRef]

- Wu, Z.; Yu, L.; Wang, J.; Dai, S.; Tan, M.; Yu, J. Hitch-Hiking Motion of Multiple Bionic Robotic Remoras With Enhanced Multimodal Locomotion. IEEE/ASME Trans. Mechatronics 2024, 1–12. [Google Scholar] [CrossRef]

- Du, R.; Li, Z.; Youcef-Toumi, K.; Alvarado, P.V. Robot Fish: Bio-inspired Fishlike Underwater Robots, 1st ed.; Springer Berlin: Heidelberg, Germany, 2015; pp. 143–145. [Google Scholar]

- Soltani-Kordshuli, F.; Miller, C.; Harris, N.; Zou, M. Laser Surface Texturing of Both Thin Polytetrafluoroethylene Coatings and Stainless Steel Substrates for Improving Tribological Properties. Polym. Test. 2023, 117, 107852. [Google Scholar] [CrossRef]

- Lv, X.; Xu, Z.; Liu, Y.; Wang, X.; Xie, S.; Xu, L.; Tan, H. Study on Liquid-Phase-Assisted Laser Surface Microtexturing and the Surface Properties of 304 Stainless Steel. J. Mater. Eng. Perform. 2023, 1–13. [Google Scholar] [CrossRef]

- Budakli, M.; Arik, M. Saturated and Superheated Water Vapor Condensation on a Custom Micro-Textured Surface. In Proceedings of the 2023 22nd IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Istanbul, Turkey, 26–29 June 2023; pp. 1–6. [Google Scholar]

- Qing, J.; Navarro-Cía, M. Analysis of the Capacity and Energy Efficiency of Metallodielectric Surface Wave Links Operating Beyond Y Band. In Proceedings of the 2024 18th European Conference on Antennas and Propagation (EuCAP), Glasgow, UK, 17–22 March 2024; pp. 1–3. [Google Scholar]

- Sun, Y.; Han, F.; Zhang, D.; Zhao, X.; Ye, D. An Underwater Soft Claw Based on Bionic Principle. In Proceedings of the 2021 IEEE International Conference on Robotics and Biomimetics (ROBIO), Sanya, China, 27–31 December 2021; pp. 973–977. [Google Scholar]

- Ionescu, O.; Cernica, I.V.; Manea, E.; Purica, M.; Corneliu, P.C.; Paun, C.; Alina, P. Microtextured photovoltaic cells system for UAVs autonomy extension. In Proceedings of the 2021 International Semiconductor Conference (CAS), Bucharest, Romania, 8–12 October 2021; pp. 99–102. [Google Scholar]

- Westgate, T.M.; Boivin, A.B.; Veerman, B.W.; Born, B.; Todd, G.; Holzman, J.F. A Corner-Cube-Cell Solar Array for Improved Capture of Optical Power and Increased Generation of Electrical Power. IEEE J. Photovoltaics 2021, 12, 344–352. [Google Scholar] [CrossRef]

- Chen, C.; Wu, S.; Zhang, T.; Wang, Y.; Shao, X.; Mo, F. Experimental Study of Electrolytic Processing of Discharge-Assisted Jet Masks. Coatings 2023, 13, 1280. [Google Scholar] [CrossRef]

- Chen, C.; Wu, S.; Wu, H.; Shan, L.; Li, K.; Wu, S. Discharge Characteristics and Mechanisms of Electrolytic Discharge Processing by Jet Mask. Coatings 2023, 13, 1933. [Google Scholar] [CrossRef]

- Chen, C.; Shao, X.; Guo, J.; Yu, Z.; Chen, Z.; Lu, X.; Jiang, Z. An Experimental Study Based on Surface Microtexture of Medical Devices. Coatings 2024, 14, 888. [Google Scholar] [CrossRef]

- Chen, X.L.; Dong, B.Y.; Fan, G.C.; Zhang, C.Y.; Liu, J.W.; Zhang, Y.J.; Guo, Z.N. Investigation on modified jet electrochemical machining of micro-channel. Int. J. Adv. Manuf. Technol. 2019, 104, 4433–4443. [Google Scholar] [CrossRef]

- Cui, Y.; Wang, F.; Hu, Q.; Zhang, W. Study on Antifatigue Crack Growth Characteristics of Ball-End Milling Bionic Surface. Coatings 2022, 12, 327. [Google Scholar] [CrossRef]

- Liu, W.; Luo, Y.; Zhao, Y.; Zhou, H.; Ao, S.; Li, Y. Electrochemical Jet Machining of Surface Texture: Improving the Strength of Hot-Pressure-Welded AA6061-CF/PA66 Joints. J. Compos. Sci. 2024, 8, 263. [Google Scholar] [CrossRef]

- Wu, M.; Guo, Z.; Qian, J.; Reynaerts, D. Multi-Ion-Based Modelling and Experimental Investigations on Consistent and High-Throughput Generation of a Micro Cavity Array by Mask Electrolyte Jet Machining. Micromachines 2022, 13, 2165. [Google Scholar] [CrossRef] [PubMed]

- Ge, Z.; Hu, Q.; Zhu, H.; Zhu, Y. Surface Tribological Properties Enhancement Using Multivariate Linear Regression Optimization of Surface Micro-Texture. Coatings 2024, 14, 1258. [Google Scholar] [CrossRef]

- Niu, S.; Wang, H.; Ming, P.; Qin, G.; Ren, L.; Liu, H.; Li, X. Electrochemical Properties and Jet Electrochemical Micromilling of (TiB+TiC)/Ti6Al4V Composites in NaCl+NaNO3 Mixed Electrolyte. Materials 2024, 17. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Xu, P.; Liu, J.; Wang, T.; Wang, S.; Guan, T.; Liu, X.; Chen, T.; Zheng, J.; Tao, J.; et al. Bio-inspired Coral-like Sensor Aiming at Ocean Wave Monitoring. In Proceedings of the 2021 China Automation Congress (CAC)., Kunming, China, 11–13 August 2021; pp. 908–912. [Google Scholar]

- Bao, H.; Liu, H.; He, J.; An, X.; Hou, S.; Song, M. Surface Damping Bionic Design of a Small Underwater Cruising Robot. Mech. Des. 2023, 40, 149–156. [Google Scholar] [CrossRef]

| Name | Description | Unit |

|---|---|---|

| X/Y/Z-axis positioning accuracy | 5 | μm |

| Z travel | 300 | mm |

| X/Y travel | 200 × 200 | mm |

| External dimensions | 1000 × 750 × 2230 | mm |

| Control system software | LabVIEW 2024 Q1 |

| Parameter Name | Numerical Values | Unit |

|---|---|---|

| Machining clearance | 0.5, 1, 1.5, 2 | Mm |

| Pulse voltages | 50, 75, 100, 125 | V |

| Jet diameter | 1, 1.5, 2 | Mm |

| Mask diameter | 500 | Μm |

| Mask thickness | 60 | Μm |

| Stainless steel molar quality | 54.94 | g/mol |

| Density of stainless steel | 7.77 | g/cm3 |

| Conductivity | 7.00 | S/m |

| Faraday’s constant | 96,486 | C/mol |

| Electrochemical equivalent | 2.1 × 10−3 | cm3(A·min) |

| Number of electrons in solution | 2.7 | Pcs |

| Processing time | 1, 2, 3, 4 | S |

| Pulse Voltage (V) | 50 | 75 | 100 | 125 |

|---|---|---|---|---|

| Breath (μm) | 532 | 552 | 565 | 573 |

| Depth (μm) | 45 | 49 | 53 | 58 |

| Machining Gap (mm) | 0.5 | 1 | 1.5 |

|---|---|---|---|

| Breath (μm) | 573 | 565 | 560 |

| Depth (μm) | 50 | 46 | 41 |

| Processing Times (s) | 1 | 2 | 3 |

|---|---|---|---|

| Breath (μm) | 522 | 565 | 593 |

| Depth (μm) | 47 | 52 | 58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Yu, Z.; Shao, X.; Zou, B.; Xu, B.; Xiao, Z.; Tang, Z. An Experimental Study Based on the Surface Microstructure of Bionic Marine Animals. Coatings 2024, 14, 1606. https://doi.org/10.3390/coatings14121606

Chen C, Yu Z, Shao X, Zou B, Xu B, Xiao Z, Tang Z. An Experimental Study Based on the Surface Microstructure of Bionic Marine Animals. Coatings. 2024; 14(12):1606. https://doi.org/10.3390/coatings14121606

Chicago/Turabian StyleChen, Chaoda, Zhuoyuan Yu, Xiaoqiang Shao, Baojian Zou, Biaoqing Xu, Zeping Xiao, and Zhenyu Tang. 2024. "An Experimental Study Based on the Surface Microstructure of Bionic Marine Animals" Coatings 14, no. 12: 1606. https://doi.org/10.3390/coatings14121606

APA StyleChen, C., Yu, Z., Shao, X., Zou, B., Xu, B., Xiao, Z., & Tang, Z. (2024). An Experimental Study Based on the Surface Microstructure of Bionic Marine Animals. Coatings, 14(12), 1606. https://doi.org/10.3390/coatings14121606