High Corrosion Resistance of Aluminum Alloy Friction Stir Welding Joints via In Situ Rolling

Abstract

1. Introduction

2. Experimental Section

3. Results and Discussion

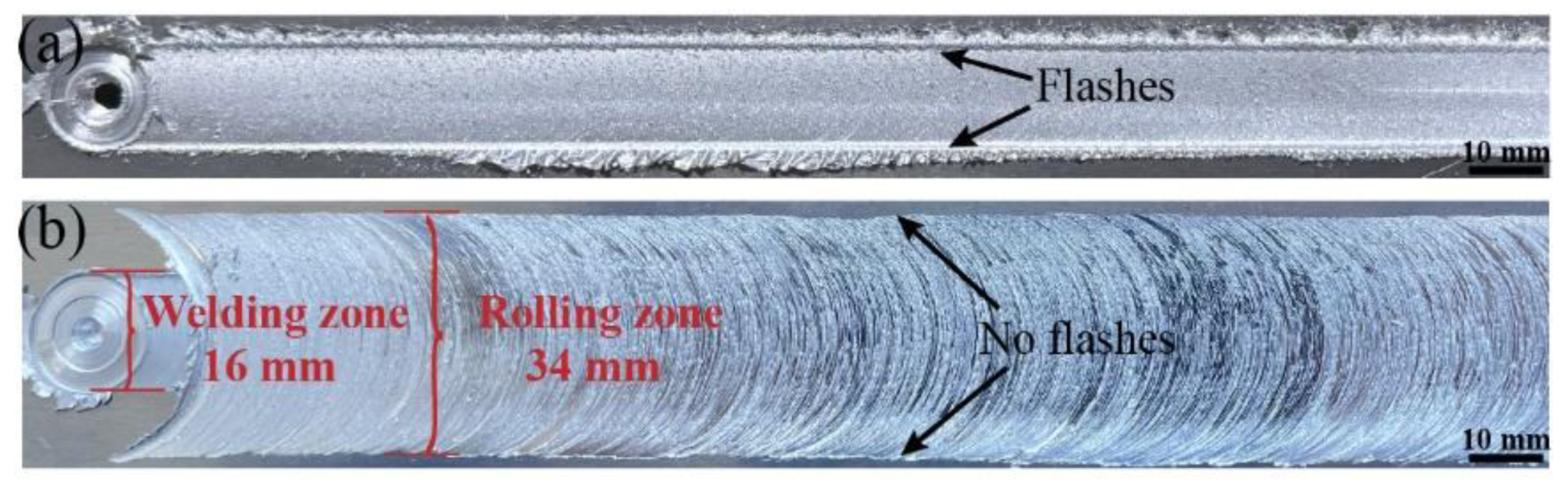

3.1. Surface Appearance

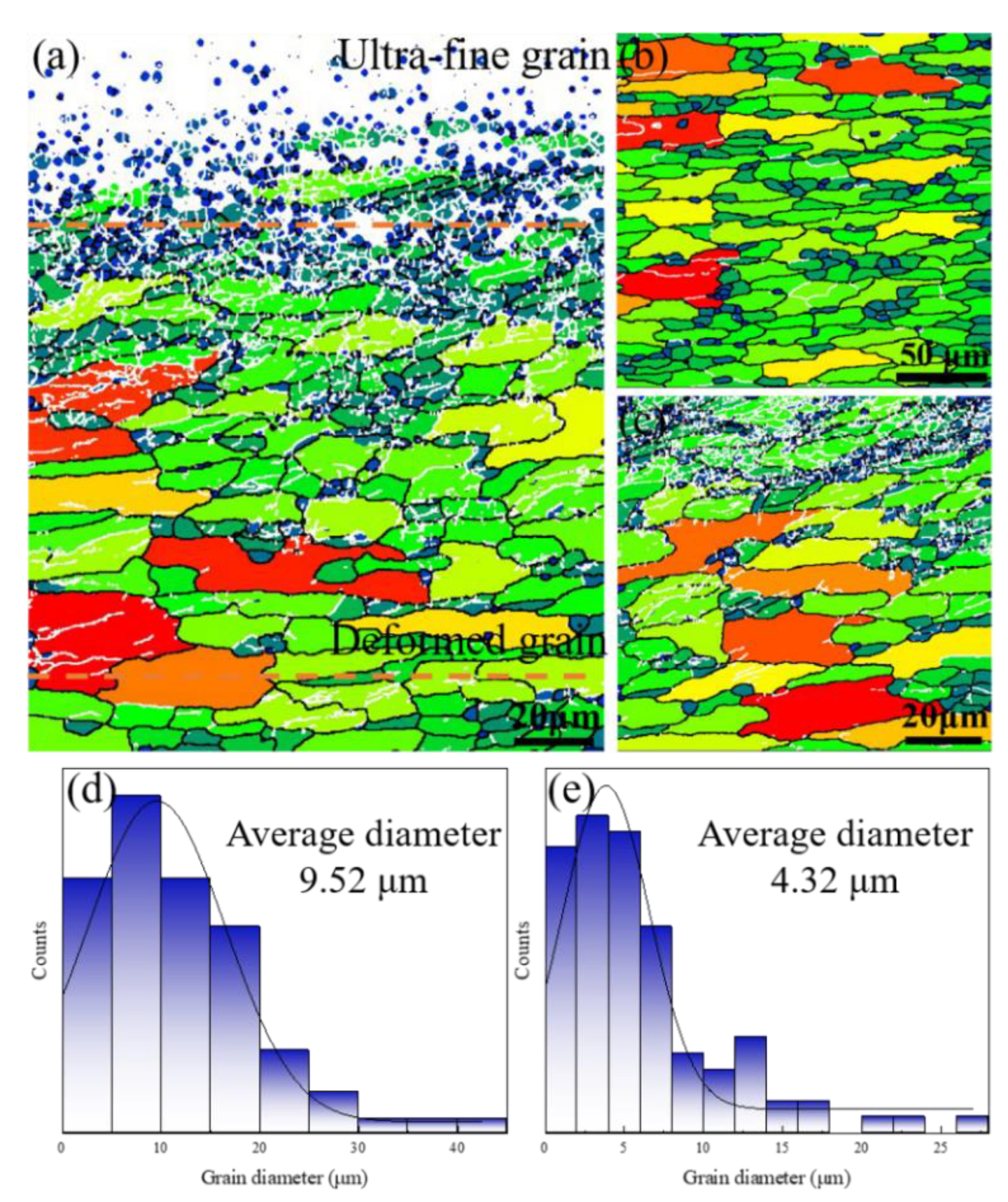

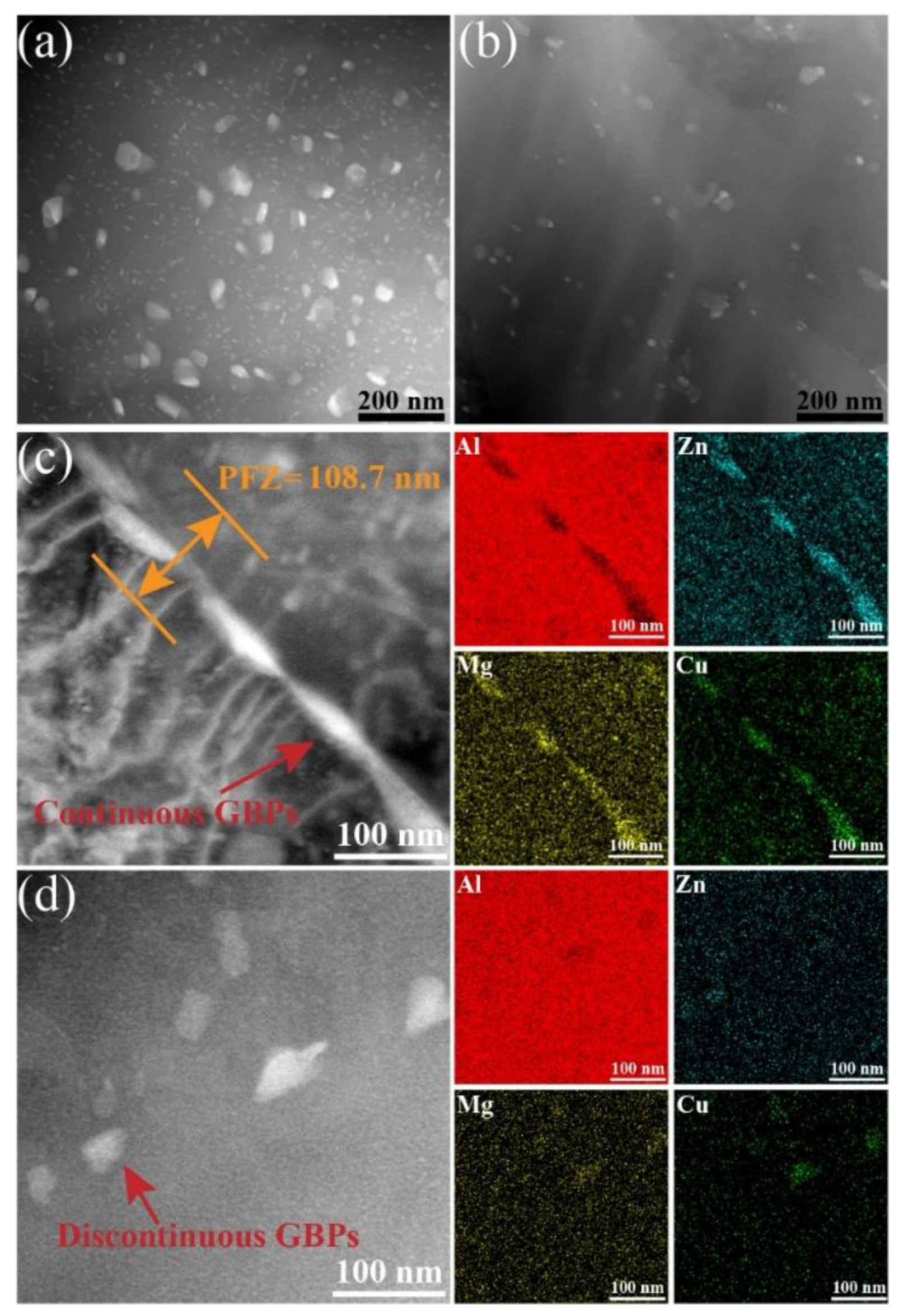

3.2. Microstructural Analysis

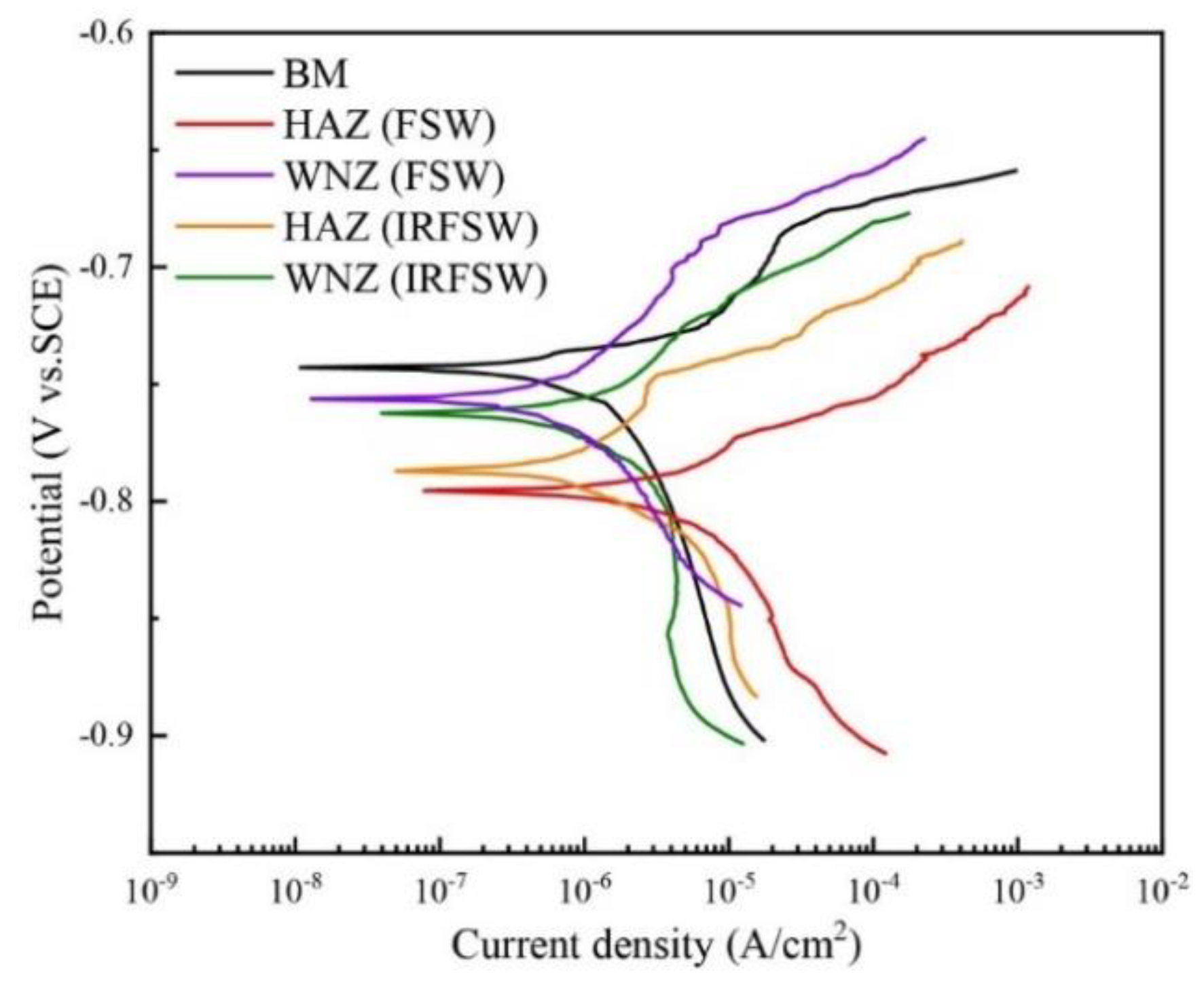

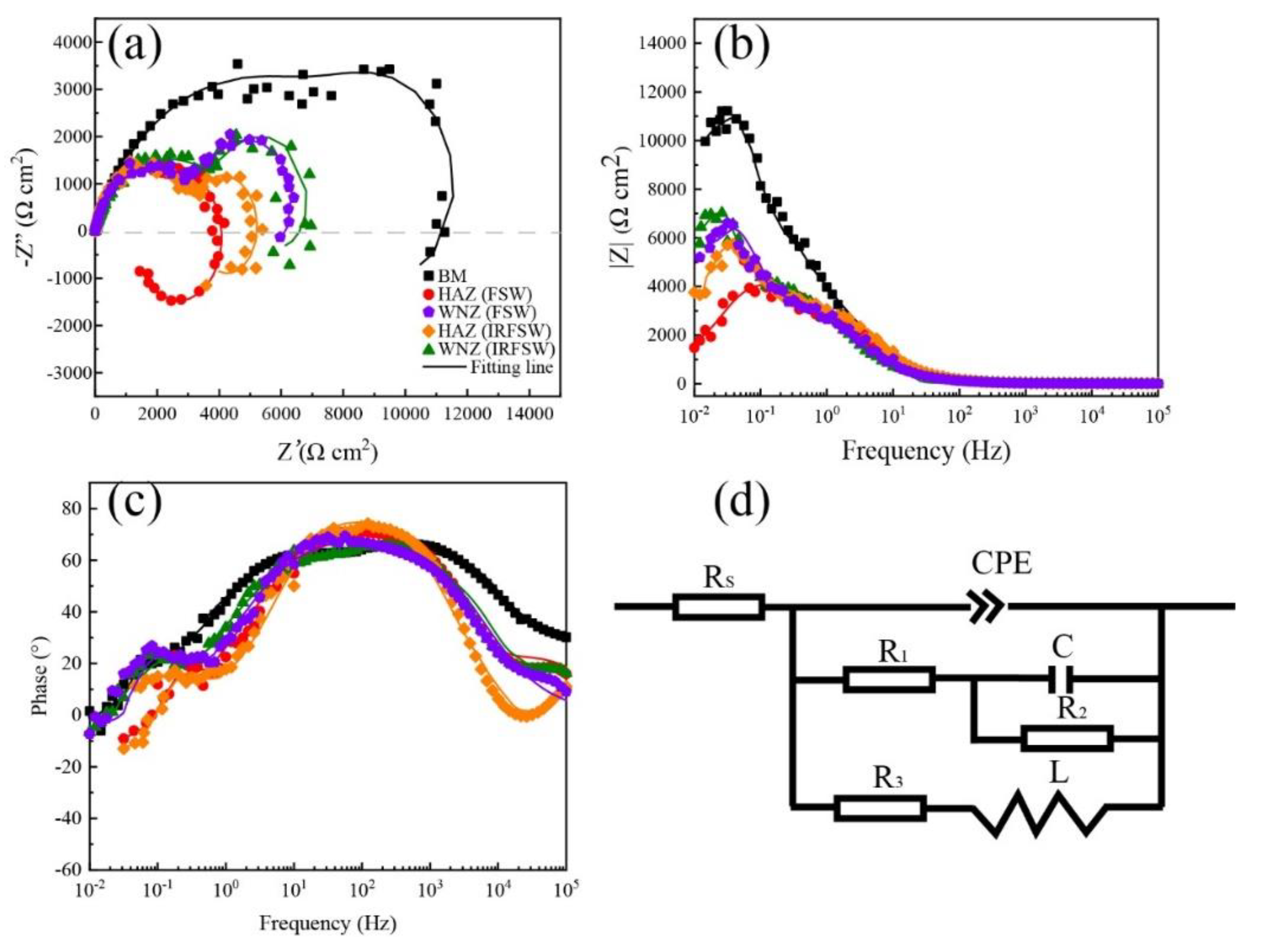

3.3. Intergranular and Electrochemical Corrosion Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Azarniya, A.; Taheri, A.K.; Taheri, K.K. Recent advances in ageing of 7xxx series aluminum alloys: A physical metallurgy perspective. J. Alloys Compd. 2019, 781, 945–983. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Umer, R.; Khan, K.A. Review of recent trends and developments in aluminium 7075 alloy and its metal matrix composites (MMCs) for aircraft applications. Results Eng. 2023, 20, 101372. [Google Scholar] [CrossRef]

- Zhang, B.; Ma, Y.; Yu, F.; Liu, Y.; Zhou, E.; Fan, Z.; Ge, E.; Li, Y.; Lin, Z. Strengthening flat-die friction self-pierce riveting joints via manipulating stir zone geometry by tailored rivet structures. Int. J. Mach. Tools Manuf. 2024, 203, 104223. [Google Scholar] [CrossRef]

- Ehiasarian, A.; Purandare, Y.; Sugumaran, A.; Hovsepian, P.; Hatto, P.; De Backer, J. Improving the Quality of Friction Stir Welds in Aluminium Alloys. Coatings 2021, 11, 539. [Google Scholar] [CrossRef]

- Liu, H.; Pu, J.; Wu, M.; Zhang, C.; Rao, J.; Long, W.; Shen, Y. Research on the Microstructure and Properties of Al Alloy/Steel CMT Welding-Brazing Joints with Al–Si Flux-Cored Welding Wires. Coatings 2023, 13, 1590. [Google Scholar] [CrossRef]

- Gibson, B.T.; Lammlein, D.H.; Prater, T.J.; Longhurst, W.R.; Cox, C.D.; Ballun, M.C.; Dharmaraj, K.J.; Cook, G.E.; Strauss, A.M. Friction stir welding: Process, automation, and control. J. Manuf. Process. 2014, 16, 56–73. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Feng, A.H.; Chen, D.L.; Shen, J. Recent Advances in Friction Stir Welding/Processing of Aluminum Alloys: Microstructural Evolution and Mechanical Properties. Crit. Rev. Solid State Mater. Sci. 2018, 43, 269–333. [Google Scholar] [CrossRef]

- Meng, X.; Xie, Y.; Sun, S.; Ma, X.; Wan, L.; Cao, J.; Huang, Y. Lightweight Design: Friction-Based Welding between Metal and Polymer. Acta Metall. Sin. (Engl. Lett.) 2023, 36, 881–898. [Google Scholar] [CrossRef]

- Rao, A.C.U.; Vasu, V.; Govindaraju, M.; Srinadh, K.S. Stress corrosion cracking behaviour of 7xxx aluminum alloys: A literature review. Trans. Nonferrous Met. Soc. China 2016, 26, 1447–1471. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Zhou, L.; Meng, G.; Liu, B.; Wang, J.; Shao, Y.; Jiang, J. Macro-galvanic effect and its influence on corrosion behaviors of friction stir welding joint of 7050-T76 Al alloy. Corros. Sci. 2020, 164, 108360. [Google Scholar] [CrossRef]

- Wang, W.; Meng, X.; Dong, W.; Xie, Y.; Ma, X.; Mao, D.; Zhang, Z.; Huang, Y. In-situ rolling friction stir welding of aluminum alloys towards corrosion resistance. Corros. Sci. 2024, 230, 111920. [Google Scholar] [CrossRef]

- Lin, Y.; Lu, C.; Wei, C.; Zheng, Z. Effect of aging treatment on microstructures, tensile properties and intergranular corrosion behavior of Al–Cu–Li alloy. Mater. Charact. 2018, 141, 163–168. [Google Scholar] [CrossRef]

- Ding, T.; Yan, H.; Chen, J.; Xia, W.; Su, B.; Zhu, H. Effects of Rolling Deformation on Microstructure, Tensile Properties and Corrosion Behaviors of High Mg Alloyed of Al-Mg Alloy. J. Mater. Eng. Perform. 2022, 31, 2168–2181. [Google Scholar] [CrossRef]

- Paglia, C.S.; Buchheit, R.G. The time–temperature–corrosion susceptibility in a 7050-T7451 friction stir weld. Mater. Sci. Eng. A 2008, 492, 250–254. [Google Scholar] [CrossRef]

- Qian, S.; Zhang, T.; Chen, Y.; Xie, J.; Chen, Y.; Lin, T.; Li, H. Effect of ultrasonic impact treatment on microstructure and corrosion behavior of friction stir welding joints of 2219 aluminum alloy. J. Mater. Res. Technol. 2022, 18, 1631–1642. [Google Scholar] [CrossRef]

- Li, W.; Jiang, R.; Huang, C.; Zhang, Z.; Feng, Y. Effect of cold sprayed Al coating on mechanical property and corrosion behavior of friction stir welded AA2024-T351 joint. Mater. Des. 2015, 65, 757–761. [Google Scholar] [CrossRef]

- Liu, P.; Sun, S.; Hu, J. Effect of laser shock peening on the microstructure and corrosion resistance in the surface of weld nugget zone and heat-affected zone of FSW joints of 7050 Al alloy. Opt. Laser Technol. 2019, 112, 1–7. [Google Scholar] [CrossRef]

- Hatamleh, O.; Singh, P.M.; Garmestani, H. Corrosion susceptibility of peened friction stir welded 7075 aluminum alloy joints. Corros. Sci. 2009, 51, 135–143. [Google Scholar] [CrossRef]

- ASTM G110–92; Standard Practice for Evaluating Intergranular Corrosion Resistance of Heat Treatable Aluminium Alloys by Immersion in Sodium Chloride + Hydogen Pexoxide Solution. ASTM: West Conshehoken, PA, USA, 2015.

- Wang, J.; Xie, Y.; Meng, X.; Zhao, Y.; Sun, S.; Li, J.; Chen, J.; Chen, H.; Ma, X.; Wang, N.; et al. Wire-based friction stir additive manufacturing towards isotropic high-strength-ductility Al-Mg alloys. Virtual Phys. Prototyp. 2024, 19, 2417369. [Google Scholar] [CrossRef]

- Liu, L.L.; Pan, Q.L.; Wang, X.D.; Xiong, S.W. The effects of aging treatments on mechanical property and corrosion behavior of spray formed 7055 aluminium alloy. J. Alloys Compd. 2018, 735, 261–276. [Google Scholar] [CrossRef]

- Sun, Q.; Han, Q.; Xu, R.; Zhao, K.; Li, J. Localized corrosion behaviour of AA7150 after ultrasonic shot peening: Corrosion depth vs. impact energy. Corros. Sci. 2018, 130, 218–230. [Google Scholar] [CrossRef]

- Guo, F.; Duan, S.; Pan, Y.; Wu, D.; Matsuda, K.; Wang, T.; Zou, Y. Stress corrosion behavior and microstructure analysis of Al-Zn-Mg-Cu alloys friction stir welded joints under different aging conditions. Corros. Sci. 2023, 210, 110821. [Google Scholar] [CrossRef]

- Kayani, S.H.; Park, S.; Euh, K.; Seol, J.B.; Kim, J.G.; Sung, H. Dislocation-aided electrochemical behavior of precipitates in stress corrosion cracking of Al–Zn–Mg–Cu alloys. Mater. Charact. 2022, 190, 112019. [Google Scholar] [CrossRef]

| Subarea | Corrosion Potential Ecorr (V vs. SCE) | Corrosion density Icorr (A/cm2) |

|---|---|---|

| BM | −0.74 ± 0.01 | 1.65 ± 0.12 × 10−7 |

| HAZ (FSW) | −0.79 ± 0.03 | 6.32 ± 0.23 × 10−6 |

| WNZ (FSW) | −0.77 ± 0.02 | 1.12 ± 0.24 × 10−6 |

| HAZ (IRFSW) | −0.78 ± 0.01 | 3.35 ± 0.35 × 10−6 |

| WNZ (IRFSW) | −0.76 ± 0.02 | 3.17 ± 0.41 × 10−7 |

| Area | Rs (Ωcm2) | CPE | R1 (kΩcm2) | R2 (kΩcm2) | C (μFcm−2) | R3 (kΩcm2) | L (kHcm−2) | Rp (kΩcm2) | |

|---|---|---|---|---|---|---|---|---|---|

| T (μΩ−1cm−2s−n) | n | ||||||||

| BM | 1.6 ± 0.2 | 9.6 ± 3.1 | 0.7 ± 0.1 | 9.9 ± 0.5 | 6.6 ± 0.2 | 42.2 ± 3.2 | 43.7 ± 3.5 | 245.5 ± 10.6 | 11.9 ± 2.6 |

| HAZ (FSW) | 3.4 ± 0.3 | 38.5 ± 4.5 | 0.7 ± 0.2 | 1.5 ± 0.3 | 3.0 ± 0.1 | 4.2 ± 0.7 | 2.1 ± 0.2 | 27.7 ± 2.8 | 1.4 ± 0.1 |

| HAZ (IRFSW) | 8.6 ± 0.3 | 52.7 ± 5.5 | 0.8 ± 0.1 | 2.1 ± 0.5 | 3.5 ± 0.2 | 13.9 ± 4.3 | 4.5 ± 0.3 | 539.1 ± 30.5 | 2.5 ± 0.2 |

| WNZ (FSW) | 4.6 ± 0.2 | 9.1 ± 1.6 | 0.8 ± 0.1 | 3.7 ± 0.2 | 4.2 ± 0.2 | 11.8 ± 3.1 | 8.0 ± 0.2 | 216.7 ± 15.3 | 3.9 ± 0.2 |

| WNZ (IRFSW) | 5.1 ± 0.1 | 7.1 ± 2.3 | 0.8 ± 0.1 | 4.5 ± 0.1 | 5.5 ± 0.1 | 35.4 ± 6.2 | 12.7 ± 0.5 | 650.6 ± 32.5 | 5.6 ± 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Meng, X.; Xie, Y.; Wang, N.; Ma, X.; Gao, J.; Huang, Y. High Corrosion Resistance of Aluminum Alloy Friction Stir Welding Joints via In Situ Rolling. Coatings 2024, 14, 1604. https://doi.org/10.3390/coatings14121604

Wang W, Meng X, Xie Y, Wang N, Ma X, Gao J, Huang Y. High Corrosion Resistance of Aluminum Alloy Friction Stir Welding Joints via In Situ Rolling. Coatings. 2024; 14(12):1604. https://doi.org/10.3390/coatings14121604

Chicago/Turabian StyleWang, Wei, Xiangchen Meng, Yuming Xie, Naijie Wang, Xiaotian Ma, Jiaze Gao, and Yongxian Huang. 2024. "High Corrosion Resistance of Aluminum Alloy Friction Stir Welding Joints via In Situ Rolling" Coatings 14, no. 12: 1604. https://doi.org/10.3390/coatings14121604

APA StyleWang, W., Meng, X., Xie, Y., Wang, N., Ma, X., Gao, J., & Huang, Y. (2024). High Corrosion Resistance of Aluminum Alloy Friction Stir Welding Joints via In Situ Rolling. Coatings, 14(12), 1604. https://doi.org/10.3390/coatings14121604