Thermal Stability of Residual Stress, Microstructure, and Mechanical Property in Shot-Peened CNT/Al-Cu-Mg Composites

Abstract

1. Introduction

2. Experimental Procedures

3. Results and Discussion

3.1. Changes in Residual Stress

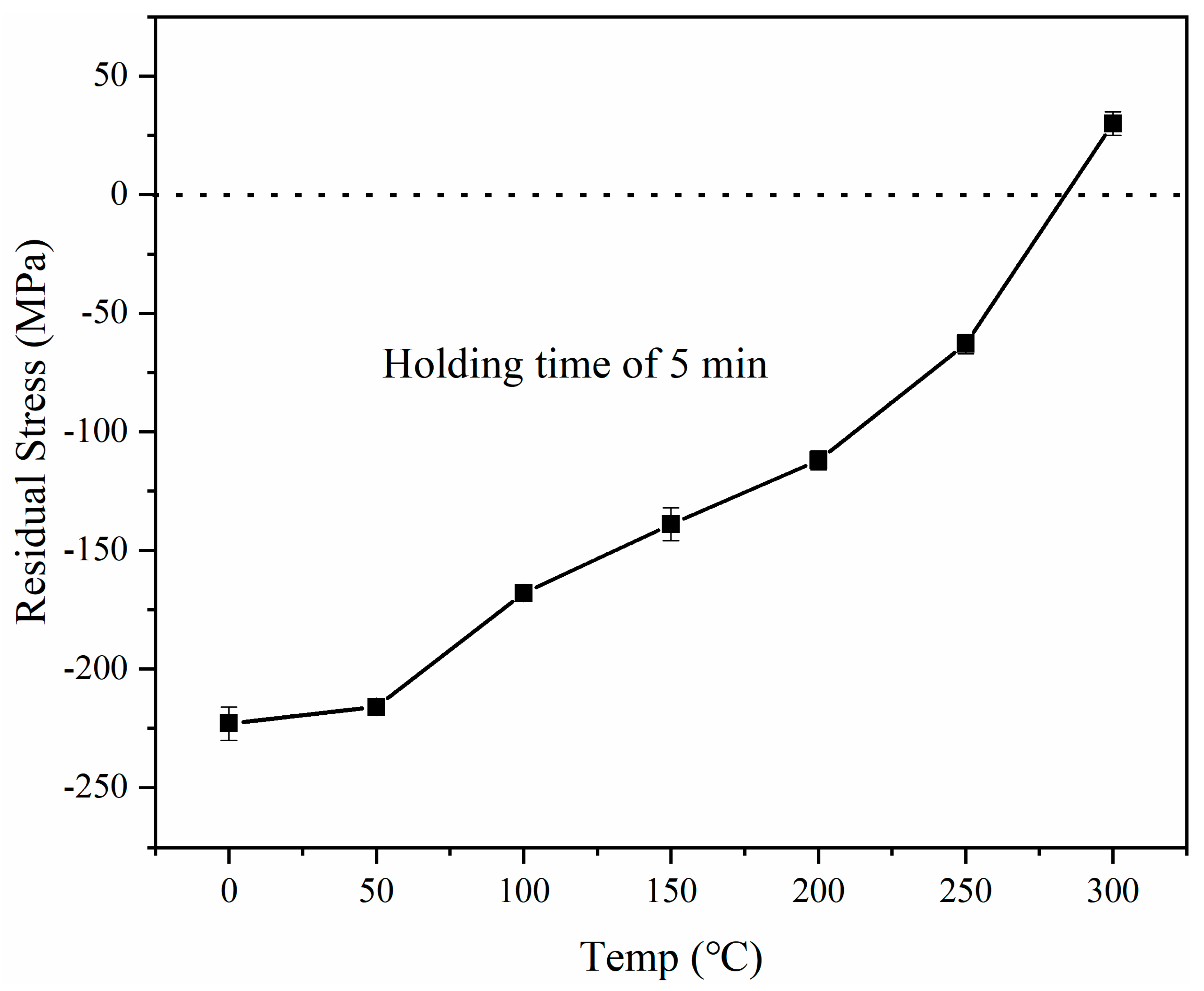

3.1.1. Continuous Heating Test

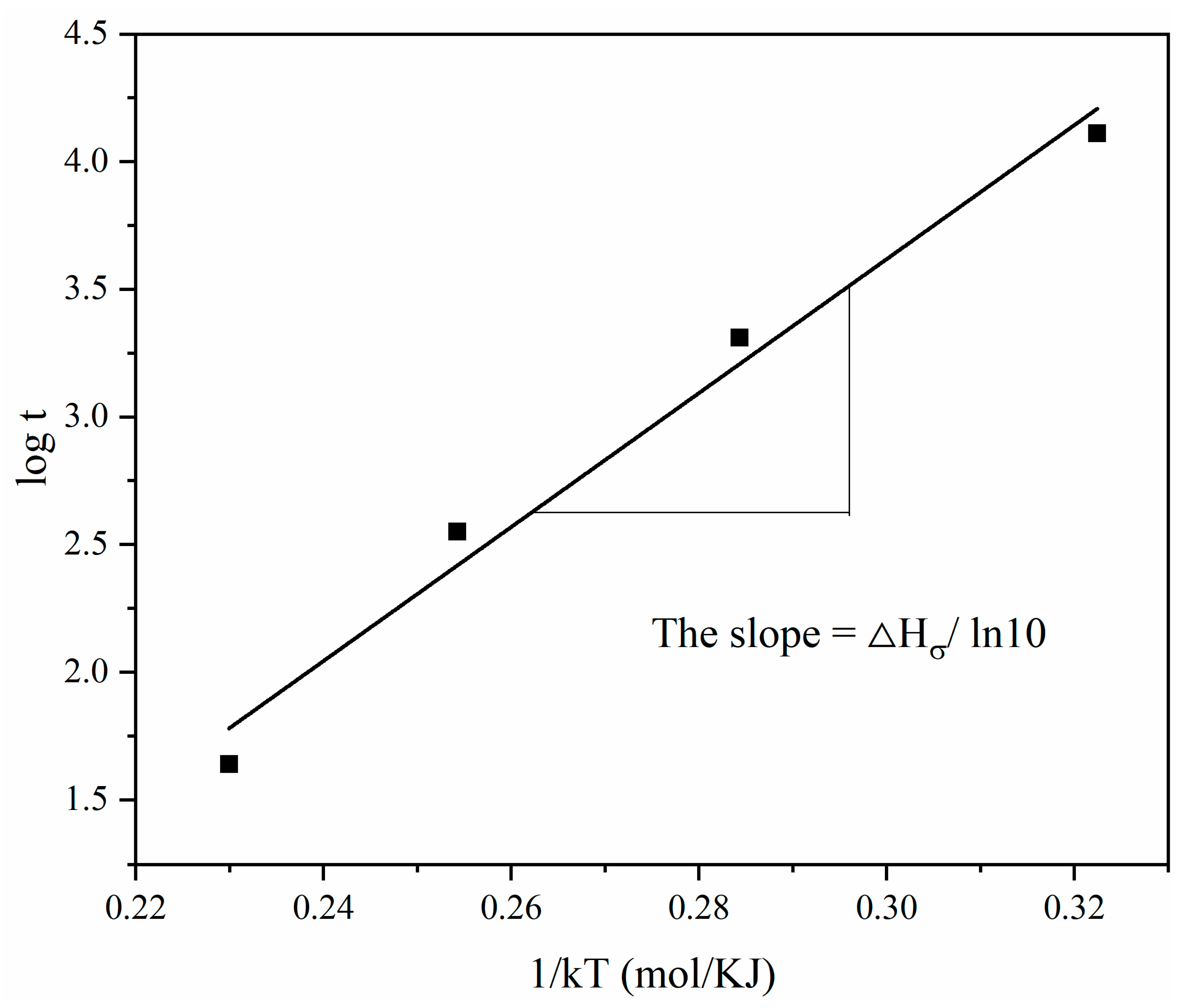

3.1.2. The Isothermal Aging Treatment

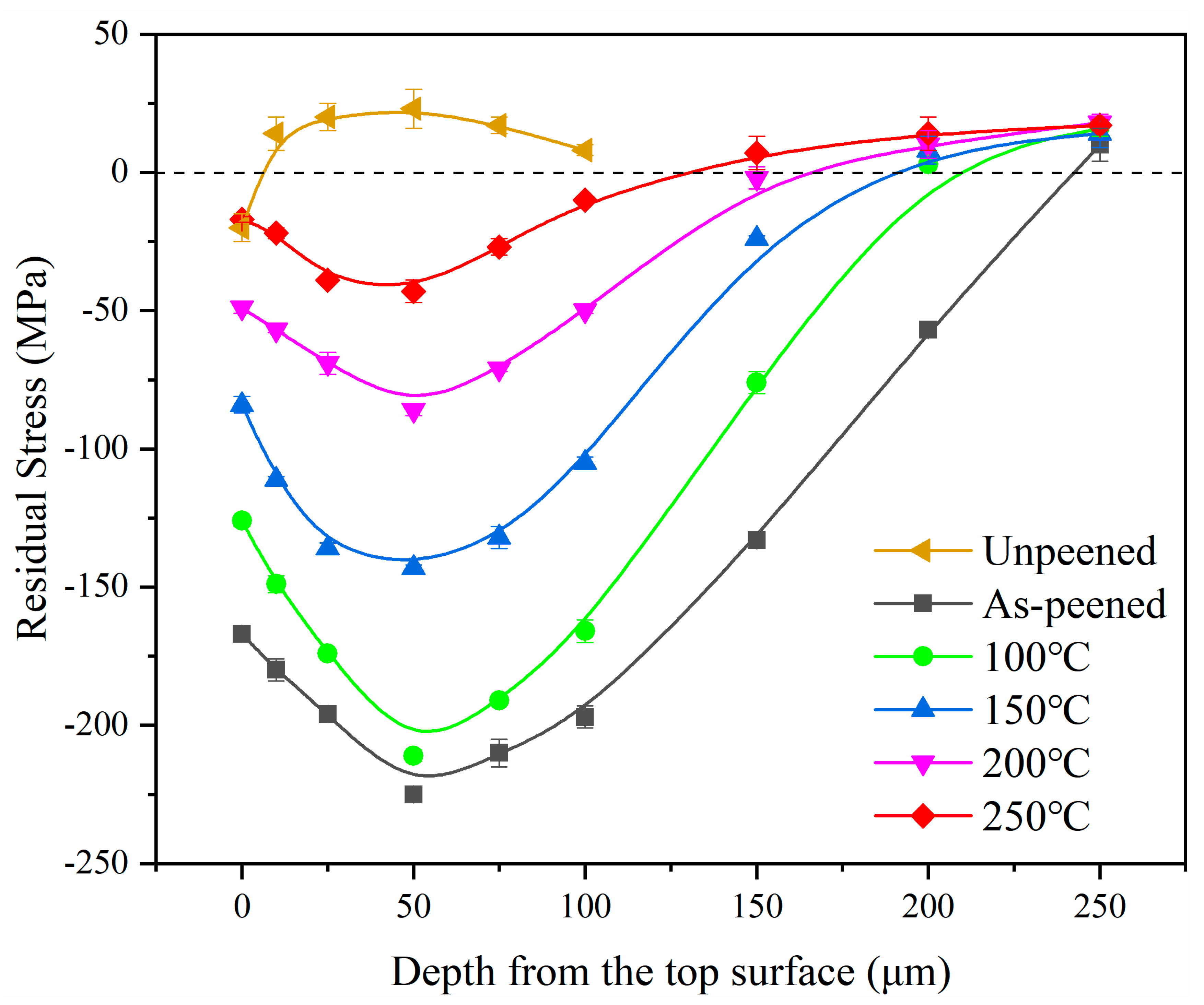

3.1.3. Changes Along Layer Depth

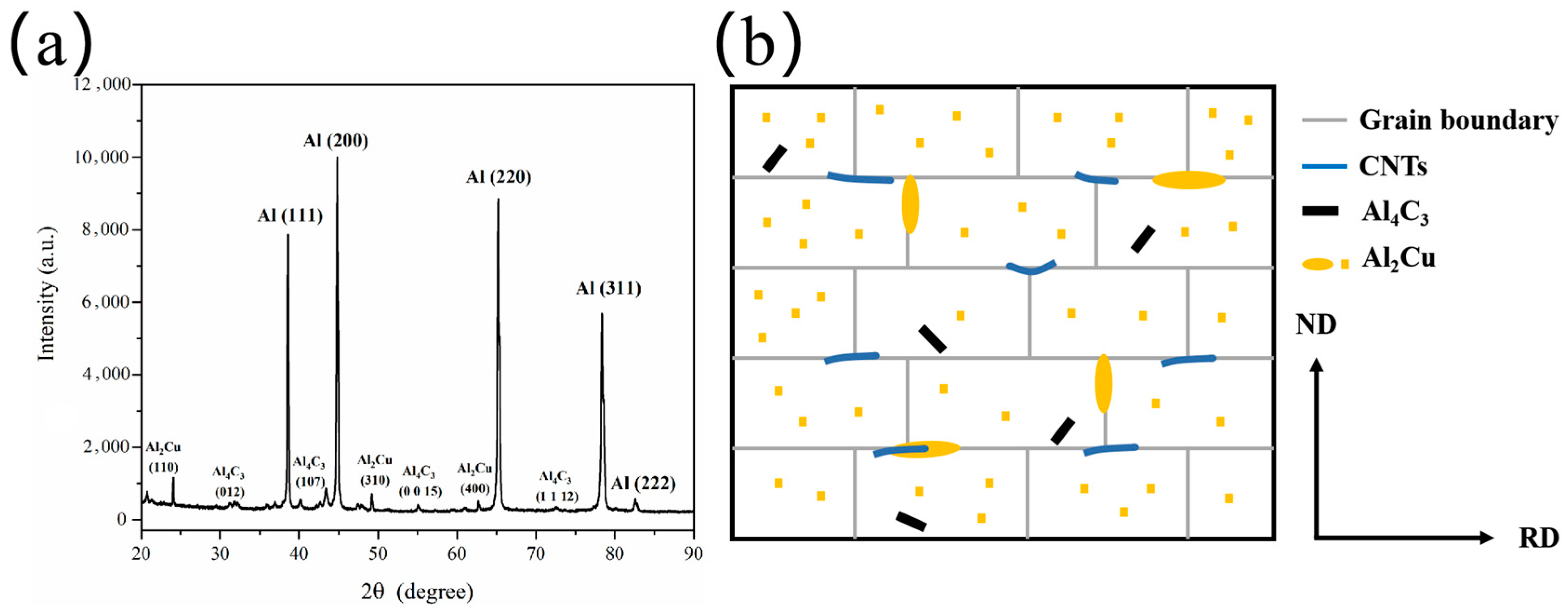

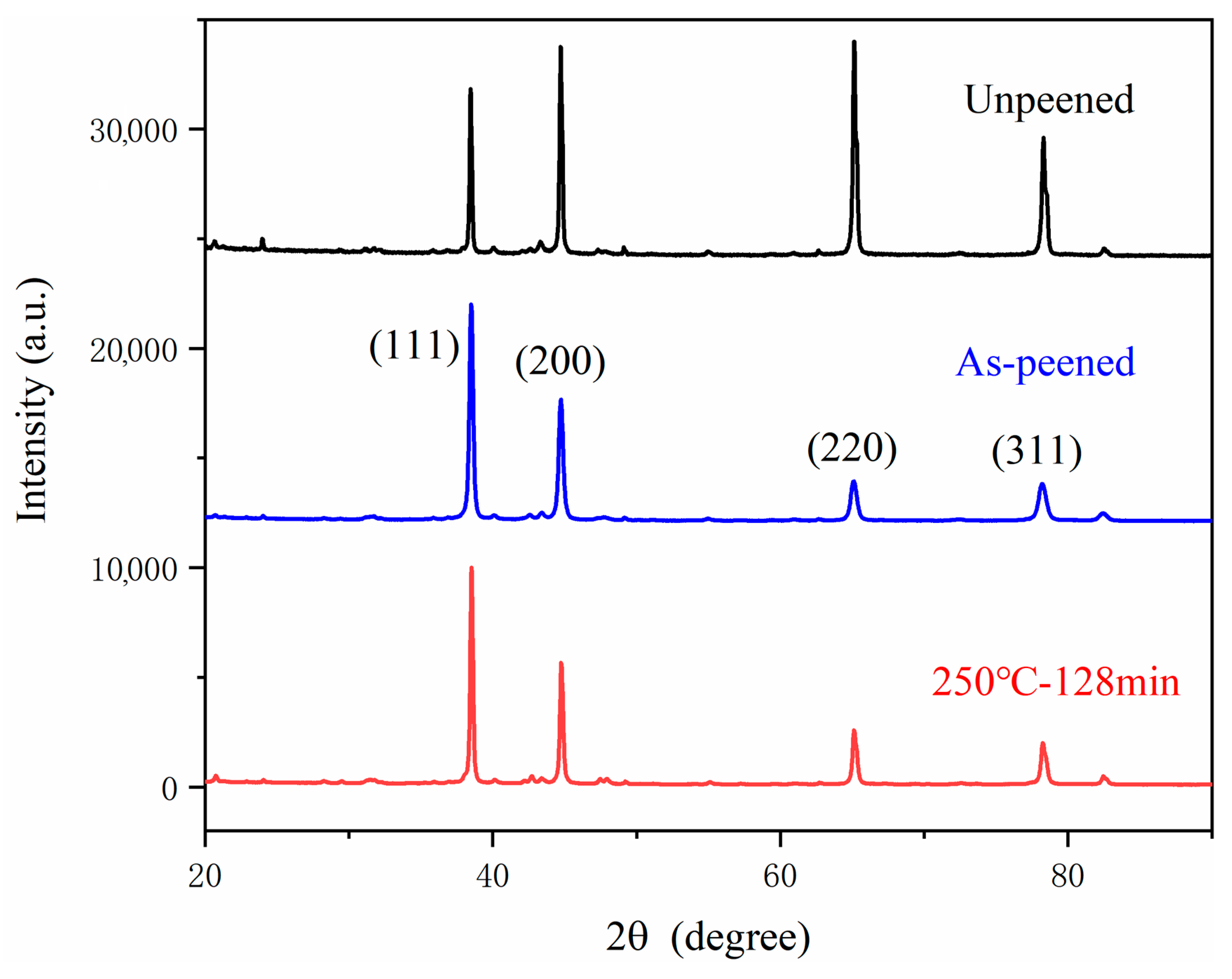

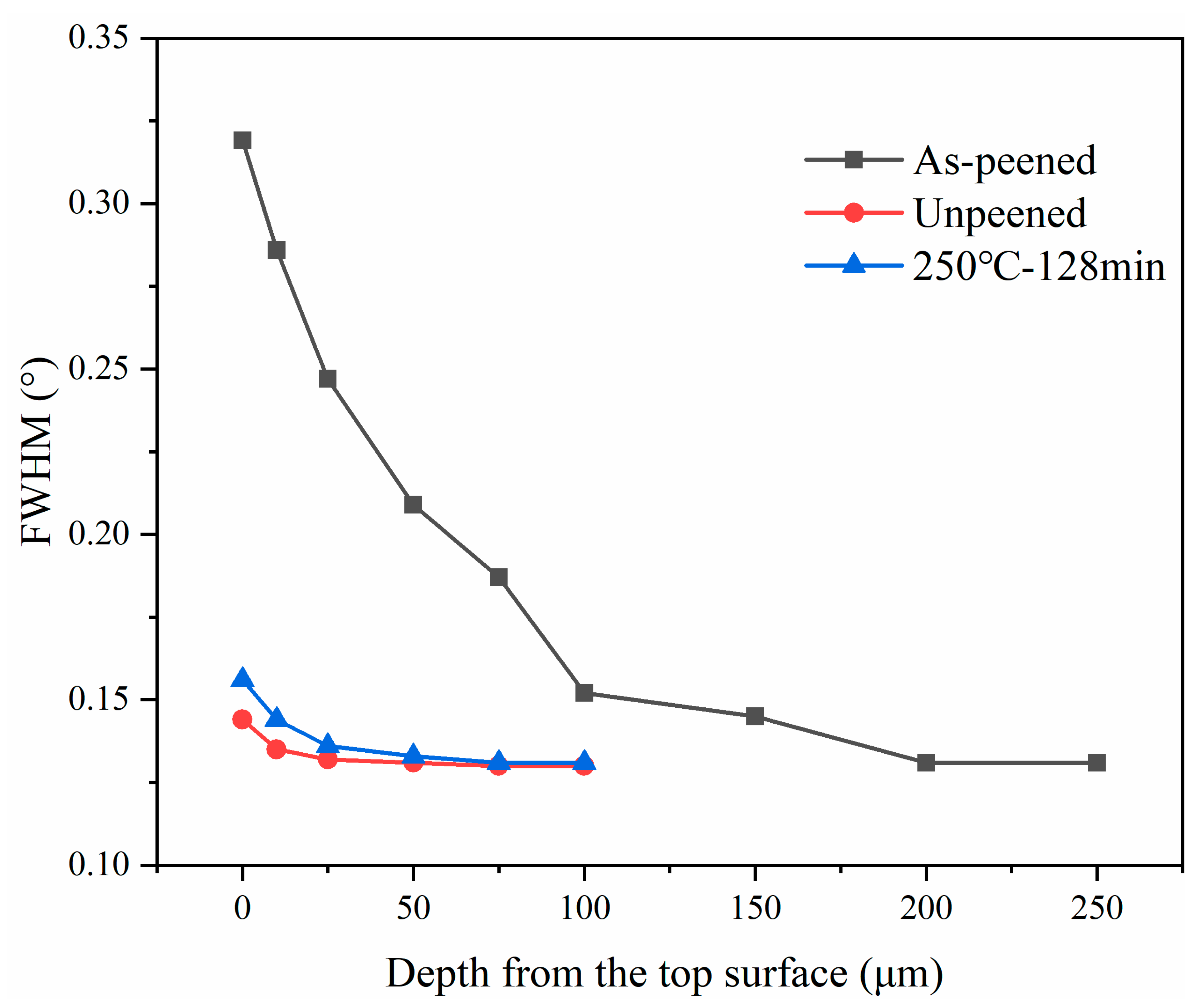

3.2. XRD Analysis

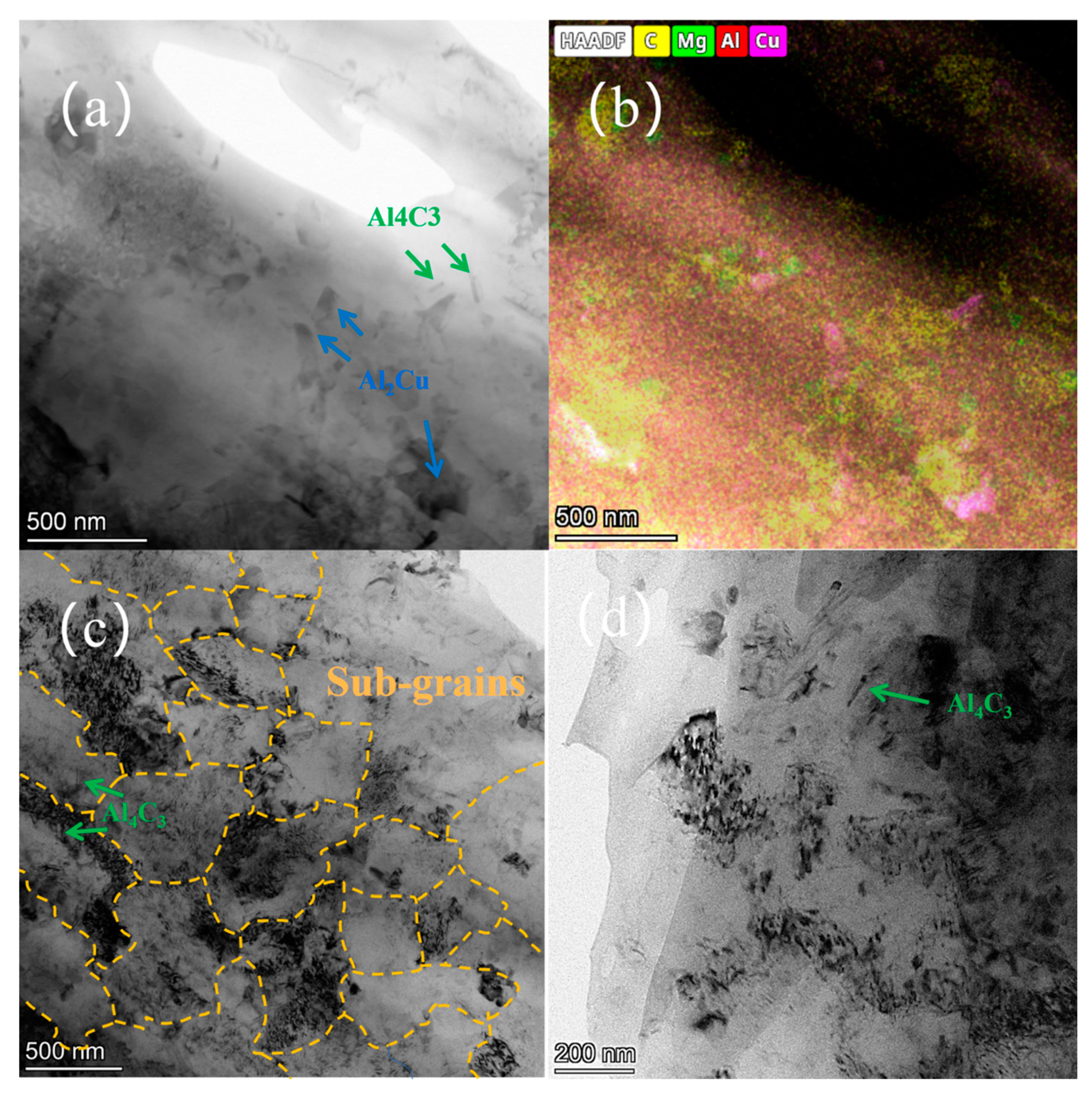

3.3. TEM Observation

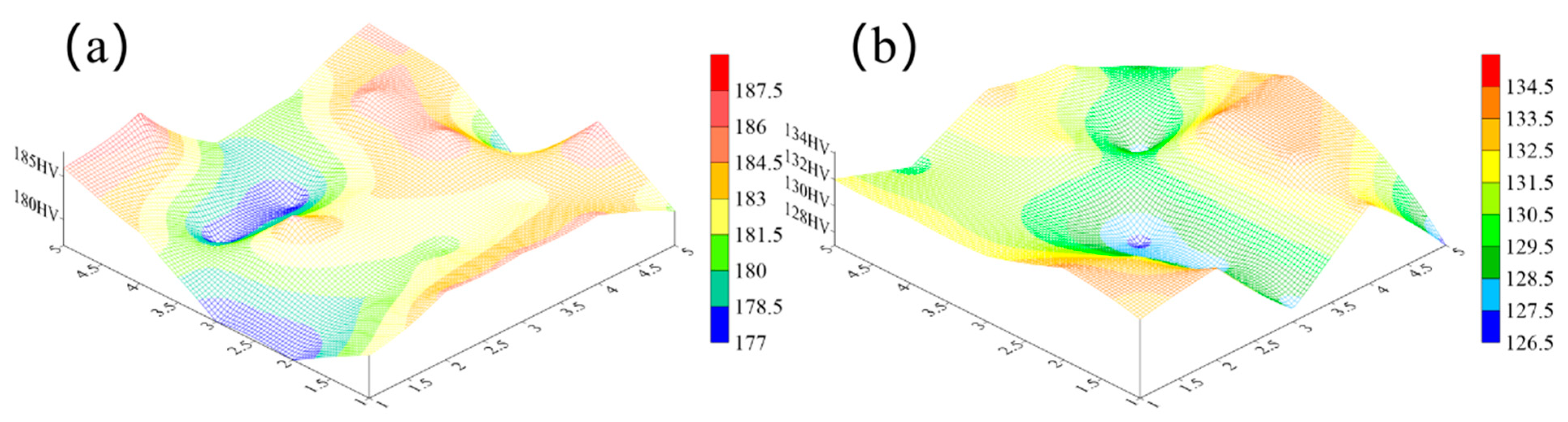

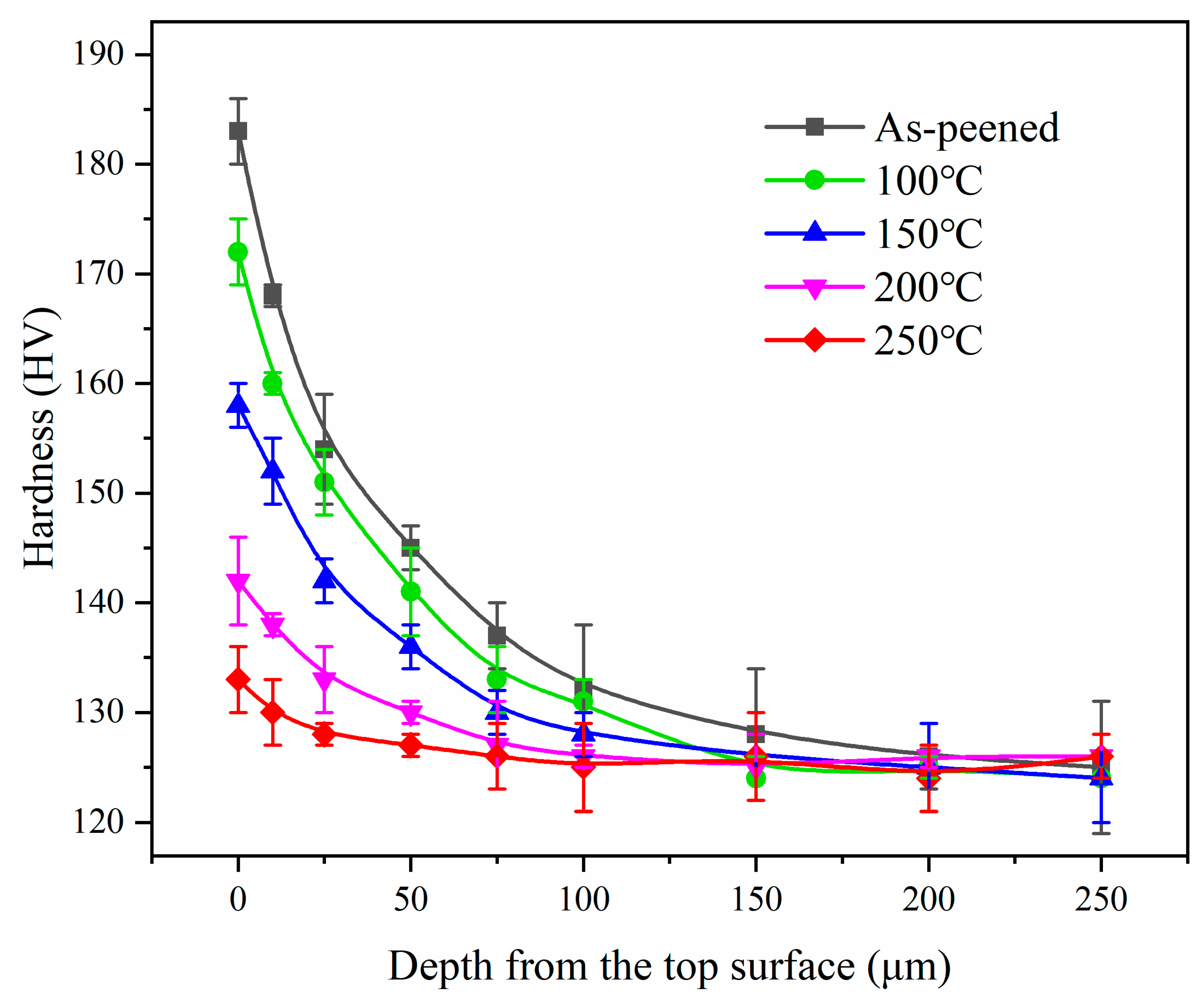

3.4. Microhardness Changes

4. Conclusions

- The CRS release mainly occurred during the initial stage of heating. After 128 min of isothermal aging treatment, the surface CRS was released by 42.7% (at 100 °C), 61.8% (at 150 °C), 77.5% (at 200 °C), and 91.9% (at 250 °C). Significant release of CRS also occurred along the depth direction, with the maximum CRS released by 6.2% (at 100 °C), 36.4% (at 150 °C), 61.8% (at 200 °C), and 80.9% (at 250 °C).

- The microstructure changes also occurred during the initial stage of heating. After 128 min of the isothermal aging treatment, the surface domain size increased by 94% (at 100 °C), 144% (at 150 °C), 178% (at 200 °C), and 222% (at 250 °C). The surface microstrain decreased by 18% (at 100 °C), 34% (at 150 °C), 42% (at 200 °C), and 49% (at 250 °C). The surface microhardness decreased by 6.0% (at 100 °C), 13.7% (at 150 °C), 22.4% (at 200 °C), and 27.3% (at 250 °C), which is consistent with the trend observed in the FWHM of the Al (111) crystal plane.

- The CNT/Al-Cu-Mg composites exhibited typical subgrain coalescence and nucleation characteristics during the isothermal aging treatment. The presence of a large number of second-phase particles such as CNT, Al2Cu, and Al4C3 at grain boundaries and their vicinities acted as pinning sites, restricting dislocation movement and grain growth, thereby enhancing the high-temperature stability of the material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zuo, G.; Bai, Y.; Tan, Z.; Fan, W.; Shi, S.; Hao, H. Temperature effects on solid state bonding joints of ultrafine-grained CNT/Al–Cu–Mg composites. Compos. Part B Eng. 2024, 284, 111681. [Google Scholar] [CrossRef]

- Wan, J.; Chen, B.; Zhou, X.; Cao, L.; Geng, H.; Shen, J.; Bahador, A.; Kondoh, K.; Li, J. CNT-induced heterogeneous matrix grain structure in CNTs/Al composites. Carbon 2024, 216, 118529. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Z.; Peng, Y.; Yan, D.; Tan, Z.; Zhou, Q.; Wang, K.; Zhou, M. Microstructure and mechanical properties of underwater friction stir welding of CNT/Al-Cu-Mg composites. J. Mater. Res. Technol. 2022, 18, 405–415. [Google Scholar] [CrossRef]

- Chen, J.; Yan, L.; Liang, S.; Cui, X.; Liu, C.; Wang, B.; Zou, L. Remarkable improvement of mechanical properties of layered CNTs/Al composites with Cu decorated on CNTs. J. Alloys Compd. 2022, 901, 163404. [Google Scholar] [CrossRef]

- Hao, J.; Gao, L.; Ma, Z. Exploration of the oxidation and ablation resistance of ultra-high-temperature ceramic coatings using machine learning. Ceram. Int. 2022, 48, 28428–28437. [Google Scholar] [CrossRef]

- Xue, N.; Li, W.; Shao, L.; Tu, Z.; Chen, Y.; Dai, S.; Ye, N.; Zhang, J.; Liu, Q.; Wang, J. Comparison of Cold-Sprayed Coatings of Copper-Based Composite Deposited on AZ31B Magnesium Alloy and 6061 T6 Aluminum Alloy Substrates. Materials 2023, 16, 5120. [Google Scholar] [CrossRef] [PubMed]

- Bai, M.; Liu, T.; Liu, B.; Li, Y.; Yu, H.; Zhao, Y.; Yang, C.; Song, L.; Liu, W. Preparation and properties of polyurethane cold galvanizing coatings with phosphoric acid modified zinc powder. Surf. Coat. Technol. 2024, 489, 131128. [Google Scholar] [CrossRef]

- Sikder, M.A.-A.; Banno, Y.; Kinoshita, K. Effect of peening treatment on fatigue strength of welded joints of aged steel. Results Eng. 2024, 23, 102781. [Google Scholar] [CrossRef]

- Fang, X.; Wang, Z.; Wang, W.; Cao, X.; Li, D.; Wang, Z.; Gong, J.; Cai, Z. Improvement mechanism of fretting fatigue lifetime of turbine dovetail tenon by shot peening combined with CuNiIn coating at 500 °C. Surf. Coat. Technol. 2024, 494, 131538. [Google Scholar] [CrossRef]

- Wang, C.; Xiong, X.; Yang, L.; Hong, Y.; She, S.; Zhang, H.; Liu, H.; Ji, V.; Li, M. Erosion-corrosion behaviour of shot peening treated nickel-aluminium bronze in simulated sand-containing seawater. Corros. Sci. 2023, 211, 110908. [Google Scholar] [CrossRef]

- Li, J.; Wang, L.; Wang, X.; Hu, Z.; Lan, H.; Wang, Z.; Pang, J.; Cheng, Y. Effect of shot peening equivalent impact force on fatigue crack growth behavior and fatigue life prediction of train brake discs. Eng. Fail. Anal. 2024, 166, 108914. [Google Scholar] [CrossRef]

- Gao, Z.A.; Gan, J.; Liu, H.; Liu, X.; Wu, W. Fatigue crack growth prediction for shot-peened steel considering residual stress relaxation. Mater. Des. 2023, 234, 112301. [Google Scholar] [CrossRef]

- He, Y.; Zhou, H.; Zhao, Y.; Zhang, T.; Liu, C.; Xu, L.; Shin, K.; Zheng, W. Investigating the thermal stability of compressive residual stress in a gradient nanostructured austenitic stainless steel by in-situ XRD and TEM. Mater. Charact. 2024, 207, 113610. [Google Scholar] [CrossRef]

- Wang, X.; Guo, M.; Luo, J.; Xie, C.; Wang, Y.; Zhang, J.; Zhuang, L. Effect of intermediate annealing time on microstructure, texture and mechanical properties of Al-Mg-Si-Cu alloy. Mater. Charact. 2018, 142, 309–320. [Google Scholar] [CrossRef]

- Zhao, Z.; Xiao, N.; Zhang, Z.; Wang, Z. Improved stress relaxation stability of a heat-resistant Al-Cu-Mg-Ag alloy with good mechanical properties by a pre-annealing/solution-aging treatment. J. Alloys Compd. 2023, 961, 171145. [Google Scholar] [CrossRef]

- Zhou, Z.; Han, M.; Xiao, X.; Lv, D.; Cong, F.; Li, C.; Liu, Y. Microstructure, mechanical properties and corrrosion behavior of Al-Zn-Mg-Cu wire under different annealing conditions. J. Mater. Res. Technol. 2024, 30, 3900–3908. [Google Scholar] [CrossRef]

- Cheng, J.C.; Chai, H.W.; Fan, G.L.; Li, Z.Q.; Xie, H.L.; Tan, Z.Q.; Bie, B.X.; Huang, J.Y.; Luo, S.N. Anisotropic spall behavior of CNT/2024Al composites under plate impact. Carbon 2020, 170, 589–599. [Google Scholar] [CrossRef]

- Yuan, C.; Zhang, Z.; Tan, Z.; Xu, L.; Zhang, S.; Fan, G.; Zhang, P.; Li, Z. Enhanced ductility by Mg addition in the CNT/Al-Cu composites via flake powder metallurgy. Mater. Today Commun. 2021, 26, 101854. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Zhao, B.; Huang, P.; Zhang, L.; Li, S.; Yu, Q. Temperature Effect on Stacking Fault Energy and Deformation Mechanisms in Titanium and Titanium-aluminium Alloy. Sci. Rep. 2020, 10, 3086. [Google Scholar] [CrossRef] [PubMed]

- Nikitin, I.; Besel, M. Residual stress relaxation of deep-rolled austenitic steel. Scr. Mater. 2008, 58, 239–242. [Google Scholar] [CrossRef]

- Yazdani, F.; Rabiee, S.M.; Jamaati, R. Comparison of conventional and severe shot peening effects on the microstructure, texture, roughness, hardness, and electrochemical behavior of austenitic stainless steel. Heliyon 2024, 10, e31284. [Google Scholar] [CrossRef]

- Vives, S.; Gaffet, E.; Meunier, C. X-ray diffraction line profile analysis of iron ball milled powders. Mater. Sci. Eng. A 2004, 366, 229–238. [Google Scholar] [CrossRef]

- Yin, A.; Yu, W.; Li, W.; Zhu, W.; Ji, V.; Jiang, C.; Wang, C. Microstructural and thermal relaxation of residual stress in dual peened TA15 titanium alloy fabricated by SLM. Mater. Charact. 2024, 218, 114496. [Google Scholar] [CrossRef]

- Zhu, W.; Liu, H.; Xing, S.; Jiang, C.; Ji, V. Surface mechanical property and residual stress stability of nanostructured CNT/Al-Cu-Mg composites induced by shot peening. Mater. Charact. 2024, 218, 114515. [Google Scholar] [CrossRef]

| Element | Al | Cu | CNT | Mg |

|---|---|---|---|---|

| Percentage (wt.%) | 93.5 | 4.0 | 1.5 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, W.; Xing, S.; Wang, L.; Yang, Z.; Yu, W.; Yin, A.; Li, W.; Jiang, C.; Ji, V. Thermal Stability of Residual Stress, Microstructure, and Mechanical Property in Shot-Peened CNT/Al-Cu-Mg Composites. Coatings 2024, 14, 1571. https://doi.org/10.3390/coatings14121571

Zhu W, Xing S, Wang L, Yang Z, Yu W, Yin A, Li W, Jiang C, Ji V. Thermal Stability of Residual Stress, Microstructure, and Mechanical Property in Shot-Peened CNT/Al-Cu-Mg Composites. Coatings. 2024; 14(12):1571. https://doi.org/10.3390/coatings14121571

Chicago/Turabian StyleZhu, Wenlong, Shilong Xing, Lianbo Wang, Zhaoyang Yang, Wenliang Yu, Ang Yin, Wenbo Li, Chuanhai Jiang, and Vincent Ji. 2024. "Thermal Stability of Residual Stress, Microstructure, and Mechanical Property in Shot-Peened CNT/Al-Cu-Mg Composites" Coatings 14, no. 12: 1571. https://doi.org/10.3390/coatings14121571

APA StyleZhu, W., Xing, S., Wang, L., Yang, Z., Yu, W., Yin, A., Li, W., Jiang, C., & Ji, V. (2024). Thermal Stability of Residual Stress, Microstructure, and Mechanical Property in Shot-Peened CNT/Al-Cu-Mg Composites. Coatings, 14(12), 1571. https://doi.org/10.3390/coatings14121571