Research on Mechanized Plasma Gouging of Weldable Construction Steels

Abstract

1. Introduction

- ⮚

- Electric arc welding: arc-air, with coated electrode, oxy-arc;

- ⮚

- Gouging with concentrated energy: plasma, laser;

- ⮚

- Thermal gouging: oxy-gas;

- ⮚

- Mechanical grinding: polishing, machining;

- ⮚

- Cold or hot plastic deformation gouging.

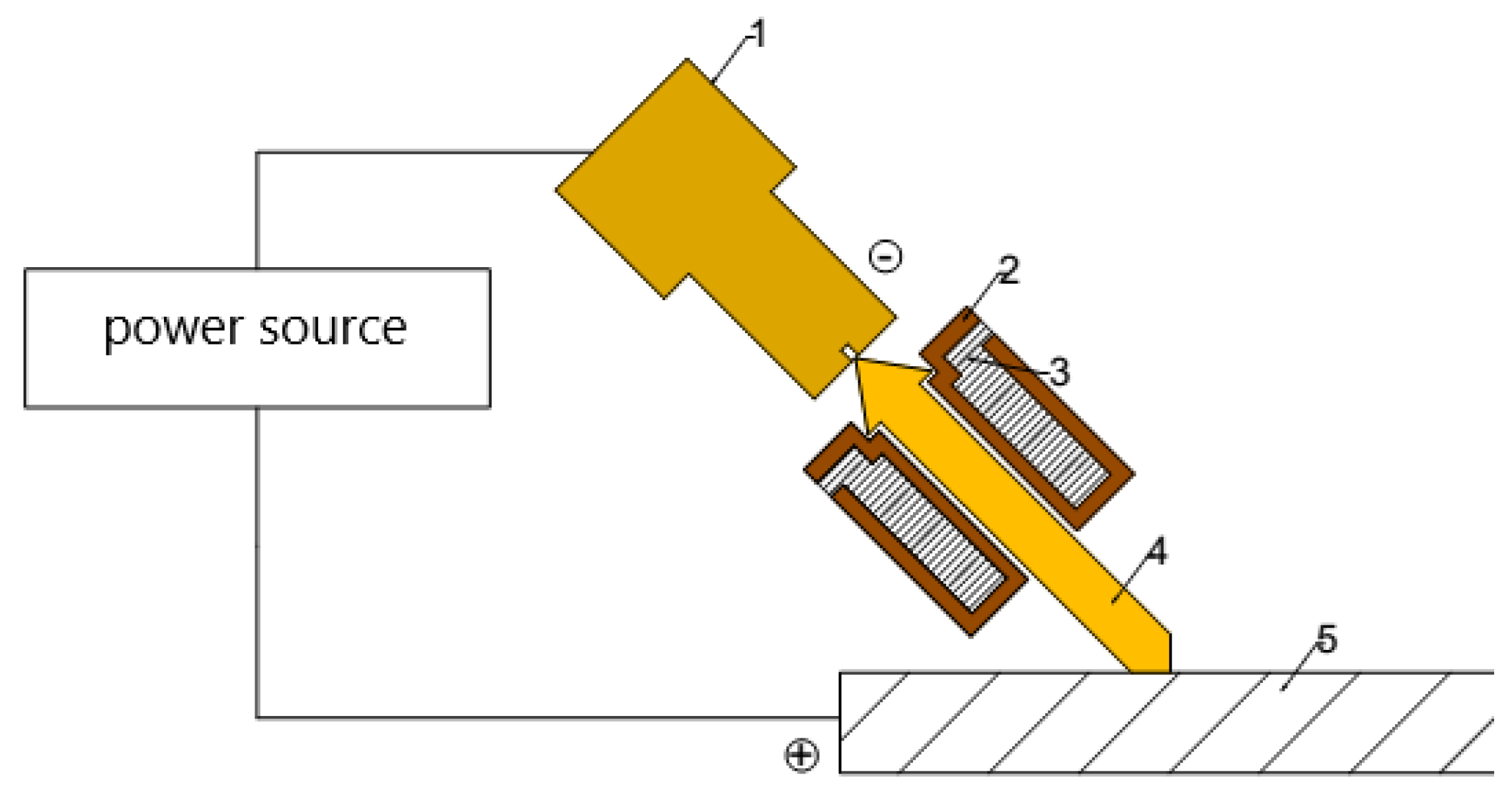

2. Experimental Data and Materials

- Non-transferred arc welding (plasma jet);

- Transferred arc welding (plasma jet);

- The welding torch is the same as the one used for plasma cutting, yet only the consumables differ, and it can be either cooled with water or gas.

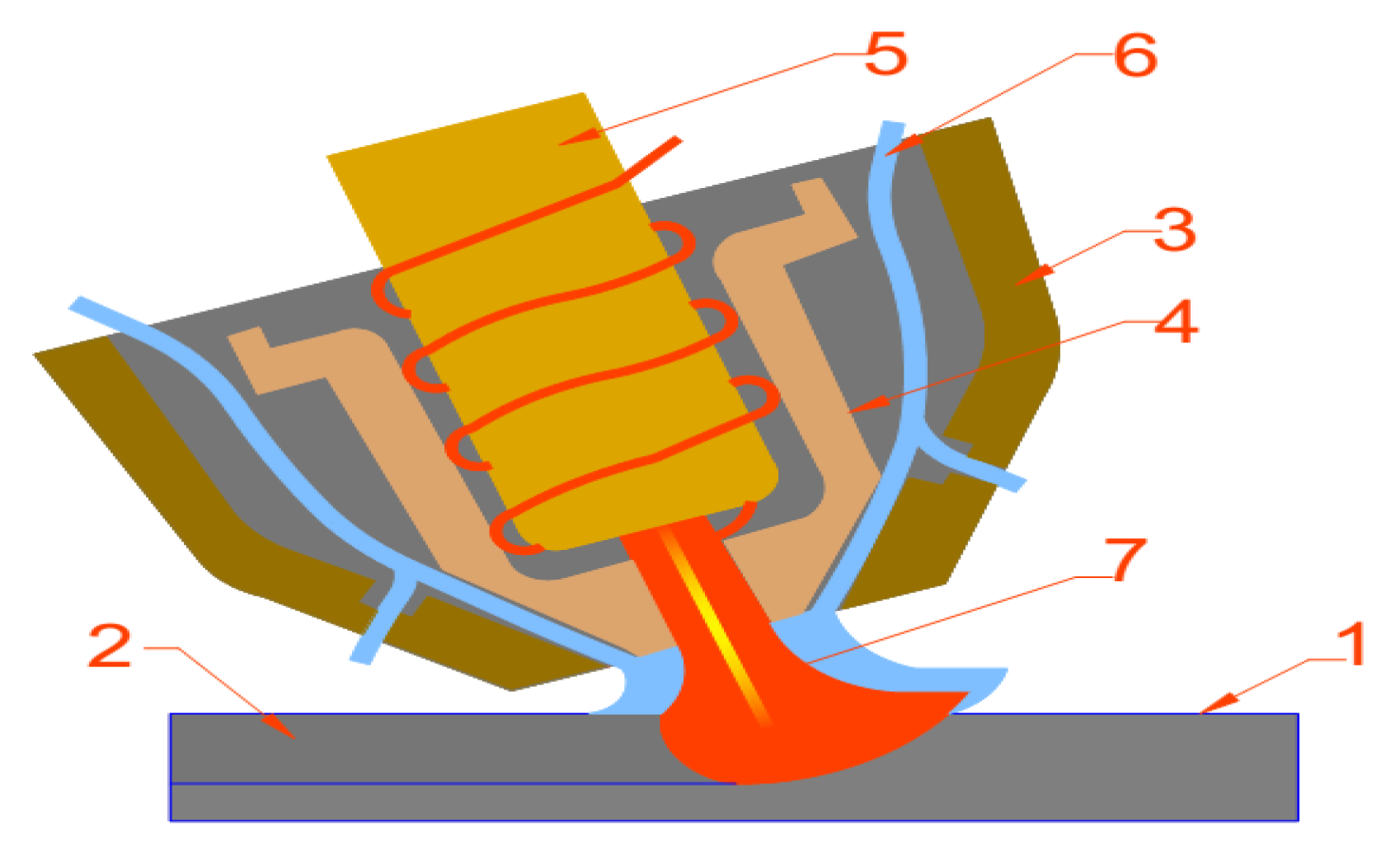

- The pilot plasma arc is created between the electrode (5) and the nozzle (3), and if the torch is brought closer to the workpiece (1) the pilot arc is extinguished and the plasma arc is created (7). The torch tilts at an angle of 40–60° and points to the gouging direction and moves at constant speed with the torch. The plasma arc (7) melts the base material and the compressed air removes the molten material from the groove (2). Behind the torch, the grooved channel (2) can be seen, which presents few asperities, yet it is clean and smooth. The main parameters of the gouging process are the current intensity, the cutting speed and the gas flow rate. These settings determine the size of the groove and the rate of removal of the molten metal. The angle of inclination of the torch has a major influence on the speed of movement, the profile of the groove and the quality of the surface. A distance of 1.5 mm must be left between the torch and the piece. Single-pass gouging can remove material up to a depth of 6 mm at a gouging current of approximately 65 A.

Steel S355J2

- ⮚

- The intensity of the gouging current is 40 A;

- ⮚

- The compressed air pressure is 0.5 MPa;

- ⮚

- The compressed air flow rate is 120 L/min;

- ⮚

- The gouging speed is 1150 mm/min;

- ⮚

- The gouging angle is 20–35°.

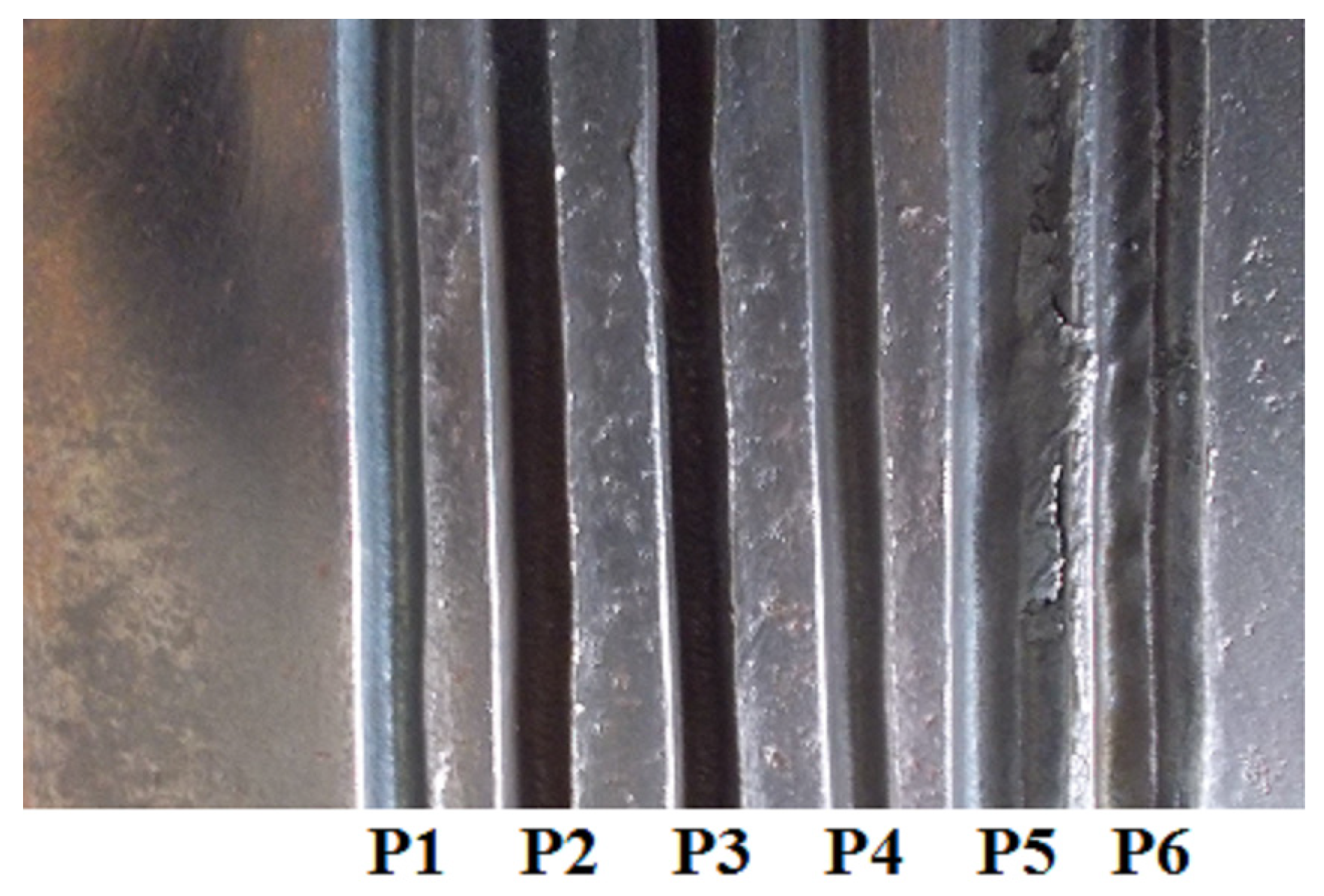

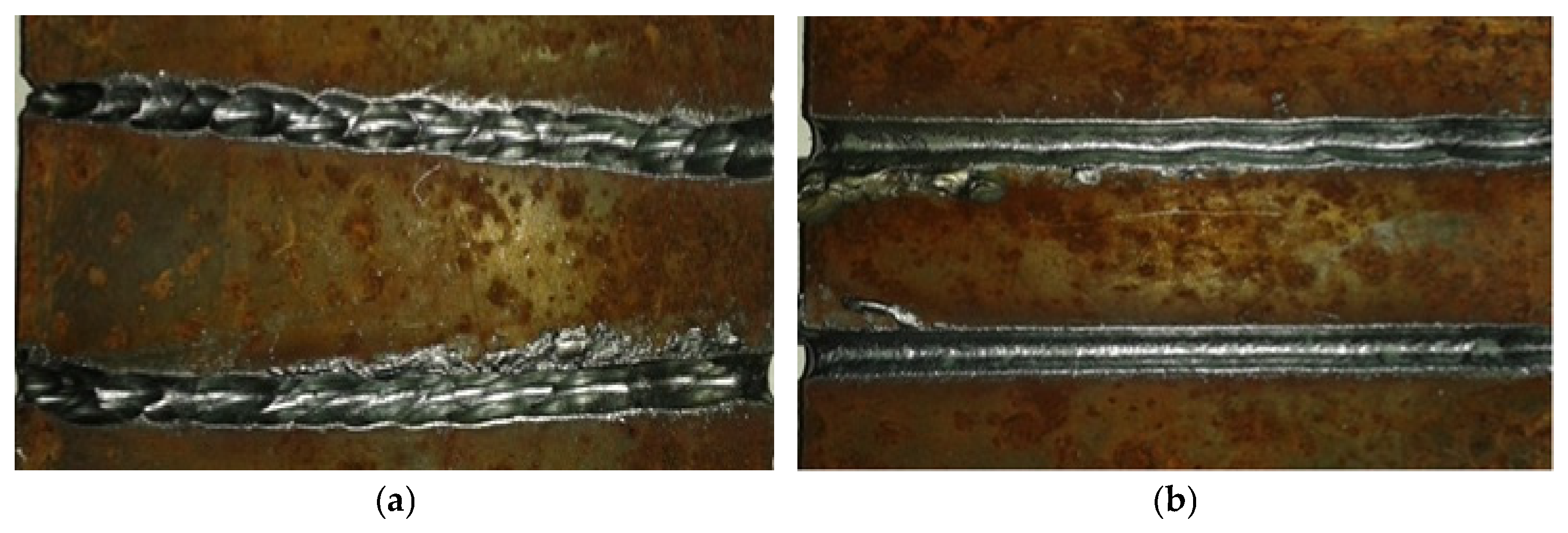

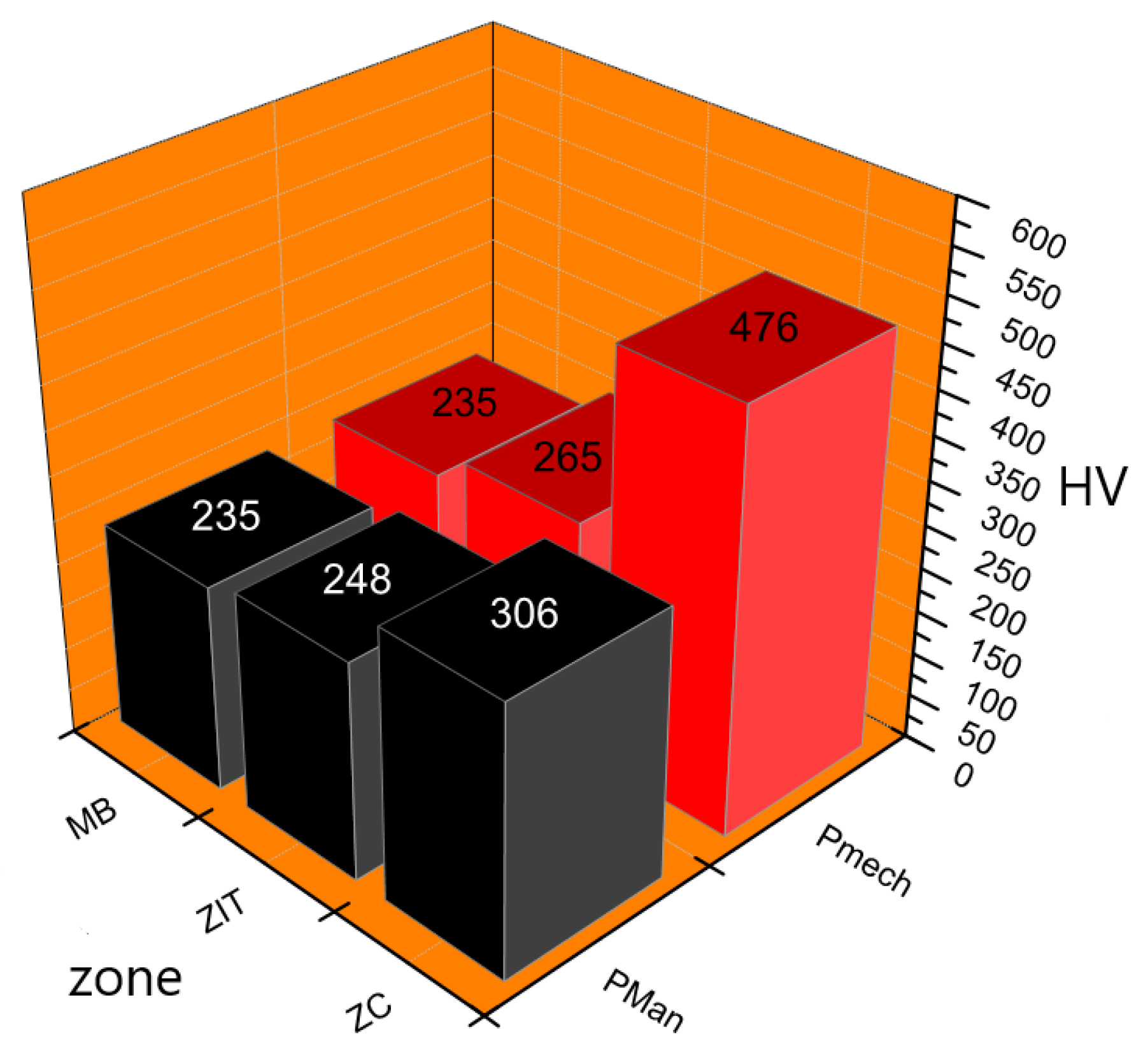

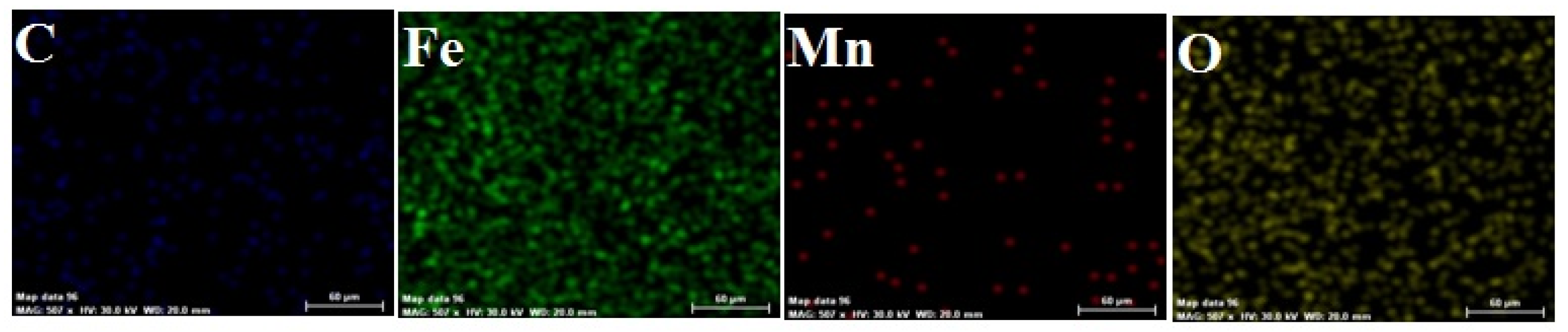

3. Results and Discussion

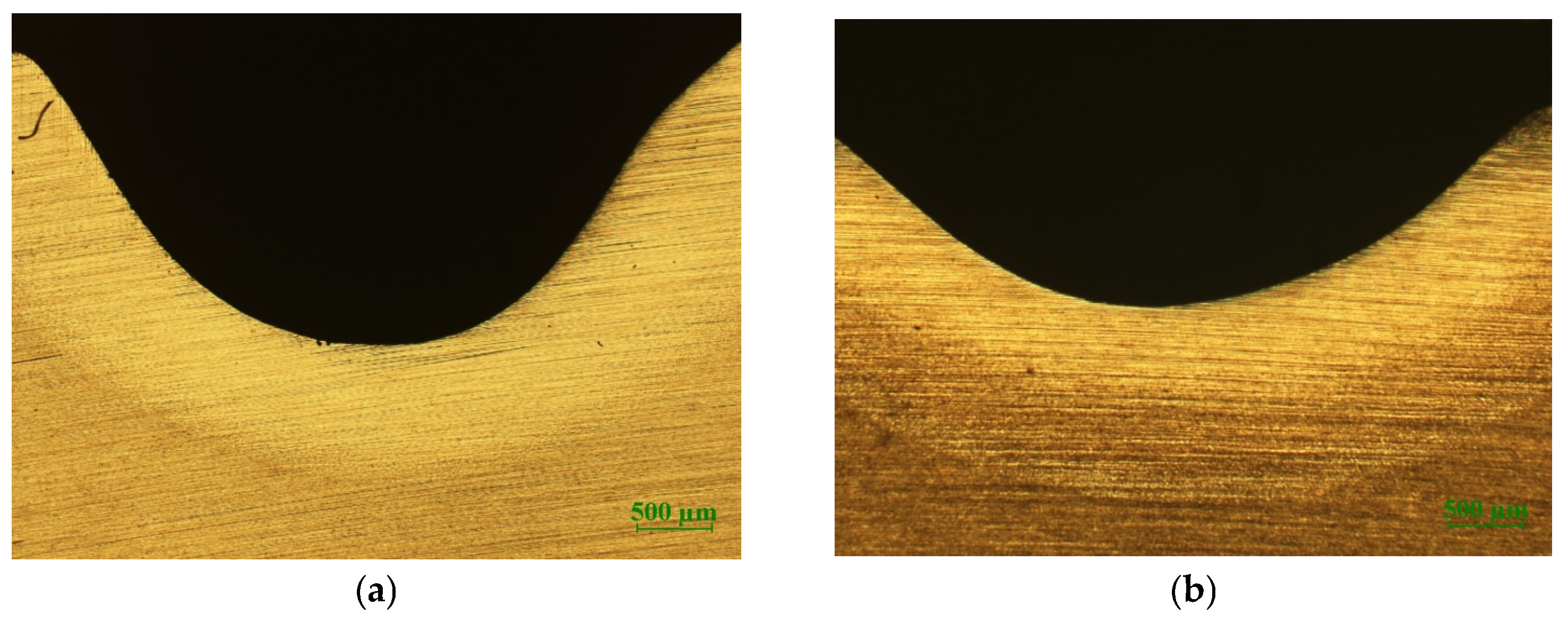

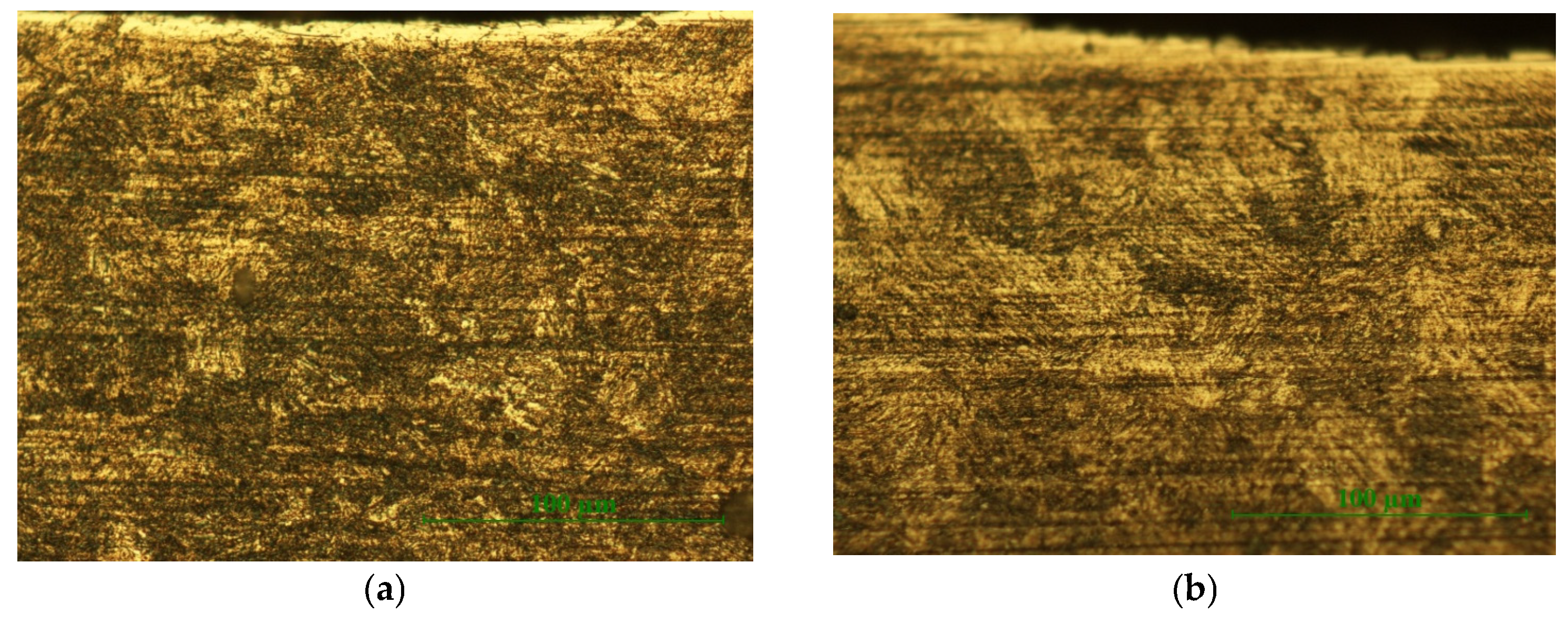

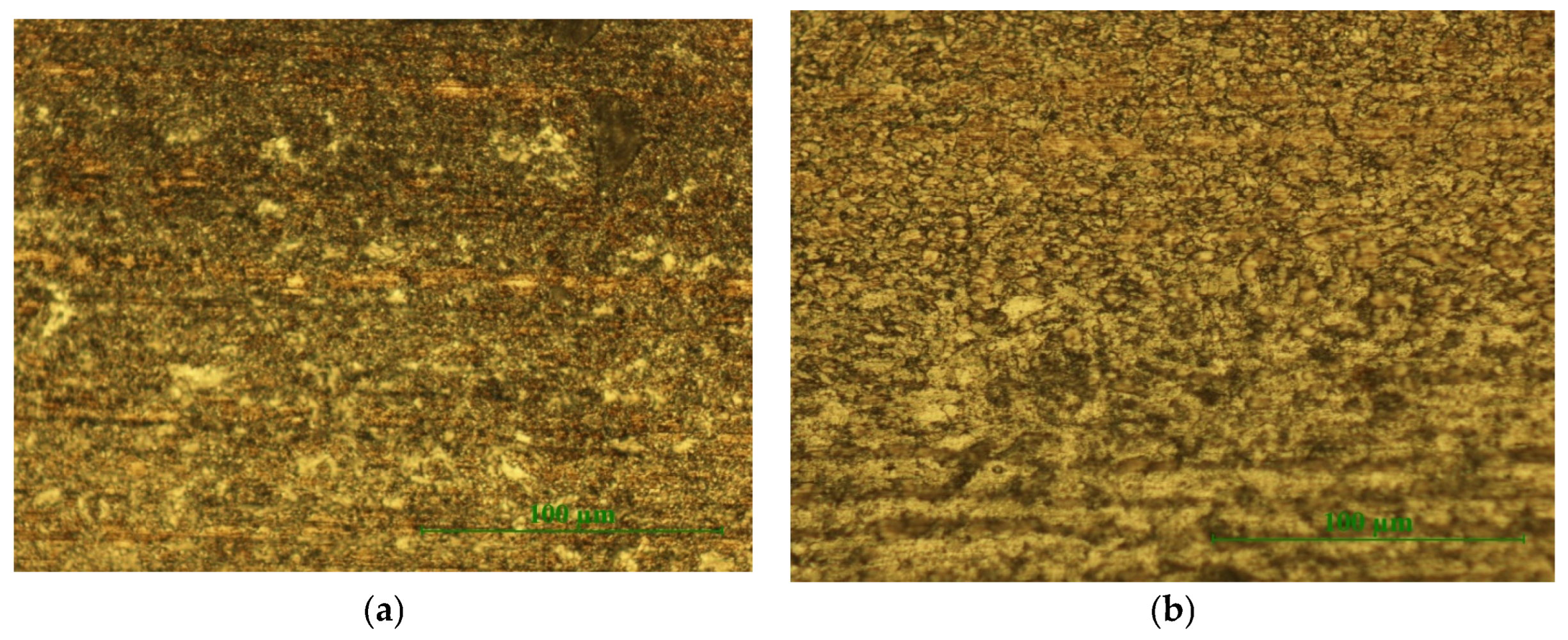

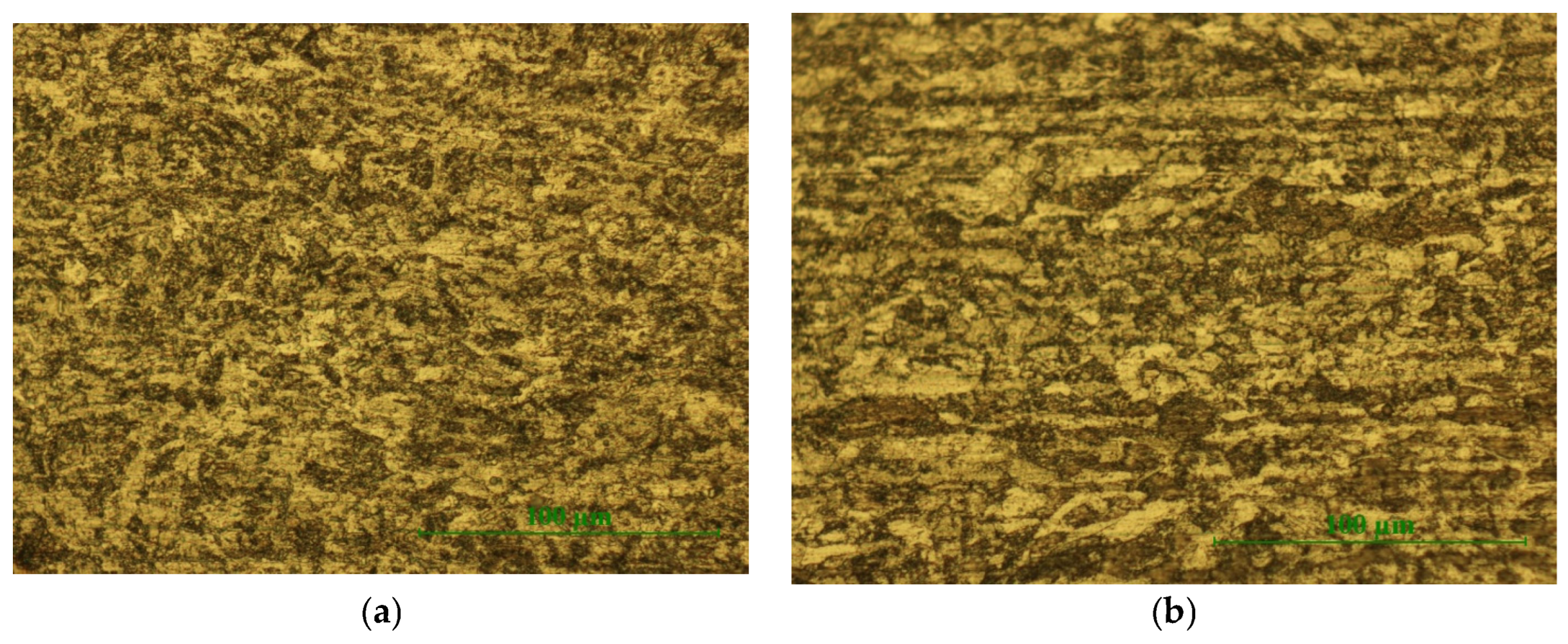

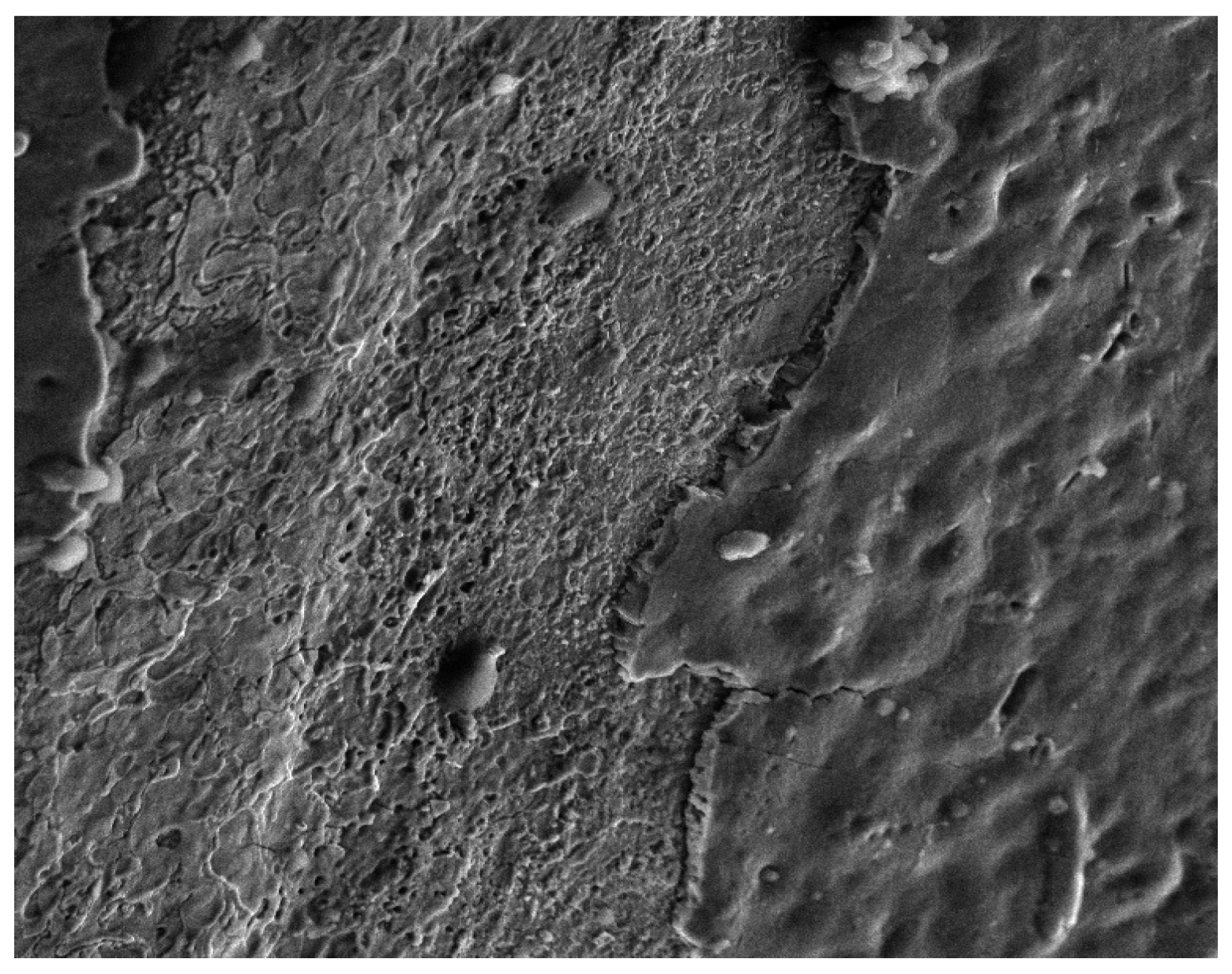

Analysis of Surfaces Obtained by Mechanized Plasma Gouging

4. Conclusions

- The results obtained in this paper show that plasma gouging is superior to air-arc gouging in terms of cutting quality and productivity. Following the quality control of the samples, no defects were detected.

- Mechanized plasma-gouged surfaces have less roughness than surfaces obtained by manual plasma gouging. This results from the constant speed and the maintenance of the processing parameters in the mechanized version.

- Plasma gouging is an ecological process, as it has a low impact on the environment.

- Due to the thermal effect, it follows that the highest level of hardness is found in the gouged area. This results from the higher cooling rate that produces harder structural constituents.

- No gas inclusions can be observed in the manually operated plasma-gouged surface, but there are avulsion zones on the surface. More advanced expulsion by spraying of the molten material was found to be achieved due to electromagnetic forces. This is due to the higher voltage applied (about 135 V). As a consequence of increasing the voltage, the gouging surface was extended. If the intensity of the current increases, then the depth expands.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cook, D.; Moring, D. Gouging: The other plasma process. Pract. Weld. Today 2004, 8, 32–34. [Google Scholar]

- Nohara, H.; Mimami, Y. 404 Evaluation of weld in a groove formed by the air plasma gouging. In Proceedings of the Materials and Processing Conference, Online, 2012. ISSN: 2424-287X. [Google Scholar] [CrossRef]

- Fernicula, R. Plasma gouging versus traditional methods. Svetsaren 2006, 61, 56–62. [Google Scholar]

- Nohara, H. Study of the Properties of Plasma Gouging Process when Compressed air is Used as an Orifice Gas. Trans. Jpn. Soc. Mech. Eng. Ser. C 2012, 78, 2331–2339. [Google Scholar] [CrossRef]

- Wang, H.X.; Wei, Y.H.; Yang, C.L. Numerical simulation of variable polarity vertical-up plasma arc welding process. Comput. Mater. Sci. 2007, 38, 571–587. [Google Scholar] [CrossRef]

- IARC. Monographs on the Evaluation of Carcinogenic RISC to Humans, Chromium, Nichel and Welding; IARC Publication: Lyon, France, 1990; Volume 49. [Google Scholar]

- Kałasznikow, A.; Michalski, M. Surface Phenomena Accompanying Plasma Gouging of S355 Steel. E3S Web Conf. 2017, 19, 03020. [Google Scholar] [CrossRef]

- Virgil, I.; Minodora, R.; Adriana, P.; Gabriel, A. Fiction and Wear Behavior of Moglice Polymer Composite through Dry Sliding Ball on Flat Reciprocating Test. Appl. Mech. Mater. 2015, 808, 137–142, ISSN: 1662-7482. [Google Scholar]

- Wang, J.; Hoang, T.; Floyd, E.; Regens, J. Metal Fume Emission from Stainless Steel Plasma Cutting. In Proceedings of the AIHce 2015, Salt Lake City, UT, USA, 30 May–4 June 2015. [Google Scholar]

- King, L.A. The Positive Collumn of Arc Temperatures in Different Gases. In Proceedings of the Uletinul Colloquium Spectrosopicum Internationale VI, Amsterdam, The Netherlands, May 1956. [Google Scholar]

- Juffus, L.; Baker, B. Pipe Welding, 1st ed.; Cengage Learning: Independence, KY, USA, 2016; ISBN 978-1-1336-9184-6. [Google Scholar]

- Concetti, A. Integrted Approaches for Designing and Optimizing Thermal Plasma Processing for Metal Cutting and Material Treatment. Ph.D. Thesis, la Universitatea di Bologna, Bologna, Italy, 2011. [Google Scholar]

- Jaberi, E.; Dehkordi, H.; Khamedi, R.; SalehFard, M. Elimination Back Gouging Operation in Submerged Arc Welding Butt without Chanfers ASTM A516. IJE TRANSACTIONS B Appl. 2014, 27, 1705–1712. [Google Scholar] [CrossRef]

- Fazakas, B.; Seculin, R.C.; Machedon-Pisu, T.; Vas, A. Aspects regarding to patinated steel gouging. Metall. New Mater. Res. 2014, 22, 7–13, ISSN: 1221-5503. [Google Scholar]

- Fazakas, B.; Seculin, R.C.; Machedon-Pisu, T.; Mon, I.C. Experimental researches and aspects regarding pipe steel gouging. Metall. New Mater. Res. 2015, 23, 25–32, ISSN: 1221-5503. [Google Scholar]

- Fazakas, B.; Cristian, S.R.; Machedon-Pisu, T.; Alin, P. Aspects regarding the characterization of the gouged surface. Adv. Mater. Res. 2015, 1128, 217–223, ISSN: 1662-8985. [Google Scholar] [CrossRef]

- Fazakas, B.; Machedon-Pisu, T.; Nicanor, C. Characterization of the Surfaces Obtained by Gouging. Mater. Sci. Forum 2017, 907, 220–226, ISSN: 1662-9752. [Google Scholar] [CrossRef]

- Fazakas, B.; Machedon-Pisu, T. Determining Microparticle Concentration in the Workplace Atmosphere during Plasma Gouging. Recent Ind. Eng. J. 2017, 18, 93–98, ISSN: 1582-0246. [Google Scholar]

- Jeffus, L.; Bower, L. Welding Skills, Processes and Practice for Entry-Level Welders; Cengage Learning: Independence, KY, USA, 2010; ISBN 13-978-1-4354-2796-9. [Google Scholar]

| Mark | C | Mn | Si | P | S | Cu | Ceq |

|---|---|---|---|---|---|---|---|

| S355J2 | 0.20 | 1.60 | 0.55 | 0.03 | 0.03 | 0.55 | 0.45 |

| Mark | Tensile Strength Rm [MPa] | Drip Limit Rp0.2 [MPa] | Elongation [%] |

|---|---|---|---|

| S355J2 | 630 | 355 | 20 |

| Mark | Gouging Current [A] | Compressed Air Flow Rate [L/min] | Compressed Air Pressure [MPa] | Gouging Angle [°] | Gouging Speed [mm/min] |

|---|---|---|---|---|---|

| S355J2 manual | 45 | 160 | 0.5 | ≈45 | ≈1250 |

| S355J2 mechanized | 45 | 160 | 0.5 | 45 | 950 |

| Mark | Gouging Width [mm] | Gouging Depth [mm] | Gouging Length [mm] |

|---|---|---|---|

| S355J2 manual | 2.2 | 2.3 | 50 |

| S355J2 mechanized | 2.4 | 2.5 | 50 |

| Samples | Gouging Current [A] | Gouging Angle [°] | Gas Flow [L/min] | Gas Pressure [MPa] | Gouging Speed [mm/min] |

|---|---|---|---|---|---|

| P1 | 30 | 25 | 120 | 0.3 | 1150 |

| P2 | 40 | 25 | 120 | 0.35 | 1150 |

| P3 | 40 | 25 | 120 | 0.5 | 1150 |

| P4 | 35 | 25 | 120 | 0.4 | 1150 |

| P5 | 40 | 25 | 120 | 0.45 | 1150 |

| P6 | 40 | 30 | 120 | 0.4 | 1150 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olah, A.; Machedon-Pisu, M.; Machedon-Pisu, T. Research on Mechanized Plasma Gouging of Weldable Construction Steels. Coatings 2024, 14, 1502. https://doi.org/10.3390/coatings14121502

Olah A, Machedon-Pisu M, Machedon-Pisu T. Research on Mechanized Plasma Gouging of Weldable Construction Steels. Coatings. 2024; 14(12):1502. https://doi.org/10.3390/coatings14121502

Chicago/Turabian StyleOlah, Arthur, Mihai Machedon-Pisu, and Teodor Machedon-Pisu. 2024. "Research on Mechanized Plasma Gouging of Weldable Construction Steels" Coatings 14, no. 12: 1502. https://doi.org/10.3390/coatings14121502

APA StyleOlah, A., Machedon-Pisu, M., & Machedon-Pisu, T. (2024). Research on Mechanized Plasma Gouging of Weldable Construction Steels. Coatings, 14(12), 1502. https://doi.org/10.3390/coatings14121502