A One-Step Novel Method to Fabricate Multigrade Ti6Al4V/TiN Composites Using Laser Powder Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

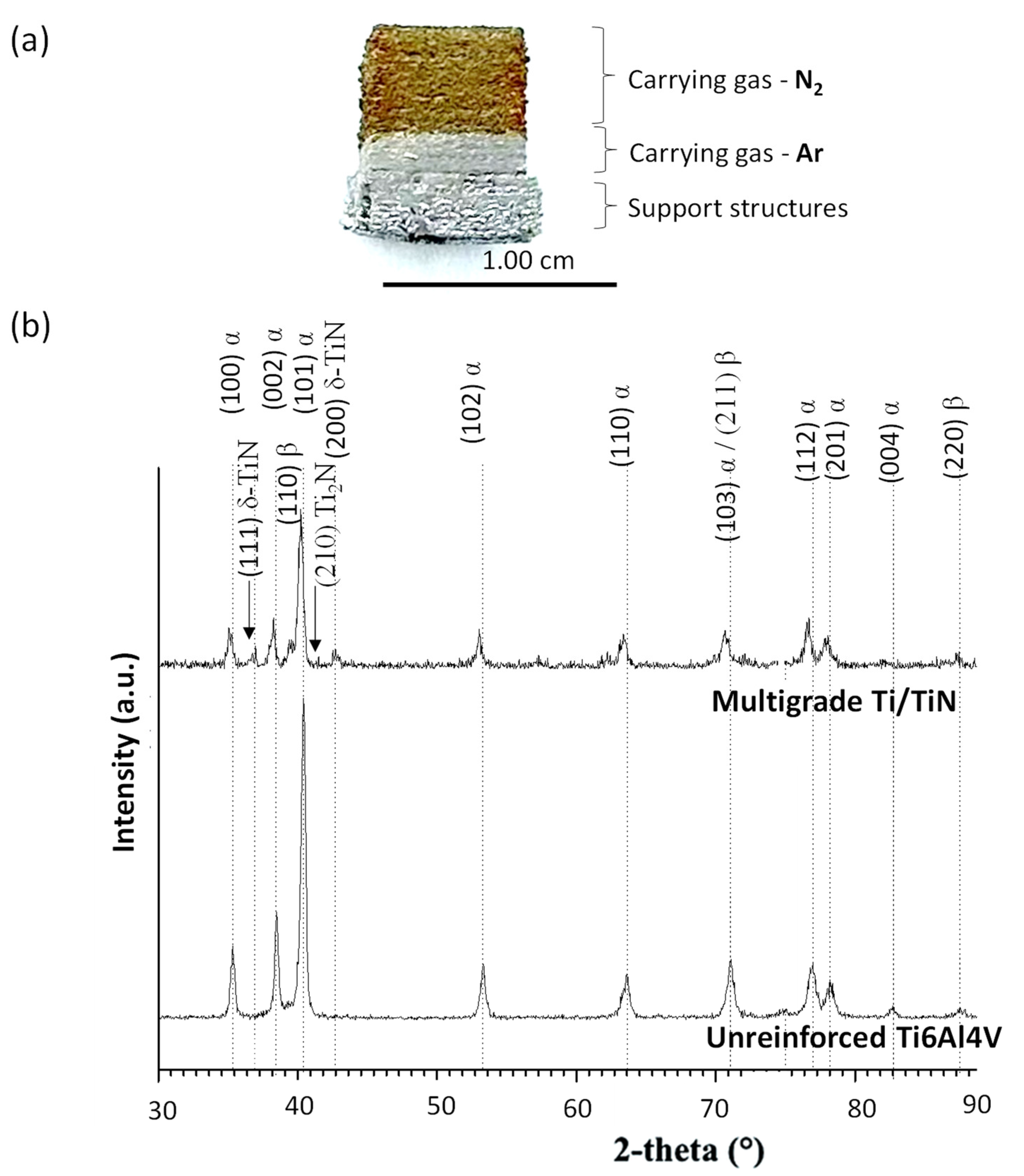

3.1. Phase Analysis

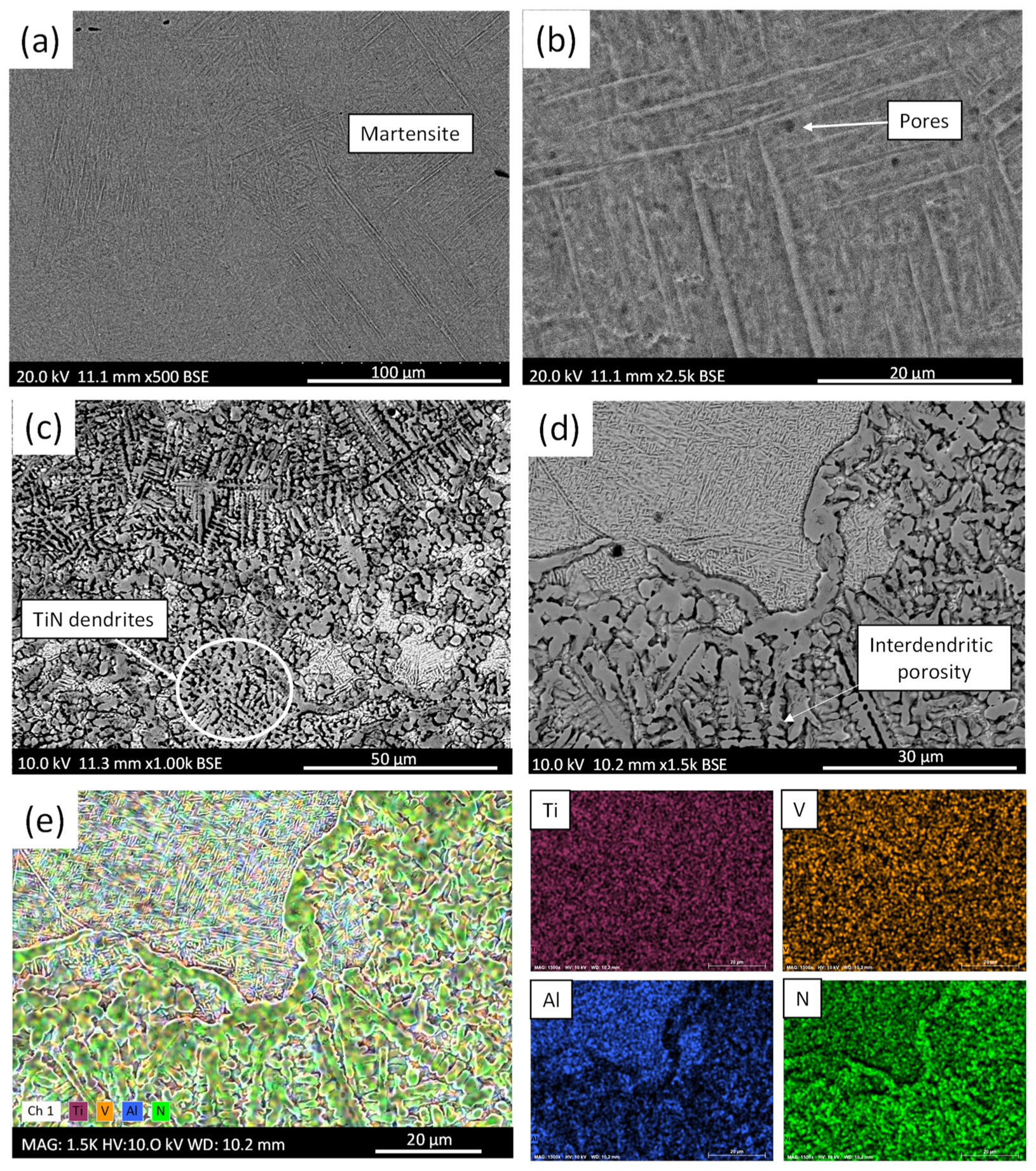

3.2. Microstructural Analysis

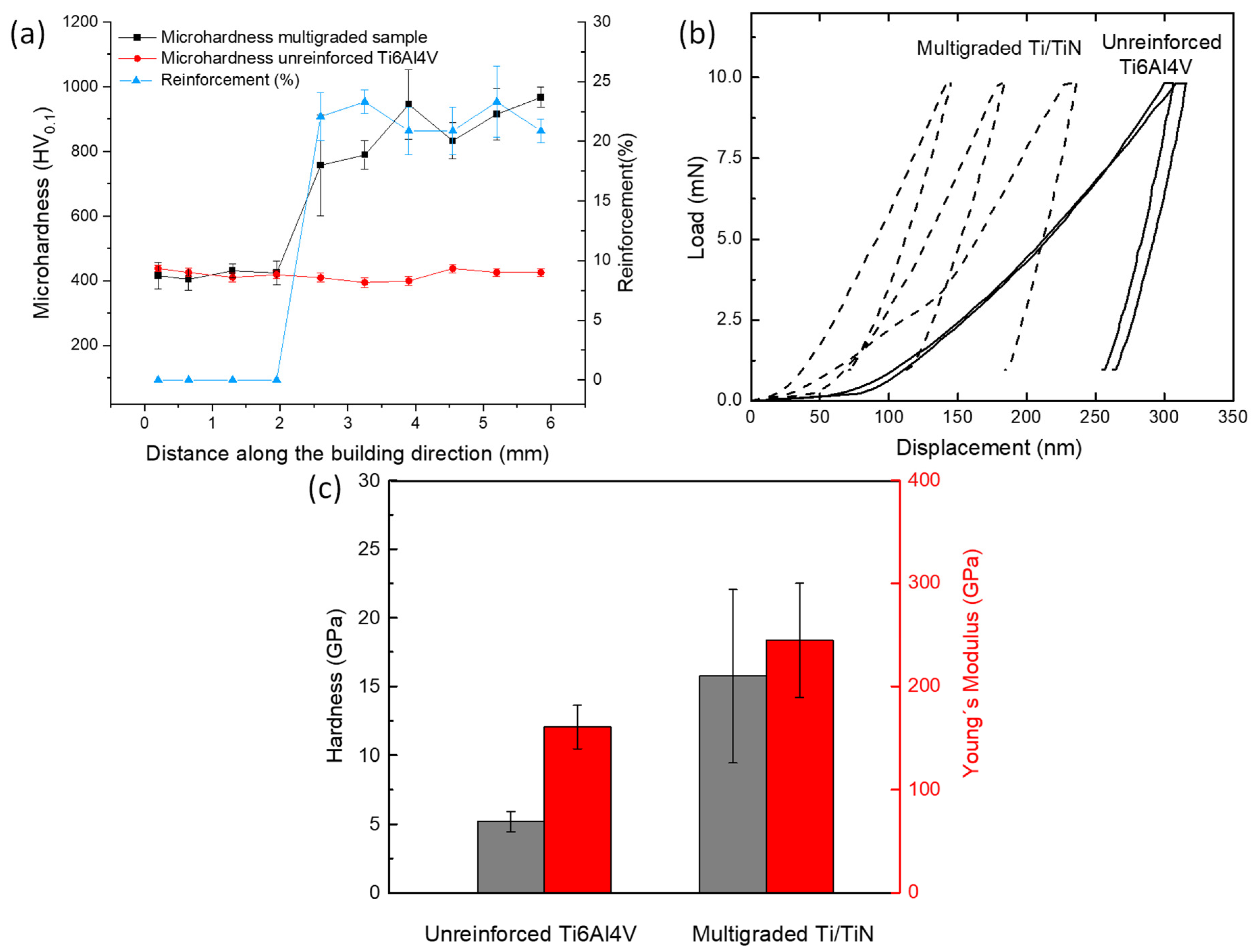

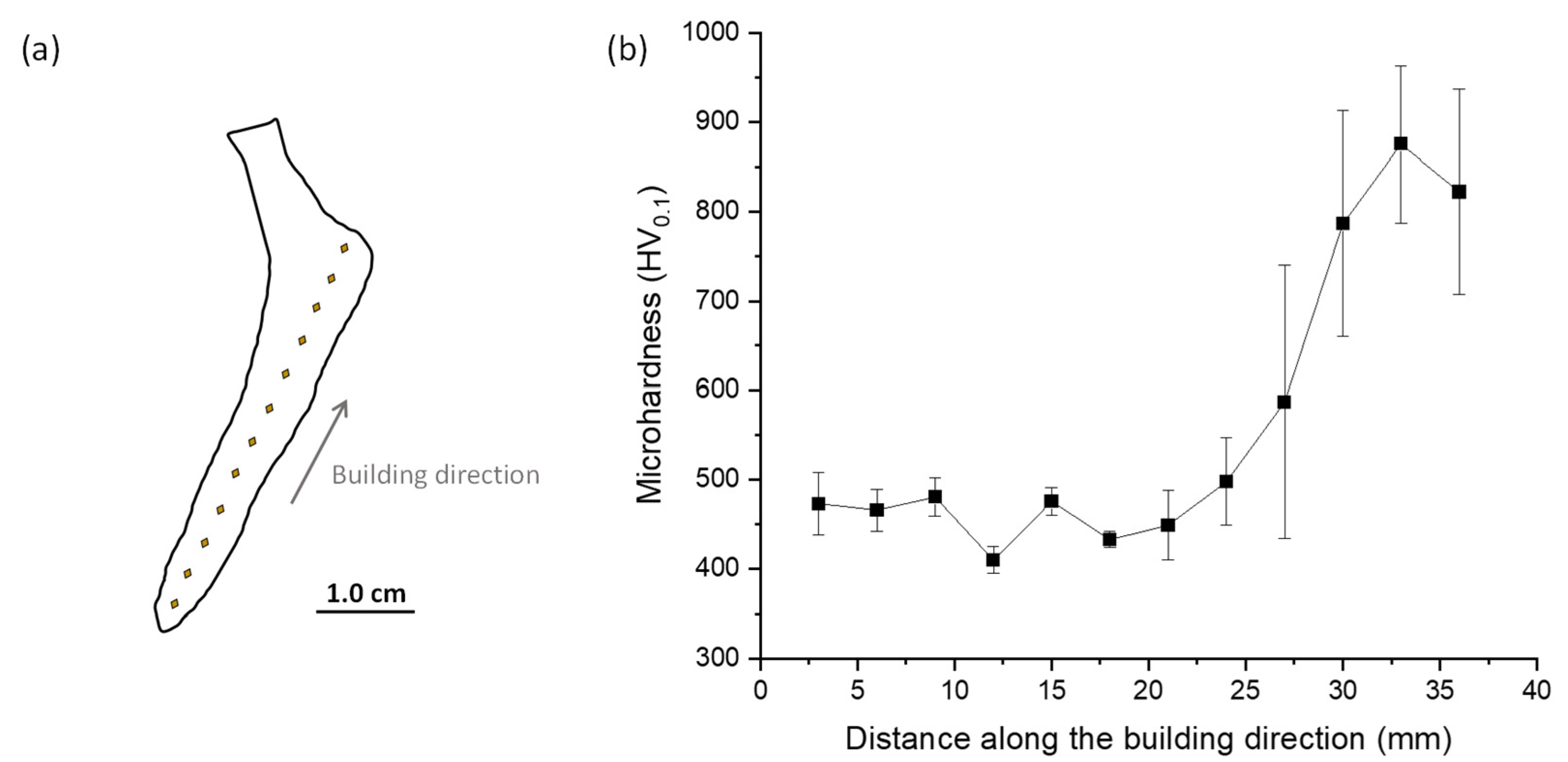

3.3. Mechanical Properties Analysis

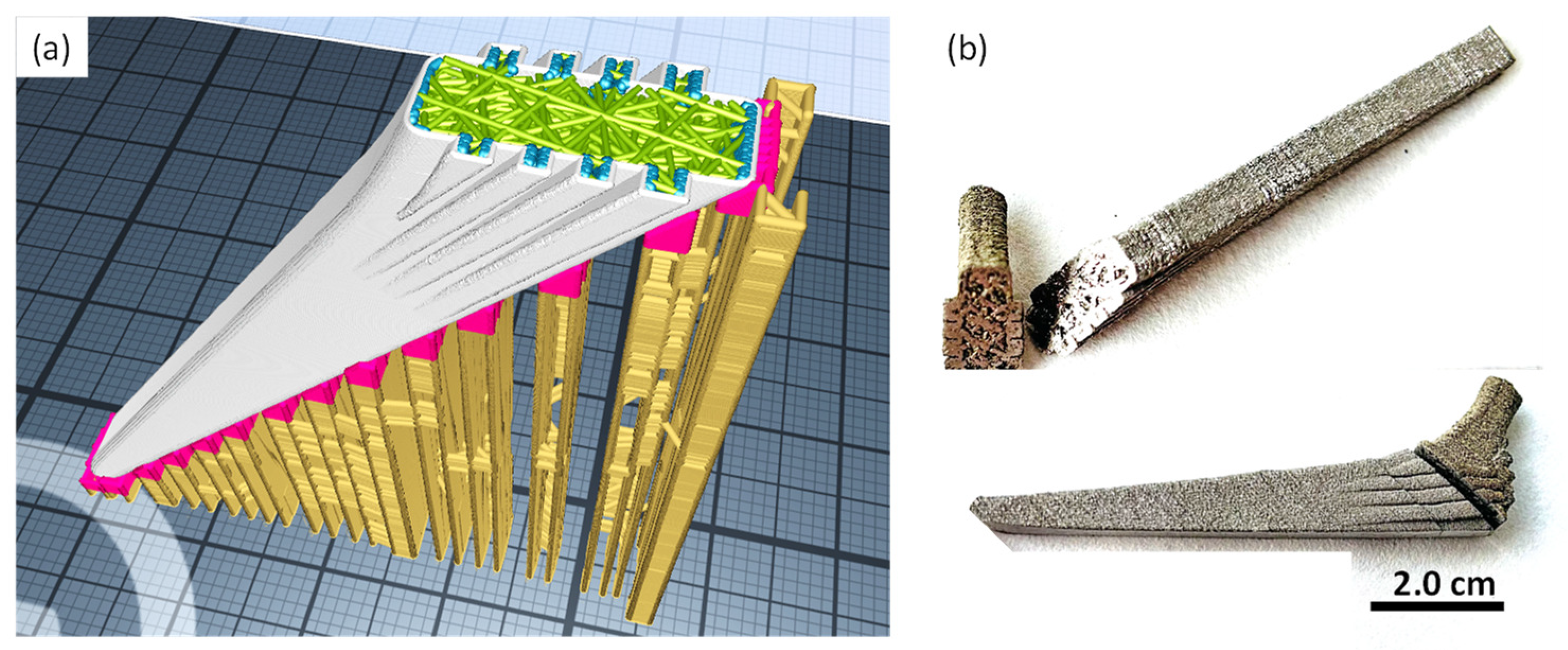

3.4. Additive Manufacturing of Hip Implant Scaled-Up Proof of Concept

4. Conclusions

- A novel one-step process for the in situ laser powder bed fusion additive manufacture of TiN-reinforced Ti6Al4V multigrade composites was successfully developed.

- TiN were formed by the nitriding reaction that occurred in situ during the sample fabrication process in an atmosphere that contained a mixture of argon and nitrogen. The proportion of TiN reinforcement in the composite increased with the amount of nitrogen present in the chamber.

- The microstructure of the printed material was evaluated using XRD and SEM, and it was concluded that a martensitic Ti6Al4V microstructure was formed in the unreinforced material, and TiN dendrites were gradually introduced into an α + β basketweave titanium matrix with the formation of a minor Ti2N.

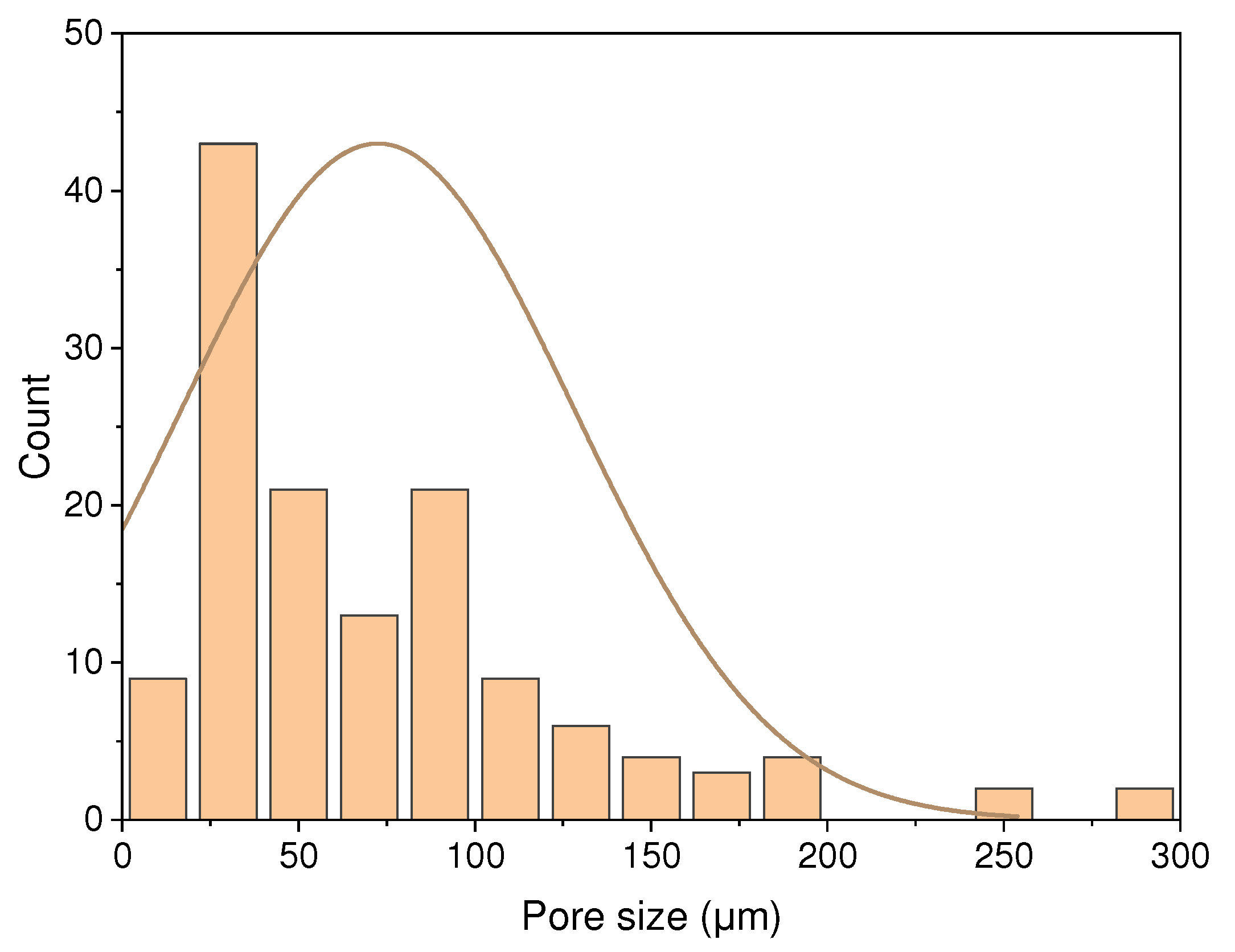

- The porosity levels and the reinforcement percentages increased with the presence of nitrogen in the printing chamber, with measurements ranging from 7 to 12% and from 15 to 25%, respectively. The voids ranged in size from 5 to 300 µm and most pores had sizes between 20 and 40 µm.

- The defectology present in the materials was analyzed. The main defects found in the printed parts were a lack of fusion voids, spherical pores, and interdendritic porosity.

- The microhardness of the Ti6Al4V/TiN was 850 ± 350 HV0.1, which is 100% higher than the unreinforced Ti6Al4V. The nanohardness and elastic modulus of Ti/TiN were ×3 and ×1.5 higher than those of the unreinforced Ti6Al4V. This makes L-PBF a promising technique to obtain harder multi-grade Ti-TiN for customized medical applications, such as hip implants.

- A scaled-up proof of concept of a hip implant stem was printed using the nitriding method; the part was functionalized by gradually changing the material from unreinforced Ti6Al4V at the bottom to Ti6Al4V/TiN composite material at the top, where fretting corrosion occurs and a material with a higher hardness and corrosion-wear resistance is required.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, N.; Hameed, P.; Ummethala, R.; Manivasagam, G.; Prashanth, K.G.; Eckert, J. Selective laser manufacturing of Ti-based alloys and composites: Impact of process parameters, application trends, and future prospects. Mater. Today Adv. 2020, 8, 100097. [Google Scholar] [CrossRef]

- Huang, N.; Leng, Y.X.; Ding, P.D. Surface Engineered Titanium Alloys for Biomedical Devices; Woodhead Publishing: Cambridge, UK, 2010; ISBN 9781845695378. [Google Scholar]

- Grabarczyk, J.; Gaj, J.; Pazik, B.; Kaczorowski, W.; Januszewicz, B. Tribocorrosion behavior of Ti6Al4V alloy after thermo-chemical treatment and DLC deposition for biomedical applications. Tribol. Int. 2021, 153, 106560. [Google Scholar] [CrossRef]

- Shi, B.; Huang, S.; Zhu, P.; Xu, C.; Guo, P.; Fu, Y. In-situ TiN reinforced composite coatings prepared by plasma spray welding on Ti6Al4V. Mater. Lett. 2020, 276, 128093. [Google Scholar] [CrossRef]

- Song, C.; Liu, M.; Deng, Z.Q.; Niu, S.P.; Deng, C.M.; Liao, H.L. A novel method for in-situ synthesized TiN coatings by plasma spray-physical vapor deposition. Mater. Lett. 2018, 217, 127–130. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, P.; Wang, X.; Chen, Y.; Liu, H.; Chen, L.; Sheng, Y.; Li, W. In-situ formation of textured TiN coatings on biomedical titanium alloy by laser irradiation. J. Mech. Behav. Biomed. Mater. 2018, 78, 143–153. [Google Scholar] [CrossRef] [PubMed]

- Yuan, S.; Lin, N.; Zou, J.; Lin, X.; Liu, Z.; Yu, Y.; Wang, Z.; Zeng, Q.; Chen, W.; Tian, L.; et al. In-situ fabrication of gradient titanium oxide ceramic coating on laser surface textured Ti6Al4V alloy with improved mechanical property and wear performance. Vacuum 2020, 176, 109327. [Google Scholar] [CrossRef]

- Avila, J.D.; Stenberg, K.; Bose, S.; Bandyopadhyay, A. Hydroxyapatite reinforced Ti6Al4V composites for load-bearing implants. Acta Biomater. 2021, 123, 379–392. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Zeng, C.; Wen, H.; Bellamy, H.; Sprunger, P.T.; Schilling, P.J.; Guo, S.M. Titanium and nitrogen interactions under laser additive manufacturing conditions. Surf. Coat. Technol. 2019, 378, 124955. [Google Scholar] [CrossRef]

- Chan, C.W.; Quinn, J.; Hussain, I.; Carson, L.; Smith, G.C.; Lee, S. A promising laser nitriding method for the design of next generation orthopaedic implants: Cytotoxicity and antibacterial performance of titanium nitride (TiN) wear nano-particles, and enhanced wear properties of laser-nitrided Ti6Al4V surfaces. Surf. Coat. Technol. 2021, 405, 126714. [Google Scholar] [CrossRef]

- Rasiya, G.; Shukla, A.; Saran, K. Additive Manufacturing-A Review. Mater. Today Proc. 2021, 47, 6896–6901. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, H.; Wang, C.; Zhou, L.; Yuan, S.; Zhang, W. A review of topology optimization for additive manufacturing: Status and challenges. Chin. J. Aeronaut. 2021, 34, 91–110. [Google Scholar] [CrossRef]

- Fereiduni, E.; Ghasemi, A.; Elbestawi, M. Selective laser melting of aluminum and titanium matrix composites: Recent progress and potential applications in the aerospace industry. Aerospace 2020, 7, 77. [Google Scholar] [CrossRef]

- Zhong, C.; Liu, J.; Zhao, T.; Schopphoven, T.; Fu, J.; Gasser, A.; Schleifenbaum, J.H. Laser metal deposition of Ti6Al4V-A brief review. Appl. Sci. 2020, 10, 764. [Google Scholar] [CrossRef]

- Lawrence, J.R.; Pou, J.; Low, D.K.Y.; Toyserkani, E. Advances in Laser Materials Processing; Woodhead Publishing: Cambridge, UK, 2010; ISBN 9781845694746. [Google Scholar]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Dargusch, M.S. Recent developments and opportunities in additive manufacturing of titanium-based matrix composites: A review. Int. J. Mach. Tools Manuf. 2018, 133, 85–102. [Google Scholar] [CrossRef]

- Bedmar, J.; Riquelme, A.; Rodrigo, P.; Torres, B.; Rams, J. Comparison of Different Additive Manufacturing Methods for 316L Stainless Steel. Materials 2021, 14, 6504. [Google Scholar] [CrossRef]

- Prabakaran, M.P.; Kannan, G.R. Optimization of CO2 Laser Beam Welding Process Parameters to Attain Maximum Weld Strength in Dissimilar Metals. Mater. Today Proc. 2018, 5, 6607–6616. [Google Scholar] [CrossRef]

- Lee, H.; Lim, C.H.J.; Low, M.J.; Tham, N.; Murukeshan, V.M.; Kim, Y.-J. Lasers in additive manufacturing: A review. Int. J. Precis. Eng. Manuf. Technol. 2017, 4, 307–322. [Google Scholar] [CrossRef]

- Bedmar, J.; de la Pezuela, J.; Riquelme, A.; Torres, B.; Rams, J. Impact of Remelting in the Microstructure and Corrosion Properties of the Ti6Al4V Fabricated by Selective Laser Melting. Coatings 2022, 12, 284. [Google Scholar] [CrossRef]

- Aversa, A.; Saboori, A.; Librera, E.; de Chirico, M.; Biamino, S.; Lombardi, M.; Fino, P. The role of Directed Energy Deposition atmosphere mode on the microstructure and mechanical properties of 316L samples. Addit. Manuf. 2020, 34, 101274. [Google Scholar] [CrossRef]

- Wei, W.; Wu, W.; Fan, S.; Duan, X. In-situ laser additive manufacturing of Ti6Al4V matrix composites by gas–liquid reaction in dilute nitrogen gas atmospheres. Mater. Des. 2021, 202, 109578. [Google Scholar] [CrossRef]

- Riquelme, A.; Rodrigo, P.; Escalera-Rodriguez, M.D.; García-Fogeda, P.; Rams, J. Influence of the feed powder composition in mechanical properties of ALN-nano-reinforced aluminium composites coatings deposited by reactive direct laser deposition. Metals 2020, 10, 926. [Google Scholar] [CrossRef]

- Abenojar, J.; Velasco, F.; Bautista, A.; Campos, M.; Bas, J.A.; Torralba, J.M. Atmosphere influence in sintering process of stainless steels matrix composites reinforced with hard particles. Compos. Sci. Technol. 2003, 63, 69–79. [Google Scholar] [CrossRef]

- Riquelme, A.; Rodrigo, P.; Escalera-Rodriguez, M.D.; Rams, J. Effect of the process parameters in the additive manufacturing of in situ Al/AlN samples. J. Manuf. Process. 2019, 46, 271–278. [Google Scholar] [CrossRef]

- Rodrigo, P.; Riquelme, A.; Escalera-Rodriguez, M.D.; Rams, J. Procedimiento de Obtención de Material Compuesto Al/AlN o Ti/TiN, Material Compuesto Al/AlN o Ti/TiN Obtenible Según Dicho Procedimiento y uso del Mismo en Revestimientos. Patent ES2598727A2, 14 September 2017. [Google Scholar]

- Mridha, S.; Baker, T.N. Crack-free hard surfaces produced by laser nitriding of commercial purity titanium. Mater. Sci. Eng. A 1994, 188, 229–239. [Google Scholar] [CrossRef]

- Na, T.W.; Kim, W.R.; Yang, S.M.; Kwon, O.; Park, J.M.; Kim, G.H.; Jung, K.H.; Lee, C.W.; Park, H.K.; Kim, H.G. Effect of laser power on oxygen and nitrogen concentration of commercially pure titanium manufactured by selective laser melting. Mater. Charact. 2018, 143, 110–117. [Google Scholar] [CrossRef]

- Choroszyński, M.; Choroszyński, M.R.; Skrzypek, S.J. Biomaterials for hip implants—Important considerations relating to the choice of materials. Bio-Algorithms Med-Syst. 2017, 13, 133–145. [Google Scholar] [CrossRef]

- Blunt, L.; Bills, P.; Jiang, X.; Hardaker, C.; Chakrabarty, G. The role of tribology and metrology in the latest development of bio-materials. Wear 2009, 266, 424–431. [Google Scholar] [CrossRef]

- Geringer, J.; Kim, K.; Pellier, J.; Macdonald, D.D. Fretting corrosion processes and wear mechanisms in medical implants. In Bio-Tribocorrosion in Biomaterials and Medical Implants; Elsevier: Amsterdam, The Netherlands, 2013; pp. 45–73. [Google Scholar]

- Maja, M.E.; Falodun, O.E.; Obadele, B.A.; Oke, S.R.; Olubambi, P.A. Nanoindentation studies on TiN nanoceramic reinforced Ti–6Al–4V matrix composite. Ceram. Int. 2018, 44, 4419–4425. [Google Scholar] [CrossRef]

- Robinson, J.H.; Ashton, I.R.T.; Jones, E.; Fox, P.; Sutcliffe, C. The effect of hatch angle rotation on parts manufactured using selective laser melting. Rapid Prototyp. J. 2019, 25, 289–298. [Google Scholar] [CrossRef]

- Al-Rubaie, K.S.; Melotti, S.; Rabelo, A.; Paiva, J.M.; Elbestawi, M.A.; Veldhuis, S.C. Machinability of SLM-produced Ti6Al4V titanium alloy parts. J. Manuf. Process. 2020, 57, 768–786. [Google Scholar] [CrossRef]

- de Rojas Candela, C.S.; Riquelme, A.; Rodrigo, P.; Rams, J. Carrying Gas Influence and Fabrication Parameters Impact in 3D Manufacturing of In Situ TiN-Ti Composites by Direct Laser Deposition. Met. Mater. Int. 2023, 29, 591–606. [Google Scholar] [CrossRef]

- Gil, F.J.; Ginebra, M.P.; Manero, J.M.; Planell, J.A. Formation of α-Widmanstätten structure: Effects of grain size and cooling rate on the Widmanstätten morphologies and on the mechanical properties in Ti6Al4V alloy. J. Alloys Compd. 2001, 329, 142–152. [Google Scholar] [CrossRef]

- Sieniawski, J.; Ziaja, W.; Kubiak, K.; Motyk, M. Microstructure and Mechanical Properties of High Strength Two-Phase Titanium Alloys. In Titanium Alloys—Advances in Properties Control; InTech: London, UK, 2013. [Google Scholar]

- Barink, M.; Meijers, H.; Spruit, M.; Fankhauser, C.; Verdonschot, N. How close does an uncemented hip stem match the final rasp position? Acta Orthop. Belg. 2004, 70, 534–539. [Google Scholar]

- Bartolomeu, F.; Costa, M.M.; Alves, N.; Miranda, G.; Silva, F.S. Additive manufacturing of NiTi-Ti6Al4V multi-material cellular structures targeting orthopedic implants. Opt. Lasers Eng. 2020, 134, 106208. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez de Rojas Candela, C.; Riquelme, A.; Rodrigo, P.; Bonache, V.; Bedmar, J.; Torres, B.; Rams, J. A One-Step Novel Method to Fabricate Multigrade Ti6Al4V/TiN Composites Using Laser Powder Bed Fusion. Coatings 2024, 14, 90. https://doi.org/10.3390/coatings14010090

Sánchez de Rojas Candela C, Riquelme A, Rodrigo P, Bonache V, Bedmar J, Torres B, Rams J. A One-Step Novel Method to Fabricate Multigrade Ti6Al4V/TiN Composites Using Laser Powder Bed Fusion. Coatings. 2024; 14(1):90. https://doi.org/10.3390/coatings14010090

Chicago/Turabian StyleSánchez de Rojas Candela, Carmen, Ainhoa Riquelme, Pilar Rodrigo, Victoria Bonache, Javier Bedmar, Belén Torres, and Joaquín Rams. 2024. "A One-Step Novel Method to Fabricate Multigrade Ti6Al4V/TiN Composites Using Laser Powder Bed Fusion" Coatings 14, no. 1: 90. https://doi.org/10.3390/coatings14010090

APA StyleSánchez de Rojas Candela, C., Riquelme, A., Rodrigo, P., Bonache, V., Bedmar, J., Torres, B., & Rams, J. (2024). A One-Step Novel Method to Fabricate Multigrade Ti6Al4V/TiN Composites Using Laser Powder Bed Fusion. Coatings, 14(1), 90. https://doi.org/10.3390/coatings14010090