The Effect of Laser Surface Remelting on the Surface Properties of Copper

Abstract

:1. Introduction

2. Experiment

2.1. Experimental Materials and Pre-Treatment

2.2. Experimental Equipment and Characterization

3. Discussion and Analysis

3.1. The Influence of Laser Parameters on the Surface Morphology

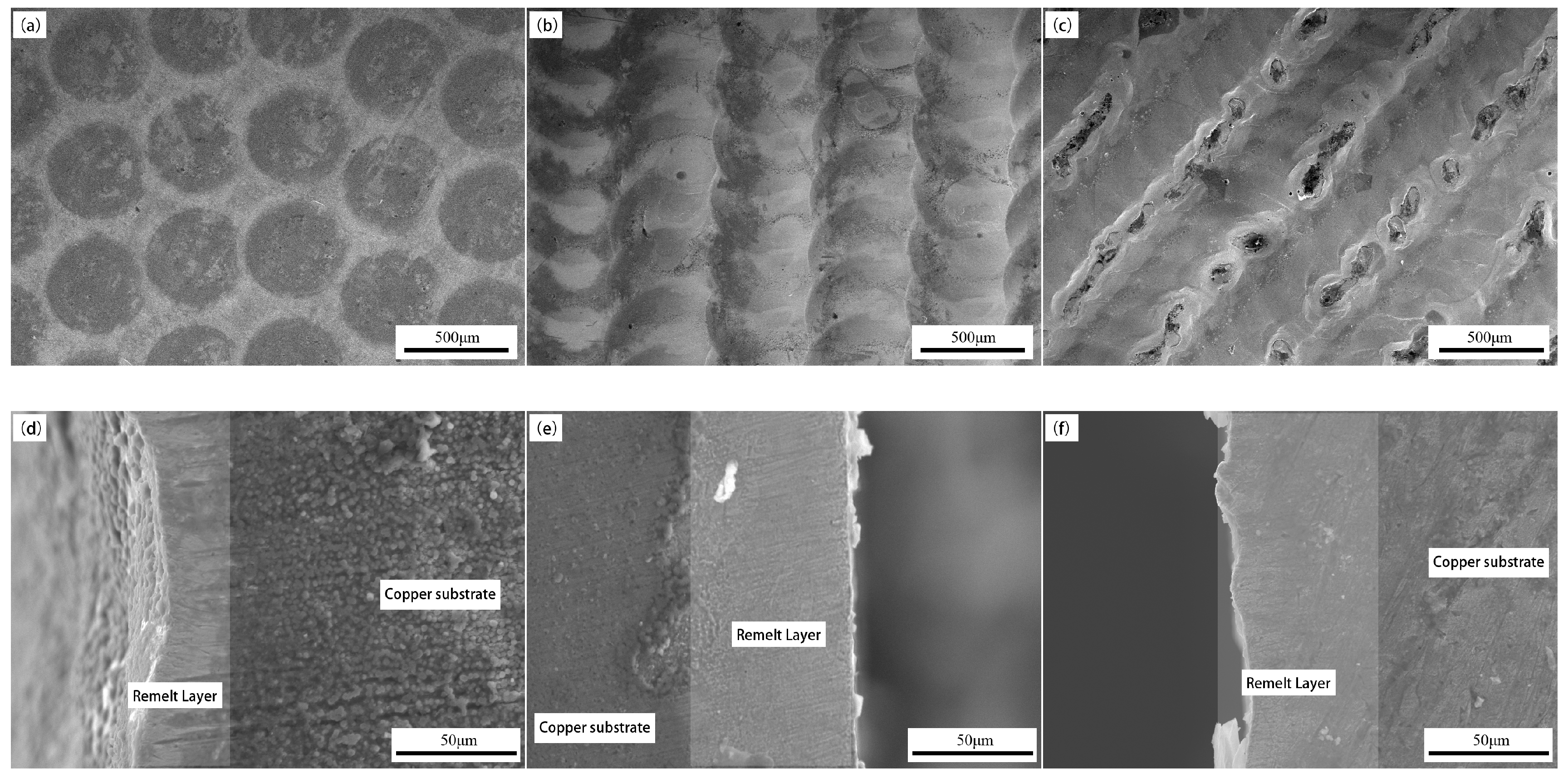

3.1.1. The Effect of Laser Frequency on the Surface Morphology

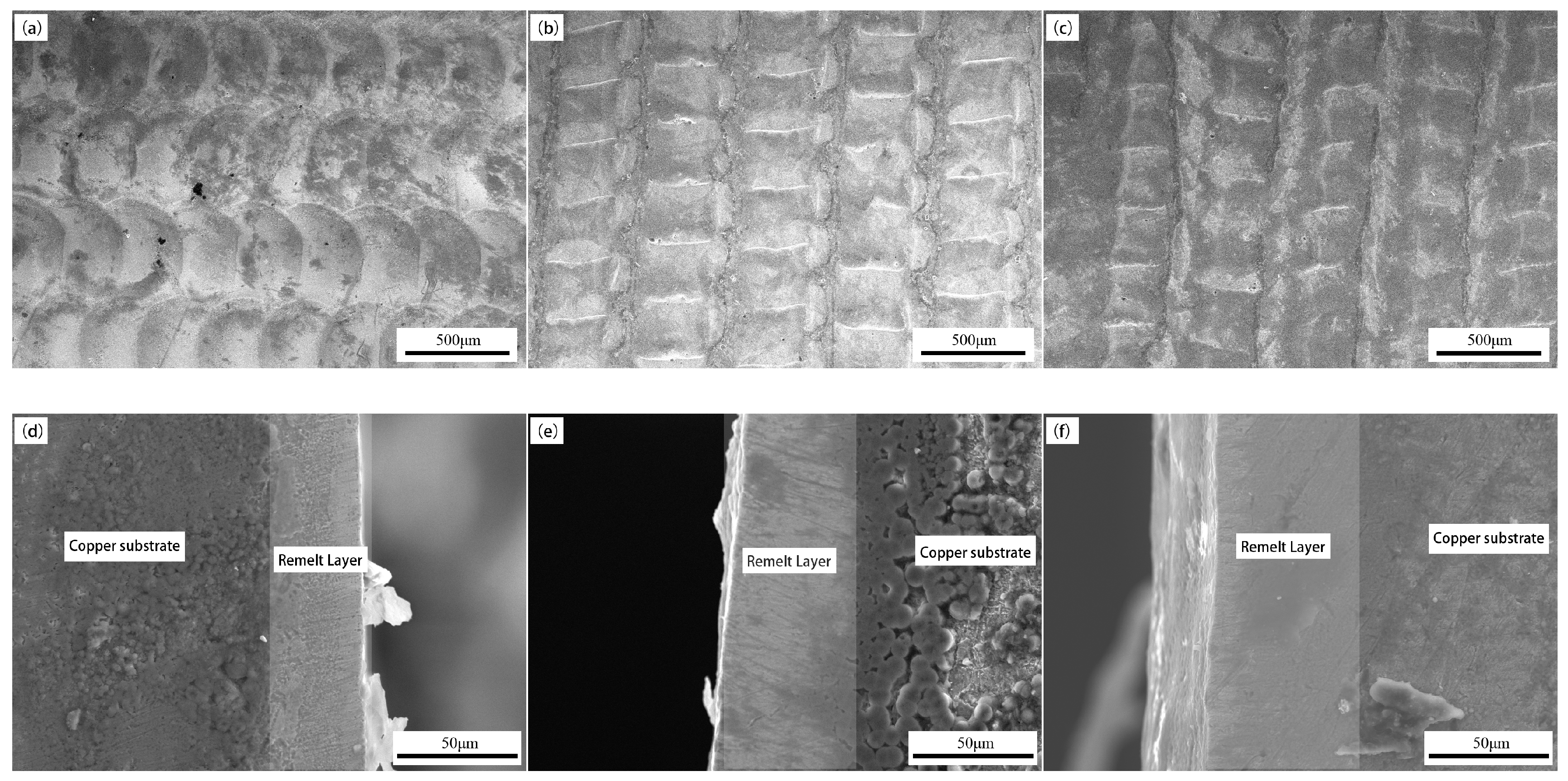

3.1.2. The Effect of Pulse Width on the Surface Morphology

3.1.3. The Effect of Laser Energy Density on the Surface Morphology

3.2. The Influence of Laser Parameters on the Surface Microhardness

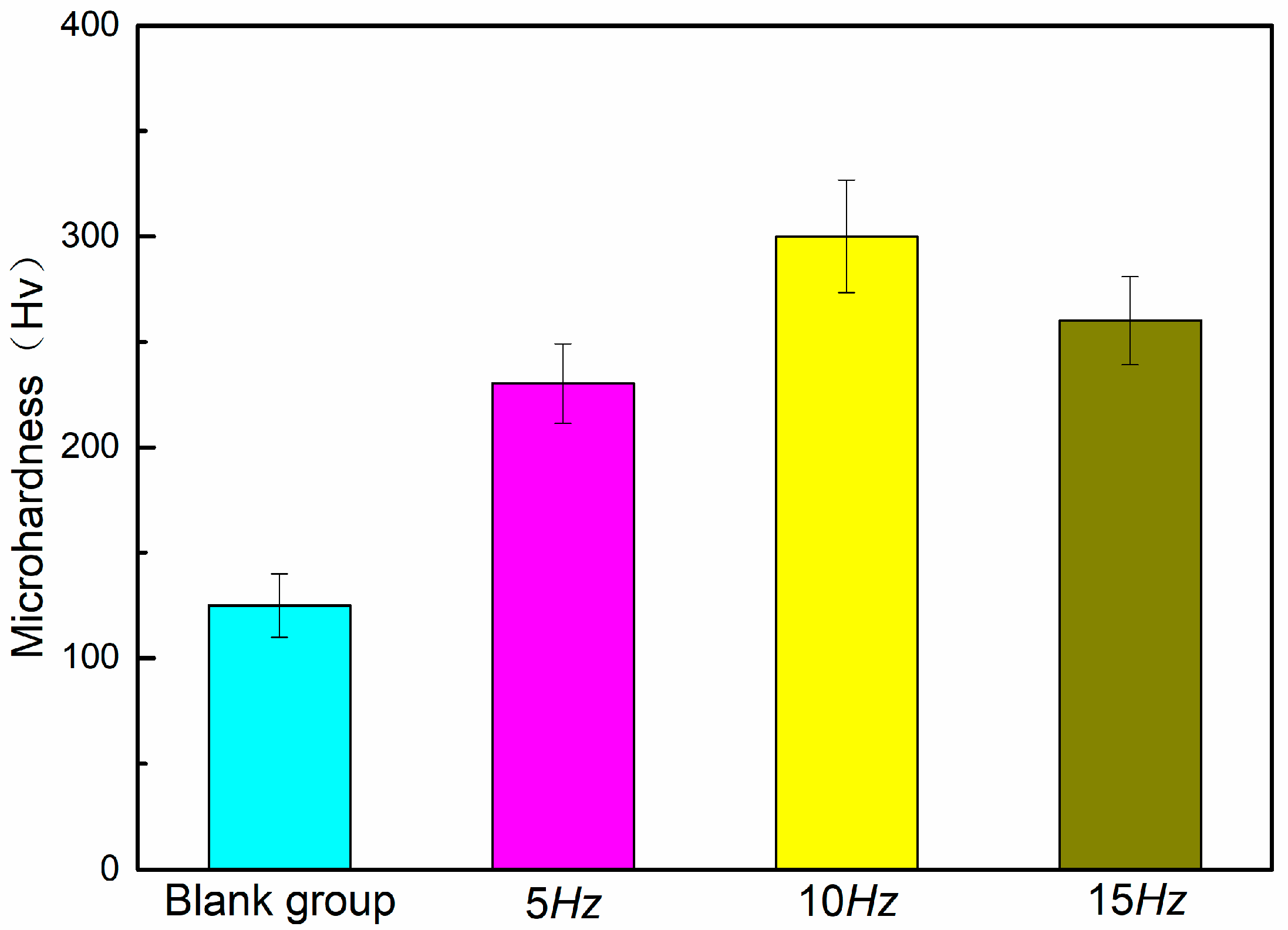

3.2.1. The Effect of Laser Frequency on Surface Microhardness

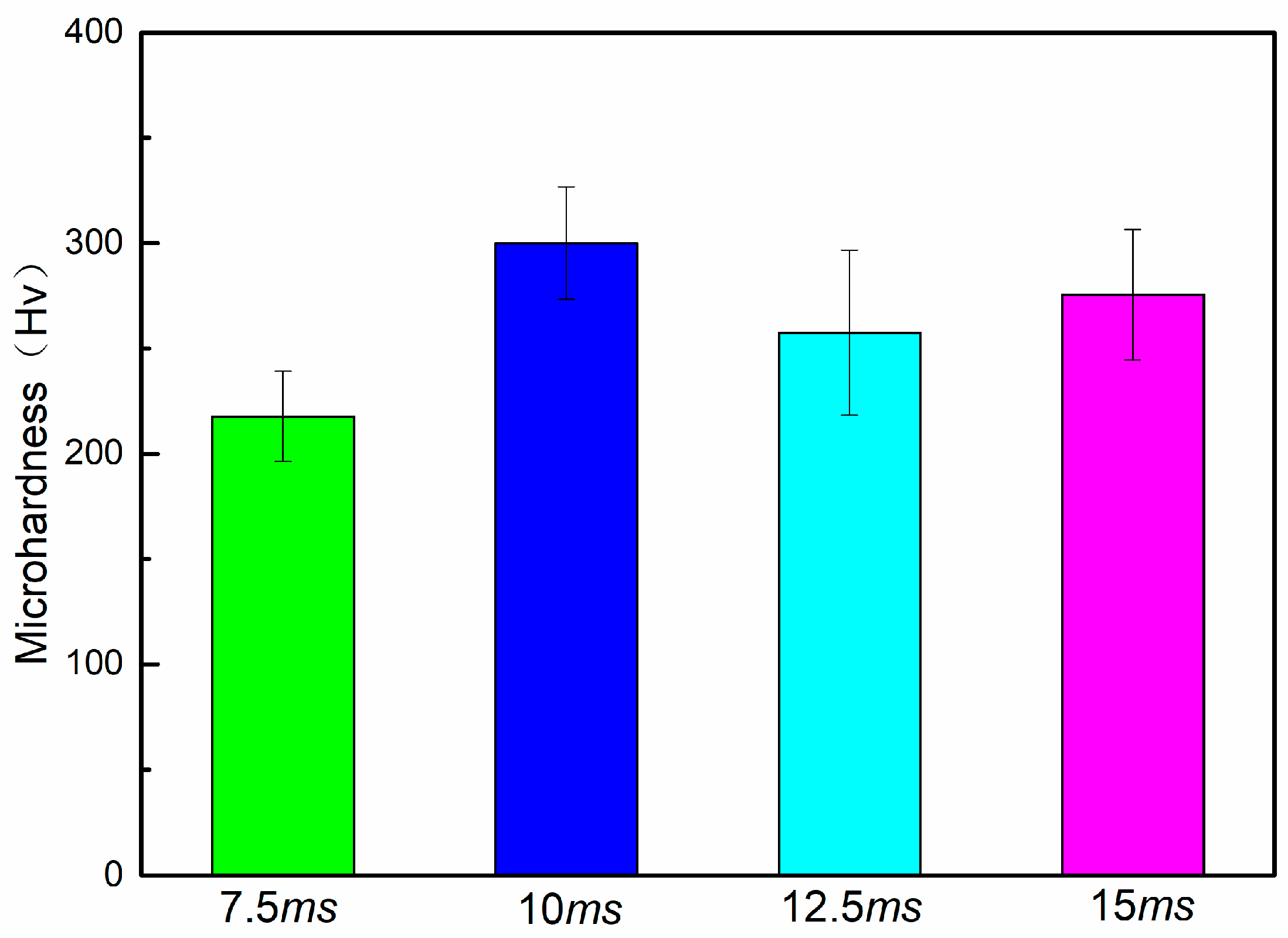

3.2.2. The Effect of Pulse Width on Surface Microhardness

3.2.3. The Effect of Energy Density on Surface Microhardness

3.3. The Influence of Laser Parameters on the Surface Wear Resistance

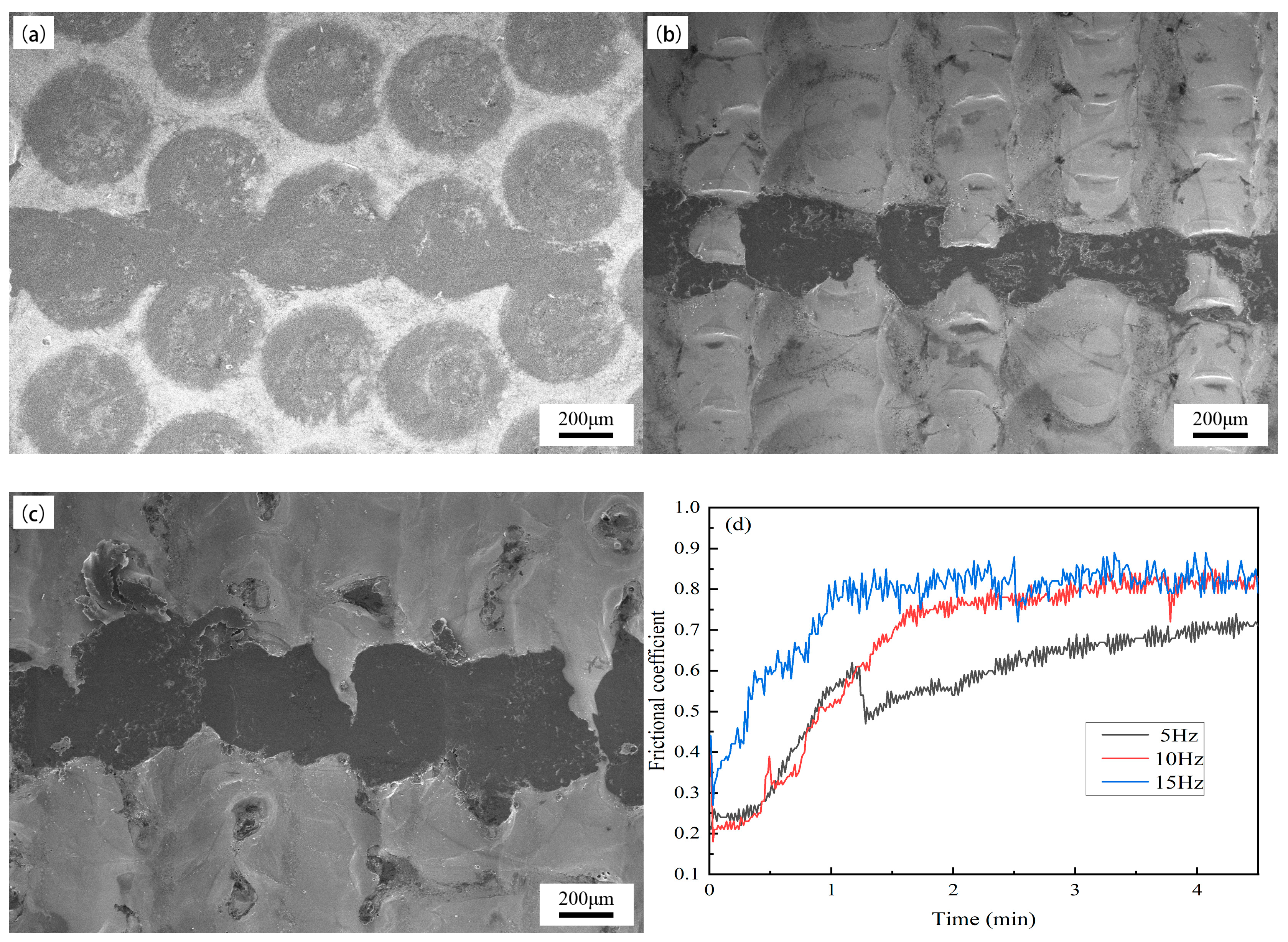

3.3.1. The Effect of Laser Frequency on the Surface Wear Resistance

3.3.2. The Effect of Pulse Width on the Surface Wear Resistance

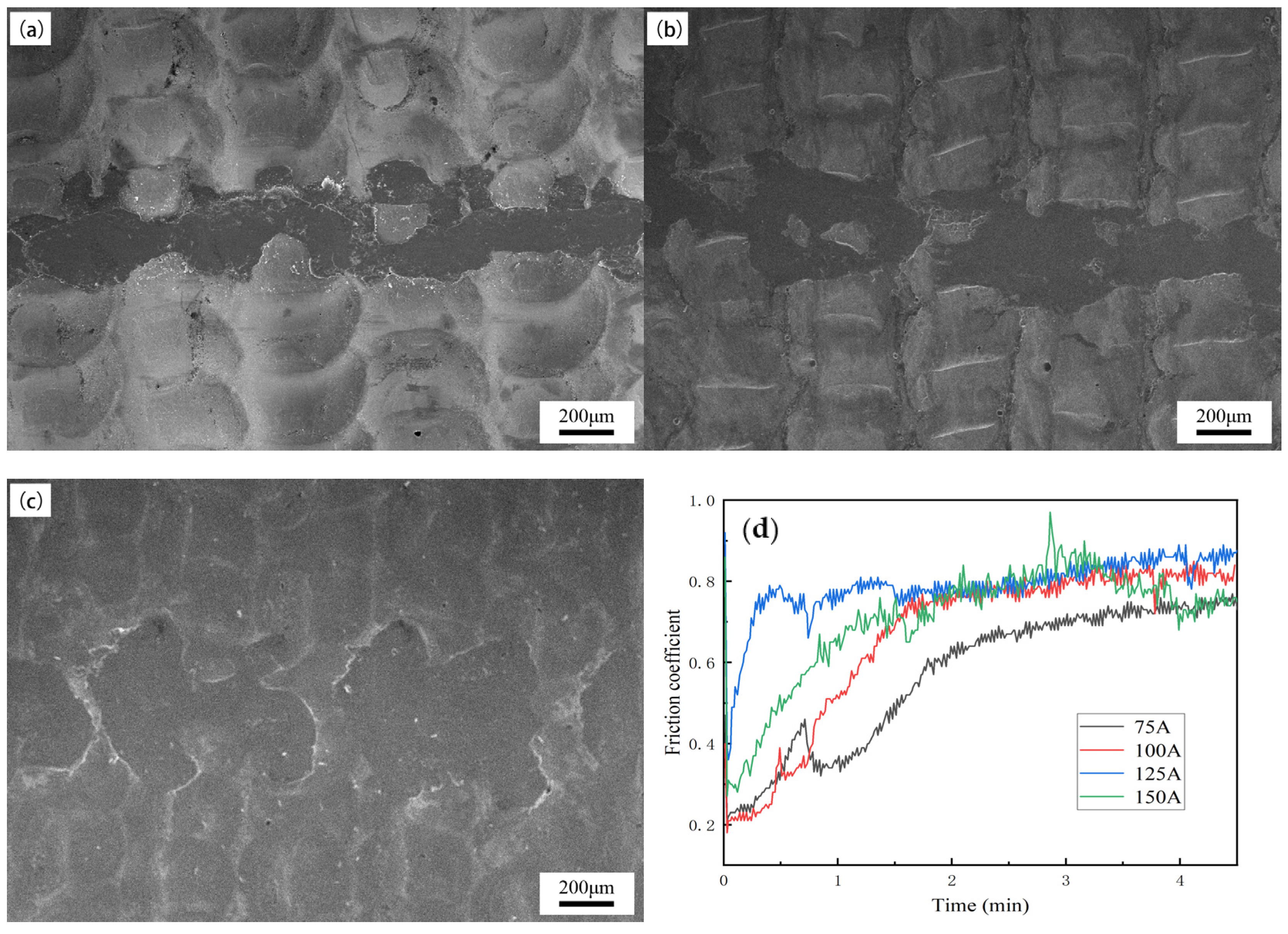

3.3.3. The Effect of Laser Energy Density on the Surface Wear Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, M.Y.; Xie, H.B.; Fang, Y.T.; Wang, H.T.; Liu, J.B. Progress in surface treatment techniques of copper and copper alloys. Chin. J. Nonferrous Met. 2021, 31, 1121–1133. [Google Scholar]

- Chen, C.; Guo, Z.H.; Guo, Y.Y.; Wang, R.Z.; Tang, E.L. Variable mechanism of electrical impedance for MCT high voltage switch under synergetic action of the mechanical and electric loads. Phys. Scr. 2023, 98, 105977. [Google Scholar] [CrossRef]

- Miao, J.; Chen, P.; Wu, J.F.; Fei, B.; Wu, X.; Liu, W.; Wan, J.F.; Wang, Y. Multi-spectral Characteristics of Arc Discharge in Switch Cabinet. J. Phys. Conf. Ser. 2022, 2359, 012005. [Google Scholar] [CrossRef]

- Yang, B.K.; Chen, Y.; Hao, W.K.; Han, Y.; Zhang, Q.; Li, Y.J.; Wang, X.F.; Huang, L.Y.; Lu, Y.L. The Corrosion Behavior of Different Silver Plating Layers as Electrical Contact Materials in Sulfur-Containing Environments. Coatings 2023, 13, 1796. [Google Scholar] [CrossRef]

- Ni, Y.Q.; Dong, G.N.; Tong, Z.; Li, X.; Wang, W. Effect of laser remelting on tribological properties of Babbitt alloy. Mater. Res. Express 2019, 6, 096570. [Google Scholar] [CrossRef]

- Zhu, J.; Hua, Y.T.; He, Q.S.; Liu, Y.; Huang, A.J.; Yang, Y.; Zhang, K. Research Progress on Laser Remelting in Selective Laser Melting. Rare Met. Mater. Eng. 2023, 52, 1932–1942. [Google Scholar]

- Wang, F.; Zuo, H.; Zhao, L.; Chen, M. Surface Quality and Property of Copper Treated by Laser Shock Peening. Prog. Laser Electron. 2017, 54, 041410. [Google Scholar] [CrossRef]

- Feng, Y.Y.; Ye, Y.X.; Lian, Z.C.; Xuan, T.D. Experimental Research on Effect of Surface Quality of Copper Treated by Laser Shock Peening. Laser Optoelectron. Prog. 2015, 52, 198–204. [Google Scholar]

- Liu, X.P.; Zhang, P.L.; Lu, Y.L.; Yan, H.; Lu, Z.S. Study on Tribological Properties of Ni-Based Silicide Coating on Copper by Laser Cladding. Chin. J. Lasers 2015, 42, 232–238. [Google Scholar]

- Li, K.; Fang, J.H.; Liao, R.B.; Jiang, Y.H.; Xu, J.; Li, J.Y.; Cao, H.J.; Luo, T.M.; Zhang, J. Research Status and Prospect of High-performance Metal Laser energy-field Surface Heat Treatment Technology. Chin. J. Lasers 2024, 4, 1–30. Available online: http://kns.cnki.net/kcms/detail/31.1339.TN.20231114.1007.032.html (accessed on 15 November 2023).

- Li, C.W.; Zhu, J.L.; Cai, Z.L.; Mei, L.; Jiao, X.D.; Du, X.; Wang, K. Microstructure and Corrosion Resistance of Underwater Laser Cladded Duplex Stainless Steel Coating after Underwater Laser Remelting Processing. Materials 2021, 14, 4965. [Google Scholar] [CrossRef]

- Xie, H.B.; Guan, W.M.; Lv, H.; Yang, H.Y.; Gao, M.Y.; Fang, Y.T.; Liu, J.B.; Wang, H.T. W-Cu/Cu composite electrodes fabricated via laser surface alloying. Mater. Charact. 2022, 185, 111715. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, H.M.; Chen, R.; He, B.; Cao, Y.G.; Liu, D. Laser surface alloying with carbon on 15-5PH steel for improved wear resistance. Surf. Eng. 2021, 37, 669–677. [Google Scholar] [CrossRef]

- He, J.Y.; Wu, X.Q.; Xie, F.Q.; Dong, M.J.; Zhou, K.; Li, L.; He, D.D.; Wang, S.Q. Microstructure and Wear Properties of Laser Remelted Microarc Oxide Coating on Titanium Alloy. Rare Met. Mater. Eng. 2023, 52, 2424–2433. [Google Scholar]

- Xiong, T.C.; Yin, Y.Y.; Lu, D.H.; Wu, G.L.; Wang, Y.; Yao, J.H. Microstructure and Mechanism of Copper Layer Processed with Laser Remelting and Electrochemical Deposition Interaction Process. Chin. J. Lasers 2023, 50, 67–79. [Google Scholar]

- Zheng, Z.J.; Zheng, X. Temperature field simulation and process optimization of SLM forming of 316L stainless steel based on laser remelting. Mater. Rep. 2024, 38, 1–12. Available online: http://kns.cnki.net/kcms/detail/50.1078.TB.20230824.1109.002.html (accessed on 15 November 2023).

- Xiong, A.H.; Liu, Y.H.; Li, K.; Zhang, H.Y.; Fu, J.Y. Numerical Simulation and Experiments of Gray Cast Iron by Laser Surface Remelting. Laser Optoelectron. Prog. 2022, 59, 247–256. [Google Scholar]

- Liu, R.; Yu, J.C.; Yang, Q.F.; Wu, Z.J.; Xi, M.Z.; Gao, S.Y. Effect of Laser Power on Mechanical Property and Strengthening Mechanism of DH36 Marine Steel. Surf. Technol. 2023, 52, 408–417. [Google Scholar]

- Li, P.; Kong, L.H.; Huang, X.; Lian, G.F.; Yang, J.W. Corrosion Resistance of Stainless-Steel Surface Based on Laser Remelting. Spec. Cast. Nonferrous Alloys 2021, 41, 995–1000. [Google Scholar]

- Zhang, P.; Zhou, H.; Wang, C.T.; Liu, Y.; Ren, L.Q. Wear properties of H13 with micron scale and nano scale grains bionic units processed by laser remelting. Optics Laser Technol. 2013, 54, 219–224. [Google Scholar] [CrossRef]

- Amaya-Vázquez, M.R.; Sánchez-Amaya, J.M.; Boukha, Z.; El Amrani, K.; Francisco, J.B. Application of Laser Remelting Treatments to Improve the Properties of Ti6Al4V Alloy. Mater. Sci. Forum 2012, 1646, 25–30. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Chen, S.; Chen, Y.; Tao, Z.; Liu, C. The Effect of Laser Surface Remelting on the Surface Properties of Copper. Coatings 2024, 14, 60. https://doi.org/10.3390/coatings14010060

Li H, Chen S, Chen Y, Tao Z, Liu C. The Effect of Laser Surface Remelting on the Surface Properties of Copper. Coatings. 2024; 14(1):60. https://doi.org/10.3390/coatings14010060

Chicago/Turabian StyleLi, Hengzheng, Shuai Chen, Yang Chen, Zichen Tao, and Conghu Liu. 2024. "The Effect of Laser Surface Remelting on the Surface Properties of Copper" Coatings 14, no. 1: 60. https://doi.org/10.3390/coatings14010060

APA StyleLi, H., Chen, S., Chen, Y., Tao, Z., & Liu, C. (2024). The Effect of Laser Surface Remelting on the Surface Properties of Copper. Coatings, 14(1), 60. https://doi.org/10.3390/coatings14010060