Research Progress of Reinforced Modification of Fast-Growing Wood

Abstract

:1. Introduction

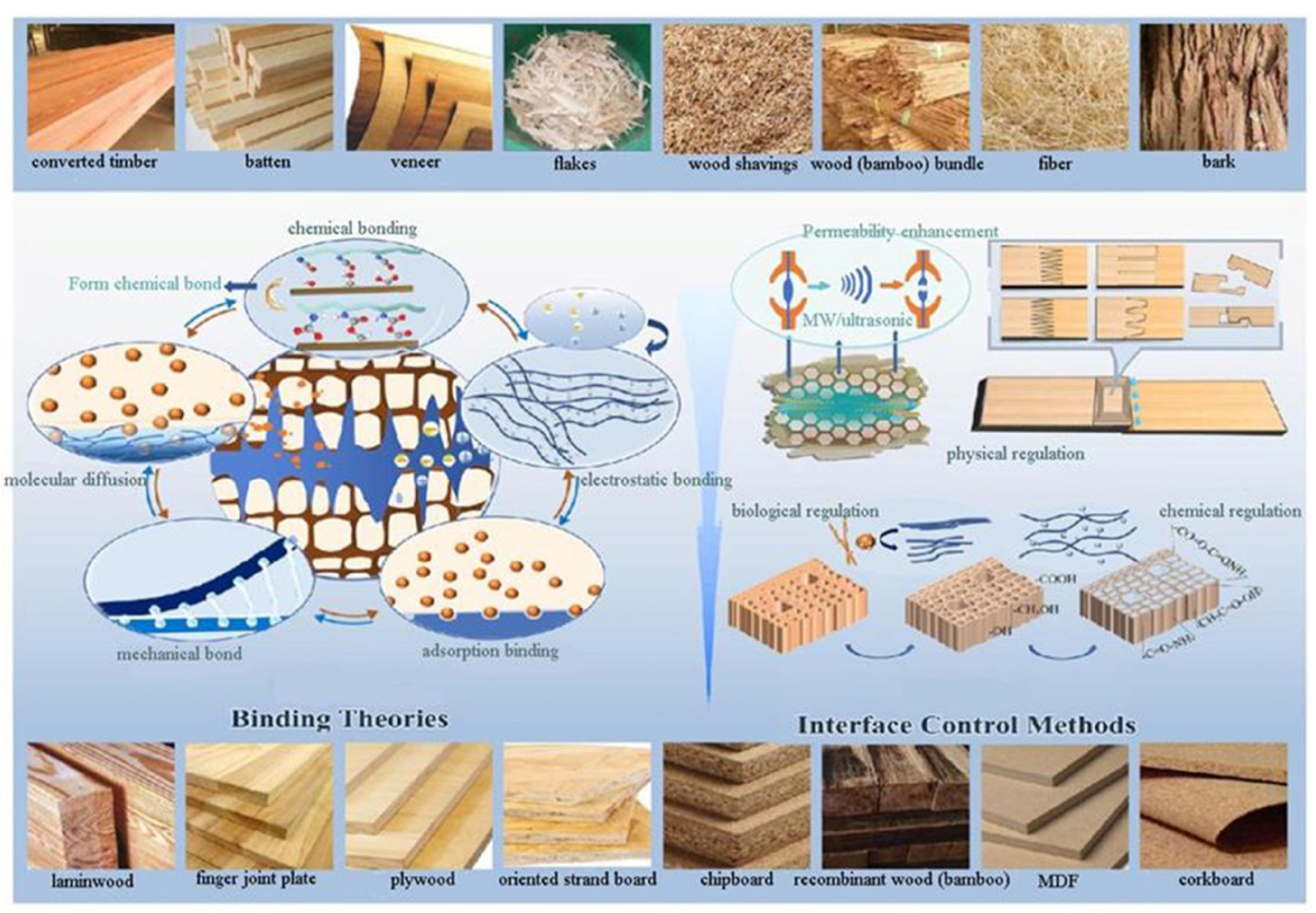

2. Wood Reinforcement Mechanism

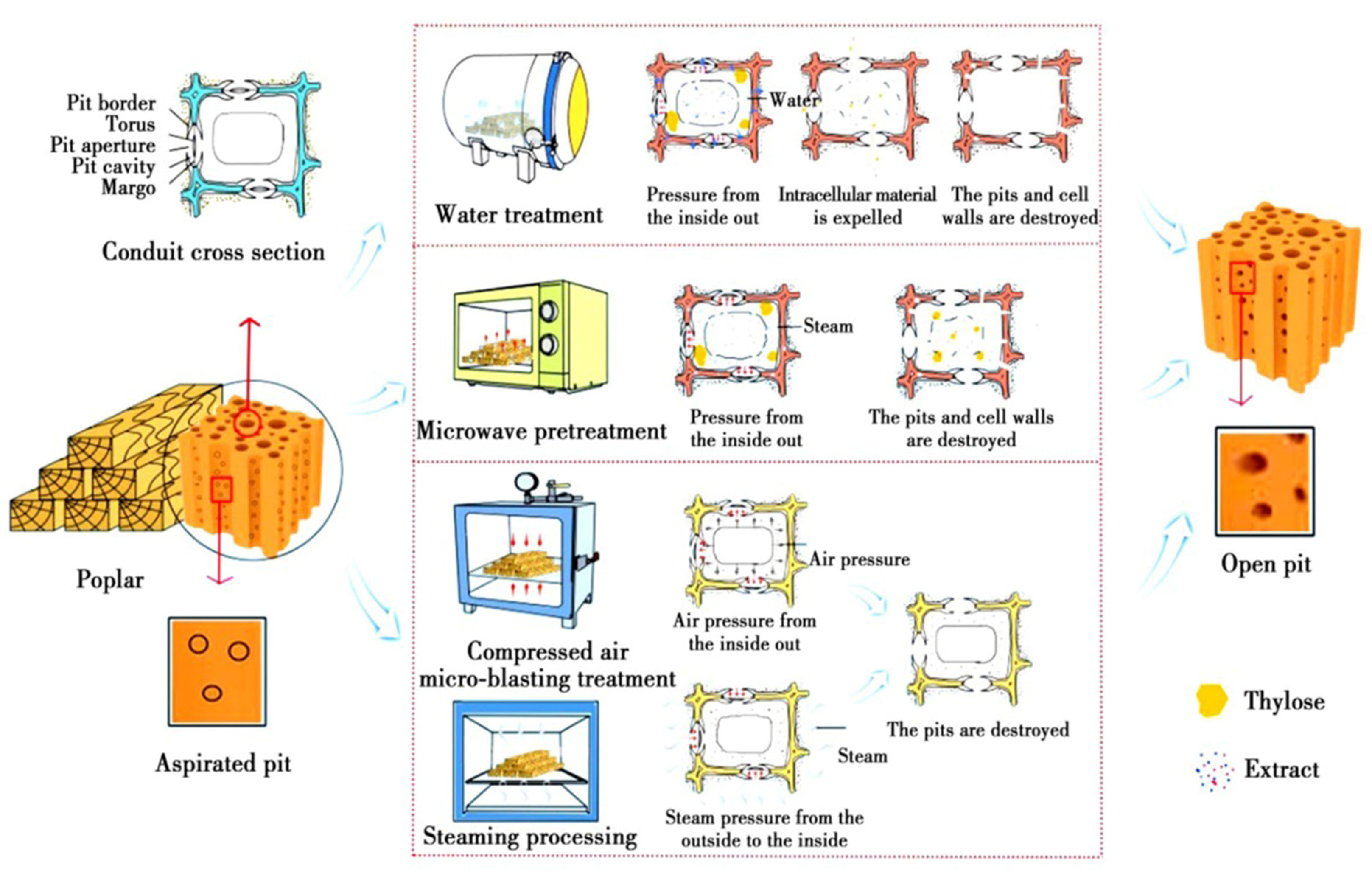

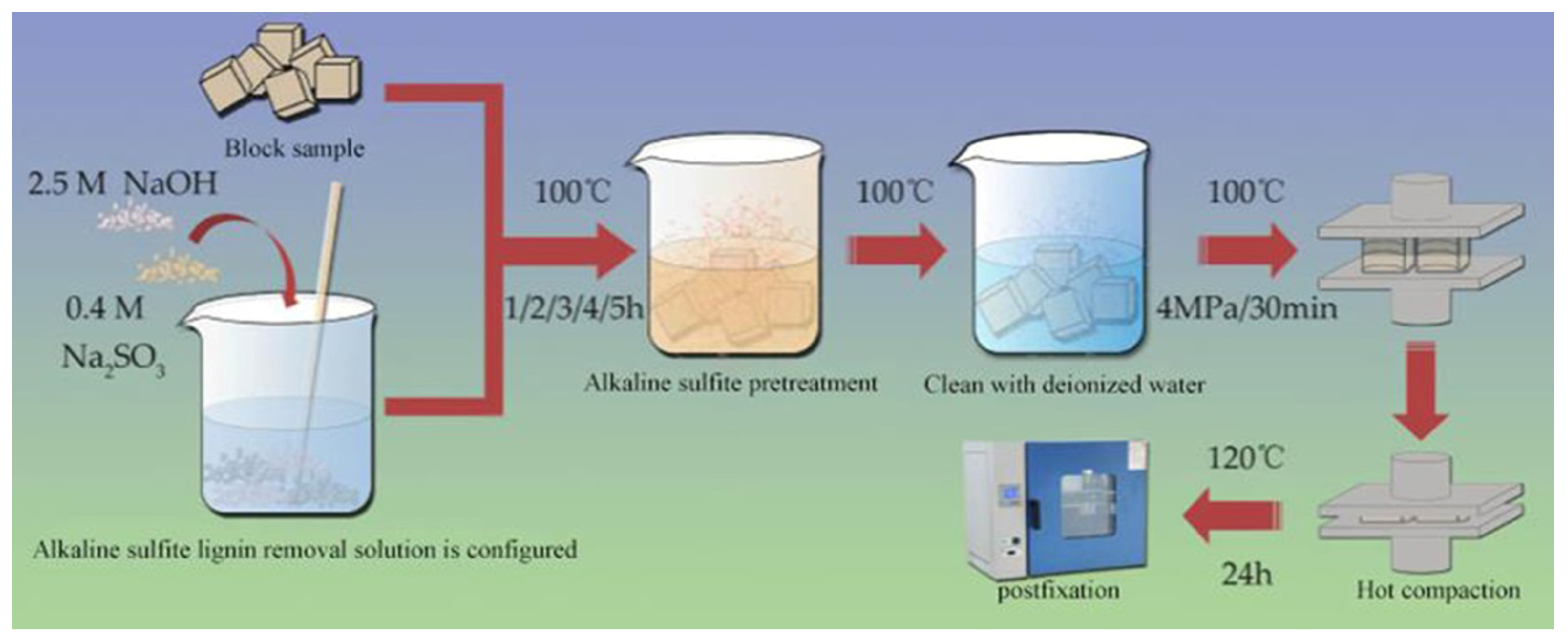

3. Wood Impregnation Modification

4. Densification

5. Wood Surface Modification

6. Other Wood Strengthening Methods

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.L. Review on China’s plantation development since the reform and opening up. For. Resour. Manag. 2019, 1, 6–11. [Google Scholar] [CrossRef]

- Chang, F.Y.; Cao, Y.W.; Cu, M.M.; Wu, Z.H. Application of new materials in modern furniture design and manufacturing. Furniture 2015, 36, 31–37. [Google Scholar] [CrossRef]

- Zhao, G.J. Nano-dimensions in wood, nano-wood, wood and inorganic nano-composites. J. Beijing For. Univ. 2002, 24, 204–207. [Google Scholar] [CrossRef]

- Song, L.Q.; Ji, F.Q.; Sun, J.P. Research progress on compression of wood. J. Northwest For. Univ. 2022, 37, 248–256. [Google Scholar] [CrossRef]

- Wang, B.L.; Feng, M.; Zhan, H.B. Research progress of surface functional modification of wood. China Surf. Eng. 2013, 26, 9–17. [Google Scholar] [CrossRef]

- Wang, J.X. The research progress and trend of study on fast growing wood strengthening treatment technology. J. Jilin For. Sci. Technol. 2017, 46, 35–38. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, P.; Zuo, Y.F.; Yuan, G.M.; Li, X.J.; Wu, Y.Q. Research progress and development trend of inorganic reinforced wood. Mater. Rep. 2019, 33, 2989–2996. [Google Scholar]

- Wang, X.D.; Yang, L. Research progress in wood permeability and its physical methods for improvement. World For. Res. 2023, 36, 59–63. [Google Scholar] [CrossRef]

- Lu, C.X.; Jiang, T.; Liu, Y. Impregnated modification research progresses of influencing factors and improvement methods of eucalyprus robusta. J. Southwest For. Univ. Nat. Sci. 2017, 37, 214–220. [Google Scholar]

- Lv, J.X.; Bao, F.C.; Jiang, X.M.; Zhou, M. Effect of steaming treatment on wood permeability. Sci. Silvae Sin. 2000, 4, 352–357. [Google Scholar] [CrossRef]

- Miao, p.; Wang, X.M.; Wei, S.W.; Xiao, X.Q.; Chen, X. Effects of three pretreatment methods on improving the permeability of Poplar wood. J. Anhui Agric. Univ. 2012, 39, 489–492. [Google Scholar] [CrossRef]

- Mao, Y.Q.; Xu, W.; Zhan, X.X. Effects of microwave pretreatment on permeability of poplar wood. China For. Prod. Ind. 2020, 57, 7–10. [Google Scholar] [CrossRef]

- He, X. Research on Characteristics and Mechanism of Poplarwood during High-Intensity Microwave Pretreatment. Ph.D. Thesis, Central South University of Forestry and Technology, Changsha, China, 2020. [Google Scholar] [CrossRef]

- Hu, J.H.; Liu, J.L. Influence of compressed-air explosion pretreatments on dyeing rubber wood veneers. Chin. J. Wood Sci. Technol. 2019, 33, 11–15. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Xia, J.W.; Wang, J.F. A review of methods of opening wood cell pathways. J. Anhui Agric. Univ. 2011, 38, 867–871. [Google Scholar]

- Bi, X.Q.; Zhang, Y.; Li, p.; Wu, Y.Q.; Yuan, G.M.; Zuo, Y.F. Research progress of poplar impregnation modification and its application in furniture. Mater. Rep. 2022, 36, 239–249. [Google Scholar] [CrossRef]

- Ji, J.J.; Wang, M.L.; Wei, L.T.; Sun, Z.B. Bonding performance of poplar wood modified with resin impregnation and steam heat-treatment. China Wood Based Panels 2023, 30, 16–21. [Google Scholar]

- Wu, G.F.; Jiang, Y.F.; Song, S.P.; Qu, P.; Yao, S.; Pu, J.W. Preparation and properties of wood/modified uf prepolymer composite materials. Spectrosc. Spectr. Anal. 2011, 31, 1083–1086. [Google Scholar] [CrossRef]

- Yue, K.; Lu, X.N.; Liu, W.Q. Reliability of mechanical performance of untreated and treated fast-growing poplar wood with PE. J. Nanjing For. Univ. Nat. Sci. Ed. 2010, 34, 49–51. [Google Scholar] [CrossRef]

- Wang, X.Y.; Zhou, W.J.; Li, C.; Han, J. Comparative research on impregnation modification of two kinds of veneer with PF resin. J. Cent. South Univ. For. Technol. 2016, 36, 120–124. [Google Scholar] [CrossRef]

- Zhu, M.B. Study on Modification Technology of Fast Growing Wood combination Impregnation Based on Phenolic Resin. Ph.D. Thesis, Kunming University of Science and Technology, Kunming, China, 2020. [Google Scholar] [CrossRef]

- Qin, Y.L.; Dong, Y.M.; Chen, L.H.; Jiang, F.; Li, J.Z. Effects of modification with melamine-urea-formaldehyde resin on the properties of hard wood and softwood. J. Anhui Agric. Univ. 2021, 48, 191–198. [Google Scholar] [CrossRef]

- Li, M.L.; Li, N.; Shan, J.C.; Luo, B.; Liu, y. Research Status and Development Trend of Wood Functional Modification by Resin Impregnation. China Wood-Based Panels 2019, 26, 1–6. [Google Scholar] [CrossRef]

- Sun, Z.Y.; Zhang, Y.; Zuo, Y.F.; Wu, Y.Q.; Wang, Z.H.; Lv, J.X. Research status and prospect of organic-inorganic compound modified fast-growing wood. Mater. Rep. 2021, 35, 5181–5187. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Lin, L.Y.; Fu, F. Modification of Chinese fir with silica sol/acrylate emulsion. Chin. J. Wood Sci. Technol. 2015, 29, 36–39. [Google Scholar] [CrossRef]

- Chai, Y.B.; Liu, J.L.; Sun, B.L.; Lv, W.H. Dimensional stability, mechanical properties and combustion performance of poplar wood modified with a mixture of muf/boric acid/borax. Chin. J. Wood Sci. Technol. 2015, 29, 5–9. [Google Scholar] [CrossRef]

- Chai, Y.B. Research on the Technology of Impregnating and Densifying plantation Wood and the Properties of Treated Wood. Ph.D. Thesis, Chinese Academy of Forestry, Beijing, China, 2007. [Google Scholar] [CrossRef]

- Xia, J. Controllability of Location and Thickness and Deformation Fixation of Populus Layered Compression. Ph.D. Thesis, Chinese Academy of Forestry, Beijing China, 2016. [Google Scholar] [CrossRef]

- Du, L.X.; Sun, Z.B.; Cai, J.B.; Wang, X.J. Study on the Modification Effect of Compression Process on Impregnation of Populus Tomentosa with UF Resin. For. Mach. Woodwork. Equip. 2012, 40, 23–27. [Google Scholar] [CrossRef]

- Li, J. Analysis on the bending mechanism and influencing factors of solid wood bending. J. For. Eng. 1998, 6, 16–18. [Google Scholar] [CrossRef]

- Xu, X.W.; Tang, Z.J.; Cui, Y.; Li, F. Poplar parquet modification by densification and surface carbonization. J. Nanjing For. Univ. Nat. Sci. Ed. 2011, 35, 65–68. [Google Scholar] [CrossRef]

- Huang, R.F.; Huang, Q.T.; Huang, Y.H.; Cai, Q.; Liu, Z.H. Density profile and dimensional stability of solid wood floor substrates treated with light compression and pressurized steam. Chin. J. Wood Sci. Technol. 2019, 33, 6–10. [Google Scholar] [CrossRef]

- Liu, D.D.; Zhang, J.Q.; Song, J.; Guan, H.Y. Study on wood surface densification mechanism in cylinder method. J. Anhui Agric. Univ. 2020, 47, 391–396. [Google Scholar] [CrossRef]

- Che, W.B. The Properties of Compressed Wood Veneer Impregnated with Mixing Solutions of Sucrose and N-Methylol Resin. Ph.D. Thesis, Northeast Forestry University, Harbin, China, 2017. [Google Scholar]

- Song, J.W.; Chen, C.J.; Zhu, S.Z.; Zhu, M.W.; Dai, J.Q.; Ray, U.; Li, Y.J.; Kuang, Y.D.; Li, Y.F.; Quispe, N.; et al. Processing bulk natural wood into a high-performance structural material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef]

- Li, T.; Zhai, Y.; He, S.M.; Gan, W.T.; Wei, Z.Y.; Heidarinejad, M.; Dalgo, D.; Mi, R.Y.; Zhao, X.P.; Song, J.W.; et al. A radiative cooling structural materal. Science 2019, 364, 760–763. [Google Scholar] [CrossRef]

- Wang, X.Q. Preparation and Performance Ofhigh-Strength Multifunctional Wood-Based composite Materials. Ph.D. Thesis, Chongqing University, Chongqing, China, 2021. [Google Scholar] [CrossRef]

- Mahendran, A.J.; Wuzella, G.; Aust, N.; Kandelbauer, A.; Müller, U. Photo cross linkable modified vegetable oil based resin for wood surface coating application. Prog. Org. Coat. 2012, 74, 697–704. [Google Scholar] [CrossRef]

- Bongiovanni, R.; Montefusco, F.; Priola, A.; Macchioni, N.; Lazzeri, S.; Sozzi, L.; Ameduri, B. High performance UV-cured coatings for wood protection. Prog. Org. Coat. 2002, 45, 359–363. [Google Scholar] [CrossRef]

- Araujo, R.C.S.; Pasa, V.M.D. Mechanical and thermal properties of polyurethane elastomers based on hydroxyl-terminated polybutadienes and bio-pitch. J. Appl. Polym. Sci. 2003, 88, 759–766. [Google Scholar] [CrossRef]

- Kocaefe, D.; Saha, S. Comparison of the protection effectiveness of acrylic polyurethane coatings containing bark extracts on three heat-treated North American wood species: Surface degradation. Appl. Surf. Sci. 2012, 258, 5283–5290. [Google Scholar] [CrossRef]

- Simchi, A.; Tamjid, E.; Pishbin, F.; Boccaccini, A.R. Recent progress in inorganic and composite coatings with bactericidal capability for orthopaedic applications. Nanomed. Nanotechnol. Biol. Med. 2010, 7, 22–39. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, T.L. Effect of vacuum impregnation on mechanical properties of fast-growing poplar. J. Northeast For. Univ. 2019, 47, 53–56. [Google Scholar] [CrossRef]

- Liu, F.; Gao, Z.X.; Zang, D.L.; Wang, C.Y.; Li, J. Mechanical stability of superhydrophobic epoxy/silica coating for better water resistance of wood. Holzforschung 2015, 69, 367–374. [Google Scholar] [CrossRef]

- Wu, Y.Q.; Jia, S.S.; Qing, Y.; Luo, S.; Liu, M. versatile and efficient method to fabricate durable superhydrophobic surfaces on wood, lignocellulosic fiber, glass, and metal substrates. J. Mater. Chem. A 2016, 4, 14111–14121. [Google Scholar] [CrossRef]

- Tu, K.K.; Kong, L.Z.; Wang, X.Q. Fabrication of superhydrophobic SiO2/epoxy resin/fluorinated alkylsilane nano composite coatings on wood surfaces. J. Nanjing For. Univ. Nat. Sci. Ed. 2017, 41, 158–162. [Google Scholar] [CrossRef]

- Zhou, X.; Kang, F.; Liao, M.R.; Gao, W.; Qin, Z.Y. Construction and characterization of mussel biomimetic superhydrophobic wood fromchemically crosslinked. China For. Prod. Ind. 2022, 59, 30–35. [Google Scholar] [CrossRef]

- Liu, Z.; Cao, J.Z. Study on hydrophobic characteristics of wood surface modified by a silica/silicone oil complex emulsion combined with thermal post-treatment. J. Beijing For. Univ. 2017, 39, 103–110. [Google Scholar] [CrossRef]

- Zhang, Y.; Xie, H.F.; Liu, W.J. Research Status of Titanium Dioxide Functionalized Wood. World For. Res. 2021, 34, 39–44. [Google Scholar] [CrossRef]

- Sun, Q.F.; Lu, Y.; Zhang, H.M.; Zhao, H.J.; Yu, H.P.; Xu, J.S.; Fu, Y.C.; Yang, D.J.; Liu, Y.X. Hydrothermal fabrication of rutile TiO2 submicrospheres on wood surface: An efficient method to prepare UV-protective wood. Mater. Chem. Phys. 2012, 133, 253–258. [Google Scholar] [CrossRef]

- Rassam, G.; Ghofrani, M.; Taghiyari, H.R.; Jamnani, B.; Khajeh, M.A. Mechanical performance and dimensional stability of nano-silver impregnated densified spruce wood. Eur. J. Wood Wood Prod. 2011, 70, 595–600. [Google Scholar] [CrossRef]

- Zhan, X.X.; Zhang, W.; Xie, X.Q.; Jia, H.L.; Zhou, X.Y. Research progress on enhanced modification of wood from fast-growing trees. Furniture 2019, 40, 13–21. [Google Scholar] [CrossRef]

- Wu, Y.Q. Newly advances in wood science and technology. J. Cent. South Univ. For. Technol. 2021, 41, 1–28. [Google Scholar] [CrossRef]

- Shu, Z. Preparation and Properties of Modified Poplarbased on Ionic Liquids. Ph.D. Thesis, Anhui Agricultural University, Hefei, China, 2023. [Google Scholar] [CrossRef]

- Song, L. Effects of Different Pretreatmenton Properties of Compressed Chinese Fir and Poplar. Ph.D. Thesis, Guangxi University, Nanning, China, 2021. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Guo, Q.; Huang, X.; Zhang, Q.; Fan, J.; Huang, J. Research Progress of Reinforced Modification of Fast-Growing Wood. Coatings 2024, 14, 53. https://doi.org/10.3390/coatings14010053

Zhang Z, Guo Q, Huang X, Zhang Q, Fan J, Huang J. Research Progress of Reinforced Modification of Fast-Growing Wood. Coatings. 2024; 14(1):53. https://doi.org/10.3390/coatings14010053

Chicago/Turabian StyleZhang, Zhaohong, Qiang Guo, Xuanxuan Huang, Qian Zhang, Jinlong Fan, and Jintian Huang. 2024. "Research Progress of Reinforced Modification of Fast-Growing Wood" Coatings 14, no. 1: 53. https://doi.org/10.3390/coatings14010053

APA StyleZhang, Z., Guo, Q., Huang, X., Zhang, Q., Fan, J., & Huang, J. (2024). Research Progress of Reinforced Modification of Fast-Growing Wood. Coatings, 14(1), 53. https://doi.org/10.3390/coatings14010053