Effect of Micro-Dimple Texture on the Tribological Performance of Brass with Titanium Nitride (TiN) Coating under Oil-Lubricated Conditions

Abstract

1. Introduction

- (a)

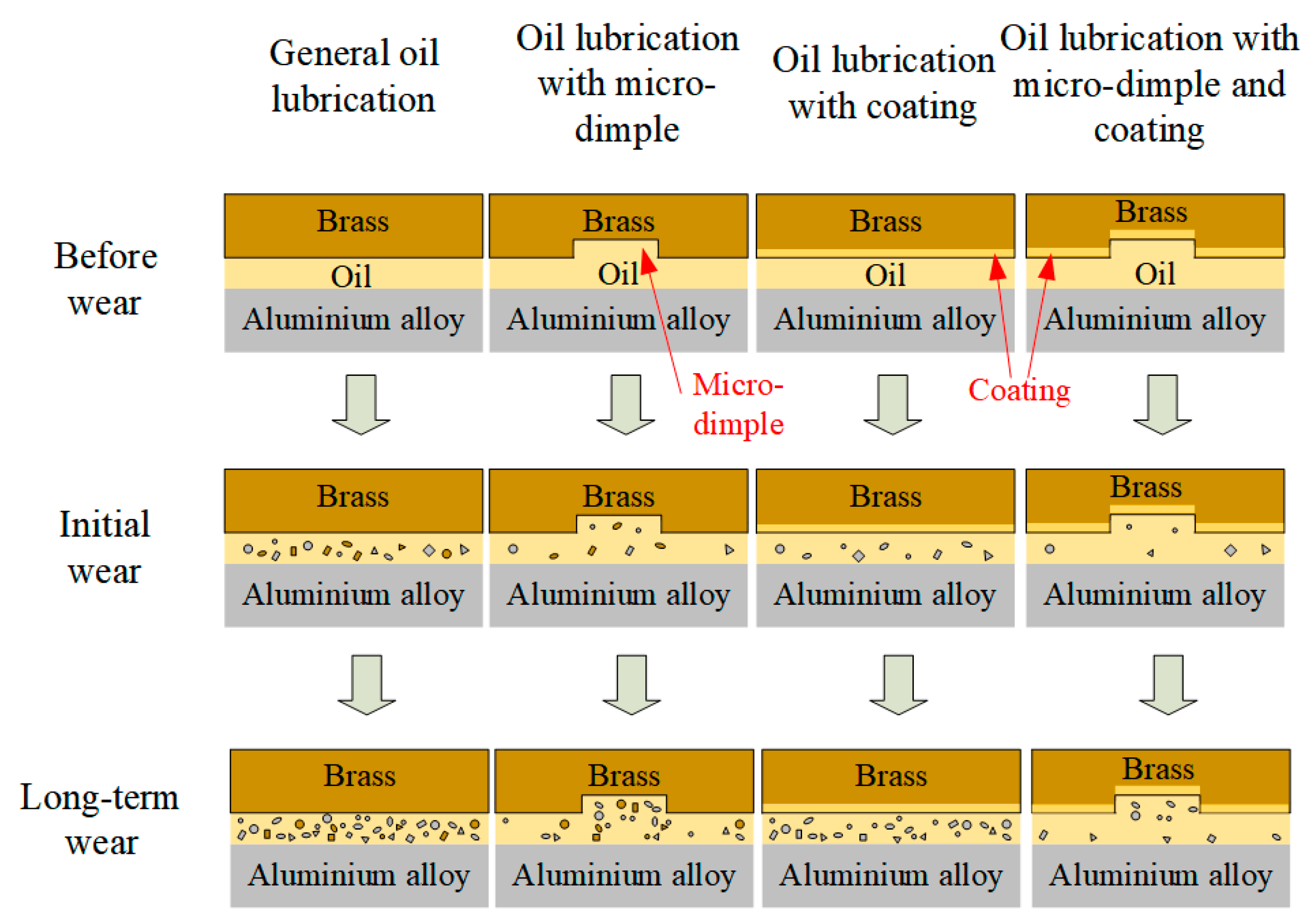

- The study presents that surface texture and TiN coating can improve the tribological properties of pin-on-disc friction pairs under oil lubrication due to their synergistic effect. TiN coating itself enhances the surface texture’s anti-wear properties, which make the enhanced surface texture further provide conditions for hydrodynamic lubrication and the migration of abrasive chips and particles.

- (b)

- The differences of the wear mechanisms of pin-on-disc friction pairs with four types of pin samples, including bare rod samples, TiN-coated samples, textured samples, and TiN-coated/textured samples, are comparatively analyzed based on the wear experiment.

- (c)

- This study provides valuable insights for the design and fabrication of mechanical friction pairs with high wear resistance under oil-lubricated conditions. In particular, it gives the guidance of optimizing the tribological properties of pin-on-disc friction pairs composed of soft and hard materials under heavy load conditions, such as the design of the slippers of plunger pump.

2. Experimental Design

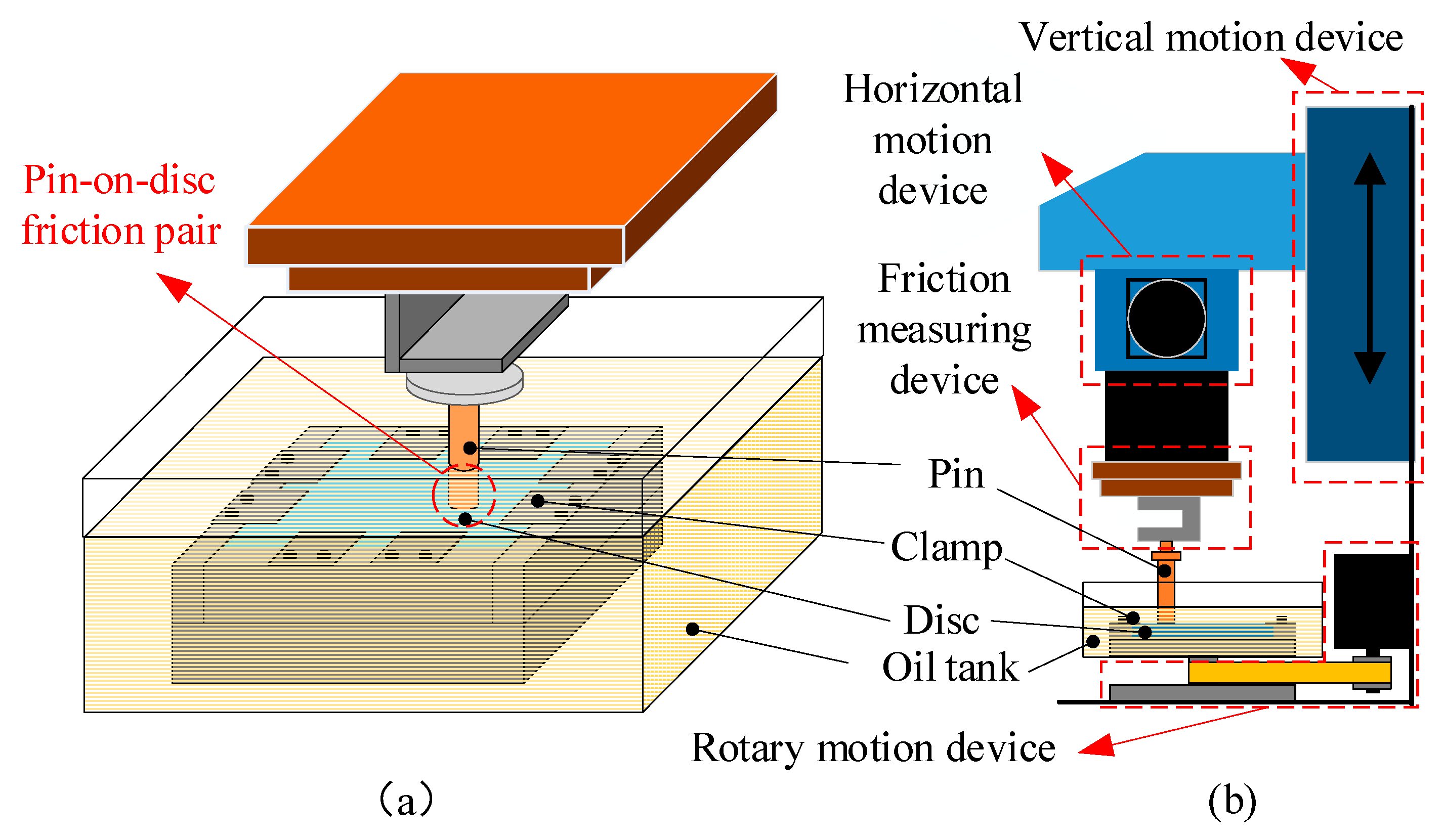

2.1. Description of Experimental Device

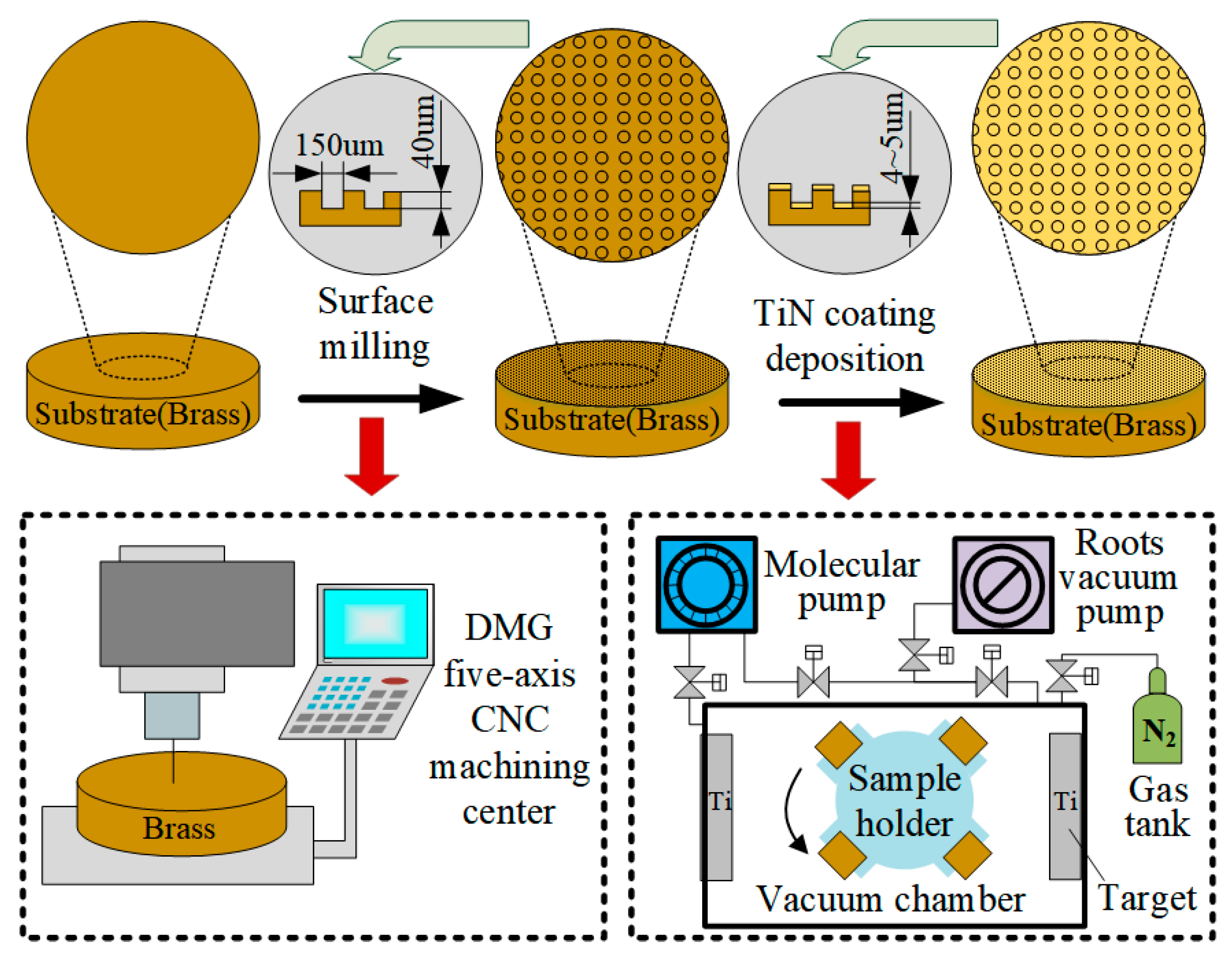

2.2. Design and Fabrication of Experimental Samples

2.3. Description of Experimental Process

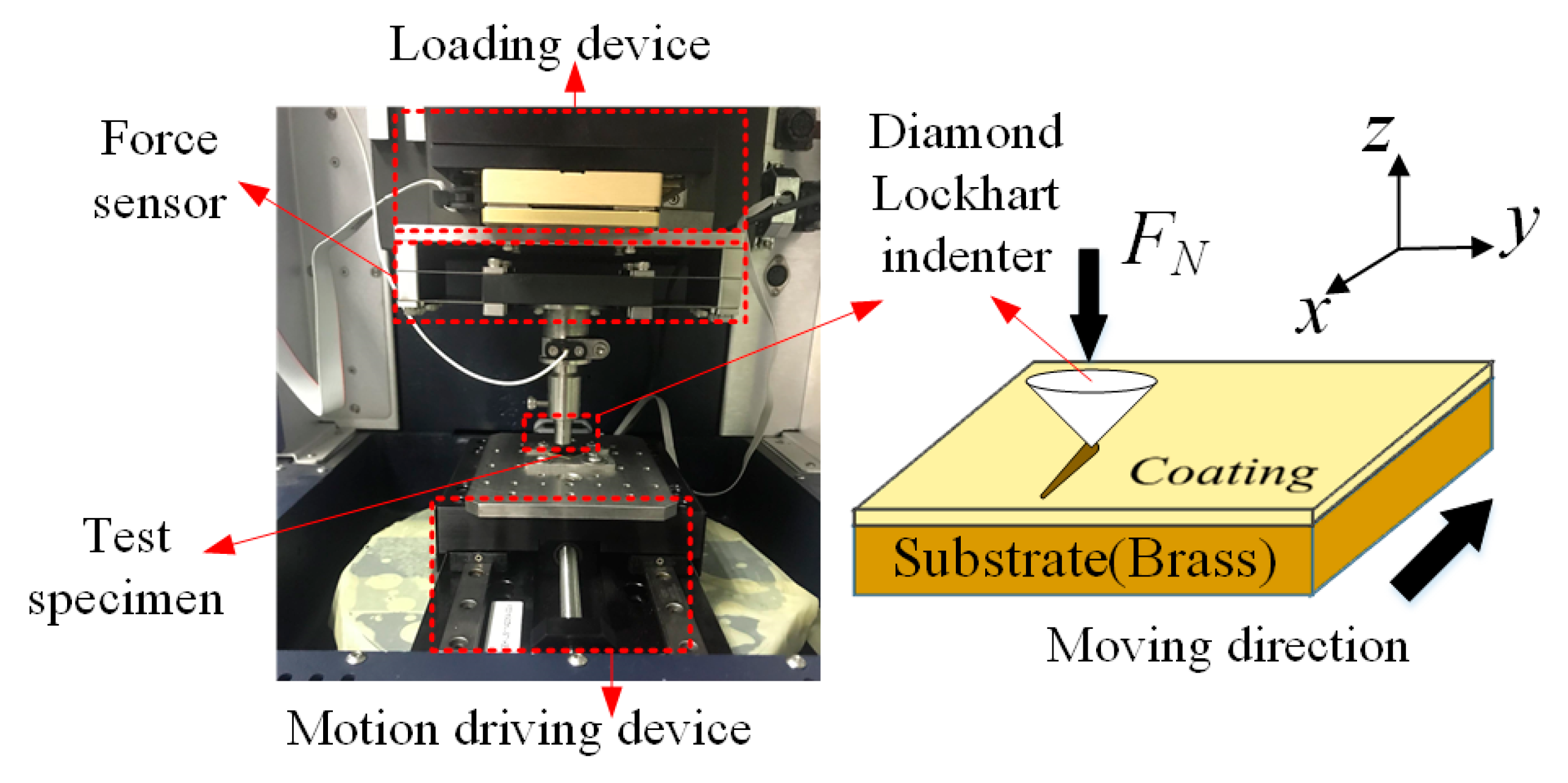

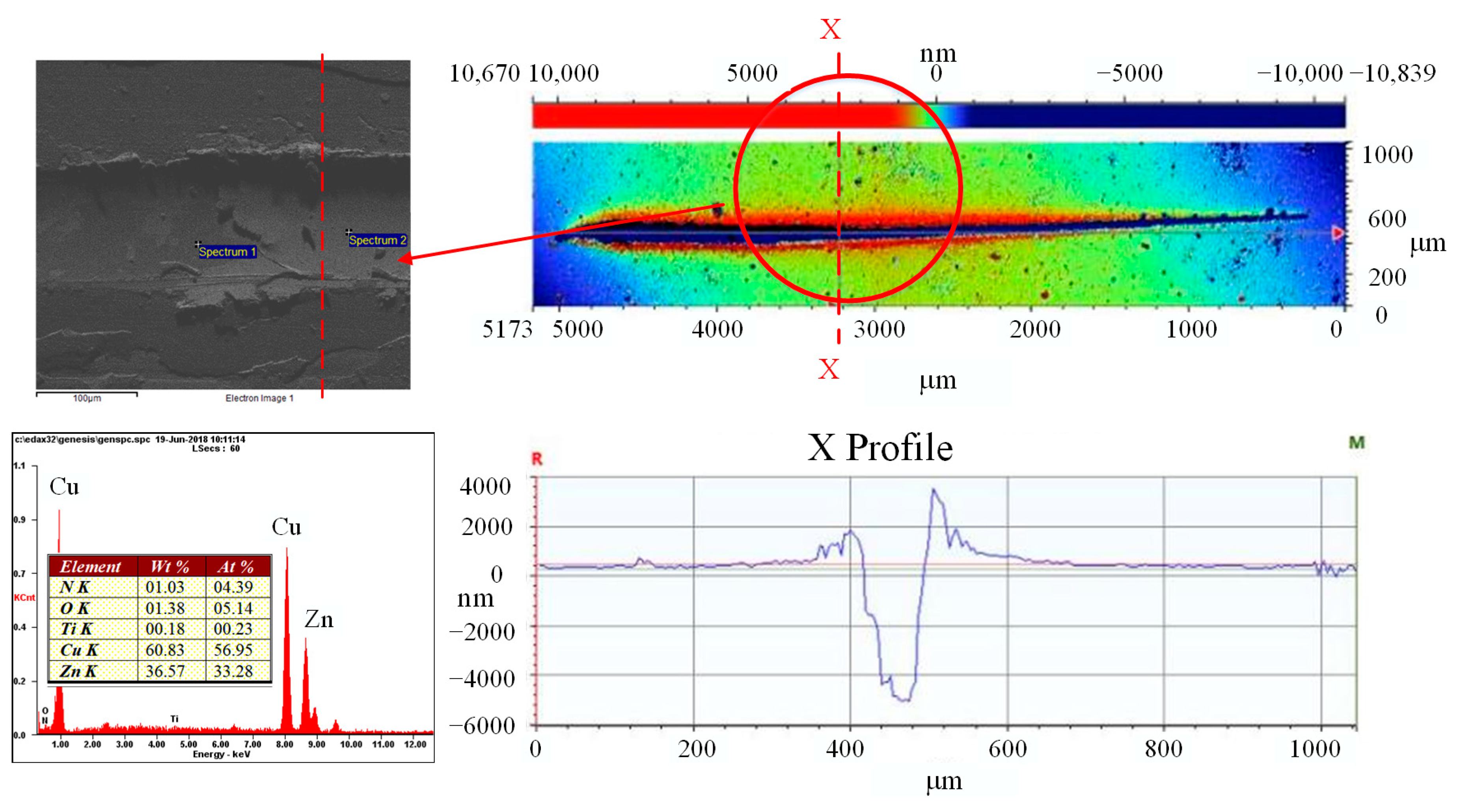

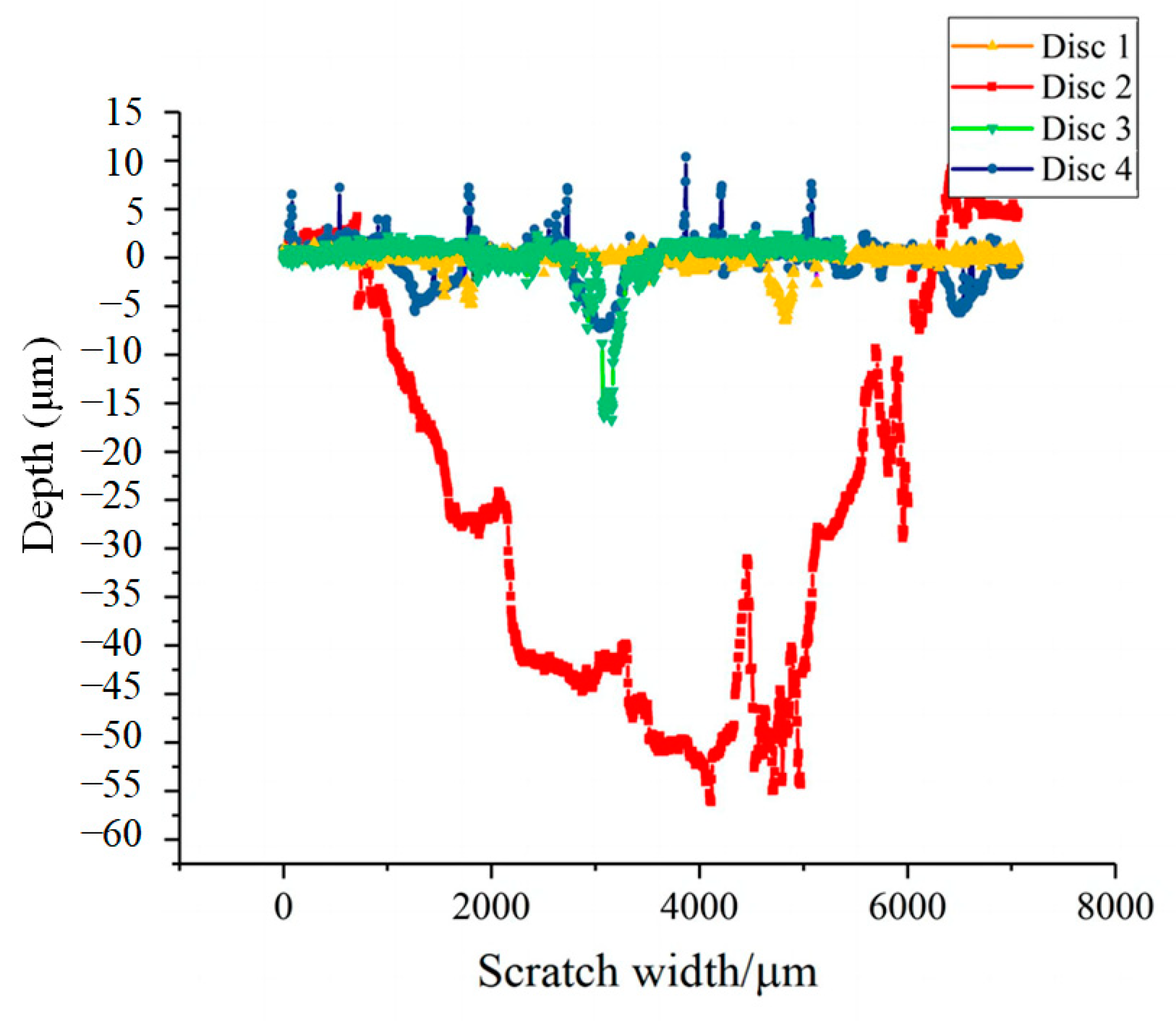

2.4. Scratch Test

3. Results and Discussions

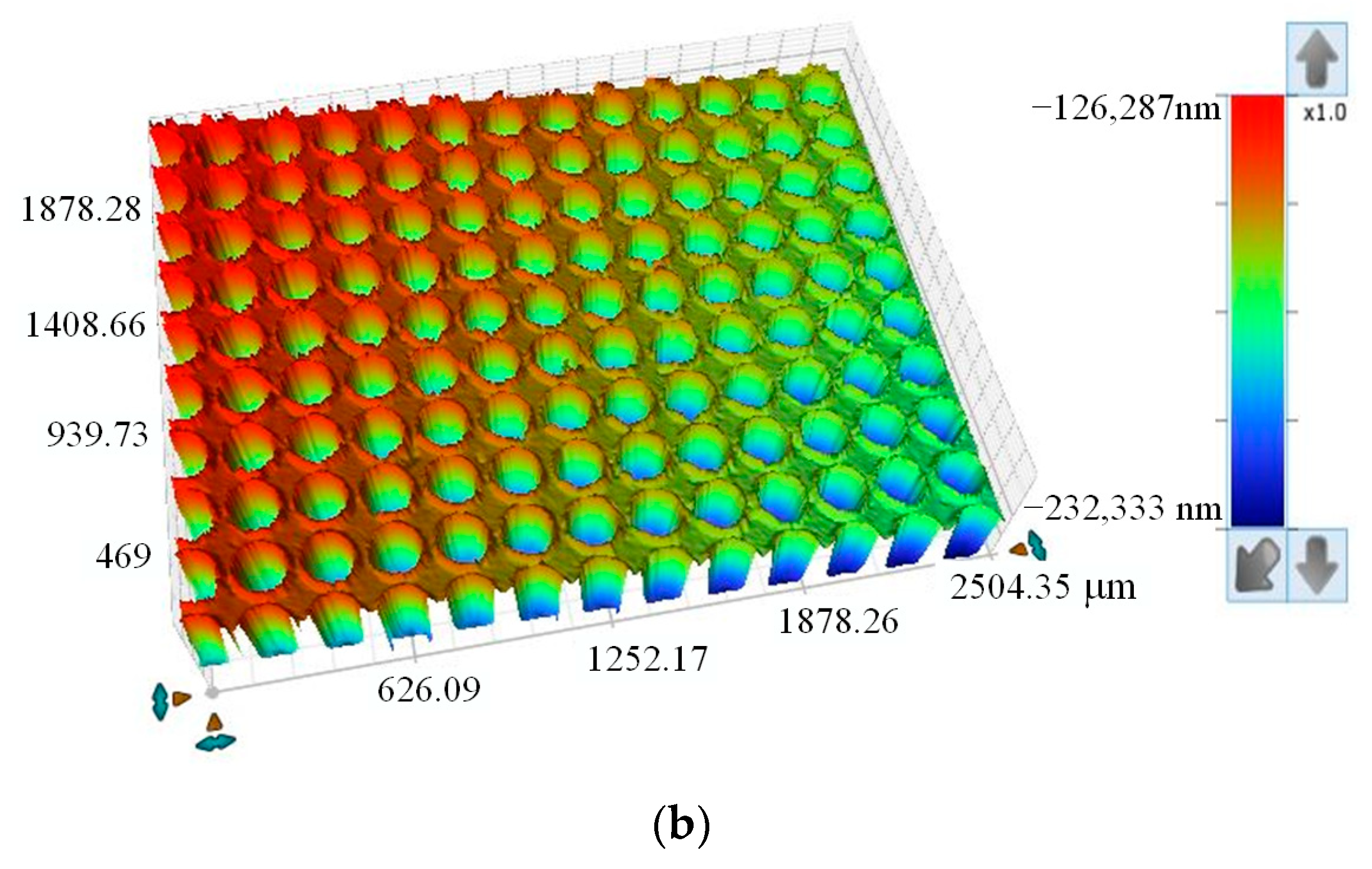

3.1. Surface Characteristics of Samples

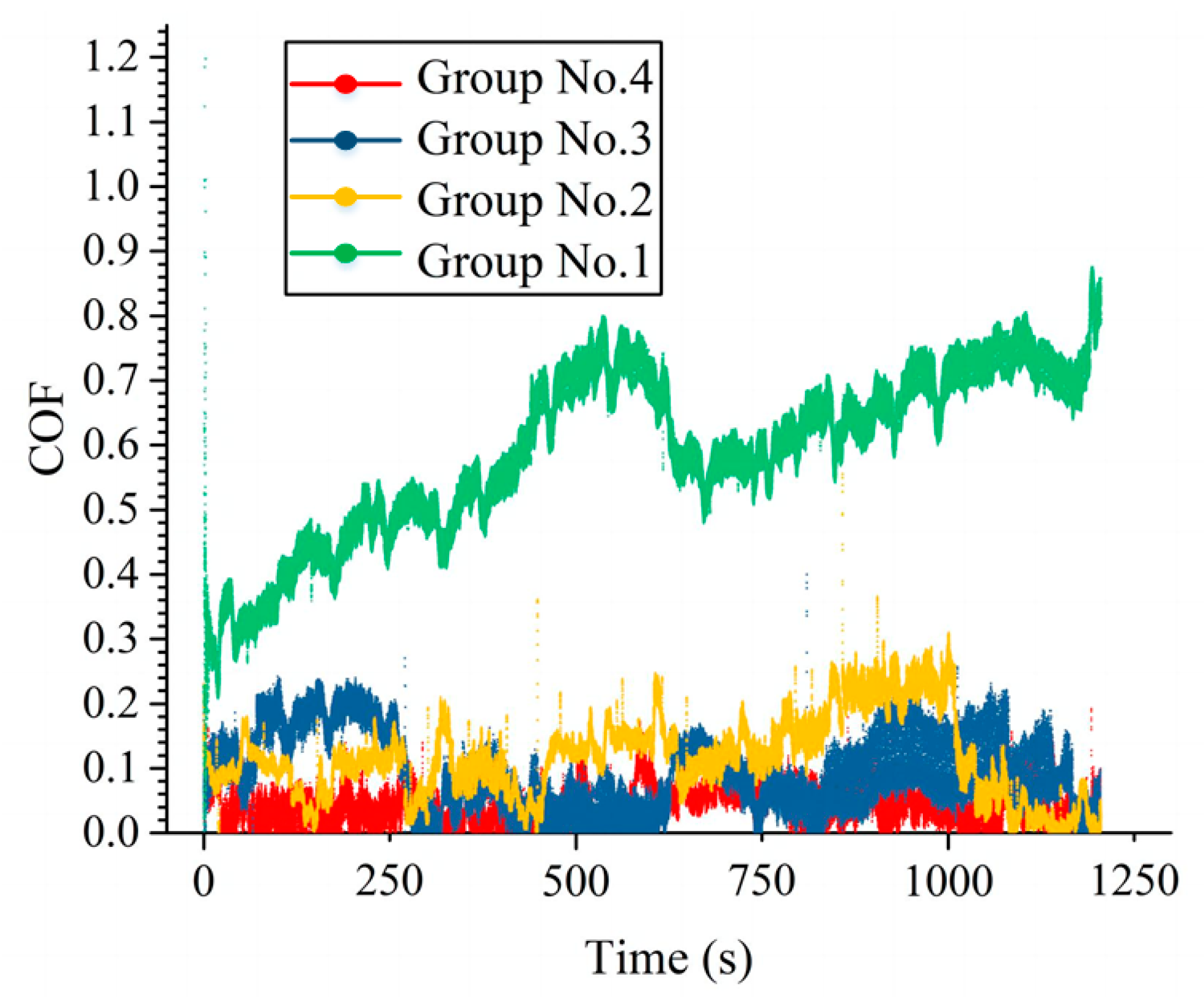

3.2. Tribological Behavior Analysis

3.3. Wear Behavior Analysis

3.4. Strengths and Limitations

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Phelan, C.; Miller, C.; Fleming, R.A.; Goss, J.A.; Rincon, C.; Wei, R.; Zou, M. Test parameter and material dependence of the frictional properties of core-shell nanostructure textured surfaces. Tribol. Int. 2022, 171, 107567. [Google Scholar] [CrossRef]

- Li, X.; Deng, J.; Zhang, L.; Liu, Y.; Yue, H.; Duan, R.; Ge, D. Effect of surface textures and electrohydrodynamically atomized WS2 films on the friction and wear properties of ZrO2 coatings. Ceram. Int. 2019, 45, 1020–1030. [Google Scholar] [CrossRef]

- Ghalot, R.S.; Lazov, L.; Yankov, E.; Angelov, N. Investigation of the Change in Roughness and Microhardness during Laser Surface Texturing of Copper Samples by Changing the Process Parameters. Coatings 2023, 13, 1970. [Google Scholar] [CrossRef]

- Phelan, C.; Miller, C.; Goss, J.A.; Rincon, C.; Wei, R.; Zou, M. Effects of Test Parameters on the Frictional Properties of Al/Diamond-Like Carbon Core-Shell Nanostructure-Textured Surfaces. Tribol. Trans. 2022, 65, 633–642. [Google Scholar] [CrossRef]

- Steck, J.G.; Afshar-Mohajer, M.; Sun, Q.; Meng, X.; Zou, M. Fabrication and tribological characterization of deformation-resistant nano-textured surfaces produced by two-photon lithography and atomic layer deposition. Tribol. Int. 2019, 132, 75–84. [Google Scholar] [CrossRef]

- Sedlacek, M.; Podgornik, B.; Ramalho, A.; Česnik, D. Influence of geometry and the sequence of surface texturing process on tribological properties. Tribol. Int. 2017, 115, 268–273. [Google Scholar] [CrossRef]

- Bergmann, P.; Grün, F.; Gódor, I.; Stadler, G.; Maier-Kiener, V. On the modelling of mixed lubrication of conformal contacts. Tribol. Int. 2018, 125, 220–236. [Google Scholar] [CrossRef]

- Shen, C.; Khonsari, M.M. Numerical optimization of texture shape for parallel surfaces under unidirectional and bidirectional sliding. Tribol. Int. 2015, 82, 1–11. [Google Scholar] [CrossRef]

- Chen, P.; Xiang, X.; Shao, T.; La, Y.; Li, J. Effect of triangular texture on the tribological performance of die steel with TiN coatings under lubricated sliding condition. Appl. Surf. Sci. 2016, 389, 61–368. [Google Scholar] [CrossRef]

- Wang, C.; Chen, J.; Zeng, L. Wear and Lubrication Performance of Different Reticular-Textured TiN-Coated Surfaces under Lubricated Conditions. Processes 2022, 10, 2605. [Google Scholar] [CrossRef]

- Shen, Z.; Wang, F.; Chen, Z.; Ruan, X.; Zeng, H.; Wang, J.; An, Y.; Fan, X. Numerical simulation of lubrication performance on chevron textured surface under hydrodynamic lubrication. Tribol. Int. 2021, 154, 106704. [Google Scholar] [CrossRef]

- Wu, Z.; Xing, Y.; Huang, P.; Liu, L. Tribological properties of dimple-textured titanium alloys under dry sliding contact. Surf. Coat. Technol. 2017, 309, 21–28. [Google Scholar] [CrossRef]

- Ezhilmaran, V.; Vasa, N.; Vijayaraghavan, L. Investigation on generation of laser assisted dimples on piston ring surface and influence of dimple parameters on friction. Surf. Coat. Technol. 2018, 335, 314–326. [Google Scholar] [CrossRef]

- Arslan, A.; Masjuki, H.; Varman, M.; Kalam, A.; Quazi, M.; Al Mahmud, K.; Gulzar, M.; Habibullah, M. Effects of texture diameter and depth on the tribological performance of DLC coating under lubricated sliding condition. Appl. Surf. Sci. 2015, 356, 1135–1149. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Yang, H.; Yang, S.; Tong, X. Study on the Matching of Surface Texture Parameters and Processing Parameters of Coated Cemented Carbide Tools. Coatings 2023, 13, 681. [Google Scholar] [CrossRef]

- Yuan, Z.; Qin, Y.; Deng, C.; Zheng, P. Synergistic effects of surface strengthening and surface micro-texture on aviation spherical plain bearing tribological properties. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 797–808. [Google Scholar] [CrossRef]

- Koszela, W.; Pawlus, P.; Reizer, R.; Liskiewicz, T. The combined effect of surface texturing and DLC coating on the functional properties of internal combustion engines. Tribol. Int. 2018, 127, 470–477. [Google Scholar] [CrossRef]

- Kumar, S.; Bergada, J.M. The effect of piston grooves performance in an axial piston pumps via CFD analysis. Int. J. Mech. Sci. 2013, 66, 168–179. [Google Scholar] [CrossRef]

- Mo, H.; Guo, Y.; Quan, S. Effect of Texture on Total Energy Consumption of High Frequency Hydraulic Impact Piston Pair. Coatings 2022, 12, 340. [Google Scholar] [CrossRef]

- Ma, G.J.; Wang, L.L.; Gao, H.X.; Zhang, J.; Reddyhoff, T. The coefficient of friction evolution of a TiN coated contact during sliding wear. Appl. Surf. Sci. 2015, 345, 109–115. [Google Scholar] [CrossRef]

- Shum, P.W.; Zhou, Z.F.; Li, K.Y. Friction and wear reduction of hard TiAlSiN coatings by an integrated approach of laser surface texturing and high-energy ion implantation. Surf. Coat. Technol. 2014, 259, 136–140. [Google Scholar] [CrossRef]

- Obikawa, T.; Kamio, A.; Takaoka, H.; Osada, A. Micro-texture at the coated tool face for high performance cutting. Int. J. Mach. Tools Manuf. 2011, 51, 966–972. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Metal target | Ti |

| Sputtering gas | Ar |

| Reaction gas | N2 |

| Ar rate (sccm) | 57 |

| N2 rate (sccm) | 152 |

| Vacuum chamber temperature (°C) | 163 |

| Deposition time (min) | 38 |

| Workpiece speed (rpm) | 4 |

| Working pressure (Pa) | 1.0 |

| Effective current (A) | 101 |

| Peak current (A) | 115 |

| Distance between target and sample (cm) | 23 |

| Group No. | Pin Sample | Disc Sample |

|---|---|---|

| 1 | Pin sample 1 (Bare rod) | Aluminum disc |

| 2 | Pin sample 2 (TiN-coated) | Aluminum disc |

| 3 | Pin sample 3 (Textured) | Aluminum disc |

| 4 | Pin sample 4 (TiN-coated/textured) | Aluminum disc |

| Parameter | Value |

|---|---|

| Density at 15 °C (kg/L) | 0.8747 |

| Dynamic viscosity at −20 °C (mPa·s) | 5418 |

| Kinematic viscosity at 100 °C (mm2/s) | 14.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Chen, J.; Ji, B.; Zhou, J.; Zeng, L.; Yang, Y. Effect of Micro-Dimple Texture on the Tribological Performance of Brass with Titanium Nitride (TiN) Coating under Oil-Lubricated Conditions. Coatings 2024, 14, 119. https://doi.org/10.3390/coatings14010119

Zhang C, Chen J, Ji B, Zhou J, Zeng L, Yang Y. Effect of Micro-Dimple Texture on the Tribological Performance of Brass with Titanium Nitride (TiN) Coating under Oil-Lubricated Conditions. Coatings. 2024; 14(1):119. https://doi.org/10.3390/coatings14010119

Chicago/Turabian StyleZhang, Cheng, Juan Chen, Binbin Ji, Jie Zhou, Liangcai Zeng, and Yuping Yang. 2024. "Effect of Micro-Dimple Texture on the Tribological Performance of Brass with Titanium Nitride (TiN) Coating under Oil-Lubricated Conditions" Coatings 14, no. 1: 119. https://doi.org/10.3390/coatings14010119

APA StyleZhang, C., Chen, J., Ji, B., Zhou, J., Zeng, L., & Yang, Y. (2024). Effect of Micro-Dimple Texture on the Tribological Performance of Brass with Titanium Nitride (TiN) Coating under Oil-Lubricated Conditions. Coatings, 14(1), 119. https://doi.org/10.3390/coatings14010119