Effect of Native Mucilage on the Mechanical Properties of Pectin-Based and Alginate-Based Polymeric Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mucilage Precipitation and Freeze-Drying

2.3. Film Solution Preparation

2.4. Film Development

2.5. Film Calcium Treatment

2.6. Film Evaluation

2.7. Experimental Design and Statistical Analysis

3. Results

3.1. Mechanical Properties of Blend Pectin–Mucilage and Alginate–Mucilage Films

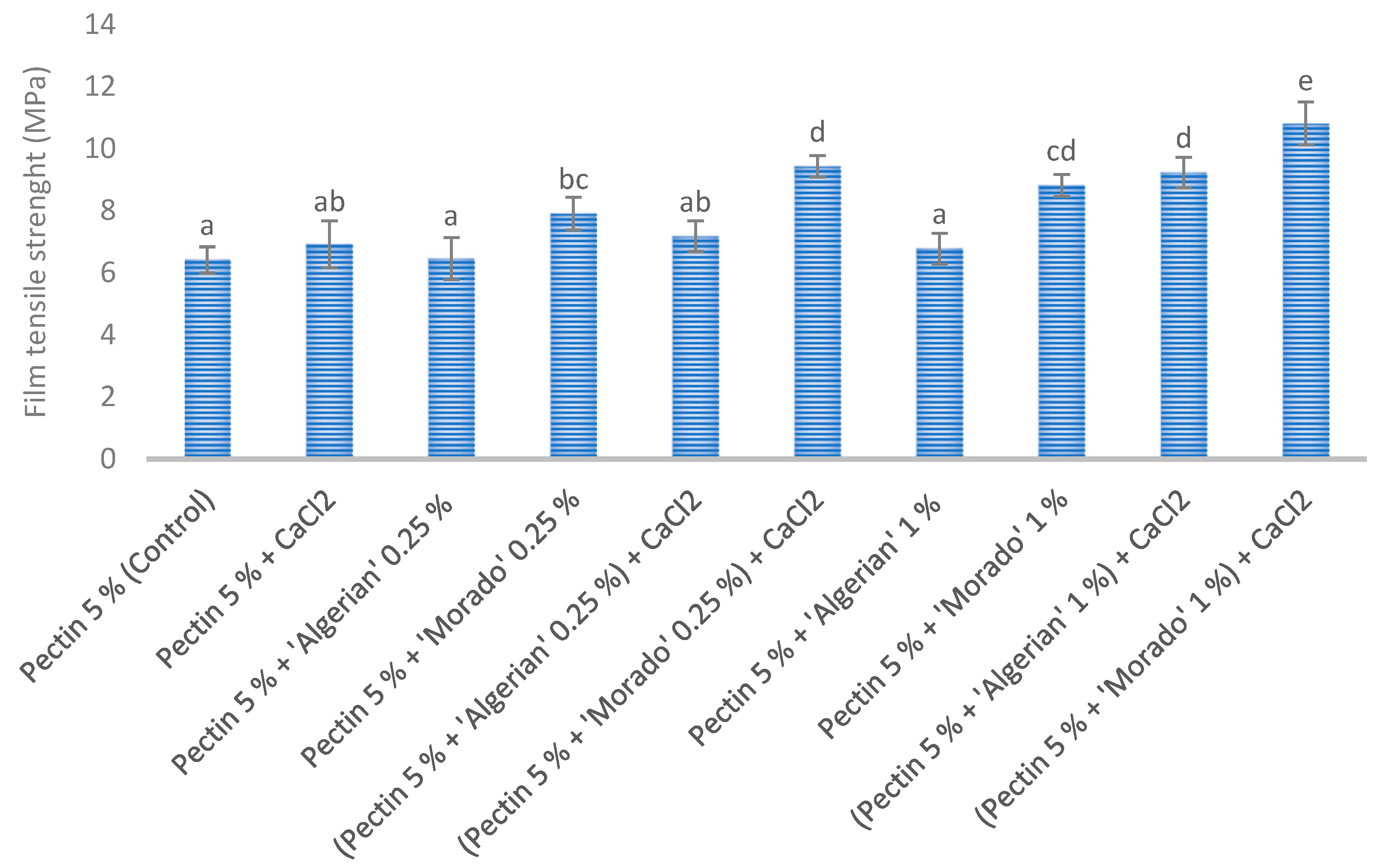

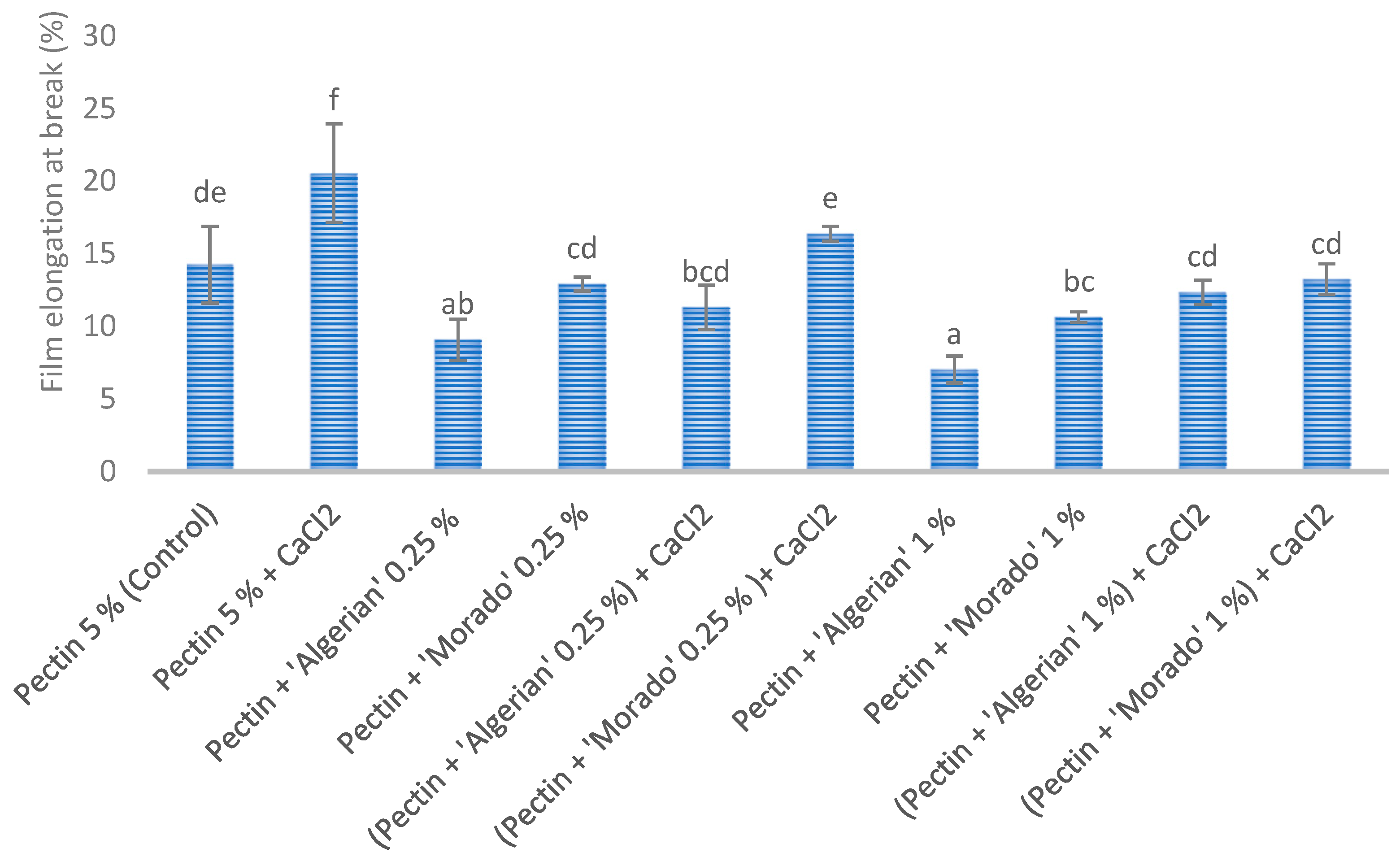

3.1.1. Blend Pectin–Mucilage Films

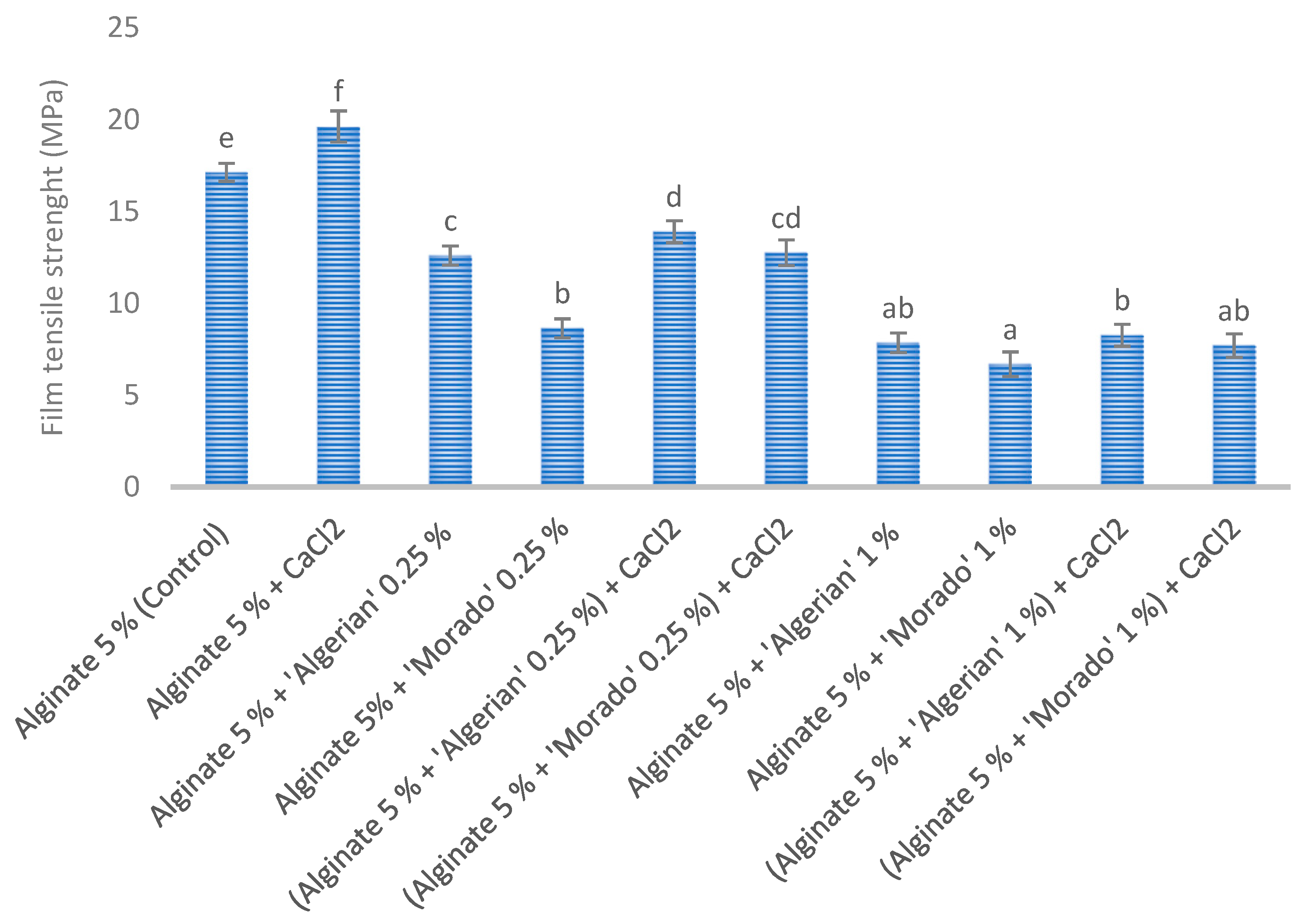

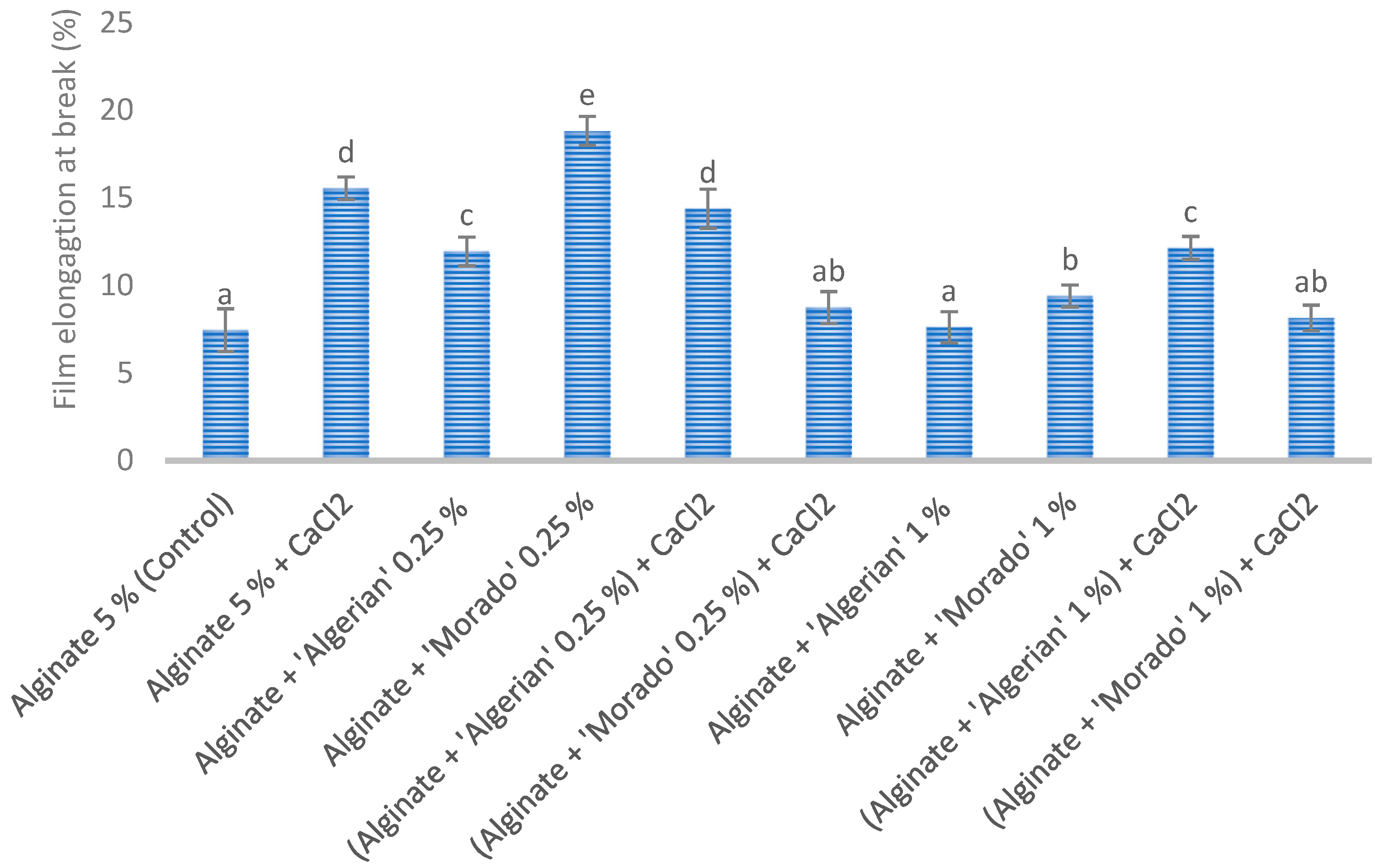

3.1.2. Blend Alginate–Mucilage Films

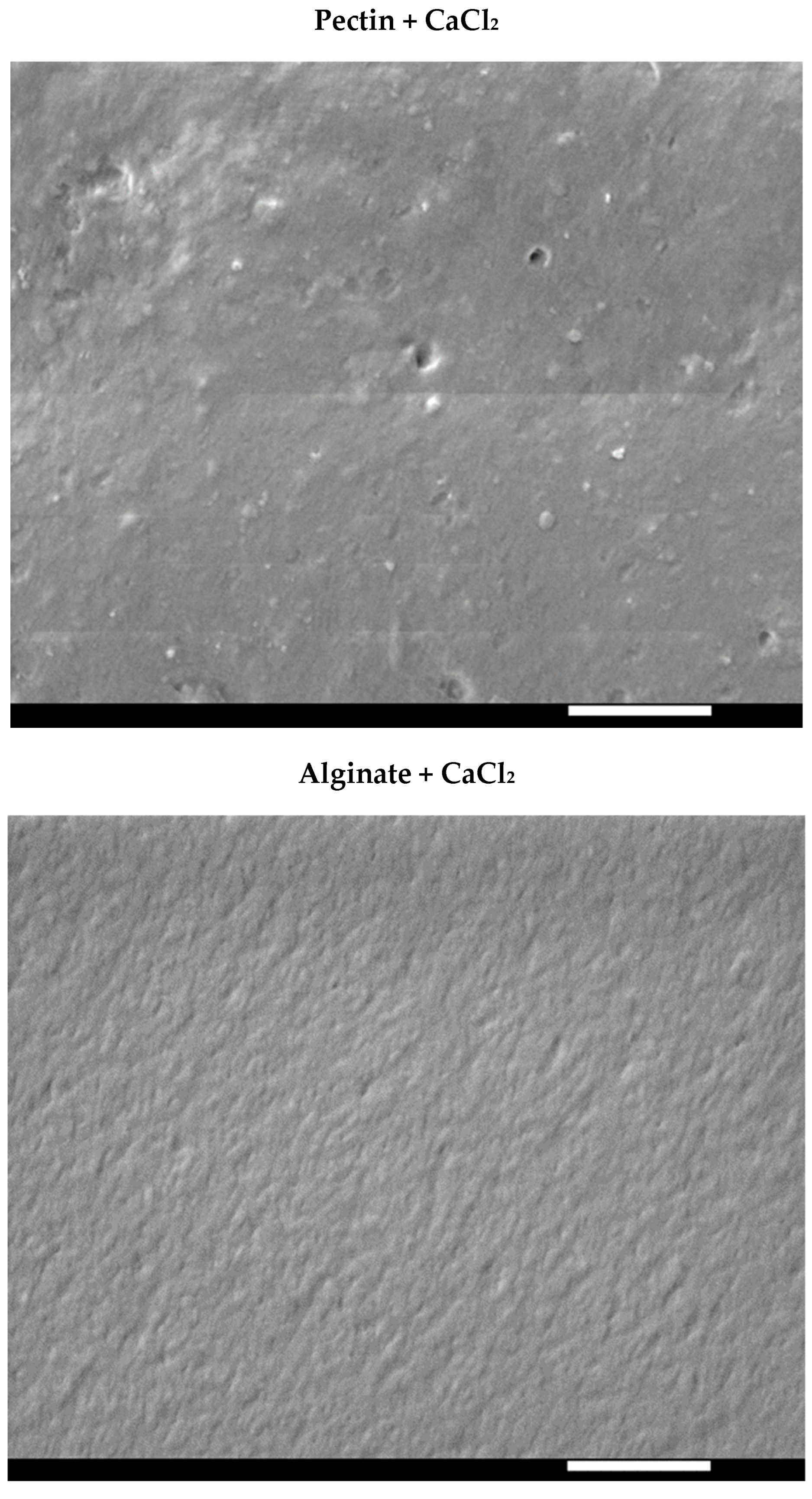

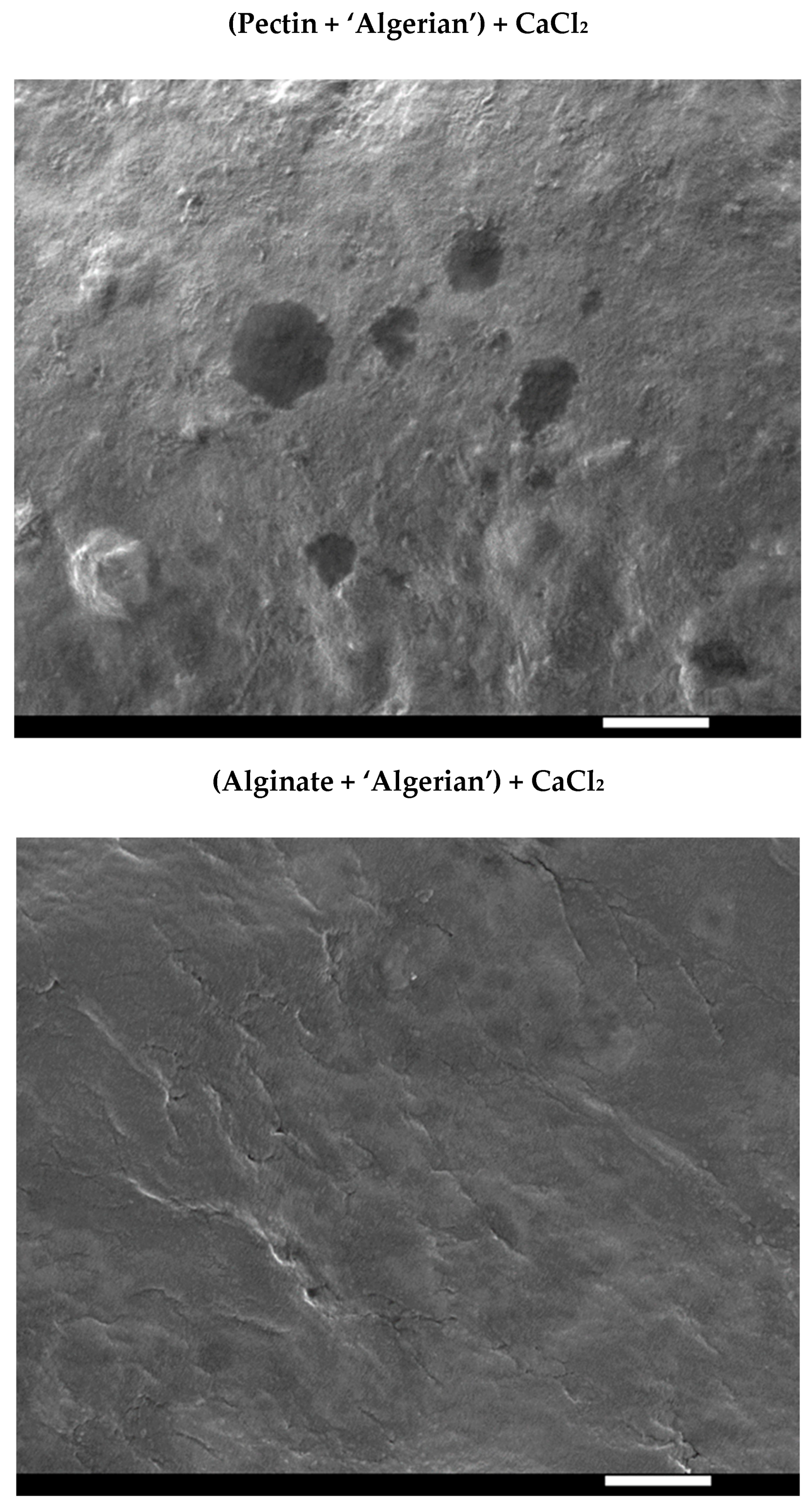

3.2. Influence of Native Mucilage Additions on the Microstructures of Pectin and Alginate Blend Films Treated with CaCl2

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohamed, S.A.A.; El-Sakhawy, M.; El-Sakhawy, M.A.M. Polysaccharides, Protein and Lipid—Based Natural Edible Films in Food Packaging: A Review. Carbohydr. Polym. 2020, 238, 116178. [Google Scholar] [CrossRef] [PubMed]

- Otoni, C.G.; Avena-Bustillos, R.J.; Azeredo, H.M.C.; Lorevice, M.V.; Moura, M.R.; Mattoso, L.H.C.; McHugh, T.H. Recent Advances on Edible Films Based on Fruits and Vegetables—A Review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1151–1169. [Google Scholar] [CrossRef]

- Asgher, M.; Qamar, S.A.; Bilal, M.; Iqbal, H.M.N. Bio-based active food packaging materials: Sustainable alternative to conventional petrochemical-based packaging materials. Food Res. Int. 2020, 137, 109625. [Google Scholar] [CrossRef] [PubMed]

- da Silva, M.A.; Bierhalz, A.C.K.; Kieckbusch, T.G. Alginate and Pectin Composite Films Crosslinked with Ca2+ Ions: Effect of the Plasticizer Concentration. Carbohydr. Polym. 2009, 77, 736–742. [Google Scholar] [CrossRef]

- Peppas, N.A.; Hilt, J.Z.; Khademhosseini, A.; Langer, R. Hydrogels in Biology and Medicine: From Molecular Principles to Bionanotechnology. Adv. Mater. 2006, 18, 1345–1360. [Google Scholar] [CrossRef]

- Hoffman, A.S. Hydrogels for Biomedical Applications. Adv. Drug Deliv. Rev. 2012, 64, 18–23. [Google Scholar] [CrossRef]

- Galus, S.; Lenart, A. Development and Characterization of Composite Edible Films Based on Sodium Alginate and Pectin. J. Food Eng. 2013, 115, 459–465. [Google Scholar] [CrossRef]

- Galus, S.; Kadzińska, J. Food Applications of Emulsion-Based Edible Films and Coatings. Trends Food Sci. Technol. 2015, 45, 273–283. [Google Scholar] [CrossRef]

- Falguera, V.; Quintero, J.P.; Jiménez, A.; Muñoz, J.A.; Ibarz, A. Edible Films and Coatings: Structures, Active Functions and Trends in Their Use. Trends Food Sci. Technol. 2011, 22, 292–303. [Google Scholar] [CrossRef]

- Liu, L.S.; Kost, J.; Yan, F.; Spiro, R.C. Hydrogels from Biopolymer Hybrid for Biomedical, Food, and Functional Food Applications. Polymers 2012, 4, 997–1011. [Google Scholar] [CrossRef]

- Tosif, M.M.; Najda, A.; Bains, A.; Zawiślak, G.; Maj, G.; Chawla, P. Starch–Mucilage Composite Films: An Inclusive on Physicochemical and Biological Perspective. Polymers 2021, 13, 2588. [Google Scholar] [CrossRef] [PubMed]

- Gheribi, R.; Khwaldia, K. Cactus Mucilage for Food Packaging Applications. Coatings 2019, 9, 655. [Google Scholar] [CrossRef]

- Damas, M.S.P.; Pereira Junior, V.A.; Nishihora, R.K.; Quadri, M.G.N. Edible Films from Mucilage of Cereus Hildmannianus Fruits: Development and Characterization. J. Appl. Polym. Sci. 2017, 134, 45223. [Google Scholar] [CrossRef]

- Zibaei, R.; Hasanvand, S.; Hashami, Z.; Roshandel, Z.; Rouhi, M.; Guimarães, J.d.T.; Mortazavian, A.M.; Sarlak, Z.; Mohammadi, R. Applications of Emerging Botanical Hydrocolloids for Edible Films: A Review. Carbohydr. Polym. 2021, 256, 117554. [Google Scholar] [CrossRef]

- Choi, H.J.; Choi, S.W.; Lee, N.; Chang, H.J. Antimicrobial Activity of Chitosan/Gelatin/Poly(vinyl alcohol) Ternary Blend Film Incorporated with Duchesnea indica Extract in Strawberry Applications. Foods 2022, 11, 3963. [Google Scholar] [CrossRef] [PubMed]

- Mo, X.; Peng, X.; Liang, X.; Fang, S.; Xie, H.; Chen, J.; Meng, Y. Development of antifungal gelatin-based nanocomposite films functionalized with natamycin-loaded zein/casein nanoparticles. Food Hydrocoll. 2021, 113, 106506. [Google Scholar] [CrossRef]

- Scognamiglio, F.S.; Gattia, D.M.; Roselli, G.; Persia, F.; De Angelis, U.; Santulli, C. Thermoplastic Starch (TPS) Films Added with Mucilage from Opuntia Ficus Indica: Mechanical, Microstructural and Thermal Characterization. Materials 2020, 13, 1000. [Google Scholar] [CrossRef] [PubMed]

- Luna-Sosa, B.; Martínez-Ávila, G.C.G.; Rodríguez-Fuentes, H.; Azevedo, A.G.; Pastrana, L.M.; Rojas, R.; Cerqueira, M.A. Pectin-Based Films Loaded with Hydroponic Nopal Mucilages: Development and Physicochemical Characterization. Coatings 2020, 10, 467. [Google Scholar] [CrossRef]

- Sandoval, D.C.G.; Sosa, B.L.; Martínez-Ávila, G.C.G.; Fuentes, H.R.; Abarca, V.H.A.; Rojas, R. Formulation and Characterization of Edible Films Based on Organic Mucilage from Mexican Opuntia Ficus-Indica. Coatings 2019, 9, 506. [Google Scholar] [CrossRef]

- Guadarrama-Lezama, A.Y.; Castaño, J.; Velázquez, G.; Carrillo-Navas, H.; Alvarez-Ramírez, J. Effect of nopal mucilage addition on physical, barrier and mechanical properties of citric pectin-based films. J. Food Sci. Technol. 2018, 55, 3739–3748. [Google Scholar] [CrossRef]

- Du Toit, A.; De Wit, M. Patent PA153178P—A Process for Extracting Mucilage from Opuntia Ficus-Indica, Aloe Barbadensis and Agave Americana. Ph.D. Thesis, University of the Free State, Bloemfontein, South Africa, 2021. [Google Scholar] [CrossRef]

- Du Toit, A. Selection, Extraction, Characterization and Application of Mucilage from Cactus Pear (Opuntia Ficus-Indica and Opuntia Robusta). Ph.D. Thesis, University of the Free State, Bloemfontein, South Africa, 2016; pp. 1–13. [Google Scholar]

- Du Toit, A.; De Wit, M.; Fouché, H.J.; Taljaard, M.; Venter, S.L.; Hugo, A. Mucilage Powder from Cactus Pears as Functional Ingredient: Influence of Cultivar and Harvest Month on the Physicochemical and Technological Properties. J. Food Sci. Technol. 2019, 56, 2404–2416. [Google Scholar] [CrossRef]

- Espino-Díaz, M.; Ornelas-Paz, J.D.J.; Martínez-Téllez, M.A.; Santillán, C.; Barbosa-Cánovas, G.V.; Zamudio-Flores, P.B.; Olivas, G.I. Development and Characterization of Edible Films Based on Mucilage of Opuntia Ficus-Indica (L.). J. Food Sci. 2010, 75, 347–352. [Google Scholar] [CrossRef] [PubMed]

- Gheribi, R.; Puchot, L.; Verge, P.; Jaoued-Grayaa, N.; Mezni, M.; Habibi, Y.; Khwaldia, K. Development of Plasticized Edible Films from Opuntia Ficus-Indica Mucilage: A Comparative Study of Various Polyol Plasticizers. Carbohydr. Polym. 2018, 190, 204–211. [Google Scholar] [CrossRef] [PubMed]

- Du, W.X.; Avena-Bustillos, R.J.; Sheng, S.; Hua, T.; McHugh, T.H. Antimicrobial Volatile Essential Oils in Edible Films for Food Safety. Sci. Against Microb. Pathog. Commun. Curr. Res. Technol. Adv. 2011, 2, 1124–1134. [Google Scholar]

- Espitia, P.J.P.; Du, W.-X.; Avena-Bustillos, R.d.J.; Soares, N.d.F.F.; McHugh, T.H. Edible Films from Pectin: Physical-Mechan.ical and Antimicrobial Properties—A Review. Food Hydrocoll. 2014, 35, 287–296. [Google Scholar] [CrossRef]

- Campos, C.A.; Gerschenson, L.N.; Flores, S.K. Development of Edible Films and Coatings with Antimicrobial Activity. Food Bioprocess Technol. 2011, 4, 849–875. [Google Scholar] [CrossRef]

- ASTM-D882; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. ASTM: Philadelphia, PA, USA, 2018.

- Harper, B.A. Understanding Interactions in Wet Alginate Film Formation Used for In-Line Food Processes. Ph.D. Thesis, The University of Guelph, Guelph, ON, Canada, 2013; 164p. [Google Scholar]

- Xu, Y.X.; Kim, K.M.; Hanna, M.A.; Nag, D. Chitosan-Starch Composite Film: Preparation and Characterization. Ind. Crops Prod. 2005, 21, 185–192. [Google Scholar] [CrossRef]

- Rhim, J.W. Physical and Mechanical Properties of Water Resistant Sodium Alginate Films. LWT-Food Sci. Technol. 2004, 37, 323–330. [Google Scholar] [CrossRef]

- Wang, L.Z.; Liu, L.; Holmes, J.; Kerry, J.F.; Kerry, J.P. Assessment of Film-Forming Potential and Properties of Protein and Polysaccharide-Based Biopolymer Films. Int. J. Food Sci. Technol. 2007, 42, 1128–1138. [Google Scholar] [CrossRef]

- Gawkowska, D.; Ciesla, J.; Zdunek, A.; Cybulska, J. The Effect of Concentration on the Cross-Linking and Gelling of Sodium Carbonate-Soluble Apple Pectins. Molecules 2019, 24, 1635. [Google Scholar] [CrossRef]

- Cárdenas, A.; Goycoolea, F.M.; Rinaudo, M. On the Gelling Behaviour of “nopal” (Opuntia Ficus Indica) Low Methoxyl Pectin. Carbohydr. Polym. 2008, 73, 212–222. [Google Scholar] [CrossRef]

- Fazilah, A.; Maizura, M.; Abd Karim, A.; Bhupinder, K.; Rajeev, B.; Uthumporn, U.; Chew, S.H. Physical and Mechanical Properties of Sago Starch—Alginate Films Incorporated with Calcium Chloride. Int. Food Res. J. 2011, 18, 1027–1033. [Google Scholar]

- Wang, L.; Auty, M.A.E.; Kerry, J.P. Physical Assessment of Composite Biodegradable Films Manufactured Using Whey Protein Isolate, Gelatin and Sodium Alginate. J. Food Eng. 2010, 96, 199–207. [Google Scholar] [CrossRef]

- Comaposada, J.; Gou, P.; Marcos, B.; Arnau, J. Physical Properties of Sodium Alginate Solutions and Edible Wet Calcium Alginate Coatings. LWT—Food Sci. Technol. 2015, 64, 212–219. [Google Scholar] [CrossRef]

- Mohnen, D. Pectin Structure and Biosynthesis. Curr. Opin. Plant Biol. 2008, 11, 266–277. [Google Scholar] [CrossRef] [PubMed]

- Larsen, B.; Salem, D.M.S.A.; Sallam, M.A.E.; Mishrikey, M.M.; Beltagy, A.I. Characterization of the Alginates from Algae Harvested at the Egyptian Red Sea Coast. Carbohydr. Res. 2003, 338, 2325–2336. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-González, S.; Martínez-Flores, H.E.; Chávez-Moreno, C.K.; Macías-Rodríguez, L.I.; Zavala-Mendoza, E.; Garnica-Romo, M.G.; Chacõn-García, L. Extraction and Characterization of Mucilage from Wild Species of Opuntia. J. Food Process Eng. 2014, 37, 285–292. [Google Scholar] [CrossRef]

- Fernandes, P.B.; Gonçalves, M.P.; Doublier, J.L. Rheological Description at the Minimum Gelling Conditions of Kappa-Carrageenan/Locust Bean Gum Systems. Top. Catal. 1994, 8, 345–349. [Google Scholar] [CrossRef]

- Sepúlveda, E.; Sáenz, C.; Aliaga, E.; Aceituno, C. Extraction and Characterization of Mucilage in Opuntia Spp. J. Arid. Environ. 2007, 68, 534–545. [Google Scholar] [CrossRef]

- Voragen, A.G.J.; Coenen, G.J.; Verhoef, R.P.; Schols, H.A. Pectin, a Versatile Polysaccharide Present in Plant Cell Walls. Struct. Chem. 2009, 20, 263–275. [Google Scholar] [CrossRef]

- Fabra, M.J.; Talens, P.; Chiralt, A. Influence of Calcium on Tensile, Optical and Water Vapour Permeability Properties of Sodium Caseinate Edible Films. J. Food Eng. 2010, 96, 356–364. [Google Scholar] [CrossRef]

- De Farias, P.M.; de Vasconcelos, L.B.; Ferreira, M.E.S.; Pascall, M.; Tapia-Blácido, D.R. Nopal Cladode (Opuntia Ficus-Indica) Flour: Production, Characterization, and Evaluation for Producing Bioactive Film. Food Packag. Shelf Life 2021, 29, 100703. [Google Scholar] [CrossRef]

| Pectin-Based Homopolymeric and Bend Films | Puncture Force (N) | Distance to Puncture (mm) | Film Thickness (mm) |

|---|---|---|---|

| Pectin 5% (Control) | 31.51 ± 3.05 bc | 3.99 ± 0.30 bc | 0.273 ± 0.046 abc |

| Pectin 5% + CaCl2 | 35.99 ± 5.38 cd | 4.67 ± 0.34 cd | 0.284 ± 0.030 abc |

| Pectin 5% + ‘Algerian’ 0.25% | 38.37 ± 3.12 de | 3.12 ± 0.47 a | 0.250 ± 0.019 abc |

| Pectin 5% + ‘Morado’ 0.25% | 38.81 ± 2.91 de | 4.06 ± 0.72 bc | 0.213 ± 0.037 a |

| (Pectin 5% + ‘Algerian’ 0.25%) + CaCl2 | 46.51 ± 2.23 f | 5.11 ± 0.26 d | 0.277 ± 0.054 abc |

| (Pectin 5% + ‘Morado’ 0.25%) + CaCl2 | 47.58 ± 3.13 f | 4.62 ± 0.31 cd | 0.278 ± 0.031 abc |

| Pectin 5% + ‘Algerian’ 1% | 28.00 ± 1.07 b | 2.96 ± 0.35 a | 0.292 ± 0.057 bc |

| Pectin 5% + ‘Morado’ 1% | 30.89 ± 2.37 bc | 4.22 ± 0.73 bc | 0.233 ± 0.020 ab |

| (Pectin 5% + ‘Algerian’ 1%) + CaCl2 | 32.97 ± 3.62 bcd | 4.38 ± 0.50 cd | 0.305 ± 0.025 c |

| (Pectin 5% + ‘Morado’ 1%) + CaCl2 | 42.58 ± 2.26 ef | 3.42 ± 0.22 ab | 0.276 ± 0.035 abc |

| Significance level | p < 0.001 | p < 0.001 | p = 0.003 |

| Alginate-Based Homopolymeric and Bend Films | Puncture Force (N) | Distance to Puncture (mm) | Film Thickness (mm) |

|---|---|---|---|

| Alginate 5% (Control) | 72.11 ± 7.51 cd | 5.55 ± 0.50 de | 0.244 ± 0.011 ab |

| Alginate 5% + CaCl2 | 83.10 ± 9.35 d | 6.24 ± 0.56 e | 0.281 ± 0.008 bc |

| Alginate 5% + ‘Algerian’ 0.25% | 64.13 ± 7.71 bcd | 5.47 ± 0.25 de | 0.267 ± 0.034 abc |

| Alginate 5% + ‘Morado’ 0.25% | 48.21 ± 10.62 ab | 4.97 ± 0.91 cd | 0.229 ± 0.051 a |

| (Alginate 5% + ‘Algerian’ 0.25%) + CaCl2 | 70.52 ± 15.57 cd | 4.82 ± 0.87 bcd | 0.256 ± 0.013 abc |

| (Alginate 5% + ‘Morado’ 0.25%) + CaCl2 | 59.07 ± 8.78 abc | 3.84 ± 0.51 abc | 0.289 ± 0.014 bc |

| Alginate 5% + ‘Algerian’ 1% | 42.85 ± 6.47 a | 3.93 ± 0.67 abc | 0.297 ± 0.034 c |

| Alginate 5% + ‘Morado’ 1% | 42.16 ± 5.70 a | 3.39 ± 0.41 a | 0.268 ± 0.014 abc |

| (Alginate 5% + ‘Algerian’ 1%) + CaCl2 | 54.18 ± 12.03 abc | 3.89 ± 0.63 abc | 0.371 ± 0.038 d |

| (Alginate 5% + ‘Morado’ 1%) + CaCl2 | 54.69 ± 11.62 abc | 3.79 ± 0.59 ab | 0.357 ± 0.014 d |

| Significance level | p < 0.001 | p < 0.001 | p < 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van Rooyen, B.; De Wit, M.; Osthoff, G.; Van Niekerk, J.; Hugo, A. Effect of Native Mucilage on the Mechanical Properties of Pectin-Based and Alginate-Based Polymeric Films. Coatings 2023, 13, 1611. https://doi.org/10.3390/coatings13091611

Van Rooyen B, De Wit M, Osthoff G, Van Niekerk J, Hugo A. Effect of Native Mucilage on the Mechanical Properties of Pectin-Based and Alginate-Based Polymeric Films. Coatings. 2023; 13(9):1611. https://doi.org/10.3390/coatings13091611

Chicago/Turabian StyleVan Rooyen, Brandon, Maryna De Wit, Gernot Osthoff, Johan Van Niekerk, and Arno Hugo. 2023. "Effect of Native Mucilage on the Mechanical Properties of Pectin-Based and Alginate-Based Polymeric Films" Coatings 13, no. 9: 1611. https://doi.org/10.3390/coatings13091611

APA StyleVan Rooyen, B., De Wit, M., Osthoff, G., Van Niekerk, J., & Hugo, A. (2023). Effect of Native Mucilage on the Mechanical Properties of Pectin-Based and Alginate-Based Polymeric Films. Coatings, 13(9), 1611. https://doi.org/10.3390/coatings13091611