Influence of Cr-Al-Si-N and DLC-Si Thin Coatings on Wear Resistance of Titanium Alloy Samples with Different Surface Conditions

Abstract

1. Introduction

2. Materials and Methods, and Equipment

2.1. Characteristics of Titanium Alloy Samples

- -

- finishing milling with GC1745 carbide end mills at a cutting speed of 60 m/min, feed rate of 0.08 mm/tooth, and depth of 0.2 mm (CTX 1250TC milling machining center, DMG, Bielefeld, Germany);

- -

- abrasive machining with lapping wheels using a suspension of silicon carbide micro-powders of grain size F800 at a cutting speed of 3 m/s (Lapmaster 24 lapping and polishing machine, Lapmaster Wolters, Mt Prospect, IL, USA).

2.2. Cr-Al-Si-N and DLC-Si Coatings Deposition Technique for Titanium Alloy Samples

2.2.1. Equipment and Technology of Coating Deposition

2.2.2. Deposition of Cr-Al-Si-N Coatings

- -

- pumping the vacuum chamber by pumps to a pressure of 0.03 Pa and heating with heaters for 60 min to a temperature of 500 °C;

- -

- cleaning of the sample surface with Ar ions for 20 min at a chamber temperature of ~500 °C, a pressure of 1.2 Pa, and a bias voltage of −650 V;

- -

- cleaning of the surface of the sample by metal ions for 20 min at a chamber temperature of ~500 °C, pressure of 2.2 Pa, bias voltage of −800 V, and Al-Si cathode current of 90 A;

- -

- Cr-Al-Si-N coating deposition in a gas mixture of 10% vol. Ar and 90% vol. N2 for 60 min at a chamber temperature of ~500 °C, pressure of 0.9 Pa, bias voltage of −80 V, and current on Cr and Al-Si cathodes of 90 A.

2.2.3. Deposition of DLC-Si and Cr-Al-Si-N/DLC-Si Coatings

- -

- the vacuum chamber is filled with a gas mixture containing 16% vol. Si(CH3)4, 6% vol. Ar, and 78% vol. N2 to form a gradient layer 5 min before the process completion;

- -

- DLC-Si coating deposition at the temperature in a vacuum chamber of up to 180 °C in a gas mixture of 3% vol. Si(CH3)4, 52% vol. Ar, and 45% vol. C2H2 for 110 min at a pressure of 1.5 Pa and a bias voltage of −500 V.

2.3. Evaluation of Physical and Mechanical Characteristics of Coatings

2.4. Evaluation of Wear Resistance of Coatings Deposited on Titanium Alloy

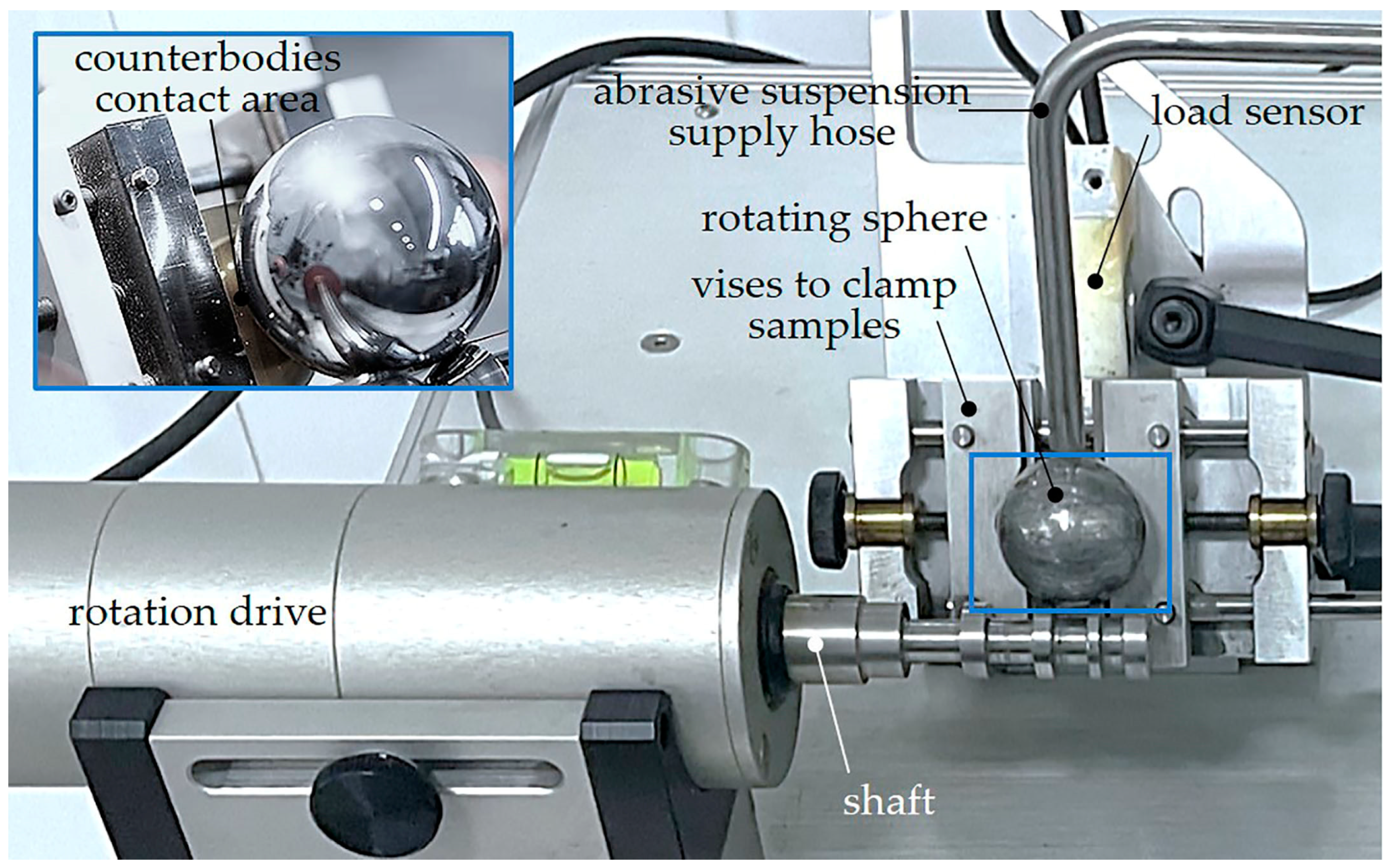

2.4.1. Resistance to Abrasion Wear

2.4.2. Resistance to Fretting Wear

- Relative displacement of counter bodies of 60 and 100 µm.

- Normal force in contact of 1 and 20 N.

- A number of friction cycles of 100,000 and 300,000 (for samples after finishing milling) and 25,000 (for samples after lapping with micro-grained abrasive).

3. Results

3.1. Microstructure and Properties of Coatings

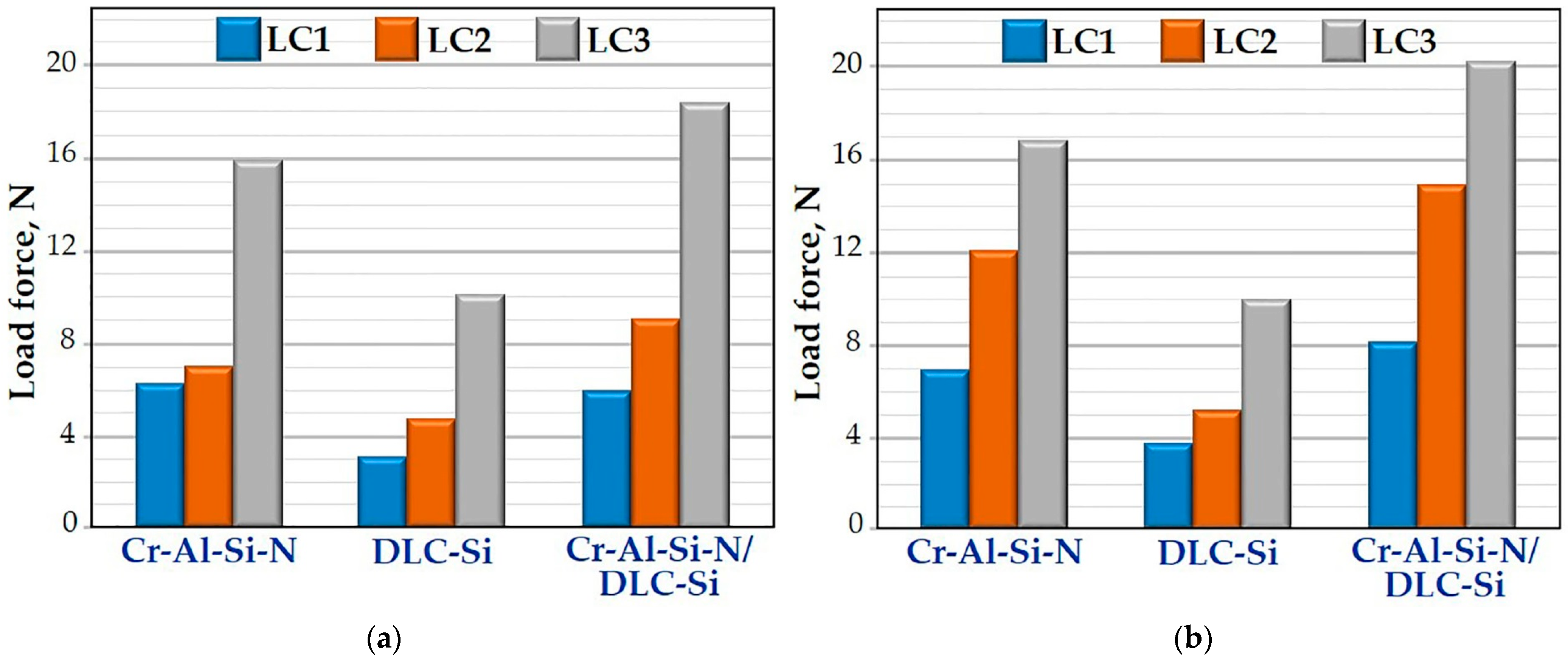

3.2. Adhesion Bond Strength of Coatings

3.3. Wear Resistance of Titanium Alloy Samples with Coatings

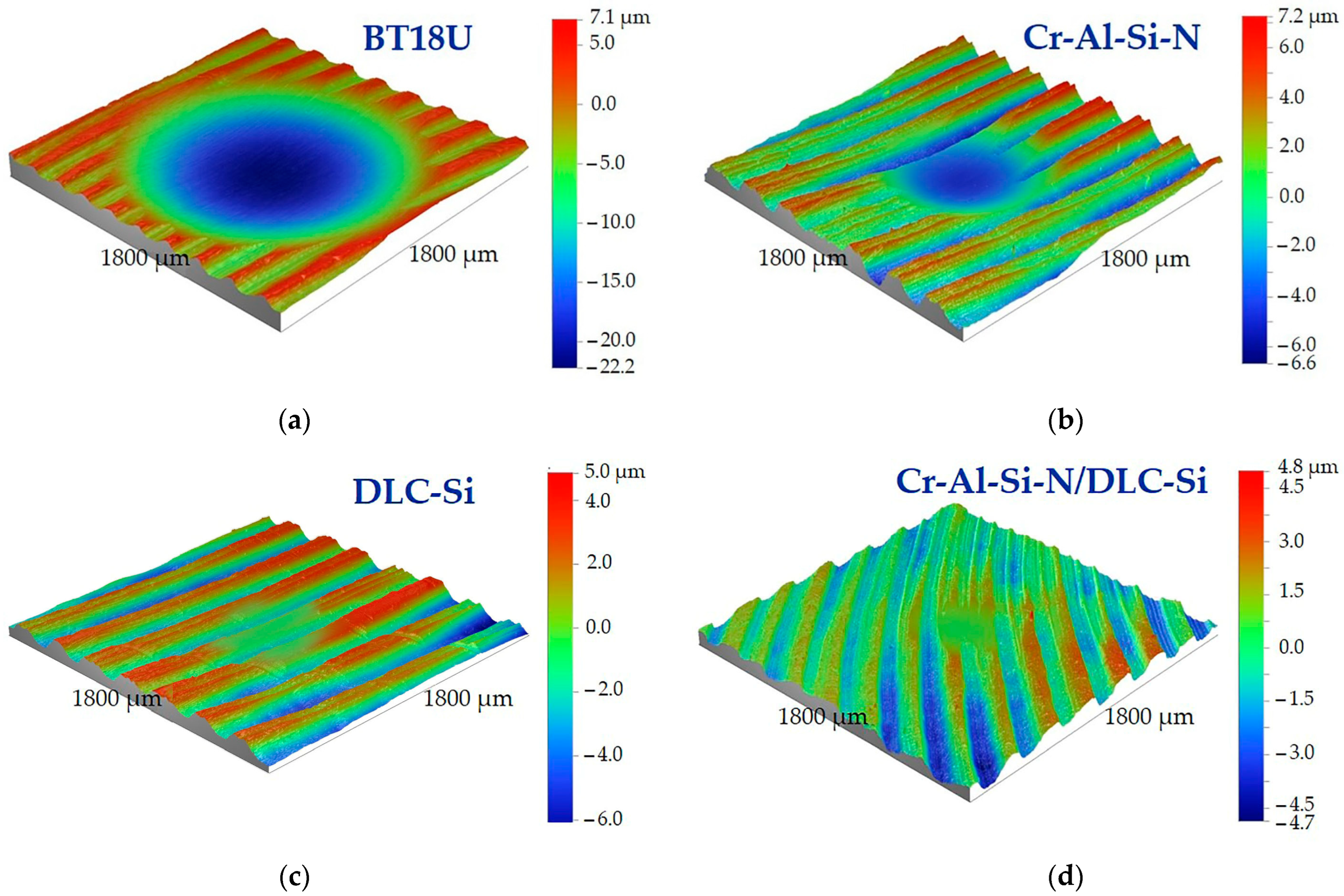

3.3.1. Wear Resistance under Abrasive Exposure

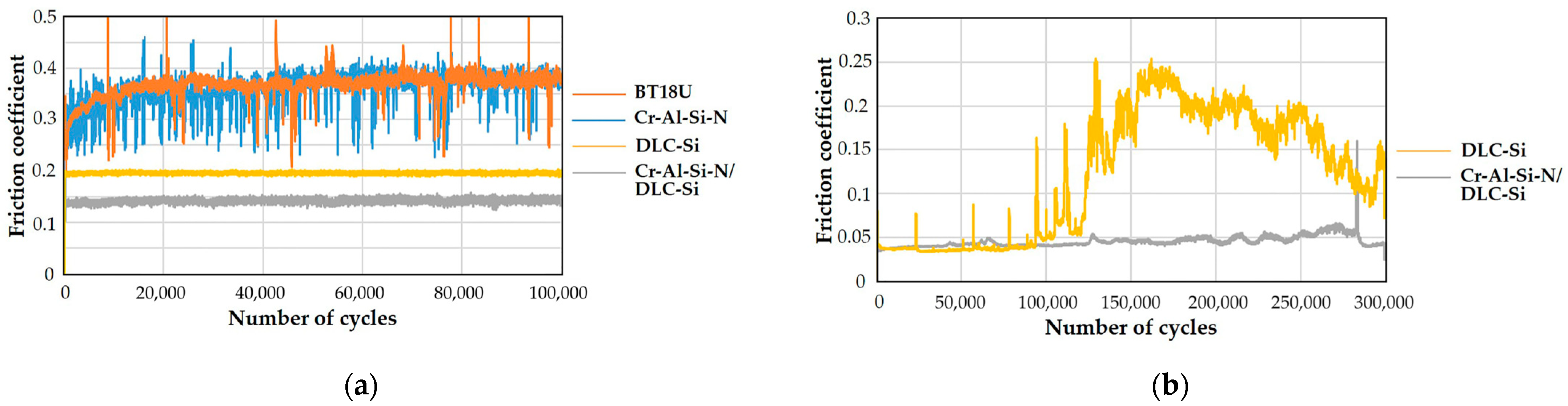

3.3.2. Wear Resistance under Fretting

4. Discussion

5. Conclusions

- (1)

- The condition of the surface layer of titanium alloy samples on which thin film coatings are deposited significantly influences the physical and mechanical properties of coatings and the wear resistance of the coated material under external loads. When coatings are deposited on a surface with numerous irregularities and grooves, the coatings replicate the characteristic microrelief. At the same time, they provide multiple increases in wear resistance under abrasive exposure and fretting wear at the expense of a principal change in the conditions of adhesive and frictional interaction in the tribo-contact area.

- (2)

- When selecting thin film coatings for deposition on sufficiently “soft” titanium alloy along with high hardness, they should have an elastic modulus similar to the base material to reduce stresses at the “titanium alloy coating” interface and provide the highest adhesive bond strength under external loads.

- (3)

- Multilayer coatings increase adhesive bond strength with titanium alloy samples by creating additional internal interfaces and deflecting the trajectory of cracks generated under the external load. In scratch testing, the delamination character along the boundary between the outer and inner layers of the coating was confirmed by the example of the Cr-Al-Si-N/DLC-Si coating.

- (4)

- The best perspectives for increase of wear resistance of titanium alloy samples under conditions of abrasive exposure and fretting wear can be provided by coatings with a minimum friction coefficient, which exhibit high lubricating ability for a prolonged period and, therefore, stable conditions in the tribo-contact area at the expense of minimization of adhesion bonding.

- (5)

- The results of complex comparative research of three coatings, Cr-Al-Si-N, DLC-Si, and Cr-Al-Si-N/DLC-Si, deposited on titanium alloy samples demonstrated an outstanding effect of the Cr-Al-Si-N/DLC-Si coating in increasing wear resistance under conditions of abrasive exposure and fretting wear. The mentioned effect is achieved by high hardness, relatively low elastic modulus, and a reduced friction coefficient, which ensures prolonged availability of the strong boundary film in the tribo-contact area, protecting the surface layer of titanium alloy from destruction and minimizing the number of wear products.

- (6)

- The obtained positive results of the laboratory condition testing may allow us to proceed to the next stage: testing the coated experimental parts on specialized stands. The next level of this study would provide an even deeper understanding of the operating mechanisms since the acting loads and the configuration of the parts’ contact surfaces are as close as possible to real operating conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Basir, A.; Muhamad, N.; Sulong, A.B.; Jamadon, N.H.; Foudzi, F.M. Recent Advances in Processing of Titanium and Titanium Alloys through Metal Injection Molding for Biomedical Applications: 2013–2022. Materials 2023, 16, 3991. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H. Enhancement of titanium alloy corrosion resistance via anodic oxidation treatment. Int. J. Electrochem. Sci. 2018, 13, 3888–3896. [Google Scholar] [CrossRef]

- Uhlmann, E.; Kersting, R.; Klein, T.B.; Cruz, M.F.; Borille, A.V. Additive Manufacturing of Titanium Alloy for Aircraft Components. Procedia CIRP 2015, 35, 55–60. [Google Scholar] [CrossRef]

- Boyer, R.R. Attributes, characteristics, and applications of titanium and its alloys. JOM 2017, 3, 15–18. [Google Scholar] [CrossRef]

- Blanco, D.; Rubio, E.M.; Lorente-Pedreille, R.M.; Sáenz-Nuño, M.A. Sustainable Processes in Aluminium, Magnesium, and Titanium Alloys Applied to the Transport Sector: A Review. Metals 2022, 12, 9. [Google Scholar] [CrossRef]

- Mehrabi, R.; Dorri, M.; Elahinia, M. Finite Element Simulation of NiTi Umbrella-Shaped Implant Used on Femoral Head under Different Loadings. Bioengineering 2017, 4, 23. [Google Scholar] [CrossRef]

- Sadrkhah, M.; Faraji, G.; Khorasani, S.; Mesbah, M. Excellent Mechanical Properties, Wettability and Biological Response of Ultrafine-Grained Pure Ti Dental Implant Surface Modified by SLActive. J. Mater. Eng. Perform. 2023. [CrossRef]

- García-Martínez, E.; Miguel, V.; Martínez-Martínez, A.; Manjabacas, M.C.; Coello, J. Sustainable Lubrication Methods for the Machining of Titanium Alloys: An Overview. Materials 2019, 12, 3852. [Google Scholar] [CrossRef]

- Seo, B.; Park, H.K.; Park, C.S.; Park, K. Role of Ta in improving corrosion resistance of titanium alloys under highly reducing condition. J. Mater. Res. Technol. 2023, 23, 4955–4964. [Google Scholar] [CrossRef]

- Yang, J.; Song, Y.; Dong, K.; Han, E.H. Research progress on the corrosion behavior of titanium alloys. Corros. Rev. 2023, 41, 5–20. [Google Scholar] [CrossRef]

- Cheng, J.; Li, F.; Zhu, S.Y.; Yu, Y.; Qiao, Z.H.; Yang, J. Electrochemical corrosion and tribological evaluation of TiAl alloy for marine application. Tribol. Int. 2017, 115, 483–492. [Google Scholar] [CrossRef]

- Belkin, P.N.; Kusmanov, S.A.; Dyakov, I.G.; Silkin, S.A.; Smirnov, A.A. Increasing Wear Resistance of Titanium Alloys by Anode Plasma Electrolytic Saturation with Interstitial Elements. J. Mater. Eng. Perform. 2017, 26, 2404–2410. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, J.; Huang, A.; Wei, P. Study on Wear Resistance of Ti-6Al-4V Alloy Composite Coating Prepared by Laser Alloying. Appl. Sci. 2021, 11, 446. [Google Scholar] [CrossRef]

- Kusmanov, S.A.; Tambovskii, I.V.; Korableva, S.S.; Mukhacheva, T.L.; D’yakonova, A.D.; Nikiforov, R.V.; Naumov, A.R. Wear Resistance Increase in Ti6Al4V Titanium Alloy Using a Cathodic Plasma Electrolytic Nitriding. Surf. Eng. Appl. Electrochem. 2022, 58, 451–455. [Google Scholar] [CrossRef]

- Cui, G.; Liu, Y.; Gao, G.; Liu, H.; Li, S.; Kou, Z. Preparation, Mechanical Properties, and High-Temperature Wear Resistance of Ti–Al–B alloy. Materials 2019, 12, 3751. [Google Scholar] [CrossRef]

- Dai, J.; Li, S.; Zhang, H.; Yu, H.; Chen, C.; Li, Y. Microstructure and high-temperature oxidation resistance of Ti-Al-Nb coatings on a Ti-6Al-4V alloy fabricated by laser surface alloying. Surf. Coat. Technol. 2018, 344, 479–488. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Vereschaka, A.S.; Grigoriev, S.N.; Kirillov, A.K.; Khaustova, O. Development and research of environmentally friendly dry technological machining system with compensation of physical function of cutting fluids. Procedia CIRP 2013, 7, 311–316. [Google Scholar] [CrossRef]

- Rakoch, A.G.; Truong, P.V.; Gladkova, A.A.; Predein, N.A. Phase composition and wear resistance of coatings formed on Vt6 (Ti–6Al–4V) titanium alloy by plasma electrolytic oxidation. Powder Metall. Funct. Coat. 2018, 1, 59–66. (In Russian) [Google Scholar] [CrossRef]

- Cressman, D.; Tury, B.; Doll, G.L. Effects of surface treatments and coatings on tribological performance of Ti–6Al–4V in the mixed fretting and gross slip regimes. Surf. Coat. Technol. 2015, 276, 260–265. [Google Scholar] [CrossRef]

- Graves, A.; Norgren, S.; Wan, W.; Singh, S.; Kritikos, M.; Xiao, C.H.; Crawforth, P.; Jackson, M. On the mechanism of crater wear in a high strength metastable β titanium alloy. Wear 2021, 484–485, 203998. [Google Scholar] [CrossRef]

- Huang, P.L.; Li, J.F.; Sun, J.; Zhou, J. Study on performance in dry milling aeronautical titanium alloy thin-wall components with two types of tools. J. Clean. Prod. 2014, 67, 258–264. [Google Scholar] [CrossRef]

- Mo, D.F.; Song, T.F.; Fang, Y.J.; Jiang, X.S.; Luo, C.Q.; Simpson, M.D.; Luo, Z.P. A review on diffusion bonding between titanium alloys and stainless steels. Adv. Mater. Sci. Eng. 2018, 2018, 8701890. [Google Scholar] [CrossRef]

- Boyer, R.R.; Foltz, J. Effect of Heat Treatment on Mechanical Properties of Titanium Alloys. In ASM Handbook, Vol. 4E, Heat Treating of Nonferrous Alloys; Totten, G.E., Ed.; ASM International: Almere, The Netherlands, 2016; pp. 555–572. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Melnik, Y.A.; Metel, A.S.; Panin, V.V. Broad beam source of fast atoms produced as a result of charge exchange collisions of ions accelerated between two plasmas. Instrum. Exp. Tech. 2009, 52, 602–608. [Google Scholar] [CrossRef]

- Sitek, R.; Kamiński, J.; Adamczyk-Cieślak, B.; Molak, R.; Spychalski, M.; Cowell, B.; McCann, J.; Roliński, E. Effect of Plasma Nitriding on Structure and Properties of Titanium Grade 2 Produced by Direct Metal Laser Sintering. Metallogr. Microstruct. Anal. 2022, 11, 852–863. [Google Scholar] [CrossRef]

- Vaché, N.; Cadoret, Y.; Dod, B.; Monceau, D. Modeling the oxidation kinetics of titanium alloys: Review, method and application to Ti-64 and Ti-6242s alloys. Corros. Sci. 2021, 178, 109041. [Google Scholar] [CrossRef]

- Chepak-Gizbrekht, M.V.; Knyazeva, A.G. Oxidation of TiAl alloy by oxygen grain boundary diffusion. Intermetallics 2023, 162, 107993. [Google Scholar] [CrossRef]

- Grigoriev, S.; Metel, A. Plasma- and Beam-Assisted Deposition Methods. In Nanostructured Thin Films and Nanodispersion Strengthened Coatings; NATO Science Series II: Mathematics, Physics and Chemistry; Voevodin, A.A., Shtansky, D.V., Levashov, E.A., Moore, J.J., Eds.; Springer: Dordrecht, The Netherlands, 2004; Volume 155, pp. 147–154. [Google Scholar] [CrossRef]

- Burkov, A.; Kulik, M.; Krutikova, V. Electrospark deposition of tungsten carbide powder on titanium alloy Ti6Al4V. Lett. Mater. 2021, 11, 175–180. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Tabakov, V.; Sitnikov, N.; Andreev, N.; Sviridova, T.; Bublikov, J. Investigation of multicomponent nanolayer coatings based on nitrides of Cr, Mo, Zr, Nb, and Al. Surf. Coat. Technol. 2020, 401, 126258. [Google Scholar] [CrossRef]

- Kuśmierczyk, F.; Zimowski, S.; Łukaszczyk, A.; Kopia, A.; Cieniek, Ł.; Moskalewicz, T. Development of Microstructure and Properties of Multicomponent MoS2/HA/PEEK Coatings on a Titanium Alloy Via Electrophoretic Deposition and Heat Treatment. Metall. Mater. Trans. A 2021, 52, 3880–3895. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Zelenkov, V.; Sitnikov, N.; Bublikov, J.; Milovich, F.; Andreev, N.; Sotova, C. Investigation of the influence of the features of the deposition process on the structural features of microparticles in PVD coatings. Vacuum 2022, 202, 111144. [Google Scholar] [CrossRef]

- Burdovitsin, V.A.; Zolotukhin, D.B.; Zavadsky, S.M. Formation of Protective and Wear-Resistant Coatings on Titanium alloys by the Combination of Fore-Vacuum Electron-Beam and Ion-Plasma Deposition. In Proceedings of the 2020 IEEE International Conference on Plasma Science (ICOPS), Singapore, 6–10 December 2020; p. 277. [Google Scholar] [CrossRef]

- Sivaprakasam, P.; Kirubel, A.; Elias, G.; Maheandera Prabu, P.; Balasubramani, P. Mathematical Modeling and Analysis of Wear Behavior of AlTiN Coating on Titanium Alloy (Ti-6Al-4V). Adv. Mater. Sci. Eng. 2021, 2021, 1098605. [Google Scholar] [CrossRef]

- Vereschaka, A.; Grigoriev, S.; Tabakov, V.; Migranov, M.; Sitnikov, N.; Milovich, F.; Andreev, N. Influence of the nanostructure of Ti-TiN-(Ti,Al,Cr)N multilayer composite coating on tribological properties and cutting tool life. Tribol. Int. 2020, 150, 106388. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Sitnikov, N.; Andreev, N.; Bublikov, J.; Kutina, N. Investigation of the properties of the Cr,Mo-(Cr,Mo,Zr,Nb)N-(Cr,Mo,Zr,Nb,Al)N multilayer composite multicomponent coating with nanostructured wear-resistant layer. Wear 2021, 468, 203597. [Google Scholar] [CrossRef]

- De Oliveira, A.; Placias, F.G.; Sobrinho, A.S.D.S.; Leite, D.M.G.; Miyakawa, W.; Neto, J.J.; Koh, I.H.J.; Liberatore, A.M.A.; Santos, M.A.; Matieli, J.E.; et al. Secondary Ion Mass Spectrometry and Atomic Force Microscopy Analysis of Silver-Doped Diamond-like Carbon Films on Titanium Alloy (Ti6Al4V) for Possible Biomedical Application. Thin Solid Films 2021, 719, 138487. [Google Scholar] [CrossRef]

- Malisz, K.; Świeczko-Żurek, B.; Sionkowska, A. Preparation and Characterization of Diamond-like Carbon Coatings for Biomedical Applications—A Review. Materials 2023, 16, 3420. [Google Scholar] [CrossRef] [PubMed]

- Derakhshandeh, M.R.; Eshraghi, M.J.; Hadavi, M.M.; Javaheri, M.; Khamseh, S.; Sari, M.G.; Zarrintaj, P.; Saeb, M.R.; Mozafari, M. Diamond-like carbon thin films prepared by pulsed-DC PE-CVD for biomedical applications. Surf. Innov. 2018, 6, 167–175. [Google Scholar] [CrossRef]

- Zhu, W.; Su, Z.; Guo, J.; Li, K.; Chen, K.; Li, W.; Yi, A.; Liao, Z.; Luo, Y.; Hu, Y.; et al. Preparation and Characterization of Diamond-like Carbon (DLC) Film on 316L Stainless Steel by Microwave Plasma Chemical Vapor Deposition (MPCVD). Diam. Relat. Mater. 2022, 122, 108820. [Google Scholar] [CrossRef]

- Ozkomur, A.; Erbil, M.; Akova, T. Diamondlike carbon coating as a galvanic corrosion barrier between dental implant abutments and nickel-chromium superstructures. Int. J. Oral Maxillofac. Implant. 2013, 28, 1037–1047. [Google Scholar] [CrossRef][Green Version]

- Wongpanya, P.; Pintitraratibodee, N.; Thumanu, K.; Euaruksakul, C. Improvement of Corrosion Resistance and Biocompatibility of 316L Stainless Steel for Joint Replacement Application by Ti-Doped and Ti-Interlayered DLC Films. Surf. Coat. Technol. 2021, 425, 127734. [Google Scholar] [CrossRef]

- Zhao, Q.; Kang, S.; Zou, F.; Huo, Z. Structure and Properties of Si and N Co-Doping on DLC Film Corrosion Resistance. Ceram. Int. 2023, 49, 2121–2129. [Google Scholar] [CrossRef]

- Zhang, T.F.; Deng, Q.Y.; Liu, B.; Wu, B.J.; Jing, F.J.; Leng, Y.X.; Huang, N. Wear and corrosion properties of diamond like carbon (DLC) coating on stainless steel, CoCrMo and Ti6Al4V substrates. Surf. Coat. Technol. 2015, 273, 12–19. [Google Scholar] [CrossRef]

- Zia, A.W.; Anestopoulos, I.; Panayiotidis, M.I.; Birkett, M. Soft Diamond-like Carbon Coatings with Superior Biocompatibility for Medical Applications. Ceram. Int. 2023, 49, 17203–17211. [Google Scholar] [CrossRef]

- Han, B.; Yan, M.; Ju, D.; Chai, M.; Sato, S. Chemical Composition and Corrosion Behavior of a-C:H/DLC Film-Coated Titanium Substrate in Simulated PEMFC Environment. Coatings 2021, 11, 820. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Vereschaka, A.A.; Sitnikov, N.N.; Milovich, F.; Bublikov, J.I.; Fyodorov, S.V.; Seleznev, A.E. Properties of (Cr,Al,Si)N-(DLC-Si) composite coatings deposited on a cutting ceramic substrate. Ceram. Int. 2020, 46, 18241–18255. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Fedorov, S.V.; Migranov, M.S.; Mosyanov, M.; Gusev, A.; Okunkova, A.A. The Effectiveness of Diamond-like Carbon a-C:H:Si Coatings in Increasing the Cutting Capability of Radius End Mills When Machining Heat-Resistant Nickel Alloys. Coatings 2022, 12, 206. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Fedorov, S.V.; Mosyanov, M. Influence of DLC Coatings Deposited by PECVD Technology on the Wear Resistance of Carbide End Mills and Surface Roughness of AlCuMg2 and 41Cr4 Workpieces. Coatings 2020, 10, 1038. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Fedorov, S.V.; Okunkova, A.A.; Pivkin, P.M.; Peretyagin, P.Y.; Ershov, A.A. Development of DLC-Coated Solid SiAlON/TiN Ceramic End Mills for Nickel Alloy Machining: Problems and Prospects. Coatings 2021, 11, 532. [Google Scholar] [CrossRef]

- Grigoriev, S.; Volosova, M.; Fyodorov, S.; Lyakhovetskiy, M.; Seleznev, A. DLC-coating application to improve the durability of ceramic tools. J. Mater. Eng. Perform. 2019, 28, 4415–4426. [Google Scholar] [CrossRef]

- Lou, J.; Gao, Z.; Zhang, J.; He, H.; Wang, X. Comparative Investigation on Corrosion Resistance of Stainless Steels Coated with Titanium Nitride, Nitrogen Titanium Carbide and Titanium-Diamond-like Carbon Films. Coatings 2021, 11, 1543. [Google Scholar] [CrossRef]

- Liskiewicz, T.W.; Al-Borno, A. DLC Coatings in Oil and Gas Production. J. Coat. Sci. Technol. 2014, 1, 59–68. [Google Scholar] [CrossRef]

- Marin, E.; Lanzutti, A.; Nakamura, M.; Zanocco, M.; Zhu, W.; Pezzotti, G.; Andreatta, F. Corrosion and scratch resistance of DLC coatings applied on chromium molybdenum steel. Surf. Coat. Technol. 2019, 378, 124944. [Google Scholar] [CrossRef]

- Guo, D.; Zhang, S.; Huang, T.; Wu, S.; Ma, X.; Guo, F. Corrosion Properties of DLC Film in Weak Acid and Alkali Solutions. Coatings 2022, 12, 1776. [Google Scholar] [CrossRef]

- Sara, K.; Eiman, A.; Mohammad, M.; Saeb, M.; Vahabi, H.; Kokanyan, N.; Laheurte, P. Magnetron-sputtered copper/diamond-like carbon composite thin films with super anti-corrosion properties. Surf. Coat. Technol. 2018, 333, 148–157. [Google Scholar] [CrossRef]

- Shang, L.; Gou, C.; Li, W.; He, D.; Wang, S. Effect of microstructure and mechanical properties on the tribological and electrochemical performances of Si/DLC films under HCl corrosive environment. Diam. Relat. Mater. 2021, 116, 108385. [Google Scholar] [CrossRef]

- Gadalov, V.; Vornacheva, I.; Voinash, S.; Ignatenko, V.; Remshev, E. The Influence of Thermocyclic Treatment on the Structure and Mechanical Properties of Pseudo-Alpha Titanium Alloys for Steam Turbine Blades. Mater. Sci. Forum 2021, 1031, 117–124. [Google Scholar] [CrossRef]

- Bhandari, L.; Kumar, J.; Balasundar, I.; Arora, A. Variability in Fatigue Life of Near-α Titanium Alloy IMI 834. Trans. Indian Inst. Met. 2021, 74, 979–989. [Google Scholar] [CrossRef]

- Daniel, J.; Žemlička, R.; Grossman, J.; Lümkemann, A.; Tapp, P.; Galamand, C.; Fořt, T. Comparison of Lifetime of the PVD Coatings in Laboratory Dynamic Impact Test and Industrial Fine Blanking Process. Materials 2020, 13, 2154. [Google Scholar] [CrossRef] [PubMed]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Milovich, F.; Andreev, N.; Bublikov, J. Investigation of wear mechanisms for the rake face of a cutting tool with a multilayer composite nanostructured Cr–CrN-(Ti,Cr,Al,Si)N coating in high-speed steel turning. Wear 2019, 438–439, 203069. [Google Scholar] [CrossRef]

- Fayed, S.M.; Chen, D.; Li, S.; Zhou, Y.; Wang, H.; Sadawy, M.M. Corrosion behavior and passive stability of multilayer DLC-Si coatings. Surf. Coat. Technol. 2022, 431, 128001. [Google Scholar] [CrossRef]

- Bociaga, D.; Sobczyk-Guzenda, A.; Komorowski, P.; Balcerzak, J.; Jastrzebski, K.; Przybyszewska, K.; Kaczmarek, A. Surface Characteristics and Biological Evaluation of Si-DLC Coatings Fabricated Using Magnetron Sputtering Method on Ti6Al7Nb Substrate. Nanomaterials 2019, 9, 812. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N.; Volosova, M.A.; Batako, A.; Vereschaka, A.A.; Sitnikov, N.N.; Seleznev, A.E. Nano-scale multi-layered coatings for improved efficiency of ceramic cutting tools. Int. J. Adv. Manuf. Technol. 2017, 90, 27–43. [Google Scholar] [CrossRef]

- Long, X.; Dong, R.; Su, Y.; Chang, C. Critical Review of Nanoindentation-Based Numerical Methods for Evaluating Elastoplastic Material Properties. Coatings 2023, 13, 1334. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Phiri, J.; Gladkov, V.I.; Ratnikov, S.N.; Yakovlev, M.G.; Levashov, E.A. Erosion and Abrasion Resistance, Mechanical Properties, and Structure of the TiN, Ti–Cr–Al–N and Cr–Al–Ti–N Coatings Deposited by CFUBMS. Prot. Met. Phys. Chem. Surf. 2019, 55, 913–923. [Google Scholar] [CrossRef]

- Lesnevskiy, L.N.; Lyakhovetskiy, M.A.; Savushkina, S.V. Fretting wear of composite ceramic coating produced on D16 aluminum-based alloy using microarc oxidation. J. Frict. Wear 2016, 37, 268–273. [Google Scholar] [CrossRef]

- Tessier, F. Determining the Nitrogen Content in (Oxy)Nitride Materials. Materials 2018, 11, 1331. [Google Scholar] [CrossRef] [PubMed]

- Miler, M.; Mirtič, B. Accuracy and precision of EDS analysis for identification of metal-bearing minerals in polished and rough particle samples. Geologija 2013, 56, 5–17. [Google Scholar] [CrossRef]

- Valiev, R.R.; Modina, Y.M.; Selivanov, K.S.; Semenova, I.P.; Khafizova, E.D.; Valiev, R.Z.; Savina, Y.N. Enhanced service properties of a protective coating on a titanium alloy with an ultrafine-grained structure. Mater. Lett. 2021, 305, 130781. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Z.; He, G. Alleviating the adverse influence of nitride coating on the fatigue performance of Ti6Al4V by Ni alloying. J. Mater. Res. Technol. 2023, 26, 517–529. [Google Scholar] [CrossRef]

- Voronin, N.A. The Effective and True Adhesive Strength of Thin Protective Coatings. J. Mach. Manuf. Reliab. 2019, 48, 320–327. [Google Scholar] [CrossRef]

- Majumdar, P.; Singh, S.B.; Chakraborty, M. Elastic modulus of biomedical titanium alloys by nano-indentation and ultrasonic techniques—A comparative study. Mater. Sci. Eng. A 2008, 489, 419–425. [Google Scholar] [CrossRef]

- Vereschaka, A.; Grigoriev, S.; Milovich, F.; Sitnikov, N.; Migranov, M.; Andreev, N.; Bublikov, J.; Sotova, C. Investigation of tribological and functional properties of Cr,Mo-(Cr,Mo) N-(Cr,Mo,Al)N multilayer composite coating. Tribol. Int. 2021, 155, 106804. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Beake, B.D. The influence of the H/E ratio on wear resistance of coating systems—Insights from small-scale testing. Surf. Coat. Technol. 2022, 442, 128272. [Google Scholar] [CrossRef]

- Volosova, M.; Grigoriev, S.; Metel, A.; Shein, A. The Role of Thin-Film Vacuum-Plasma Coatings and Their Influence on the Efficiency of Ceramic Cutting Inserts. Coatings 2018, 8, 287. [Google Scholar] [CrossRef]

- Drobný, P.; Mercier, D.; Koula, V.; Škrobáková, S.I.; Čaplovič, Ľ.; Sahul, M. Evaluation of Adhesion Properties of Hard Coatings by Means of Indentation and Acoustic Emission. Coatings 2021, 11, 919. [Google Scholar] [CrossRef]

- Vereschaka, A.S.; Grigoriev, S.N.; Sotova, E.S.; Vereschaka, A.A. Improving the efficiency of the cutting tools made of mixed ceramics by applying modifying nano-scale multilayered coatings. Adv. Mater. Res. 2013, 712–715, 391–394. [Google Scholar] [CrossRef]

- Zlamal, T.; Mrkvica, I.; Szotkowski, T.; Malotova, S. The Influence of Surface Treatment of PVD Coating on Its Quality and Wear Resistant. Coatings 2019, 9, 439. [Google Scholar] [CrossRef]

- Benti, H.G.; Woldeyohannes, A.D.; Yigezu, B.S. Improving the Efficiency of Cutting Tools through Application of Filtered Cathodic Vacuum Arc Deposition Coating Techniques: A Review. Adv. Mater. Sci. Eng. 2022, 2022, 1450805. [Google Scholar] [CrossRef]

- Zia, A.W.; Zhou, Z.; Li, L.K.Y. A new approach to create isolated carbon particles by sputtering: A detailed parametric study and a concept of carbon particles embedded carbon coatings. Diam. Relat. Mater. 2017, 76, 97–107. [Google Scholar] [CrossRef]

- Chen, J.; Bull, S.J. Approaches to investigate delamination and interfacial toughness in coated systems: An overview. J. Phys. D Appl. Phys. 2011, 44, 34001. [Google Scholar] [CrossRef]

- Dolgov, N.A. Analytical methods to determine the stress state in the substrate-coating system under mechanical loads. Strength Mater. 2016, 48, 658–667. [Google Scholar] [CrossRef]

- Fang, G.; Ren, J.; Shi, J.; Gao, X.; Song, Y. Thermal Stress Analysis of Environmental Barrier Coatings Considering Interfacial Roughness. Coatings 2020, 10, 947. [Google Scholar] [CrossRef]

- Vereschaka, A.; Grigoriev, S.; Chigarev, A.; Milovich, F.; Sitnikov, N.; Andreev, N.; Sotova, C.; Bublikov, J. Development of a Model of Crack Propagation in Multilayer Hard Coatings under Conditions of Stochastic Force Impact. Materials 2021, 14, 260. [Google Scholar] [CrossRef] [PubMed]

| Material | Elements Composition, % Mass | |||||||

|---|---|---|---|---|---|---|---|---|

| Ti | Al | Zr | Sn | Nb | Mo | Si | Admixtures | |

| BT18U | 84.5 | 6.8 | 4.2 | 2.1 | 1.2 | 0.8 | 0.25 | 0.15 |

| Material | Tensile Strength, MPa | Impact Toughness, kJ/m2 | Relative Elongation, % | Hardness HRC |

|---|---|---|---|---|

| BT18U | 1010 ± 40 | 230 ± 6 | 9 ± 2 | 34 ± 2 |

| Coating Composition | Applied Load, mN | Martens Hardness, GPa | Elastic Modulus, GPa | Coating Thickness, μm |

|---|---|---|---|---|

| Cr-Al-Si-N | 4.0 | 30 ± 3 | 370 ± 7 | 3.2 ± 0.15 |

| DLC-Si | 23 ± 2 | 248 ± 7 | 2.3 ± 0.1 | |

| Cr-Al-Si-N/DLC-Si | 24 ± 1 | 185 ± 8 | 3.1 ± 0.15/2.0 ± 0.1 |

| Group of Samples | Sample Types | Parameter Values of the Surface Layer Profile | |

|---|---|---|---|

| Total Height of the Profile Rt, μm | Arithmetic Mean Deviation of the Assessed Profile Ra, μm | ||

| After finishing milling | BT18U | 3.5 | 0.55 |

| With Cr-Al-Si-N coating | 3.8 | 0.26 | |

| With DLC-Si coating | 2.8 | 0.2 | |

| With Cr-Al-Si-N/DLC-Si coating | 3.6 | 0.32 | |

| After lapping with micro-grained abrasive | BT18U | 0.49 | 0.03 |

| With Cr-Al-Si-N coating | 1.6 | 0.09 | |

| With DLC-Si coating | 1.9 | 0.07 | |

| With Cr-Al-Si-N/DLC-Si coating | 1.7 | 0.08 | |

| Coatings | Element Number | Element Symbol | Element Name | Atomic Concentration, % | Atomic Concentration Error, % 1 | Weight Concentration, % | Weight Concentration Error, % 2 |

|---|---|---|---|---|---|---|---|

| Cr-Al-Si-N | 22 | Ti | Titanium | 49.69 | 0.25 | 70.31 | 0.26 |

| 8 | O | Oxygen | 34.10 | 1.71 | 16.12 | 0.60 | |

| 7 | N | Nitrogen | 5.62 | 0.28 | 3.02 | 0.09 | |

| 13 | Al | Aluminum | 7.63 | 0.04 | 6.52 | 0.02 | |

| 40 | Zr | Zirconium | 2.96 | 0.01 | 4.03 | 0.03 | |

| DLC-Si | 22 | Ti | Titanium | 48.12 | 0.24 | 69.89 | 0.25 |

| 8 | O | Oxygen | 33.02 | 1.65 | 15.6 | 0.57 | |

| 7 | N | Nitrogen | 5.38 | 0.27 | 3.04 | 0.08 | |

| 13 | Al | Aluminum | 6.76 | 0.03 | 5.98 | 0.02 | |

| 6 | C | Carbon | 4.5 | 0.23 | 2.21 | 0.06 | |

| 40 | Zr | Zirconium | 2.22 | 0.01 | 3.28 | 0.02 | |

| Cr-Al-Si-N/DLC-Si | 8 | O | Oxygen | 23.16 | 1.16 | 15.25 | 0.40 |

| 7 | N | Nitrogen | 21.72 | 1.09 | 13.02 | 0.33 | |

| 24 | Cr | Chromium | 20.96 | 0.10 | 33.87 | 0.12 | |

| 13 | Al | Aluminum | 20.06 | 0.10 | 21.90 | 0.06 | |

| 22 | Ti | Titanium | 5.22 | 0.03 | 8.89 | 0.03 | |

| 14 | Si | Silicon | 4.99 | 0.02 | 5.05 | 0.02 | |

| 6 | C | Carbon | 3.89 | 0.19 | 2.02 | 0.05 |

| Group of Samples | Exposure Time, min | Volume Abrasive Wear, ×103 μm3 | |||

|---|---|---|---|---|---|

| Uncoated Samples | Cr-Al-Si-N Coating | DLC-Si Coating | Cr-Al-Si-N/DLC-Si Coating | ||

| Coatings deposited after finishing milling | 5 | 8454 | 2753 | 324 | 177 |

| 10 | 12,485 | 3631 | 1271 | 1149 | |

| 15 | 18,182 | 4846 | 1377 | 1475 | |

| 20 | 62,831 | 5452 | 2459 | 1986 | |

| Coatings deposited after lapping with micro-grained abrasive | 5 | 6767 | 913 | 205 | 188 |

| 10 | 19,739 | 1996 | 459 | 434 | |

| 15 | 26,360 | 2641 | 803 | 774 | |

| 20 | 64,322 | 4214 | 1993 | 1809 | |

| Group of Samples | Number of Cycles | Load, N | Offset, μm | Volume Abrasive Wear, ×103 μm3 | |||

|---|---|---|---|---|---|---|---|

| Uncoated Samples | Cr-Al-Si-N Coating | DLC-Si Coating | Cr-Al-Si-N/DLC-Si Coating | ||||

| Coatings deposited after finishing milling | 100,000 | 1 | 60 | 1239 (min) | 673 (min) | 13 (min) | 1.1 (min) |

| 1429 (max) | 780 (max) | 17 (max) | 1.8 (max) | ||||

| 300,000 | 20 | 100 | – | – | 10,939 (min) | 458 (min) | |

| – | – | 13,820 (max) | 746 (max) | ||||

| Coatings deposited after lapping with micro-grained abrasive | 25,000 | 1 | 60 | 568 (min) | 156 (min) | 5 (min) | 1.1 (min) |

| 825 (max) | 182 (max) | 9 (max) | 1.3 (max) | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Volosova, M.A.; Lyakhovetsky, M.A.; Mitrofanov, A.P.; Melnik, Y.A.; Okunkova, A.A.; Fedorov, S.V. Influence of Cr-Al-Si-N and DLC-Si Thin Coatings on Wear Resistance of Titanium Alloy Samples with Different Surface Conditions. Coatings 2023, 13, 1581. https://doi.org/10.3390/coatings13091581

Volosova MA, Lyakhovetsky MA, Mitrofanov AP, Melnik YA, Okunkova AA, Fedorov SV. Influence of Cr-Al-Si-N and DLC-Si Thin Coatings on Wear Resistance of Titanium Alloy Samples with Different Surface Conditions. Coatings. 2023; 13(9):1581. https://doi.org/10.3390/coatings13091581

Chicago/Turabian StyleVolosova, Marina A., Maxim A. Lyakhovetsky, Artem P. Mitrofanov, Yury A. Melnik, Anna A. Okunkova, and Sergey V. Fedorov. 2023. "Influence of Cr-Al-Si-N and DLC-Si Thin Coatings on Wear Resistance of Titanium Alloy Samples with Different Surface Conditions" Coatings 13, no. 9: 1581. https://doi.org/10.3390/coatings13091581

APA StyleVolosova, M. A., Lyakhovetsky, M. A., Mitrofanov, A. P., Melnik, Y. A., Okunkova, A. A., & Fedorov, S. V. (2023). Influence of Cr-Al-Si-N and DLC-Si Thin Coatings on Wear Resistance of Titanium Alloy Samples with Different Surface Conditions. Coatings, 13(9), 1581. https://doi.org/10.3390/coatings13091581