Abstract

A nano-silver solution, urea-formaldehyde resin-coated nano-silver solution microcapsules (AgNPS@UF), and melamine-formaldehyde resin-coated chitosan-modified nano-silver solution microcapsules (CS-AgNPS@MF) were added into the coatings at different contents for comparative tests to explore an anti-bacterial agent with the best anti-bacterial properties in the water-based coatings on Andoung wood (Monopetalanthus spp.). As the content of anti-bacterial agents increased, AgNPS@UF had the best anti-bacterial property towards Staphylococcus aureus and Escherichia coli, with anti-bacterial rates of 79.0% and 82.1%, respectively. The optical and mechanical properties of the coating quickly worsened as the content of anti-bacterial agents increased. The anti-bacterial coatings with AgNPS@UF have the minimum chromatic aberration change of 6.5. The anti-bacterial coating with 5% content of AgNPS@UF decreased the aging rate. This coating had good optical properties, and its liquid-resistant level is 2. When the 5% content of AgNPS@UF was added, after high-temperature accelerated aging and ultraviolet (UV) aging, the anti-bacterial rates of the coating with AgNPS@UF decreased toward Escherichia coli from 82.1% to 62.2% and decreased toward Staphylococcus aureus from 79.3% to 61.1%, respectively. This shows that the coating had a long-lasting anti-bacterial property. The anti-bacterial property of the coating after high-temperature accelerated aging was superior to that after the UV aging. The incorporation of AgNPS@UF in water-based coatings protects people from the risks of Escherichia coli and Staphylococcus aureus more effectively with long-lasting property. The research results provide a reference for the preparation of anti-bacterial water-based coatings on the surface of the Andoung wood.

1. Introduction

Wood is used extensively in the furniture industry [1,2,3]. Due to the extremely limited amount of wood, wood needs to be utilized with high quality and efficiency [4,5]. A coating process is widely applied on wood surfaces. The adhesives used in the most coating processes, like the adhesives used in the furniture assembly process mentioned above, can produce harmful substances [6], causing a lot of pollution. Environmentally friendly materials should be protected and reasonably utilized. An ecological concept of sustainable development should be upheld, and this concept will continue forever. [7]. Wood is susceptible to invasion by pests, pathogens, fungi, and other microorganisms [8], which makes the wood easily damaged and shortens the service period of furniture. Andoung wood (Monopetalanthus spp.) is a porous material that is lightweight with a medium strength. Andoung wood is easy to work with and has good nail grip, wear resistance, corrosion resistance, and fast-drying properties. However, Andoung wood is prone to warping and cracking, and it is often subject to a microbial attack by bacteria and other organisms. The wood surface needs to be treated with an anti-bacterial treatment. An anti-bacterial agent is applied to the wood surface by a coating process to form an anti-bacterial coating. The majority of wood substrates are treated with coatings. The coating helps keep the structure and composition of the wood stable. The coating can also decorate the surface [9,10,11]. Water-based coatings have excellent properties such as safety and environmental friendliness [12]. An anti-bacterial solution that is added to coatings can provide a certain anti-bacterial property without affecting the properties of the substrate [13,14,15,16]. A nano-silver solution is environmentally friendly and non-toxic [17], but an exposure of nano-silver to the air not only reduces the anti-bacterial properties of coatings but also affects the transparency of the coatings, causing a low decorative effect of the coatings on the wood surface [18].

Microcapsules are controlled release and insulating [19]. When added to coatings, the microcapsules can provide a variety of properties to the substrate surface without affecting the original substrate structure. In a coating process, the use of microcapsules that are added to the coating is more convenient and has a better decorative effect on the surface [20]. However, an anti-bacterial activity needs to be guaranteed while also considering the durability of the anti-bacterial property. Therefore, to ensure the durability of the anti-bacterial properties of the coating, the anti-bacterial agent needs to be encapsulated in microcapsules. There was a relationship between the content of the anti-bacterial agent and the anti-bacterial property of the coating. When the content of the anti-bacterial agent was increased, the anti-bacterial property of the coating was enhanced accordingly. But if the amount of anti-bacterial agent was too high, it might affect the physical properties and the durability of the coating. Thus, the amount of anti-bacterial agent needed to be controlled to ensure that the coating has good anti-bacterial properties while meeting other property requirements.

In this paper, the nano-silver solution, urea-formaldehyde resin-coated nano-silver solution microcapsules (AgNPS@UF), and melamine-formaldehyde resin-coated chitosan-modified nano-silver solution microcapsules (CS-AgNPS@MF) were used as three anti-bacterial agents. The anti-bacterial coatings were prepared at 1%, 2%, 3%, 4%, 5%, 6%, and 7% content of anti-bacterial agents, respectively. The mechanical, optical, and other physicochemical properties of the coatings were investigated. The anti-bacterial durability of the coatings was investigated by both ultraviolet (UV) aging and high-temperature accelerated aging. The optical properties of the coatings were compared before and after aging to select the optimum anti-bacterial agent. The aim of this study is to investigate the factors affecting the anti-bacterial properties of water-based coatings toward Staphylococcus aureus and Escherichia coli. And the aim is also to discover an anti-bacterial agent with a higher anti-bacterial rate. The core wall structure of microcapsules isolates internal anti-bacterial agents from the outside environment and prolongs the duration of the anti-bacterial property. The microcapsules cause a slow release of the anti-bacterial agent, thus they have a long-lasting anti-bacterial property. Therefore, it can be assumed that the anti-bacterial agent encapsulated into microcapsules will have better anti-bacterial properties in the coating.

2. Materials and Methods

2.1. Materials

The base material was the Andoung wood. The Andoung wood is the radial heartwood, the density is approximately 0.75 g/cm3, and the size is 50 mm × 100 mm × 5 mm. The wood was pre-treated in a constant temperature and humidity chamber before the test, with a moisture content controlled to within 15%. After the pre-treatment, the density of the wood reached 0.7 g/cm3. The surface was sanded with 800# sandpaper to make it burr-free and smooth. The surface was wiped off with a damp cloth to complete the pre-treatment of the wood. The required materials for the test are shown in Table S1.

2.2. Preparation of Microcapsules

2.2.1. AgNPS@UF

The preparation method of AgNPS@UF was developed from previous studies [21].

(1) Preparation of wall materials urea-formaldehyde (UF) prepolymer: The 7.0 g urea and 9.47 g formaldehyde were weighed according to the molar ratio of 1:1. After adding the magnetic rotor to the beaker, the beaker was placed in a water bath. The mixture was stirred thoroughly. The temperature of the reaction was set at 70 °C. The rotation speed was set to 1000 r/min. The 2 mL of triethanolamine was added dropwise to the beaker to bring the pH value of the solution to 8–9. A layer of plastic wrap was placed over the mouth of the beaker to prevent the prepolymer from deteriorating in contact with air. After approximately 30 min, the solution became colorless and transparent. The solution was cooled naturally at room temperature.

(2) Preparation of core emulsion: The 8.4 g of nano-silver solution was weighed for use. The 33.6 g of ethanol, the 0.75 g of Span-80, and 0.05 g of Tween-80 were weighed, added into a beaker, respectively, and stirred with a glass rod until dissolved. The emulsifier concentration was approximately 2%. The emulsifier solution was added dropwise to the nano-silver solution. The temperature of the water bath was controlled at 60 °C. And the rotation speed was at 1000 r/min. The core solution was emulsified for 1 h.

(3) Preparation of AgNPS@UF: The rotation speed of the water bath was kept at 1000 r/min. The UF prepolymer was added slowly and drop-by-drop to the core emulsion using a dropper. The pH value of the solution was adjusted to approximately 2.5–3 using 8% citric acid monohydrate. The reaction was completed in a water bath for 3 h. After 3 days, the uncoated wall materials, core materials, and remaining emulsion were repeatedly rinsed in a vacuum extractor using the distilled water and ethanol. The microcapsules were poured into Petri dishes and dried in an oven at 60 °C for 48 h to obtain the AgNPS@UF.

2.2.2. CS-AgNPS@MF

(1) Dissolution of chitosan: The 30 g of acetic acid solution with a concentration of 1% was prepared. The 0.36 g of chitosan powders were weighed and added to the acetic acid solution to degrade the chitosan. The pH value was adjusted to 5 using 0.5 mol/L NaOH. The temperature of the water bath was set to 30 °C. The solution was stirred with a magnetic stirring rotor for 30 min to obtain a clear, transparent, and thick chitosan solution.

(2) Preparation of chitosan-modified nano-silver solution (CS-AgNPS) as an anti-bacterial agent: In accordance with the ratio of chitosan to silver ions, the 9 g nano-silver solution was slowly dripped into the chitosan solution that was completely dissolved in the previous step. The CS-AgNPS anti-bacterial agent was obtained after thorough stirring [22,23].

(3) Preparation of melamine-formaldehyde prepolymer (the wall materials): The 14.52 g of 37% formaldehyde solution and 7.29 g of melamine were added to the beaker in a molar ratio of 3:1. The 36.45 mL of distilled water was added. The solution was stirred slowly using a magnetic stirring rotor. The pH value of the solution was adjusted to 8–9 by adding the triethanolamine dropwise. The temperature of the water bath was raised to 70 °C and stirred at 800 r/min for 30 min to obtain the melamine-formaldehyde prepolymer.

(4) Emulsification of CS-AgNPS (the core material): The 1.5% Span-80 emulsifier solution was prepared using 0.75 g of Span-80 and 49.25 g of ethanol. The CS-AgNPS was added dropwise to the beaker. After thorough stirring again, the temperature of the water bath was adjusted to 60 °C. Then, the reaction was carried out at 800 r/min for 1 h to obtain the core emulsion.

(5) After the melamine-formaldehyde prepolymer cooled to room temperature, the water bath was maintained at a low rotation speed. The melamine-formaldehyde prepolymer was slowly added to the CS-AgNPS using a dropper. The pH value was then adjusted to approximately 3.5 with citric acid monohydrate. When the temperature was raised to 60 °C, the reaction was maintained at a constant temperature for 3 h.

(6) After 3 days of placement, the solution showed significant sedimentation. The sediment was repeatedly rinsed with absolute ethanol using a distillation vacuum extractor until the liquid after filtration was clear. The CS-AgNPS@MF were obtained after drying in an oven at 60 °C for 2 days.

2.3. Coating Preparation

AgNPS@UF, CS-AgNPS@MF, and the nano-silver solution as three anti-bacterial agents were added into the water-based coatings at the content of 1%, 2%, 3%, 4%, 5%, 6%, and 7%, respectively, to prepare the anti-bacterial coating. The specific formulation scheme of the coating is shown in Table 1. The mass of the anti-bacterial coating was fixed at 4 g. The coatings were applied on Andoung wood using a manual brushing method, with 1 g of coating per layer, for a total of 4 layers at approximately 0.02 g/cm2. After applying the first primer, the coated Andoung wood was placed in an oven at 60 °C for 20 min to dry and was then removed. The dry primer was sanded smooth with 800# sandpaper before applying the second primer. Following the above method, after applying the first top coat, the coated Andoung wood was placed into a 60 °C oven to dry for 20 min and was then removed. The surface of the top coat was smoothly sanded with 800# sandpaper. Then the second top coat was applied. After the coating had dried naturally for 12 h, the anti-bacterial properties of the coatings could be tested.

Table 1.

Anti-bacterial coating configuration parameters.

2.4. Testing and Characterisation

2.4.1. Optical Properties

(1) Chromatic aberration: According to GB/T 11186.3-1989 [24], an SEGT-J color difference meter (Suzhou Weifu Photoelectric Technology Co., Ltd., Suzhou, China) was used to measure the colorimetric values of coatings. The test positions of the coating were fixed. The L, a, and b colorimetric values were recorded. The coating without the microcapsules was used as a reference sample. The chromatic aberration between the coating with and without the microcapsules, ΔE, was obtained by using Equation (1). The L* indicates the brightness difference of the anti-bacterial coating, the a* indicates the red-green difference of the anti-bacterial coating, and the b* indicates the yellow-blue difference of the anti-bacterial coating.

ΔE = [(ΔL*)2 + (Δa*)2 + (Δb*)2]1/2

(2) Gloss: According to GB/T 9754-2007 [25], by using an HG268 intelligent gloss meter (Shenzhen Linshang Technology Co., Ltd., Shenzhen, China), the gloss of anti-bacterial coatings with the microcapsules was tested at the 20°, 60°, and 85° incidence angles, respectively. The gloss of anti-bacterial coatings with and without the microcapsules were then compared to each other. The higher the gloss, the better the coating appearance.

2.4.2. Mechanical Properties

(1) Hardness: According to GB/T 6739-2006 [26], the 6 H-6 B pencils (Shenzhen Forest Precision Instrument Co., Ltd., Guangzhou, China) were used to measure the coating hardness. The pencil was kept at 45° to the coating under a load of 1.0 kg for the scratch test. The maximum pencil hardness which was used to scratch the coating was recorded as the coating hardness.

(2) Adhesion: By GB/T 4893.4-2013 [27], the adhesion was tested with a QFH-HG600 coating scriber (Hebei Zhongke Beigong Test Instrument Co., Ltd., Cangzhou, China). A blade was used to scratch the coating at 90° vertically to form the grid lines. Afterwards, an area in grid lines was quickly adhered to with a tape and then removed for observing the peeling of the coating. The adhesion level was in descending order from 0 to 5. The coating did not peel at level 0.

2.4.3. Chemical Properties

- (1)

- Microstructure morphology and chemical composition

A Zeiss Axio Scope A1 optical microscope (OM, Carl Zeiss, Oberkohen, Germany), and a Zeiss Sigma 300 scanning electron microscope (SEM, FEI Company, Hillsboro, OR, USA) were used to observe the morphology of the coating microstructure before and after the anti-bacterial test. The chemical compositions of the coating before and after anti-bacterial test were analyzed by a VERTEX 80 V infrared spectrometer (FTIR, Bruker GmbH, Karlsruhe, Germany) in the range of 4000–500 cm−1.

- (2)

- Aging test

In accordance with GB/T 1740-2007 [28] and the Feller artificial accelerated aging test method, the blast drying oven was thermostatically controlled at 120 °C. The prepared coatings were tested for UV photo-oxidation using UVA-340 fluorescent lamps. By simulating the UV visible light in natural light as the light source, the UV aging of the coating was accelerated through a UV irradiation. The temperature range of the UV aging was 10 °C to 70 °C with the humidity ≥95%. The chromatic aberration and gloss of the Andoung wood surface coating were tested at time intervals to characterize the changes in the coating before and after aging.

- (3)

- Resistance to cold liquid

Referring to GB/T 4893.1-2021 [29], the coating surface was prepared to be clean and free from bacterial infestation in advance. A filter paper was cut into round pieces and wetted in the cold liquid. Then, the filter paper was picked up with tweezers and moved to the coating. It was coated with glassware at this time for approximately 16–24 h. After removing the filter paper, the glassware was coated again. The liquid was wiped from the surface after 24 h. The sample was placed under natural light to check the damage to the coating. Comparing the test area with the surroundings, the coating property of cold liquid resistance was rated according to phenomena such as swelling, bulging, and fibrous protrusion, with levels 1–5 in order. The standard for the liquid-resistant levels of the coating is shown in Table 2.

Table 2.

Standard for the liquid-resistant level of the coating.

- (4)

- Anti-bacterial test

The Escherichia coli and Staphylococcus aureus slant media were preserved at 0–5 °C. The Escherichia coli and Staphylococcus aureus for the test were inoculated onto the nutrient agar medium plates at a constant temperature of 36–38 °C. The nutrient agar medium plates with the Escherichia coli and Staphylococcus aureus were incubated in the constant temperature and humidity chamber for 18–20 h. A small number of fresh bacteria was then scraped onto the nutrient agar medium using an inoculation loop. The bacteria were added to the nutritious broth fluid. The required concentration of the nutritious broth fluid for the test was (5.0–10.0) × 105 cfu/mL (number of colonies per mL of sample) of the bacterial solution.

According to the GB/T 4789.2-2022 standard [30], a pipette was used to take the 0.4 mL–0.5 mL of test bacterial solution to add dropwise onto the blank control sample and the anti-bacterial coating sample, respectively. A plastic film was sterilized for use. Using the sterilized forceps, the sample was covered with the plastic film. It was necessary to ensure that there were no air bubbles between the plastic film and the sample. The suspension was gently pressed down to spread in all directions so that the sample could be touched evenly by the bacteria. The samples were placed in the constant temperature and humidity chamber for 24 h, with the temperature controlled at 38 °C and relative humidity >90%.

The samples’ surface and plastic films were repeatedly rinsed using 20 mL of eluent. The eluent with Escherichia coli and Staphylococcus aureus was added to the nutrient agar medium plates. The nutrient agar medium plates containing bacteria were prepared completely after the temperature had been lowered to 45 °C and when the nutrient agar had solidified. Colonies were produced after 48 h incubation in a constant temperature and humidity chamber at 38 °C. The number of live bacteria was counted by a colony counter. The number of live bacteria determined above was multiplied by 1 × 103 for the actual value of live bacteria recovered from each sample after 24 h incubation as in Equation (2).

R = (B − C)/B

R = anti-bacterial rate, expressed in %.

B = the actual value of live bacteria recovered after 24 h incubation for the blank control sample, in CFU.

C = the actual value of live bacteria recovered after 24 h incubation for anti-bacterial coating, in CFU.

Four replications were completed for each sample. The test results show good reproducibility within a 5% error. A new sample was used for each test.

3. Results and Discussion

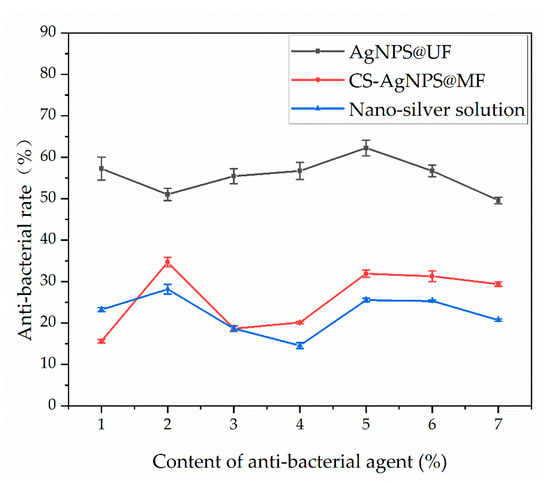

3.1. Effect of Anti-bacterial Agents on the Anti-bacterial Properties of the Coatings

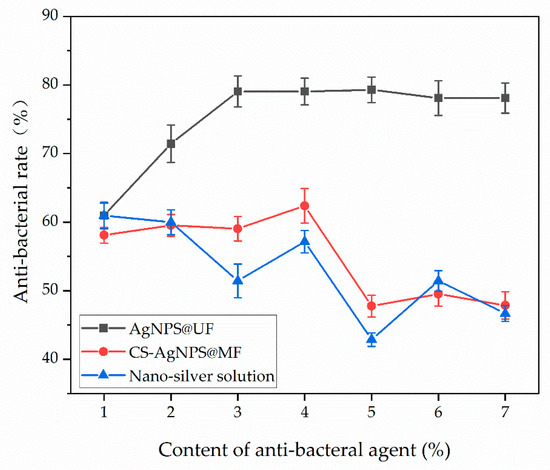

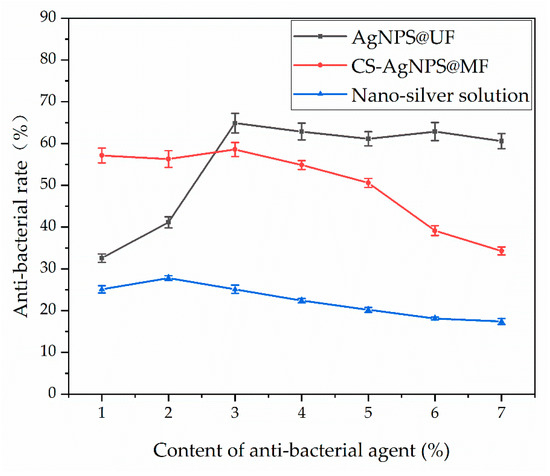

The effect of the three anti-bacterial agents with different contents on the anti-bacterial properties of the coating toward Staphylococcus aureus is shown in Figure 1. The effect of the AgNPS@UF as the anti-bacterial agent shows an increasing trend with increasing content. However, the effect of the CS-AgNPS@MF and the nano-silver solution as the anti-bacterial agents show the opposite trend. At the content of 1%, the anti-bacterial rate of the nano-silver solution was up to 61%. This shows that the nano-silver solution was inherently anti-bacterial. The coatings with AgNPS@UF show the anti-bacterial rate of up to 79% at 3% and 4% content of AgNPS@UF. The coatings with CS-AgNPS@MF show the anti-bacterial rate of up to 62.4% at the 4% content of AgNPS@UF. The two kinds of microcapsules were superior to the uncoated nano-silver solution as anti-bacterial agents.

Figure 1.

Anti-bacterial properties toward the Staphylococcus aureus of the coating with three anti-bacterial agents.

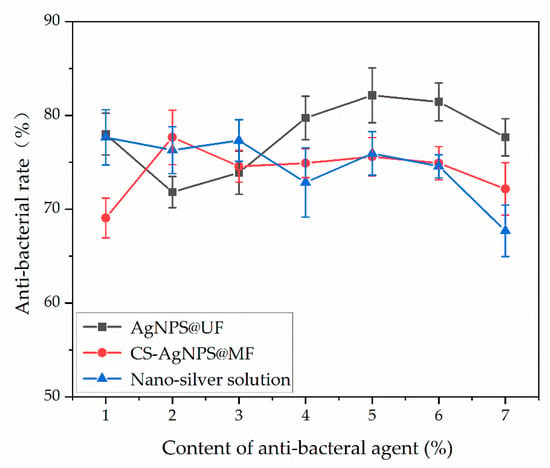

Anti-bacterial coatings prepared at different contents of anti-bacterial agents toward the Escherichia coli were analyzed for anti-bacterial properties as shown in Figure 2. The AgNPS@UF were superior to CS-AgNPS@MF when the content of anti-bacterial agents was 1–3%, while the nano-silver solution showed excellent anti-bacterial properties with an anti-bacterial rate of up to 77.7%. The AgNPS@UF failed to achieve a certain anti-bacterial property due to lower added content. The low AgNPS@UF content affected the overall anti-bacterial properties of the coatings. It also indicated that the release of anti-bacterial agents from the micropores of AgNPS@UF was hampered. Whereas the nano-silver solution, which was unencapsulated into the microcapsules alone, was able to present a good anti-bacterial property at low content due to the absence of the wall material encapsulation. As shown in Figure 2, the anti-bacterial properties of the coating with AgNPS@UF were the best, reaching a maximum anti-bacterial rate of 82.1% at AgNPS@UF content of 5%. The other two anti-bacterial agents were close to each other, with anti-bacterial rates of 75.6% and 75.9%, respectively, at 5% content of anti-bacterial agent. However, as the content of anti-bacterial agents continued to increase, three anti-bacterial agents showed an apparent downward trend. At the same content of anti-bacterial agent, coatings with AgNPS@UF had good anti-bacterial properties, especially for anti-bacterial properties toward the Staphylococcus aureus, because Escherichia coli were inhibited at the low concentration of silver ions, whereas the growth-inhibitory effects on Staphylococcus aureus were mild [31]. Through statistical analysis [32], a significant difference for the anti-bacterial properties toward the Staphylococcus aureus of coating was found, as shown in Table S2. As shown in Table S3, there is no difference for the anti-bacterial properties toward the Escherichia coli of coating. The anti-bacterial properties decreased at high contents of anti-bacterial agents. It showed that nano-silver solution only requires a small amount to achieve good anti-bacterial properties. It also indicated that the silver ions have strong anti-bacterial properties toward the Escherichia coli, so the three anti-bacterial agents have the same and good anti-bacterial properties toward Escherichia coli. The nano-silver solution only guaranteed the anti-bacterial properties of the coating in the short term. The microcapsules, instead, had the advantage of being able to encapsulate the nano-silver solution, so that they could improve the anti-bacterial properties of the coating due to the core wall structure which has a microporous wall to achieve a slow release of core materials.

Figure 2.

Anti-bacterial properties toward Escherichia coli of the coating with three anti-bacterial agents.

3.2. Effect of Anti-Bacterial Agents on Physicochemical Properties of Coatings

3.2.1. Gloss

Table 3 shows the gloss measured at 20°, 60°, and 85° incidence angles for three types of coatings with the anti-bacterial microcapsules and the nano-silver solution, respectively.

Table 3.

Surface coating gloss with different contents of anti-bacterial agents.

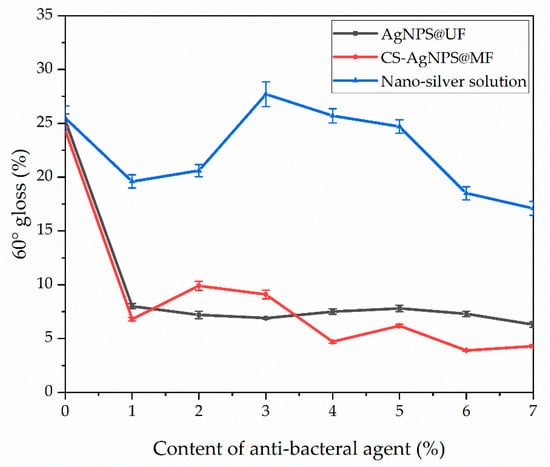

Concerning the standard for the gloss test [33], the gloss at 60° as the reference value is shown in Figure 3. The gloss of the coating with the nano-silver solution was the best among the three anti-bacterial agents. The average gloss value of the coating without the two types of microcapsules was up to 25.0%. With the increasing content of nano-silver solution, the gloss tended to decrease. The reason was that the water-based coating had a soft hardness with water as a main medium. The nano-silver solution was prepared by physical methods which also contained water as the medium. When the content of the anti-bacterial agent was ≥4%, the gloss of the coatings with the microcapsules gradually decayed. The trend of the gloss curve also tended to level off. At the same content, the gloss of coating with AgNPS@UF were better than those with CS-AgNPS@MF. At the 5% content of AgNPS@UF, the gloss of the coating with AgNPS@UF was 7.8%, while the gloss of the coating with CS-AgNPS@MF was only 6.3%. As shown in Tables S4–S6, there is a significant difference for the coating gloss. The coating gloss with two kinds of microcapsules was inferior to that with uncoated nano-silver solution as the anti-bacterial agent. The microcapsules are the core wall structure, while the wall materials themselves were white. When the microcapsules were added to the water-based coating, the agglomerates occurred making the microcapsules stick together, which increased the roughness [34] and led to a decrease in the gloss of the coatings.

Figure 3.

Gloss trend of anti-bacterial coatings with different contents of anti-bacterial agents.

3.2.2. Mechanical Properties

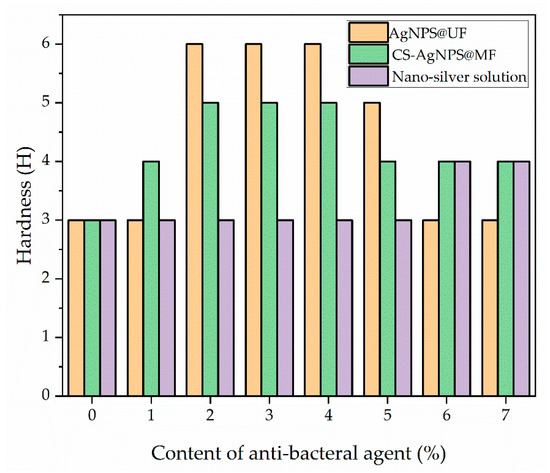

Figure 4 shows the trend in hardness for different anti-bacterial coatings. The hardness of the coating without the microcapsules was 3 H. The hardness of the coating did not change by increasing the amount of nano-silver solution. When the 6%–7% content of the nano-silver solution was added, the hardness of the coating reached 4 H. In this case, the proper amount of nano-silver solution relieved the stress on the coating. The hardness of the coating with AgNPS@UF increased with the increased content, indicating that the microcapsules added to the water-based coating increased the strength of the interface between the coating and the wood. The main reason was that UF resin as a polymer material had good mechanical properties such as tensile resistance. The anti-bacterial coating could play a role in resisting external forces [35,36], but the hardness of the coating decreased when the AgNPS@UF content was 5%. When the AgNPS@UF and CS-AgNPS@MF content was increased from 4% to 7%, the high content microcapsules changed the internal coating structure. The density was affected and led to an increase in the internal stress of the coating, therefore, the hardness of the water-based coating with AgNPS@UF and CS-AgNPS@MF decreased. The hardness of coatings first increases and then decreases with the increasing content of AgNPS@UF and CS-AgNPS@MF, while that with nano-silver solution remains unchanged and then increases. The hardness of coating with appropriate microcapsule content is higher than that without microcapsules.

Figure 4.

The hardness of anti-bacterial coatings with different contents of anti-bacterial agents.

The adhesion was a standard for testing the mechanical properties of the coating. As shown in Table 4, variation occurred in the adhesion of the coating with different contents of anti-bacterial agents.

Table 4.

Adhesion of anti-bacterial coatings with different contents of anti-bacterial agents.

The adhesion of the coating obtained by adding the nano-silver solution directly with the water-based coating was level 0. The coating did not peel off when the coating was scratched with a lattice knife and then removed with the tape. The water-based coating had good adhesion. When the nano-silver solution was encapsulated in the UF resin, the adhesion of the coating gradually decreased. The microcapsules damaged the coating structure. The UF resin, as the wall materials, had its disadvantages of brittleness and poor toughness. When the AgNPS@UF content was 3%, the adhesion of the coating with AgNPS@UF decreased to level 3. Meanwhile, the adhesion level of the coating with CS-AgNPS@MF was low. When the CS-AgNPS@MF content was 1%, the coating adhesion was level 3. As shown in Table S7, there was a significant difference for the coating adhesion. The coatings’ adhesion with two kinds of microcapsules were inferior to that with nano-silver solution as anti-bacterial agents. The reason is that the microcapsules were damaged due to stress concentration, reducing the coating adhesion. When subjected to forces, the decrease in bonding viscosity of the coating to the wood surface led to peeling of the coating.

3.3. Effect of High-Temperature Accelerated Aging on Chromatic Aberration

The energy absorbed by the substances that make up the coating exceeds the bond energy, leading to degradation reactions. After aging, the surface of the coating will be damaged by powdering, cracks, bubbles, and other aging phenomena such as oxidation, yellowing, fading, and embrittlement [37,38], which leads to changes in the color of the coating.

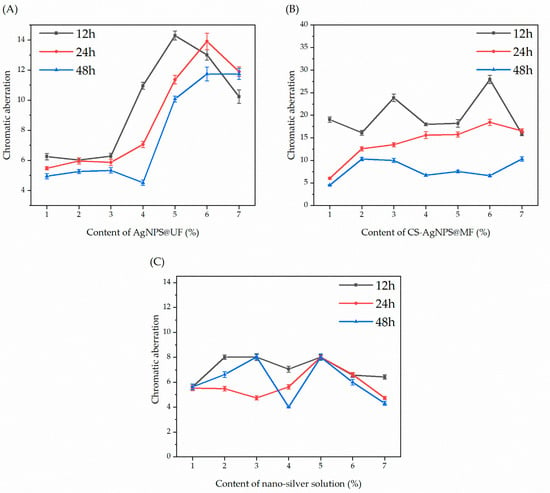

The trend in chromatic aberration of the coating after high-temperature accelerated aging with different anti-bacterial agents is shown in Figure 5. Figure 5A shows the chromatic aberration of the anti-bacterial coating with AgNPS@UF. The chromatic aberration of the coating applied to the surface of the Andoung wood tended to increase as the AgNPS@UF content increased, with a positive correlation. The change in the chromatic aberration of the coating after aging was the greatest when the content of the anti-bacterial agent was 4%. The chromatic aberration decreased from 11 after 12 h of high-temperature accelerated aging to 4.5 after 48 h of high-temperature accelerated aging, with a decrease of 6.5. When the AgNPS@UF content was 5%, the chromatic aberration of the coating increased. The high-temperature accelerated aging caused certain damage to the coating. Figure 5B shows the chromatic aberration for the anti-bacterial coating with CS-AgNPS@MF. In comparison to the coating with AgNPS@UF, it showed a significantly larger chromatic aberration overall, with the chromatic aberration ranging within 30. The chromatic aberration of three kinds of anti-bacterial coating increased as the amount of anti-bacterial agent increased. As the aging time increased, there was a positive correlation between the content of the anti-bacterial agent and the chromatic aberration of the coating. When the CS-AgNPS@MF content was 6%, the chromatic aberration decreased from 27.9 for 12 h to 6.62 for 48 h of high-temperature accelerated aging, respectively, with a decrease of 21.28. Figure 5C shows the trend of chromatic aberration changes of anti-bacterial coating with the nano-silver solution after high-temperature accelerated aging. As the aging time increased, the chromatic aberration did not change significantly. It showed that the water-based nano-silver solution mixed directly with the water-based coating had no protective effect on the coating when subjected to high-temperature accelerated aging. The AgNPS@UF and CS-AgNPS@MF which were added to the water-based coatings increased the diffuse reflection on the coating and resulted in a change in the chromatic aberration with increasing aging time. Comparing the coatings with AgNPS@UF and CS-AgNPS@MF, the anti-bacterial coating with AgNPS@UF showed a smaller change in chromatic aberration with increasing aging time and had excellent optical properties. As shown in Tables S8–S10, after high-temperature accelerated aging, a significant difference for the chromatic aberration of coating with CS-AgNPS@MF was observed. This was due to the high-temperature resistance of the melamine formaldehyde resin at high temperatures. Comparing the two microcapsules, the coating with AgNPS@UF shows a small change in chromatic aberration with increased aging time and excellent optical properties. AgNPS@UF and CS-AgNPS@MF have white wall materials, which increased the chromatic aberration of the coating compared to the nano-silver solution.

Figure 5.

Trend in chromatic aberration of the coating after high-temperature accelerated aging with different anti-bacterial agents: (A) AgNPS@UF, (B) CS-AgNPS@MF, and (C) Nano-silver solution.

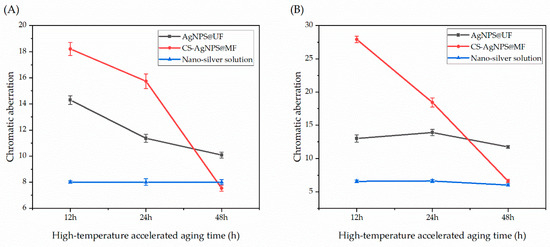

As observed from the above results, as the aging time increased, the chromatic aberration of the coatings with the three anti-bacterial agents changed significantly after 48 h of high-temperature accelerated aging. The coatings with 5% and 6% content of anti-bacterial agents after high-temperature accelerated aging had good anti-bacterial properties. Therefore, a comparative analysis was carried out on the chromatic aberration of the coating with different content anti-bacterial agents after high-temperature accelerated aging, as shown in Figure 6. Figure 6A shows the anti-bacterial coating prepared at 5% content of anti-bacterial agents, where the chromatic aberration for CS-AgNPS@MF decreased from 18.2 to 7.5 after 48 h of high-temperature accelerated aging. Similarly, in the same situation, the chromatic aberration of 14.3 obtained by AgNPS@UF was reduced to 10.1 after 48 h of high-temperature accelerated aging (Figure 6A). The reason for the decrease in chromatic aberration was the ability of the UF resin to have good encapsulation properties, avoiding the run-off of the anti-bacterial agent and reducing the chromatic aberration of the coating. Figure 6B shows the trend of the chromatic aberration of the coatings with the three anti-bacterial agents at the content of 6%. In general, the chromatic aberration trend of coating with 6% content of anti-bacterial agent was the same as the trend of that with 5% content. The greatest variation in chromatic aberration occurred in the coating with CS-AgNPS@MF, followed by the coating with AgNPS@UF, while the chromatic aberration of the coatings with the nano-silver solution showed little variation. The main reason was a rapid evaporation of the nano-silver solution. Nano-silver solution was prevented from guaranteeing long-lasting anti-bacterial properties. The anti-bacterial coatings with 5% content of AgNPS@UF showed good optical properties after high-temperature accelerated aging. The high-temperature accelerated aging caused the microcapsules to rupture, resulting in a tighter alignment of the particles in the coating and a deeper color. High-temperature accelerated aging caused changes in the structure and color of the polymer.

Figure 6.

The effect of different contents of 5% (A) and 6% (B) anti-bacterial agents on the chromatic aberration of the coating after high-temperature accelerated aging.

3.4. Liquid Resistance High-Temperature Accelerated Aging

An important aspect of the physical and chemical properties of the coating was the property of liquid resistance. Stains and watermarks were inevitable in everyday applications of wood materials and could be reduced or avoided if the wood surface was protected by the coating. Table 5 shows the liquid-resistant level of the coating with different contents of anti-bacterial agents after high-temperature accelerated aging.

Table 5.

Liquid-resistant level of the coating with different contents of anti-bacterial agents.

For the red ink test, the anti-bacterial coating with AgNPS@UF was heavily stained, leaving a filter paper shape on the coating. It indicated that the liquid-resistant level of coating with AgNPS@UF is at 5 for red ink. It also showed obvious dents on the coating with AgNPS@UF to a detergent. The coating showed a good color after an ethanol test with little distinction. As the AgNPS@UF content increased, the liquid-resistant level of coating to the red ink gradually increased to level 1 after high-temperature accelerated aging. Similarly, in the case of detergent, the AgNPS@UF provided some protection to the coating. The anti-bacterial coating with CS-AgNPS@MF left deep red traces on the contact surface of the coating and the filter paper when tested with the red ink. In the case of detergent, the traces on coating with CS-AgNPS@MF were only visible when observed under a light source from different angles. It showed that the coating with CS-AgNPS@MF has some protective effect. The liquid resistance of the coating with CS-AgNPS@MF to the ethanol proved to be good. As the content of the AgNPS@UF increased, the liquid-resistant level of the coating increased to level 1. The coating can protect itself by releasing the anti-bacterial agent. The high content of anti-bacterial agents in the coating improves the liquid resistance of the coating after high-temperature accelerated aging. As shown in Tables S11–S13, for the liquid resistance of the coating, it shows a significant difference for the red ink. It shows that coating with AgNPS@UF has better liquid resistance toward red ink than CS-AgNPS@MF and nano-silver solution. It showed that the increasing AgNPS@UF content in the water-based coating increases the sealing properties and acts as a barrier, making it impossible for liquids to impregnate the wood.

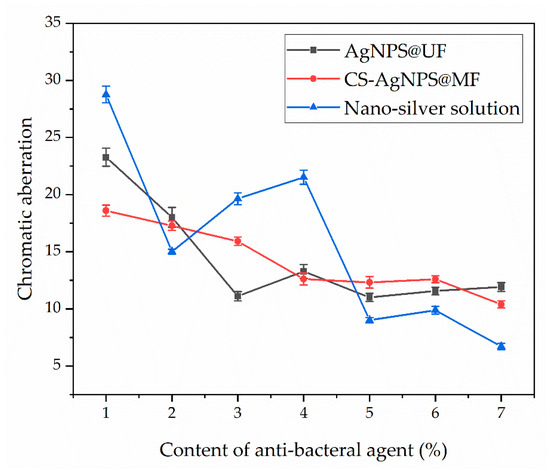

The L, a, and b values of the coating after the liquid resistance were compared to that before liquid resistance. Figure 7 shows the chromatic aberration trend of the anti-bacterial coating with different contents of anti-bacterial agents after the test of liquid resistance. The chromatic aberration of the coating decreased as the content of anti-bacterial agents increased. The chromatic aberration of the coating with the content of nano-silver solution of 1% was 28.8. When the content of anti-bacterial agents reached 2%, the chromatic aberration for the anti-bacterial coatings all decreased. As the content of anti-bacterial agents continued to increase, only the chromatic aberration of the anti-bacterial coatings with the nano-silver solution began to increase from 2% content of nano-silver solution. The chromatic aberration of the anti-bacterial coating with AgNPS@UF showed a decreasing trend when the AgNPS@UF content reached 4%. The longer the liquid stayed on the coating, the more likely it was to leave scarring. This was especially true for red ink, as it was inherently dark in color. The defects in the coating increased after high-temperature accelerated aging, resulting in an increased variation between the test and non-test areas. As time increased, the liquid had dried and molded onto the wood and no longer penetrated the wood, the corresponding L, a, and b values began to drop, and the resulting chromatic aberration changed. Concerning the liquid-resistant level of the coating (Table 5), it follows the trend of the chromatic aberration change. The coatings with AgNPS@UF and CS-AgNPS@MF were able to mitigate the penetration of liquids, and the anti-bacterial coating with AgNPS@UF content of 5% had the lowest chromatic aberration and the best liquid resistance after high-temperature accelerated aging. After liquid resistance and high-temperature accelerated aging, the chromatic aberration of the coating shows no difference, as shown in Table S14. It showed that the three anti-bacterial agents all prevent the liquid from penetrating the coating.

Figure 7.

Effect of anti-bacterial agents on chromatic aberration after liquid resistance and after high-temperature accelerated aging.

3.5. Effect of High-Temperature Accelerated Aging and UV Aging on the Anti-Bacterial Durability of Coatings

3.5.1. Effect of High-Temperature Accelerated Aging on the Anti-Bacterial Durability of Coatings

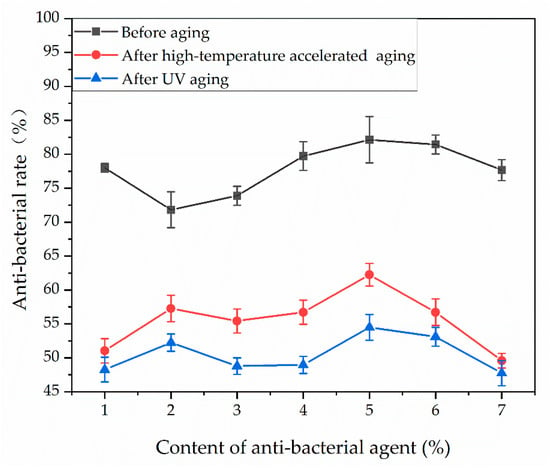

Referring to the GB/T 21866-2008 standard [39], the anti-bacterial durability of the coating can be characterized by high-temperature accelerated aging or UV aging with a duration of 48 h. Figure 8 shows the anti-bacterial property of the coating towards Escherichia coli after high-temperature accelerated aging. In the case of Escherichia coli, the anti-bacterial properties of the coatings with three anti-bacterial agents decreased after high-temperature accelerated aging. However, the most rapid decrease in the anti-bacterial test was observed in the coatings with the nano-silver solution, which was due to the rapid evaporation of the nano-silver solution after high-temperature accelerated aging. When the content of two types of microcapsules was 5%, the anti-bacterial rate of the coating with AgNPS@UF decreased from 82.1% to 62.2%, and the anti-bacterial rate of the coating with CS-AgNPS@MF decreased from 75.6% to 31.9%, respectively, after high-temperature accelerated aging. For the anti-bacterial property toward Escherichia coli, three kinds of anti-bacterial coating after high-temperature accelerated aging show a significant difference, as shown in Table S15. When microcapsules were added to water-based coatings, the wall materials were able to absorb some of the heat and oxygen, effectively protecting the core materials. The anti-bacterial properties of the coating with CS-AgNPS@MF and AgNPS@UF were thus superior to the coating with the nano-silver solution. The anti-bacterial rate of coating with CS-AgNPS@MF was lower than that of coating with AgNPS@UF. The main reason was that high-temperature accelerated aging caused damage such as bulging and cracking of the anti-bacterial coating. The CS-AgNPS was dehydrated when heated, which resulted in increased rupture of the wall materials, leading to the rapid release of the core materials. High-temperature accelerated aging occurred with the combined action of oxygen and heat, which caused decomposition or oxidation of the coating [40,41,42], resulting in changes to the appearance of the coating. As the coating had undergone a physical and chemical reaction, the anti-bacterial agent in the coating was subject to decomposition by the combined action of heat and oxygen, resulting in a decrease in the anti-bacterial properties of the coating with the anti-bacterial agent after high-temperature accelerated aging.

Figure 8.

Anti-bacterial property toward Escherichia coli of the coating after high-temperature accelerated aging.

Figure 9 shows the anti-bacterial property of the coating towards Staphylococcus aureus after high-temperature accelerated aging. The anti-bacterial properties of the coatings with three anti-bacterial agents showed a decreasing trend after high-temperature accelerated aging. The anti-bacterial property of the coating with the nano-silver solution decreased from 61.0% to 25.1%, which is the fastest decrease observed in the anti-bacterial properties. It indicated that the anti-bacterial property of the coating with nano-silver solution was the worst after high-temperature accelerated aging. The anti-bacterial properties of the coating increased with the increased AgNPS@UF content before and after high-temperature accelerated aging. At 4% AgNPS@UF content, the coating with AgNPS@UF has the anti-bacterial rate of 79% before high-temperature accelerated aging, and the anti-bacterial rate of 62.9% after high-temperature accelerated aging. At 5% AgNPS@UF content, the coating with AgNPS@UF has the anti-bacterial rate of 79.3% before high-temperature accelerated aging, and the anti-bacterial rate of 61.1% after high-temperature accelerated aging. The anti-bacterial rate of coating with CS-AgNPS@MF was 58.6% before high-temperature accelerated aging and 59% after high-temperature accelerated aging when the content of the anti-bacterial agent was 3%. When the content of the anti-bacterial agent was 5%, the anti-bacterial rate of the coating with CS-AgNPS@MF was 47.8% and 50.6% after high-temperature accelerated aging. For the anti-bacterial property toward Staphylococcus aureus, three kinds of anti-bacterial coating after high-temperature accelerated aging show a significant difference, as shown in Table S16. The anti-bacterial property of coating with CS-AgNPS@MF slightly decreased after high-temperature accelerated aging indicating that high-temperature accelerated aging damaged the anti-bacterial coating. It showed that the coating with CS-AgNPS@MF maintained a long-lasting anti-bacterial property. After high-temperature accelerated aging, the anti-bacterial agent lost its reactivity, which decreased the anti-bacterial property of the silver ions, so the water-based coating with an unencapsulated nano-silver solution did not guarantee a long-lasting anti-bacterial property.

Figure 9.

Anti-bacterial property towards Staphylococcus aureus of the coating after high-temperature accelerated aging.

3.5.2. Comparison of UV Aging and High-Temperature Accelerated Aging on Anti-Bacterial Durability toward Escherichia coli

The previous results show that the coatings with AgNPS@UF have good anti-bacterial properties and can maintain a more stable anti-bacterial durability towards Escherichia coli than Staphylococcus aureus after high-temperature accelerated aging (Figure 8 and Figure 9). Therefore, a comparison was carried out on the anti-bacterial property of the coating with AgNPS@UF towards Escherichia coli after the high-temperature accelerated aging and the UV aging (Figure 10). Figure 10 shows that the anti-bacterial properties of coating with AgNPS@UF decrease as the content of the anti-bacterial agent increased. The higher the AgNPS@UF content, the better the anti-bacterial properties of coating with AgNPS@UF. The anti-bacterial properties of the coating with AgNPS@UF after the high-temperature accelerated aging were better than those after the UV aging. The anti-bacterial rate range of the coating with AgNPS@UF after the high-temperature accelerated aging was from 49.6% to 62.2%, while the anti-bacterial rate range of the coating with AgNPS@UF after the UV aging was from 47.2% to 53.1%. Therefore, when the same content of anti-bacterial agents was added, the coating with AgNPS@UF after the UV aging did not maintain good anti-bacterial properties. After the high-temperature accelerated aging, the anti-bacterial rate towards Escherichia coli of the coating with 5% AgNPS@UF content was 62.2%, which is higher than that after UV aging. As shown in Table S17, there is a significant difference for the anti-bacterial properties toward Escherichia coli of coating with AgNPS@UF before aging, after high-temperature accelerated aging, and after UV aging. The anti-bacterial property of coating with 5% AgNPS@UF after UV aging decreased in a worse manner than high-temperature accelerated aging. The anti-bacterial coatings with AgNPS@UF undergo an irreversible deformation, resulting in the decrease in anti-bacterial properties. Although the temperature of the high-temperature accelerated aging was higher than that of UV aging, the coatings with AgNPS@UF were able to maintain a good surface performance. The space for UV aging is open, and there are impurities in the air environment, which can easily breed bacteria on the coating. With the same content of anti-bacterial agents, it is not possible to maintain good anti-bacterial properties.

Figure 10.

Comparison of anti-bacterial properties toward Escherichia coli of the coating with AgNPS@UF before aging, after the high-temperature accelerated aging, and after the UV aging.

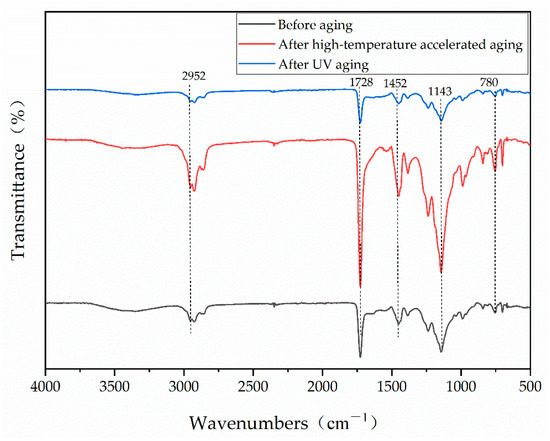

3.5.3. Chemical Composition Analysis

Figure 11 shows the FTIR of the coatings with AgNPS@UF before and after high-temperature accelerated aging and UV aging. The characteristic peak of the C=O group of a water-based acrylic resin in the water-based coatings was 1728 cm−1. The characteristic peaks of -CH3 in C-H in the wall materials and UF resin, are 2952 cm−1 and 1452 cm−1, respectively. The 1143 cm−1 peak was the characteristic absorption peak of C-O. It can be seen in Figure 11 that the trends of the FTIR spectra of the coatings before and after aging were essentially the same. The intensity of the peak for the high-temperature accelerated aging was higher than that for the UV aging, which indicated that the high-temperature accelerated aging damaged the coating more than the UV aging. A comparison of the two aging methods revealed that only the intensity of the characteristic peaks changed, no peaks appeared or disappeared, and the chemical compositions of the coating had no change before and after high-temperature accelerated aging and UV aging.

Figure 11.

FTIR of the coatings with AgNPS@UF before and after high-temperature accelerated aging and UV aging.

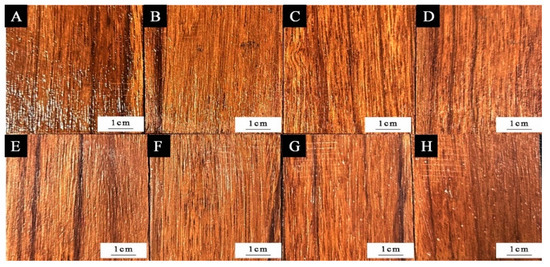

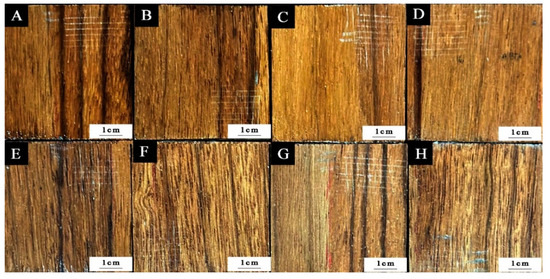

Figure 12 shows photos of the coating with AgNPS@UF before aging. Figure 12A–H corresponds to the 0–7% AgNPS@UF content. The coatings with AgNPS@UF on the Andoung wood were smooth and flat. The wood grain texture could be clearly seen. The gloss was good, too.

Figure 12.

Photos of coatings with different AgNPS@UF contents before aging: (A) 0%, (B) 1%, (C) 2%, (D) 3%, (E) 4%, (F) 5%, (G) 6%, and (H) 7%.

Figure 13 shows the photos of coating with AgNPS@UF after the high-temperature accelerated aging. The color of the wood grain texture then changed from the initial reddish brown to a darker brown after the high-temperature accelerated aging due to variations of the chemical composition contained in the wood. The high-temperature accelerated aging at the temperature of 120 °C caused the coating with AgNPS@UF on the Andoung wood to become even darker in color. The reason for the darker color of the coatings after accelerated high-temperature aging was that the cellulose and the hemicellulose in the wood would break down at a high temperature.

Figure 13.

The photos of coatings with different AgNPS@UF contents after the high-temperature accelerated aging: (A) 0%, (B) 1%, (C) 2%, (D) 3%, (E) 4%, (F) 5%, (G) 6%, and (H) 7%.

Figure 14 shows the photos of coatings with AgNPS@UF after the UV aging. The UV irradiation accelerated the aging of the wood. The color of the coating with AgNPS@UF on the Andoung wood gradually lightened, resulting in a loss of gloss on the wood surface. As a result, both high-temperature accelerated aging and UV aging decreased the gloss of the coating. Therefore, the coating needed to be protected to prolong its life. The coating with microcapsules can protect wood successfully.

Figure 14.

The photos of coatings with different AgNPS@UF contents after the UV aging: (A) 0%, (B) 1%, (C) 2%, (D) 3%, (E) 4%, (F) 5%, (G) 6%, and (H) 7%.

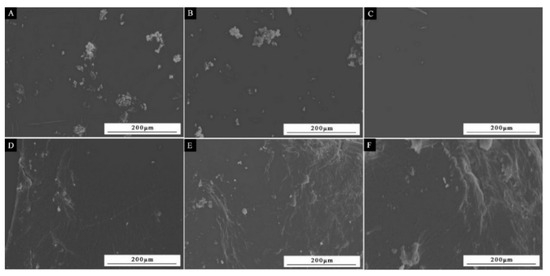

3.5.4. Microstructural Analysis of Coating

The results of the anti-bacterial test, gloss test, chromatic aberration test, liquid resistance test, high-temperature accelerated aging test, and UV aging test show that the coatings with 5% content of AgNPS@UF had good overall property, which has an application value. Therefore, the coating with 5% content of AgNPS@UF was selected for a microstructural analysis and compared with the other two anti-bacterial agents. Figure 15 shows the SEM images of the microscopic morphology of the coating before and after the anti-bacterial test with 5% content of AgNPS@UF, CS-AgNPS@MF, and nano-silver solution. Figure 15A,D shows the morphology of the coating with AgNPS@UF before and after the anti-bacterial test for Escherichia coli. It can be seen in Figure 15A that the AgNPS@UF are added to the water-based coating before the anti-bacterial test for Escherichia coli. Figure 15D shows that when the Escherichia coli were inoculated onto the coating, the silver ions in the AgNPS@UF were released from the pores of the microcapsule. Thus, the growth of the Escherichia coli was inhibited. Figure 15B,E showed the morphology of the coating with CS-AgNPS@MF before and after the anti-bacterial test. Figure 15B showed the CS-AgNPS@MF were added in the water-based coating before the anti-bacterial test. Figure 15E shows bacterial inoculation onto the coating. The CS-AgNPS was slowly released from the wall materials to kill Escherichia coli [43,44]. Figure 15C,F showed a comparison of the coating with the nano-silver solution before and after the anti-bacterial test. When the Escherichia coli was inoculated onto the coating, the direct exposure of the nano-silver solution to air decreased its anti-bacterial properties, resulting in the growth of Escherichia coli on the coating. Therefore, the coating with 5% AgNPS@UF content has good anti-bacterial properties towards Escherichia coli. AgNPS@UF can maintain a long-lasting anti-bacterial property by slowing down the release of core materials compared to nano-silver solution, and AgNPS@UF have a higher release efficiency compared to CS-AgNPS@MF, therefore, the coating with AgNPS@UF has better anti-bacterial properties than that with CS-AgNPS@MF and nano-silver solution.

Figure 15.

SEM images of water-based coatings with 5% content of anti-bacterial agent before anti-bacterial property towards Escherichia coli: (A) AgNPS@UF, (B) CS-AgNPS@MF, (C) nano-silver solution, and after anti-bacterial property towards Escherichia coli: (D) AgNPS@UF, (E) CS-AgNPS@MF, and (F) nano-silver solution.

4. Conclusions

Under the same content of anti-bacterial agents, the water-based coatings with AgNPS@UF on the Andoung wood exhibit better anti-bacterial properties compared to that with CS-AgNPS@MF and with nano-silver solution. The gloss of the coatings shows a downward trend with the increasing content of the three anti-bacterial agents. The hardness of the coatings increased with the increasing content of the three anti-bacterial agents, while the adhesion of the coatings decreased. Compared to CS-AgNPS@MF and nano-silver solution, the coatings with AgNPS@UF on the Andoung wood had a smaller variation in chromatic aberration and better optical properties after the high-temperature accelerated aging. The water-based coatings with the AgNPS@UF and CS-AgNPS@MF had good liquid resistance. The chemical composition of the water-based coatings and AgNPS@UF after the high-temperature accelerated aging and the UV aging did not change. The coatings with AgNPS@UF maintain long-lasting anti-bacterial properties after high-temperature accelerated aging. Compared to UV aging, the coatings with a 5% content of AgNPS@UF had better anti-bacterial durability towards Escherichia coli after high-temperature accelerated aging. This paper aims to find a long-lasting anti-bacterial agent which has fewer negative effects on the physicochemical properties and better anti-bacterial properties of the water-based coatings on Andoung wood. Anti-bacterial tests were carried out for two kinds of bacteria (Escherichia coli and Staphylococcus aureus) that are commonly used in the test. Through comprehensive analysis, the water-based coatings with AgNPS@UF on Andoung wood have good mechanical, optical, and anti-bacterial properties when the AgNPS@UF content is 5%, which can more effectively inhibit the growth of bacteria on the coatings. AgNPS@UF can increase the added value of wooden furniture while protecting people from Escherichia coli and Staphylococcus aureus for a long time. It is expected that anti-bacterial agents with higher anti-bacterial rates can be prepared in the future. The anti-bacterial microcapsules with compound features are expected to be developed in the future to expand the capabilities of furniture coatings.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/coatings13091518/s1, Table S1: List of experimental material information; Table S2: Significance analysis of anti-bacterial properties toward the Staphylococcus aureus of the coating; Table S3: Significance analysis of anti-bacterial properties toward the Escherichia coli of the coating; Table S4: Significance analysis of 20° gloss of anti-bacterial coatings; Table S5: Significance analysis of 60° gloss of anti-bacterial coatings; Table S6: Significance analysis of 85° gloss of anti-bacterial coatings; Table S7: Significance analysis of the coating adhesion; Table S8: Significance analysis of chromatic aberration of the coating after high-temperature accelerated aging with AgNPS@UF; Table S9: Significance analysis of chromatic aberration of the coating after high-temperature accelerated aging with CS-AgNPS@MF; Table S10: Significance analysis of chromatic aberration of the coating after high-temperature accelerated aging with nano-silver solution; Table S11: Significance analysis of liquid resistance toward red ink of the coating; Table S12: Significance analysis of liquid resistance toward detergent of the coating; Table S13: Significance analysis of liquid resistance toward ethanol of the coating; Table S14: Significance analysis of chromatic aberration of the coating after liquid resistance and after high-temperature accelerated aging; Table S15: Significance analysis of the anti-bacterial property toward Escherichia coli of the coating after high-temperature accelerated aging; Table S16: Significance analysis of the anti-bacterial property toward Staphylococcus aureus of the coating after high-temperature accelerated aging; Table S17: Significance analysis of the anti-bacterial properties toward Escherichia coli of the coating with AgNPS@UF before aging, after the high-temperature accelerated aging, and after the UV aging.

Author Contributions

Conceptualization, methodology, validation, resources, data management, and supervision, Y.Z., writing—review and editing, P.P., and formal analysis and investigation, X.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This project was partly supported by the Natural Science Foundation of Jiangsu Province (BK20201386).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare that there were no conflict of interest.

References

- Ayrilmis, N. A Review on Electrostatic Powder Coatings for the Furniture Industry. Int. J. Adhes. Adhes. 2022, 113, 103062. [Google Scholar] [CrossRef]

- Hu, W.G.; Luo, M.Y.; Hao, M.M.; Tang, B.; Wan, C. Study on the Effects of Selected Factors on the Diagonal Tensile Strength of Oblique Corner Furniture Joints Constructed by Wood Dowel. Forests 2023, 14, 1149. [Google Scholar] [CrossRef]

- Weng, M.Y.; Zhu, Y.T.; Mao, W.G.; Zhou, J.C.; Xu, W. Nano-Silica/Urea-Formaldehyde Resin-Modified Fast-Growing Lumber Performance Study. Forests 2023, 14, 1440. [Google Scholar] [CrossRef]

- Luo, Y.R.; Xu, W. Optimization of Panel Furniture Plates Rework Based on Intelligent Manufacturing. Bioresources 2023, 18, 5198–5208. [Google Scholar] [CrossRef]

- Li, R.R.; He, C.J.; Wang, X.D. Evaluation and Modeling of Processability of Laser Removal Technique for Bamboo Outer Layer. JOM 2021, 73, 2423–2430. [Google Scholar] [CrossRef]

- Hu, W.G.; Yu, R.Z.; Luo, M.Y.; Konukcu, A.C. Study on Tensile Strength of Single Dovetail Joint: Experimental, Numerical, and Analytical Analysis. Wood Mater. Sci. Eng. 2022, 18, 1478–1486. [Google Scholar] [CrossRef]

- Luo, Z.Y.; Xu, W.; Wu, S.S. Performances of Green Velvet Material (PLON) Used in Upholstered Furniture. Bioresources 2023, 18, 5108–5119. [Google Scholar] [CrossRef]

- Hu, W.G.; Yu, R.Z. Mechanical and acoustic characteristics of four wood species subjected to bending load. Maderas-Cienc. Tecnol. 2023, 25, 39. [Google Scholar]

- Zhang, S.W.; Yu, A.X.; Song, X.Q.; Liu, X.Y. Synthesis and Characterization of Waterborne UV-Curable Polyurethane Nanocomposites Based on the Macromonomer Surface Modification of Colloidal Silica. Prog. Org. Coat. 2013, 76, 1032–1039. [Google Scholar] [CrossRef]

- Gurau, L.; Ayrilmis, N.; Benthien, J.T.; Ohlmeyer, M.; Kuzman, M.K.; Racasan, S. Effect of Species and Grinding Disc Distance on the Surface Roughness Parameters of Medium Density Fiberboard. Eur. J. Wood Wood Prod. 2017, 75, 335–346. [Google Scholar] [CrossRef]

- Buryova, D.; Sedlak, P. Life Cycle Assessment of Coated and Thermally Modified Wood Facades. Coatings 2021, 11, 1487. [Google Scholar] [CrossRef]

- Zafar, F.; Ghosal, A.; Sharmin, E.; Chaturvedi, R.; Nishat, N. A Review on Cleaner Production of Polymeric and Nanocomposite Coatings Based on Waterborne Polyurethane Dispersions from Seed Oils. Prog. Org. Coat. 2019, 131, 259–275. [Google Scholar] [CrossRef]

- Zhou, J.C.; Xu, W. An Aesthetic Transparent Wood Resistant to Escherichia Coli Based on Interface Optimization. Eur. J. Wood Wood Prod. 2023, 1–11. [Google Scholar] [CrossRef]

- Peng, X.R.; Zhang, Z.K. Improvement of paint adhesion of environmentally friendly paint film on wood surface by plasma treatment. Prog. Org. Coat. 2019, 134, 255–263. [Google Scholar] [CrossRef]

- Han, Y.Y.; Chen, S.L.; Yang, M.; Zou, H.T.; Zhang, Y.L. Inorganic Matter Modified Water-Based Copolymer Prepared by Chitosan-Starch-CMC-Na-PVAL as an Environment-Friendly Coating Material. Carbohydr. Polym. 2020, 234, 115925. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.H.; He, J.L.; Zhang, Y.Z.; Hong, Y.M.; Wang, X.P. Understanding the Interface Structures of Water-Based and Solvent-Based poly(methyl methacrylate) Coatings at the Molecular Level. Appl. Surf. Sci. 2022, 579, 152239. [Google Scholar] [CrossRef]

- Maryan, A.S.; Gorji, M. Synthesize of Nano-silver Using Cellulose or Glucose as a Reduction Agent: The Study of Their Anti-bacterial Activity on Polyurethan Fibers. Bulg. Chem. Commun. 2016, 48, 151–155. [Google Scholar]

- Chinkamonthong, R.; Kositchaiyong, A.; Sombatsompop, N. Effects of Thermal and UV Aging on Antibacterial Properties of Linear Low-Density polyethylene and poly(vinyl chloride) Films Containing Nano-Silver Colloid. J. Plast. Film. Sheeting 2013, 29, 144–162. [Google Scholar] [CrossRef]

- Ma, C.C.; Wang, W.; Kong, D.B.; Li, W.; Chen, S.G. A Novel All-Organic Microcapsule with Excellent Long-Term Antibacterial and Anti-Corrosion Performances. J. Colloid Interf. Sci. 2023, 634, 553–562. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, X.X. Preparation of Resin-Coated Waterborne Coating Microcapsules and Its Effect on the Properties of Waterborne Coating for Wood Surfaces. Coatings 2022, 12, 1394. [Google Scholar] [CrossRef]

- Pan, P.; Yan, X.X. Preparation of Antibacterial Nanosilver Solution Microcapsules and Their Impact on the Performance of Andoung Wood Surface Coating. Polymers 2023, 15, 1722. [Google Scholar] [CrossRef] [PubMed]

- Arif, D.; Niazi, M.B.K.; Ul-Haq, N.; Anwar, M.N.; Hashmi, E. Preparation of Antibacterial Cotton Fabric Using Chitosan-Silver Nanoparticles. Fiber. Polym. 2015, 16, 1519–1526. [Google Scholar] [CrossRef]

- Chang, Y.J.; Yan, X.X. Preparation and Self-Repairing Properties of MF-Coated Shellac Water-Based Microcapsules. Coatings 2020, 10, 778. [Google Scholar] [CrossRef]

- GB/T 11186.3-1989; Methods for Measuring the Colour of Coating Films. Part III: Calculation of Colour Differences. Standardization Administration of the People’s Republic of China: Beijing, China, 1990.

- GB/T 9754-2007; Coatings and Varnishes-Determination of Specular Gloss of Non-Metallic Coating Films at 20°, 60° and 85°. Standardization Administration of the People’s Republic of China: Beijing, China, 2007.

- GB/T 6739-2006; Coating and Varnishes-Determination of Film Hardness by Pencil Test. Standardization Administration of the People’s Republic of China: Beijing, China, 2006.

- GB/T 4893.4-2013; Test of Surface Coatings of Furniture-Part 4: Determination of Adhesion-Cross Cut. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- GB/T 1740-2007; Determination of Resistance to Heat and Humidity of Coating Films. Standardization Administration of the People’s Republic of China: Beijing, China, 2007.

- GB/T 4893.1-2021; Test of Surface Coatings of Furniture—Part 1: Determination of Surface Resistance to Cold Liquids. Standardization Administration of the People’s Republic of China: Beijing, China, 2021.

- GB/T 4789.2-2022; Microbiological Examination of Food Hygiene—Examination of the Residue of Antibiotics in Fresh Milk. Standardization Administration of the People’s Republic of China: Beijing, China, 2022.

- Kim, J.S.; Kuk, E.; Yu, K.N.; Kim, J.H.; Park, S.J.; Lee, H.J.; Kim, S.H.; Park, Y.K.; Park, Y.H.; Hwang, C.Y.; et al. Antimicrobial Effects of Silver Nanoparticles. Nanomed-Nanotechnol. 2007, 3, 95–101. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Shi, Z.; Huang, T.; Zhao, H.; Kaner, J. Impact of Swiping Direction on the Interaction Performance of Elderly-Oriented Smart Home Interface: EEG and Eye-Tracking Evidence. Front. Psychol. 2023, 14, 1089769. [Google Scholar] [CrossRef] [PubMed]

- Li, R.R.; He, C.J.; Wang, X.D. Effects of Processing Parameters on Mass Loss and Coating Properties of Poplar Plywood during CO2 Laser Modification. Eur. J. Wood Wood Prod. 2022, 80, 899–906. [Google Scholar] [CrossRef]

- Deng, X.; Mammen, L.; Butt, H.J.; Vollmer, D. Candle Soot as a Template for a Transparent Robust Superamphiphobic Coating. Science 2012, 335, 67–70. [Google Scholar] [CrossRef]

- Zheng, H.P.; Guo, M.Y.; Shao, Y.W.; Wang, Y.Q.; Liu, B.; Meng, G.Z. Graphene Oxide Poly(Urea-Formaldehyde) Composites for Corrosion Protection of Mild Steel. Corros. Sci. 2018, 139, 1–12. [Google Scholar] [CrossRef]

- Li, Z.; Ma, H.Y.; Zheng, H.P.; Li, Z.; Meng, F.D.; Liu, R.; Oguzie, E.E.; Liu, L. Urea-formaldehyde resin covered etched basalt as durable composite coating with antibacterial activity and corrosion resistance. Corros. Sci. 2022, 209, 110760. [Google Scholar] [CrossRef]

- Chang, Y.J.; Wu, Z.H. Effect of Sandpaper Meshes on the Performance of Tilia Sp. Self-Repairing Coatings. Polymers 2023, 15, 2835. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, R.; Luo, J. Improvement of Anti-Aging Property of UV-Curable Coatings with Silica-Coated TiO2. Prog. Org. Coat. 2023, 179, 107479. [Google Scholar] [CrossRef]

- GB/T 21866-2008; Test Method and Effect for the Anti-Bacterial Capability of Coatings Film. Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- Diamantino, T.C.; Goncalves, R.; Pascoa, S.; Alves, I.N.; Carvalho, M.J. Accelerated Aging Tests to Selective Solar Absorber Coatings for Low-Temperature Applications. Sol. Energy Mater. Sol. Cells 2021, 232, 111320. [Google Scholar] [CrossRef]

- Niranjan, K.; Plaza, A.C.; Grifo, T.; Bordas, M.; Soum-Glaude, A.; Barshilia, H.C. Performance Evaluation and Durability Studies of W/WAlSiN/SiON/SiO2 Based Spectrally Selective Solar Absorber Coating for High-Temperature Applications: A Comprehensive Study on Thermal and Solar Accelerated Ageing. Sol. Energy 2021, 227, 457–467. [Google Scholar] [CrossRef]

- Torres, J.F.; Ellis, I.; Coventry, J. Degradation Mechanisms and Non-Linear Thermal Cycling Effects in a High-Temperature Light-Absorber Coating. Sol. Energy Mater. Sol. Cells 2020, 218, 110719. [Google Scholar] [CrossRef]

- Sanchez-Navarro, M.M.; Cuesta-Garrote, N.; Aran-Ais, F.; Orgiles-Barcelo, C. Microencapsulation of Melaleuca alternifolia (Tea Tree) Oil as Biocide for Footwear Applications. J. Dispers. Sci. Technol. 2011, 32, 1722–1727. [Google Scholar] [CrossRef]

- Wen, P.H.; Wang, Y.D.; Wang, N.; Zhang, S.W.; Peng, B.; Deng, Z.W. Preparation and characterization of melamine-formaldehyde/Ag composite microspheres with surface-enhanced Raman scattering and antibacterial activities. J. Colloid Interf. Sci. 2018, 531, 544–554. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).