Abstract

Plant extracts (PEs) are natural substances that perform interesting bioactivities. However, they have some limitations. In this work, PEs from licorice, eucalyptus, sage, and thyme were produced and characterized. These extracts showed good bioactive properties. Alginate-based edible coatings and films incorporated with the extracts were produced and their antimicrobial and antioxidant properties were determined. The results showed that the coatings completely inhibited or reduced the growth of all bacteria (E. coli, P. aeruginosa, B. cereus, L. monocytogenes, and S. aureus), except the coating with sage extract. However, only the films incorporated with licorice and eucalyptus could inhibit the growth of Gram-positive bacteria and none of the films were able to inhibit Gram-negative bacteria. The film incorporated with sage extract was the one with the best antifungal property. All films possess a good antioxidant property (ABTS: 942.52–5654.62; DPPH: 1040.67–5162.93 Trolox equivalents (µM)/mg film). Based on the results, it is possible to conclude that alginate coatings and films with PEs present good bioactive properties and can potentially be used as new, biodegradable packages. However, further experiments need to be performed to assess their safety profile, and to prove that they can be a real alternative to traditional food packaging.

1. Introduction

Nowadays, food packaging containers are the target of increasing attention. Traditional food packaging accounts for 36.9% of the plastics demand, being considered the largest market for the plastic industry [1,2]. However, these materials are mostly petroleum-based plastics, contributing to environmental pollution. Additionally, the potential migration of plastic packaging material into the food during storage suggests a serious health problem [1,3].

Active food packaging consists in the incorporation of some additives into the packaging film or within the packaging material, and has been put forward as an innovative technology to substitute for current food containers [4]. It can reduce or retard the growth of microorganisms, thus increasing safety and quality, and extending food shelf life [5]. It can preserve foods by scavenging, adsorbing, absorbing, emitting, releasing, or removing gases and other substances, thus reducing food waste [4]. Active packages also keep the moisture levels low and ensure that the food is at an appropriate temperature [4]. Edible coatings can be considered an alternative smart packaging. A coating is a thin polymer layer (approximately 10–20 μm) that is directly formed on the food surface [6]. Biobased coatings are low cost (due to the reduction in the amount of polymer and thus reduction in CO2 emissions) and have lower processing temperatures (which can avoid thermal degradation of active agents) [6]. The thin layer formed by the coating between the food and the environment acts as a selective barrier to water, gases (oxygen and carbon dioxide), and solutes, thus improving the shelf life of products by delaying food spoilage, preventing oxidation, and protecting it from moisture and pathogen invasion [7,8]. Therefore, these materials can be used to pack fresh foods, such as meat, fish, fruits, and vegetables [8].

Alginate is a polysaccharide extracted from the brown seaweeds of the Phaeophyceae class [7], composed of units of β-D-mannuronic acid and β-L-guluronic acid [3]. This polysaccharide is a good film/ coating forming agent due to its colloidal properties [9], producing strong films, impermeable to oils and fats and with good oxygen barriers, and having the ability to improve the flavor and texture of foods as well as delaying lipid oxidation [10]. However, due to alginate’s hydrophilic nature, these films/ coatings may have poor water resistance [9].

Plant extracts (PEs), because of their high concentration in phenolic compounds, have been recognized for their antioxidant and antimicrobial properties [11,12]. They can be effective at low concentrations, are cost-effective and easy to apply, present low toxicity levels and high stability during processing, and do not affect the sensory characteristics of food products [12]. However, the bioactivities of PEs may suffer alterations due to environmental stress, such as high temperatures, which can cause epimerization and oxygen exposure [13]. Furthermore, poor bioavailability and lack of targeting capacity can limit their efficiency [14]. However, the incorporation of PEs into polymeric films/ coatings increases their stability, bioactivity, and antimicrobial potential [15]. Normally, high concentrations of these substances are needed to achieve the desired bioactive properties, but their application in edible films or coatings reduces the need, since these formulations are controlled release systems allowing their gradual release onto food surfaces [16,17].

The present work aimed at the development of natural antimicrobial and antioxidant coatings, based on alginate and incorporated with PEs, for food applications. Four extracts (Salvia officinalis L. (S. officinalis), Eucalyptus obliqua L’Hér, (E. obliqua), Thymus vulgaris L. (T. vulgaris), and Glycyrrhiza glabra L. (G. glabra)) were obtained through optimized extraction processes, using mathematical models, which assured the maximum concentration of phenolic compounds. These PEs were characterized for different biological properties. Then, coatings were incorporated with the selected bioactive PEs and their functionalities were determined.

2. Materials and Methods

2.1. Production and Characterization of Plant Extracts

S. officinalis L. (Lamiaceae), E. obliqua L’Hér (Myrtaceae), T. vulgaris L. (Lamiaceae), and G. glabra L. (Fabaceae) were provided, as dry leaves, by a company producer (Deifil Technology Lda, Vieira do Minho, Braga, Portugal). After reception, the samples were crushed to obtain a fine and homogeneous powder.

The extracts were obtained from optimized extraction processes, using mathematical models (RSM) to obtain the maximum extract yield and the maximum concentration of phenolic compounds, with reduced costs associated with the extraction (time, temperature, and % of ethanol). The extraction procedures, namely heat-assisted extraction by maceration, were performed using a thermostatic water bath under continuous electromagnetic stirring (CIMAREC i Magnetic Stirrer with a fixed agitation speed of 500 rpm; Thermo Scientific, San Jose, CA, USA) under the required conditions of the work plan (t, T, and S), according to a procedure previously described by Caleja et al. [18] Each sample (600 mg) was mixed with 20 mL of solvent. For S. officinalis, the optimal extract conditions were: time 63 min, temperature 79 °C, and solvent 56.7% of ethanol. For E. obliqua, the optimal extract conditions were: time 119.95 min, temperature 76.49 °C, and solvent 25.09% of ethanol. For T. vulgaris, the optimal extract conditions were: time 89 min, temperature 98 °C, and solvent 3% of ethanol. For G. glabra, the optimal extract conditions were: time 102.13 min, temperature 63.9 °C, and solvent 52.20% of ethanol.

Subsequently, the samples were filtered through filter paper (Whatmann n° 4) and the ethanolic fraction of the obtained extracts was evaporated under reduced pressure (100 rpm, 40 °C) (rotary evaporator, Heidolph, Schwabach, Germany). Finally, both extracts were frozen and lyophilized. The obtained extracts were then analyzed using a Dionex Ultimate 3000 UPLC system (Thermo Scientific, San Jose, CA, USA) equipped with a quaternary pump, an automatic injector at 5 °C, a degasser, and a column compartment with an automated thermostat. The detection of the compounds was undertaken with a diode detector (DAD), applying three wavelengths (280, 330, and 370 nm) coupled to a mass spectrometry (MS) detector. The spectrometer used for the detection of MS was the Linear Ion Trap LTQ XL (ThermoFinnigan, San Jose, CA, USA) equipped with an ESI source (electrospray ionization source). For the compound’s separation, a Waters Spherisorb S3 ODS-2 reverse phase C18 column was used (4.6 × 150 mm, 3 μm) (Milford, CT, USA). The compounds were identified and quantified considering the UV spectra and retention times, and by comparing them with authentic standards (Table 1). The results were expressed as mg of compound detected per g of extract (mg/g extract) [19].

Table 1.

Information about calibration curves used in the phenolic compounds’ identification.

The concentration range of calibration curves was: 2.5–100 μg/mL.

2.2. Evaluation of the Bioactive Potential of the Extracts Obtained through the Optimization Process

2.2.1. Antioxidant Analysis

For the determination of antioxidant activity in the selected different extracts (eucalyptus, sage, thyme, and licorice), four in vitro tests were performed: the 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical-scavenging activity test, the reducing power test, the thiobarbituric acid reactive substance (TBARS) test [20], and the cellular antioxidant activity assay (CAA) [21]. To determine the corresponding EC50 values (sample concentration providing 50% of scavenging activity or 0.5 absorbance in the reducing power assay), serial dilutions of the freeze-dried extract re-dissolved in ethanol were prepared. Trolox (6-hydroxy-2,5,7,8-tetramethylchroman-2-carboxylic acid) was used as the positive control in all assays.

The results were expressed as EC50 values for DPPH, reducing power, and TBARS, and as a percentage of inhibition of the oxidation reaction for the CAA assay.

2.2.2. Evaluation of Antimicrobial Activity

Six strains of bacteria were tested, three being Gram-positive: Staphylococcus aureus (S. aureus ATCC 11632), Bacillus cereus (B. cereus food isolate), Listeria monocytogenes (L. monocytogenes NCTC 7973), and three Gram-negative: Escherichia coli (E. coli ATCC 25922), Enterobacter cloacae (E. cloacae ATCC 35030), and Salmonella typhimurium (S. typhimurium ATCC 13311). For antifungal assays, six micromycetes were used: Aspergillus fumigatus (A. fumigatus human isolate), Aspergillus niger (A. niger ATCC 6275), Aspergillus versicolor (A. versicolor ATCC11730), Penicillium funiculosum (P. funiculosum ATCC 36839), Trichoderma viride (T. viride IAM 5061), and Penicillium verrucosum var. cyclopium (P. verrucosum var. cyclopium food isolate). These organisms were acquired in the Mycology Laboratory of the Department of Plant Physiology of the Institute of Biological Research “Siniša Stanković” at the University of Belgrade in Serbia.

The antimicrobial activity was evaluated using a microdilution assay as described by Carocho et al. [22] A series of dilutions of the extracts ranging from 20 to 0.0313 mg/mL were used for this test and the minimum inhibitory concentration (MIC) was defined as the lowest concentration at which no microbial growth was observed. The minimum bactericidal concentration (MBC) and the minimum fungicidal concentration (MFC) were determined by sub-culturing the test dilutions on agar plates and observing the microbial growth. The MBC and MFC were considered the lowest concentrations at which 99.9% of the microbial population was killed. The results were expressed as mg/mL. The MIC, MBC, and MFC values of commercial food preservatives sodium sulphite (E221) and potassium metabisulphite (E224) were also determined and compared with the ones obtained for the plant extracts.

2.3. Preparation of Alginate Coatings/Films Incorporated with Plant Extracts

Alginate coatings were obtained by dissolving sodium alginate 3% (w/v) (Sigma-Aldrich Chemie Gmbh. (St. Louis, MO, USA)) in hot distilled water. Then, 2.5% (v/v) glycerol (≥99.5%; Sigma-Aldrich Chemie Gmbh. (USA)) was added to the alginate solution and the mixture was left to stir for 2 h at room temperature. After that, 1% (w/v) sodium tripolyphosphate (TPP; 85%) solution (Sigma-Aldrich Chemie Gmbh., USA) was added to the alginate/ glycerol mixture under constant stirring. Coatings with PEs were obtained by adding the different plant extracts (2% w/v) to the solution and leaving to stir until the extract was completely dissolved.

In order to determine, as realistically as possible, the bioactivities of the coatings and mimic what happens when they are applied to food products, 20 mL of the coating solution was poured into 10 cm diameter plastic Petri dishes and left to dry at 30 °C for 48 h, forming films.

2.4. Antimicrobial Activity of the Films/Coatings

The antibacterial activity of the films and coatings with PEs and the film and coating without an antimicrobial agent was determined against bacteria B. cereus, L. monocytogenes, S. aureus, E. coli, and Pseudomonas aeruginosa (P. aeruginosa). The antifungal activity of the films was tested against fungi A. niger, Penicillium expansum (P. expansum), Fusarium verticillioides (F. verticilllioides), and Cladosporium sp. The bacterial cultures were cultivated on Mueller–Hinton agar (Biokar Diagnostics, Allonne, France) at 37 °C for 24 h and the fungal cultures were grown on Sabouraud dextrose agar (Conda, Madrid, Spain) at 25 °C for 7 days.

2.4.1. Antibacterial Activity

The antibacterial activity of the coatings was studied through the determination of growth inhibition curves as described by Alexandre et al. [23] Briefly, aliquots of the coatings were mixed with an overnight bacterial inoculum of 108 colony-forming units (CFU) mL−1. These mixtures were then transposed into a 96-well microplate (Sarstedt, Germany) and the optical density (OD) at 600 nm was assessed for a 24 h period at 37 °C (1 h intervals) using a microplate reader (Multiskan GO, Thermo Scientific, Vantaa, Finland). Aliquots of the different bacterial inoculum in Mueller–Hinton broth were used as positive controls and aliquots of the coatings solutions without inoculum were used as negative controls. The increase in OD was therefore considered to be a result of bacterial growth. Each condition was tested in triplicate.

The antibacterial activity of the films was determined by the viable cell method as described by Campos et al. [24]. Before the test, an overnight liquid culture of the selected bacteria was prepared in Mueller–Hinton broth (Biokar Diagnostics, France), and the optical density was adjusted to 0.2 at λ = 610 nm, which corresponds to about 108 CFU mL−1. Then, the liquid cultures were diluted in Mueller–Hinton broth to an inoculum concentration of 105/106 CFU mL−1.

All the films were cut into 1 cm discs and sterilized by placing them under UV light for 10 min for each side. After that, the film discs were distributed into sterile tubes and 200 µL of the inoculum was placed over each disc. The films were left in contact with inoculum for different times (0, 2, 4, 6, 8, 16, 24 h) at 37 °C. After the incubation, 1.8 mL of peptone water was added to each tube and the solution was homogenized until the disc was completely dissolved; then, 4 ten-fold dilutions of each tube were undertaken in sterile peptone water. Aliquots (20 µL) of each dilution were pipetted on Mueller–Hinton agar plates, incubated at 37 °C for 24 h, and the colonies were counted. The results were expressed as log CFU/g film and the detection limit of the test was 2.3 log CFU/g film. Two replicates of each film were used at each time point and plated in duplicate. Therefore, the results are the average values of 4 counts per film per time point.

2.4.2. Antifungal Activity

The antifungal activity was determined for the films and the applied method was adapted from Guimarães et al. [25] It evaluated the ability of the fungi to grow on the films’ surface.

Briefly, the films with PEs were cut into 2 cm discs and sterilized as described above. Then, film discs were placed in the center of Sabouraud dextrose agar plates and 10 µL of a spore suspension (105 spores/mL) of the selected fungi was inoculated into the center of the disc. The suspension of the spores was obtained by collecting spores using a TWS solution [TWS: 0.05% Tween 80 (Sigma-Aldrich Chemie Gmbh., USA); 0.85% NaCl (Sigma-Aldrich Chemie Gmbh., USA)]. Then, the number of spores was counted in a Neubauer Chamber and diluted on Sabouraud dextrose broth to a concentration of 105 spores/mL.

The plates were incubated at 25 °C for 7 d and the diameter of the fungal colony was measured. Each film was tested for each fungal species in duplicate and two independent tests were performed.

The percentage of inhibition was calculated based on the reduction of the fungal growth in the films with PEs when compared to the growth of the fungus on the control film (i.e., film without PE), following Equation (1):

where Dc is the diameter of the fungal colony in the control film and Df is the diameter of the fungal colony in the film with extract.

2.5. Antioxidant Activity of the Films

The antioxidant activity of the films with Pes was determined by 2,2’-azino-bis (3-ethylbenzothiazoline-6-sulfonic acid) (ABTS) and DPPH scavenging assays. Briefly, each film was cut into 1 mg pieces, which were placed into test tubes. Then, 2–8 mL of ABTS or DPPH was pipetted into each tube. The tubes with ABTS were left to react for 6 min and DPPH reaction occurred for 30 min. After the incubation time, the solutions’ absorbance was measured in a spectrophotometer at 734 nm (ABTS) and 515 nm (DPPH). Both reactions were carried out at room temperature and in the dark.

Trolox solutions in a range of 0–2000 µM were used to obtain the standard curve. The results were expressed as µM Trolox equivalents per mg of film (Trolox equivalents (µM)/mg film). All analyses were performed in quadruplicate.

2.6. Statistical Analysis

The results were expressed as mean ± standard deviation (SD). All analyses were performed in triplicate, and for statistical analysis the SPSS Statistics (IBM SPSS Statistics v. 25., IBMCorp, Armonk, NY, USA) program was used. A one-way analysis of variance (one-way ANOVA) followed by Tukey’s HSD post hoc test (after prior confirmation of homoscedasticity) was applied.

3. Results

3.1. Characterization of Plant Extracts

The identified molecules and their quantification are presented in Table 2. In this context, phenolic compounds were tentatively identified according to their retention time (Rt), maximum absorbance wavelength (λmax), pseudomolecular ion ([M–H]−), and respective fragmentation pattern (MS2). For all samples, it was possible to identify eighty-one phenolic compounds: twenty-three phenolic acids (p-hydroxycinnamic and rosmarinic acid derivatives), thirty-nine flavonoids (flavanone, flavone, flavan-3-ol, and flavonol), twenty hydrolyzable tannins, and six saponins. Regarding the twenty-one phenolic acids, peak 1 ([M–H]− at m/z 311) presented a fragmentation pattern that allowed identification as caftaric acid (dicaffeoyltartaric acid). Peaks 2, 3, and 5 were tentatively identified as caffeic acid hexosides based on the signal MS2 fragment at m/z 179 [caffeic acid—H]−, revealing the loss of a hexosyl moiety (−162 u) and of acetyl residue −42 u for caffeic acid acetylhexoside (peak 5). Peak 23 and 24 ([M–H]− at m/z 353), peak 28 ([M–H]− at m/z 337), and peak 30 ([M–H]− at m/z 499) were assigned as O-caffeoylquinic acid, 3-p-coumaroylquinic acid, and caffeoyl-coumaroyl-quinic acid, respectively. These assumptions were made due to the hierarchical fragmentation pattern described by Clifford et al. [26] The pseudomolecular ion of compounds 7, 58, and 59 ([M–H]− at m/z 537) matched the caffeic acid trimers salvianolic acids H/I and lithospermic acid A. Peak 15 showed a pseudomolecular ion [M–H]− at m/z 719 and an MS2 majority fragment at m/z 359, corresponding to [M-2H]2−. These mass characteristics coincided with sagerinic acid, a rosmarinic acid dimer (caffeic acid tetramer). Peak 16, 55, 56, and 71 (rosmarinic acid, [M–H]− at m/z 359) were positively identified according to their retention, mass spectra, and UV characteristics compared with commercial standards. Peak 57 ([M–H]− at m/z 539) was identified as yunnaneic acid D, based on its UV and mass characteristics [19]. Peak 54 ([M–H]− at m/z 555) was tentatively assigned as salvianolic acid K, due to a similar fragmentation pattern to that presented by Carocho, et al. [27] Peak 22 showed a [M–H]− ion at m/z 783, and main fragments at m/z 481 (loss of HHDP) and 301 (ellagic acid). Based on these fragments, this compound was identified as bis-HHDP-glucose. Peak 26 showed a [M–H]− ion at m/z 633, and main fragments at m/z 481 (loss of gallic acid) and 331 (loss of HHDP) were identified as galloyl-HHDP glucose. Peak 41 showed a [M–H] − ion at m/z 933 and [M–H]−2 at m/z 466. These peaks also had a common fragment at m/z 301, and it was suggested that these fragmentation patterns could be related to the presence of different isomeric forms of castalagin or vescalagin. Peaks 25 and 27 showed a [M–H]− ion at m/z 785 and [M–H]−2 at m/z 392, fragments at m/z 615, 301, and 169 (gallic acid). These compounds were tentatively identified as digalloyl-HHDP-glucose. Peak 29 showed a [M–H]− ion at m/z 787, main fragments at m/z 331 (loss of three galloyl moieties), and 169 (gallic acid) loss of glucose (−162 u). This was tentatively identified as tetragalloyl-glucose. Peaks 32 ([M–H]− at m/z 477), 36, 37 ([M–H]− at m/z 447), and 38 ([M–H]− at m/z 461) showed fragments at m/z 315 and 300, corresponding to a methyl ellagic acid linked to sugars hexoside (−162 u), pentosidine (−132 u), and deoxyhexoside (−146 u), respectively. Ellagic acid and related glycosides can be distinguished in UV−vis by their characteristic spectra at 260 and 360 nm as compared to ellagitannin spectra. Peaks 33 and 34 ([M–H]− at m/z 497) also yielded fragment ions at m/z 169 and 313, and these mass features are coherent with the structure of eucaglobulin or globulusin B, previously reported in the leaves of genus Eucalyptus [28]. Flavonoids detected in the analyzed samples mainly belonged to the group of flavones. Luteolin and apigenin derivatives were identified according to their UV and mass spectra. Peaks 4 ([M–H]− at m/z 447); 6, 45, 46, and 63 ([M–H]− at m/z 593); 17 ([M–H]− at m/z 401); 20, 21, 48, 65, and 66 ([M–H]− at m/z 563) presented a fragmentation pattern that allowed identification as different apigenin-linked sugars. Peaks 8, 47, and 60 ([M–H]− at m/z 637); 9, 10, 11, and 18 ([M–H]− at m/z 533); 13 ([M–H]− at m/z 593); 14 and 52 ([M–H]− at m/z 461); 19 ([M–H]− at m/z 769); 40 ([M–H]− at m/z 895); and 53 ([M–H]− at m/z 447) presented a fragment ion at m/z 285 that allowed identification as different luteolin-linked sugars. The remaining compounds (peaks 31, 35, 39, and 50) corresponded to flavonol glycosides. Compounds 31 ([M–H]− at m/z 609), 35 ([M–H]− at m/z 447), 39, and 50 ([M–H]− at m/z 447) released a unique MS2 fragment at m/z 301 (quercetin), from the loss of rutinoside (−308 u), rhamnoside (−146 u), glucoside (−162 u), and galactoside (−162 u) moieties, respectively. Peak 61 ([M–H]− at m/z 209) was tentatively identified as glucaric acid, which is a member of the family of molecules known as oxidized sugars. Peak 62 ([M–H]− at m/z 711) coincided with a glucoliquiritin apioside, according to a study carried out by Kitagawa, et al. [29] Peaks 64 and 70 presented a pseudomolecular ion [M–H]− at m/z 565, releasing a fragment ion at m/z 271 (294 u, loss of a pentosyl and hexosyl moieties), and a UV spectrum coherent with a flavanone. These characteristics match the structure of naringenin-7-O-apiosyl-glucoside reported by Martins et al. [30] Peaks 67, 68, 73, 74, and 75 presented the same pseudomolecular ion [M–H]− at m/z 549, all of them releasing a main MS2 fragment at m/z 255 from the loss of 132 + 162 u (pentosyl + hexosyl residues), pointing to the corresponding different apiosylglucosides of (iso)liquiritigenin, reported to occur as major flavonoids in the Glycyrrhiza genus. Peak 69 showed a pseudomolecular ion ([M–H]− at m/z 577) and a UV spectrum coherent with the C-glycosylflavones and was tentatively identified as isoviolanthin. Peaks 76–81 were tentatively described as licorice glycoside D/B ([M–H]− at m/z 685), 22-acetoxyl-rhaoglycyrrhizin ([M–H]− at m/z 1025), 24- hydroxyl-glycyrrhizin/licorice saponin G2 ([M–H]− at m/z 837), and glycyrrhizin ([M–H]− at m/z 821) owing their mass spectrum characteristics being similar to these saponin compounds that are found in the Glycyrrhiza genus [31].

Table 2.

Retention time (Rt), wavelengths of maximum absorption in the visible region (λmax), mass spectral data, quantification, and tentative identification of the phenolic compounds present in the S. officinalis, E. obliqua, T. vulgaris, and G. glaba.

Rosmarinic acid was the most abundant phenolic acid in S. officinalis (51 mg/g dw) and T. vulgaris (32 mg/g dw). At the same time, bis-HHDP-glucose was the most abundant hydrolyzable tannin found in E. obliqua. S. officinalis presented the highest concentration of flavonoids, namely flavones (66 mg/g dw) and phenolic acids (63 mg/g dw), and especially caffeic acid derivatives. Finally, liquiritin and liquiritigenin isomers were the most abundant compounds in the extracts of G. glaba, with 14.28 mg/g dw in total.

3.2. Evaluation of the Bioactive Potential of the Extracts

3.2.1. Antioxidant Activity

The results obtained in the antioxidant evaluation of the crude plant extracts, expressed in EC50 values and % of inhibition, are shown in Table 3. The eucalyptus extract stood out with the best activity in most assays (DPPH, reducing power and TBARS), while the licorice extract showed a higher percentage of inhibition in the CAA assay (values of 50%), followed by thyme extract with 31% of inhibition. Comparing with the positive control, it was possible to verify that the studied extracts have excellent antioxidant action.

Table 3.

Antioxidant activity of eucalyptus, sage, thyme, and licorice extracts.

Several studies have been developed to determine the antioxidant activity of these aromatic and medicinal plants. Namely, Bello et al. [32] studied the antioxidant properties of Eucalyptus globulus Labill leaf extracts and the results showed notable antioxidant activity. Moreover, Li et al. [33] evaluated the in vitro and in vivo antioxidant activity of eucalyptus leaf polyphenol extract, using chemical methods, a cellular model, and an animal model. The results showed strong reducing power in a chemical-based assay. Pereira et al. [34] analyzed the antioxidant activity capacity (measured through the free radical scavenging activity, reducing power, and lipid peroxidation inhibition) of infusions prepared from irradiated thyme, and the results showed very promising action. The same antioxidant capacity was investigated and detected for the species of S. officinalis L. and G. glabra L., studied by Grzegorczyk et al. [35] and Esmaeili et al. [36] This antioxidant action, clearly identified in the present study, may be correlated with the presence of phenolic compounds, which have the potential for reducing oxides of certain molecules, the capacity to compete for active sites and receptors in the various cellular structures, or can even modulate the expression of genes that encode proteins involved in intracellular defense mechanisms against oxidative and degenerative processes of cellular structures [37].

Although there are other studies in the literature, they do not mention that the extracts are obtained through optimized extraction processes, which makes the present study new and innovative, with technological advantages for industrial application.

3.2.2. Antimicrobial Activity

The antibacterial activity of eucalyptus, sage, thyme, and licorice extracts was tested against a panel of six bacteria, including three Gram-positive bacteria (S. aureus, B. cereus, and L. monocytogenes) and three Gram-negative bacteria (E. coli, S. typhimurium, and E. cloacae). Table 4 presents the MIC and MBC values obtained for each tested extract. The licorice extract showed higher antibacterial activity when compared to the other extracts and to both commercial food preservatives. E. coli emerged as the most sensitive strain to all plant extracts tested.

Table 4.

Antimicrobial activity (mg/mL) of eucalyptus, sage, thyme, and licorice extracts.

In the evaluation of antifungal activity (Table 4), it was possible to observe inhibitory and fungicidal action by all extracts. Values ranged from 0.5–4 mg/mL for MIC and 1–8 mg/mL for MFC. In an overview, the results obtained demonstrate that the sage extract presented the best antifungal performance. However, against the fungi A. niger and P. verrucosum var. cyclopium, all extracts analyzed showed the same performance. This agrees with previous studies carried out by other authors, where the antimicrobial potential of these species against several microbial strains is clearly detected [37,38,39]. In general, the antimicrobial activity of the tested PEs is better than both of the commercial food preservatives (Table 4).

Regarding the bioactivities studied, this antimicrobial action may be related to the presence of bioactive compounds in the composition of the extracts, such as phenolic compounds. However, contrary to what is found in the literature, these extracts are obtained from extraction methods optimized by mathematical models in order to guarantee the maximum yield and concentration of compounds of interest, while reducing the costs associated with the extraction process.

3.3. Alginate Coatings and Films with Plant Extracts

PEs are rich in phenolic compounds that confer on them a series of bioactive properties, such as antimicrobial and antioxidant behavior [38].

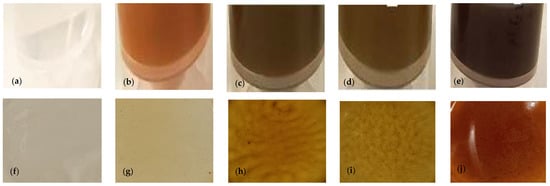

Due to the proven bioactive potential, the selected extracts were incorporated into alginate coatings (Figure 1). The concentration of extract on the coatings was 2% (w/v). An alginate coating without extract was also produced and used as a control in the antimicrobial and antioxidant tests. Alginate was selected for the coating/ film matrix due to its ability to form transparent, uniform, and high-quality films/ coatings [39]. Glycerol was used as a plasticizer to increase flexibility [40], and TPP was applied as a crosslinking agent to improve the mechanical resistance of the produced formulations [11,41].

Figure 1.

Photographs of the alginate coatings and films. (a) Alginate coating without extract; (b) alginate coating with licorice extract; (c) alginate coating with eucalyptus extract; (d) alginate coating with sage extract; and (e) alginate coating with thyme extract. Alginate films. (f) Alginate film without extract; (g) alginate film with licorice extract; (h) alginate film with eucalyptus extract; (i) alginate film with sage extract; and (j) alginate film with thyme extract.

As previously mentioned, in order to determine more realistically the bioactivities of the coatings and mimic what happens when they are applied to the food surface, films were produced with the coating solutions by the traditional casting method. Figure 1 illustrates the different films.

3.4. Evaluation of the Bioactive Potential of the Coatings/Films

3.4.1. Antibacterial Activity

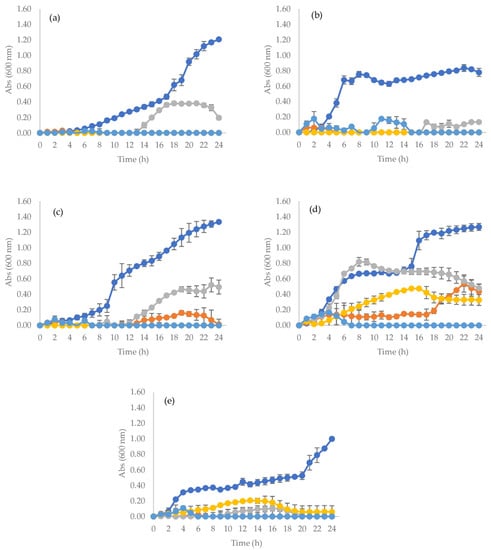

All coatings were tested against bacterial species S. aureus, B. cereus, L. monocytogenes, E. coli, and P. aeruginosa. The growth inhibition curves are shown in Figure 2.

Figure 2.

Growth inhibition curves of selected bacteria in contact with alginate + TPP coating ( ), alginate + TPP + licorice coating (

), alginate + TPP + licorice coating ( ), alginate + TPP + eucalyptus coating (

), alginate + TPP + eucalyptus coating ( ), alginate + TPP + sage coating (

), alginate + TPP + sage coating ( ) and alginate + TPP + thyme coating (

) and alginate + TPP + thyme coating ( ). The coating with alginate and TPP (no extract) is the control. Bacterial strains: (a) S. aureus, (b) B. cereus, (c) L. monocytogenes, (d) E. coli and (e) P. aeruginosa.

). The coating with alginate and TPP (no extract) is the control. Bacterial strains: (a) S. aureus, (b) B. cereus, (c) L. monocytogenes, (d) E. coli and (e) P. aeruginosa.

), alginate + TPP + licorice coating (

), alginate + TPP + licorice coating ( ), alginate + TPP + eucalyptus coating (

), alginate + TPP + eucalyptus coating ( ), alginate + TPP + sage coating (

), alginate + TPP + sage coating ( ) and alginate + TPP + thyme coating (

) and alginate + TPP + thyme coating ( ). The coating with alginate and TPP (no extract) is the control. Bacterial strains: (a) S. aureus, (b) B. cereus, (c) L. monocytogenes, (d) E. coli and (e) P. aeruginosa.

). The coating with alginate and TPP (no extract) is the control. Bacterial strains: (a) S. aureus, (b) B. cereus, (c) L. monocytogenes, (d) E. coli and (e) P. aeruginosa.

All coatings incorporated with PEs presented significant antimicrobial activity against all studied bacterial species. In fact, the coating incorporated with thyme extract was able to completely inhibit the growth of all bacteria tested in this study. The coating with licorice extract was able to completely inhibit the growth of S. aureus, B. cereus, L. monocytogenes, and P. aeruginosa. It did not completely inhibit the growth of E. coli, but it significantly reduced its growth. The coating incorporated with eucalyptus extract was also able to kill the Gram-positive bacteria. This coating could not completely inhibit the growth of Gram-negative bacteria, but it decreased their development. The sage-incorporated coating was only able to completely inhibit P. aeruginosa, making it the coating with the least antimicrobial activity. The coating without PEs did not inhibit any of the studied bacteria, thus acting as a positive control. In general, when an extract is incorporated into a coating, its antimicrobial activity decreases or its effective concentration lowers. In fact, the sage extract presented antibacterial activity against B. cereus, L. monocytogenes, S. aureus, and E. coli (MIC = 0.25 mg/mL) (Table 4). However, when the same extract is incorporated into a coating at 2% (w/v), its antibacterial activity decreases, since this coating was not able to inhibit the growth of the same bacterial species (Figure 2). The licorice extract presented an MIC value of less than 0.25 mg/mL for E. coli (Table 4). However, a coating with this extract at 2% (w/v) was not able to inhibit this bacterium (Figure 2). These results are possible due to the fact that the bioactive molecules within the extracts interact with other components of the coating, thus reducing their antibacterial activity.

There are some studies that report the incorporation of PEs into alginate edible coatings [42,43,44], but none of them incorporated extracts of licorice, eucalyptus, sage, and thyme, attesting to the innovation of the present work. Additionally, the antibacterial activity of the coating solutions is usually determined by the disc diffusion method [43], or it is studied on the surfaces onto which the coatings are applied [44,45].

When a coating is applied to a surface it dries and a thin film is formed. Thus, to verify if the antibacterial activity of a coating is maintained when it is transformed into a film, films were produced with the coating solutions and direct inoculation with each strain was simulated to reproduce the contamination on the surface of the food product.

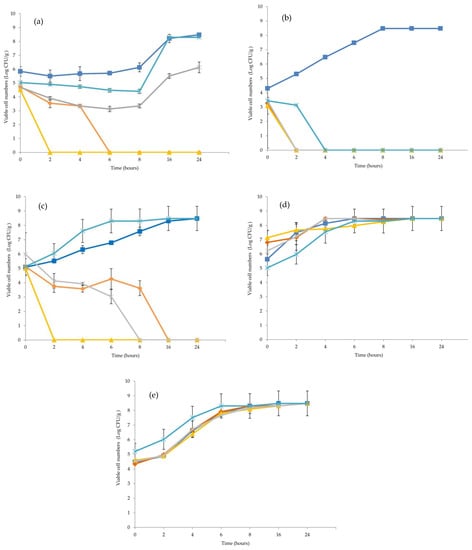

All films were tested against bacterial species S. aureus, B. cereus, L. monocytogenes, E. coli, and P. aeruginosa using the viable cell count assay. The results are shown in Figure 3.

Figure 3.

Growth inhibition curves of selected bacteria in contact with alginate + TPP film ( ), alginate + TPP + licorice film (

), alginate + TPP + licorice film ( ) alginate + TPP + eucalyptus film (

) alginate + TPP + eucalyptus film ( ), alginate + TPP + sage film (

), alginate + TPP + sage film ( ) and alginate + TPP + thyme film (

) and alginate + TPP + thyme film ( ). The film with alginate and TPP (no extract) is the control. Bacterial strains: (a) S. aureus, (b) B. cereus, (c) L. monocytogenes, (d) E. coli and (e) P. aeruginosa.

). The film with alginate and TPP (no extract) is the control. Bacterial strains: (a) S. aureus, (b) B. cereus, (c) L. monocytogenes, (d) E. coli and (e) P. aeruginosa.

), alginate + TPP + licorice film (

), alginate + TPP + licorice film ( ) alginate + TPP + eucalyptus film (

) alginate + TPP + eucalyptus film ( ), alginate + TPP + sage film (

), alginate + TPP + sage film ( ) and alginate + TPP + thyme film (

) and alginate + TPP + thyme film ( ). The film with alginate and TPP (no extract) is the control. Bacterial strains: (a) S. aureus, (b) B. cereus, (c) L. monocytogenes, (d) E. coli and (e) P. aeruginosa.

). The film with alginate and TPP (no extract) is the control. Bacterial strains: (a) S. aureus, (b) B. cereus, (c) L. monocytogenes, (d) E. coli and (e) P. aeruginosa.

As expected, the film with alginate and TPP (no extract) did not show any inhibitory activity against the studied bacteria and acted as a control, since all microorganisms grew in an exponential manner when exposed to this film. This result is similar to that reported by Aydin and Zorlu [46] and Engin et al. [47].

The films incorporated with licorice and eucalyptus extracts were able to inhibit the growth of all tested Gram-positive bacteria. In fact, in the case of the film with eucalyptus extract, only 2 h were necessary to completely inhibit the growth of these microorganisms. The film with licorice extract was able to inhibit the growth of B. cereus after 2 h of incubation but it took longer to reduce the viability of S. aureus (6 h) and L. monocytogenes (16 h). The film incorporated with sage extract was able to inhibit the growth of B. cereus (2 h) and L. monocytogenes (8 h) but did not completely inhibit S. aureus. The film with thyme extract was only able to inhibit the growth of B. cereus and it took 4 h to completely inhibit this bacterium. However, none of the produced films were able to inhibit the growth of Gram-negative bacteria.

The main mechanism of action of PEs in bacterial cells seems to be the rupture of the cell membrane [48,49,50,51,52,53], which leads to leakage of cell content [49,52] and subsequent death. PEs also cause depletion/leakage of intracellular ATP [52,54] and disrupt the cell metabolism by destroying proteins and/or inhibiting their synthesis [51]. Gram-positive bacteria are usually more susceptible to antimicrobial agents due to their cell wall, which is mainly composed of peptidoglycan. This molecule forms robust cell walls however, it poorly restricts the diffusion of small molecules across the membrane, contributing to the high susceptibility of Gram-positive bacteria to PEs. On the other hand, the cell wall of Gram-negative bacteria possesses a lipopolysaccharide layer that decreases the permeability of the cell to PEs [46,55]. As previously mentioned in this study, although the selected PEs presented antibacterial activity against both Gram-positive and Gram-negative bacteria when incorporated into alginate films, they seem to lose their activity (similarly to what happened with the coatings). The possible existence of chemical interactions between hydroxyl groups in the film and phenolic compounds that could block the active sites of PEs [56] may explain why no growth inhibition for Gram-negative bacteria, when exposed to the films incorporated with PEs, was observed.

There are several studies reporting the incorporation of PEs into alginate films [46,47,57,58,59]. However, none of them incorporated extracts of licorice, eucalyptus, sage, and thyme, attesting to the innovation of the present work. Additionally, the antibacterial activity of films is usually determined by the disc diffusion method [46,47,57,60] and not by the viable cell count assay, as performed in this study, which mimics more accurately the real interaction of contaminant microorganisms and films. Nevertheless, it is possible to compare the results of this work with studies that produced films with other polymers and/or incorporated other extracts into films. Campos et al. [24] produced methylcellulose films incorporated with Ginja cherry extract, studied their antimicrobial activity by the viable cell method, and concluded that their films were able to inhibit S. aureus (which also occurred in the present work for the films incorporated with licorice and eucalyptus extracts) and E. coli (which was not verified in this study for all the tested films). However, the concentration of extract on the films produced by Campos et al. [24] was 3% (w/v), while in this work the maximum concentration of extracts tested on the films was 2% (w/v). Thus, it is not possible to say whether an increase in the extracts’ concentration would not produce the same effect verified by Campos et al. [24] A similar method was performed by Amankwaah et al. [61] to determine the antibacterial activity of chitosan films incorporated with different concentrations of green tea extract against E. coli. All films produced by these authors were able to inhibit E. coli after 24 h of incubation. However, the extract concentrations applied to the films (5, 10, and 15% (w/v)) were much higher than the one used in the films of this work.

It is important to mention that the concentration of a PE in a film should not be higher than 5% (w/v) because higher extract concentrations can impair the film properties and increase the migration of extract molecules into the food products [24]. In this study, the authors followed this recommendation even though their films were not able to inhibit Gram-negative bacteria.

Usually, the incorporation of an extract into a film decreases its antimicrobial activity (when compared with the activities of the crude extract and the coatings). In fact, the thyme extract presented antibacterial activity against B. cereus, L. monocytogenes, S. aureus, and E. coli (MIC = 0.25–1 mg/mL) (Table 4). When the same extract is incorporated into a coating at 2% (w/v), it is possible to verify that it was able to completely inhibit these bacteria (Figure 2), suggesting that the antibacterial potential of the extract is maintained. However, for a film obtained through the same coating, the antibacterial activity decreases since the film was only able to inhibit the growth of B. cereus (Figure 3).

This different behavior observed for PEs when they were incorporated into films or coatings is probably due to the nature of the different matrices. In a solid matrix (film), the bioactive compounds are less dispersed and are released more slowly than in a liquid matrix (coating). Moreover, the phenolic compounds of the extracts (their main antimicrobial molecules) may be establishing links in the film network that impair their action. This can potentially explain why the authors obtained different antimicrobial activities for the crude PEs versus when they were incorporated into films or coating matrices.

3.4.2. Antifungal Activity

The antifungal activity of the films was determined for the species A. niger, P. expansum, F. verticillioides, and Cladosporium sp. using the adapted method of Guimarães et al. [25], which evaluated the ability of the fungi to grow on film surfaces.

The results were expressed as the percentage of inhibition, i.e., the reduction of the fungal growth in the films with PEs when compared to the growth of the fungus in the control (Table 5).

Table 5.

Antifungal activity of the films incorporated with plant extracts against some fungal species.

The film incorporated with sage extract was the one that presented the best antifungal activity. This film was able to inhibit the growth of Cladosporium sp. completely and presented an inhibition percentage of 83% for F. verticillioides and 48% for A. niger. For P. expansum, the inhibition percentage was only 13%. The films incorporated with licorice and thyme extracts were the ones that presented lower antifungal activity. In fact, the only fungus that presented some inhibition when exposed to these films was A. niger (47% inhibition percentage for licorice and 21% for thyme). For the other studied fungal species, no inhibition was detected. The film incorporated with eucalyptus extract was able to completely inhibit the growth of Cladosporium sp. and presented some inhibition for A. niger (33%) and for F. verticillioides (40%). This film was not able to inhibit P. expansum.

There are studies that attest to the antifungal activity of polymeric films incorporated with PEs [56,62,63,64,65]. However, many of these studies describe the incorporation of extracts into films that are not made of alginate and, to the best of our knowledge, none of them incorporated extracts of licorice, eucalyptus, sage, and thyme into the films. Moreover, the antifungal activity of films is usually determined by the disc diffusion assay [62,66], not by calculating the inhibition percentage, as performed in this study. Yan et al. [66] produced alginate/starch films incorporated with rosemary extract in a range between 0.3 to 1.2%, tested them by diffusion assay against A. niger, and concluded that the films did not inhibit this fungus. In the present study, the authors tested alginate films with four plant extracts against the same fungus and concluded that all films showed some growth inhibition. However, the concentration of all extracts incorporated into the films was higher than the concentration range used by Yan et al. [66] Aloui et al. [67] made alginate films incorporated with gallnut extract in a range from 2.5 to 50% and also tested them against A. niger. They concluded that their films did not have antifungal activity, but they tested the activity of the film-forming solution and not the film itself, which could be the reason why they did not have a positive result, unlike the authors of this study.

Mirón-Mérida et al. [68] tested the antifungal activity of gellan gum films incorporated with coffee extract, using a similar method to that employed in this work. Their results of percentage of inhibition for F. verticillioides ranged from 35% (for the less concentrated film) to 55% (for the film with a higher concentration of extract). In the present work, the authors achieved higher inhibition percentages for the films incorporated with eucalyptus and sage extracts than those obtained by Mirón-Mérida et al. [68] for the same fungus. All these results seem to indicate that the antifungal activity of polymeric films with PEs depends on the incorporated extract, since some extracts can produce higher antifungal activities than others when applied to the films at equal or even lower concentrations. The antifungal activity of a film is also influenced by the tested fungal species because a film can present different properties when exposed to different species.

Similarly to what was verified for the antibacterial activity, the antifungal potential of a PE was different for the crude extract versus when it was incorporated into a film. This could potentially be explained by the possibility of the existence of chemical interactions between hydroxyl groups in the film and the extracts’ phenolic compounds, which could block the active sites of PEs [56].

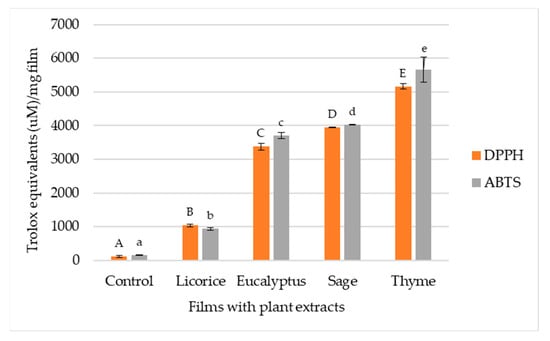

3.4.3. Antioxidant Activity

The films were also tested for their antioxidant activity by ABTS and DPPH scavenging assays, as these are widely used methods to determine this property in hydrophilic and lipophilic substances, respectively.

Initially, the antioxidant activity of the films dissolved in water (results not shown) was tested, as performed in various studies [47,69,70,71]. However, it was verified that the values of antioxidant activity were almost residual and probably did not correspond to the real ones. Thus, the antioxidant activity was tested directly on the solid films, obtaining much higher values via both ABTS and DPPH (Figure 4) and simulating more realistically the contact with the food surface.

Figure 4.

Antioxidant activity of alginate and TPP films incorporated with licorice, eucalyptus, and sage extracts. The alginate film with TPP (no extract) was considered the control film. Different letters in the bars mean to statistically significant variances (p < 0.05 according to Tukey’s HSD test).

The control film (ABTS: 161.17 Trolox equivalents (µM)/mg film; DPPH: 124.38 Trolox equivalents (µM)/mg film) presented a residual antioxidant activity when compared to the films with PEs. However, the values of antioxidant activity of this film are not zero because alginate itself has a specific antioxidant activity [72]. The films incorporated with PEs show significantly higher values of antioxidant activity when compared to the control film, which means that the addition of an extract to a film increases its antioxidant potential [73].

The film incorporated with thyme extract was the one that presented the best antioxidant activity by both ABTS (5654.62 Trolox equivalents (µM)/mg film) and DPPH (5162.93 Trolox equivalents (µM)/mg film), followed by the film with sage extract (ABTS: 4024.17 Trolox equivalents (µM)/mg film; DPPH: 3954.81 Trolox equivalents (µM)/mg film). The film incorporated with eucalyptus extract presented an ABTS value of 3706.30 Trolox equivalents (µM)/mg film and a DPPH value of 3377.97 Trolox equivalents (µM)/mg film. The film incorporated with licorice extract (ABTS: 942.52 Trolox equivalents (µM)/mg film; DPPH: 1040.67 Trolox equivalents (µM)/mg film) was the one with the least antioxidant activity.

In the films incorporated with eucalyptus, sage, and thyme extracts, the scavenging activity of ABTS is greater than the antioxidant activity resulting from the DPPH method. On the contrary, the film incorporated with licorice extract exhibits greater antioxidant activity by DPPH. This may indicate that the bioactive molecules present in the extracts of eucalyptus, sage, and thyme have a hydrophilic profile, whereas licorice extract presents lipophilic behavior [59]. The high values of antioxidant activity demonstrated by the films incorporated with PEs, especially the ones with thyme, sage, and eucalyptus, can be indicative that these films have the ability to capture free radicals and prevent the oxidation of food products [59]. Thus, these formulations can potentially constitute an alternative to synthetic additives used in the extension of the shelf life of food products [74].

4. Conclusions

In this work, extracts from licorice, eucalyptus, sage, and thyme were produced. These extracts presented good bioactive properties (namely, antioxidant and antimicrobial) that may be mainly associated with their rich content of phenolic compounds.

When incorporated into alginate coatings and films, this conferred on them good antioxidant and antimicrobial potential against some selected microbial strains. Additionally, the incorporation of an extract into these formulations changes their antimicrobial activity, which is usually higher in the coating. Furthermore, these formulations were produced with materials obtained from natural sources and can potentially be an alternative to conventional synthetic plastics, which are responsible for environmental pollution. However, further experiments need to be performed on these coatings to study their cytotoxic and genotoxic profiles. It is also important to apply the coatings onto food matrices and evaluate their bioactivity.

Author Contributions

Conceptualization: A.I.L., F.K.T. and M.P.; methodology: A.I.L., C.C., E.P., A.M., T.C.F., T.B.A., S.S., M.I. and M.S.; validation: A.I.L., C.C., E.P., A.M., T.B.A. and S.S.; formal analysis: A.I.L., C.C., E.P., T.C.F., M.I. and M.S.; investigation: A.I.L., C.C., E.P., A.M., T.B.A. and S.S.; resources: F.K.T. and M.P.; writing—original draft preparation: A.I.L., C.C. and E.P.; writing—review and editing: A.I.L., A.M., F.K.T., M.P. and L.B.; supervision, M.P., F.K.T. and L.B.; project administration: L.B.; funding acquisition: L.B. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by project BIOma—Soluções integradas de BIOeconomia para a Mobilização da cadeia Agroalimentar (POCI-01-0247-FEDER-046112), co-financed by Fundo Europeu de Desenvolvimento Regional (FEDER) through Programa Operacional Competitividade de Internacionalização (POCI). This research was also funded by National Funds from FCT—Fundação para a Ciência e a Tecnologia through projects UIDB/50016/2020 (CBQF), UIDB/00690/2020, UIDP/00690/2020 (CIMO), and LA/P/0007/2020 (SusTEC).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available within the article.

Acknowledgments

Author Lillian Barros would like to acknowledge her contract through the institutional scientific employment program. Authors Ana Isabel Lopes and Adma Melo would like to acknowledge their individual grants. The authors are also grateful to “DEIFIL” for providing the plant material. The graphical abstract was created with BioRender.com.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Aitboulahsen, M.; El Galiou, O.; Laglaoui, A.; Bakkali, M.; Hassani Zerrouk, M. Effect of Plasticizer Type and Essential Oils on Mechanical, Physicochemical, and Antimicrobial Characteristics of Gelatin, Starch, and Pectin-Based Films. J. Food Process. Preserv. 2020, 44, e14480. [Google Scholar] [CrossRef]

- Piñeros-Hernandez, D.; Medina-Jaramillo, C.; López-Córdoba, A.; Goyanes, S. Edible Cassava Starch Films Carrying Rosemary Antioxidant Extracts for Potential Use as Active Food Packaging. Food Hydrocoll. 2017, 63, 488–495. [Google Scholar] [CrossRef]

- Mahcene, Z.; Khelil, A.; Hasni, S.; Akman, P.K.; Bozkurt, F.; Birech, K.; Goudjil, M.B.; Tornuk, F. Development and Characterization of Sodium Alginate Based Active Edible Films Incorporated with Essential Oils of Some Medicinal Plants. Int. J. Biol. Macromol. 2020, 145, 124–132. [Google Scholar] [CrossRef]

- Sharma, S.; Barkauskaite, S.; Jaiswal, S.; Duffy, B.; Jaiswal, A.K. Development of Essential Oil Incorporated Active Film Based on Biodegradable Blends of Poly (Lactide)/Poly (Butylene Adipate-Co-Terephthalate) for Food Packaging Application. J. Packag. Technol. Res. 2020, 4, 235–245. [Google Scholar] [CrossRef]

- Amalraj, A.; Haponiuk, J.T.; Thomas, S.; Gopi, S. Preparation, Characterization and Antimicrobial Activity of Polyvinyl Alcohol/Gum Arabic/Chitosan Composite Films Incorporated with Black Pepper Essential Oil and Ginger Essential Oil. Int. J. Biol. Macromol. 2020, 151, 366–375. [Google Scholar] [CrossRef] [PubMed]

- López de Dicastillo, C.; Bustos, F.; Guarda, A.; Galotto, M.J. Cross-Linked Methyl Cellulose Films with Murta Fruit Extract for Antioxidant and Antimicrobial Active Food Packaging. Food Hydrocoll. 2016, 60, 335–344. [Google Scholar] [CrossRef]

- Augusto, A.; Dias, J.R.; Campos, M.J.; Alves, N.M.; Pedrosa, R.; Silva, S.F.J. Influence of Codium tomentosum Extract in the Properties of Alginate and Chitosan Edible Films. Foods 2018, 7, 53. [Google Scholar] [CrossRef]

- Kaya, M.; Khadem, S.; Cakmak, Y.S.; Mujtaba, M.; Ilk, S.; Akyuz, L.; Salaberria, A.M.; Labidi, J.; Abdulqadir, A.H.; Deligöz, E. Antioxidative and Antimicrobial Edible Chitosan Films Blended with Stem, Leaf and Seed Extracts of Pistacia terebinthus for Active Food Packaging. RSC Adv. 2018, 8, 3941–3950. [Google Scholar] [CrossRef]

- Shit, S.C.; Shah, P.M. Edible Polymers: Challenges and Opportunities. J. Polym. 2014, 2014, 427259. [Google Scholar] [CrossRef]

- Atta, O.M.; Manan, S.; Shahzad, A.; Ul-Islam, M.; Ullah, M.W.; Yang, G. Biobased Materials for Active Food Packaging: A Review. Food Hydrocoll. 2022, 125, 107419. [Google Scholar] [CrossRef]

- Bashir, A.; Jabeen, S.; Gull, N.; Islam, A.; Sultan, M.; Ghaffar, A.; Khan, S.; Sagar, S.; Jamil, T. Co-Concentration Effect of Silane with Natural Extract on Biodegradable Polymeric Films for Food Packaging. Int. J. Biol. Macromol. 2018, 106, 351–359. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Liu, L.; Gong, X.; Chi, F.; Ma, Z. Fabrication and Comparison of Active Films from Chitosan Incorporating Different Spice Extracts for Shelf Life Extension of Refrigerated Pork. LWT 2021, 135, 110181. [Google Scholar] [CrossRef]

- Kaur, N.; Bains, A.; Kaushik, R.; Dhull, S.B.; Melinda, F.; Chawla, P. A Review on Antifungal Efficiency of Plant Extracts Entrenched Polysaccharide-Based Nanohydrogels. Nutrients 2021, 13, 2055. [Google Scholar] [CrossRef] [PubMed]

- Yang, K.; Han, Q.; Chen, B.; Zheng, Y.; Zhang, K.; Li, Q.; Wang, J. Antimicrobial Hydrogels: Promising Materials for Medical Application. Int. J. Nanomed. 2018, 13, 2217–2263. [Google Scholar] [CrossRef]

- Bal-Öztürk, A.; Özkahraman, B.; Özbaş, Z.; Yaşayan, G.; Tamahkar, E.; Alarçin, E. Advancements and Future Directions in the Antibacterial Wound Dressings—A Review. J. Biomed. Mater. Res. Part B Appl. Biomater. 2021, 109B, 703–716. [Google Scholar] [CrossRef]

- Ghasemlou, M.; Aliheidari, N.; Fahmi, R.; Shojaee-Aliabadi, S.; Keshavarz, B.; Cran, M.J.; Khaksar, R. Physical, Mechanical and Barrier Properties of Corn Starch Films Incorporated with Plant Essential Oils. Carbohydr. Polym. 2013, 98, 1117–1126. [Google Scholar] [CrossRef]

- Benavides, S.; Villalobos-Carvajal, R.; Reyes, J.E. Physical, Mechanical and Antibacterial Properties of Alginate Film: Effect of the Crosslinking Degree and Oregano Essential Oil Concentration. J. Food Eng. 2012, 110, 232–239. [Google Scholar] [CrossRef]

- Caleja, C.; Barros, L.; Prieto, M.A.; Bento, A.; Oliveira, M.B.P.P.; Ferreira, I.C.F.R. Development of a Natural Preservative Obtained from Male Chestnut Flowers: Optimization of a Heat-Assisted Extraction Technique. Food Funct. 2019, 10, 1352–1363. [Google Scholar] [CrossRef]

- Barros, L.; Pereira, E.; Calhelha, R.C.; Dueñas, M.; Carvalho, A.M.; Santos-Buelga, C.; Ferreira, I.C.F.R. Bioactivity and Chemical Characterization in Hydrophilic and Lipophilic Compounds of Chenopodium ambrosioides L. J. Funct. Foods 2013, 5, 1732–1740. [Google Scholar] [CrossRef]

- Barros, L.; Dueñas, M.; Dias, M.I.; Sousa, M.J.; Santos-Buelga, C.; Ferreira, I.C.F.R. Phenolic Profiles of Cultivated, in Vitro Cultured and Commercial Samples of Melissa officinalis L. Infusions. Food Chem. 2013, 136, 1–8. [Google Scholar] [CrossRef]

- Wolfe, K.L.; Liu, R.H. Cellular Antioxidant Activity (CAA) Assay for Assessing Antioxidants, Foods, and Dietary Supplements. J. Agric. Food Chem. 2007, 55, 8896–8907. [Google Scholar] [CrossRef] [PubMed]

- Carocho, M.; Barros, L.; Calhelha, R.C.; Ćirić, A.; Soković, M.; Santos-Buelga, C.; Morales, P.; Ferreira, I.C.F.R. Melissa officinalis L. Decoctions as Functional Beverages: A Bioactive Approach and Chemical Characterization. Food Funct. 2015, 6, 2240–2248. [Google Scholar] [CrossRef] [PubMed]

- Alexandre, E.M.C.; Silva, S.; Santos, S.A.O.; Silvestre, A.J.D.; Duarte, M.F.; Saraiva, J.A.; Pintado, M. Antimicrobial Activity of Pomegranate Peel Extracts Performed by High Pressure and Enzymatic Assisted Extraction. Food Res. Int. 2019, 115, 167–176. [Google Scholar] [CrossRef] [PubMed]

- Campos, D.; Piccirillo, C.; Pullar, R.C.; Castro, P.M.L.; Pintado, M.M.E. Characterization and Antimicrobial Properties of Food Packaging Methylcellulose Films Containing Stem Extract of Ginja Cherry. J. Sci. Food Agric. 2014, 94, 2097–2103. [Google Scholar] [CrossRef]

- Guimarães, A.; Ramos, O.; Cerqueira, M.; Venâncio, A.; Abrunhosa, L. Active Whey Protein Edible Films and Coatings Incorporating Lactobacillus buchneri for Penicillium nordicum Control in Cheese. Food Bioprocess Technol. 2020, 13, 1074–1086. [Google Scholar] [CrossRef]

- Clifford, M.N.; Johnston, K.L.; Knight, S.; Kuhnert, N. Hierarchical Scheme for LC-MSn Identification of Chlorogenic Acids. J. Agric. Food Chem. 2003, 51, 2900–2911. [Google Scholar] [CrossRef]

- Carocho, M.; Barros, L.; Barreira, J.C.M.; Calhelha, R.C.; Soković, M.; Fernández-Ruiz, V.; Buelga, C.S.; Morales, P.; Ferreira, I.C.F.R. Basil as Functional and Preserving Ingredient in “Serra Da Estrela” Cheese. Food Chem. 2016, 207, 51–59. [Google Scholar] [CrossRef]

- Hasegawa, T.; Takano, F.; Takata, T.; Niiyama, M.; Ohta, T. Bioactive Monoterpene Glycosides Conjugated with Gallic Acid from the Leaves of Eucalyptus globulus. Phytochemistry 2008, 69, 747–753. [Google Scholar] [CrossRef]

- Kitagawa, I.; Chen, W.Z.; Hori, K.; Harada, E.; Yasuda, N.; Yoshikawa, M.; Ren, J. Chemical Studies of Chinese Licorice-Roots. I. Elucidation of Five New Flavonoid Constituents from the Roots of Glycyrrhiza glabra L. Collected in Xinjiang. Chem. Pharm. Bull. 1994, 42, 1056–1062. [Google Scholar] [CrossRef]

- Martins, N.; Barros, L.; Dueñas, M.; Santos-Buelga, C.; Ferreira, I.C.F.R. Characterization of Phenolic Compounds and Antioxidant Properties of Glycyrrhiza glabra L. Rhizomes and Roots. RSC Adv. 2015, 5, 26991–26997. [Google Scholar] [CrossRef]

- Schmid, C.; Dawid, C.; Peters, V.; Hofmann, T. Saponins from European Licorice Roots (Glycyrrhiza glabra). J. Nat. Prod. 2018, 81, 1734–1744. [Google Scholar] [CrossRef] [PubMed]

- Bello, M.; Jiddah-kazeem, B.; Fatoki, T.H.; Ibukun, E.O.; Akinmoladun, A.C. Antioxidant Property of Eucalyptus globulus Labill. Extracts and Inhibitory Activities on Carbohydrate Metabolizing Enzymes Related to Type-2 Diabetes. Biocatal. Agric. Biotechnol. 2021, 36, 102111. [Google Scholar] [CrossRef]

- Li, W.; Zhang, X.; He, Z.; Chen, Y.; Li, Z.; Meng, T.; Li, Y.; Cao, Y. In Vitro and in Vivo Antioxidant Activity of Eucalyptus Leaf Polyphenols Extract and Its Effect on Chicken Meat Quality and Cecum Microbiota. Food Res. Int. 2020, 136, 109302. [Google Scholar] [CrossRef]

- Pereira, E.; Barros, L.; Antonio, A.L.; Cabo Verde, S.; Santos-Buelga, C.; Ferreira, I.C.F.R. Infusions from Thymus vulgaris L. Treated at Different Gamma Radiation Doses: Effects on Antioxidant Activity and Phenolic Composition. LWT 2016, 74, 34–39. [Google Scholar] [CrossRef]

- Grzegorczyk, I.; Matkowski, A.; Wysokińska, H. Antioxidant Activity of Extracts from in Vitro Cultures of Salvia officinalis L. Food Chem. 2007, 104, 536–541. [Google Scholar] [CrossRef]

- Esmaeili, H.; Karami, A.; Hadian, J.; Saharkhiz, M.J.; Nejad Ebrahimi, S. Variation in the Phytochemical Contents and Antioxidant Activity of Glycyrrhiza glabra Populations Collected in Iran. Ind. Crops Prod. 2019, 137, 248–259. [Google Scholar] [CrossRef]

- Etchepare, M.A.; de Menezes, M.F.D.S.C.; Rodrigues, L.Z.; Codevilla, C.; Menezes, C. Microencapsulação de Compostos Bioativos Pelo Método de Extrusão. Ciência E Nat. 2015, 37, 97–105. [Google Scholar] [CrossRef][Green Version]

- Talón, E.; Trifkovic, K.T.; Nedovic, V.A.; Bugarski, B.M.; Vargas, M.; Chiralt, A.; González-Martínez, C. Antioxidant Edible Films Based on Chitosan and Starch Containing Polyphenols from Thyme Extracts. Carbohydr. Polym. 2017, 157, 1153–1161. [Google Scholar] [CrossRef]

- Nair, M.S.; Tomar, M.; Punia, S.; Kukula-Koch, W.; Kumar, M. Enhancing the Functionality of Chitosan- and Alginate-Based Active Edible Coatings/Films for the Preservation of Fruits and Vegetables: A Review. Int. J. Biol. Macromol. 2020, 164, 304–320. [Google Scholar] [CrossRef]

- Bisht, A.S.; Alam, M.S.; Bhatia, S.; Gupta, S.K. Studies on Development and Evaluation of Glycerol Incorporated Cellulose and Alginate Based Edible Films. Indian J. Agric. Biochem. 2017, 30, 67–72. [Google Scholar] [CrossRef]

- Gierszewska, M.; Ostrowska-Czubenko, J.; Jakubowska, E. Characteristics of Ascorbic Acid Release from TPP-Crosslinked Chitosan/Alginate Polyelectrolyte Complex Membranes. Prog. Chem. Appl. Chitin Its Deriv. 2018, XXIII, 76–87. [Google Scholar] [CrossRef]

- Aloui, H.; Khwaldia, K.; Sánchez-González, L.; Muneret, L.; Jeandel, C.; Hamdi, M.; Desobry, S. Alginate Coatings Containing Grapefruit Essential Oil or Grapefruit Seed Extract for Grapes Preservation. Int. J. Food Sci. Technol. 2014, 49, 952–959. [Google Scholar] [CrossRef]

- Hasan, K.; Islam, R.; Hasan, M.; Sarker, S.H.; Biswas, M.H. Effect of Alginate Edible Coatings Enriched with Black Cumin Extract for Improving Postharvest Quality Characteristics of Guava (Psidium guajava L.) Fruit. Food Bioprocess Technol. 2022, 15, 2050–2064. [Google Scholar] [CrossRef]

- Raybaudi-Massilia, R.M.; Mosqueda-Melgar, J.; Martín-Belloso, O. Edible Alginate-Based Coating as Carrier of Antimicrobials to Improve Shelf-Life and Safety of Fresh-Cut Melon. Int. J. Food Microbiol. 2008, 121, 313–327. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Jia, Y.; Hu, Y.; Xia, X.; Li, Y.; Zhou, J.; Liu, Y. Effect of Citrus Wilsonii Tanaka Extract Combined with Alginate-Calcium Coating on Quality Maintenance of White Shrimps (Litopenaeus vannamei Boone). Food Control 2016, 68, 83–91. [Google Scholar] [CrossRef]

- Aydin, G.; Zorlu, E.B. Characterisation and Antibacterial Properties of Novel Biodegradable Films Based on Alginate and Roselle (Hibiscus sabdariffa L.) Extract. Waste Biomass Valoriz. 2022, 13, 2991–3002. [Google Scholar] [CrossRef]

- Engin, M.S.; Zamahay, F.; Kalkan, S.; Otağ, M.R. Physical, Mechanical, and Bioactive Properties of Edible Film Based on Sodium Alginate Enriched with Lythrum salicaria L. Extract. J. Food Process. Preserv. 2022, 46, e16620. [Google Scholar] [CrossRef]

- Sadiq, M.B.; Tarning, J.; Cho, T.Z.A.; Anal, A.K. Activities and Possible Modes of Action of Acacia nilotica (L.) Del. against Multidrug-Resistant Escherichia coli and Salmonella. Molecules 2017, 22, 47. [Google Scholar] [CrossRef]

- Chew, Y.L.; Mahadi, A.M.; Wong, K.M.; Goh, J.K. Anti-Methicillin-Resistance Staphylococcus Aureus (MRSA) Compounds from Bauhinia kockiana Korth. And Their Mechanism of Antibacterial Activity. BMC Complement. Altern. Med. 2018, 18, 70. [Google Scholar] [CrossRef]

- Álvarez-Martínez, F.J.; Rodríguez, J.C.; Borrás-Rocher, F.; Barrajón-Catalán, E.; Micol, V. The Antimicrobial Capacity of Cistus salviifolius and Punica granatum Plant Extracts against Clinical Pathogens Is Related to Their Polyphenolic Composition. Sci. Rep. 2021, 11, 588. [Google Scholar] [CrossRef]

- Zhou, D.; Liu, Z.-H.; Wang, D.-M.; Li, D.-W.; Yang, L.-N.; Wang, W. Chemical Composition, Antibacterial Activity and Related Mechanism of Valonia and Shell from Quercus variabilis Blume (Fagaceae) against Salmonella paratyphi a and Staphylococcus aureus. BMC Complement. Altern. Med. 2019, 19, 271. [Google Scholar] [CrossRef]

- Xu, M.; Xue, H.; Li, X.; Zhao, Y.; Lin, L.; Yang, L.; Zheng, G. Chemical Composition, Antibacterial Properties, and Mechanism of Smilax china L. Polyphenols. Appl. Microbiol. Biotechnol. 2019, 103, 9013–9022. [Google Scholar] [CrossRef]

- Mombeshora, M.; Mukanganyama, S. Antibacterial Activities, Proposed Mode of Action and Cytotoxicity of Leaf Extracts from Triumfetta welwitschii against Pseudomonas aeruginosa. BMC Complement. Altern. Med. 2019, 19, 315. [Google Scholar] [CrossRef]

- Roshan, N.; Riley, T.V.; Knight, D.R.; Steer, J.H.; Hammer, K.A. Natural Products Show Diverse Mechanisms of Action against Clostridium difficile. J. Appl. Microbiol. 2019, 126, 468–479. [Google Scholar] [CrossRef] [PubMed]

- Gonelimali, F.D.; Lin, J.; Miao, W.; Xuan, J.; Charles, F.; Chen, M.; Hatab, S.R. Antimicrobial Properties and Mechanism of Action of Some Plant Extracts Against Food Pathogens and Spoilage Microorganisms. Front. Microbiol. 2018, 9, 1639. [Google Scholar] [CrossRef] [PubMed]

- Saberi, B.; Chockchaisawasdee, S.; Golding, J.B.; Scarlett, C.J.; Stathopoulos, C.E. Characterization of Pea Starch-Guar Gum Biocomposite Edible Films Enriched by Natural Antimicrobial Agents for Active Food Packaging. Food Bioprod. Process. 2017, 105, 51–63. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, H.; Yang, S.; Zeng, J.; Wu, Z. Sodium Alginate-Based Green Packaging Films Functionalized by Guava Leaf Extracts and Their Bioactivities. Materials 2019, 12, 2923. [Google Scholar] [CrossRef]

- Lim, L.I.; Tan, H.L.; Pui, L.P. Development and Characterization of Alginate-Based Edible Film Incorporated with Hawthorn berry (Crataegus pinnatifida) Extract. J. Food Meas. Charact. 2021, 15, 2540–2548. [Google Scholar] [CrossRef]

- Santos, L.G.; Silva, G.F.A.; Gomes, B.M.; Martins, V.G. A Novel Sodium Alginate Active Films Functionalized with Purple Onion Peel Extract (Allium cepa). Biocatal. Agric. Biotechnol. 2021, 35, 102096. [Google Scholar] [CrossRef]

- Nazir, S.; Wani, I.A. Development and Characterization of an Antimicrobial Edible Film from Basil Seed (Ocimum basilicum L.) Mucilage and Sodium Alginate. Biocatal. Agric. Biotechnol. 2022, 44, 102450. [Google Scholar] [CrossRef]

- Amankwaah, C.; Li, J.; Lee, J.; Pascall, M.A. Antimicrobial Activity of Chitosan-Based Films Enriched with Green Tea Extracts on Murine norovirus, Escherichia coli, and Listeria innocua. Int. J. Food Sci. 2020, 2020, 3941924. [Google Scholar] [CrossRef]

- Türe, H.; Eroğlu, E.; Soyer, F.; Özen, B. Antifungal Activity of Biopolymers Containing Natamycin and Rosemary Extract against Aspergillus niger and Penicillium roquefortii. Int. J. Food Sci. Technol. 2008, 43, 2026–2032. [Google Scholar] [CrossRef]

- Lozano-Navarro, J.I.; Díaz-Zavala, N.P.; Velasco-Santos, C.; Martínez-Hernández, A.L.; Tijerina-Ramos, B.I.; García-Hernández, M.; Rivera-Armenta, J.L.; Páramo-García, U.; Reyes-de la Torre, A.I. Antimicrobial, Optical and Mechanical Properties of Chitosan–Starch Films with Natural Extracts. Int. J. Mol. Sci. 2017, 18, 997. [Google Scholar] [CrossRef]

- Muriel-Galet, V.; Cran, M.J.; Bigger, S.W.; Hernández-Muñoz, P.; Gavara, R. Antioxidant and Antimicrobial Properties of Ethylene Vinyl Alcohol Copolymer Films Based on the Release of Oregano Essential Oil and Green Tea Extract Components. J. Food Eng. 2015, 149, 9–16. [Google Scholar] [CrossRef]

- Chakravartula, S.S.N.; Lourenço, R.V.; Balestra, F.; Bittante, A.M.Q.B.; Sobral, P.J.d.A.; Rosa, M.D. Influence of Pitanga (Eugenia uniflora L.) Leaf Extract and/or Natamycin on Properties of Cassava Starch/Chitosan Active Films. Food Packag. Shelf Life 2020, 24, 100498. [Google Scholar] [CrossRef]

- Yan, Q.; Zhang, J.; Dong, H.; Hou, H.; Guo, P. Properties and Antimicrobial Activities of Starch–Sodium Alginate Composite Films Incorporated with Sodium Dehydroacetate or Rosemary Extract. J. Appl. Polym. Sci. 2013, 127, 1951–1958. [Google Scholar] [CrossRef]

- Aloui, H.; Deshmukh, A.R.; Khomlaem, C.; Kim, B.S. Novel Composite Films Based on Sodium Alginate and Gallnut Extract with Enhanced Antioxidant, Antimicrobial, Barrier and Mechanical Properties. Food Hydrocoll. 2021, 113, 106508. [Google Scholar] [CrossRef]

- Mirón-Mérida, V.A.; Yáñez-Fernández, J.; Montañez-Barragán, B.; Huerta, B.E.B. Valorization of Coffee Parchment Waste (Coffea arabica) as a Source of Caffeine and Phenolic Compounds in Antifungal Gellan Gum Films. LWT 2019, 101, 167–174. [Google Scholar] [CrossRef]

- Norajit, K.; Kim, K.M.; Ryu, G.H. Comparative Studies on the Characterization and Antioxidant Properties of Biodegradable Alginate Films Containing Ginseng Extract. J. Food Eng. 2010, 98, 377–384. [Google Scholar] [CrossRef]

- Bojorges, H.; Ríos-Corripio, M.A.; Hernández-Cázares, A.S.; Hidalgo-Contreras, J.V.; Contreras-Oliva, A. Effect of the Application of an Edible Film with Turmeric (Curcuma longa L.) on the Oxidative Stability of Meat. Food Sci. Nutr. 2020, 8, 4308–4319. [Google Scholar] [CrossRef] [PubMed]

- Fabra, M.J.; Falcó, I.; Randazzo, W.; Sánchez, G.; López-Rubio, A. Antiviral and Antioxidant Properties of Active Alginate Edible Films Containing Phenolic Extracts. Food Hydrocoll. 2018, 81, 96–103. [Google Scholar] [CrossRef]

- Sellimi, S.; Younes, I.; Ayed, H.B.; Maalej, H.; Montero, V.; Rinaudo, M.; Dahia, M.; Mechichi, T.; Hajji, M.; Nasri, M. Structural, Physicochemical and Antioxidant Properties of Sodium Alginate Isolated from a Tunisian Brown Seaweed. Int. J. Biol. Macromol. 2015, 72, 1358–1367. [Google Scholar] [CrossRef]

- Dou, L.; Li, B.; Zhang, K.; Chu, X.; Hou, H. Physical Properties and Antioxidant Activity of Gelatin-Sodium Alginate Edible Films with Tea Polyphenols. Int. J. Biol. Macromol. 2018, 118, 1377–1383. [Google Scholar] [CrossRef] [PubMed]

- Romani, V.P.; Hernández, C.P.; Martins, V.G. Pink Pepper Phenolic Compounds Incorporation in Starch/Protein Blends and Its Potential to Inhibit Apple Browning. Food Packag. Shelf Life 2018, 15, 151–158. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).