Long-Term Performance Analysis of Epoxy Resin Ultra-Thin Wearing Course Overlay on Cement Concrete Pavement

Abstract

:1. Introduction

2. Materials and Experiment Methods

2.1. Materials

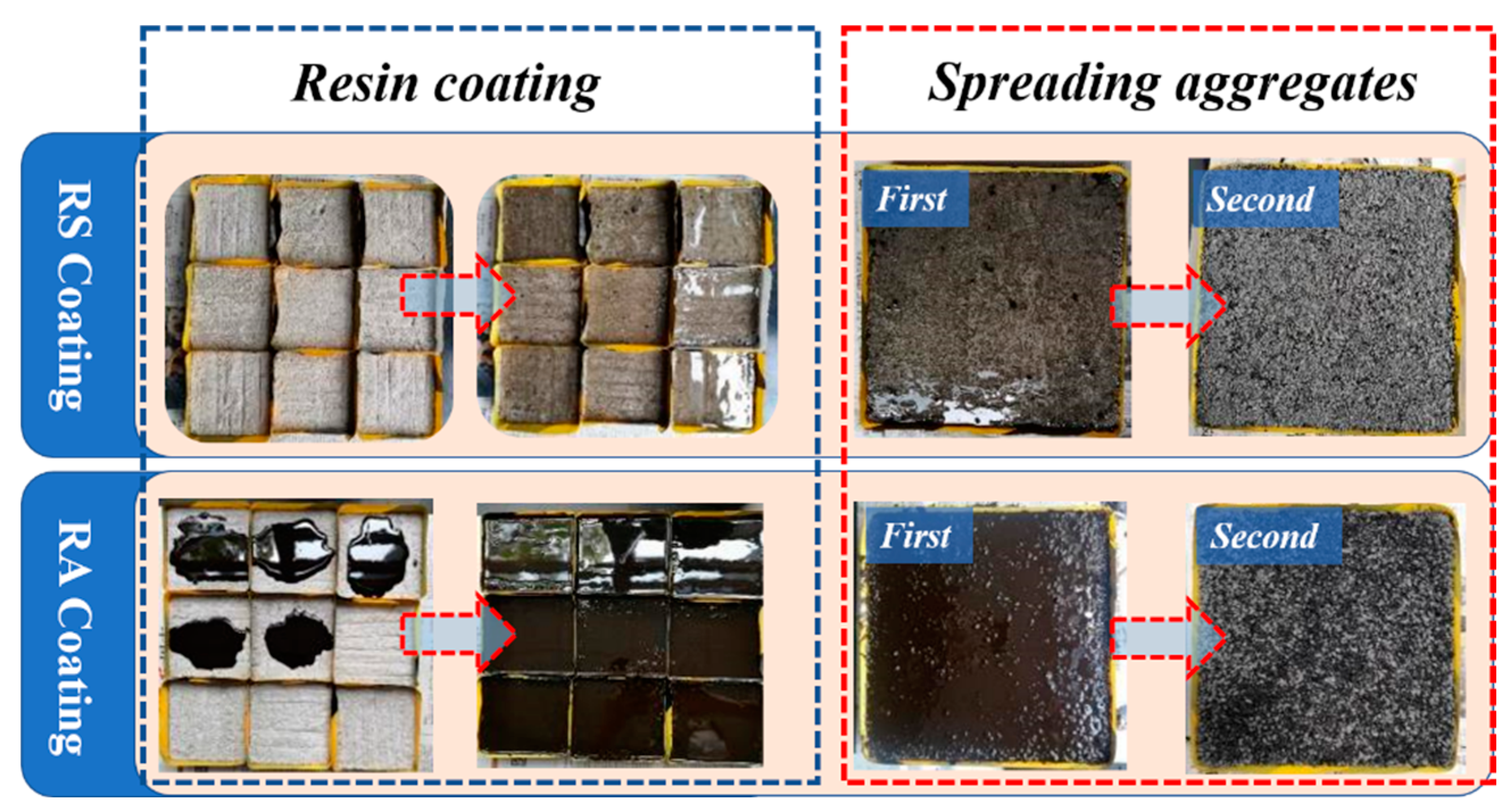

2.2. Preparation

2.3. Test Methods

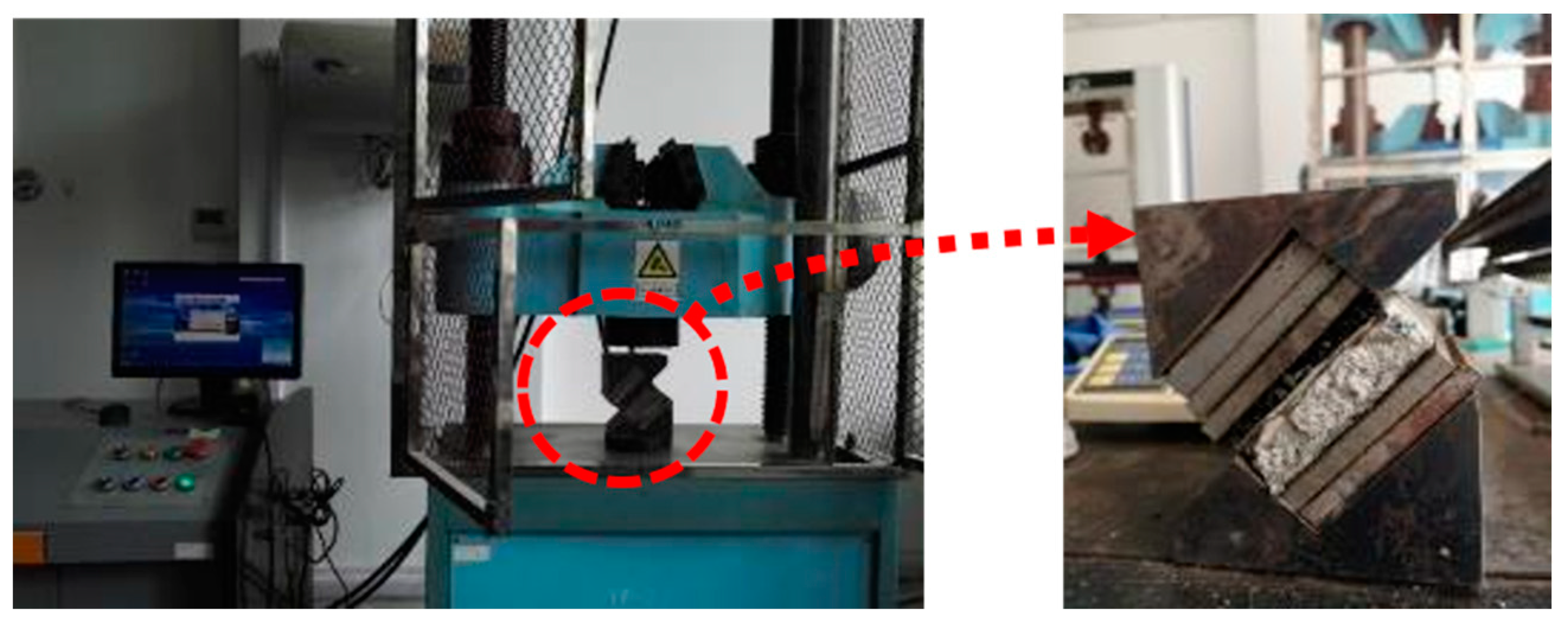

2.3.1. Shear Test

2.3.2. Hamburg Rutting Test

2.3.3. Durability Tests

- (1)

- Damp heat impact test

- (2)

- Thermal oxygen aging impact test

- (3)

- Ultraviolet (UV) aging impact test

3. Results and Discussion

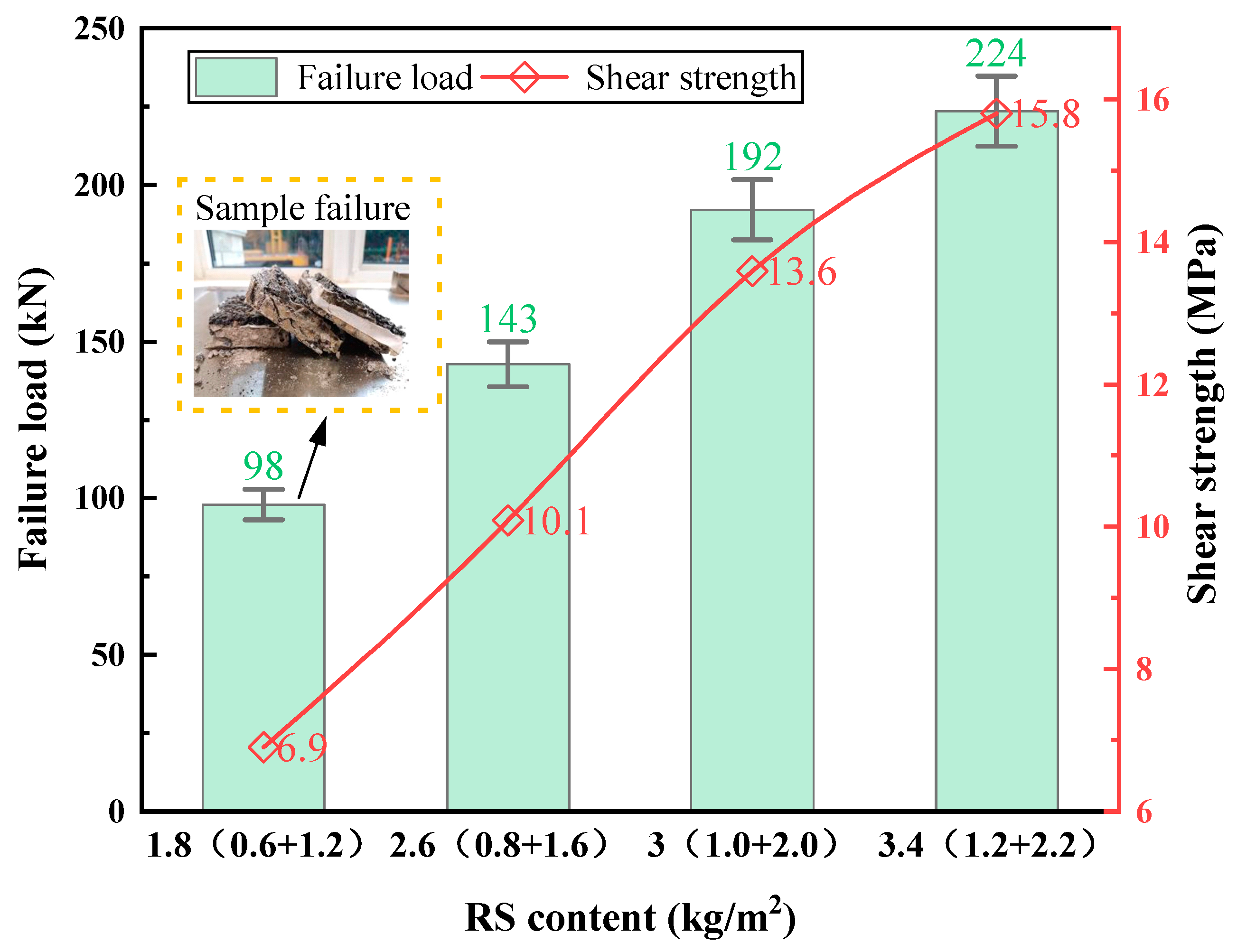

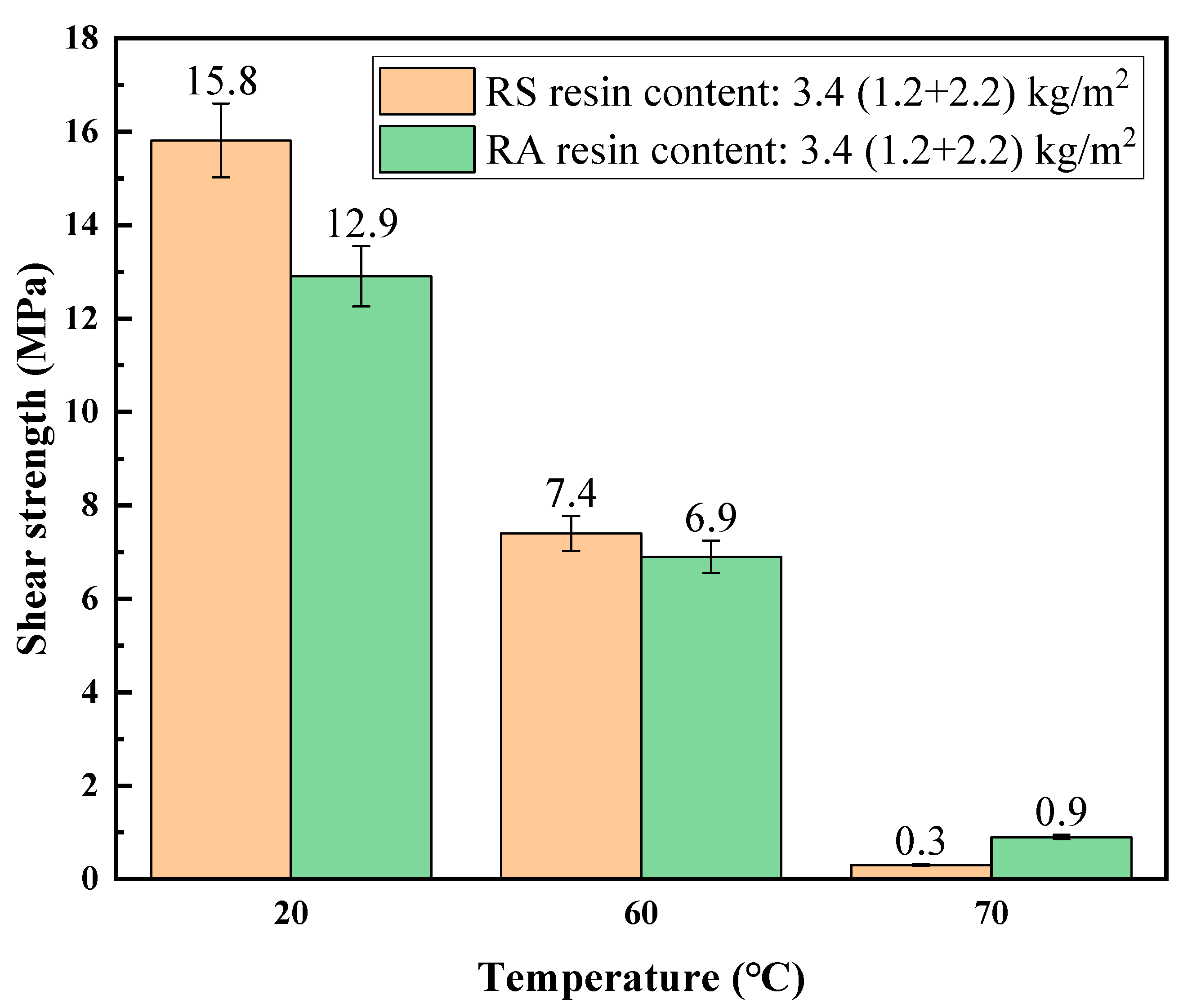

3.1. Determination of the Optimal Dosage of Epoxy Resin Overlay

3.2. High-Temperature Shear Performance of Epoxy Resin Overlay

- (1)

- High-temperature shear test results

- (2)

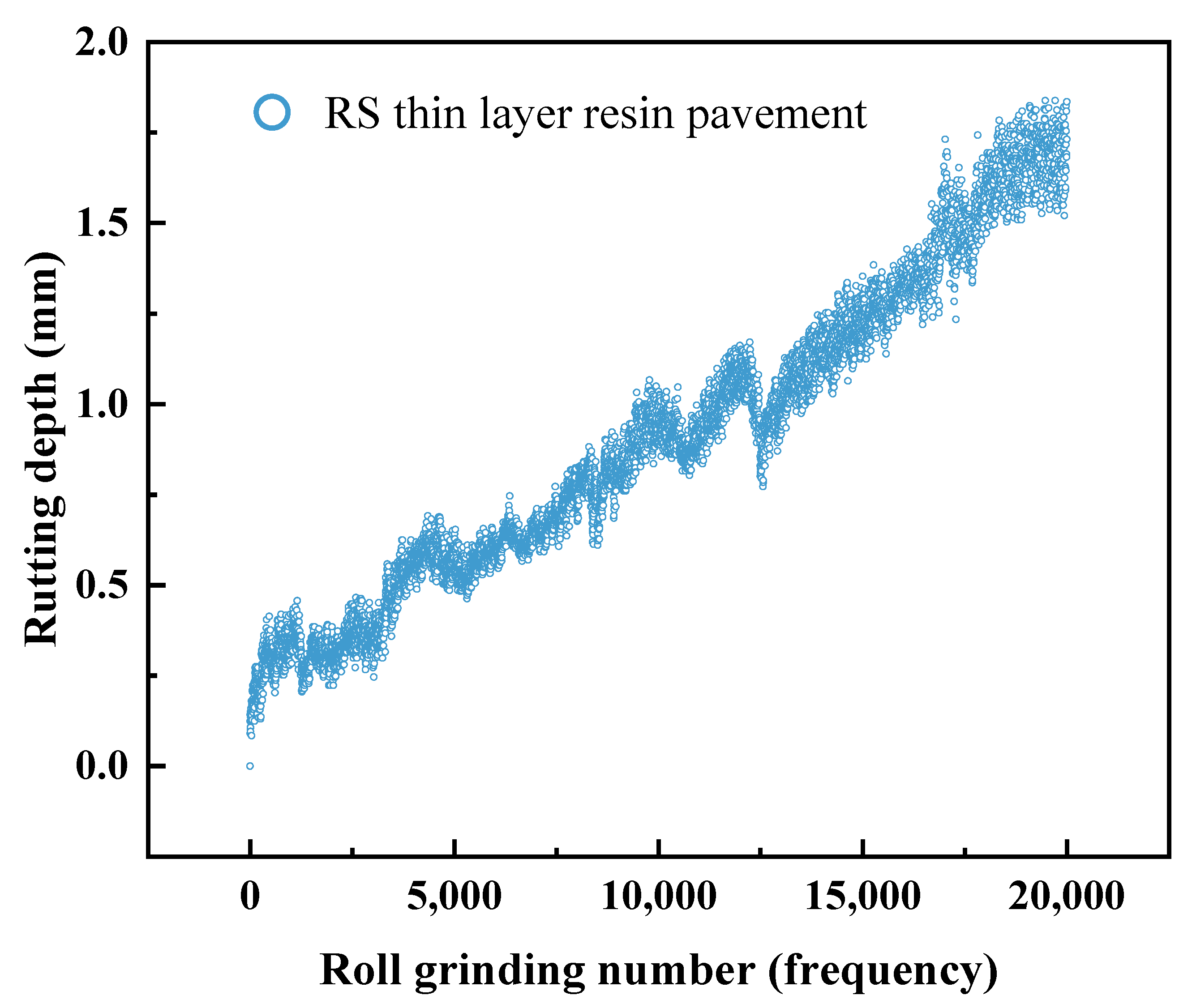

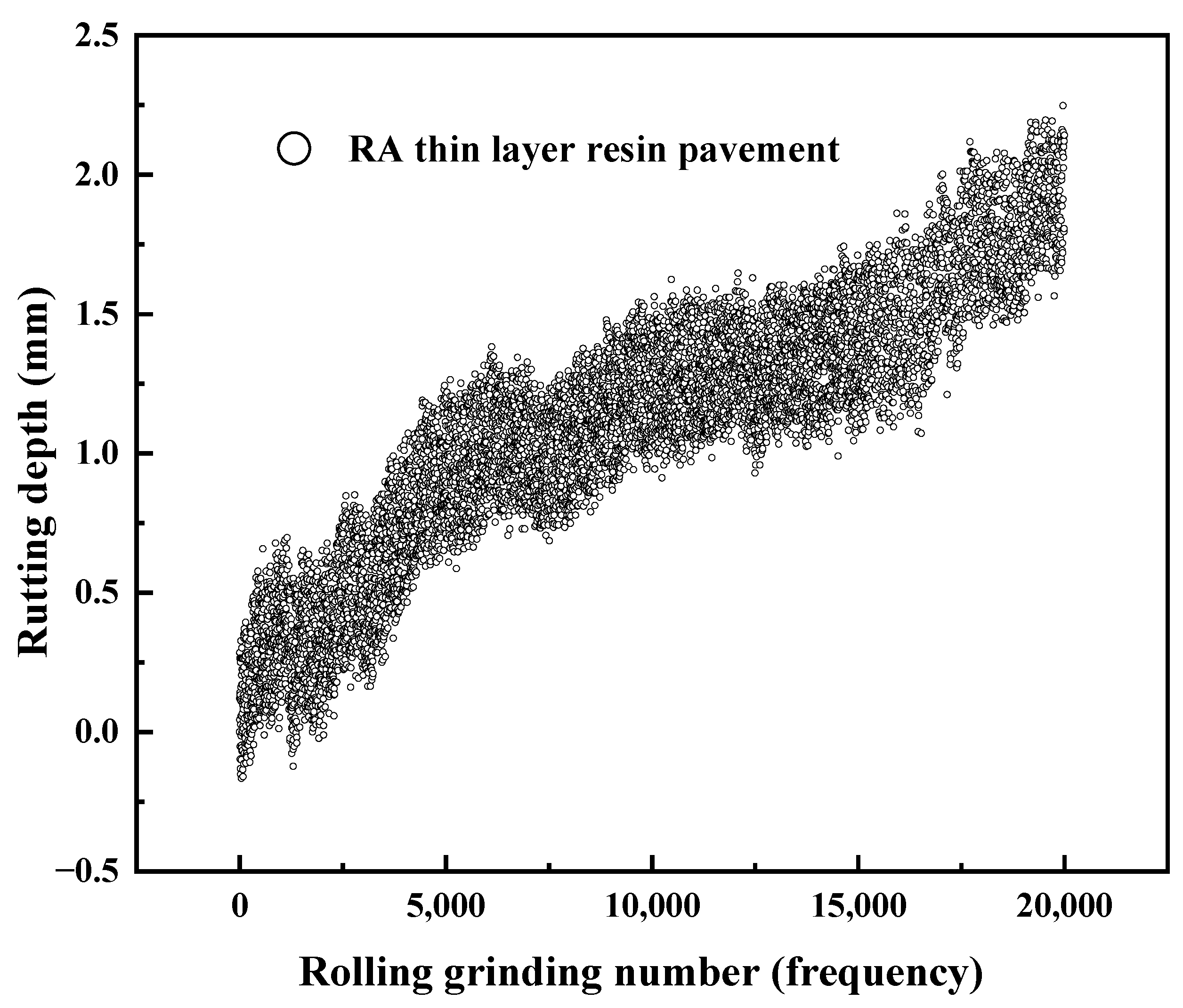

- Hamburg rutting test results

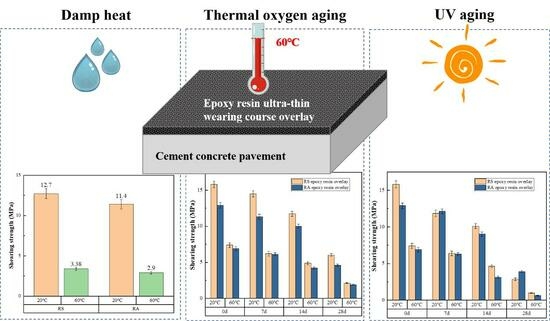

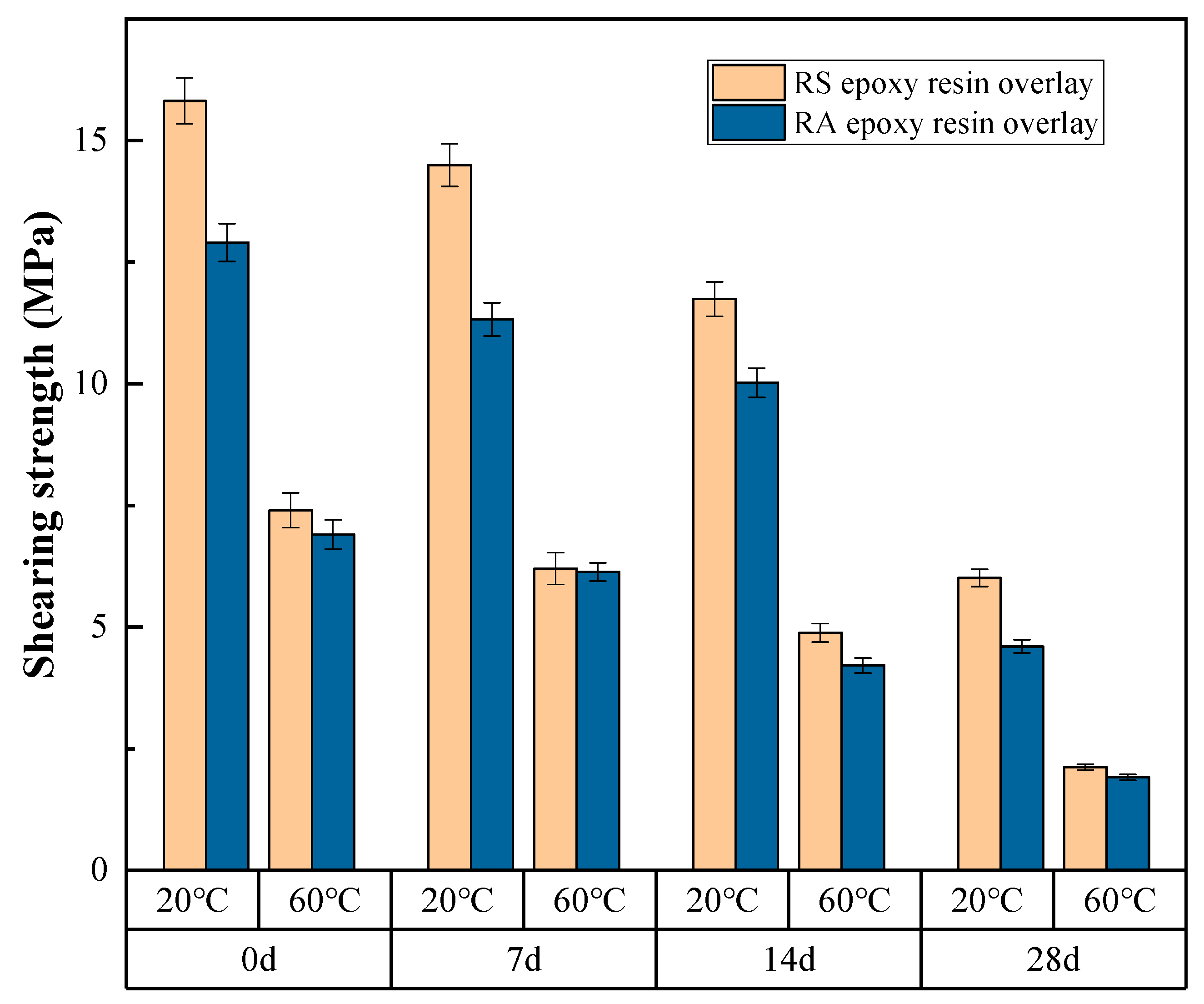

3.3. Durability Performance Evaluation of Epoxy Resin Overlay

3.3.1. Effect of Damp Heat on Shear Resistance of Epoxy Resin Overlay

3.3.2. Effect of Thermal Oxygen Aging on Shear Resistance of Epoxy Resin Overlay

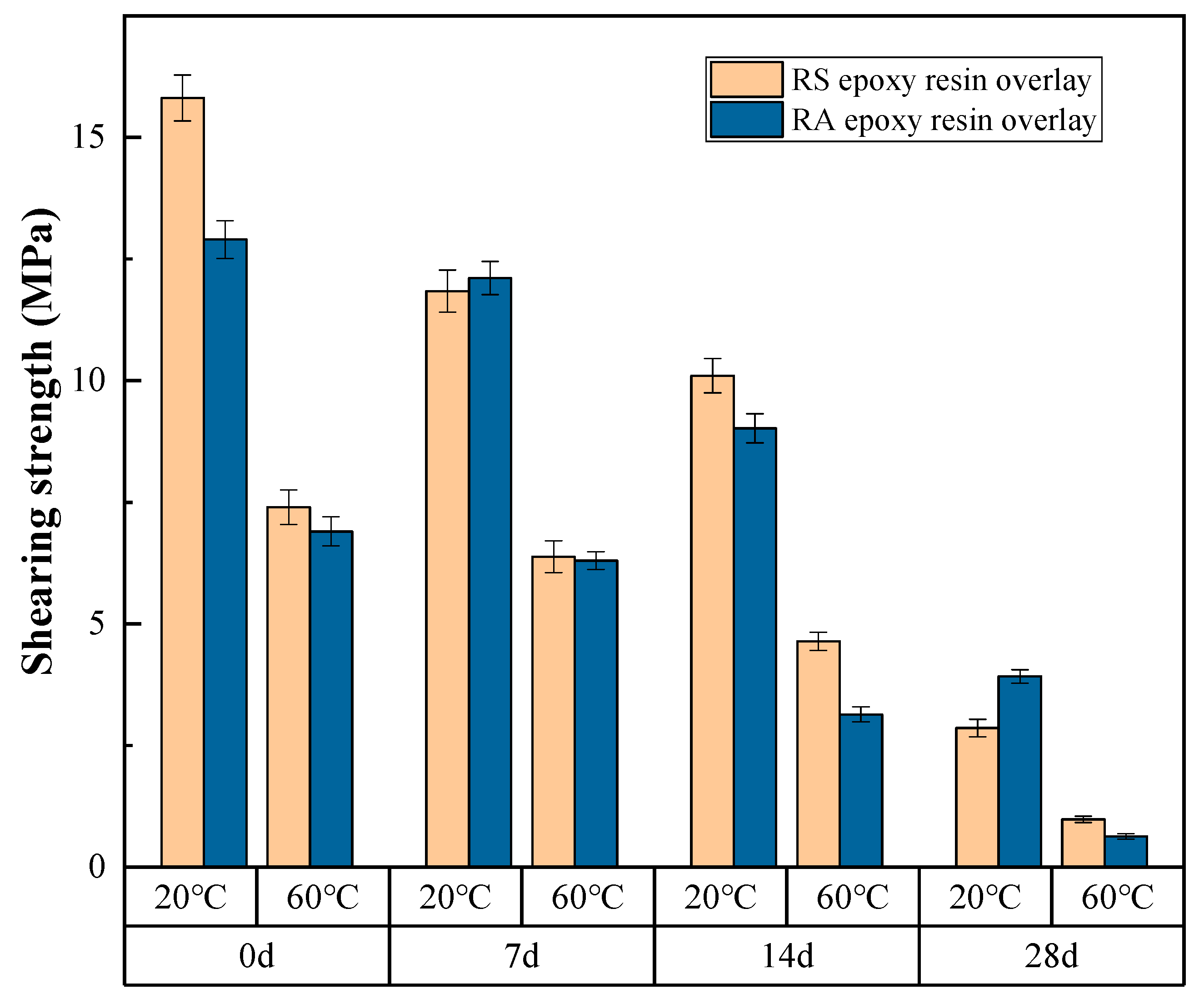

3.3.3. Effect of UV Aging on the Shear Resistance of Epoxy Resin Overlay

4. Conclusions

- (1)

- Through shear tests, it was found that the shear strength of epoxy resin overlay grew with the increase in epoxy resin content, and the optimal content was set as 3.4 kg/m2. The Hamburg rutting test results showed that the epoxy resin overlay exhibited satisfactory high-temperature performance and water resistance, and the RS epoxy resin overlay had better high-temperature performance and water resistance than the RA epoxy resin overlay. Moreover, the shear performance of the epoxy resin overlay was severely affected by high temperature.

- (2)

- Compared with the overlay specimens without damp heat, the damp heat led to more significant shear strength loss. The shear strength of both epoxy resin overlays after water immersion was reduced, especially at 60 °C, indicating that the water immersion caused the shear strength decline due to the water damage to the overlay interface. Moreover, the RS epoxy resin overlay showed similar damp heat resistance to the RS epoxy resin overlay.

- (3)

- As for the thermal oxygen aging effect, it was reflected that the short-term thermal oxygen aging had a minor impact on the shear performance of the epoxy resin overlay. However, with the increase in thermal oxygen aging duration, the shear strength of epoxy resin overlay significantly decreased, especially at 60 °C, due to the aging of epoxy resin binders. The shear strength at 60 °C of the RS and RA epoxy resin overlays decreased by 71.4% and 72.2%, respectively, after 28 days of aging. Additionally, the RS epoxy resin overlay had superior thermal oxygen aging resistance to the RA epoxy resin overlay.

- (4)

- Regarding the UV aging impact, it was also found that the shear performance of epoxy resin overlay rapidly decreased as the UV aging duration grew, whether at 20 °C or 60 °C. After 28 days of UV aging, the shear strength of the RS and RA epoxy resin overlays decreased by 86.8% and 90.1%, respectively. Moreover, the UV aging led to a more significant impact on the shear performance of the epoxy resin overlay than thermal oxygen aging, and the RS epoxy resin overlay had superior UV aging resistance to RA epoxy resin overlay.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chan, S.; Lane, B.; Kazmierowski, T.; Lee, W. Pavement preservation: A solution for sustainability. Transp. Res. Rec. 2011, 2235, 36–42. [Google Scholar] [CrossRef]

- Mahmoud, A.; Coleri, E.; Batti, J.; Covey, D. Development of a Field Torque Test to Evaluate In-Situ Tack Coat Performance. Constr. Build. Mater. 2017, 135, 377–385. [Google Scholar] [CrossRef]

- Phares, B.M.; Dahlberg, J.M. Polymer Concrete Overlay Evaluation: Tech Transfer (No. InTrans Project 13-463); Iowa State University, Institute for Transportation: Ames, IA, USA, 2016. [Google Scholar]

- Editorial Department of China Journal of Highway and Transport. Review on China’s Pavement Engineering Research·2020. China J. Highw. Transp. 2020, 10, 1–66. (In Chinese) [Google Scholar]

- Fowler, D.W.; Whitney, D.W. Long-Term Performance of Polymer Concrete for Bridge Decks. Nchrp Synthesis of Highway Practice; National Academies Press: Washington, DC, USA, 2012. [Google Scholar]

- Sprinkel, M. Twenty-Five Year Experience with Polymer Concrete Bridge Deck Overlays; Virginia Research Council: Charlottesville, VA, USA, 2003. [Google Scholar]

- Hong, B.; Lu, G.; Gao, J.; Dong, S.; Wang, D. Green tunnel pavement: Polyurethane ultra-thin friction course and its performance characterization. J. Clean. Prod. 2020, 289, 125131. [Google Scholar] [CrossRef]

- Deng, M.; Cao, X.; He, Z.; Wei, K.; Tang, B. Experimental and Molecular Dynamics Simulation Investigation on Filler Reinforcement for Property Enhancement of PU Composites. Mech. Adv. Mater. Struct. 2022, 30, 2780–2792. [Google Scholar] [CrossRef]

- Deng, M.; Ding, Y.; He, Z.; Shan, B.; Cao, X.; Tang, B. Investigation on Performances and Nano-Adhesion Behavior of Ultra-Thin Wearing Course Using Polyurethane as Binder. Constr. Build. Mater. 2021, 278, 122349. [Google Scholar] [CrossRef]

- Wu, D.; Han, Y.; Jin, X. Research on Key Technology of Anti-sliding Treatment of Resin Thin Layer of Bascule Bridge Steel Panel. In Proceedings of the 8th International Conference on Civil Engineering, Singapore, 11–14 March 2021; pp. 495–507. [Google Scholar]

- Stenko, M.S.; Chawalwala, A.J. Thin Polysulfide Epoxy Bridge Deck Overlays. Trans. Res. Rec. 2001, 1749, 64–67. [Google Scholar] [CrossRef]

- Horn, M.; Stewart, C.F. (Eds.) Field Evaluation of Concrete Polymerization as a Bridge Deck Seal; Final Report, No. CA-DOT-ST4174-1-74-4; Transportation Research Board: Washington, DC, USA, 1974. [Google Scholar]

- Attanayake, U.; Mazumder, A.F. Performance-Based Approach for Deciding the Age of New Concrete for Thin Epoxy Overlay Application. Transp. Res. Rec. 2021, 2675, 1055–1068. [Google Scholar] [CrossRef]

- Freeseman, K.; Wang, K.; Tan, Y. Bond Strength and Chloride Resistance of Epoxy and Concrete Overlays on Bridge Decks. Int. J. Pavement Eng. 2022, 23, 916–921. [Google Scholar] [CrossRef]

- Kayan, A. Recent Studies on Single Site Metal Alkoxide Complexes as Catalysts for Ring Opening Polymerization of Cyclic Compounds. Catal. Surv. Asia 2020, 24, 87–103. [Google Scholar] [CrossRef]

- Cong, P.L.; Chen, S.F.; Yu, J.Y.; Chen, H.X. Compatibility and Mechanical Properties of Epoxy Resin Modified Asphalt Binders. Inter. J. Pav. Res. Technol. 2011, 4, 118–123. (In Chinese) [Google Scholar]

- Parvizi, A.; Garrett, K.W.; Bailey, J.E. Constrained Cracking in Glass Fibre-Reinforced Epoxy Cross-Ply Laminates. J. Mater. Sci. 1978, 13, 195–201. [Google Scholar] [CrossRef]

- Liu, S.X.; Xu, Z.Q.; Zhao, F.C.; Jiang, A.F.; Li, H.; Yang, H.M.; Chen, J.H. Research progress on aging and anti-aging of epoxy resin materials. Equip. Environ. Eng. 2023, 1, 127–134. (In Chinese) [Google Scholar]

- Zhang, D.J.; Liu, G.; Bao, J.W.; Tang, B.M.; Zhong, X.Y.; Chen, B.X. Environmental aging performance and mechanism of T700 carbon fiber reinforced epoxy resin matrix composites. Acta Mater. Compos. Sin. 2016, 7, 1390–1399. (In Chinese) [Google Scholar]

- Yu, B.; Jiang, Z.; Yang, J. Long-Term Moisture Effects on the Interfacial Shear Strength between Surface Treated Carbon Fiber and Epoxy Matrix. Compos. Part Appl. Sci. Manuf. 2015, 78, 311–317. [Google Scholar] [CrossRef]

- Niu, Y.F.; Yan, Y.; Yao, J.W. Hygrothermal Aging Mechanism of Carbon Fiber/Epoxy Resin Composites Based on Quantitative Characterization of Interface Structure. Polym. Test. 2021, 94, 107019. [Google Scholar] [CrossRef]

- Zheng, Q.; Morgan, R.J. Synergistic Thermal-Moisture Damage Mechanisms of Epoxies and Their Carbon Fiber Composites. J. Compos. Mater. 1993, 27, 1465–1478. [Google Scholar] [CrossRef]

- Wang, M.; Xu, X.; Ji, J.; Yang, Y.; Shen, J.; Ye, M. The Hygrothermal Aging Process and Mechanism of the Novolac Epoxy Resin. Compos. Part B Eng. 2016, 107, 1–8. [Google Scholar] [CrossRef]

- Zhai, Z.; Feng, L.; Li, G.; Liu, Z.; Chang, X. The Anti-Ultraviolet Light (UV) Aging Property of Aluminium Particles/Epoxy Composite. Prog. Org. Coat. 2016, 101, 305–308. [Google Scholar] [CrossRef]

- JTG 3420-2020; Testing Methods of Cement and Concrete for Highway Engineering. Research Institute of Highway Ministry of Transport: Beijing, China, 2020.

- Wu, Y.H.; Xiao, P.; Wu, B.W.; Lou, K.; Shen, Q.C. Interlaminar Shear Resistance Test of Ultra-thin Wearing Layer Overlay Pavement. China Sci. 2022, 7, 739–745+758. (In Chinese) [Google Scholar]

- Mohammad, L.N.; Bae, A.; Elseifi, M.A.; Button, J.; Patel, N. Effects of Pavement Surface Type and Sample Preparation Method on Tack Coat Interface Shear Strength. Trans. Res. Rec. 2010, 2180, 93–101. [Google Scholar] [CrossRef]

- AASHTO T 324-2019; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures. US-AASHTO: Washington, DC, USA, 2019.

- Yang, L.Y.; Tan, Y.Q.; Dong, Y.M.; Li, E.G. Rutting Resistance Property of Warm Recycled Asphalt Mixture. Appl. Mech. Mater. 2012, 204–208, 3749–3753. [Google Scholar] [CrossRef]

- Wang, W.-H.; Huang, C.-W. Establishing Indicators and an Analytic Method for Moisture Susceptibility and Rutting Resistance Evaluation Using a Hamburg Wheel Tracking Test. Materials 2020, 13, 3269. [Google Scholar] [CrossRef]

| Index | Unit | RS Epoxy Resin | RA Epoxy Resin |

|---|---|---|---|

| Solids content | % | 99.7 | 99.7 |

| Tensile strength (25 °C) | MPa | 20.3 | 10.6 |

| Elongation at break (25 °C) | % | 45.0 | 30.5 |

| Tensile strength (25 °C) | Mpa | 7.6 | 18.0 |

| Tensile strength (60 °C) | Mpa | 4.8 | 4.8 |

| Aging Mode | Aging Time | ||

|---|---|---|---|

| Indoor simulation | 7 days | 14 days | 28 days |

| Outdoor aging | 6 months | 12 months | 24 months |

| Materials | Temperature (°C) | Stress (MPa) | Rolling Times (Freq) | Rutting Depth (mm) |

|---|---|---|---|---|

| RA | 60 | 0.7 | 20,000 | 1.731 |

| RS | 2.142 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, X.; Chen, Y.; Xu, W.; Zhang, Z.; Sun, G.; Wang, T. Long-Term Performance Analysis of Epoxy Resin Ultra-Thin Wearing Course Overlay on Cement Concrete Pavement. Coatings 2023, 13, 1455. https://doi.org/10.3390/coatings13081455

Zheng X, Chen Y, Xu W, Zhang Z, Sun G, Wang T. Long-Term Performance Analysis of Epoxy Resin Ultra-Thin Wearing Course Overlay on Cement Concrete Pavement. Coatings. 2023; 13(8):1455. https://doi.org/10.3390/coatings13081455

Chicago/Turabian StyleZheng, Xiaoguang, Yajie Chen, Wanwan Xu, Zhen Zhang, Guoqiang Sun, and Tao Wang. 2023. "Long-Term Performance Analysis of Epoxy Resin Ultra-Thin Wearing Course Overlay on Cement Concrete Pavement" Coatings 13, no. 8: 1455. https://doi.org/10.3390/coatings13081455

APA StyleZheng, X., Chen, Y., Xu, W., Zhang, Z., Sun, G., & Wang, T. (2023). Long-Term Performance Analysis of Epoxy Resin Ultra-Thin Wearing Course Overlay on Cement Concrete Pavement. Coatings, 13(8), 1455. https://doi.org/10.3390/coatings13081455