Atmospheric Microplasma Treatment Based on Magnetically Controlled Fe–Al Dynamic Platform for Organic and Biomaterials Surface Modification

Abstract

1. Introduction

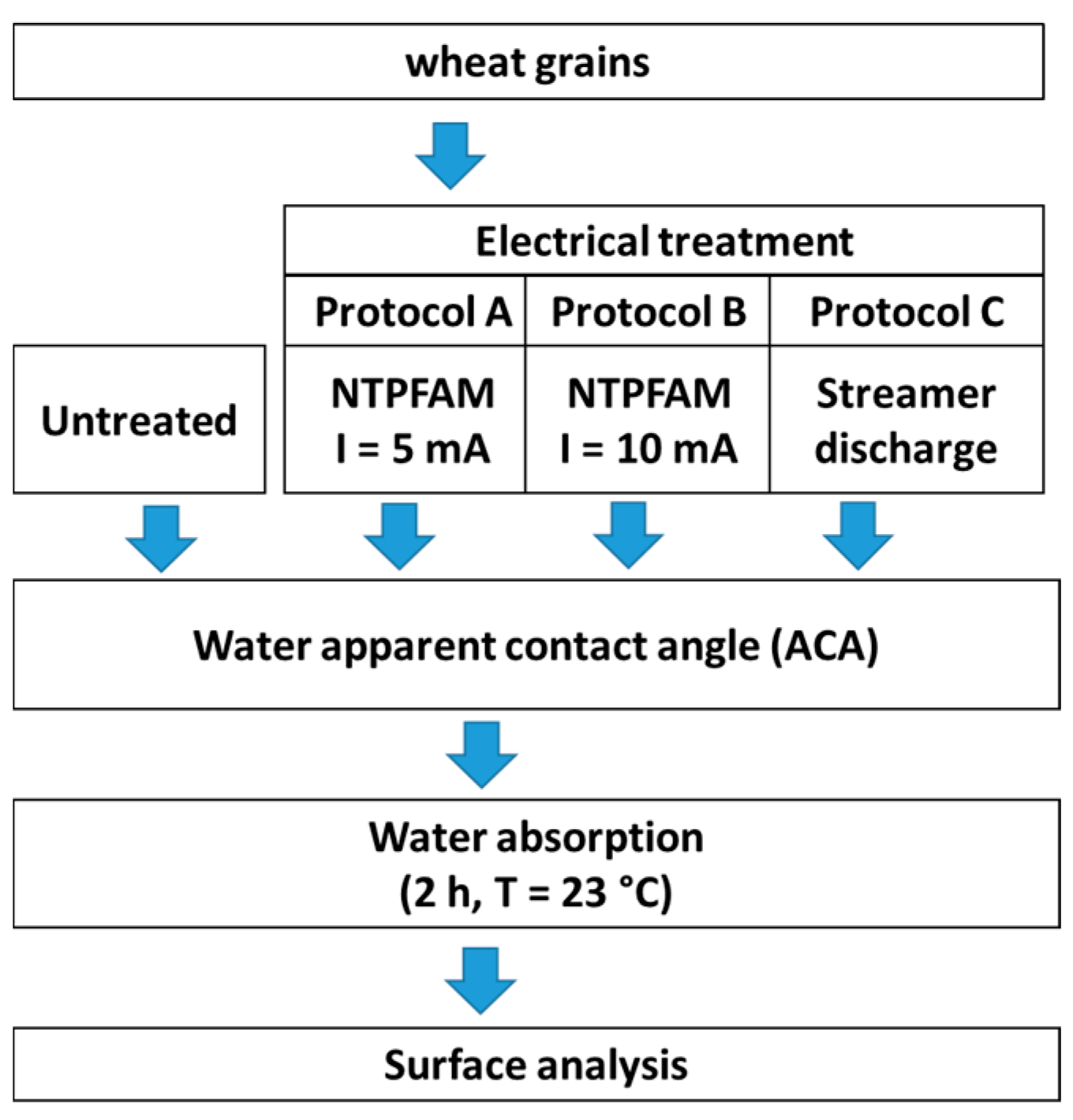

2. Materials and Methods

2.1. Materials and Samples Preparation

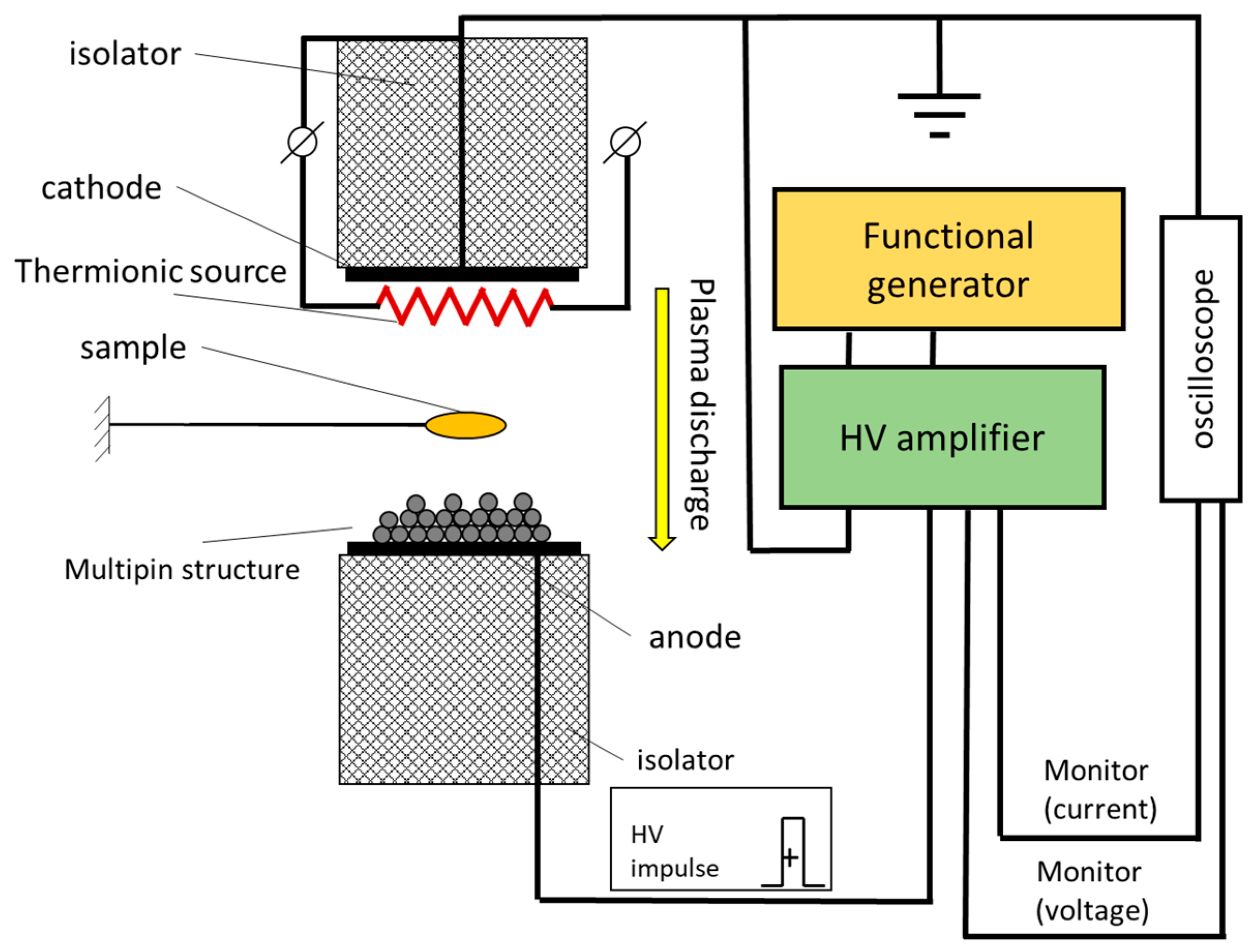

2.2. Experimental Setup

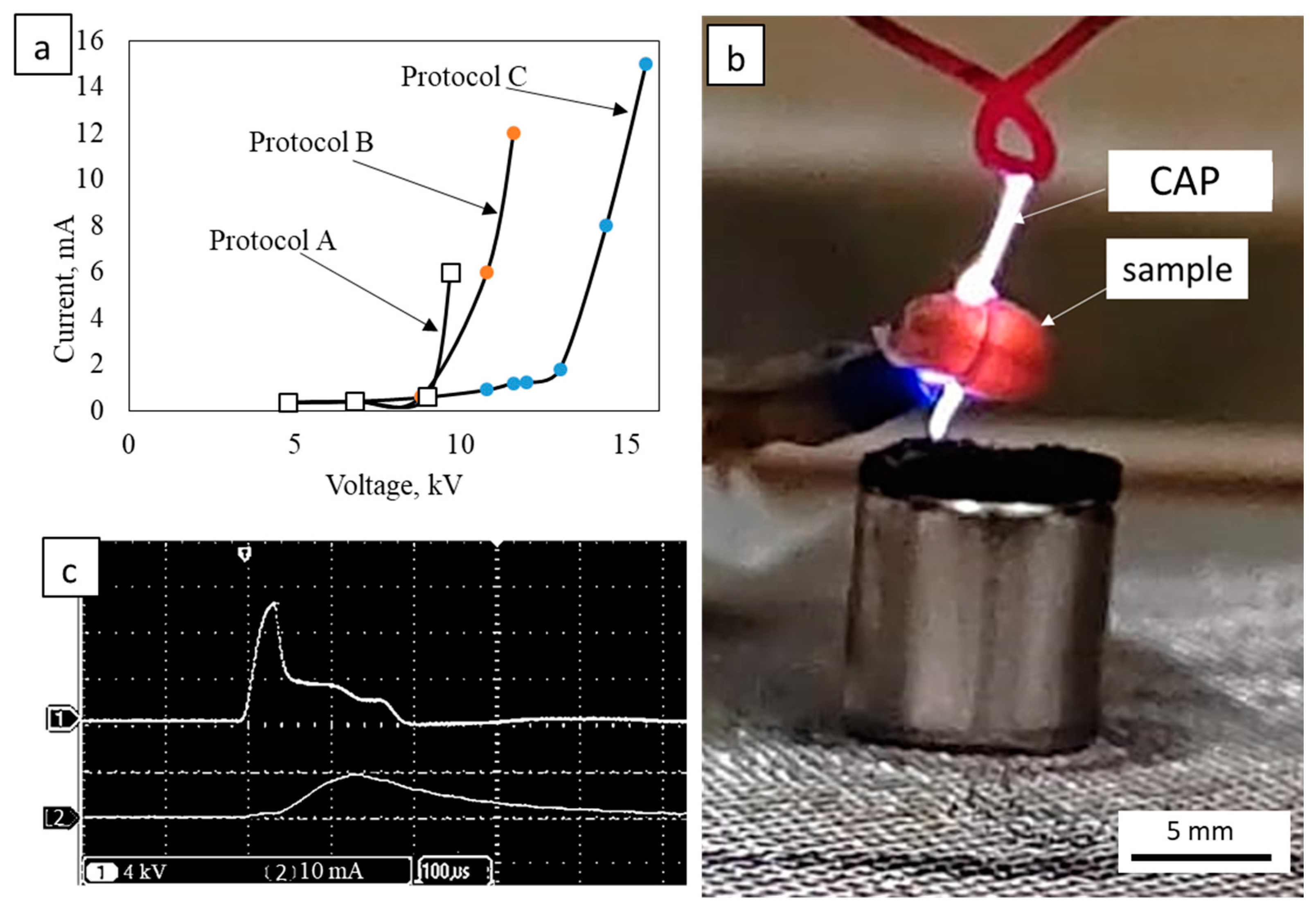

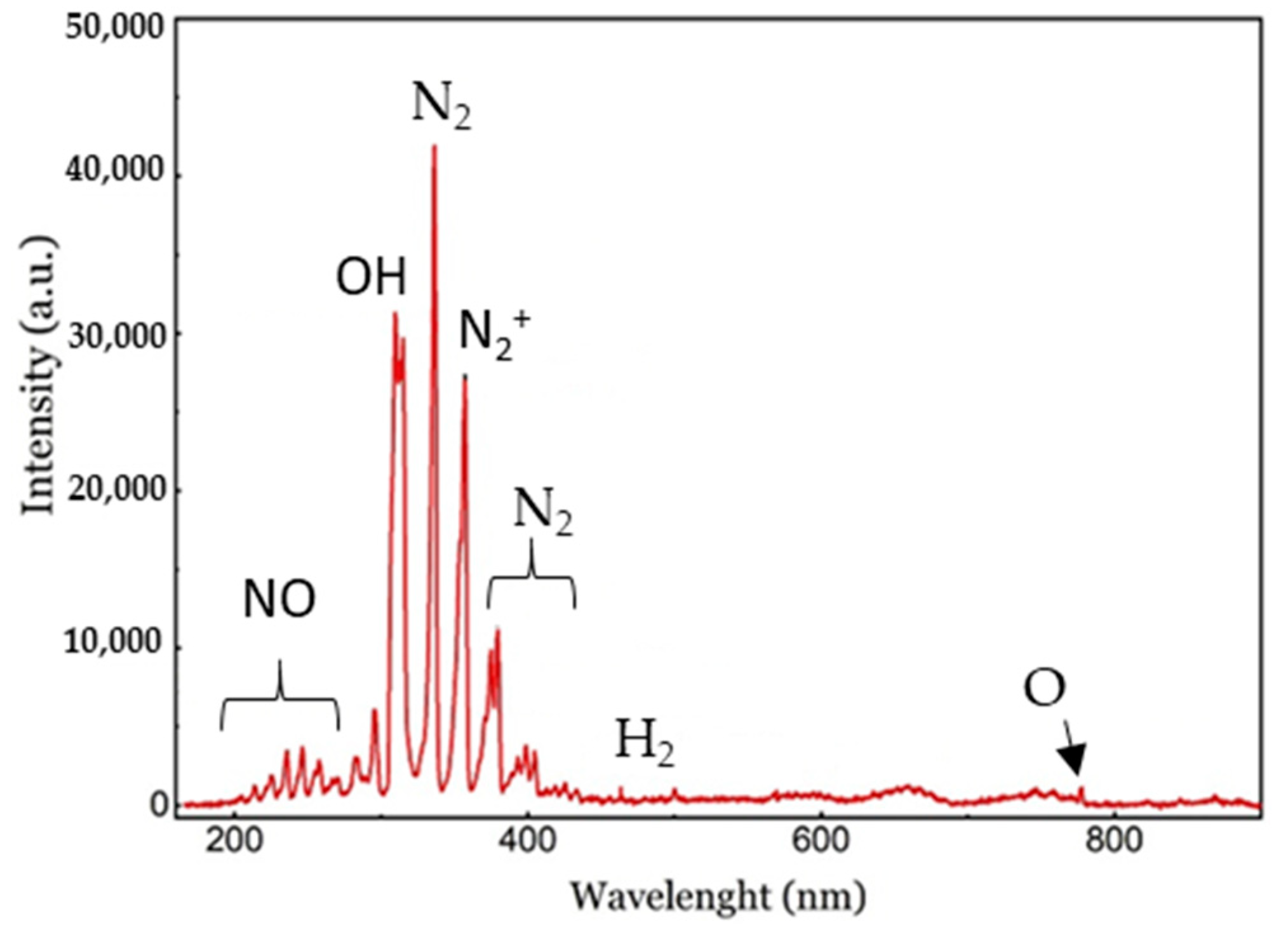

2.3. CAP Fundamental Aspects

2.4. Water Uptake

2.5. Characterizations

3. Results and Discussion

3.1. Atmospheric Microplasma Characteristics

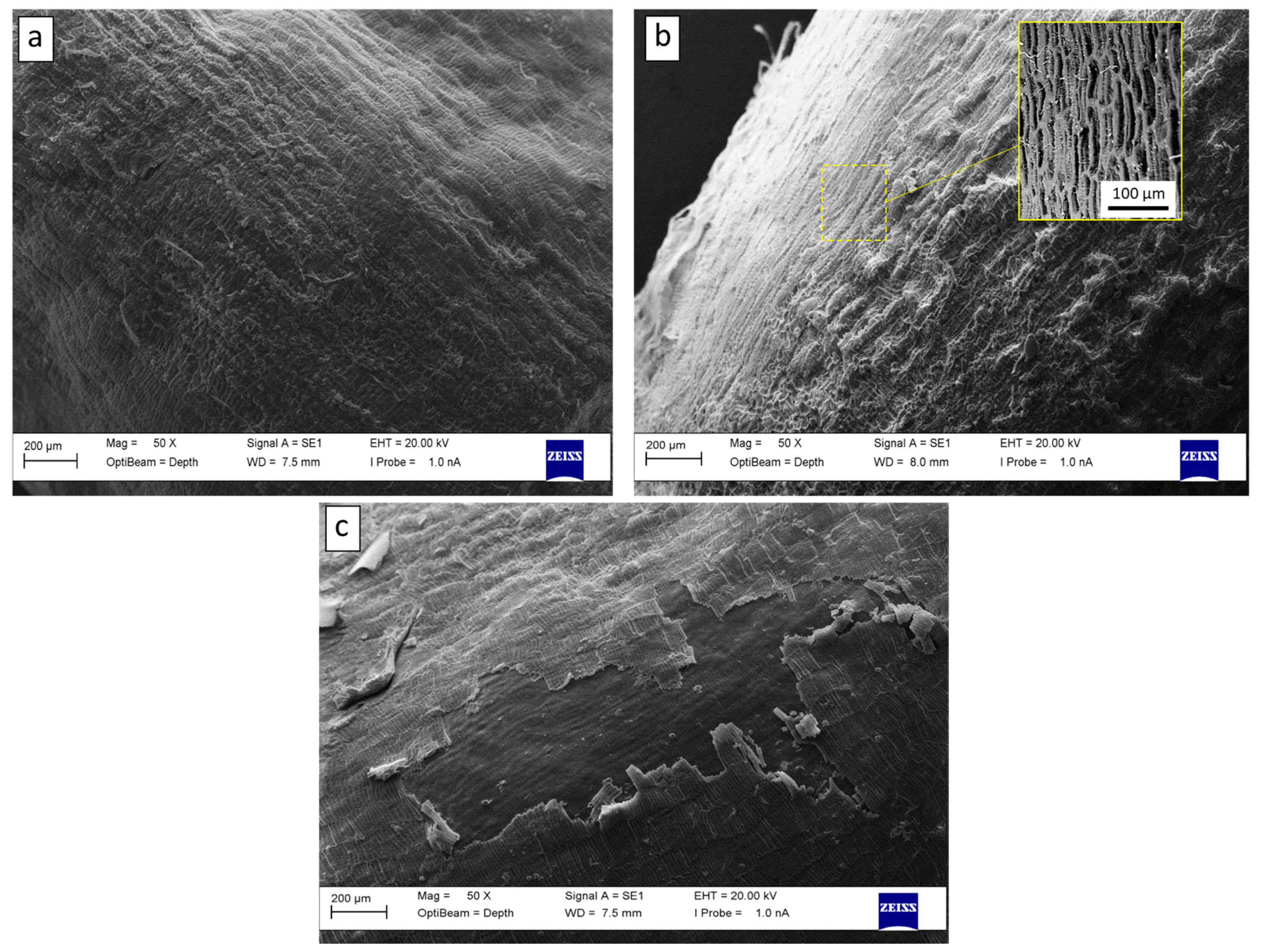

3.2. Surface Modification

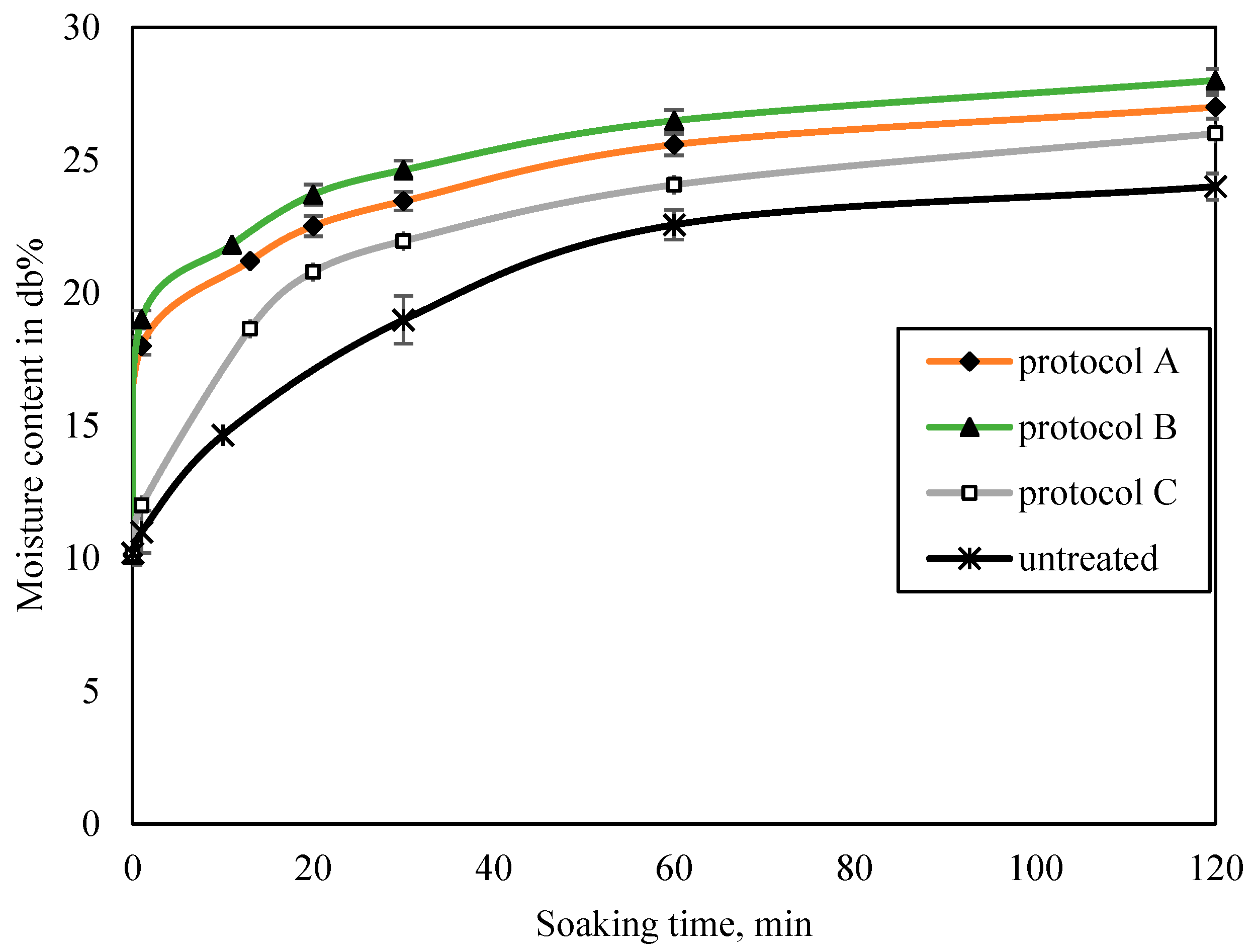

3.3. Influence of CAP Treatment on Water Uptake

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Iqbal, M.; Dinh, D.K.; Abbas, Q.; Imran, M.; Sattar, H.; Ul Ahmad, A. Controlled Surface Wettability by Plasma Polymer Surface Modification. Surfaces 2019, 2, 349–371. [Google Scholar] [CrossRef]

- Hashizume, H.; Kitano, H.; Mizuno, H.; Abe, A.; Yuasa, G.; Tohno, S.; Tanaka, H.; Ishikawa, K.; Matsumoto, S.; Sakakibara, H.; et al. Improvement of Yield and Grain Quality by Periodic Cold Plasma Treatment with Rice Plants in a Paddy Field. Plasma Process. Polym. 2021, 18, 2000181. [Google Scholar] [CrossRef]

- Zhao, X.; Hu, J.; Nie, J.; Chen, D.; Qin, G.; Zhang, E. Enhanced Antibacterial Activity, Corrosion Resistance and Endothelialization Potential of Ti-5Cu Alloy by Oxygen and Nitrogen Plasma-Based Surface Modification. J. Mater. Sci. Technol. 2023, in press. [Google Scholar] [CrossRef]

- Kaseem, M.; Fatimah, S.; Nashrah, N.; Ko, Y.G. Recent Progress in Surface Modification of Metals Coated by Plasma Electrolytic Oxidation: Principle, Structure, and Performance. Prog. Mater. Sci. 2021, 117, 100735. [Google Scholar] [CrossRef]

- Mravlje, J.; Regvar, M.; Vogel-Mikuš, K. Development of Cold Plasma Technologies for Surface Decontamination of Seed Fungal Pathogens: Present Status and Perspectives. J. Fungi 2021, 7, 650. [Google Scholar] [CrossRef]

- Misnal, M.F.I.; Redzuan, N.; Zainal, M.N.F.; Ahmad, N.; Raja Ibrahim, R.K.; Agun, L. Cold Plasma: A Potential Alternative for Rice Grain Postharvest Treatment Management in Malaysia. Rice Sci. 2022, 29, 1–15. [Google Scholar] [CrossRef]

- Fang, M.J. The Effect of Low-Pressure Plasma Treatment of Seeds on the Plant Resistance to Pathogens and Crop Yields. J. Phys. D Appl. Phys. 2020, 53, 244001. [Google Scholar] [CrossRef]

- Dubinov, A.E.; Lazarenko, E.R.; Selemir, V.D. Effect of Glow Discharge Air Plasma on Grain Crops Seed. IEEE Trans. Plasma Sci. 2000, 28, 180–183. [Google Scholar] [CrossRef]

- Scholtz, V.; Šerá, B.; Khun, J.; Šerý, M.; Julák, J. Effects of Nonthermal Plasma on Wheat Grains and Products. J. Food Qual. 2019, 2019, 7917825. [Google Scholar] [CrossRef]

- Baldanov, B.B.; Ranzhurov, T.V.; Sordonova, M.N.; Budazhapov, L.V. Changes in the Properties and Surface Structure of Grain Seeds under the Influence of a Glow Dischargeat Atmospheric Pressure. Plasma Phys. Rep. 2020, 46, 110–114. [Google Scholar] [CrossRef]

- Randeniya, L.K.; de Groot, G.J.J.B. Non-Thermal Plasma Treatment of Agricultural Seeds for Stimulation of Germination, Removal of Surface Contamination and Other Benefits: A Review. Plasma Process. Polym. 2015, 12, 608–623. [Google Scholar] [CrossRef]

- Li, L.; Jiang, J.; Li, J.; Shen, M.; He, X.; Shao, H.; Dong, Y. Effects of Cold Plasma Treatment on Seed Germination and Seedling Growth of Soybean. Sci. Rep. 2014, 4, 5859. [Google Scholar] [CrossRef]

- de Groot, G.J.J.B.; Hundt, A.; Murphy, A.B.; Bange, M.P.; Mai-Prochnow, A. Cold Plasma Treatment for Cotton Seed Germination Improvement. Sci. Rep. 2018, 8, 14372. [Google Scholar] [CrossRef]

- Leti, L.-I.; Gerber, I.C.; Mihaila, I.; Galan, P.-M.; Strajeru, S.; Petrescu, D.-E.; Cimpeanu, M.-M.; Topala, I.; Gorgan, D.-L. The Modulatory Effects of Non-Thermal Plasma on Seed’s Morphology, Germination and Genetics—A Review. Plants 2022, 11, 2181. [Google Scholar] [CrossRef]

- Burducea, I.; Burducea, C.; Mereuta, P.-E.; Sirbu, S.-R.; Iancu, D.-A.; Istrati, M.-B.; Straticiuc, M.; Lungoci, C.; Stoleru, V.; Teliban, G.-C.; et al. Helium Atmospheric Pressure Plasma Jet Effects on Two Cultivars of Triticum aestivum L. Foods 2023, 12, 208. [Google Scholar] [CrossRef] [PubMed]

- Chaple, S.; Sarangapani, C.; Jones, J.; Carey, E.; Causeret, L.; Genson, A.; Duffy, B.; Bourke, P. Effect of Atmospheric Cold Plasma on the Functional Properties of Whole Wheat (Triticum aestivum L.) Grain and Wheat Flour. Innov. Food Sci. Emerg. Technol. 2020, 66, 102529. [Google Scholar] [CrossRef]

- Los, A.; Ziuzina, D.; Boehm, D.; Cullen, P.J.; Bourke, P. Investigation of Mechanisms Involved in Germination Enhancement of Wheat (Triticum aestivum) by Cold Plasma: Effects on Seed Surface Chemistry and Characteristics. Plasma Process. Polym. 2019, 16, 1800148. [Google Scholar] [CrossRef]

- Zhang, B.; Li, R.; Yan, J. Study on Activation and Improvement of Crop Seeds by the Application of Plasma Treating Seeds Equipment. Arch. Biochem. Biophys. 2018, 655, 37–42. [Google Scholar] [CrossRef]

- Stolárik, T.; Henselová, M.; Martinka, M.; Novák, O.; Zahoranová, A.; Černák, M. Effect of Low-Temperature Plasma on the Structure of Seeds, Growth and Metabolism of Endogenous Phytohormones in Pea (Pisum sativum L.). Plasma Chem. Plasma Process. 2015, 35, 659–676. [Google Scholar] [CrossRef]

- Karim, N.; Shishir, M.R.I.; Bao, T.; Chen, W. Effect of Cold Plasma Pretreated Hot-Air Drying on the Physicochemical Characteristics, Nutritional Values and Antioxidant Activity of Shiitake Mushroom. J. Sci. Food Agric. 2021, 101, 6271–6280. [Google Scholar] [CrossRef]

- Pothiraja, R.; Lackmann, J.-W.; Keil, G.; Bibinov, N.; Awakowicz, P. Biological Decontamination Using Pulsed Filamentary Microplasma Jet. In Plasma for Bio-Decontamination, Medicine and Food Security; Springer: Berlin/Heidelberg, Germany, 2012; pp. 45–55. [Google Scholar]

- Ahn, J.Y.; Kil, D.Y.; Kong, C.; Kim, B.G. Comparison of Oven-Drying Methods for Determination of Moisture Content in Feed Ingredients. Asian-Australas. J. Anim. Sci. 2014, 27, 1615–1622. [Google Scholar] [CrossRef] [PubMed]

- Shorstkii, I.A.; Yakovlev, N. Method of Absorbing Material Formation Based on Magnetically Controlled Particles of Fe3O4. Inorg. Mater. Appl. Res. 2020, 11, 1236–1243. [Google Scholar] [CrossRef]

- Reimer, L. Scanning Electron Microscopy: Physics of Image Formation and Microanalysis; Springer: Berlin/Heidelberg, Germany, 2013; Volume 45. [Google Scholar]

- Westover, T.L.; Franklin, A.D.; Cola, B.A.; Fisher, T.S.; Reifenberger, R.G. Photo- and Thermionic Emission from Potassium-Intercalated Carbon Nanotube Arrays. J. Vac. Sci. Technol. B 2010, 28, 423–434. [Google Scholar] [CrossRef]

- Tang, H.; Cheng, X. Measurement of Liquid Surface Tension by Fitting the Lying Droplet Profile. Measurement 2022, 188, 110379. [Google Scholar] [CrossRef]

- Shorstkii, I.A.; Yakovlev, N. Experimental Study of a Townsend Discharge with a Multipoint Cathode on a Dynamic Platform Made of Magnetically Controlled Fe and Fe–Al Particles. Tech. Phys. 2021, 66, 1276–1285. [Google Scholar] [CrossRef]

- Shorstkii, I.A. Cold Plasma Pretreatment in Plant Material Drying. Food Process. Tech. Technol. 2022, 52, 613–622. [Google Scholar] [CrossRef]

- Dhayal, M.; Lee, S.-Y.; Park, S.-U. Using Low-Pressure Plasma for Carthamus tinctorium L. Seed Surface Modification. Vacuum 2006, 80, 499–506. [Google Scholar] [CrossRef]

- Sera, B.; Špatenka, P.; Šerý, M.; Vrchotova, N.; Hrušková, I. Influence of Plasma Treatment on Wheat and Oat Germination and Early Growth. IEEE Trans. Plasma Sci. 2010, 38, 2963–2968. [Google Scholar] [CrossRef]

- Petrukhina, D.I.; Polyakova, I.V.; Gorbatov, S.A. Biocide Effect of Non-Thermal Atmospheric Pressure Plasma. Food Process. Tech. Technol. 2021, 51, 86–97. [Google Scholar] [CrossRef]

- Rasooli, Z.; Barzin, G.; Mahabadi, T.D.; Entezari, M. Stimulating Effects of Cold Plasma Seed Priming on Germination and Seedling Growth of Cumin Plant. S. Afr. J. Bot. 2021, 142, 106–113. [Google Scholar] [CrossRef]

- Yodpitak, S.; Mahatheeranont, S.; Boonyawan, D.; Sookwong, P.; Roytrakul, S.; Norkaew, O. Cold Plasma Treatment to Improve Germination and Enhance the Bioactive Phytochemical Content of Germinated Brown Rice. Food Chem. 2019, 289, 328–339. [Google Scholar] [CrossRef] [PubMed]

- Rathjen, J.R.; Strounina, E.V.; Mares, D.J. Water Movement into Dormant and Non-Dormant Wheat (Triticum aestivum L.) Grains. J. Exp. Bot. 2009, 60, 1619–1631. [Google Scholar] [CrossRef] [PubMed]

- Qiu, L.; Zhang, M.; Tang, J.; Adhikari, B.; Cao, P. Innovative Technologies for Producing and Preserving Intermediate Moisture Foods: A Review. Food Res. Int. 2019, 116, 90–102. [Google Scholar] [CrossRef] [PubMed]

- Ikmal Misnal, M.F.; Redzuan, N.; Firdaus Zainal, M.N.; Raja Ibrahim, R.K.; Ahmad, N.; Agun, L. Emerging Cold Plasma Treatment on Rice Grains: A Mini Review. Chemosphere 2021, 274, 129972. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shorstkii, I.; Mounassar, E.H.A. Atmospheric Microplasma Treatment Based on Magnetically Controlled Fe–Al Dynamic Platform for Organic and Biomaterials Surface Modification. Coatings 2023, 13, 1362. https://doi.org/10.3390/coatings13081362

Shorstkii I, Mounassar EHA. Atmospheric Microplasma Treatment Based on Magnetically Controlled Fe–Al Dynamic Platform for Organic and Biomaterials Surface Modification. Coatings. 2023; 13(8):1362. https://doi.org/10.3390/coatings13081362

Chicago/Turabian StyleShorstkii, Ivan, and Emad Hussein Ali Mounassar. 2023. "Atmospheric Microplasma Treatment Based on Magnetically Controlled Fe–Al Dynamic Platform for Organic and Biomaterials Surface Modification" Coatings 13, no. 8: 1362. https://doi.org/10.3390/coatings13081362

APA StyleShorstkii, I., & Mounassar, E. H. A. (2023). Atmospheric Microplasma Treatment Based on Magnetically Controlled Fe–Al Dynamic Platform for Organic and Biomaterials Surface Modification. Coatings, 13(8), 1362. https://doi.org/10.3390/coatings13081362