PTFE-Containing Coating Obtained on Ti by Spraying and PEO Pretreatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Coatings Formation

2.3. Composite Coatings Formation

2.4. Analysis of Coatings Composition and Morphology

2.5. Electrochemical Properties of Coatings

2.6. Assessment Adhesion Characteristics

2.7. Wettability of Coatings

3. Results and Discussion

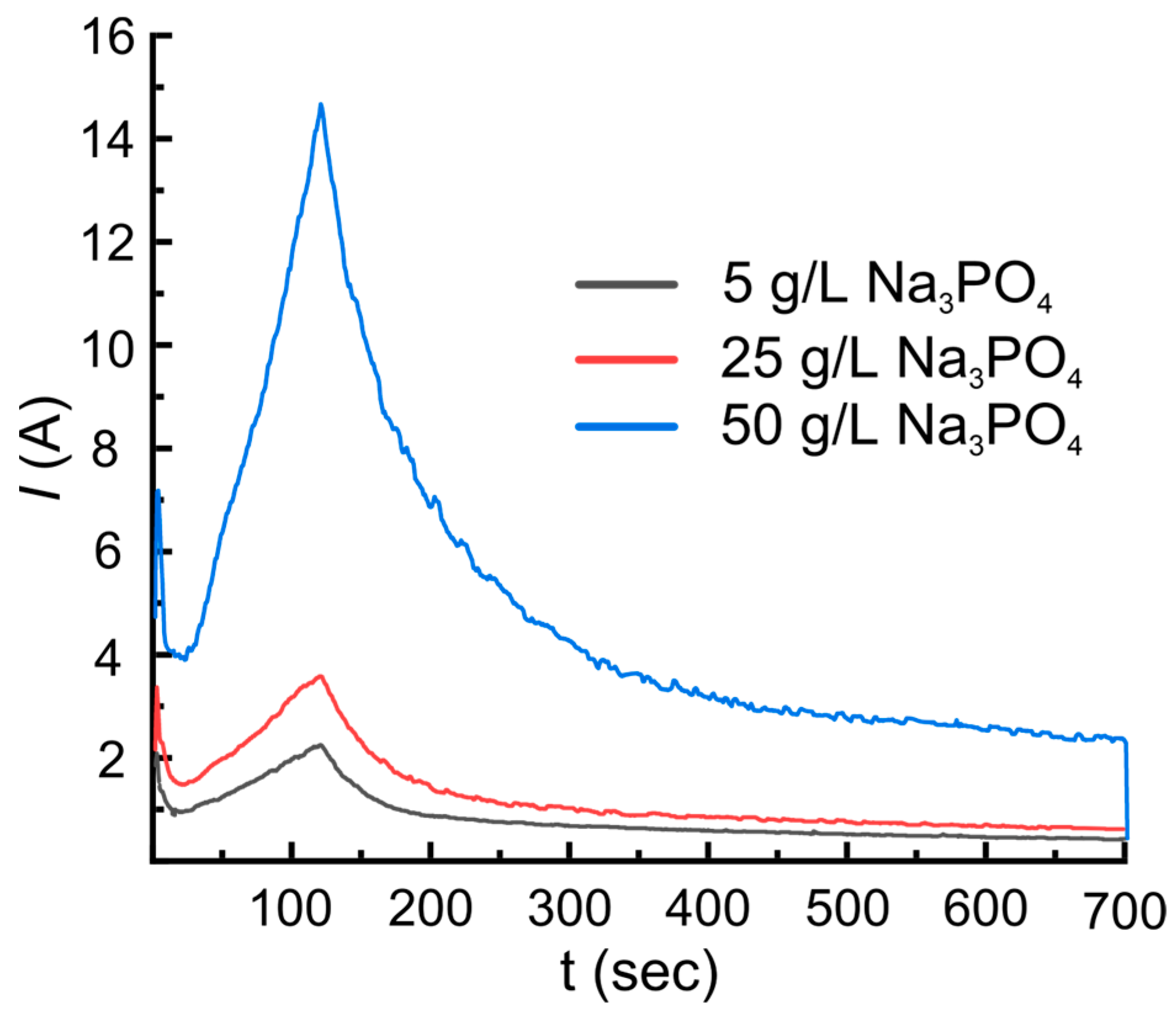

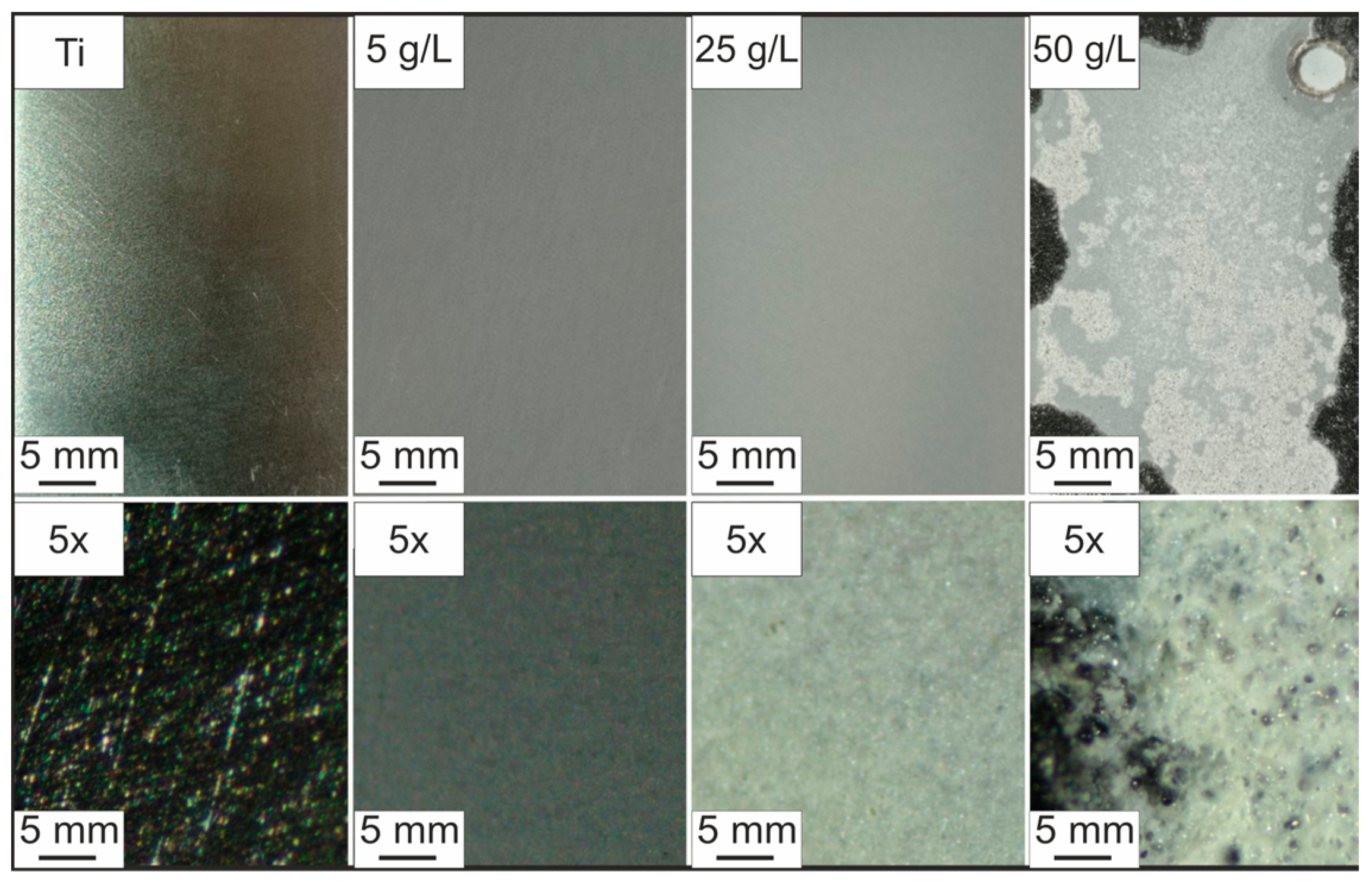

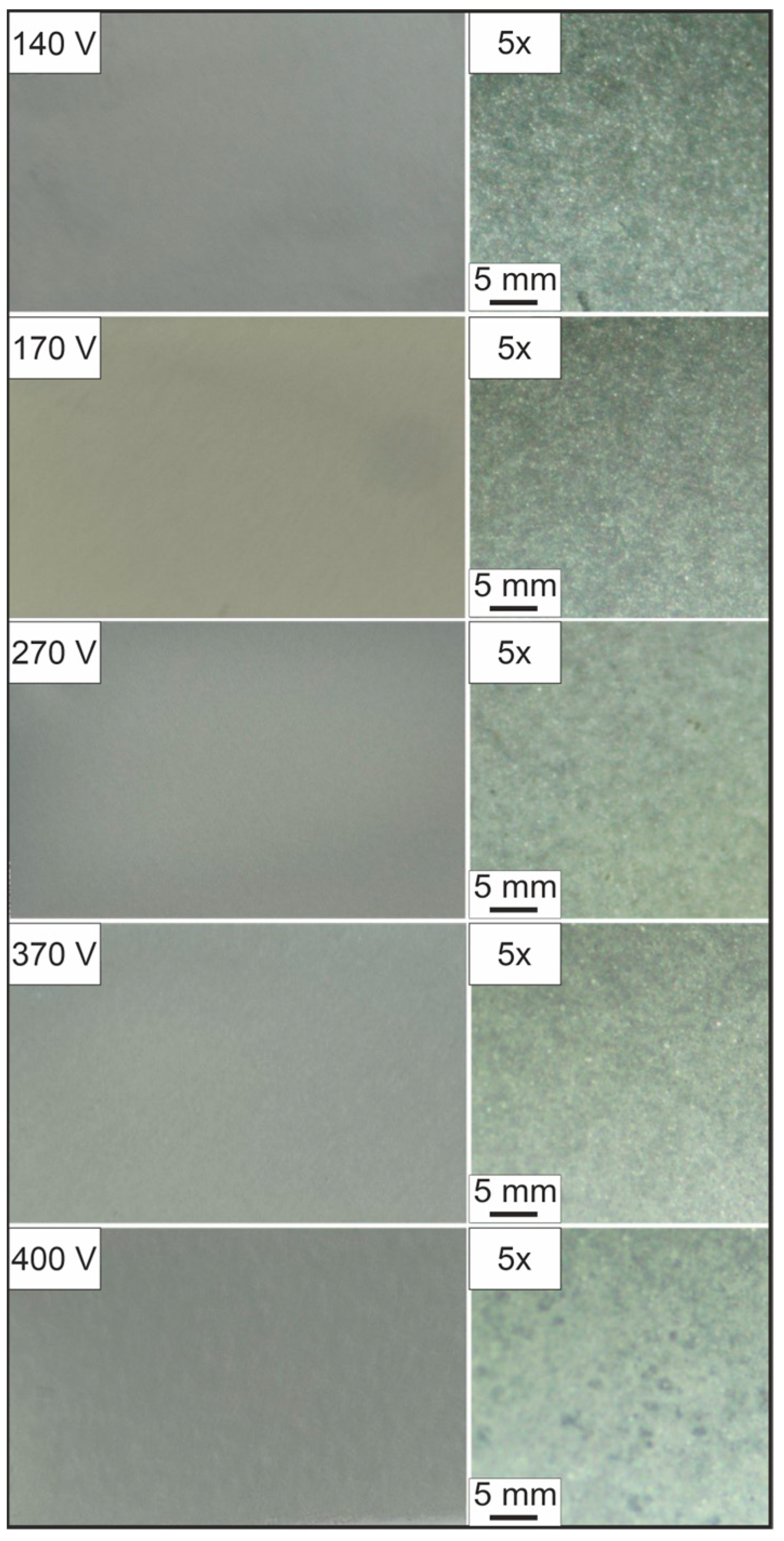

3.1. Formation PEO Coating on VT1-0 Commercially Pure Titanium

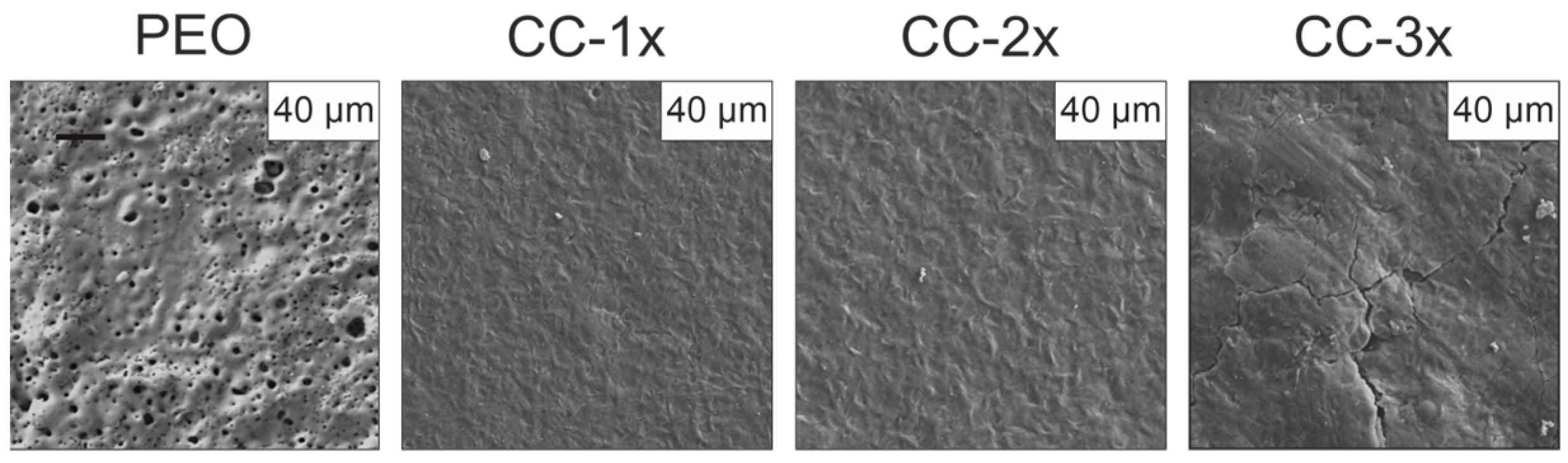

3.2. Formation of Composite Coatings by Spray-Coating

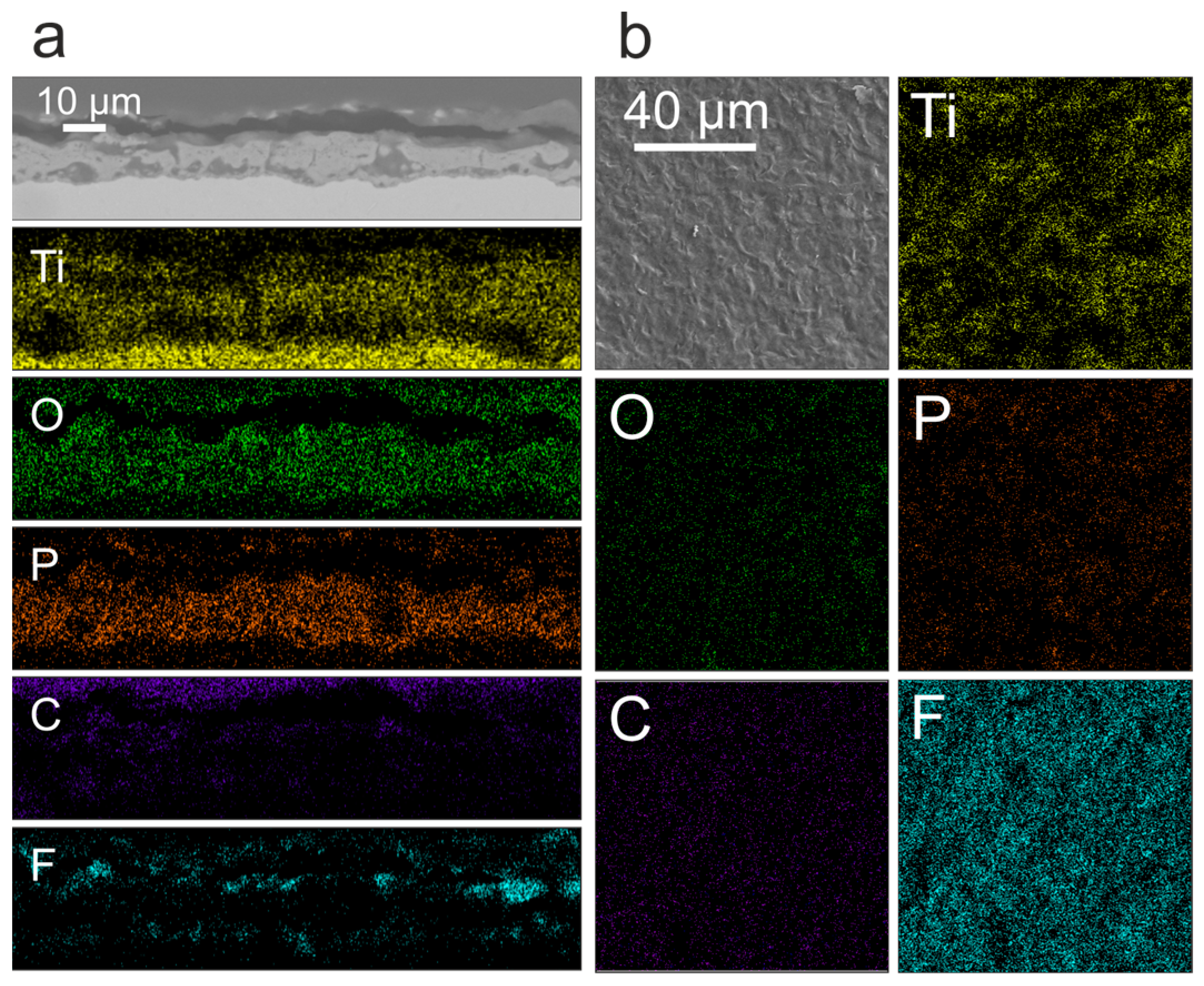

3.3. Composition and Morphology of Coatings

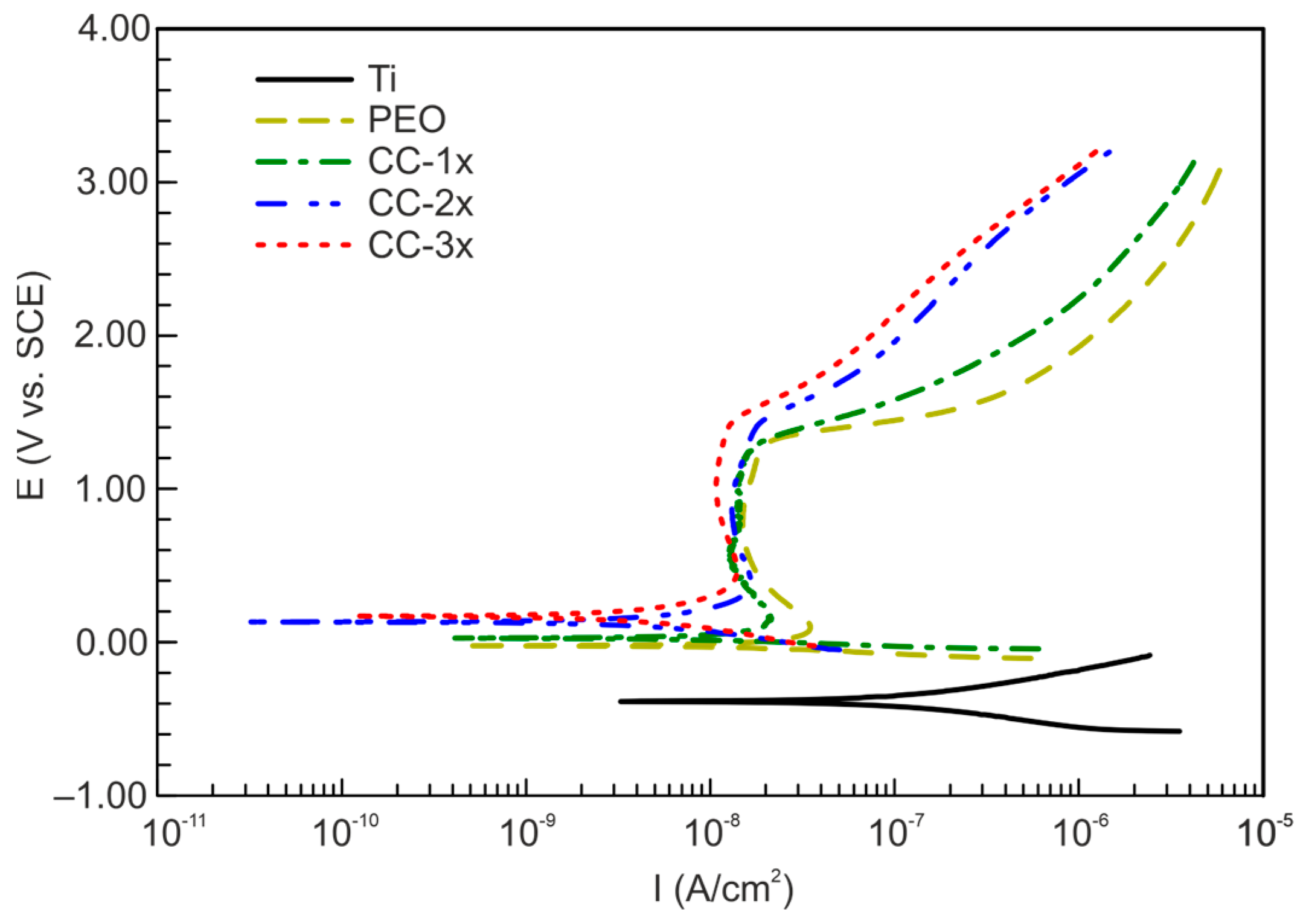

3.4. Electrochemical Properties of Coatings

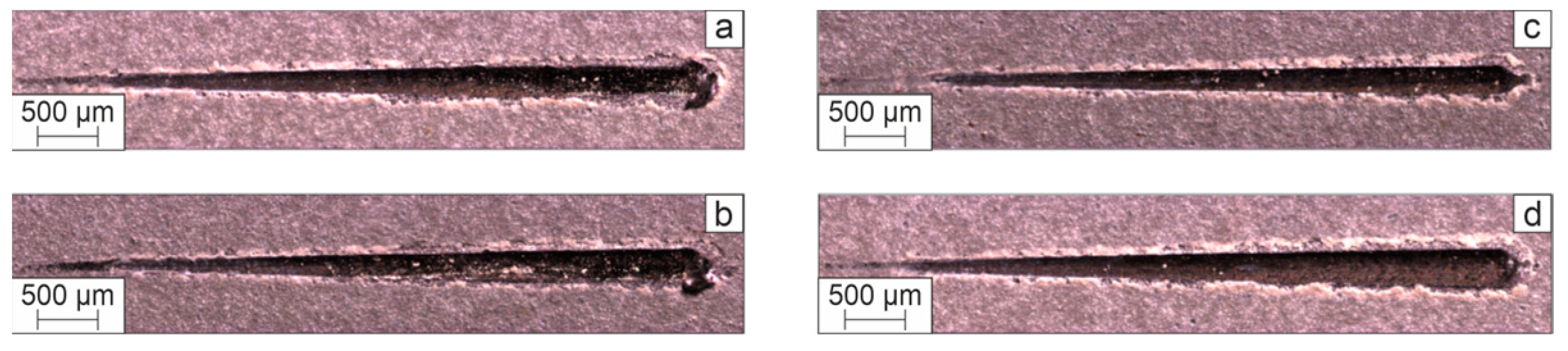

3.5. Adhesion Characteristics of Coatings

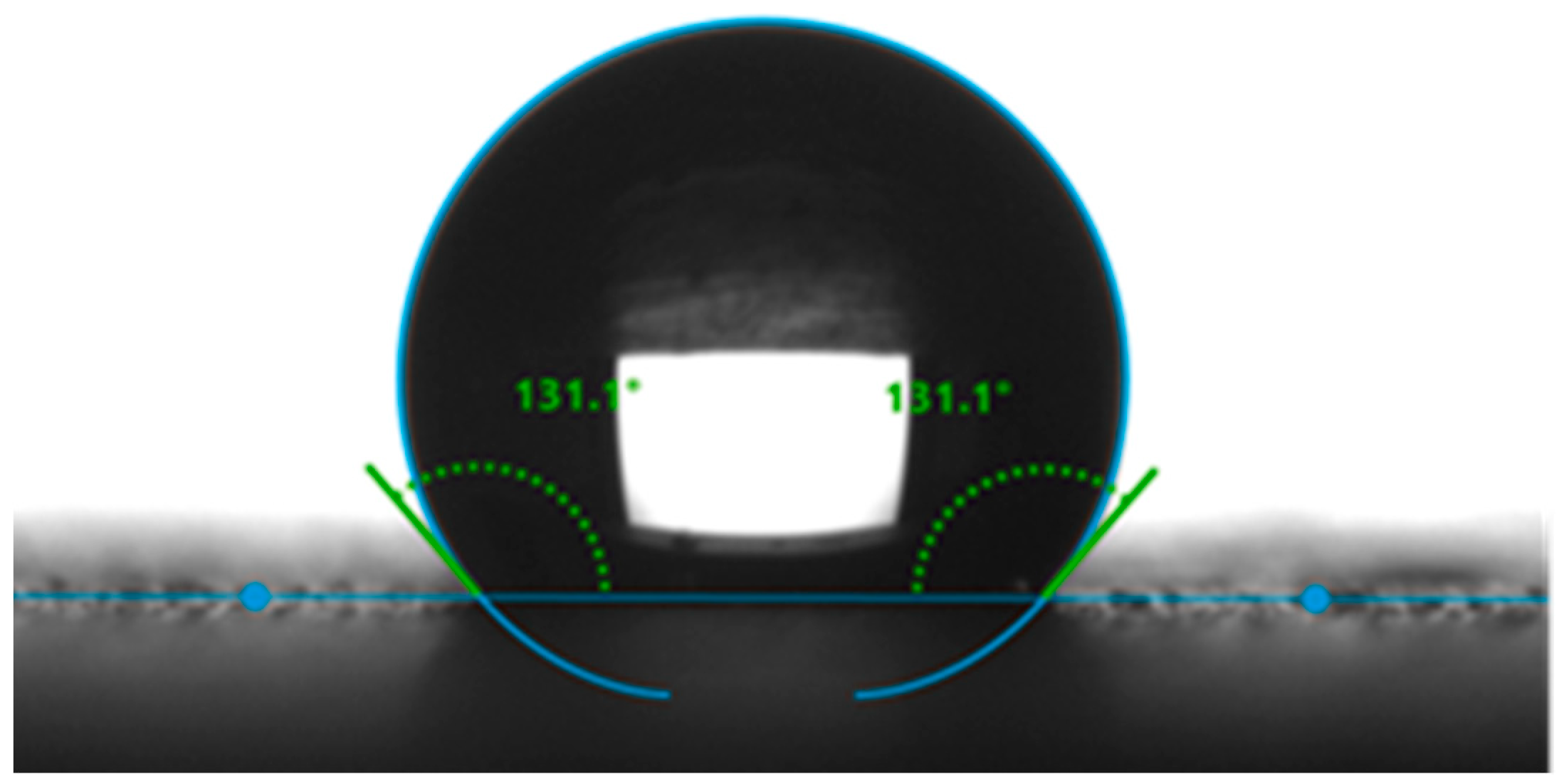

3.6. Wettability of Coatings

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mashtalyar, D.V.; Nadaraia, K.V.; Imshinetskiy, I.M.; Belov, E.A.; Filonina, V.S.; Suchkov, S.N.; Sinebryukhov, S.L.; Gnedenkov, S.V. Composite coatings formed on Ti by PEO and fluoropolymer treatment. Appl. Surf. Sci. 2021, 536, 147976. [Google Scholar] [CrossRef]

- Aliofkhazraei, M.; Macdonald, D.D.; Matykina, E.; Parfenov, E.V.; Egorkin, V.S.; Curran, J.A.; Troughton, S.C.; Sinebryukhov, S.L.; Gnedenkov, S.V.; Lampke, T.; et al. Review of plasma electrolytic oxidation of titanium substrates: Mechanism, properties, applications and limitations. Appl. Surf. Sci. Adv. 2021, 5, 100121. [Google Scholar] [CrossRef]

- Lingwei, M.; Wang, J.; Zhang, D.; Huang, Y.; Huang, L.; Wang, P.; Qian, H.; Li, X.; Terryn, H.A.; Mol, J.M. Dual-Action Self-Healing Protective Coatings with Photothermal Responsive Corrosion Inhibitor Nanocontainers. Chem. Eng. J. 2021, 404, 127118. [Google Scholar]

- Del Olmo, R.; López, E.; Matykina, E.; Tiringer, U.; Mol, J.M.C.; Mohedano, M.; Arrabal, R. Hybrid PEO/sol-gel coatings loaded with Ce for corrosion protection of AA2024-T3. Prog. Org. Coat. 2023, 182, 107667. [Google Scholar] [CrossRef]

- Ren, S.; Cui, M.; Liu, C.; Wang, L. A comprehensive review on ultrathin, multi-functionalized, and smart graphene and graphene-based composite protective coatings. Corros. Sci. 2023, 212, 110939. [Google Scholar] [CrossRef]

- Liu, T.; Ma, L.; Wang, X.; Wang, J.; Qian, H.; Zhang, D.; Li, X. Self-healing corrosion protective coatings based on micro/nanocarriers: A review. Corros. Commun. 2021, 1, 18–25. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Sinebryukhov, S.L.; Mashtalyar, D.V.; Nadaraia, K.V.; Kiryukhin, D.P.; Kichigina, G.A.; Kushch, P.P.; Buznik, V.M. Composite coatings formed on the PEO-layers with the use of solutions of tetrafluoroethylene telomers. Surf. Coat. Technol. 2018, 346, 53–62. [Google Scholar] [CrossRef]

- Kaseem, M.; Fatimah, S.; Nashrah, N.; Ko, Y.G. Recent progress in surface modification of metals coated by plasma electrolytic oxidation: Principle, structure, and performance. Prog. Mater. Sci. 2020, 117, 100735. [Google Scholar] [CrossRef]

- Mashtalyar, D.V.; Nadaraia, K.V.; Sinebryukhov, S.L.; Gnedenkov, S.V. Protective Composite Coatings Formed on Mg Alloy Surface by PEO Using Organofluorine Materials. J. Mater. Sci. Technol. 2017, 33, 661–667. [Google Scholar] [CrossRef]

- Xu, K.; Yang, Z.; Sun, W.; Wang, L.; Fan, J.; Zhang, H.; Wu, T.; Yu, S.; Nie, X.; Li, W.; et al. Acid permeability related corrosion protection properties of PTFE coatings for waste heat recovery. Corros. Sci. 2023, 218, 111141. [Google Scholar] [CrossRef]

- Tsai, D.-S.; Tsai, Y.-C.; Chou, C.-C. Corrosion passivation of magnesium alloy with the duplex coatings of plasma electrolytic oxidation and tetrafluoroethylene-based polymers. Surf. Coat. Technol. 2019, 366, 15–23. [Google Scholar] [CrossRef]

- Wang, K.; Xiong, D. Construction of lubricant composite coating on Ti6Al4V alloy using micro-arc oxidation and grafting hydrophilic polymer. Mater. Sci. Eng. C. 2018, 90, 219–226. [Google Scholar] [CrossRef] [PubMed]

- Küçükosman, R.; Şüküroğlu, E.E.; Totik, Y.; Şüküroğlu, S. Investigation of wear behavior of graphite additive composite coatings deposited by micro arc oxidation-hydrothermal treatment on AZ91 Mg alloy. Surf. Interfaces 2021, 22, 100894. [Google Scholar] [CrossRef]

- Ivanou, D.K.; Starykevich, M.; Lisenkov, A.D.; Zheludkevich, M.L.; Xue, H.B.; Lamaka, S.V.; Ferreira, M.G.S. Plasma anodized ZE41 magnesium alloy sealed with hybrid epoxy-silane coating. Corros. Sci. 2013, 73, 300–308. [Google Scholar] [CrossRef]

- Nadaraia, K.V.; Suchkov, S.N.; Imshinetskiy, I.M.; Mashtalyar, D.V.; Kosianov, D.Y.; Belov, E.A.; Sinebryukhov, S.L.; Gnedenkov, S.V. New superhydrophobic composite coatings on Mg-Mn-Ce magnesium alloy. J. Magnes. Alloy. 2023, 11, 1721–1739. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Khrisanfova, O.A.; Sinebryukhov, S.L.; Puz’, A.V.; Gnedenkov, A.S. Composite Protective Coating on Nitinol Surface. Mater. Manuf. Process. 2008, 23, 879–883. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Sinebryukhov, S.L.; Mashtalyar, D.V.; Egorkin, V.S.; Tsvetnikov, A.K.; Minaev, A.N. Composite Polymer-Containing Protective Layers on Titanium. Prot. Met. 2008, 44, 704–709. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Sinebryukhov, S.L. Composite Polymer Containing Coatings on the Surface of Metals and Alloys. Corros. Sci. 2009, 16, 387–405. [Google Scholar] [CrossRef]

- Mashtalyar, D.V.; Gnedenkov, S.V.; Sinebryukhov, S.L.; Nadaraia, K.V. Formation of the composite coatings as a method of restoration of titanium products after exploration. Non-Ferrous Met. 2017, 42, 8–11. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Vovna, V.I.; Gordienko, P.S.; Sinebryukhov, S.L.; Cherednichenko, A.I.; Shchukarev, A.V. Chemical Composition of Antifriction Micro-arc Oxide Coating on Titanium Alloy BT16. Prot. Met. 2001, 37, 192–196. [Google Scholar] [CrossRef]

- Zhu, M.; Song, Y.; Liu, Z.; Xu, D.; Dong, K.; Han, E.H. Optimization of thermal control and corrosion resistance of PEO coatings on 7075 aluminum alloy by frequency alteration. Surf. Coat. Technol. 2022, 446, 128797. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Sinebryukhov, S.L. Electrochemical Impedance Spectroscopy of Oxide Layers on the Titanium Surface. Russ. J. Electrochem. 2005, 41, 858–865. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Sinebryukhov, S.L.; Sergienko, V.I. Electrochemical Impedance Simulation of a Metal Oxide Heterostructure/Electrolyte Interface: A Review. Rus. J. Electrochem. 2006, 42, 197–211. [Google Scholar] [CrossRef]

- Sharifi, H.; Aliofkhazraei, M.; Darband, G.B.; Rouhaghdam, A.S. Characterization of PEO nanocomposite coatings on titanium formed in electrolyte containing atenolol. Surf. Coat. Technol. 2016, 304, 438–449. [Google Scholar] [CrossRef]

- Sopchenski, L.; Popat, K.; Soares, P. Bactericidal activity and cytotoxicity of a zinc doped PEO titanium coating. Thin Solid Film. 2018, 660, 477–483. [Google Scholar] [CrossRef]

- Santos-Coquillat, A.; Mohedano, M.; Martinez-Campos, E.; Arrabal, R.; Pardo, A.; Matykina, E. Bioactive multi-elemental PEO-coatings on titanium for dental implant applications. Mater. Sci. Eng. C 2019, 97, 738–752. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, Y.; Chen, X.-H.; Yang, J.-A.; Pan, H.; Chen, D.; Wang, L.; Zhang, J.; Zhu, D.; Wu, S.; et al. Fundamental Theory of Biodegradable Metals—Definition, Criteria, and Design. Adv. Funct. Mater. 2019, 29, 1805402. [Google Scholar] [CrossRef]

- Gu, Y.; Chen, C.F.; Bandopadhyay, S.; Ning, C.; Zhang, Y.; Guo, Y. Corrosion mechanism and model of pulsed DC microarc oxidation treated AZ31 alloy in simulated body fluid. Appl. Surf. Sci. 2012, 258, 6116–6126. [Google Scholar] [CrossRef]

- Castellanos, A.; Altube, A.; Vega, J.M.; García-Lecina, E.; Díez, J.A.; Grande, H.J. Effect of different post-treatments on the corrosion resistance and tribological properties of AZ91D magnesium alloy coated PEO. Surf. Coat. Technol. 2015, 278, 99–107. [Google Scholar] [CrossRef]

- Staicopolus, D.N. The computation of surface tension and of contact angle by the sessile-drop method. J. Colloid Sci. 1962, 17, 439–447. [Google Scholar] [CrossRef]

- Erbil, H.Y. The debate on the dependence of apparent contact angles on drop contact area or three-phase contact line: A review. Surf. Sci. Rep. 2014, 69, 325–365. [Google Scholar] [CrossRef]

- Viades-Trejo, J.; Gracia-Fadrique, J. Spinning drop method: From Young–Laplace to Vonnegut. Colloids Surf. A Physicochem. Eng. Asp. 2007, 302, 549–552. [Google Scholar] [CrossRef]

- Fronzi, M.; Assadi, M.; Hanaor, D. Theoretical insights into the hydrophobicity of low index CeO2 surfaces. Appl. Surf. Sci. 2019, 478, 68–74. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

| Sample | Designation |

|---|---|

| Bare titanium | Ti |

| PEO coating | PEO |

| PEO coating with SPTFE (composite coating) | CC |

| Designation | CC-1x | CC-2x | CC-3x |

|---|---|---|---|

| Volume of dispersion, mL/cm2 | 0.35 | 0.65 | 0.95 |

| Parameters | d 1, µm | Ps 2, % | Pcs 3, % |

|---|---|---|---|

| PEO | 7 | 14.45 | 4.40 |

| CC-1x | 7 | - | 3.81 |

| CC-2x | 8 | - | 3.76 |

| CC-3x | 10 | - | 3.58 |

| Sample | Sa, µm | Sq, µm |

|---|---|---|

| PEO | 2.0 | 2.4 |

| CC-1x | 1.5 | 1.8 |

| CC-2x | 1.2 | 1.5 |

| CC-3x | 1.1 | 1.3 |

| Sample | EC (V vs. SCE) | IC (A/cm2) | RP (Ω × cm2) |

|---|---|---|---|

| Ti | –0.38 | 1.3 × 10–7 | 3.5 × 105 |

| PEO | –0.07 | 1.7 × 10–8 | 1.1 × 106 |

| CC-1x | 0.03 | 1.6 × 10–8 | 1.6 × 106 |

| CC-2x | 0.13 | 8.2 × 10–9 | 7.2 × 106 |

| CC-3x | 0.13 | 7.2 × 10–9 | 9.5 × 106 |

| Sample | R1 (Ω × cm2) | CPE1 | R2 (Ω × cm2) | CPE2 | R3 (Ω × cm2) | CPE3 | |||

|---|---|---|---|---|---|---|---|---|---|

| Q1 (Ω–1 × cm–2 × sn) | n1 | Q2 (Ω–1 × cm 2 × sn) | n2 | Q3 (Ω–1 × cm–2 × sn) | n3 | ||||

| Ti | – | – | – | 3.4 × 105 | 5.4 × 10–5 | 0.92 | – | – | – |

| PEO | 9.4 × 103 | 4.1 × 10–8 | 0.96 | 2.1 × 106 | 3.5 × 10–6 | 0.58 | – | – | – |

| CC-1x | 1.4 × 103 | 1.2 × 10–8 | 0.88 | 1.9 × 104 | 7.7 × 10–7 | 0.83 | 3.5 × 105 | 2.6 × 10–6 | 0.51 |

| CC-2x | 6.2 × 104 | 7.2 × 10–10 | 0.98 | 5.7 × 106 | 1.1 × 10–8 | 0.67 | – | – | – |

| CC-3x | 1.4 × 105 | 1.2 × 10–9 | 0.95 | 1.2 × 108 | 3.4 × 10–8 | 0.38 | – | – | – |

| Sample | LC2, H | LC3, H |

|---|---|---|

| PEO | 13.8 ± 0.2 | 30.6 ± 0.4 |

| CC-1x | 15.2 ± 0.3 | 36.8 ± 0.4 |

| CC-2x | 18.6 ± 0.2 | 38.2 ± 0.5 |

| CC-3x | 19.7 ± 0.4 | 38.8 ± 0.6 |

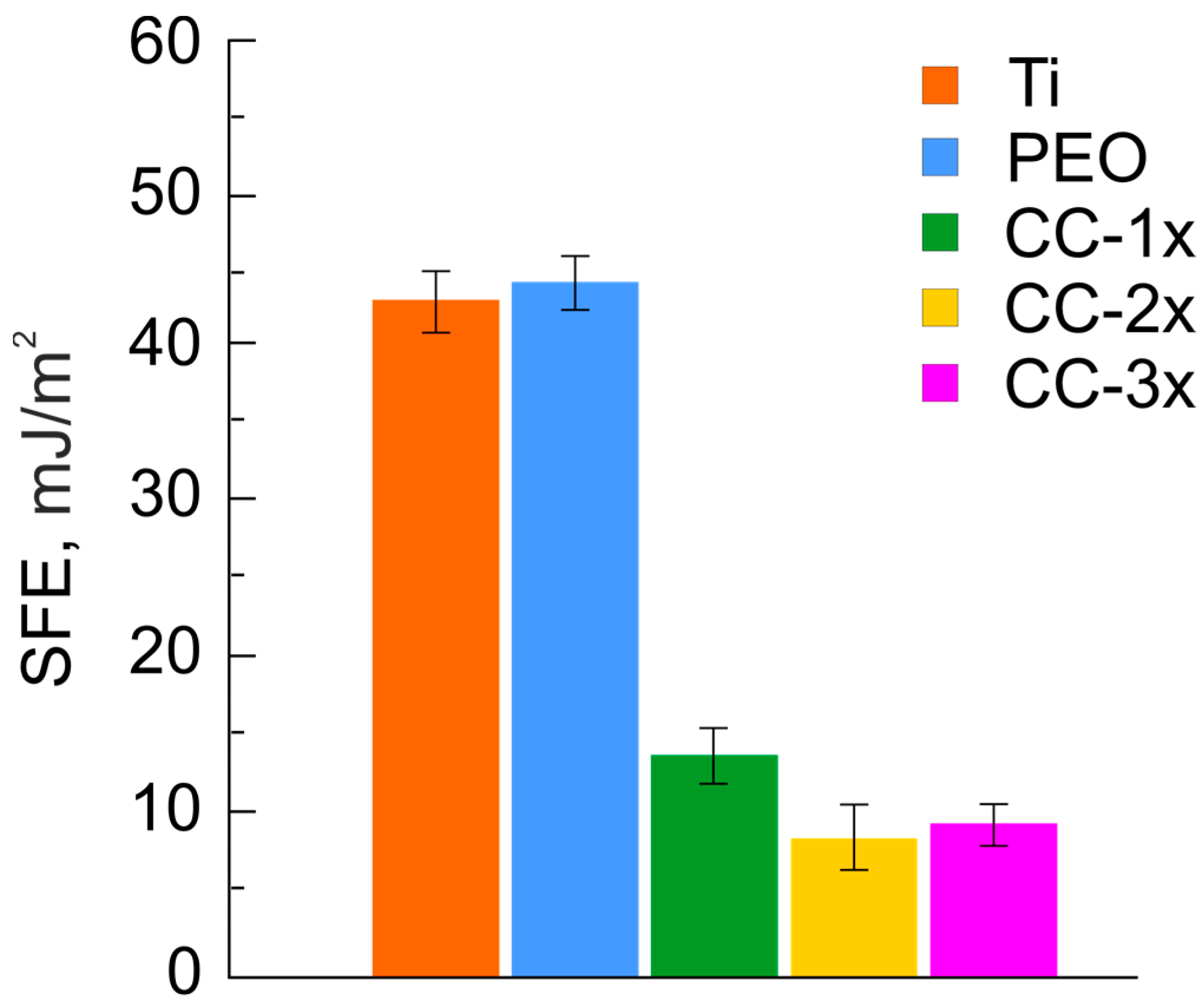

| Sample | CA (°) | CAH (°) |

|---|---|---|

| Ti | 75.1 ± 0.3 | – |

| PEO | 75.2 ± 1.4 | – |

| CC-1x | 131.3 ± 0.6 | 39.0 ± 0.5 |

| CC-2x | 130.2 ± 2.9 | 40.7 ± 0.6 |

| CC-3x | 128.1 ± 2.7 | 49.7 ± 0.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mashtalyar, D.V.; Pleshkova, A.I.; Piatkova, M.A.; Nadaraia, K.V.; Imshinetskiy, I.M.; Belov, E.A.; Suchkov, S.N.; Sinebryukhov, S.L.; Gnedenkov, S.V. PTFE-Containing Coating Obtained on Ti by Spraying and PEO Pretreatment. Coatings 2023, 13, 1249. https://doi.org/10.3390/coatings13071249

Mashtalyar DV, Pleshkova AI, Piatkova MA, Nadaraia KV, Imshinetskiy IM, Belov EA, Suchkov SN, Sinebryukhov SL, Gnedenkov SV. PTFE-Containing Coating Obtained on Ti by Spraying and PEO Pretreatment. Coatings. 2023; 13(7):1249. https://doi.org/10.3390/coatings13071249

Chicago/Turabian StyleMashtalyar, Dmitry V., Arina I. Pleshkova, Mariia A. Piatkova, Konstantine V. Nadaraia, Igor M. Imshinetskiy, Evgeny A. Belov, Sergey N. Suchkov, Sergey L. Sinebryukhov, and Sergey V. Gnedenkov. 2023. "PTFE-Containing Coating Obtained on Ti by Spraying and PEO Pretreatment" Coatings 13, no. 7: 1249. https://doi.org/10.3390/coatings13071249

APA StyleMashtalyar, D. V., Pleshkova, A. I., Piatkova, M. A., Nadaraia, K. V., Imshinetskiy, I. M., Belov, E. A., Suchkov, S. N., Sinebryukhov, S. L., & Gnedenkov, S. V. (2023). PTFE-Containing Coating Obtained on Ti by Spraying and PEO Pretreatment. Coatings, 13(7), 1249. https://doi.org/10.3390/coatings13071249