Improvement of Optical Confinement for Terahertz Vertical-Cavity Surface-Emitting Laser with Square-Lattice Photonic Crystal Structure

Abstract

1. Introduction

2. Theoretical and Computational Analysis

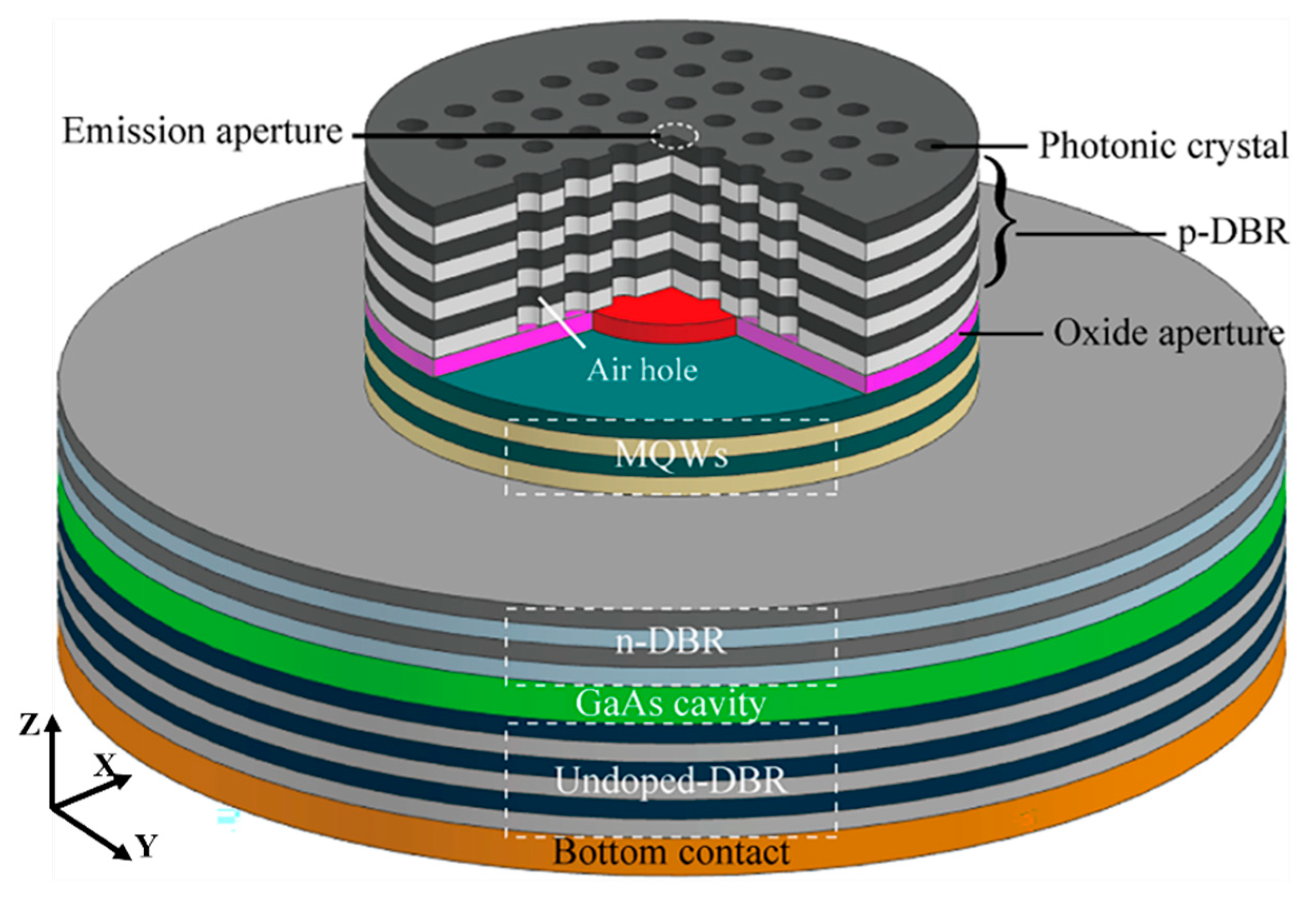

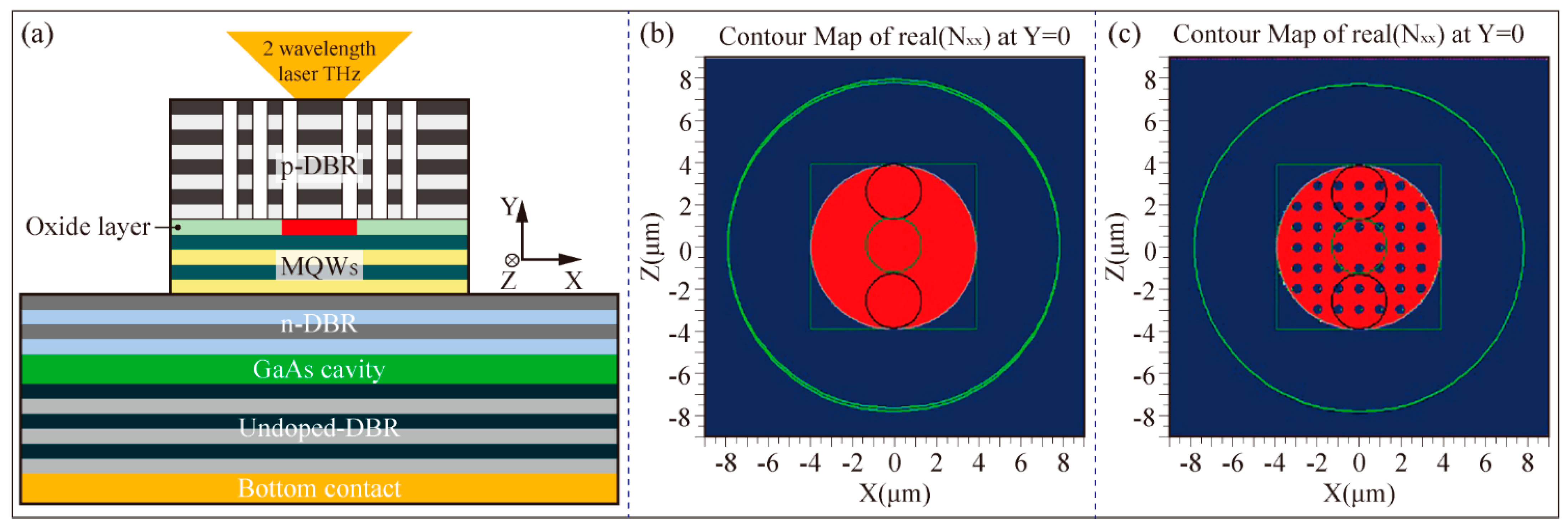

2.1. The Basic Structure of the Square-Lattice PhC-VCSEL

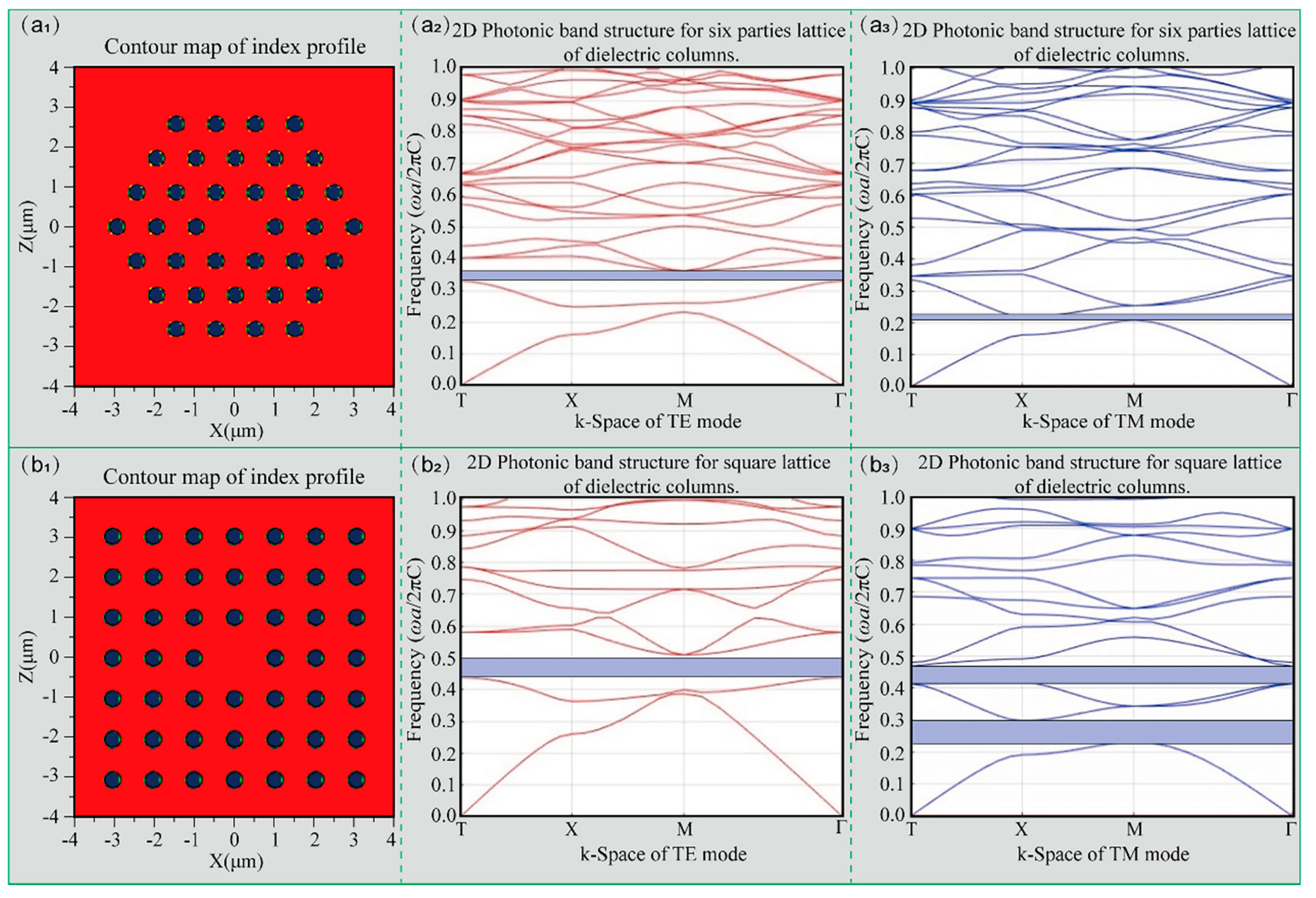

2.2. Design of the Square Lattice Photonic Crystal Structure

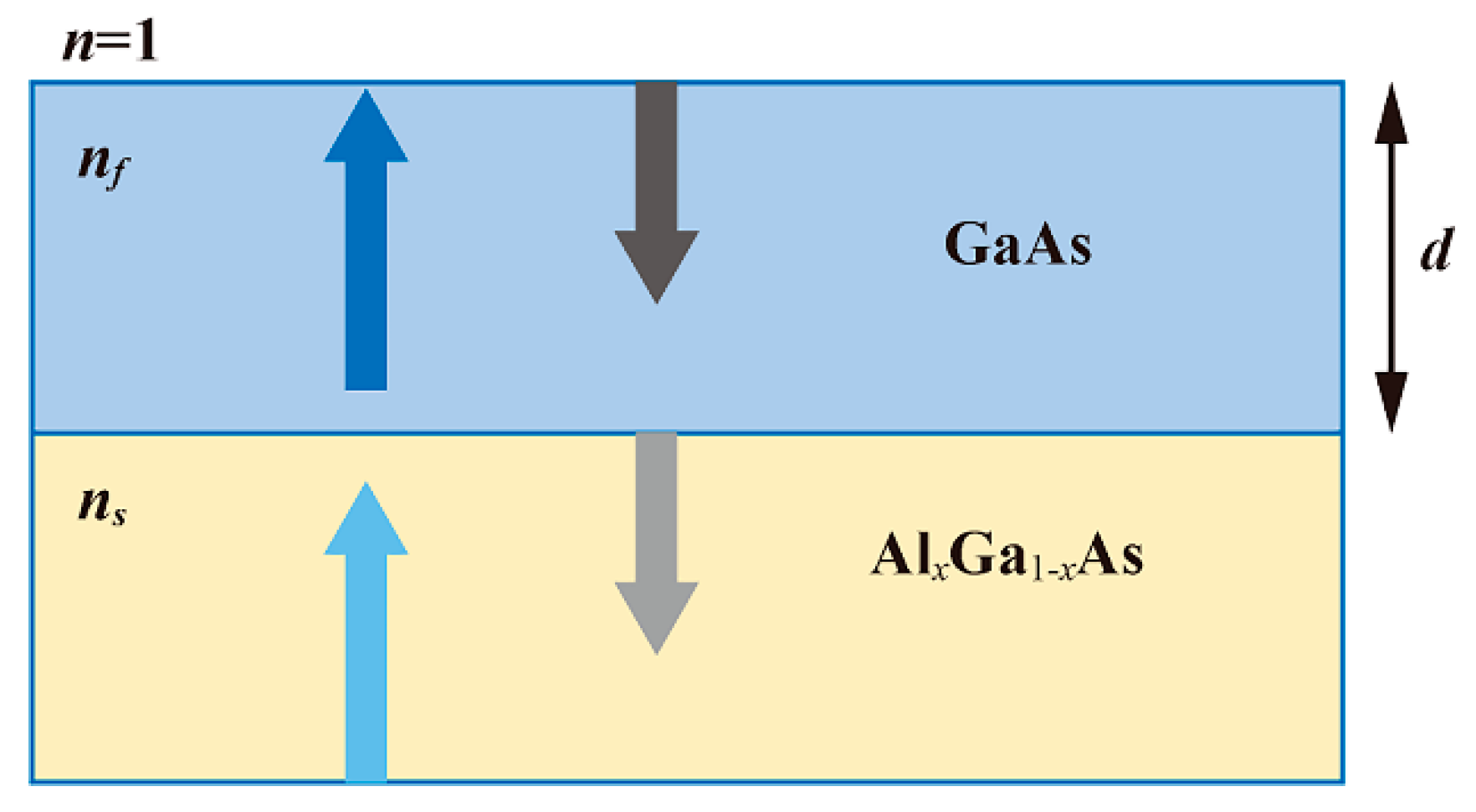

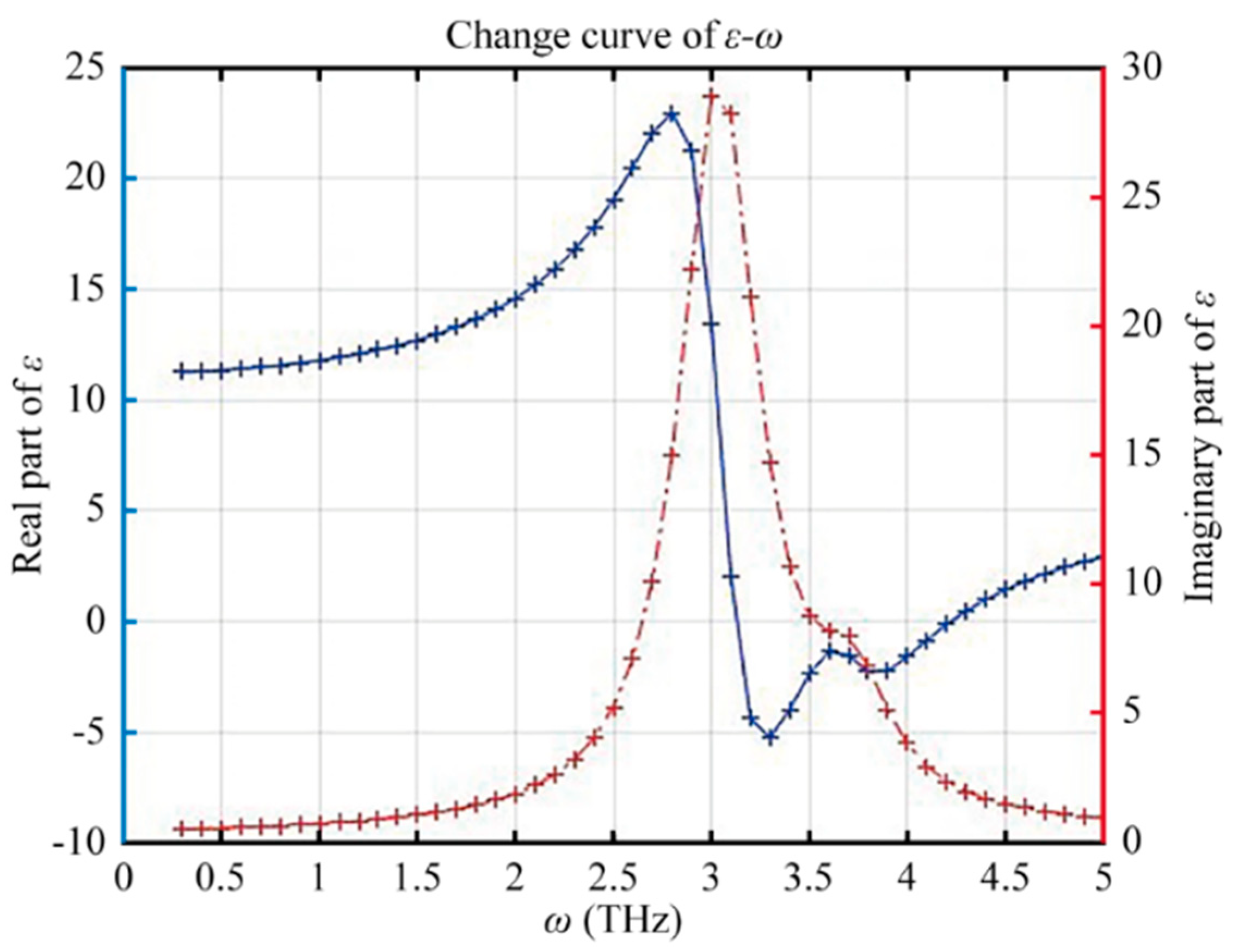

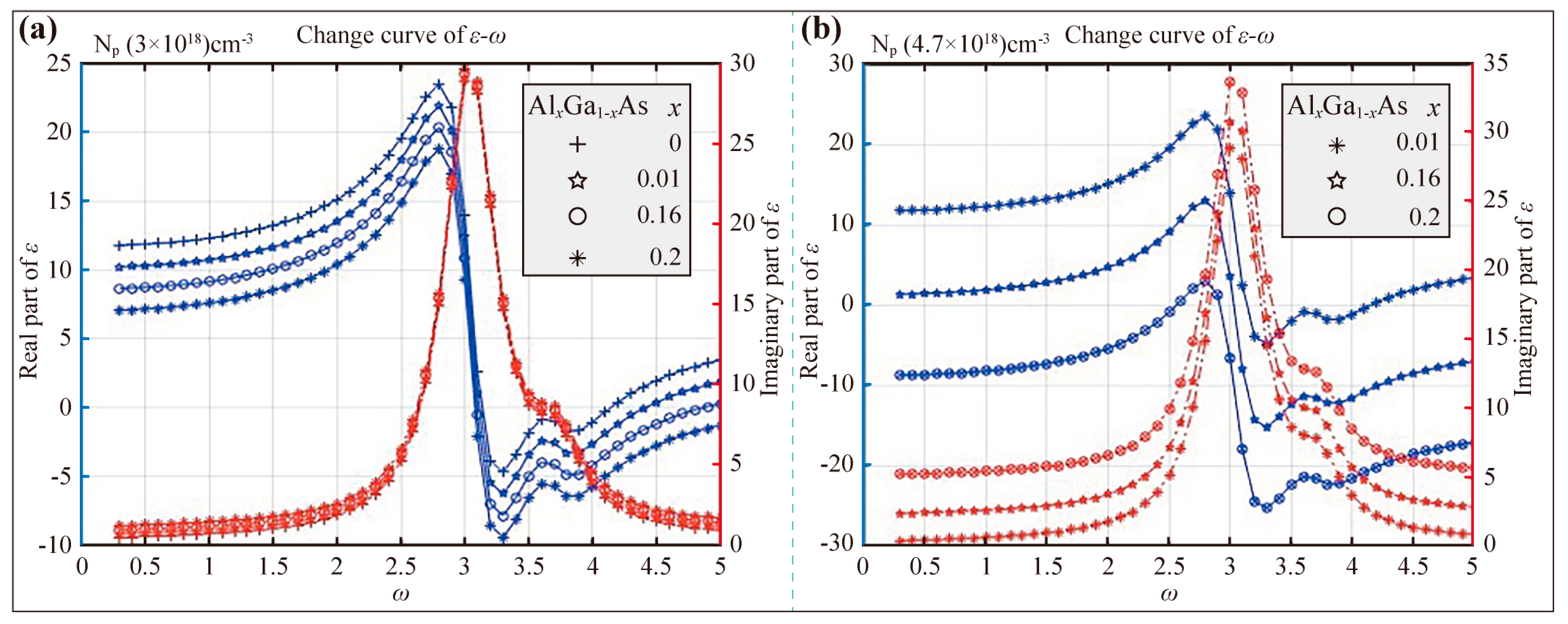

3. Dielectric Constant Analysis of GaAs and AlxGa1-xAs

4. Simulation Method and Calculation Model of VCSEL

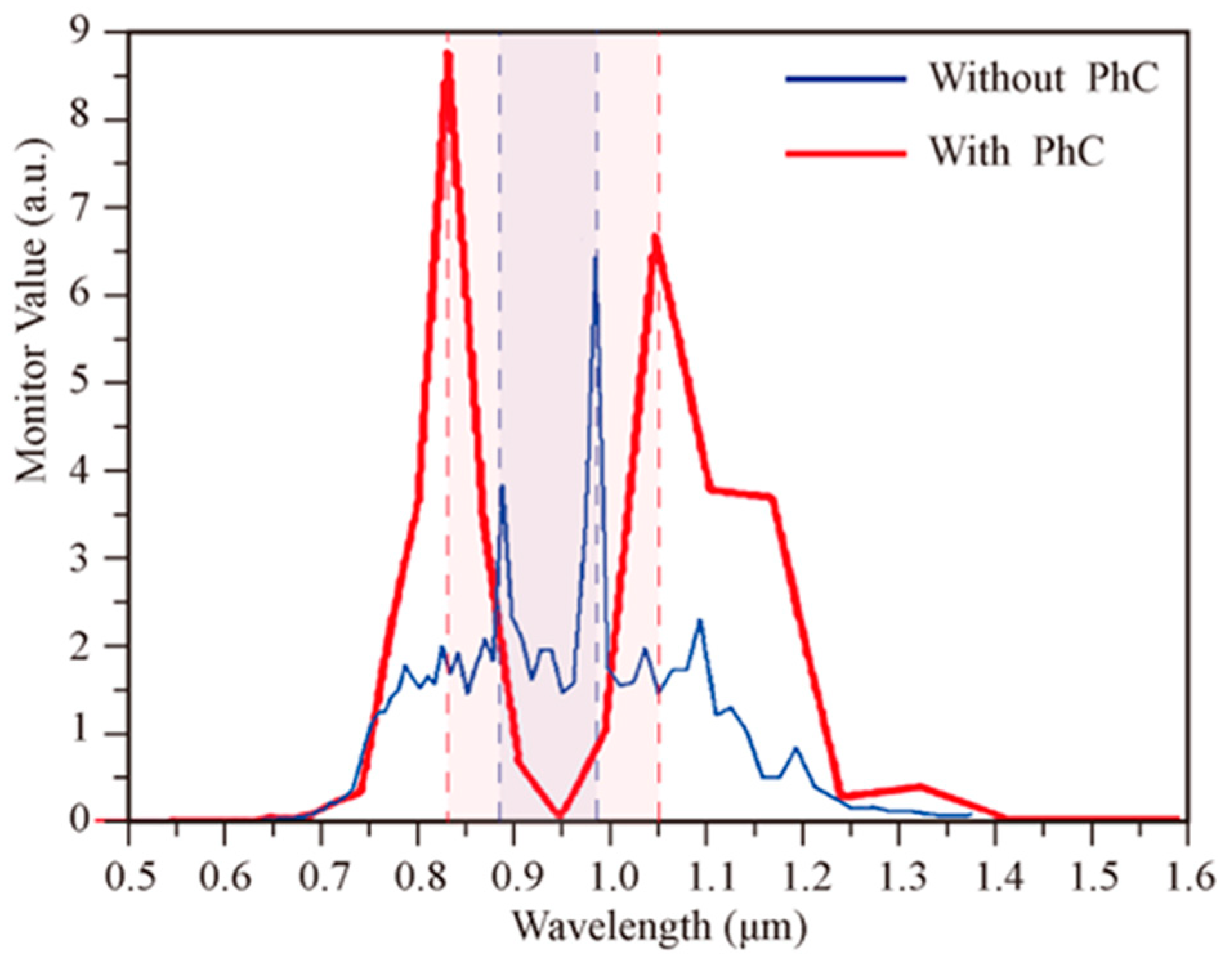

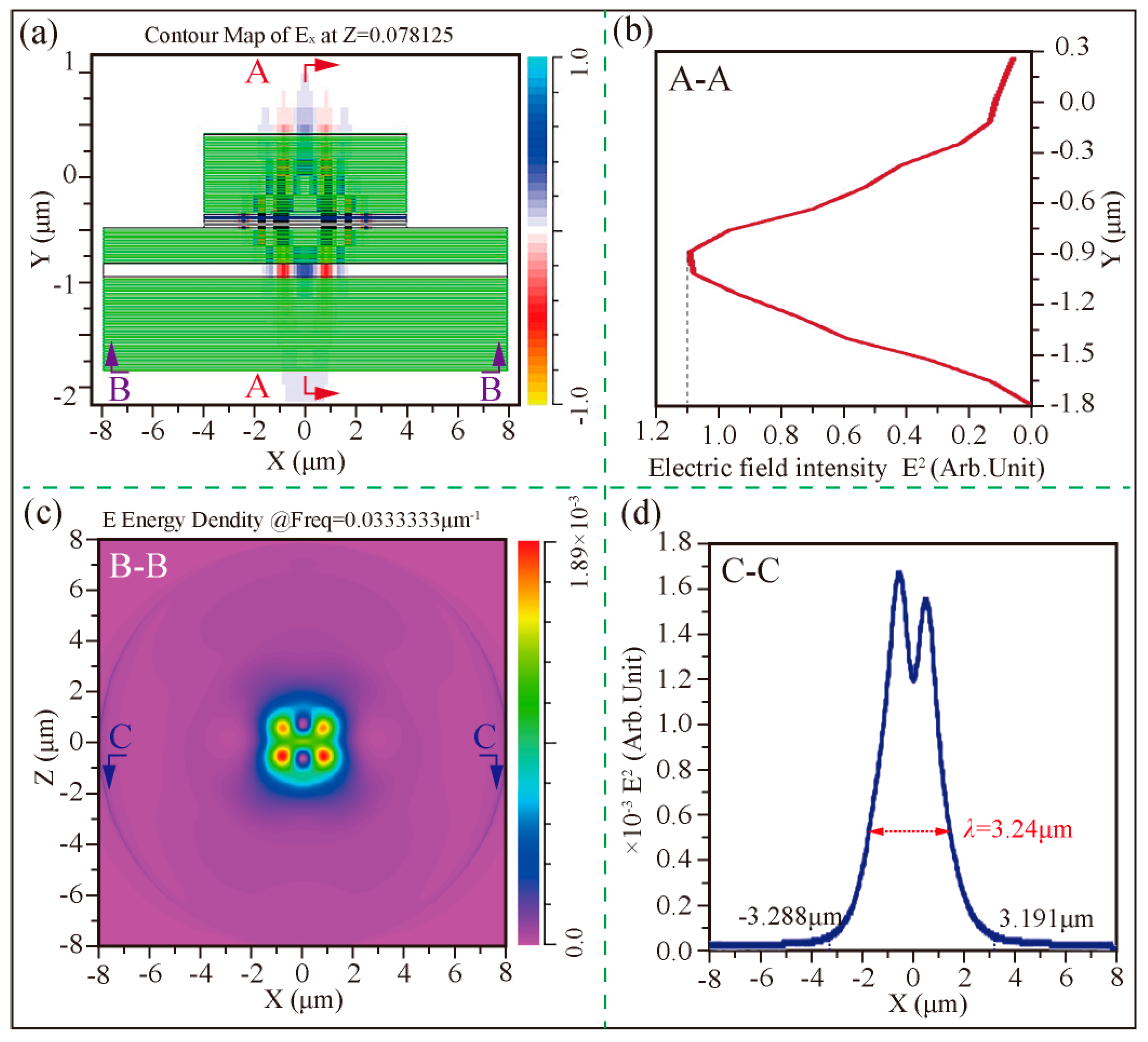

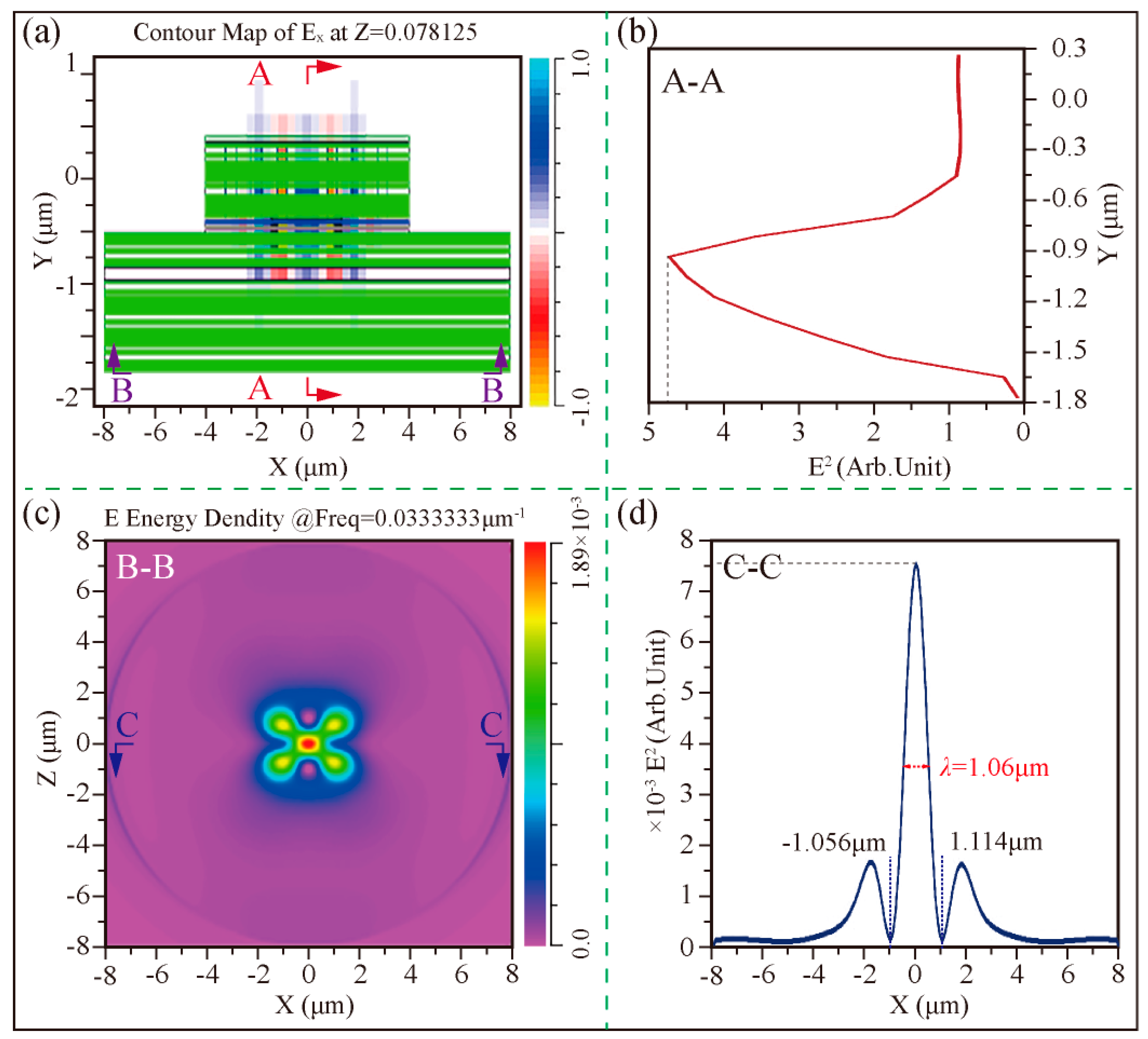

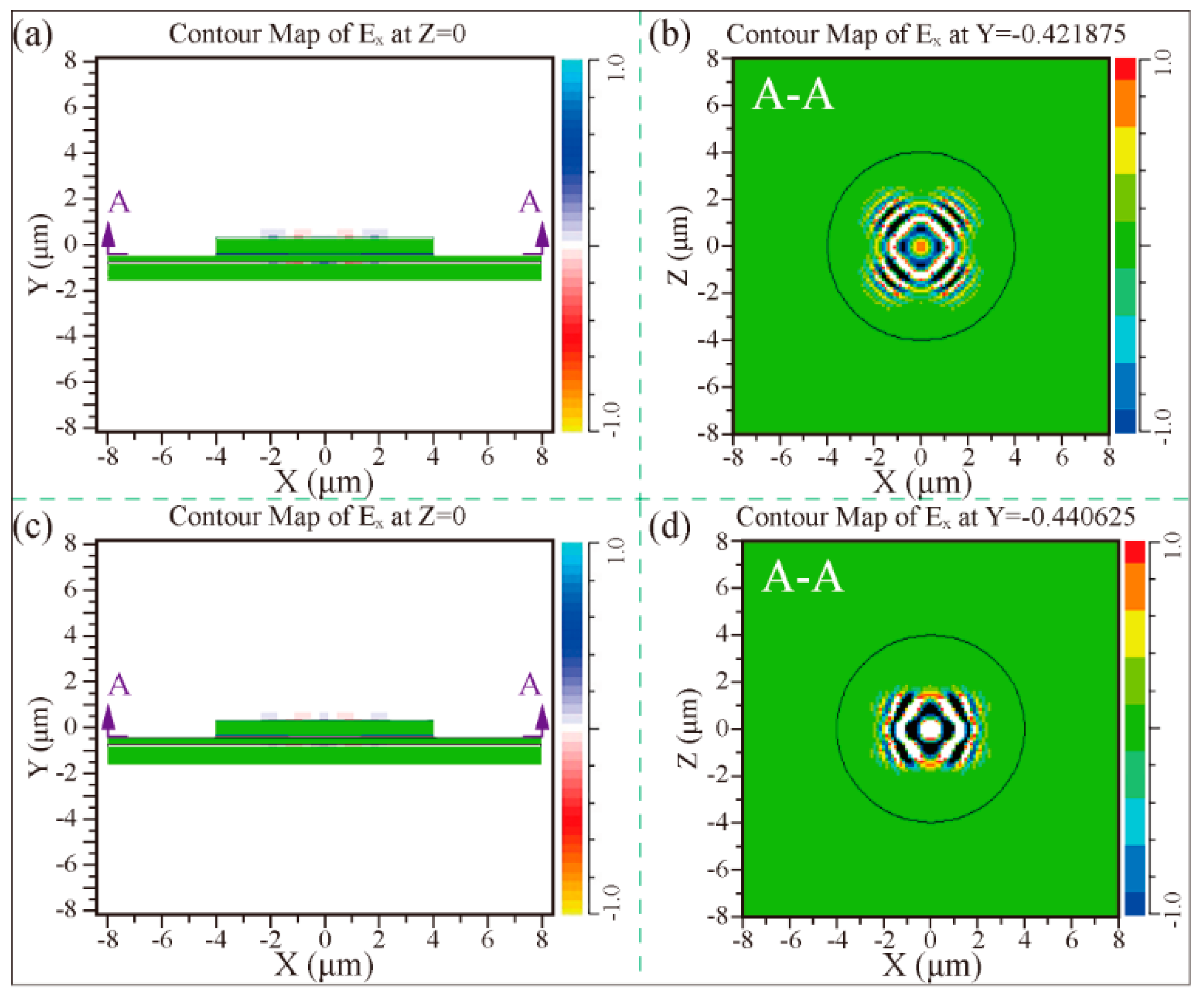

5. The Influence of Photonic Crystal on the Optical Confinement of VCSEL

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yakasai, I.K.; Abas, P.E.; Begum, F. Proposal of Highly Birefringent Porous Core Photonic Crystal Fibre for Polarisation Maintaining Terahertz Wave Guidance. In Proceedings of the IEEE 8th International Conference on Photonics (ICP), Kota Bharu, Malaysia, 12 May–30 June 2020. [Google Scholar] [CrossRef]

- Němec, H.; Duvillaret, L.; Garet, F.; Kužel, P.; Xavier, P.; Richard, J.; Rauly, D. Thermally tunable filter for terahertz range based on a one-dimensional photonic crystal with a defect. J. Appl. Phys. 2004, 96, 4072–4075. [Google Scholar] [CrossRef]

- Chassagneux, Y.; Colombelli, R.; Maineult, W.; Barbieri, S.; Beere, H.E.; Ritchie, D.A.; Khanna, S.P.; Linfield, E.H.; Davies, A.G. Electrically pumped photonic-crystal terahertz lasers controlled by boundary conditions. Nature 2009, 457, 174–178. [Google Scholar] [CrossRef] [PubMed]

- Strzebonski, P.J.; North, W.; Jahan, N.; Choquette, K.D. Analysis of Coherence and Coupling in Vertical Cavity Surface Emitting Laser Arrays. IEEE J. Quantum Electron. 2022, 58, 1–8. [Google Scholar] [CrossRef]

- Garnache, A.; Seghilani, M.; Sellahi, M.; Paquet, R.; Chomet, B.; Myara, M.; Blin, S.; LeGratiet, L.; Beaudoin, G.; Sagnes, I.; et al. Generation of new spatial and temporal coherent light states using III-V semiconductor laser technology: VORTEX, continuum, dual frequency for THz. Phys. Chem. Appl. Nanostruct. 2017, 9734, 471–474. [Google Scholar] [CrossRef]

- Scalera, V.; Hudl, M.; Neeraj, K.; Perna, S.; D’Aquino, M.; Bonetti, S.; Serpico, C. Analysis in k-Space of Magnetization Dynamics Driven by Strong Terahertz Fields. IEEE Trans. Magn. 2020, 57, 1–5. [Google Scholar] [CrossRef]

- Singh, G.; Kaur, G. Design and Implementation of Photonic Crystal Vertical Cavity Surface Emitting Laser. In Proceedings of the International Conference on Signal Processing and Communication (ICSC), Noida, India, 7–9 March 2019; pp. 32–36. [Google Scholar] [CrossRef]

- Irfan, M.; Yim, J.-H.; Kim, C.; Lee, S.W.; Jho, Y.-D. Phase change in terahertz waves emitted from differently doped graphite: The role of carrier drift. Appl. Phys. Lett. 2013, 103, 201108. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, Z.; Liu, W.; Jia, Q.; Lu, Y. Terahertz Filters and Polarizers Using 2-D Subwavelength Hole Arrays. IEEE Photon-J. 2018, 11, 1–7. [Google Scholar] [CrossRef]

- Kumar, S.; Williams, B.; Kohen, S.; Hu, Q.; Reno, J.L. High temperature continuous-wave operation of terahertz quantum cascade lasers. In Proceedings of the Conference on Lasers and Electro-Optics 1, San Francisco, CA, USA, 16–21 May 2004. [Google Scholar]

- Tang, H.; Zhao, L.; Zhu, P.; Zou, X.; Qi, J.; Cheng, Y.; Qiu, J.; Hu, X.; Song, W.; Xiang, D.; et al. Stable and Scalable Multistage Terahertz-Driven Particle Accelerator. Phys. Rev. Lett. 2021, 127, 074801. [Google Scholar] [CrossRef]

- Matlis, N.; Ahr, F.; Calendron, A.-L.; Cankaya, H.; Cirmi, G.; Eichner, T.; Fallahi, A.; Fakhari, M.; Hartin, A.; Hemmer, M.; et al. Acceleration of electrons in THz driven structures for AXSIS. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2018, 909, 27–32. [Google Scholar] [CrossRef]

- Singh, A.; Pashkin, A.; Winnerl, S.; Welsch, M.; Beckh, C.; Sulzer, P.; Leitenstorfer, A.; Helm, M.; Schneider, H. Up to 70 THz bandwidth from an implanted Ge photoconductive antenna excited by a femtosecond Er:fibre laser. Light. Sci. Appl. 2020, 9, 1–7. [Google Scholar] [CrossRef]

- Takigawa, S.; Noda, S. Mode analysis of two-dimensional photonic crystal terahertz lasers with gain/loss dispersion characteristics. J. Opt. Soc. Am. B 2010, 27, 2556–2567. [Google Scholar] [CrossRef]

- Sultana, J.; Islam, S.; Faisal, M.; Islam, M.R.; Ng, B.W.-H.; Ebendorff-Heidepriem, H.; Abbott, D. Highly birefringent elliptical core photonic crystal fiber for terahertz application. Opt. Commun. 2018, 407, 92–96. [Google Scholar] [CrossRef]

- Garai, S.K.; Mukhopadhyay, S. A method of optical implementation of frequency encoded different logic operations using second harmonic and difference frequency generation techniques in non-linear material. Optik 2010, 121, 715–721. [Google Scholar] [CrossRef]

- Kitada, T.; Lu, X.; Minami, Y.; Kumagai, N.; Morita, K. Room-temperature two-color lasing by current injection into a GaAs/AlGaAs coupled multilayer cavity fabricated by wafer bonding. Jpn. J. Appl. Phys. 2018, 57, 04FH03. [Google Scholar] [CrossRef]

- Suhara, T.; Avetisyan, Y.; Ito, H. Theoretical analysis of laterally emitting terahertz-wave generation by difference-frequency generation in channel waveguides. IEEE J. Quantum Electron. 2003, 39, 166–171. [Google Scholar] [CrossRef]

- Russell, P.S.; Birks, T.A.; Knight, J.C.; Cregan, R.F.; Mangan, B.J.; De Sandro, J.-P. Silica/Air Photonic Crystal Fibres. Jpn. J. Appl. Phys. 1998, 37, 45. [Google Scholar] [CrossRef]

- Cregan, R.F.; Mangan, B.J.; Knight, J.C.; Birks, T.A.; Russell, P.S.J.; Roberts, P.J.; Allan, D.C. Single-Mode Photonic Band Gap Guidance of Light in Air. Science 1999, 285, 1537–1539. [Google Scholar] [CrossRef]

- Malka, D.; Katz, G. An Eight-Channel C-Band Demux Based on Multicore Photonic Crystal Fiber. Nanomaterials 2018, 8, 845. [Google Scholar] [CrossRef]

- Malka, D.; Peled, A. Power splitting of 1 × 16 in multicore photonic crystal fibers. Appl. Surf. Sci. 2017, 417, 34–39. [Google Scholar] [CrossRef]

- Chow, E.; Lin, S.Y.; Wendt, J.R.; Johnson, S.; Joannopoulos, J.D. Quantitative analysis of bending efficiency in photonic-crystal waveguide bends at λ = 1.55 μm wavelengths. Opt. Lett. 2001, 26, 286–288. [Google Scholar] [CrossRef]

- Buczynski, R.; Bookey, H.; Pysz, D.; Stepien, R.; Kujawa, I.; McCarthy, J.; Waddie, A.; Kar, A.; Taghizadeh, M. Supercontinuum generation up to 2.5 μm in photonic crystal fiber made of lead-bismuth-galate glass. Laser Phys. Lett. 2010, 7, 666–672. [Google Scholar] [CrossRef]

- Singer, A.M.; Hameed, M.F.O.; Heikal, A.M.; El-Mikati, H.A.; Obayya, S.S.A. Highly birefringent slotted core photonic crystal fiber for terahertz waveguiding. Opt. Quantum Electron. 2020, 53, 9. [Google Scholar] [CrossRef]

- De, M.; Gangwar, R.K.; Singh, V.K. Designing of highly birefringence, dispersion shifted decagonal photonic crystal fiber with low confinement loss. Photon- Nanostructures Fundam. Appl. 2017, 26, 15–23. [Google Scholar] [CrossRef]

- Kitada, T.; Tanaka, F.; Takahashi, T.; Morita, K.; Isu, T. GaAs/AlAs coupled multilayer cavity structures for terahertz emission devices. Appl. Phys. Lett. 2009, 95, 111106. [Google Scholar] [CrossRef]

- Rzesnicki, T.; Piosczyk, B.; Kern, S.; Illy, S.; Jin, J.; Samartsev, A.; Schlaich, A.; Thumm, M. 2.2-MW Record Power of the 170-GHz European Preprototype Coaxial-Cavity Gyrotron for ITER. IEEE Trans. Plasma Sci. 2010, 38, 1141–1149. [Google Scholar] [CrossRef]

- Czyszanowski, T.; Sarzała, R.P.; Dems, M.; Nakwaski, W.; Thienpont, H.; Panajotov, K. Optimal photonic-crystal parameters assuring single-mode operation of 1300 nm AlInGaAs vertical-cavity surface-emitting laser. J. Appl. Phys. 2009, 105, 093102. [Google Scholar] [CrossRef]

- Liu, A.; Xing, M.; Qu, H.; Chen, W.; Zhou, W.; Zheng, W. Reduced divergence angle of photonic crystal vertical-cavity surface-emitting laser. Appl. Phys. Lett. 2009, 94, 191105. [Google Scholar] [CrossRef]

- Xu, K.; Fang, M.; Huang, Z. Compact vertical-cavity surface-emitting laser based on all-dielectric metasurfaces. Opt. Commun. 2020, 475, 126257. [Google Scholar] [CrossRef]

- Song, D.-S.; Kim, S.-H.; Park, H.-G.; Kim, C.-K.; Lee, Y.H. Single-mode photonic-crystal vertical cavity surface emitting laser. In Proceedings of the Conference on Lasers and Electro-Optics, Long Beach, CA, USA, 19–22 May 2002. [Google Scholar] [CrossRef]

- Fernandes, H.C.C.; Medeiros, J.L.G.; Junior, I.M.A.; Brito, D.B. Photonic Crystal at Millimeter Waves Applications. PIERS Online 2007, 3, 689–694. [Google Scholar] [CrossRef]

- Hu, Z.G.; Rinzan, M.B.M.; Matsik, S.G.; Perera, A.G.U.; Von Winckel, G.; Stintz, A.; Krishna, S. Optical characterizations of heavily doped p-type AlxGa1−xAs and GaAs epitaxial films at terahertz frequencies. J. Appl. Phys. 2005, 97, 093529. [Google Scholar] [CrossRef]

- Vassant, S.; Pardo, F.; Bouchon, P.; Marquier, F.; Greffet, J.J.; Pelouard, J.L. Optical control of THz reflectivity with surface waves. Proc. SPIE-Int. Soc. Opt. Eng. 2011, 8119, 81190H. [Google Scholar] [CrossRef]

- Yee, K. Numerical solution of initial boundary value problems involving Maxwell’s equations in isotropic media. IEEE Trans. Antennas Propag. 1966, 14, 302–307. [Google Scholar] [CrossRef]

- Lee, Y.-S. Principles of Terahertz Science and Technology; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar] [CrossRef]

- Herasimovich, A.; Shokhovets, S.; Goldhahn, R.; Gobsch, G. The dielectric function of a GaAs/AlGaAs single quantum well: Calculation and comparison with experiment. Thin Solid Films 2004, 450, 199–202. [Google Scholar] [CrossRef]

| Layer | Thickness (nm) | Material | Number of Plies |

|---|---|---|---|

| p-DBR | 8/17 | AlGaAs/GaAs | 28 pairs |

| Oxide layer | 30 | AlAs/Al2O3 | - |

| MQW cavity | 16.8/3.6 | GaAs/InGaAs | 3 pairs |

| 16/4.4 | GaAs/InGaAs | 3 pairs | |

| n-DBR | 8/17 | GaAs/AlGaAs | 12.5 pairs |

| GaAs cavity | 3/2λ | GaAs | - |

| Undoped-DBR | 8/17 | AlGaAs/GaAs | 34 pairs |

| Bottom contact | - | GaAs (113) B substrate | - |

| ε∞ | ωLO | ωTO | γ |

|---|---|---|---|

| 11 | 292.1 cm−1 | 268.7 cm−1 | 2.4 cm−1 |

| 11 | 34.24 μm | 37.22 μm | 4166.67 μm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Haraguchi, M.; Zhang, X.; Wang, P.; Sun, S. Improvement of Optical Confinement for Terahertz Vertical-Cavity Surface-Emitting Laser with Square-Lattice Photonic Crystal Structure. Coatings 2023, 13, 972. https://doi.org/10.3390/coatings13060972

Wang Y, Haraguchi M, Zhang X, Wang P, Sun S. Improvement of Optical Confinement for Terahertz Vertical-Cavity Surface-Emitting Laser with Square-Lattice Photonic Crystal Structure. Coatings. 2023; 13(6):972. https://doi.org/10.3390/coatings13060972

Chicago/Turabian StyleWang, Yadi, Masanobu Haraguchi, Xingbo Zhang, Pingping Wang, and Shufeng Sun. 2023. "Improvement of Optical Confinement for Terahertz Vertical-Cavity Surface-Emitting Laser with Square-Lattice Photonic Crystal Structure" Coatings 13, no. 6: 972. https://doi.org/10.3390/coatings13060972

APA StyleWang, Y., Haraguchi, M., Zhang, X., Wang, P., & Sun, S. (2023). Improvement of Optical Confinement for Terahertz Vertical-Cavity Surface-Emitting Laser with Square-Lattice Photonic Crystal Structure. Coatings, 13(6), 972. https://doi.org/10.3390/coatings13060972