Optical Characterization of Al Island Films: A Round Robin Test

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication and Measurements

2.2. Optical Characterization Approaches

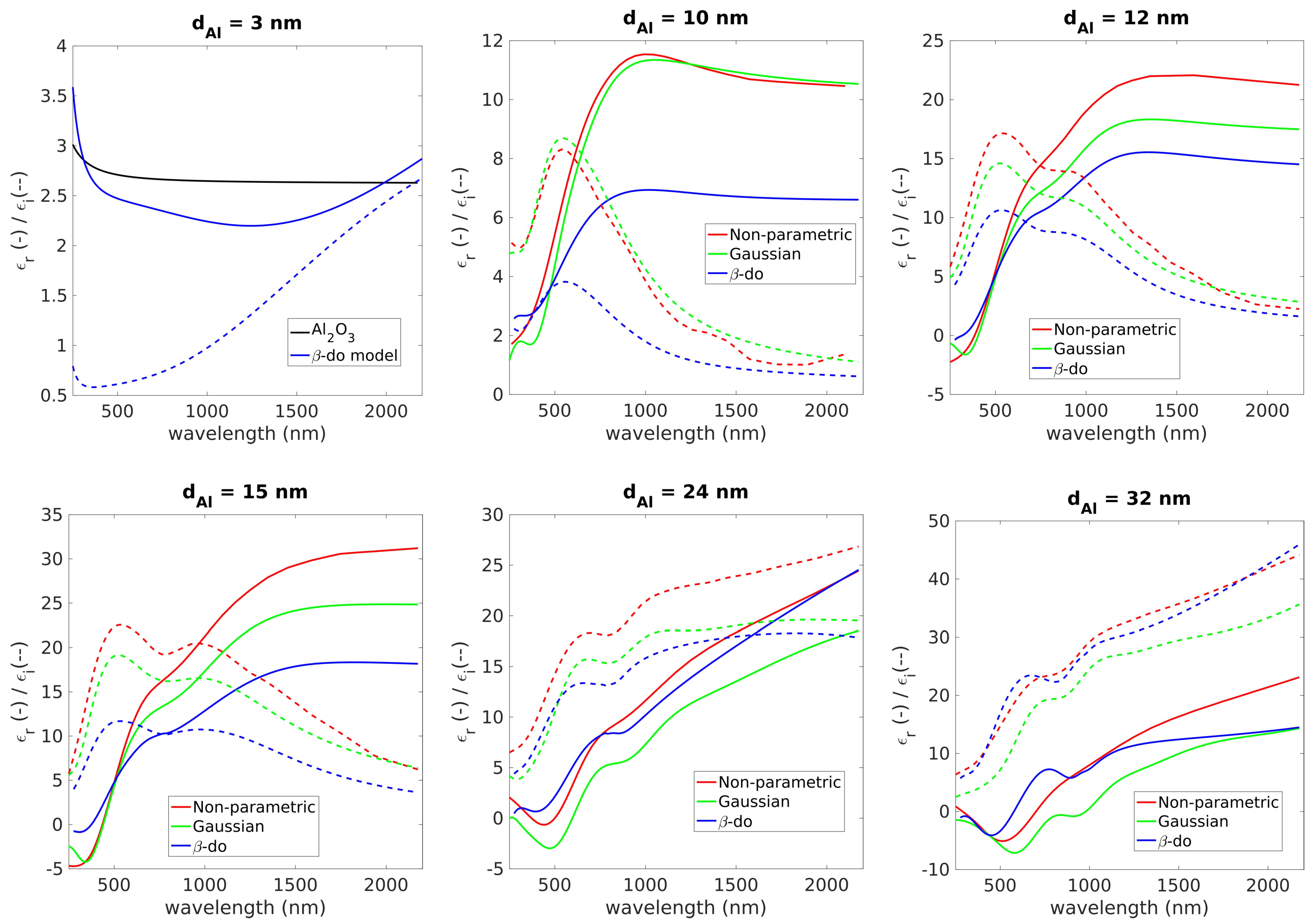

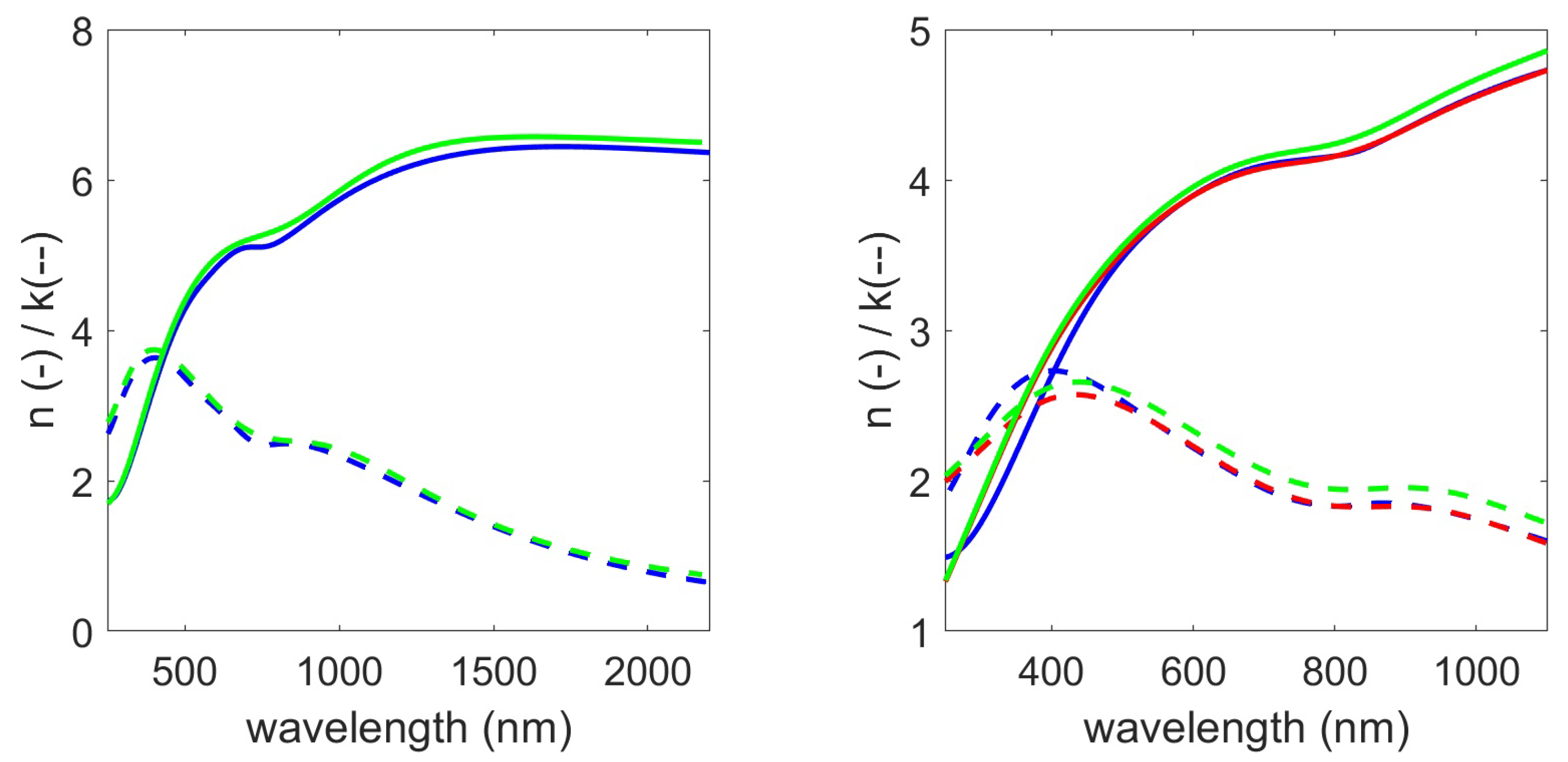

- Non-parametric model: This approach is based on the assumption that the wavelength-dependencies of the real (n) and imaginary (k) part of the MIF effective refractive index are arbitrary smooth functions [14,22,24]. The discrepancy function to be minimized is:where M is the total number of measurements, q is an index that runs over different types of spectra, j runs over wavelengths (or photon energy) of the spectra, is the computed spectra, is the experimental data and is the corresponding experimental uncertainty. The parameters and are regularization constants that control the smoothness of the optical constants dispersion and and are the second derivatives of the optical constants with respect to wavelength. The analysis has been performed using the OTF Studio software [31] taking into account spectra of ellipsometric angles and , depolarization degree and transmittance measured with the V-VASE ellipsometer.

- Gaussian oscillators: The MIFs’ effective optical constants are modelled with a set of Gaussian oscillators, as described in [9]. The effective dielectric function assuming the contribution of N oscillators reads as:withwhere E is the photon energy. The first term on the right-hand side of Equation (2), , accounts for the polarization mechanisms that occur at photon energies above the measured spectral range. The second term is a sum of Gaussian oscillators that is used to model localized surface plasmon resonance and interband transitions. Each Gaussian oscillator is defined through its amplitude (), central energy () and broadening (). In this case, the discrepancy function to be minimized is:with p being the total number of parameters to be optimized, , and . The analysis is performed with the WVASE software including the spectra of ellipsometric angles and , depolarization degree, and transmittance measured with the V-VASE ellipsometer.

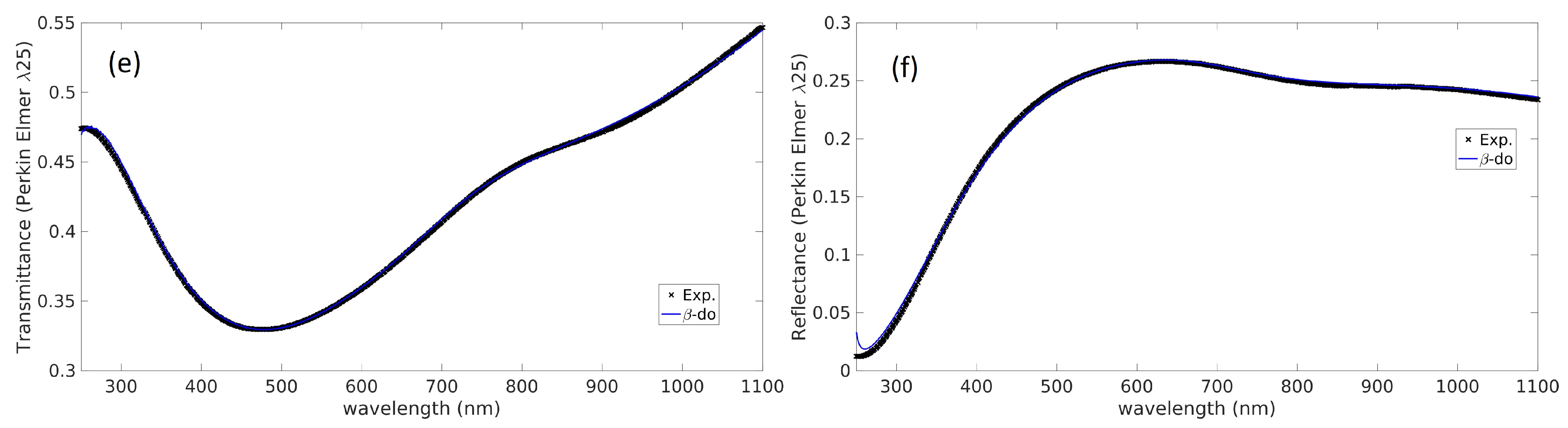

- -do model: The -do model [18,19] essentially consists of a multiple-oscillator model where each oscillator is replaced by a distribution in order to account for inhomogeneous line broadening. The dielectric function is then expressed as a sum over N oscillators:withandIn this case, the discrepancy function reads aswith being , , , , and . The values and correspond to the target thicknesses of the MIF and of the AlO layer. The analysis was done using a software developed by Steffen Wilbrandt for the analysis of spectrophotometric data. Reflectance and transmittance spectra measured with Lambda 25 and transmittance spectra measured with the V-VASE ellipsometer were used. It turns out that using only spectrophotometric data leads to a significant multiplicity of solutions and therefore it was often necessary to include weak bounds on the thickness values in the discrepancy function ( 0 in Equation (9)) to avoid non-physical solutions.

3. Results and Discussion

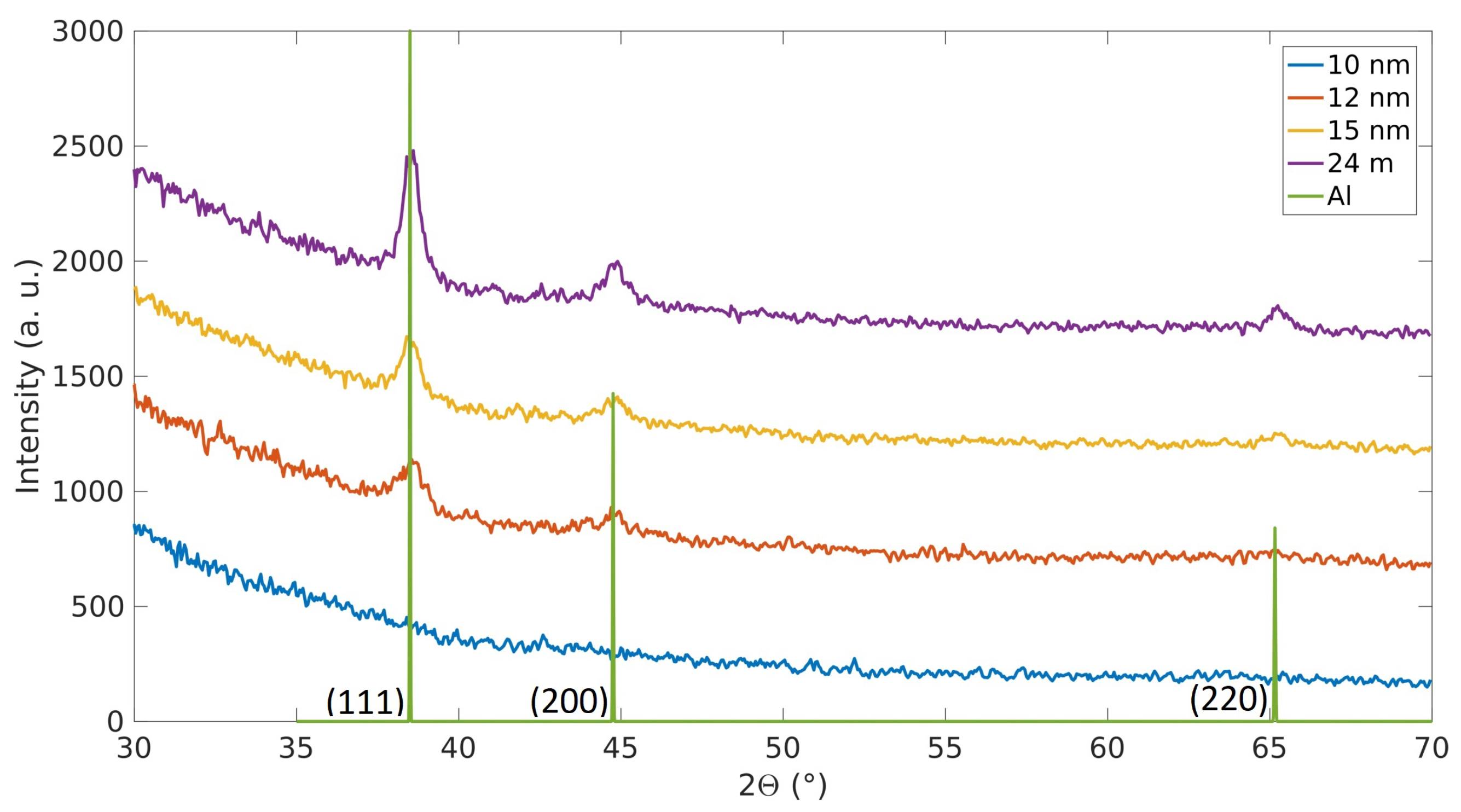

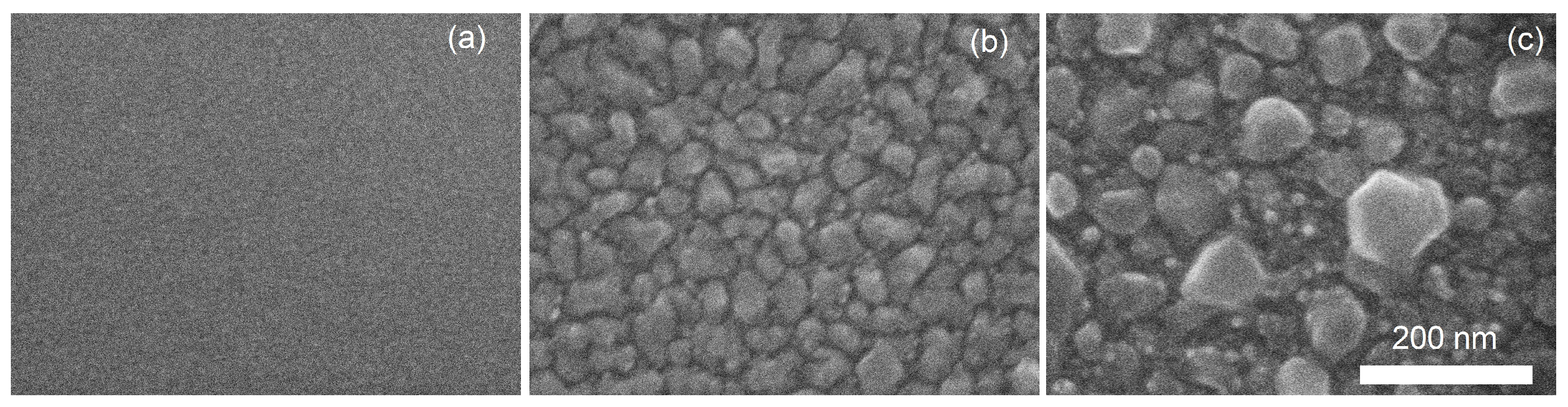

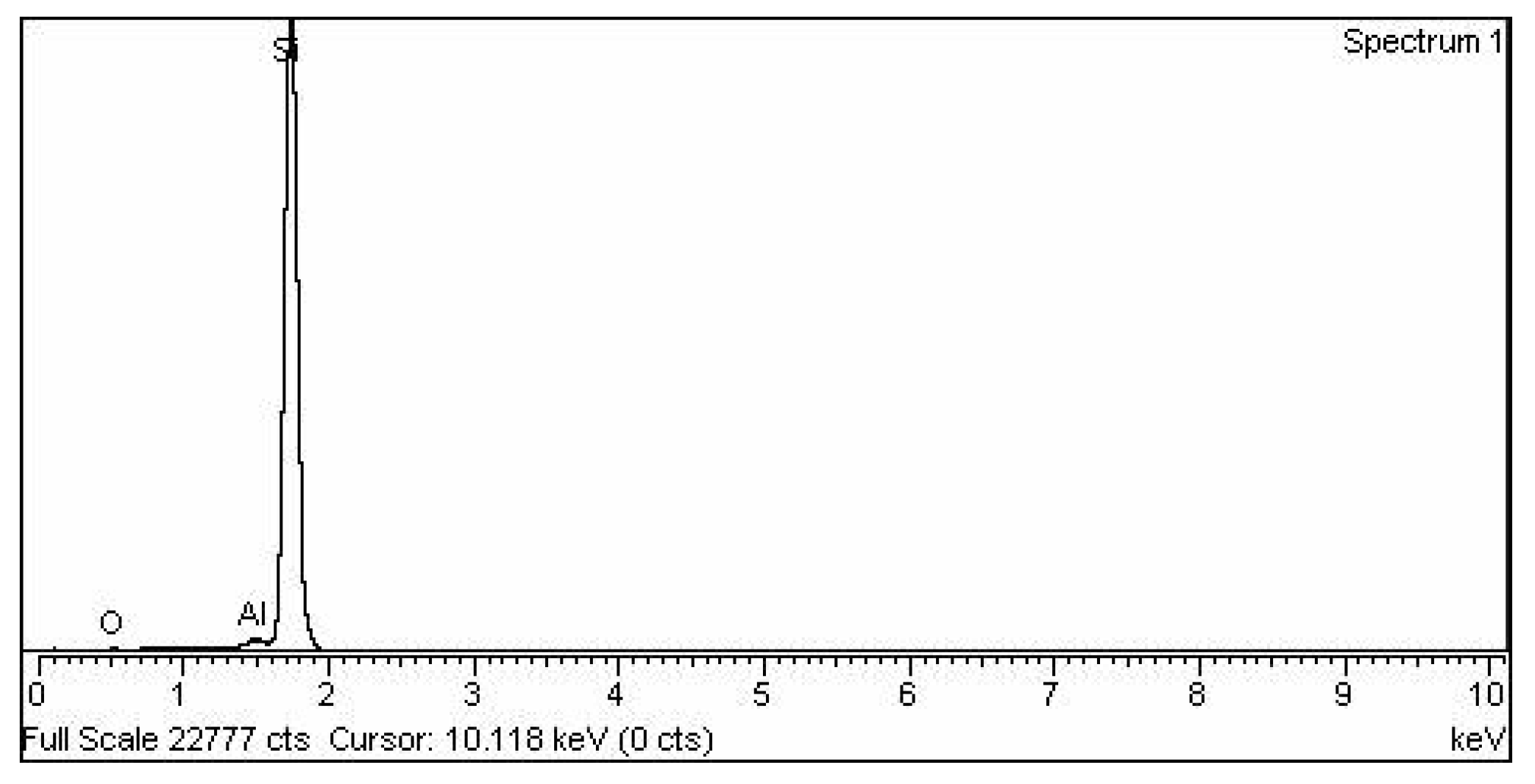

3.1. Structural Characterization

3.2. Optical Characterization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kaiser, N. Review of the fundamentals of thin-film growth. Appl. Opt. 2002, 41, 3053–3060. [Google Scholar] [CrossRef] [PubMed]

- Stenzel, O.; Macleod, A. Metal-dielectric composite optical coatings: Underlying physics, main models, characterization, design and application aspects. Adv. Opt. Technol. 2012, 1, 463–481. [Google Scholar] [CrossRef]

- Ghobadi, A.; Ghobadi, T.G.U.; Ozbay, E. Lithography-free metamaterial absorbers: Opinion. Opt. Mater. Express 2022, 12, 524–532. [Google Scholar] [CrossRef]

- Janicki, V.; Amotchkina, T.V.; Sancho-Parramon, J.; Zorc, H.; Trubetskov, M.K.; Tikhonravov, A.V. Design and production of bicolour reflecting coatings with Au metal island films. Opt. Express 2011, 19, 25521–25527. [Google Scholar] [CrossRef] [PubMed]

- Yu, R.; Mazumder, P.; Borrelli, N.F.; Carrilero, A.; Ghosh, D.S.; Maniyara, R.A.; Baker, D.; García de Abajo, F.J.; Pruneri, V. Structural coloring of glass using dewetted nanoparticles and ultrathin films of metals. ACS Photo. 2016, 3, 1194–1201. [Google Scholar] [CrossRef]

- Nath, J.; Smith, E.; Maukonen, D.; Peale, R.E. Optical Salisbury screen with design-tunable resonant absorption bands. J. Appl. Phys. 2014, 115, 193103. [Google Scholar] [CrossRef]

- Li, Z.; Butun, S.; Aydin, K. Large-area, lithography-free super absorbers and color filters at visible frequencies using ultrathin metallic films. ACS Photo. 2015, 2, 183–188. [Google Scholar] [CrossRef]

- Willey, R.R.; Stenzel, O. Designing Optical Coatings with Incorporated Thin Metal Films. Coatings 2023, 13, 369. [Google Scholar] [CrossRef]

- Sancho-Parramon, J.; Janicki, V.; Zorc, H. On the dielectric function tuning of random metal-dielectric nanocomposites for metamaterial applications. Opt. Express 2010, 18, 26915–26928. [Google Scholar] [CrossRef]

- Held, M.; Stenzel, O.; Wilbrandt, S.; Kaiser, N.; Tünnermann, A. Manufacture and characterization of optical coatings with incorporated copper island films. Appl. Opt. 2012, 51, 4436–4447. [Google Scholar] [CrossRef]

- Biegański, P.; Dobierzewska-Mozrzymas, E.; Kępiński, L. Application of effective medium theory with consideration of island shapes to interpret optical properties of discontinuous Pt films. Appl. Opt. 2012, 51, 6945–6951. [Google Scholar] [CrossRef] [PubMed]

- de Vries, A.J.; Kooij, E.S.; Wormeester, H.; Mewe, A.A.; Poelsema, B. Ellipsometric study of percolation in electroless deposited silver films. J. Appl. Phys. 2007, 101, 053703. [Google Scholar] [CrossRef]

- Hövel, M.; Gompf, B.; Dressel, M. Dielectric properties of ultrathin metal films around the percolation threshold. Phys. Rev. B 2010, 81, 035402. [Google Scholar] [CrossRef]

- Amotchkina, T.V.; Janicki, V.; Sancho-Parramon, J.; Tikhonravov, A.V.; Trubetskov, M.K.; Zorc, H. General approach to reliable characterization of thin metal films. Appl. Opt. 2011, 50, 1453–1464. [Google Scholar] [CrossRef]

- Sancho-Parramon, J.; Janicki, V.; Zorc, H. Tuning the effective dielectric function of thin film metal-dielectric composites by controlling the deposition temperature. J. Nanophoto. 2011, 5, 051805. [Google Scholar] [CrossRef]

- Lončarić, M.; Sancho-Parramon, J.; Zorc, H. Optical properties of gold island films—A spectroscopic ellipsometry study. Thin Solid Film. 2011, 519, 2946–2950. [Google Scholar] [CrossRef]

- Brendel, R.; Bormann, D. An infrared dielectric function model for amorphous solids. J. Appl. Phys. 1992, 71, 1–6. [Google Scholar] [CrossRef]

- Wilbrandt, S.; Stenzel, O. Empirical extension to the multioscillator model: The beta-distributed oscillator model. Appl. Opt. 2017, 56, 9892–9899. [Google Scholar] [CrossRef]

- Stenzel, O.; Wilbrandt, S. Beta-distributed oscillator model as an empirical extension to the Lorentzian oscillator model: Physical interpretation of the β_do model parameters. Appl. Opt. 2019, 58, 9318–9325. [Google Scholar] [CrossRef]

- Wilbrandt, S.; Stenzel, O.; Liaf, A.; Munzert, P.; Schwinde, S.; Stempfhuber, S.; Felde, N.; Trost, M.; Seifert, T.; Schröder, S. Spectrophotometric Characterization of Thin Semi-Transparent Aluminum Films Prepared by Electron Beam Evaporation and Magnetron Sputtering. Coatings 2022, 12, 1278. [Google Scholar] [CrossRef]

- Stenzel, O.; Wilbrandt, S.; He, J.Y.; Stempfhuber, S.; Schröder, S.; Tünnermann, A. A Model Surface for Calculating the Reflectance of Smooth and Rough Aluminum Layers in the Vacuum Ultraviolet Spectral Range. Coatings 2023, 13, 122. [Google Scholar] [CrossRef]

- Stenzel, O.; Petrich, R. Flexible construction of error functions and their minimization: Application to the calculation of optical constants of absorbing or scattering thin-film materials from spectrophotometric data. J. Phys. Appl. Phys. 1995, 28, 978. [Google Scholar] [CrossRef]

- Djurišić, A.B.; Chan, Y.; Li, E.H. Progress in the room-temperature optical functions of semiconductors. Mater. Sci. Eng. Rep. 2002, 38, 237–293. [Google Scholar] [CrossRef]

- Amotchkina, T.V.; Trubetskov, M.K.; Tikhonravov, A.V.; Janicki, V.; Sancho-Parramon, J.; Zorc, H. Comparison of two techniques for reliable characterization of thin metal–dielectric films. Appl. Opt. 2011, 50, 6189–6197. [Google Scholar] [CrossRef] [PubMed]

- Franklin, D.; He, Z.; Mastranzo Ortega, P.; Safaei, A.; Cencillo-Abad, P.; Wu, S.T.; Chanda, D. Self-assembled plasmonics for angle-independent structural color displays with actively addressed black states. Proc. Natl. Acad. Sci. USA 2020, 117, 13350–13358. [Google Scholar] [CrossRef]

- McPeak, K.M.; Jayanti, S.V.; Kress, S.J.; Meyer, S.; Iotti, S.; Rossinelli, A.; Norris, D.J. Plasmonic films can easily be better: Rules and recipes. ACS Photo. 2015, 2, 326–333. [Google Scholar] [CrossRef]

- Nguyen, H.V.; An, I.; Collins, R. Evolution of the optical functions of thin-film aluminum: A real-time spectroscopic ellipsometry study. Phys. Rev. B 1993, 47, 3947. [Google Scholar] [CrossRef]

- Nguyen, H.V.; An, I.; Collins, R. Evolution of the optical functions of aluminum films during nucleation and growth determined by real-time spectroscopic ellipsometry. Phys. Rev. Lett. 1992, 68, 994. [Google Scholar] [CrossRef]

- Dobrowolski, J.; Ho, F.; Waldorf, A. Determination of optical constants of thin film coating materials based on inverse synthesis. Appl. Opt. 1983, 22, 3191–3200. [Google Scholar] [CrossRef]

- Palik, E.D. Handbook of Optical Constants of Solids; Academic Press: Cambridge, MA, USA, 1998; Volume 3. [Google Scholar]

- Trubetskov, M. OTF Studio Software. Available online: https://www.otfstudio.com (accessed on 4 May 2023).

- Arwin, H.; Aspnes, D.E. Unambiguous determination of thickness and dielectric function of thin films by spectroscopic ellipsometry. Thin Solid Film. 1984, 113, 101–113. [Google Scholar] [CrossRef]

- Hilfiker, J.N.; Singh, N.; Tiwald, T.; Convey, D.; Smith, S.M.; Baker, J.H.; Tompkins, H.G. Survey of methods to characterize thin absorbing films with spectroscopic ellipsometry. Thin Solid Film. 2008, 516, 7979–7989. [Google Scholar] [CrossRef]

| (nm) | 3 | 10 | 12 | 15 | 24 | 32 | |

|---|---|---|---|---|---|---|---|

| Non-parametric model | (nm) | 0 | 4.5 | 8.7 | 9.1 | 19.8 | 25.8 |

| (nm) | 20.0 | 20.2 | 28.2 | 25.8 | 26.1 | 21.4 | |

| Gaussian oscillators | (nm) | 0 | 4.6 | 10.8 | 11.4 | 26.4 | 34.5 |

| (nm) | 19.9 | 15.9 | 25.7 | 23.3 | 16.8 | 10.1 | |

| -do | (nm) | 3.0 | 9.8 23.3 | 13.9 | 16.8 | 25.9 | 27.2 |

| (nm) | 15.0 | 14.6 8.0 | 23.4 | 19.0 | 19.2 | 19.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sancho-Parramon, J.; Amochkina, T.; Wilbrandt, S.; Kamble, H.; Janicki, V.; Salamon, K.; Stenzel, O.; Trubetskov, M. Optical Characterization of Al Island Films: A Round Robin Test. Coatings 2023, 13, 1073. https://doi.org/10.3390/coatings13061073

Sancho-Parramon J, Amochkina T, Wilbrandt S, Kamble H, Janicki V, Salamon K, Stenzel O, Trubetskov M. Optical Characterization of Al Island Films: A Round Robin Test. Coatings. 2023; 13(6):1073. https://doi.org/10.3390/coatings13061073

Chicago/Turabian StyleSancho-Parramon, Jordi, Tatiana Amochkina, Steffen Wilbrandt, Hrishikesh Kamble, Vesna Janicki, Krešimir Salamon, Olaf Stenzel, and Michael Trubetskov. 2023. "Optical Characterization of Al Island Films: A Round Robin Test" Coatings 13, no. 6: 1073. https://doi.org/10.3390/coatings13061073

APA StyleSancho-Parramon, J., Amochkina, T., Wilbrandt, S., Kamble, H., Janicki, V., Salamon, K., Stenzel, O., & Trubetskov, M. (2023). Optical Characterization of Al Island Films: A Round Robin Test. Coatings, 13(6), 1073. https://doi.org/10.3390/coatings13061073