Surface Smoothing by Gas Cluster Ion Beam Using Decreasing Three-Step Energy Treatment

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yamada, I. Historical milestones and future prospects of cluster ion beam technology. Appl. Surf. Sci. 2014, 310, 77–88. [Google Scholar] [CrossRef]

- Popok, V.N. Energetic cluster ion beams: Modification of surfaces and shallow layers. Mater. Sci. Eng. R 2011, 72, 137–157. [Google Scholar] [CrossRef]

- Ieshkin, A.E.; Tolstoguzov, A.B.; Korobeishchikov, N.G.; Pelenovich, V.O.; Chernysh, V.S. Gas-dynamic sources of cluster ions for basic and applied research. Physics-Uspekhi 2022, 65, 677–705. [Google Scholar] [CrossRef]

- Henkes, P.R.W.; Klingelhöfer, R. Micromachining with cluster ions. Vacuum 1989, 39, 541–542. [Google Scholar] [CrossRef]

- MacCrimmon, R.; Hautala, J.; Gwinn, M.; Sherman, S. Gas cluster ion beam infusion processing of semiconductors. Nucl. Instrum. Methods B 2006, 242, 427–430. [Google Scholar] [CrossRef]

- Toyoda, N.; Yamada, I. MgF2 and LaF3 thin film formation with gas cluster ion beam assisted deposition. Surf. Coat. Technol. 2007, 201, 8620–8623. [Google Scholar] [CrossRef]

- Teo, E.J.; Toyoda, N.; Yang, C.; Bettiol, A.A.; Teng, J.H. Nanoscale smoothing of plasmonic films and structures using gas cluster ion beam irradiation. Appl. Phys. A 2014, 117, 719–723. [Google Scholar] [CrossRef]

- Ieshkin, A.E.; Svyakhovskiy, S.E.; Chernysh, V.S. Fabrication of optically smooth surface on the cleavage of porous silicon by gas cluster ion irradiation. Vacuum 2018, 148, 272–275. [Google Scholar] [CrossRef]

- Korobeishchikov, N.G.; Nikolaev, I.V.; Roenko, M.A. Effect of argon cluster ion beam on fused silica surface morphology. Nucl. Instrum. Methods B 2019, 438, 1–5. [Google Scholar] [CrossRef]

- Song, J.H.; Choi, D.K.; Choi, W.K. Dependence of surface smoothing, sputtering and etching phenomena on cluster ion dosages. Nucl. Instrum. Methods B 2002, 196, 268–274. [Google Scholar] [CrossRef]

- Ieshkin, A.; Kireev, D.; Ozerova, K.; Senatulin, B. Surface ripples induced by gas cluster ion beam on copper surface at elevated temperatures. Mater. Lett. 2020, 272, 127829. [Google Scholar] [CrossRef]

- Smirnov, B.M. Fractal clusters. Sov. Phys. Usp. 1986, 29, 481–505. [Google Scholar] [CrossRef]

- Toyoda, N.; Yamada, I. Evaluation of charge state of gas cluster ions by means of individual crater observations. Nucl. Instrum. Methods B 2013, 307, 269–272. [Google Scholar] [CrossRef]

- Yamada, I.; Matsuo, J.; Toyoda, N.; Kirkpatrick, A. Materials processing by gas cluster ion beams. Mater. Sci. Eng. R 2001, 34, 231–295. [Google Scholar] [CrossRef]

- Insepov, Z.; Yamada, I. Molecular dynamics study of shock wave generation by cluster impact on solid targets. Nucl. Instrum. Methods B 1996, 112, 16–22. [Google Scholar] [CrossRef]

- Toyoda, N.; Kitani, H.; Hagiwara, N.; Aoki, T.; Matsuo, J.; Yamada, I. Angular distributions of the particles sputtered with Ar cluster ions. Mater. Chem. Phys. 1998, 54, 262–265. [Google Scholar] [CrossRef]

- Matsuo, J.; Toyoda, N.; Yamada, I. Nanofabrication technology by gas cluster ion beams. J. Vac. Sci. Technol. B 1996, 14, 3951–3954. [Google Scholar] [CrossRef]

- Popok, V.N.; Prasalovich, S.V.; Campbell, E.E.B. Surface nanostructuring by implantation of cluster ions. Vacuum 2004, 76, 265–272. [Google Scholar] [CrossRef]

- Allen, L.P.; Fenner, D.B.; DiFilippo, V.; Santeufemio, C.; Degenkolb, E.; Brooks, W.; Mack, M.; Hautala, J. Substrate smoothing using gas cluster ion beam processing. J. Electron. Mater. 2001, 30, 829–833. [Google Scholar] [CrossRef]

- Isogai, H.; Toyoda, E.; Senda, T.; Izunome, K.; Kashima, K.; Toyoda, N.; Yamada, I. Dependence of recovery of Si surface damaged by GCIB irradiation on annealing temperature. Nucl. Instrum. Methods B 2008, 266, 2533–2536. [Google Scholar] [CrossRef]

- Ieshkin, A.; Kireev, D.; Chernysh, V.; Molchanov, A.; Serebryakov, A.; Chirkin, M. Decomposition of AFM images of ultrasmooth optical surface polished with gas cluster ion beam. Surf. Topogr. Metrol. Prop. 2019, 7, 025016. [Google Scholar] [CrossRef]

- Toyoda, N.; Hagiwara, N.; Matsuo, J.; Yamada, I. Surface smoothing mechanism of gas cluster ion beams. Nucl. Instrum. Methods B 2000, 161–163, 980–985. [Google Scholar] [CrossRef]

- Aoki, T.; Seki, T.; Matsuo, J. Molecular dynamics simulations for gas cluster ion beam processes. Vacuum 2010, 84, 994–998. [Google Scholar] [CrossRef]

- Matsuo, J.; Ninomiya, S.; Nakata, Y.; Ichiki, K.; Aoki, T.; Seki, T. Size effect in cluster collision on solid surfaces. Nucl. Instrum. Methods B 2007, 257, 627–631. [Google Scholar] [CrossRef]

- Averback, R.; Ghaly, M. MD studies of the interactions of low energy particles and clusters with surfaces. Nucl. Instrum. Methods Phys. Res. B 1994, 90, 191–201. [Google Scholar] [CrossRef]

- Houzumi, S.; Mochiji, K.; Toyoda, N.; Yamada, I. Scanning Tunneling Microscopy Observation of Graphite Surfaces Irradiated with Size-Selected Ar Cluster Ion Beams. Jpn. J. Appl. Phys. 2005, 44, 6252–6254. [Google Scholar] [CrossRef]

- Gspann, J. Microstructuring by nanoparticle impact lithography. Sensor Actuator. A 1995, 51, 37–39. [Google Scholar] [CrossRef]

- Insepov, Z.; Manory, R.; Matsuo, J.; Yamada, I. Proposal for a hardness measurement technique without indentor by gas-cluster-beam bombardment. Phys. Rev. B 2000, 61, 8744–8752. [Google Scholar] [CrossRef]

- Seah, M.P. Universal Equation for Argon Gas Cluster Sputtering Yields. Phys. Chem. C 2013, 117, 12622–12632. [Google Scholar] [CrossRef]

- Greer, J.A.; Fenner, D.B.; Hautala, J.; Allen, L.P.; DiFilippo, V.; Toyoda, N.; Yamada, I.; Matsuo, J.; Minami, E.; Katsumata, H. Etching, smoothing, and deposition with gas-cluster ion beam Technology. Surf. Coat. Technol. 2000, 133–134, 273–282. [Google Scholar] [CrossRef]

- Seki, T.; Matsuo, J. Development of 1 mA cluster ion beam source. Nucl. Instrum. Methods B 2005, 237, 455–458. [Google Scholar] [CrossRef]

- Pelenovich, V.O.; Zeng, X.M.; Ieshkin, A.E.; Chernysh, V.S.; Tolstogouzov, A.B.; Yang, B.; Fu, D.J. Development of a Gas Cluster Ion Source and Its Application for Surface Treatment. J. Synch. Investig. 2019, 13, 344–350. [Google Scholar] [CrossRef]

- Mashita, T.; Toyoda, N.; Yamada, I. Surface Smoothing of Polycrystalline Substrates with Gas Cluster Ion Beams. Jpn. J. Appl. Phys. 2010, 49, 06GH09. [Google Scholar] [CrossRef]

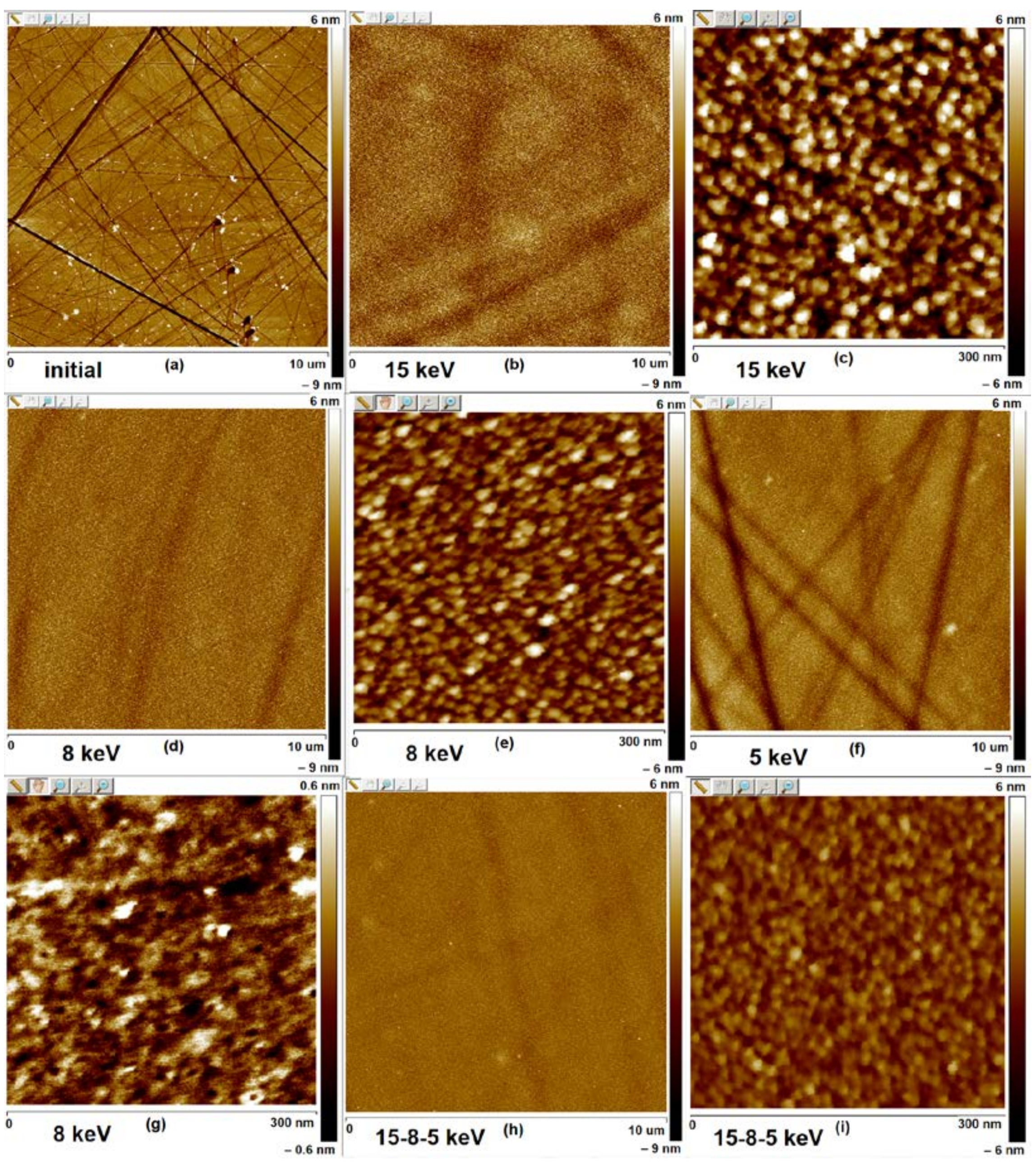

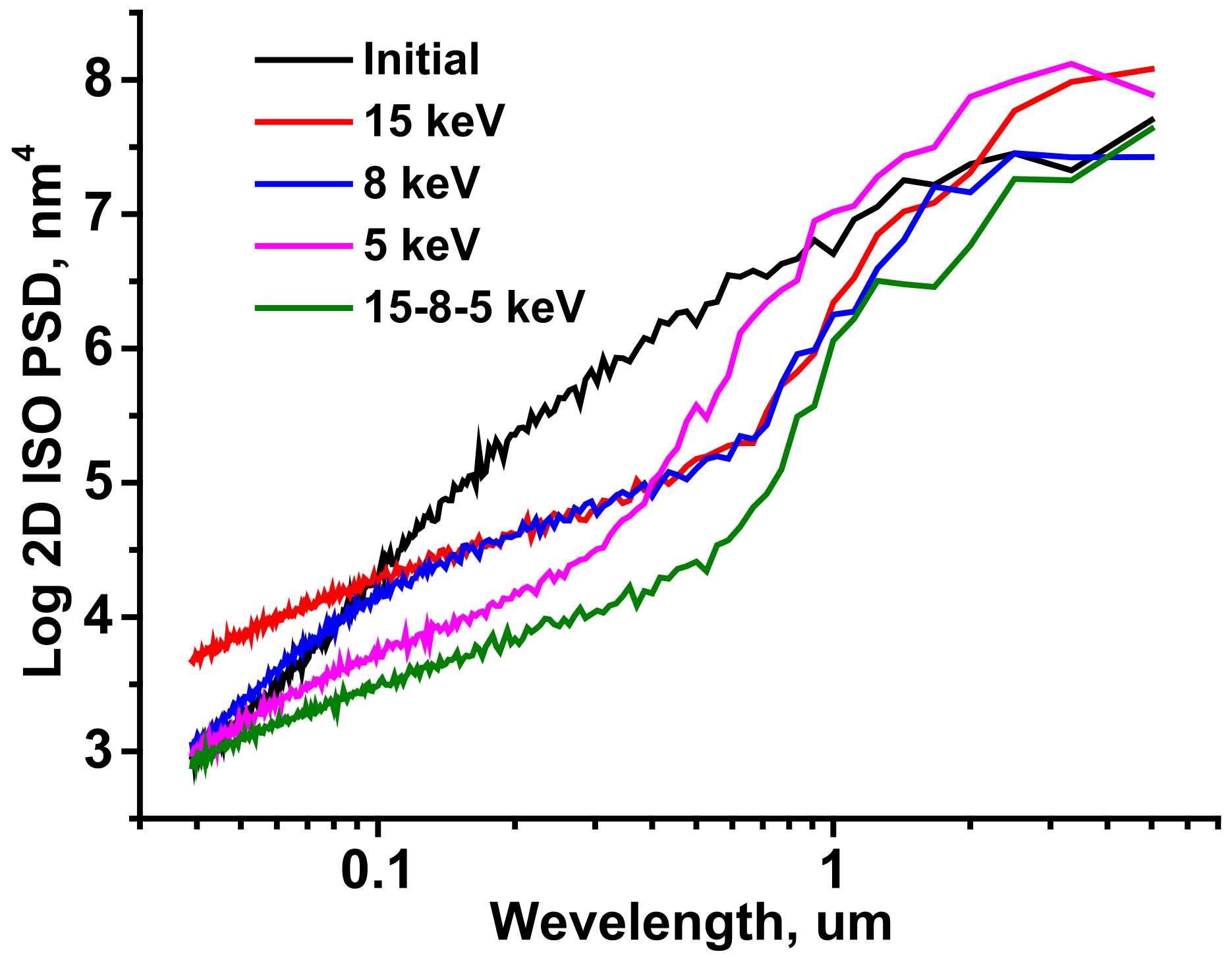

| Cluster Energy E, keV | Ion Fluence D, ×1016 cm−2 | Treatment Time, min | Roughness Rq (10 × 10 μm2), nm | Roughness Rq (0.3 × 0.3 μm2), nm |

|---|---|---|---|---|

| Initial surface | - | - | 1.69 | 0.51 |

| 15 | 6 | 15 | 1.64 | 2.39 |

| 8 | 6 | 12 | 1.06 | 1.55 |

| 5 | 6 | 20 | 1.15 | 1.19 |

| 15-8-5 | 2-2-2 | 5-4-7 | 0.65 | 0.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pelenovich, V.; Zeng, X.; Zhang, X.; Fu, D.; Lei, Y.; Yang, B.; Tolstoguzov, A. Surface Smoothing by Gas Cluster Ion Beam Using Decreasing Three-Step Energy Treatment. Coatings 2023, 13, 942. https://doi.org/10.3390/coatings13050942

Pelenovich V, Zeng X, Zhang X, Fu D, Lei Y, Yang B, Tolstoguzov A. Surface Smoothing by Gas Cluster Ion Beam Using Decreasing Three-Step Energy Treatment. Coatings. 2023; 13(5):942. https://doi.org/10.3390/coatings13050942

Chicago/Turabian StylePelenovich, Vasiliy, Xiaomei Zeng, Xiangyu Zhang, Dejun Fu, Yan Lei, Bing Yang, and Alexander Tolstoguzov. 2023. "Surface Smoothing by Gas Cluster Ion Beam Using Decreasing Three-Step Energy Treatment" Coatings 13, no. 5: 942. https://doi.org/10.3390/coatings13050942

APA StylePelenovich, V., Zeng, X., Zhang, X., Fu, D., Lei, Y., Yang, B., & Tolstoguzov, A. (2023). Surface Smoothing by Gas Cluster Ion Beam Using Decreasing Three-Step Energy Treatment. Coatings, 13(5), 942. https://doi.org/10.3390/coatings13050942