Experimental and Numerical Investigations on the Impact of Surface Conditions on Self-Piercing Riveted Joint Quality

Abstract

1. Introduction

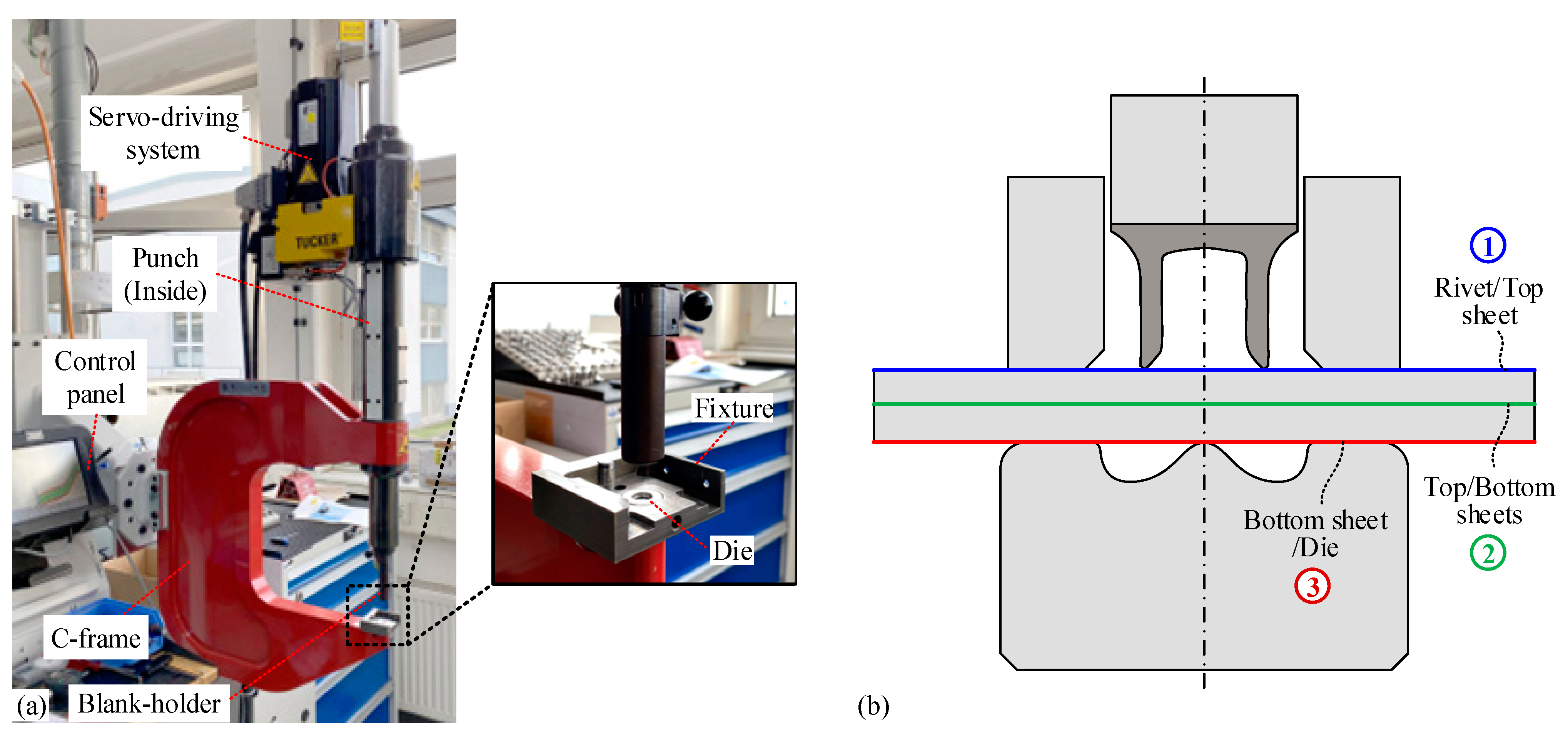

2. Experimental Setup

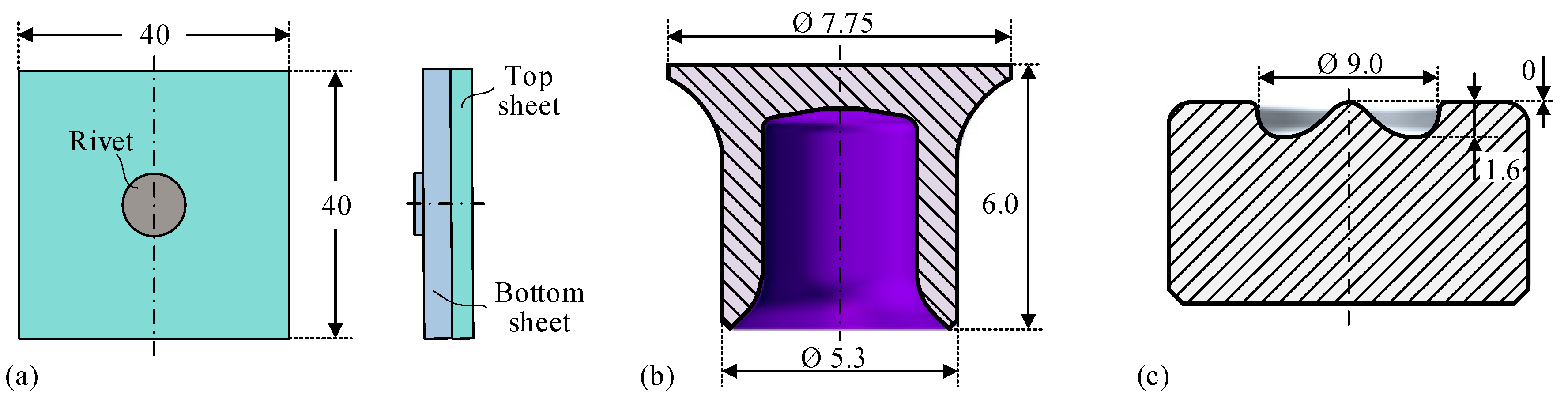

2.1. Rivet and Sheet Materials

2.2. Experiment Design

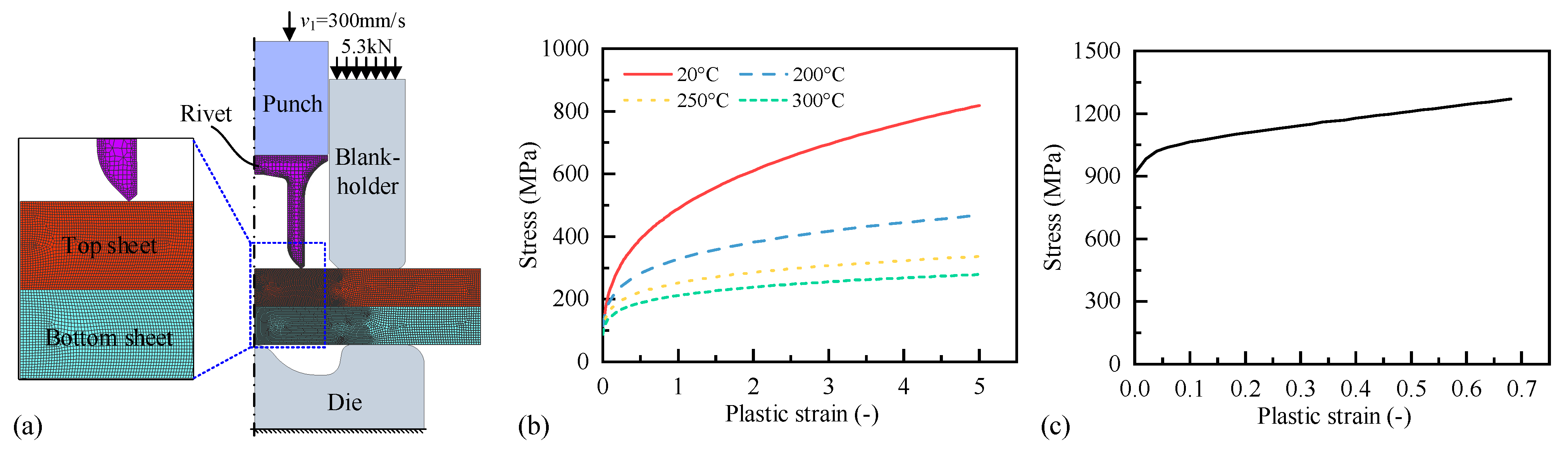

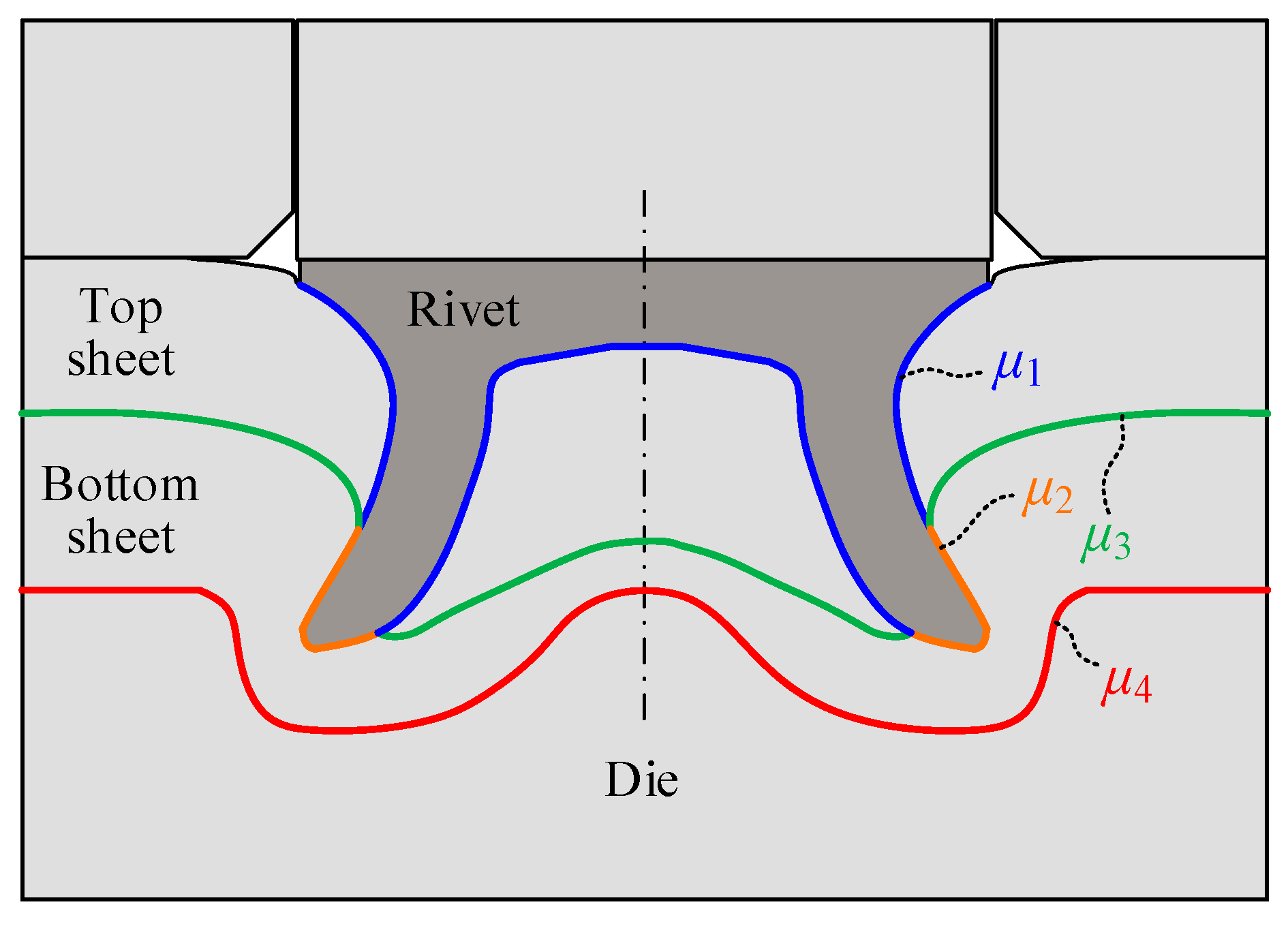

3. Finite Element (FE) Model

3.1. Model Description

3.2. Simulation Design

4. Results and Discussion

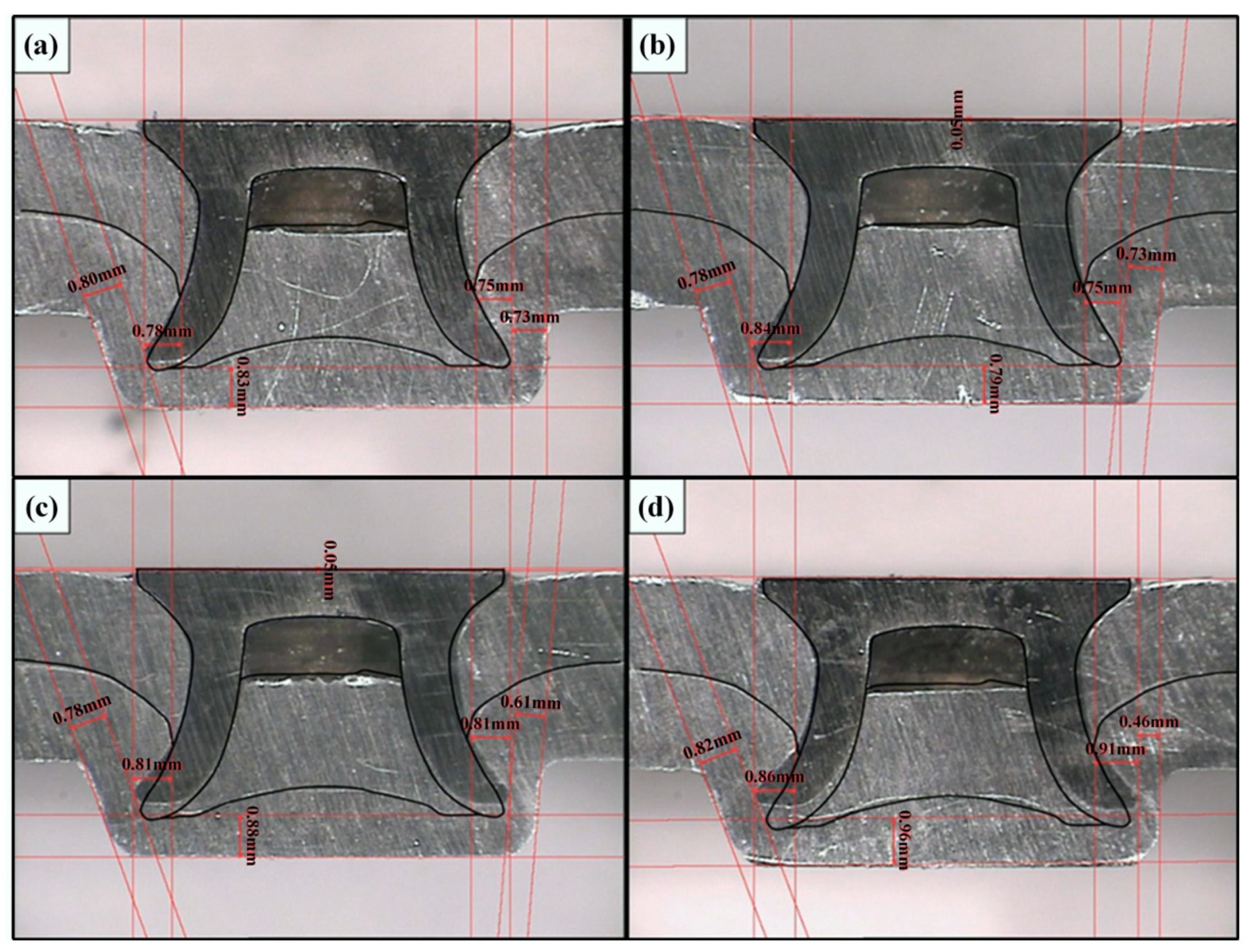

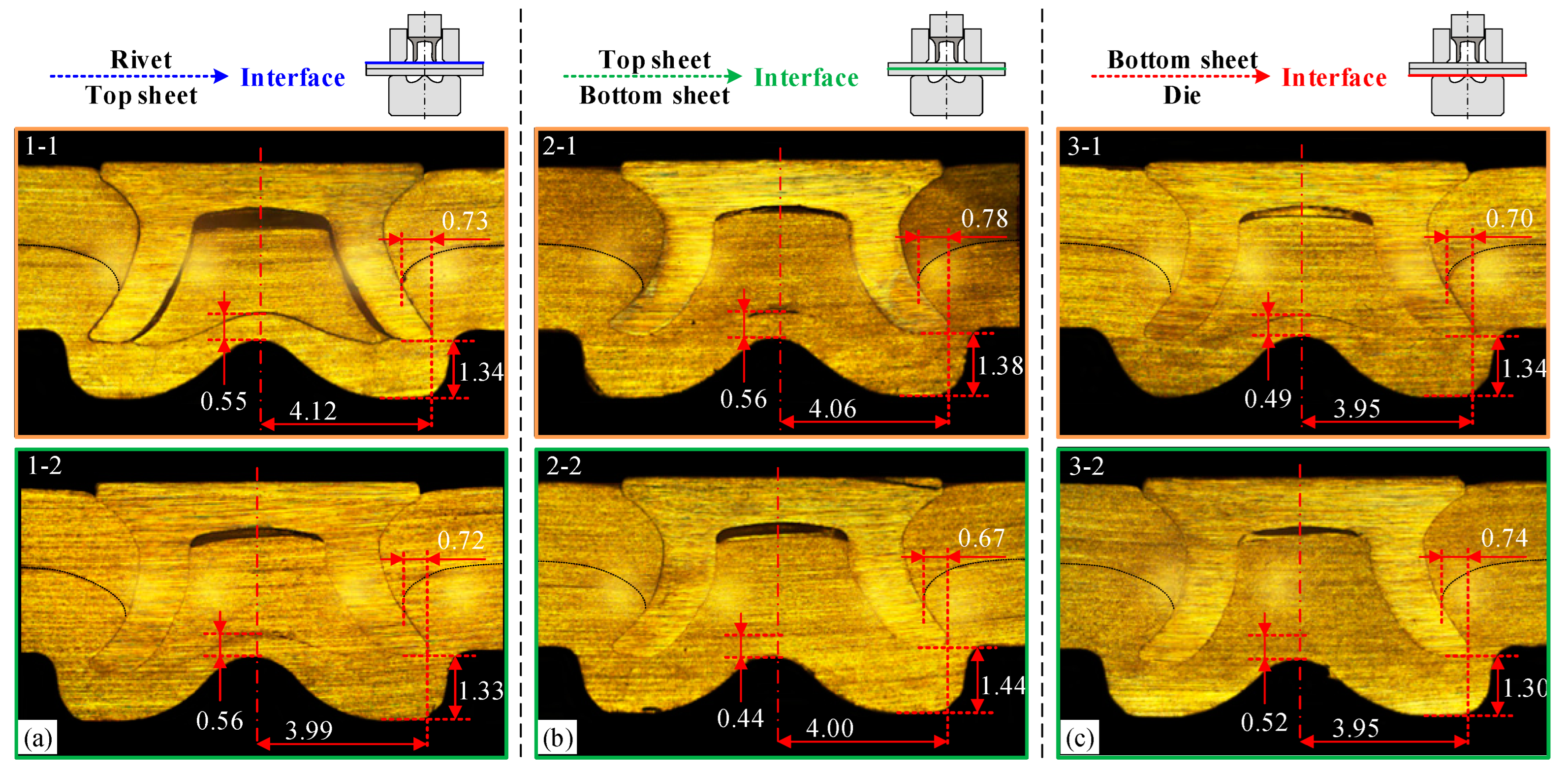

4.1. Experimental Results

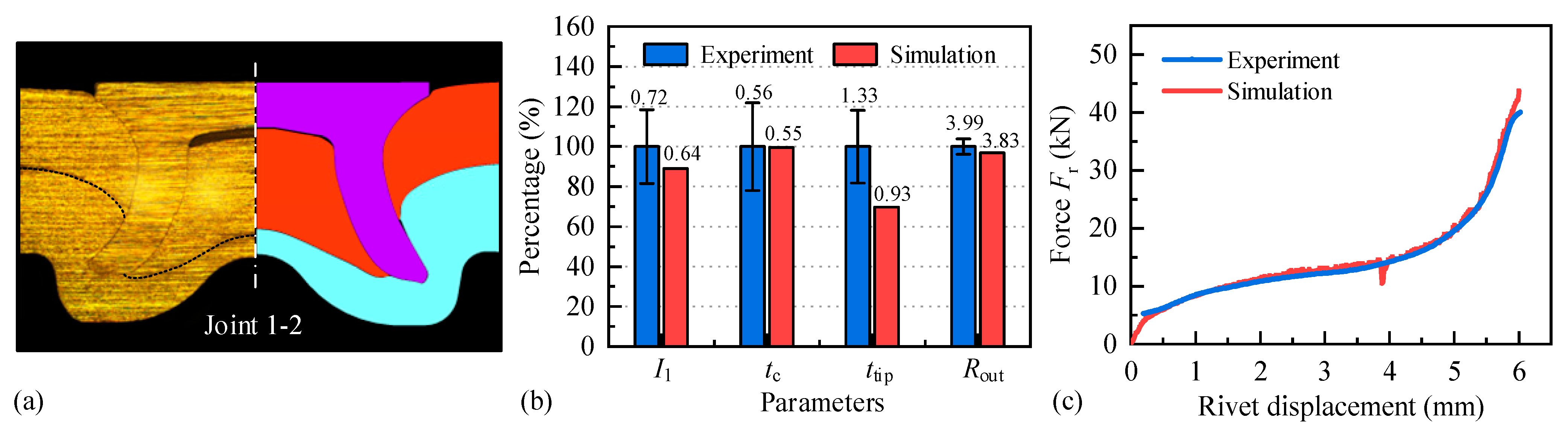

4.2. FE Model Validation

4.3. Impact of Friction Coefficients at Different Contact Interfaces

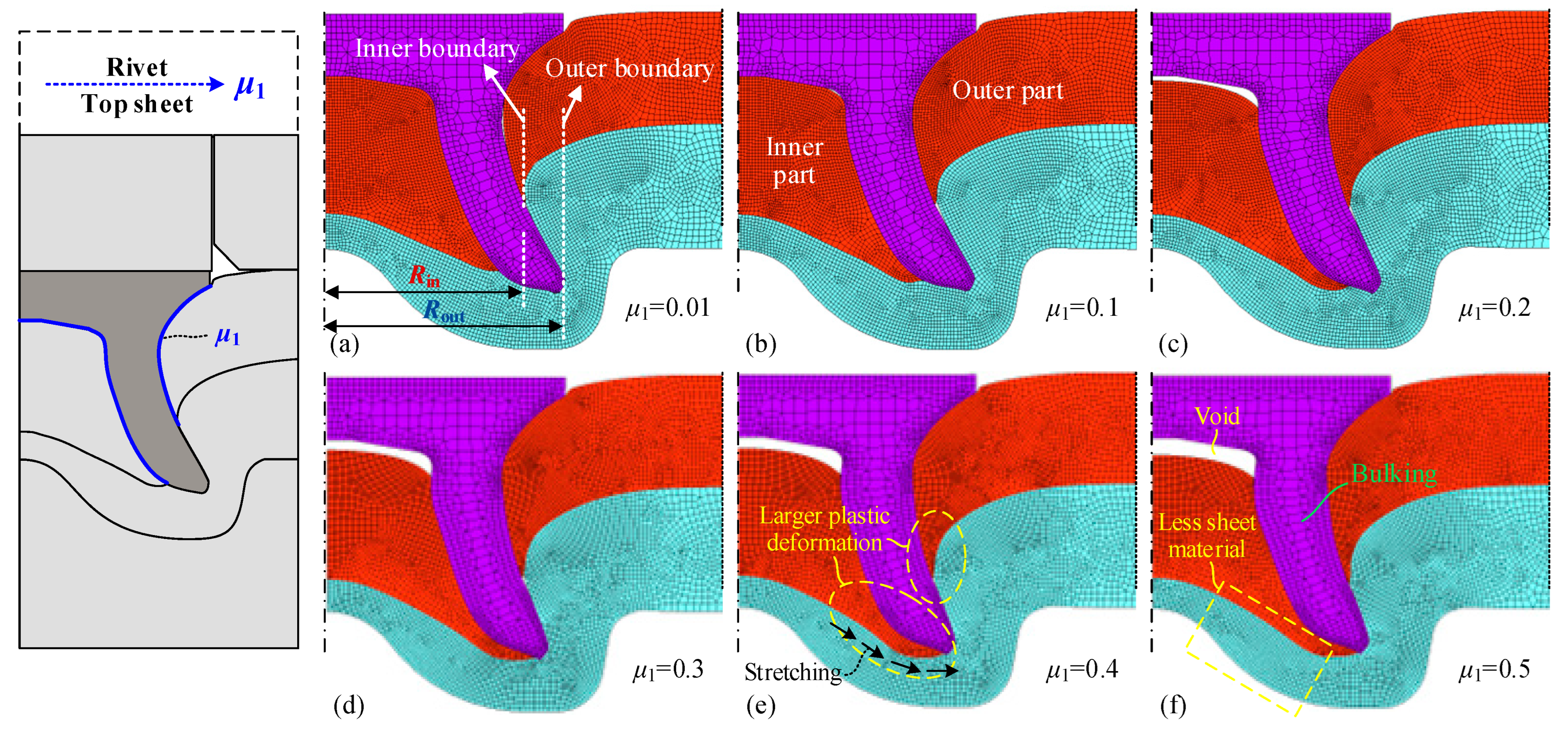

4.3.1. Between Rivet and Top Sheet (μ1)

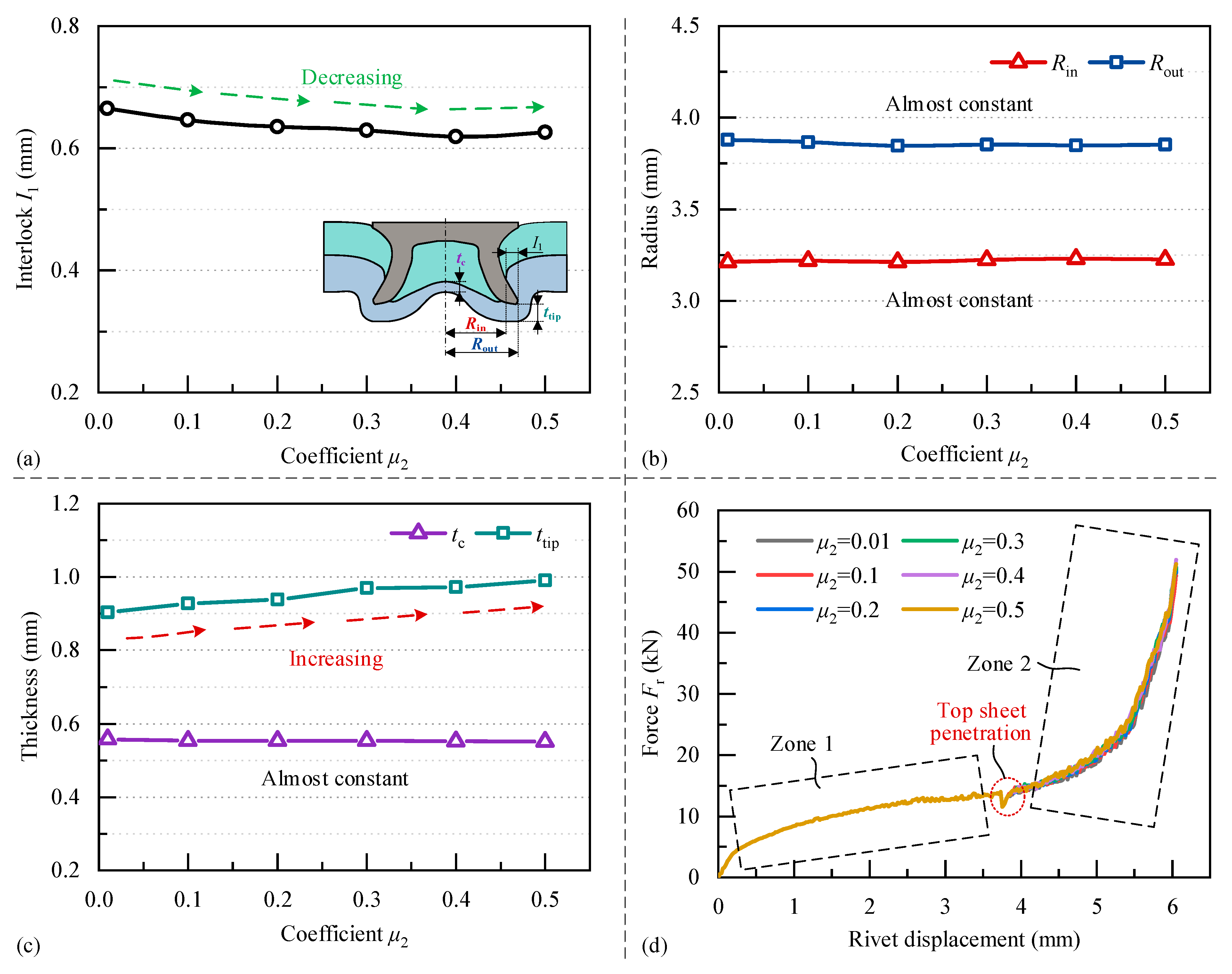

4.3.2. Between Rivet and Bottom Sheet (μ2)

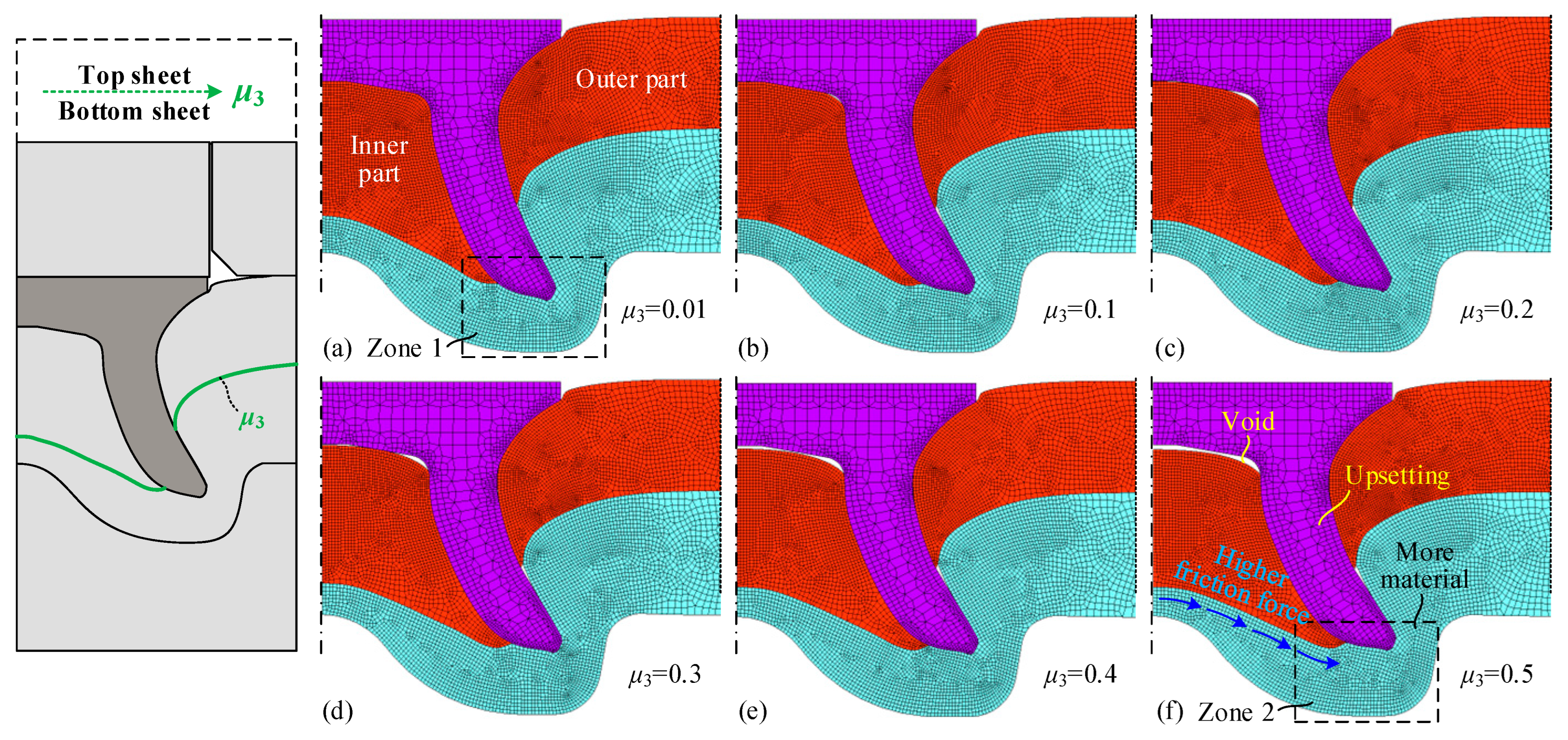

4.3.3. Between Top and Bottom Sheets (μ3)

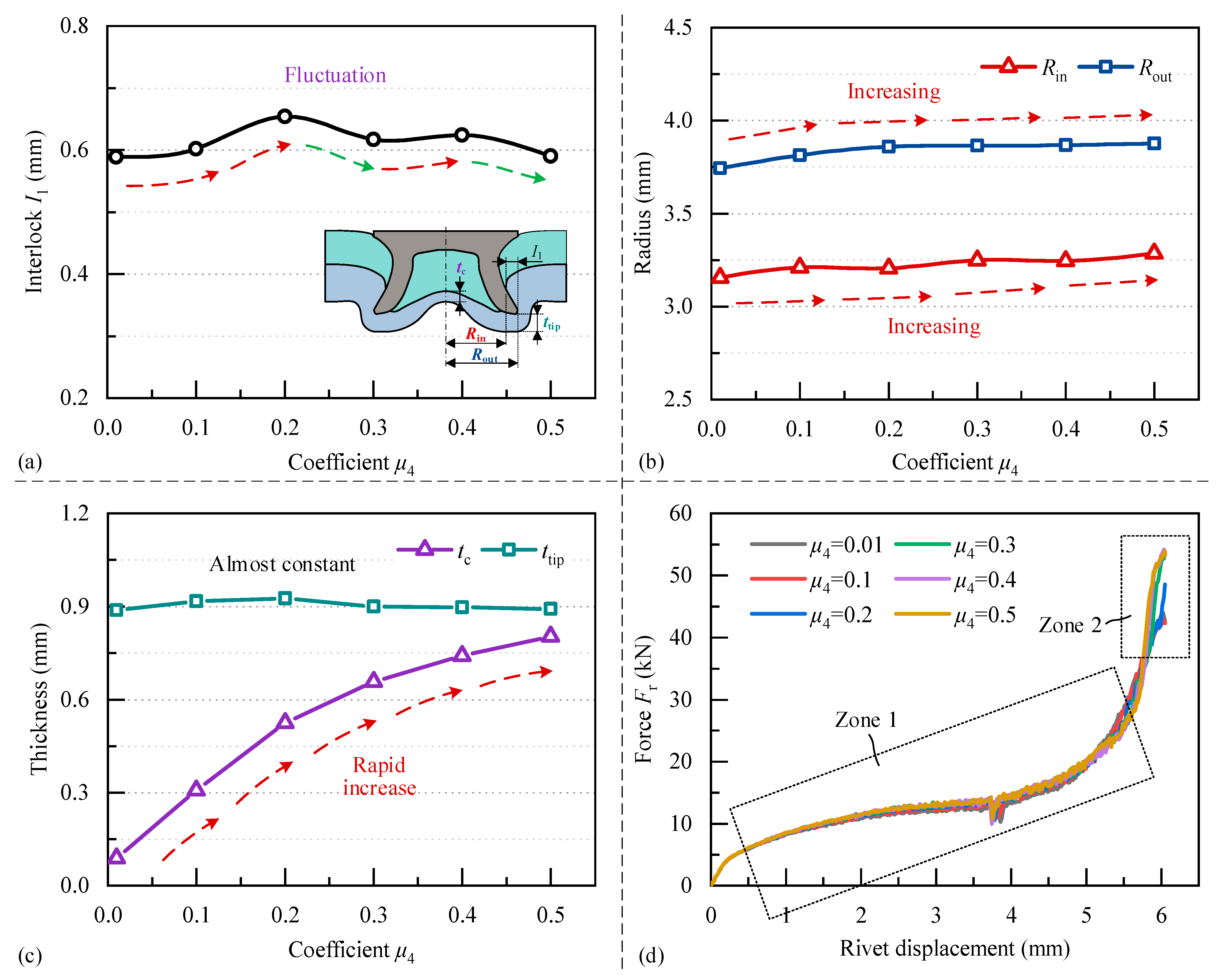

4.3.4. Between Bottom Sheet and Die (μ4)

5. Conclusions

- (1)

- Reducing the friction coefficient between the rivet and top sheet (μ1) by applying coatings or lubricating oil on the rivet can effectively increase the magnitudes of interlock (I1) and remaining bottom sheet thickness at the joint centre (tc). The joining force can also be reduced with a greater μ1, providing the benefits of less energy consumption and longer service life of the die.

- (2)

- The joint quality was less affected by the friction coefficient between the rivet and bottom sheet (μ2). In practice, reducing the magnitude of μ2 by rivet coating or other strategies can slightly increase the I1 without imposing apparent influences on the tc and riveting force.

- (3)

- Increasing the friction coefficient between top and bottom sheets (μ3) can lead to a greater rivet shank flaring distance. The μ3 imposes opposite influences on the ttip and tc and therefore can be adjusted by modifying the contact surface condition to balance the magnitudes of the ttip and tc for better joint quality.

- (4)

- The friction coefficient between the bottom sheet and die (μ4) imposes a critical impact on the magnitude of the tc by affecting the bottom sheet deformation behaviour. Reducing the μ4 by applying lubricating oil at the bottom sheet/die interface or increasing the μ4 with a rougher die surface can reduce or increase the tc to optimise the joint quality.

- (5)

- Among the four friction coefficients at contact interfaces, the μ1 and μ4 impose greater influences on the magnitudes of joint quality indicators. The identified changing trends of I1, Rout, ttip and tc with varying friction coefficients are beneficial for a quick selection of friction coefficients with the inverse method in FE model development process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; De Smet, P.; Haszler, A.; Vieregge, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Mortimer, J. Jaguar Uses X350 Car to Pioneer Use of Self-Piercing Rivets. Ind. Robot An Int. J. 2001, 28, 192–198. [Google Scholar] [CrossRef]

- Hewitt, R. Self-Piercing Riveting (SPR) in Automated Vehicle Construction. In Self-Piercing Riveting: Properties, Processes and Applications; Woodhead Publishing: Sawston, Cambridge, UK, 2014; pp. 181–207. ISBN 9781845695354. [Google Scholar]

- Abe, Y.; Kato, T.; Mori, K. Self-Piercing Riveting of High Tensile Strength Steel and Aluminium Alloy Sheets Using Conventional Rivet and Die. J. Mater. Process. Technol. 2009, 209, 3914–3922. [Google Scholar] [CrossRef]

- Li, D.; Chrysanthou, A.; Patel, I.; Williams, G. Self-Piercing Riveting-vA Review. Int. J. Adv. Manuf. Technol. 2017, 92, 1777–1824. [Google Scholar] [CrossRef]

- Liu, Y.; Li, H.; Zhao, H.; Liu, X. Effects of the Die Parameters on the Self-Piercing Riveting Process. Int. J. Adv. Manuf. Technol. 2019, 105, 3353–3368. [Google Scholar] [CrossRef]

- Haque, R.; Beynon, J.H.; Durandet, Y. Characterisation of Force-Displacement Curve in Self-Pierce Riveting. Sci. Technol. Weld. Join. 2012, 17, 476–488. [Google Scholar] [CrossRef]

- Wakuda, M.; Yamauchi, Y.; Kanzaki, S.; Yasuda, Y. Effect of Surface Texturing on Friction Reduction between Ceramic and Steel Materials under Lubricated Sliding Contact. Wear 2003, 254, 356–363. [Google Scholar] [CrossRef]

- Han, S.L.; Tang, X.D.; Gao, Y.; Zeng, Q.L. Effects of Friction Factors on Flat Bottom Self-Pierce Riveting Joints of AZ31 Magnesium Alloy. Mater. Res. Innov. 2015, 19, S10-235–S10-238. [Google Scholar] [CrossRef]

- Li, D. Influence of Aluminium Sheet Surface Modification on the Self-Piercing Riveting Process and the Joint Static Lap Shear Strength. Int. J. Adv. Manuf. Technol. 2017, 93, 2685–2695. [Google Scholar] [CrossRef]

- Han, L.; Chrysanthou, A. Evaluation of Quality and Behaviour of Self-Piercing Riveted Aluminium to High Strength Low Alloy Sheets with Different Surface Coatings. Mater. Des. 2008, 29, 458–468. [Google Scholar] [CrossRef]

- Li, D. Influence of Local Surface Texture by Tool Impression on the Self-Piercing Riveting Process and the Static Lap Shear Strength. J. Manuf. Process. 2017, 29, 298–309. [Google Scholar] [CrossRef]

- Lovell, M.; Higgs, C.F.; Deshmukh, P.; Mobley, A. Increasing Formability in Sheet Metal Stamping Operations Using Environmentally Friendly Lubricants. J. Mater. Process. Technol. 2006, 177, 87–90. [Google Scholar] [CrossRef]

- Karim, M.A.; Jeong, T.E.; Noh, W.; Park, K.Y.; Kam, D.H.; Kim, C.; Nam, D.G.; Jung, H.; Park, Y. Do Joint Quality of Self-Piercing Riveting (SPR) and Mechanical Behavior under the Frictional Effect of Various Rivet Coatings. J. Manuf. Process. 2020, 58, 466–477. [Google Scholar] [CrossRef]

- Uhe, B.; Kuball, C.M.; Merklein, M.; Meschut, G. Influence of the Rivet Coating on the Friction during Self-Piercing Riveting. Key Eng. Mater. 2021, 883, 11–18. [Google Scholar] [CrossRef]

- Rossel, M.; Meschut, G. Investigation of the Friction Conditions of Self-Pierce Rivets by Means of a Compression-Torsion Tribometer. Prod. Eng. 2022, 16, 673–682. [Google Scholar] [CrossRef]

- Tassler, T.; Israel, M.; Goede, M.F.; Dilger, K.; Dröder, K. Robust Joining Point Design for Semi-Tubular Self-Piercing Rivets. Int. J. Adv. Manuf. Technol. 2018, 98, 431–440. [Google Scholar] [CrossRef]

- Zhao, H.; Han, L.; Liu, Y.; Liu, X. Modelling and Interaction Analysis of the Self-Pierce Riveting Process Using Regression Analysis and FEA. Int. J. Adv. Manuf. Technol. 2021, 113, 159–176. [Google Scholar] [CrossRef]

- Carandente, M.; Dashwood, R.J.; Masters, I.G.; Han, L. Improvements in Numerical Simulation of the SPR Process Using a Thermo-Mechanical Finite Element Analysis. J. Mater. Process. Technol. 2016, 236, 148–161. [Google Scholar] [CrossRef]

- Moraes, J.F.C.; Jordon, J.B.; Ilieva, E.I. Influence of the Friction Coefficient in Self-Pierce Riveting Simulations: A Statistical Analysis. SAE Int. J. Mater. Manuf. 2018, 11, 123–130. [Google Scholar] [CrossRef]

- Huang, L.; Wu, Y.; Huff, G.; Huang, S.; Ilinich, A.; Freis, A.; Luckey, G. Sensitivity Study of Self-Piercing Rivet Insertion Process Using Smoothed Particle Galerkin Method. 16h Int. LS-DYNA Users Conf. 2020, 1–11. [Google Scholar]

- Mucha, J. A Study of Quality Parameters and Behaviour of Self-Piercing Riveted Aluminium Sheets with Different Joining Conditions. Stroj. Vestn. J. Mech. Eng. 2011, 57, 323–333. [Google Scholar] [CrossRef]

- Hoang, N.H.; Hopperstad, O.S.; Langseth, M.; Westermann, I. Failure of Aluminium Self-Piercing Rivets: An Experimental and Numerical Study. Mater. Des. 2013, 49, 323–335. [Google Scholar] [CrossRef]

- Han, L.; Chrysanthou, A.; O’Sullivan, J.M. Fretting Behaviour of Self-Piercing Riveted Aluminium Alloy Joints under Different Interfacial Conditions. Mater. Des. 2006, 27, 200–208. [Google Scholar] [CrossRef]

- Wituschek, S.; Kuball, C.M.; Merklein, M.; Lechner, M. Test Method for Friction Characterization of Rivets. Defect Diffus. Forum 2020, 404 DDF, 132–137. [Google Scholar] [CrossRef]

- Wang, X.; Wang, C.; Mu, R. Numerical Simulation and Experimental Study on Self-Piercing Riveting of DC03 / 6016 Dissimilar Sheets. In Proceedings of the International Conference on Electron Device and Mechanical Engineering, Suzhou, China, 1–3 May 2020; pp. 463–466. [Google Scholar]

- Karathanasopoulos, N.; Pandya, K.S.; Mohr, D. Self-Piercing Riveting Process: Prediction of Joint Characteristics through Finite Element and Neural Network Modeling. J. Adv. Join. Process. 2021, 3, 100040. [Google Scholar] [CrossRef]

- Deng, J.H.; Lyu, F.; Chen, R.M.; Fan, Z.S. Influence of Die Geometry on Self-Piercing Riveting of Aluminum Alloy AA6061-T6 to Mild Steel SPFC340 Sheets. Adv. Manuf. 2019, 7, 209–220. [Google Scholar] [CrossRef]

- Rusia, A.; Weihe, S. Development of an End-to-End Simulation Process Chain for Prediction of Self-Piercing Riveting Joint Geometry and Strength. J. Manuf. Process. 2020, 57, 519–532. [Google Scholar] [CrossRef]

- Hönsch, F.; Domitner, J.; Sommitsch, C.; Götzinger, B. Modeling the Failure Behavior of Self-Piercing Riveting Joints of 6xxx Aluminum Alloy. J. Mater. Eng. Perform. 2020, 29, 4888–4897. [Google Scholar] [CrossRef]

- Moraes, J.F.C.; Jordon, J.B.; Su, X.; Barkey, M.E.; Jiang, C.; Ilieva, E. Effect of Process Deformation History on Mechanical Performance of AM60B to AA6082 Self-Pierce Riveted Joints. Eng. Fract. Mech. 2019, 209, 92–104. [Google Scholar] [CrossRef]

- Amro, E.; Kouadri-Henni, A. Joining of Polymer-Metal Lightweight Structures Using Self-Piercing Riveting (SPR) Technique: Numerical Approach and Simulation Results. In Proceedings of the AIP Conference Proceedings, Palermo, Italy, 23–25 April 2018; Volume 1960, p. 050001. [Google Scholar]

- Huang, L.; Guo, H.; Shi, Y.; Huang, S.; Su, X. Fatigue Behavior and Modeling of Self-Piercing Riveted Joints in Aluminum Alloy 6111. Int. J. Fatigue 2017, 100, 274–284. [Google Scholar] [CrossRef]

- Hirsch, F.; Müller, S.; Machens, M.; Staschko, R.; Fuchs, N.; Kästner, M. Simulation of Self-Piercing Riveting Processes in Fibre Reinforced Polymers: Material Modelling and Parameter Identification. J. Mater. Process. Technol. 2017, 241, 164–177. [Google Scholar] [CrossRef]

- He, X.; Xing, B.; Zeng, K.; Gu, F.; Ball, A. Numerical and Experimental Investigations of Self-Piercing Riveting. Int. J. Adv. Manuf. Technol. 2013, 69, 715–721. [Google Scholar] [CrossRef]

- Han, L.; Thornton, M.; Shergold, M. A Comparison of the Mechanical Behaviour of Self-Piercing Riveted and Resistance Spot Welded Aluminium Sheets for the Automotive Industry. Mater. Des. 2010, 31, 1457–1467. [Google Scholar] [CrossRef]

- Liu, Y.; Han, L.; Zhao, H.; Liu, X. Evaluation and Correction of Cutting Position’s Effects on Quality Indicator Measurement of Self-Piercing Riveted Joint. Mater. Des. 2021, 202, 109583. [Google Scholar] [CrossRef]

- Zhao, H.; Han, L.; Liu, Y.; Liu, X. Analysis of Joint Formation Mechanisms for Self-Piercing Riveting (SPR) Process with Varying Joining Parameters. J. Manuf. Process. 2022, 73, 668–685. [Google Scholar] [CrossRef]

- Schmid, S.R.; Wilson, W.R.D. Lubrication of Aluminum Rolling by Oil-in-Water Emulsions. Tribol. Trans. 1995, 38, 452–458. [Google Scholar] [CrossRef]

| Authors | Model Type | Software | Friction Coefficients |

|---|---|---|---|

| Rusia and Weihe [29] | 2D | LS-DYNA | 0.12 between deformable parts 0.2 between tools and deformable parts |

| Wang et al. [26] | 2D | DEFORM-2D | 0.12 between all parts |

| Karathanasopoulos et al. [27] | 2D | ABAQUS | 0.2 between all parts |

| Hönsch et al. [30] | 2D | Simufact.Forming | 0.1 for rivet/sheets, 0.3 for sheets/die, 0.2 for others |

| Deng et al. [28] | 2D | Simufact.Forming | 0.2 between all parts |

| Moraes et al. [31] | 3D | ABAQUS | 0.4 for punch/rivet, 0.15 for others |

| AMRO et al. [32] | 2D | ABAQUS | 0.2 between all parts |

| Huang et al. [33] | 3D | ABAQUS | 0.2 between all parts |

| Hirsch et al. [34] | 3D | ABAQUS | 0.0 for composite sheet/rivet, 0.3 for others |

| Carandente et al. [19] | 2D | Simufact.Forming | 0.09 for top/bottom sheets, 0.15 for bottom sheet/die, 0.15 for top sheet/blank-holder |

| He et al. [35] | 2D | LS-DYNA | 0.15 for top sheet/blank-holder, 0.15 for top/bottom sheets, 0.25 for others |

| Mechanical Properties | Young’s Modulus (GPa) | Tensile Strength(MPa) | Elongation (%) | Hardness (HV) | |

| 70 | 240 | 22 | 63.5 | ||

| Nominal composition (wt%) | Si | Fe | Cu | Mn | Mg |

| 0~0.40 | 0~0.40 | 0~0.10 | 0~0.50 | 2.60~3.60 |

| Joint No. | Thickness (mm) | Rivet (Boron Steel) | Die | Contact Interface | Surface Modification Method | |

|---|---|---|---|---|---|---|

| Top Sheet/Tt (AA5754) | Bottom Sheet/Tb (AA5754) | |||||

| 1-1 | 1.8 | 2.0 | C5.3*6.0 (280 ± 30 HV10) | Pip die | Rivet/top sheet | Oil lubrication |

| 1-2 | Sandpaper grinding | |||||

| 2-1 | Top/bottom sheet | Oil lubrication | ||||

| 2-2 | Sandpaper grinding | |||||

| 3-1 | Bottom sheet/die | Oil lubrication | ||||

| 3-2 | Sandpaper grinding | |||||

| Friction Coefficient | I1 | Rin | Rout | tc | ttip | |

|---|---|---|---|---|---|---|

| Rivet/top sheet (μ1) | ↑ | ↓↓ |  | ↓↓ | ↓ | ~~ |

| Rivet/bottom sheet (μ2) | ↑ | ↓ |  |  |  | ↑ |

| Top/bottom sheets (μ3) | ↑ | ~~ | ↑ | ↑↑ | ↓ | ↑↑ |

| Bottom sheet/die (μ4) | ↑ | ~~ | ↑ | ↑ | ↑↑ |  |

.

.Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, H.; Han, L.; Liu, Y.; Liu, X. Experimental and Numerical Investigations on the Impact of Surface Conditions on Self-Piercing Riveted Joint Quality. Coatings 2023, 13, 858. https://doi.org/10.3390/coatings13050858

Zhao H, Han L, Liu Y, Liu X. Experimental and Numerical Investigations on the Impact of Surface Conditions on Self-Piercing Riveted Joint Quality. Coatings. 2023; 13(5):858. https://doi.org/10.3390/coatings13050858

Chicago/Turabian StyleZhao, Huan, Li Han, Yunpeng Liu, and Xianping Liu. 2023. "Experimental and Numerical Investigations on the Impact of Surface Conditions on Self-Piercing Riveted Joint Quality" Coatings 13, no. 5: 858. https://doi.org/10.3390/coatings13050858

APA StyleZhao, H., Han, L., Liu, Y., & Liu, X. (2023). Experimental and Numerical Investigations on the Impact of Surface Conditions on Self-Piercing Riveted Joint Quality. Coatings, 13(5), 858. https://doi.org/10.3390/coatings13050858