Effect of Various Metal Oxide Insulating Layers on the Magnetic Properties of Fe-Si-Cr Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

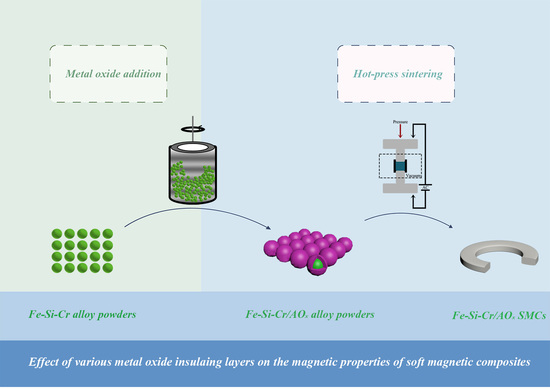

2.2. Experimental Process

2.2.1. Material Preparation

2.2.2. Material Characterization

3. Results and Discussion

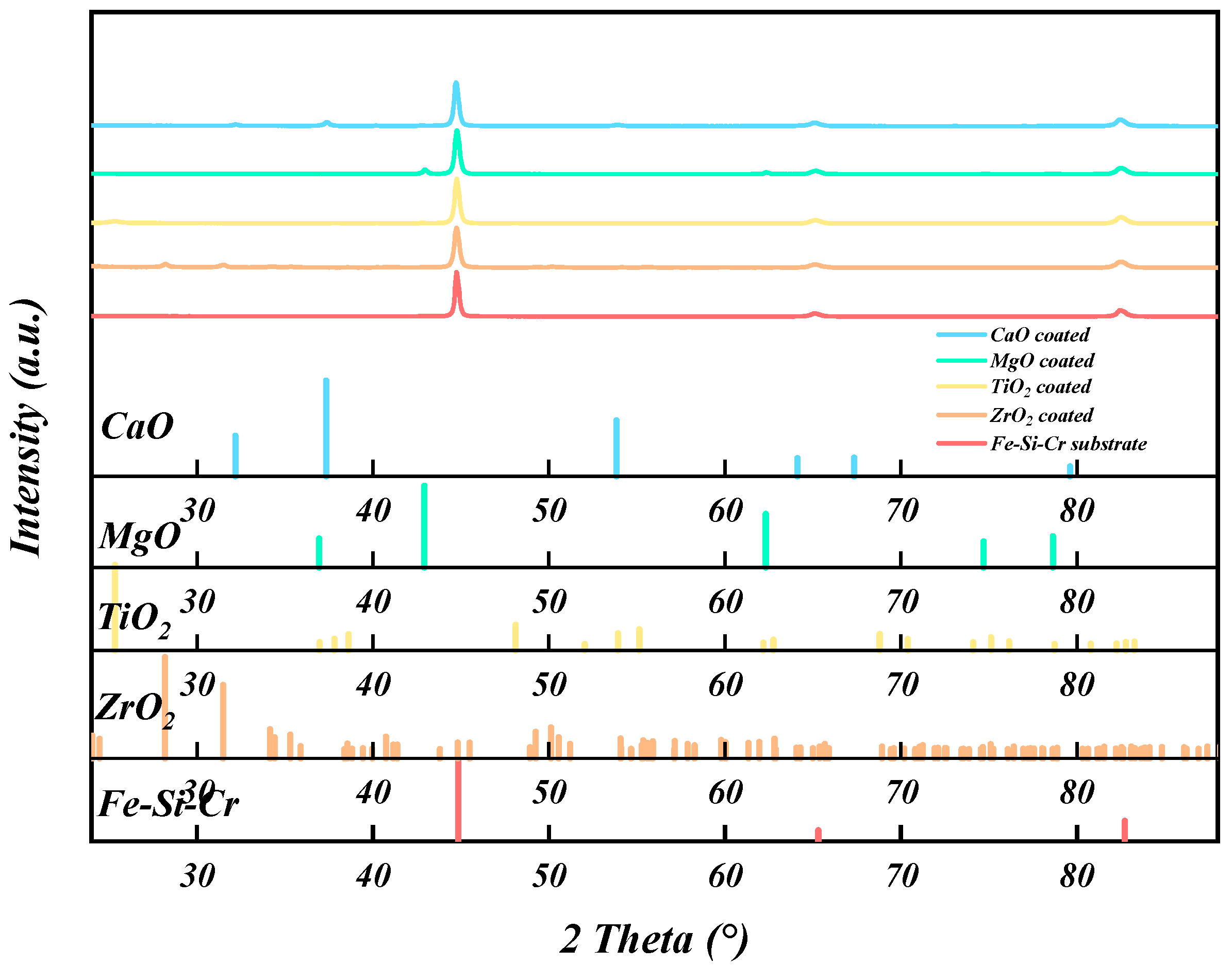

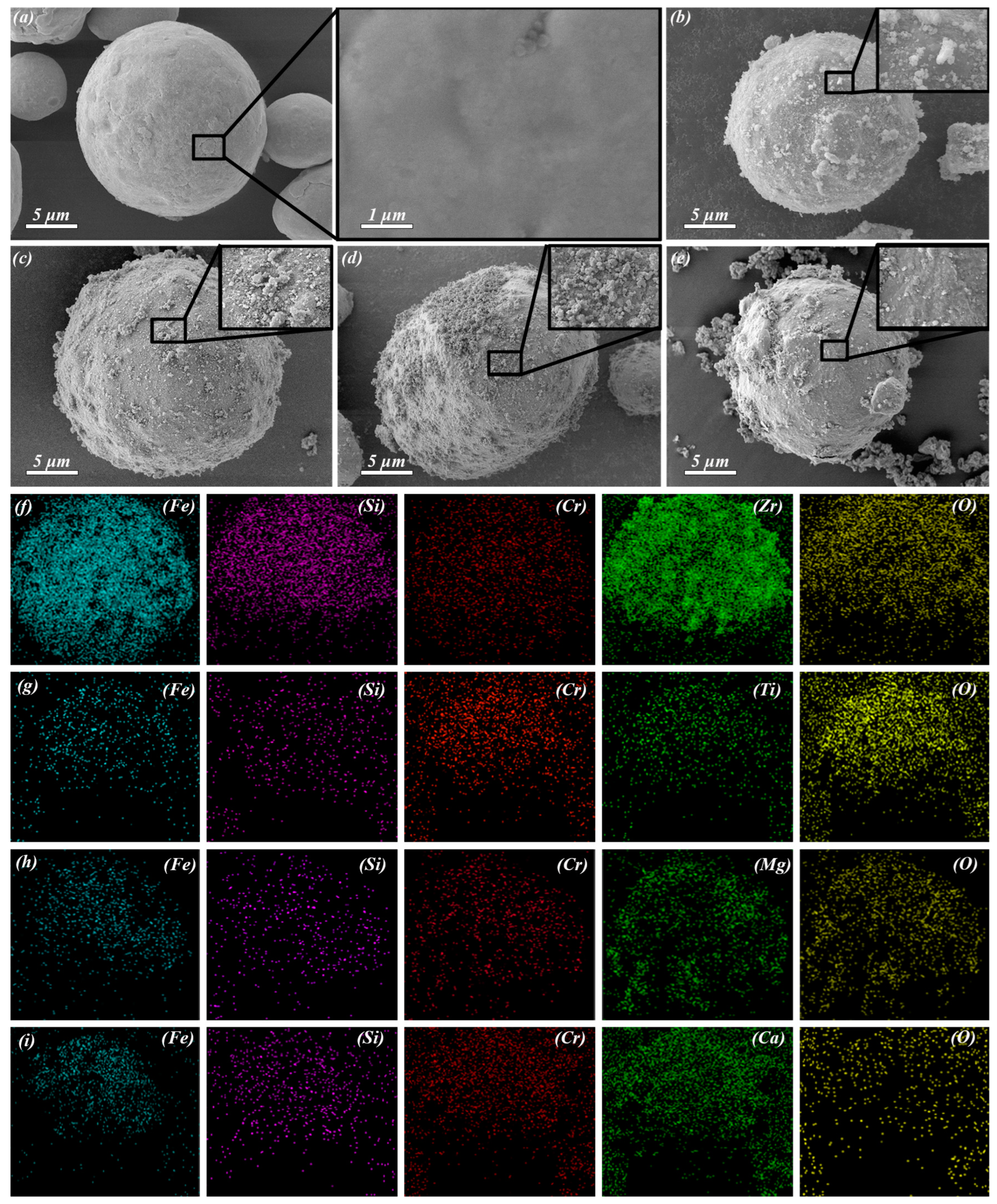

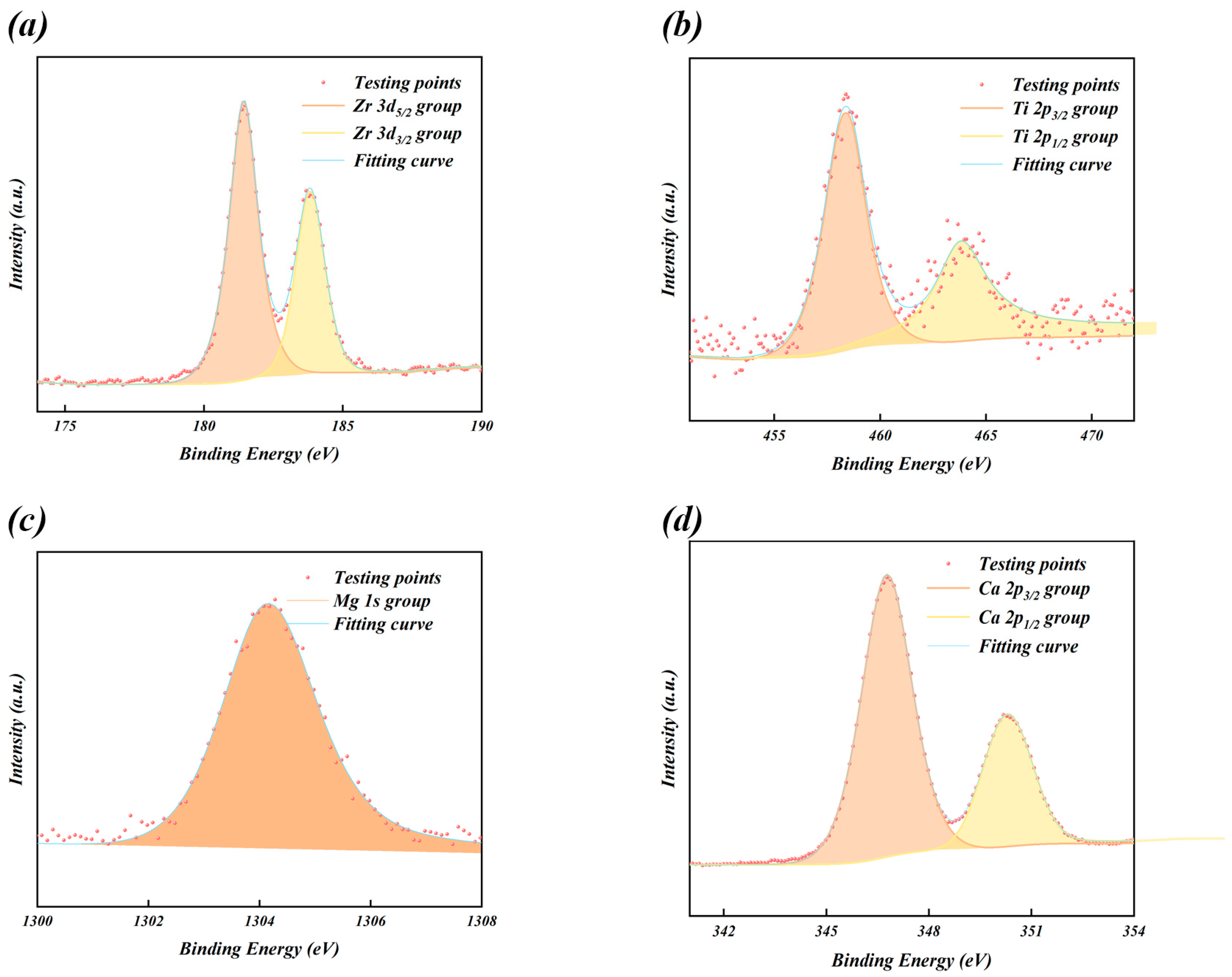

3.1. Microstructure of Fe-Si-Cr/AOx Composite Powders and SMCs

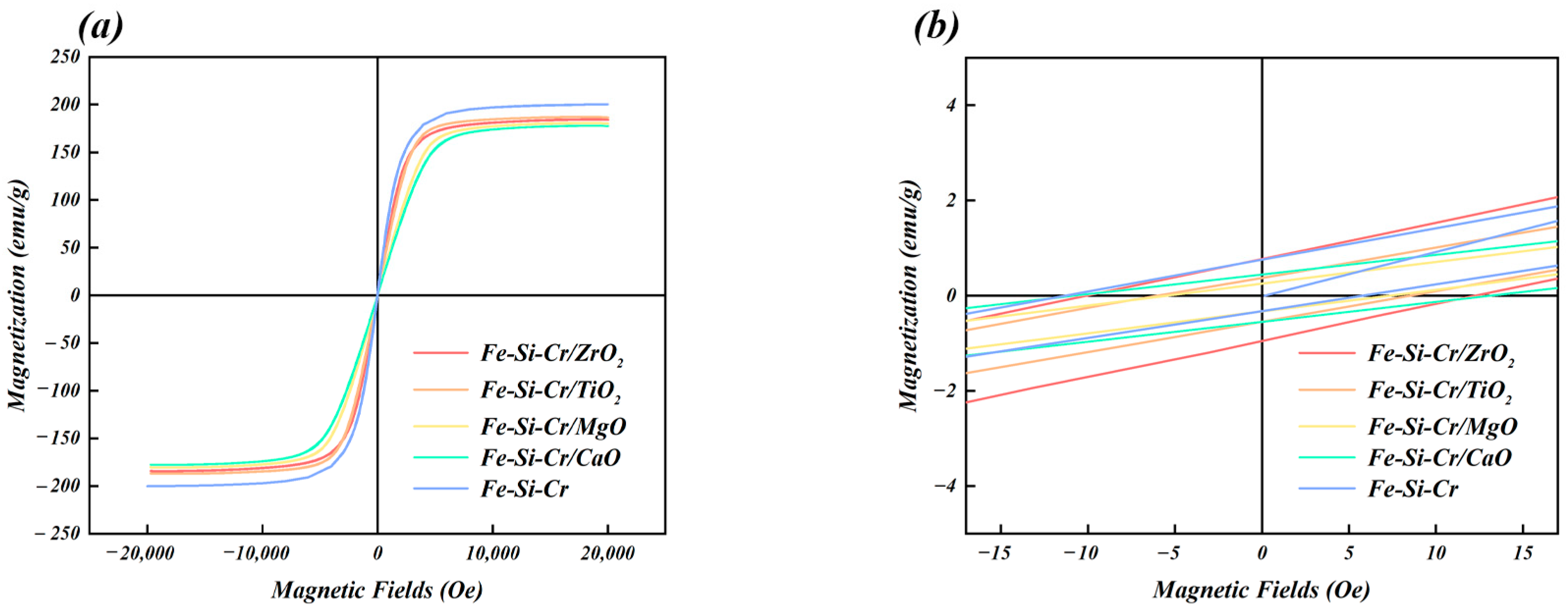

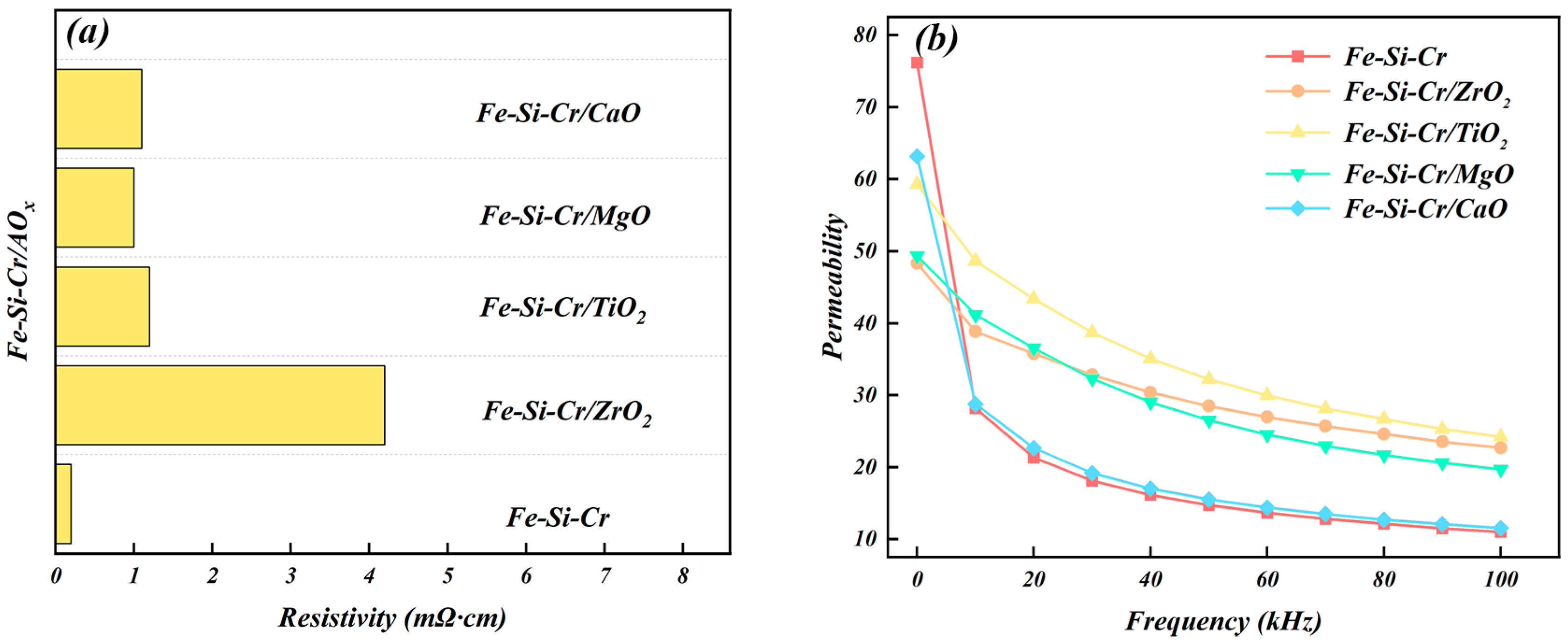

3.2. Effect of Distinct Metal Oxide Insulating Layers on the Magnetic Properties of the SMCs

4. Conclusions

- Four metal oxides, ZrO2, TiO2, MgO, and CaO, were successfully coated on the surface of the Fe-Si-Cr alloy powder via ball milling. Thus, a heterogeneous Fe-Si-Cr/AOx core–shell structure was formed, wherein the Fe-Si-Cr alloy powder and the metal oxides comprised the core and shell, respectively. These powdered raw materials were used for the subsequent preparation of Fe-Si-Cr/AOx SMCs.

- Compared to common metal oxide powders such as MgO, CaO, and TiO2, ZrO2 powder is harder and less prone to breakage and refinement during ball milling. This resulted in a lower degree of agglomeration on the surface of the Fe-Si-Cr alloy powder, forming an insulating layer with superior uniformity and integrity. The insulating layer resists peeling and collapse during subsequent hot pressing and heat treatment processes, ultimately providing a high-quality insulating layer for SMCs.

- For equal amounts of each metal oxide, the sintered insulating layer comprising ZrO2 possessed the highest density and uniformity, which minimized the magnetic dilution effect, leading to the highest resistivity (4.2 mΩ·cm) and lowest total (580.8 kW/m3 for P10mt/100kHz) and eddy current (470.0 kW/m3 for Pec 10mt/100kHz) losses in the corresponding SMCs. The magnetic permeability also stabilized earlier at lower frequencies (>40 kHz).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Luo, Z.; Feng, B.; Chen, D.; Yang, Z.; Jiang, S.; Wang, J.; Wu, Z.; Li, G.; Li, Y.; Fan, X. Preparation and magnetic performance optimization of FeSiAl/Al2O3–MnO–Al2O3 soft magnetic composites with particle size adjustment. J. Mater. Sci. Mater. Electron. 2021, 33, 850–860. [Google Scholar] [CrossRef]

- Talaat, A.; Suraj, M.; Byerly, K.; Wang, A.; Wang, Y.; Lee, J.; Ohodnicki, P. Review on soft magnetic metal and inorganic oxide nanocomposites for power applications. J. Alloys Compd. 2021, 870, 159500. [Google Scholar] [CrossRef]

- Meng, B.; Hou, J.; Ning, F.; Yang, B.; Zhou, B.; Yu, R. Low-loss and high-induction Fe-based soft magnetic composites coated with magnetic insulating layers. J. Magn. Magn. Mater. 2019, 492, 165651. [Google Scholar] [CrossRef]

- Wang, J.; Song, S.; Sun, H.; Hang, G.; Xue, Z.; Wang, C.; Chen, W.; Chen, D. Insulation layer design for soft magnetic composites by synthetically comparing their magnetic properties and coating process parameters. J. Magn. Magn. Mater. 2021, 519, 165651. [Google Scholar] [CrossRef]

- Yuan, H.-J.; Lu, C.-X.; Zhang, S.-C.; Wu, G.-P. Preparation and characterization of a polyimide coating on the surface of carbon fibers. New Carbon Mater. 2015, 30, 115–121. [Google Scholar] [CrossRef]

- Wu, S.; Sun, A.; Zhai, F.; Wang, J.; Zhang, Q.; Xu, W.; Logan, P.; Volinsky, A.A. Annealing effects on magnetic properties of silicone-coated iron-based soft magnetic composites. J. Magn. Magn. Mater. 2012, 324, 818–822. [Google Scholar] [CrossRef]

- Jin, X.; Li, T.; Jia, Z.; Shi, H.; Xue, D. Over 100 MHz cut-off frequency mechanism of Fe-Si soft magnetic composites. J. Magn. Magn. Mater. 2022, 556, 169366. [Google Scholar] [CrossRef]

- Dong, B.; Qin, W.; Su, Y.; Wang, X. Magnetic properties of FeSiCr@MgO soft magnetic composites prepared by magnesium acetate pyrolysis for high-frequency applications. J. Magn. Magn. Mater. 2021, 539, 168350. [Google Scholar] [CrossRef]

- Geng, K.; Xie, Y.; Xu, L.; Yan, B. Structure and magnetic properties of ZrO2-coated Fe powders and Fe/ZrO2 soft magnetic composites. Adv. Powder Technol. 2017, 28, 2015–2022. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, X.; Hu, W.; Luo, Z.; Yang, Z.; Li, G.; Li, Y. Microstructure and magnetic properties of MnO2 coated iron soft magnetic composites prepared by ball milling. J. Magn. Magn. Mater. 2020, 514, 167295. [Google Scholar] [CrossRef]

- Yaghtin, M.; Taghvaei, A.H.; Hashemi, B.; Janghorban, K. Effect of heat treatment on magnetic properties of iron-based soft magnetic composites with Al2O3 insulation coating produced by sol-gel method. J. Alloys Compd. 2013, 581, 293–297. [Google Scholar] [CrossRef]

- Shi, X.; Chen, X.; Wan, K.; Zhang, B.; Duan, P.; Zhang, H.; Zeng, X.; Liu, W.; Su, H.; Zou, Z.; et al. Enhanced magnetic and mechanical properties of gas atomized Fe-Si-Al soft magnetic composites through adhesive insulation. J. Magn. Magn. Mater. 2021, 534, 168040. [Google Scholar] [CrossRef]

- Averback, R.S.; Ehrhart, P.; Popov, A.I.; Sambeek, A.V. Defects in ion implanted and electron irradiated MgO and Al2O3. Radiat. Eff. Defects Solids 1995, 136, 169–173. [Google Scholar] [CrossRef]

- Tardío, M.; Ramírez, R.; González, R.; Chen, Y.; Kokta, M.R. Electrical conductivity in magnesium-doped Al2O3 crystals at moderate temperatures. Radiat. Eff. Defects Solids 2001, 155, 409–413. [Google Scholar] [CrossRef]

- Kotomin, E.A.; Kuzovkov, V.N.; Popov, A.I.; Vila, R. Kinetics of F center annealing and colloid formation in Al2O3. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2016, 374, 107–110. [Google Scholar] [CrossRef]

- Zhou, B.; Dong, Y.; Liu, L.; Chang, L.; Bi, F.; Wang, X. Enhanced soft magnetic properties of the Fe-based amorphous powder cores with novel TiO2 insulation coating layer. J. Magn. Magn. Mater. 2019, 474, 1–8. [Google Scholar] [CrossRef]

- Choi, S.; Lee, S.; Bon, C.Y.; Lee, K.; Choi, S.J.; Yoo, S.I. Novel Fabrication Method for a High-Performance Soft-Magnetic Composite Composed of Alumina-Coated Fe-Based Metal Powder. J. Electron. Mater. 2020, 50, 664–674. [Google Scholar] [CrossRef]

- Vega, L.E.R.; Leiva, D.R.; Neto, R.L.; Silva, W.B.; Silva, R.A.; Ishikawa, T.T.; Kiminami, C.S.; Botta, W.J. Improved ball milling method for the synthesis of nanocrystalline TiFe compound ready to absorb hydrogen. Int. J. Hydrogen Energy 2020, 45, 2084–2093. [Google Scholar] [CrossRef]

- Yuan, W.; Sun, K.; Tian, J.; Li, Y.; Wang, Z.; Liu, B.; Fan, R. Improved magnetic properties of iron-based soft magnetic composites with a double phosphate-SiO2 shells structure. J. Mater. Sci. Mater. Electron. 2021, 32, 21472–21482. [Google Scholar] [CrossRef]

- Luo, X.; Zhang, K.; Zhou, Y.; Wu, H.; Xie, H. In situ construction of Fe3Al@Al2O3 core-shell particles with excellent electromagnetic absorption. J. Colloid Interface Sci. 2022, 611, 306–316. [Google Scholar] [CrossRef]

- Gupta, G.; Mondal, K.; Balasubramaniam, R. In situ nanocrystalline Fe–Si coating by mechanical alloying. J. Alloys Compd. 2009, 482, 118–122. [Google Scholar] [CrossRef]

- Wang, R.; He, Y.; Kong, H.; Wang, J.; Wu, Z.; Wang, H. Influence of sintering temperature on heterogeneous-interface structural evolution and magnetic properties of Fe-Si soft magnetic powder cores. Ceram. Int. 2022, 48, 29854–29861. [Google Scholar] [CrossRef]

- Qiu, Y.; Wang, R.; He, Y.; Kong, H.; Li, S.; Wu, Z. Effects of axial pressure on the evolution of core-shell heterogeneous structures and magnetic properties of Fe-Si soft magnetic powder cores during hot-press sintering. RSC Adv. 2022, 12, 19875–19884. [Google Scholar] [CrossRef] [PubMed]

- Hsiang, H.I.; Fan, L.F.; Hung, J.J. Phosphoric acid addition effect on the microstructure and magnetic properties of iron-based soft magnetic composites. J. Magn. Magn. Mater. 2018, 447, 1–8. [Google Scholar] [CrossRef]

- Moon, B.K.; Kwon, I.M.; Jeong, J.H.; Kim, C.S.; Yi, S.S.; Kim, P.S.; Choi, H.; Kim, J.H. Synthesis and luminescence characteristics of Eu3+-doped ZrO2 nanoparticles. J. Lumin. 2007, 122, 855–857. [Google Scholar] [CrossRef]

- Le Anh, D.U.C.; Hieu, P.M.; Quang, N.M. A New Chemical Mechanical Slurry for Polishing Yttrium Aluminium Garnet Material with Magnesium Oxide, Sodium Metasilicate Pentahydrate and Zirconium Dioxide Abrasive Particles. J. Mach. Eng. 2023, 23, 5–17. [Google Scholar]

- Li, N.-N.; Li, G.-L.; Wang, H.-D.; Kang, J.-J.; Dong, T.-S. Influence of TiO2 content on the mechanical and tribological properties of Cr2O3-based coating. Mater. Des. 2015, 88, 906–914. [Google Scholar] [CrossRef]

- Yin, D.; Niu, X.; Zhang, K.; Wang, J.; Cui, Y. Preparation of MgO doped colloidal SiO2 abrasive and their chemical mechanical polishing performance on c-, r-and a-plane sapphire substrate. Ceram. Int. 2018, 44, 14631–14637. [Google Scholar] [CrossRef]

- Klabunde, K.J.; Stark, J.; Koper, O.; Mohs, C.; Park, D.G.; Decker, S.; Jiang, Y.; Lagadic, I.; Zhang, D. Nanocrystals as stoichiometric reagents with unique surface chemistry. J. Phys. Chem. 1996, 100, 12142–12153. [Google Scholar] [CrossRef]

- Zheng, K.L.; Yan, P.F.; Wei, X.S.; Yan, B. Study of the nano-network structure in the friction transfer film of the hybrid reinforced aluminum-based composite. Wear 2022, 494–495, 204268. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, J.; Xu, Y.; Qian, S.; Wang, B.; Liu, F.; Liu, X. Biological Behavior of Osteoblast-like Cells on Titania and Zirconia Films Deposited by Cathodic Arc Deposition. Biointerphases 2012, 7, 60. [Google Scholar] [CrossRef] [PubMed]

- Anderson, J.A.; Fierro, J.L.G. Bulk and Surface Properties of Copper-Containing Oxides of the General Formula LaZr1−xCuxO3. J. Solid State Chem. 1994, 108, 305–313. [Google Scholar] [CrossRef]

- Bender, H.; Chen, W.; Portillo, J.; Hove, L.V.D.; Vandervorst, W. AES and XPS analysis of the interaction of Ti with Si and SiO2 during RTA. Appl. Surf. Sci. 1989, 38, 37–47. [Google Scholar] [CrossRef]

- Wang, R.; Ren, J.; Wu, J.; Wu, L. Characteristics and mechanism of toluene removal by double dielectric barrier discharge combined with an Fe2O3/TiO2/gamma-Al2O3 catalyst. RSC Adv. 2020, 10, 41511–41522. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Wang, B.; Zheng, J.; Li, H. Study on Mineral structure transformation of coal ash at high ash melting Temperature using XPS. Spectrosc. Spectr. Anal. 2018, 38, 2296–2301. [Google Scholar]

- Demri, B.; Muster, D. XPS study of some calcium compounds. J. Mater. Process. Technol. 1995, 55, 311–314. [Google Scholar] [CrossRef]

- Gemeay, A.H.; Keshta, B.E.; El-Sharkawy, R.G.; Zaki, A.B. Chemical insight into the adsorption of reactive wool dyes onto amine-functionalized magnetite/silica core-shell from industrial wastewaters. Environ. Sci. Pollut. Res. Int. 2020, 27, 32341–32358. [Google Scholar] [CrossRef]

- Luo, Z.; Feng, B.; Yang, Z.; Chen, D.; Jiang, S.; Wang, J.; Wu, Z.; Liu, X.; Li, G.; Li, Y. Highly enhancing electromagnetic properties in Fe-Si/MnO-SiO2 soft magnetic composites by improving coating uniformity. Adv. Powder Technol. 2021, 32, 4846–4856. [Google Scholar] [CrossRef]

- Xue, Y.; Pu, G.; Yu, M.; Chen, S.; Gan, L.; Lin, L.; Yang, C.; Wang, Z.; Wang, H.; Huang, Z.; et al. Effects of air annealing treatments on the microstructure, components, and mechanical properties of magnetron sputtered Al2O3–Cr2O3–ZrO2 composite coatings. Ceram. Int. 2022, 49, 7589–7599. [Google Scholar] [CrossRef]

- Jin, C.Z.; Yang, Y.; Yang, X.A.; Wang, S.B.; Zhang, W.B. Visible photocatalysis of Cr(VI) at g/L level in Si/N-TiO2 nanocrystals synthesized by one-step co-hydrolysis method. Chem. Eng. J. 2020, 398, 125641. [Google Scholar] [CrossRef]

- Kocsis, B.; Varga, L.K.; Zsoldos, I. Preparation of soft magnetic composite from Fe-6.9wt%Si by different heat treatment strategies. IOP Conf. Ser. Mater. Sci. Eng. 2020, 903, 012042. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Huang, H.; He, H.; Wu, Z.; Wang, X.; Wang, R. Effect of Various Metal Oxide Insulating Layers on the Magnetic Properties of Fe-Si-Cr Systems. Coatings 2023, 13, 804. https://doi.org/10.3390/coatings13040804

Huang Z, Huang H, He H, Wu Z, Wang X, Wang R. Effect of Various Metal Oxide Insulating Layers on the Magnetic Properties of Fe-Si-Cr Systems. Coatings. 2023; 13(4):804. https://doi.org/10.3390/coatings13040804

Chicago/Turabian StyleHuang, Zhenyi, Huaqin Huang, Hao He, Zhaoyang Wu, Xuesong Wang, and Rui Wang. 2023. "Effect of Various Metal Oxide Insulating Layers on the Magnetic Properties of Fe-Si-Cr Systems" Coatings 13, no. 4: 804. https://doi.org/10.3390/coatings13040804

APA StyleHuang, Z., Huang, H., He, H., Wu, Z., Wang, X., & Wang, R. (2023). Effect of Various Metal Oxide Insulating Layers on the Magnetic Properties of Fe-Si-Cr Systems. Coatings, 13(4), 804. https://doi.org/10.3390/coatings13040804