Localized Corrosion Mechanism of Q125 Casing Steel in Residual Acid Solution during Oil Reservoir Acidizing

Abstract

:1. Introduction

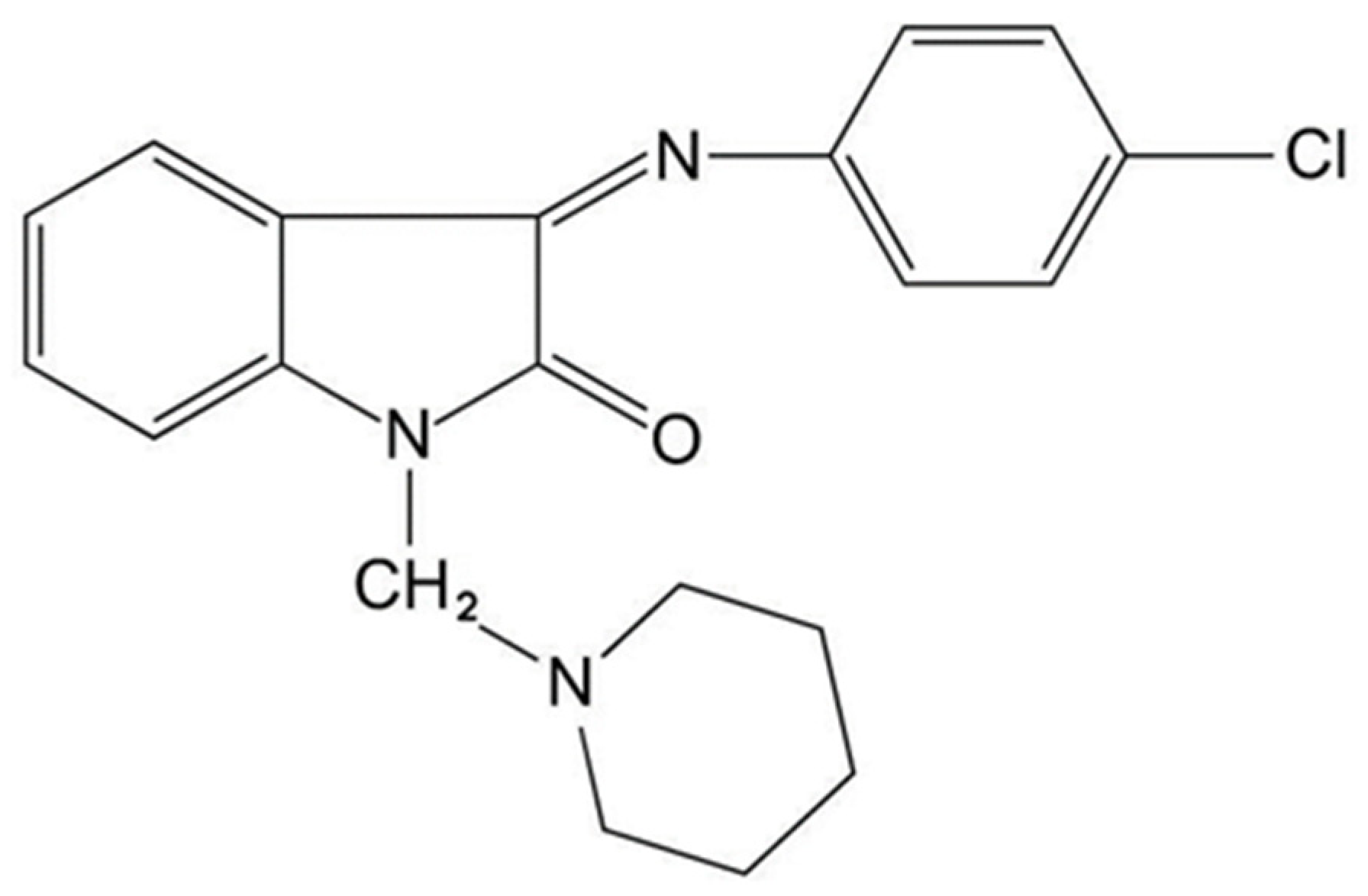

2. Materials and Methods

2.1. Materials and Pretreatment

2.2. Test Procedures

3. Results

3.1. Uniform Corrosion Rate

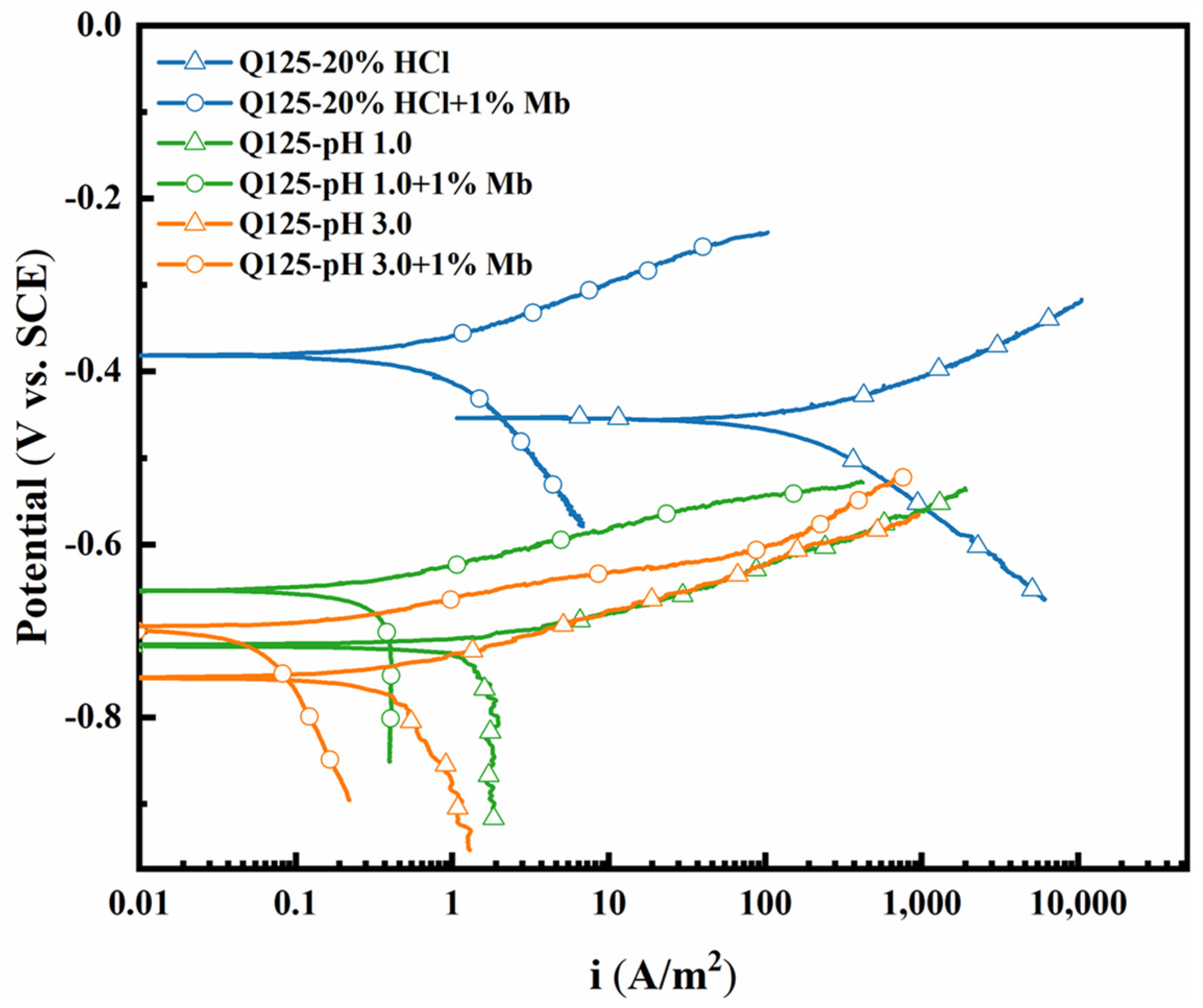

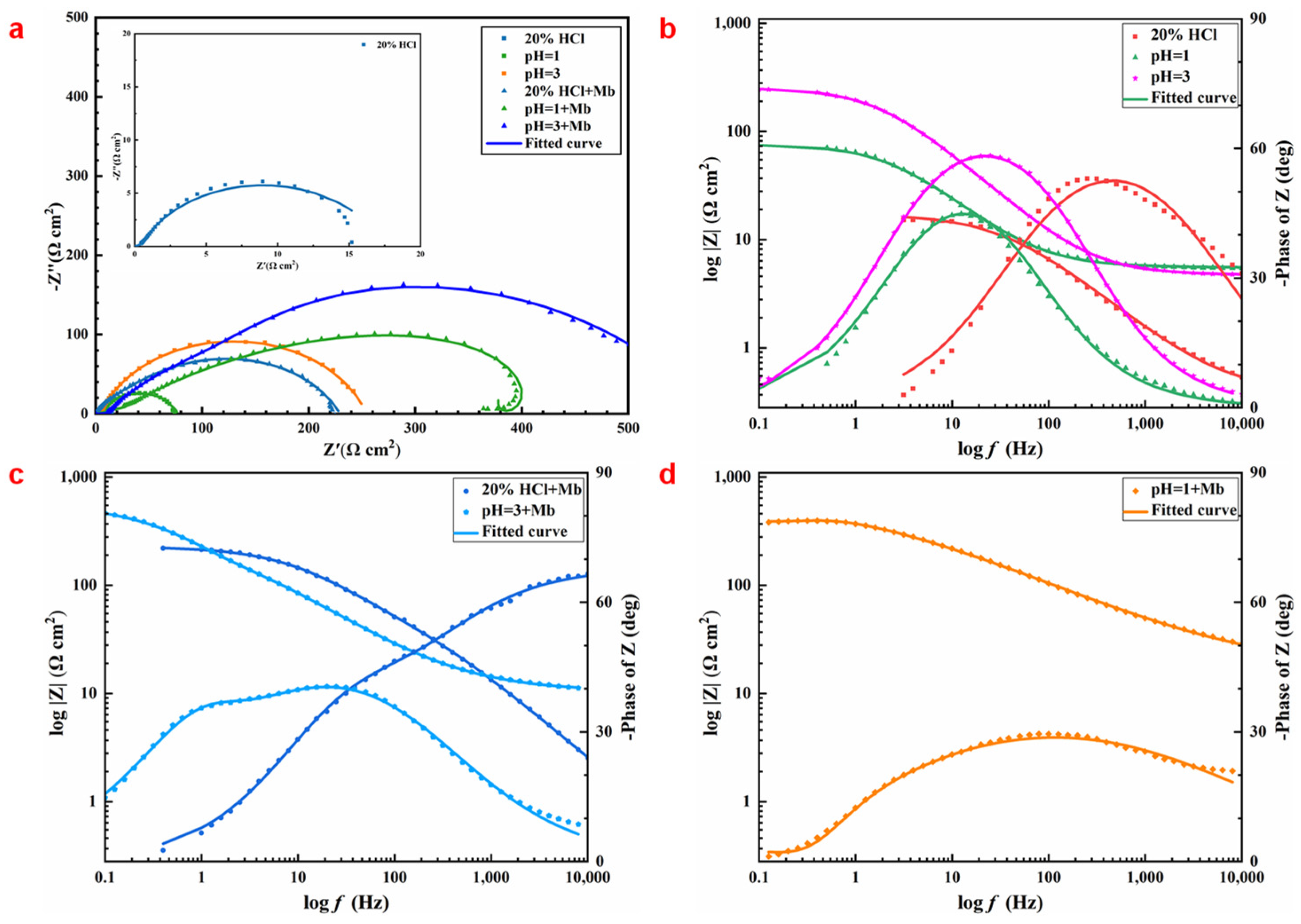

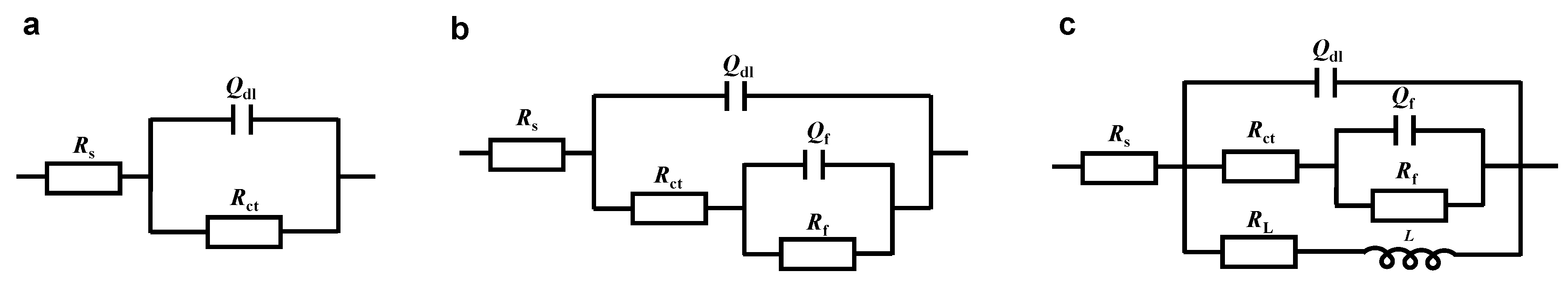

3.2. Electrochemical Measurements

3.3. Surface Morphology Analysis

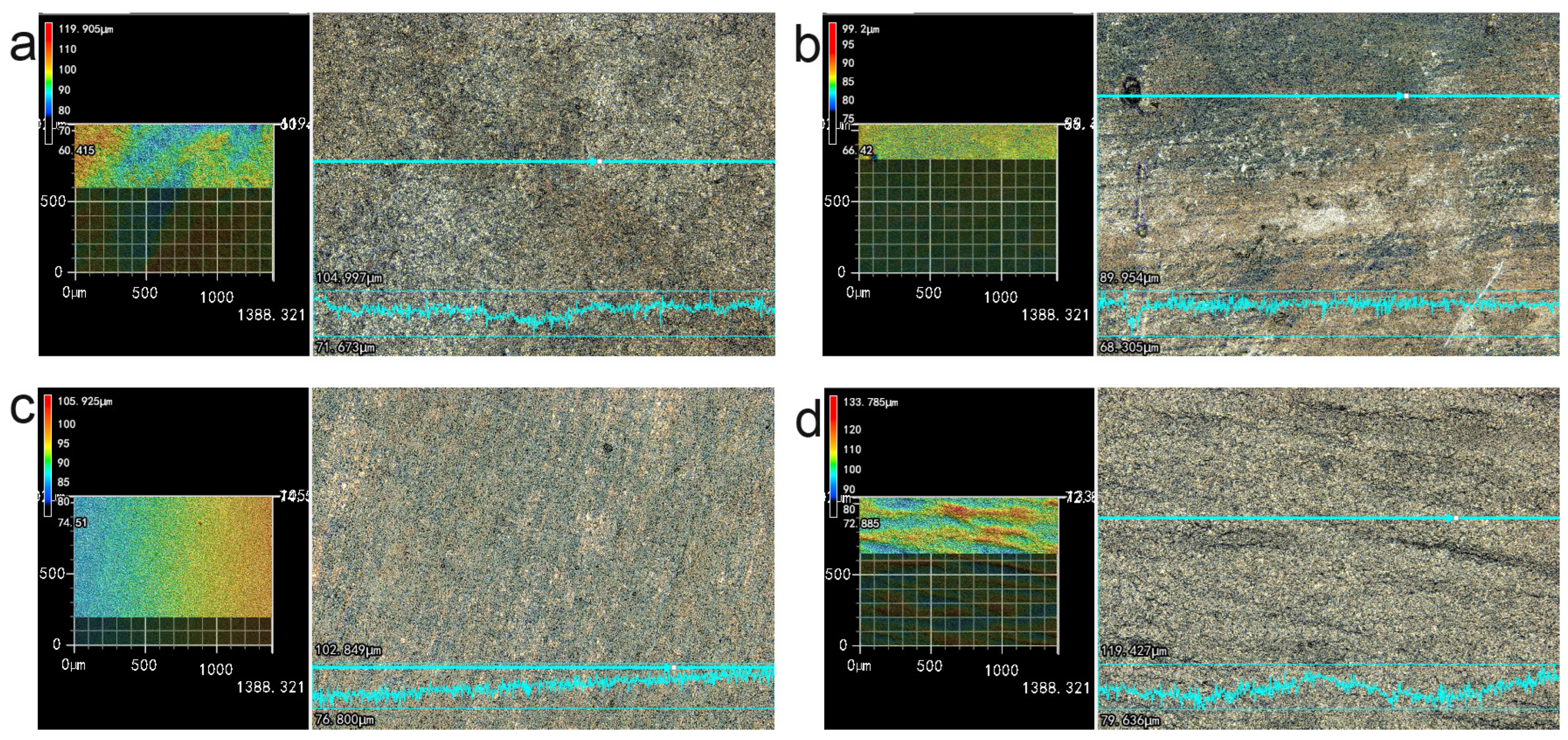

3.4. 3D Profilometry

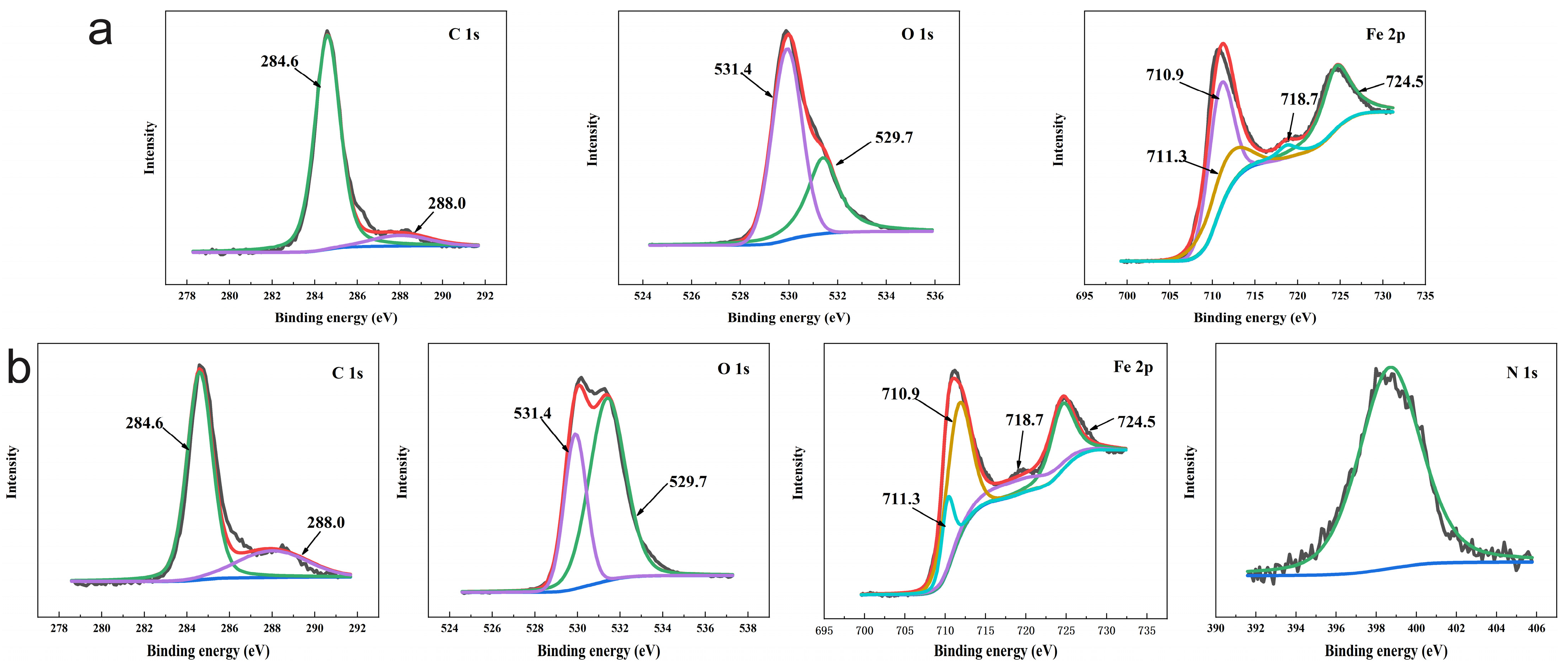

3.5. XPS Analysis

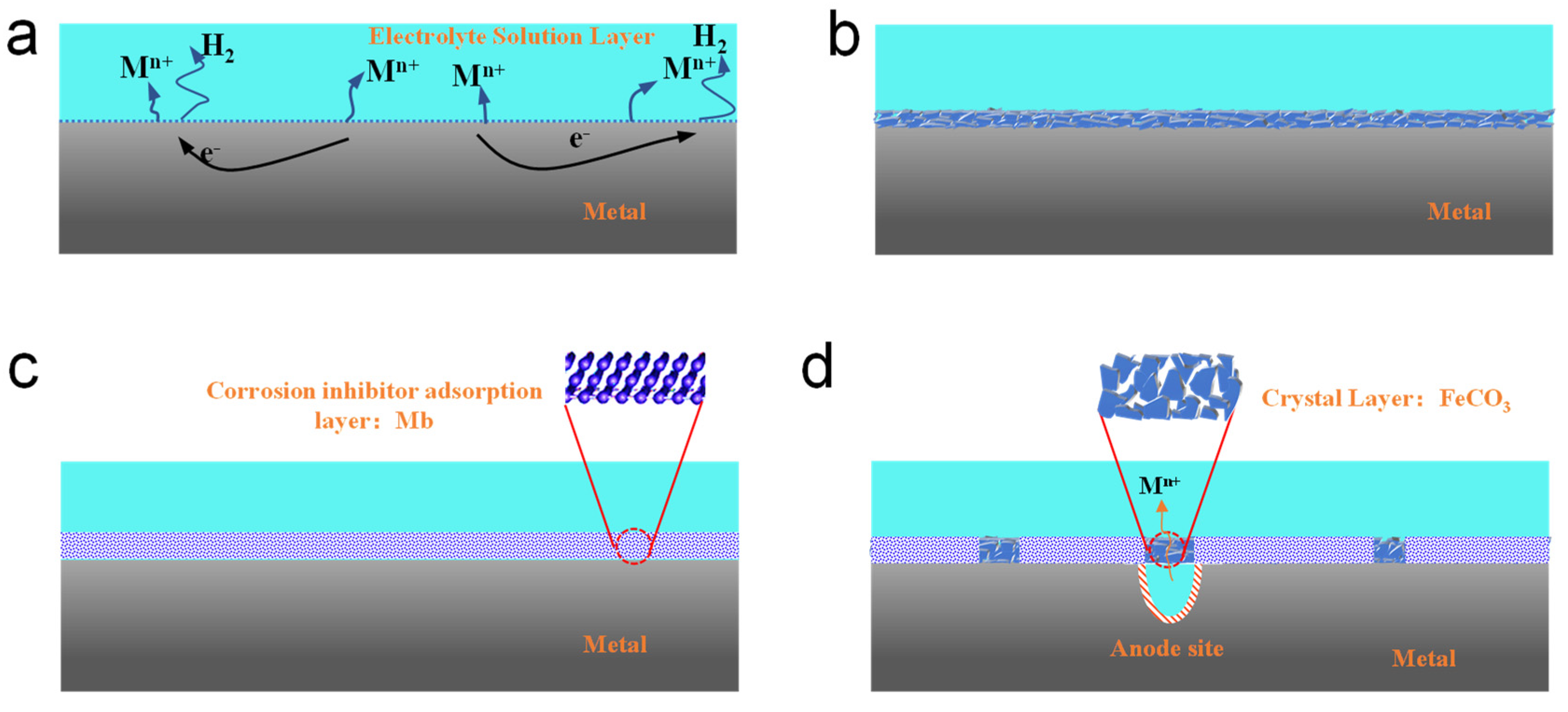

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lou, Q.; Du, W.; Han, X.; Liu, W.; Song, H. Study on the Mechanical Properties of 125S Casing for oil and gas wells. J. Phys. Conf. Ser. 2020, 1605, 012123. [Google Scholar] [CrossRef]

- Li, Z.B.; Lu, L.; Bi, Z.Y.; Zhang, F.; Huang, X.J.; Liu, Y.M. Heat treatment process of Q125 grade SEW oil casing steel. Cailiao Rechuli Xuebao/Trans. Mater. Heat Treat. 2016, 37, 156–161. [Google Scholar]

- Farrokhrouz, M.; Taheri, A.; Keshavarz, A. Numerical reactive flow transport simulation on core samples during acid fracturing in carbonaceous shale. J. Nat. Gas Sci. Eng. 2020, 84, 103615. [Google Scholar] [CrossRef]

- Shen, C.; Alvarez, V.; Koenig, J.D.B.; Luo, J.-L. Gum Arabic as corrosion inhibitor in the oil industry: Experimental and theoretical studies. Corros. Eng. Sci. Technol. 2019, 54, 444–454. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, M.; Zhou, C.; Dai, Y.; Liu, F.; Li, J. Study of alternating acid fracturing treatment in carbonate formation based on true tri-axial experiment. J. Pet. Sci. Eng. 2020, 192, 107268. [Google Scholar] [CrossRef]

- Zhang, R.; Hou, B.; Zhou, B.; Liu, Y.; Xiao, Y.; Zhang, K. Effect of acid fracturing on carbonate formation in southwest China based on experimental investigations. J. Nat. Gas Sci. Eng. 2020, 73, 103057. [Google Scholar] [CrossRef]

- Sheng, M.; Khan, W.A.; Cheng, S.; Zhang, P.; Tian, S.; Xu, Q. Characteristics of micro-fracturing in shales induced by dilute acid. J. Nat. Gas Sci. Eng. 2021, 88, 103855. [Google Scholar] [CrossRef]

- Kumar, H.; Yadav, V. Highly efficient and eco-friendly corrosion inhibitor for mild steel in 5 M HCl: An anti-pitting and anti-cracking agent. Chem. Data Collect. 2020, 30, 100552. [Google Scholar] [CrossRef]

- Yadav, M.; Sharma, D.; Sarkar, T.K. Adsorption and corrosion inhibitive properties of synthesized hydrazine compounds on N80 steel/hydrochloric acid interface: Electrochemical and DFT studies. J. Mol. Liq. 2015, 212, 451–460. [Google Scholar] [CrossRef]

- Akalezi, C.O.; Maduabuchi, A.C.; Enenebeaku, C.K.; Oguzie, E.E. Experimental and DFT evaluation of adsorption and inhibitive properties of Moringa oliefera extract on mild steel corrosion in acidic media. Arab. J. Chem. 2020, 13, 9270–9282. [Google Scholar] [CrossRef]

- Lin, B.-L.; Shao, J.-J.; Xu, Y.-Y.; Lai, Y.-M.; Zhao, Z.-N. Adsorption and corrosion of renewable inhibitor of Pomelo peel extract for mild steel in phosphoric acid solution. Arab. J. Chem. 2021, 14, 103114. [Google Scholar] [CrossRef]

- Zafari, S.; Sarabi, A.A.; Movassagh, B. A novel green corrosion inhibitor based on task-specific benzimidazolium ionic liquid for carbon steel in HCl. Corros. Eng. Sci. Technol. 2020, 55, 589–601. [Google Scholar] [CrossRef]

- Ayeni, A.O.; Akinyele, O.F.; Hosten, E.C.; Fakola, E.G.; Olalere, J.T.; Egharevba, G.O.; Watkins, G.M. Synthesis, crystal structure, experimental and theoretical studies of corrosion inhibition of 2-((4-(2-hydroxy-4-methylbenzyl)piperazin-1-yl)methyl)-5-methylphenol—A Mannich base. J. Mol. Struct. 2020, 1219, 128539. [Google Scholar] [CrossRef]

- Ahamad, I.; Prasad, R.; Quraishi, M.A. Adsorption and inhibitive properties of some new Mannich bases of Isatin derivatives on corrosion of mild steel in acidic media. Corros. Sci. 2010, 52, 1472–1481. [Google Scholar] [CrossRef]

- Ferkous, H.; Djellali, S.; Sahraoui, R.; Benguerba, Y.; Behloul, H.; Çukurovali, A. Corrosion inhibition of mild steel by 2-(2-methoxybenzylidene) hydrazine-1-carbothioamide in hydrochloric acid solution: Experimental measurements and quantum chemical calculations. J. Mol. Liq. 2020, 307, 112957. [Google Scholar] [CrossRef]

- Pan, Y.; Zhan, F.T.; Yang, Z. Effect of Carbon Chain Length of Hydrophobic Group of Mannich Bases on Their Corrosion Inhibition Performance. Mater. Prot. 2015, 48, 23–25+50. [Google Scholar] [CrossRef]

- Guo, H.; Dong, X.; Yang, J.; Xu, X. Synthesis and performance evaluation of double Mannich base acidizing corrosion inhibitor. Mod. Chem. Ind. 2020, 40, 180–184. [Google Scholar] [CrossRef]

- ASTM G1-03(2017)e1; Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens. ASTM Standard: Philadelphia, PA, USA, 2017; pp. 1–9. [CrossRef]

- ASTM G31-72(2004); Standard Practice for Laboratory Immersion Corrosion Testing of Metals. ASTM Standard: Philadelphia, PA, USA, 2004; pp. 1–8. [CrossRef]

- Ferreira, E.S.; Giacomelli, C.; Giacomelli, F.C.; Spinelli, A. Evaluation of the inhibitor effect of l-ascorbic acid on the corrosion of mild steel. Mater. Chem. Phys. 2004, 83, 129–134. [Google Scholar] [CrossRef]

- Tang, Y.; Guo, X.P.; Zhang, G.A. Corrosion behaviour of X65 carbon steel in supercritical-CO2 containing H2O and O2 in carbon capture and storage (CCS) technology. Corros. Sci. 2017, 118, 118–128. [Google Scholar] [CrossRef]

- Heuer, J.K.; Stubbins, J.F. An XPS characterization of FeCO3 films from CO2 corrosion. Corros. Sci. 1999, 41, 1231–1243. [Google Scholar] [CrossRef]

- Guo, S.; Xu, L.; Zhang, L.; Chang, W.; Lu, M. Corrosion of alloy steels containing 2% chromium in CO2 environments. Corros. Sci. 2012, 63, 246–258. [Google Scholar] [CrossRef]

| Condition | ba mV/dec | bc mV/dec | rp | Ecorr/mV | icorr/mA cm−2 |

|---|---|---|---|---|---|

| 20% HCl | 61.55 | 95.24 | 8.2 | −453.2 | 1.60 |

| 20% HCl + Mb | 66.19 | 126.2 | 232.1 | −381.2 | 0.081 |

| pH 1.0 | 43.78 | 511 | 42.1 | −717.2 | 0.42 |

| pH 1.0 + Mb | 47.02 | 548.7 | 463.3 | −652.7 | 0.041 |

| pH 3.0 | 51.56 | 235.5 | 140.1 | −753.6 | 0.13 |

| pH 3.0 + Mb | 54.69 | 251.9 | 524.2 | −694.7 | 0.037 |

| Condition | Qdl (Ω−1 cm−2 s−ndl) | ndl | Rct (Ω cm2) | Qf (Ω−1 cm−2 s−ndl) | nf | Rf (Ω cm2) | L (H cm−2) | RL (Ω cm2) |

|---|---|---|---|---|---|---|---|---|

| 20% HCl | 9.67 × 10−5 | 0.75 | 16.74 | |||||

| 20% HCl + Mb | 9.34 × 10−4 | 0.75 | 76.95 | 1.8 × 10−4 | 0.74 | 151.7 | ||

| pH 1.0 | 1.57 × 10−3 | 0.8 | 69 | |||||

| pH 1.0 + Mb | 3.93 × 10−7 | 0.93 | 14.35 | 4.76 × 10−4 | 0.48 | 504.7 | 1541 | 1188 |

| pH 3.0 | 5.56 × 10−4 | 0.8 | 250.9 | |||||

| pH 3.0 + Mb | 8.64 × 10−4 | 0.61 | 330.2 | 6.89 × 10−4 | 1 | 240.5 |

| Region | Fe | C | O | Cl |

|---|---|---|---|---|

| A | 51.59 | 29.06 | 19.26 | 0.09 |

| B | 44.96 | 36.29 | 18.26 | 0.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, W.; Ma, Z.; Wang, Z.; Zhang, J.; Li, K.; Wen, L.; Li, C.; Jiang, X.; Xu, Z. Localized Corrosion Mechanism of Q125 Casing Steel in Residual Acid Solution during Oil Reservoir Acidizing. Coatings 2023, 13, 710. https://doi.org/10.3390/coatings13040710

Yan W, Ma Z, Wang Z, Zhang J, Li K, Wen L, Li C, Jiang X, Xu Z. Localized Corrosion Mechanism of Q125 Casing Steel in Residual Acid Solution during Oil Reservoir Acidizing. Coatings. 2023; 13(4):710. https://doi.org/10.3390/coatings13040710

Chicago/Turabian StyleYan, Wei, Zelin Ma, Zhi Wang, Jingru Zhang, Kepei Li, Lei Wen, Chen Li, Xiaohui Jiang, and Zhengxian Xu. 2023. "Localized Corrosion Mechanism of Q125 Casing Steel in Residual Acid Solution during Oil Reservoir Acidizing" Coatings 13, no. 4: 710. https://doi.org/10.3390/coatings13040710

APA StyleYan, W., Ma, Z., Wang, Z., Zhang, J., Li, K., Wen, L., Li, C., Jiang, X., & Xu, Z. (2023). Localized Corrosion Mechanism of Q125 Casing Steel in Residual Acid Solution during Oil Reservoir Acidizing. Coatings, 13(4), 710. https://doi.org/10.3390/coatings13040710