Failure Analysis of Printed Circuit Board Solder Joint under Thermal Shock

Abstract

1. Introduction

2. Methods

2.1. Research Object

2.2. Thermal Shock Test

2.3. Finite Element Analysis

2.4. Characterization

3. Results and Discussion

3.1. Morphology of Solder Joints

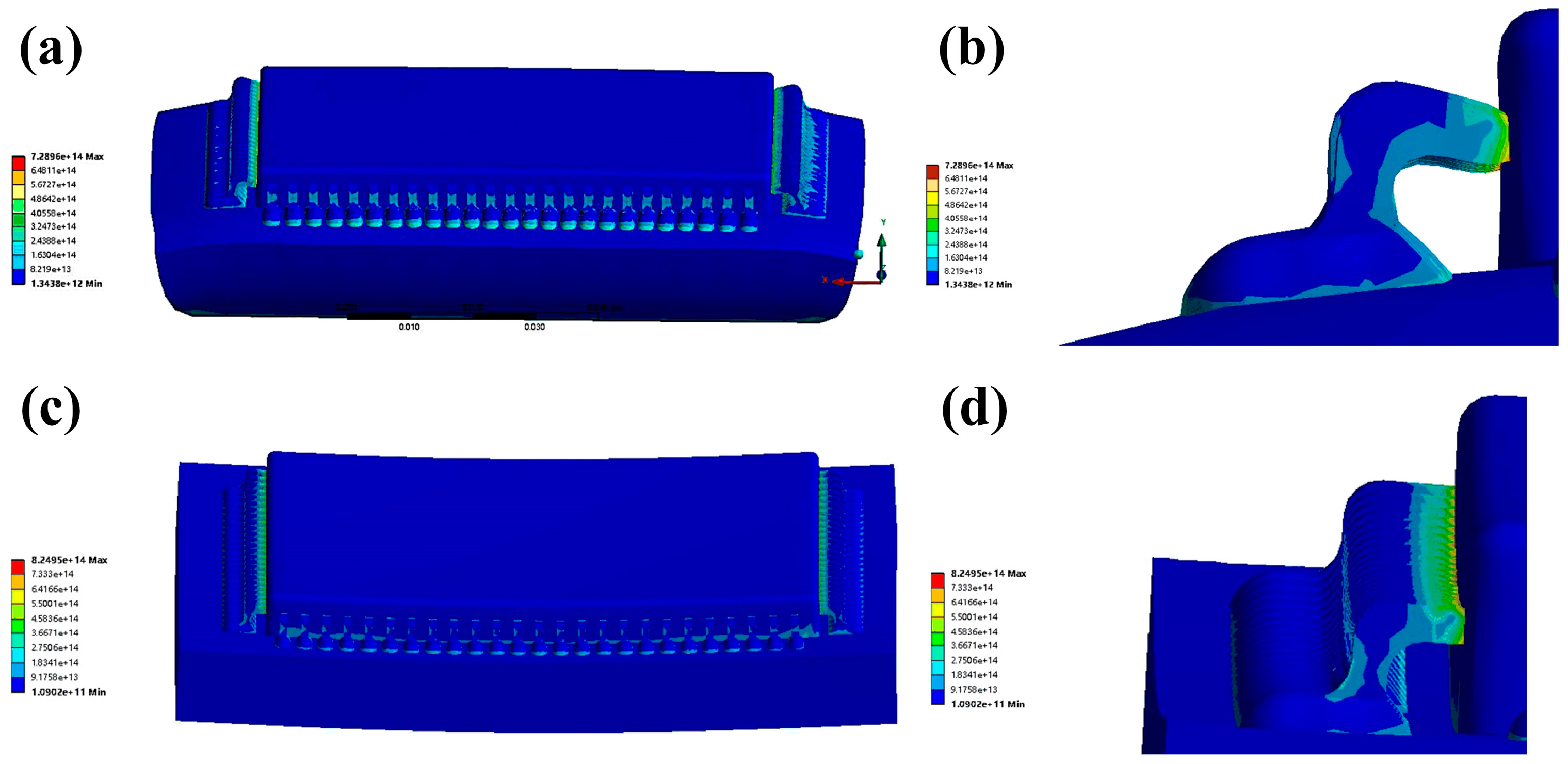

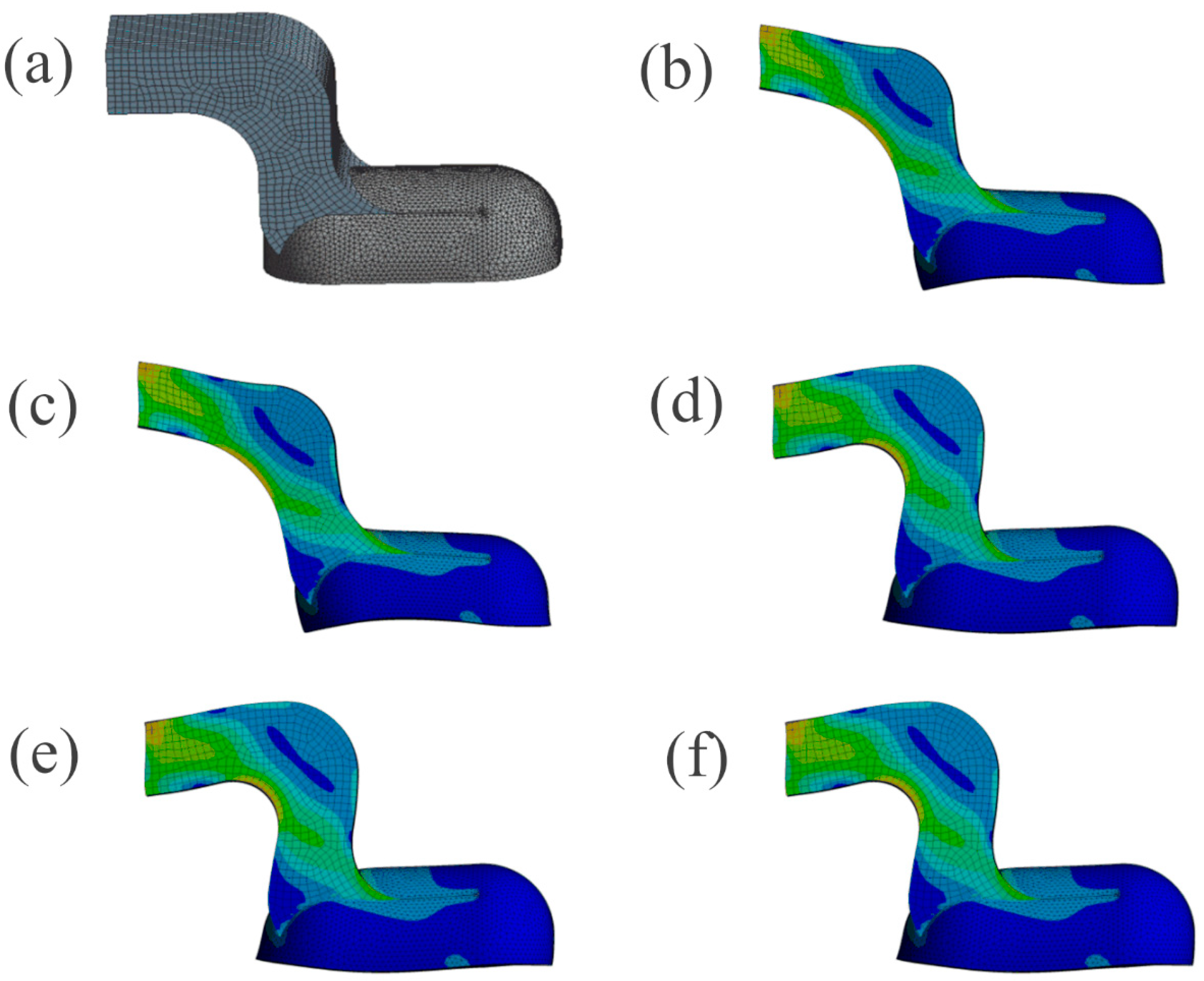

3.2. Finite Element Analysis

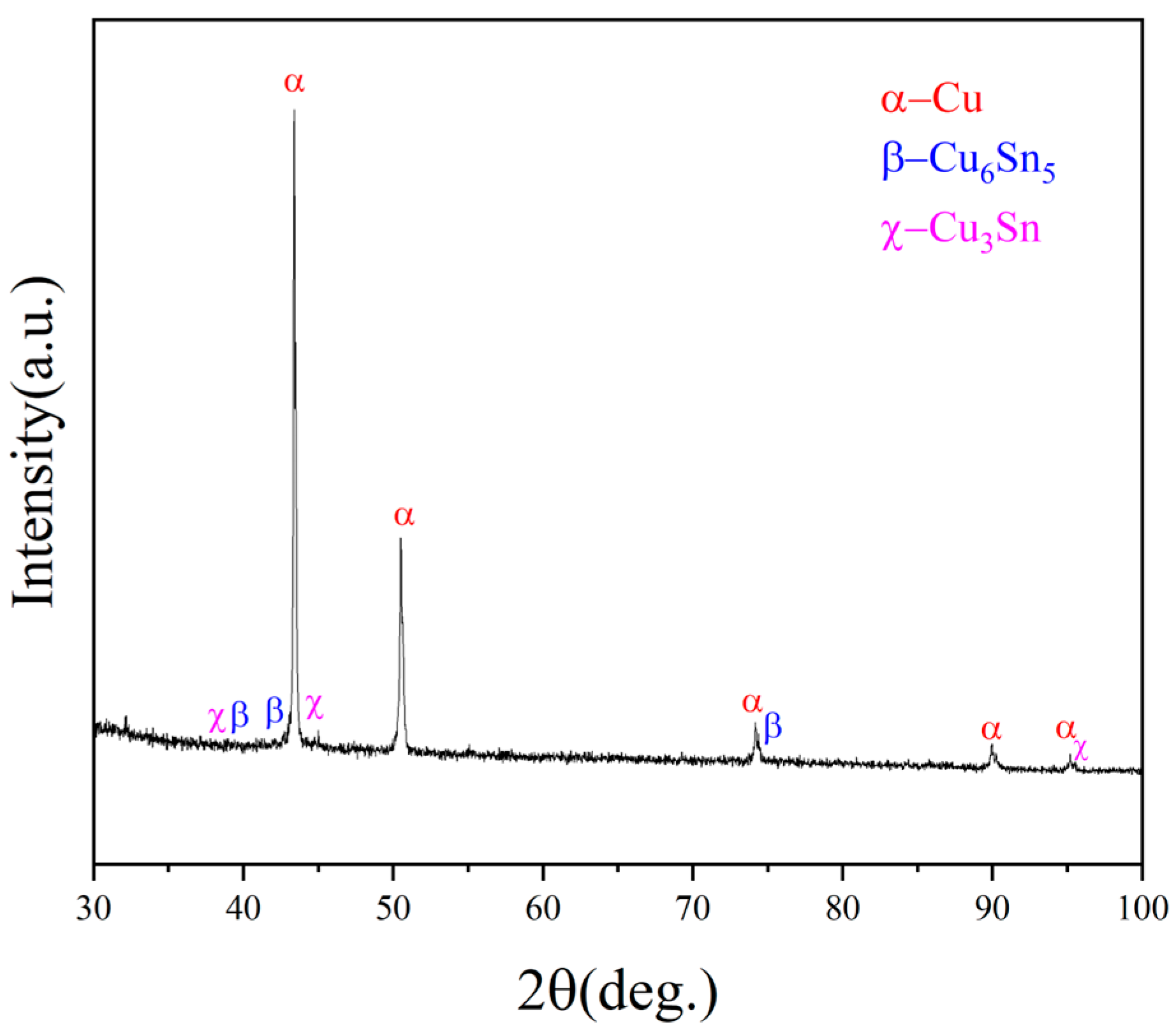

3.3. Thermal Shock Analysis

4. Conclusions

- When a PCB board is subjected to thermal shock, the difference in the thermal expansion coefficient between Cu and solder will lead to a high stress concentration.

- Cracks at the solder/Cu lead interface and the solder/Cu bottom plate joint are the main reasons for solder joint failure.

- The simulation results show that the crack location is consistent with the position of the maximum stress and strain of the simulated solder joint.

- The formation and growth of brittle Cu6Sn5 and Cu3Sn phases at the interface accelerated the failure of solder joints.

- Reducing the use of PCBs in −18 to 155 °C thermal shock environments effectively avoids solder joint failure caused by Cu6Sn5 and Cu3Sn phase precipitation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alshihmani, H.; Maghrebi, M.-J.; Sardarabadi, M. Thermal performance prediction of a phase change material based heat-sink cooling system for a printed circuit board, using response surface method. J. Energy Storage 2022, 55, 105499. [Google Scholar] [CrossRef]

- Atintoh, A.; Kpobie, W.; Bonfoh, N.; Fendler, M.; Addiego, F.; Lipinski, P. Multiscale characterization of the mechanical behavior of a printed circuit board (PCB). Mater. Today Commun. 2023, 34, 104968. [Google Scholar] [CrossRef]

- Kumar, V.; Gupta, M. Comparative study of different natural fibre printed circuit board (PCB) composites. Mater. Today Proc. 2021, 44, 2097–2101. [Google Scholar] [CrossRef]

- Tang, J.; Wan, X.; Zhang, L. A sustainable printed circuit board derived hierarchically porous carbon/polyaniline composites for supercapacitors. Ceram. Int. 2022. [Google Scholar] [CrossRef]

- Kumar, N.; Maurya, A. Development of lead free solder for electronic components based on thermal analysis. Mater. Today Proc. 2022, 62, 2163–2167. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, M.; Lin, J.; Lu, S. Effect of temperature on the corrosion behavior of lead-free solders under polyvinyl chloride fire smoke atmosphere. J. Mater. Res. Technol. 2021, 15, 3088–3098. [Google Scholar] [CrossRef]

- Xiao, J.; Tong, X.; Liang, J.; Chen, Q.; Tang, Q. Microstructure and morphology of the soldering interface of Sn–2.0Ag–1.5Zn low Ag content lead-free solder ball and different substrates. Heliyon 2023, 9, e12952. [Google Scholar] [CrossRef]

- Yahaya, M.Z.; Nazeri, M.F.M.; Salleh, N.A.; Kurt, A.; Kheawhom, S.; Illés, B.; Skwarek, A.; Abdullah, A.M.; Mohamad, A.A. Selective etching of lead-free solder alloys: A brief review. Mater. Today Commun. 2022, 33, 104520. [Google Scholar] [CrossRef]

- Chen, J.; He, Z.; Liu, J.; Wang, Y.; Hodgson, M.; Gao, W. Antibacterial anodic aluminium oxide-copper coatings on aluminium alloys: Preparation and long-term antibacterial performance. Chem. Eng. J. 2023, 461, 141873. [Google Scholar] [CrossRef]

- Wang, D.; Chen, G.; Wang, A.; Wang, Y.; Qiao, Y.; Liu, Z.; Qi, Z.; Liu, C.T. Corrosion behavior of single- and poly-crystalline dual-phase TiAl-Ti3Al alloy in NaCl solution. Int. J. Miner. Metall. Mater. 2023, 30, 689–696. [Google Scholar] [CrossRef]

- Amagai, M. A study of nanoparticles in Sn–Ag based lead free solders. Microelectron. Reliab. 2008, 48, 1–16. [Google Scholar] [CrossRef]

- Niranjani, V.; Rao, B.C.; Sarkar, R.; Kamat, S. The influence of addition of nanosized molybdenum and nickel particles on creep behavior of Sn–Ag lead free solder alloy. J. Alloys Compd. 2012, 542, 136–141. [Google Scholar] [CrossRef]

- Tunthawiroon, P.; Kanlayasiri, K. Effects of Ag contents in Sn–xAg lead-free solders on microstructure, corrosion behavior and interfacial reaction with Cu substrate. Trans. Nonferrous Met. Soc. China 2019, 29, 1696–1704. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, B.; Tay, S.L.; Hou, F.; Gao, W.; Xiong, C. The microstructure and properties of sol-enhanced Sn–TiO2 nanocomposite coatings. Int. J. Mod. Phys. B 2017, 31, 1744025. [Google Scholar] [CrossRef]

- Freitas, E.S.; Osório, W.R.; Spinelli, J.E.; Garcia, A. Mechanical and corrosion resistances of a Sn–0.7wt.%Cu lead-free solder alloy. Microelectron. Reliab. 2014, 54, 1392–1400. [Google Scholar] [CrossRef]

- Kanlayasiri, K.; Mookam, N. Influence of Cu content on microstructure, grain orientation and mechanical properties of Sn–xCu lead-free solders. Trans. Nonferrous Met. Soc. China 2022, 32, 1226–1241. [Google Scholar] [CrossRef]

- Qu, D.; Li, C.; Bao, L.; Kong, Z.; Duan, Y. Structural, electronic, and elastic properties of orthorhombic, hexagonal, and cubic Cu3Sn intermetallic compounds in Sn–Cu lead-free solder. J. Phys. Chem. Solids 2020, 138, 109253. [Google Scholar] [CrossRef]

- Gao, W.; Cao, D.; Jin, Y.; Zhou, X.; Cheng, G.; Wang, Y. Microstructure and properties of Cu-Sn-Zn-TiO2 nano-composite coatings on mild steel. Surf. Coat. Technol. 2018, 350, 801–806. [Google Scholar] [CrossRef]

- El-Daly, A.; Hammad, A. Elastic properties and thermal behavior of Sn–Zn based lead-free solder alloys. J. Alloys Compd. 2010, 505, 793–800. [Google Scholar] [CrossRef]

- Mayappan, R.; Ahmad, Z.A. Effect of Bi addition on the activation energy for the growth of Cu5Zn8 intermetallic in the Sn–Zn lead-free solder. Intermetallics 2010, 18, 730–735. [Google Scholar] [CrossRef]

- Nazeri, M.F.M.; Mohamad, A.A. Corrosion measurement of Sn–Zn lead-free solders in 6M KOH solution. Measurement 2014, 47, 820–826. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, W.; He, Z.; Jin, Y.; Qiao, Y.; Cheng, G.; Gao, W.; Zhi, Z. Cu–Sn–Zn nanocomposite coatings prepared by TiO2 sol-enhanced electrodeposition. J. Appl. Electrochem. 2020, 50, 875–885. [Google Scholar] [CrossRef]

- Ben Romdhane, E.; Roumanille, P.; Guédon-Gracia, A.; Pin, S.; Nguyen, P.; Frémont, H. From early microstructural evolution to intergranular crack propagation in SAC solders under thermomechanical fatigue. Microelectron. Reliab. 2021, 126, 114288. [Google Scholar] [CrossRef]

- Gan, G.-S.; Huang, T.; Chen, S.-Q.; Jiang, L.-J.; Cheng, D.-Y.; Zhang, S.-Y. Low-temperature interconnection and strengthening mechanism of Cu/Cu joint with SAC particles solders. Mem.-Mater. Devices Circuits Syst. 2023, 4, 100026. [Google Scholar] [CrossRef]

- Wu, M.-L.; Lan, J.-S. Reliability and failure analysis of SAC 105 and SAC 1205N lead-free solder alloys during drop test events. Microelectron. Reliab. 2018, 80, 213–222. [Google Scholar] [CrossRef]

- Cheng, S.; Huang, C.-M.; Pecht, M. A review of lead-free solders for electronics applications. Microelectron. Reliab. 2017, 75, 77–95. [Google Scholar] [CrossRef]

- Muhammad, N.; Fang, Z.; Shoaib, M. Remaining useful life (RUL) estimation of electronic solder joints in rugged environment under random vibration. Microelectron. Reliab. 2020, 107, 113614. [Google Scholar] [CrossRef]

- Dalton, E.; Ren, G.; Punch, J.; Collins, M.N. Accelerated temperature cycling induced strain and failure behaviour for BGA assemblies of third generation high Ag content Pb-free solder alloys. Mater. Des. 2018, 154, 184–191. [Google Scholar] [CrossRef]

- Shnawah, D.A.; Sabri, M.F.M.; Badruddin, I.A. A review on thermal cycling and drop impact reliability of SAC solder joint in portable electronic products. Microelectron. Reliab. 2012, 52, 90–99. [Google Scholar] [CrossRef]

- Matin, M.; Vellinga, W.; Geers, M. Thermomechanical fatigue damage evolution in SAC solder joints. Mater. Sci. Eng. A 2007, 445–446, 73–85. [Google Scholar] [CrossRef]

- Jiang, N.; Zhang, L.; Liu, Z.-Q.; Sun, L.; Long, W.-M.; He, P.; Xiong, M.-Y.; Zhao, M. Reliability issues of lead-free solder joints in electronic devices. Sci. Technol. Adv. Mater. 2019, 20, 876–901. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.-J.; Xue, S.-B.; Wang, J.-X.; Zhang, X.; Zhang, L.; Yu, S.-L.; Wang, H. Mechanical properties of QFP micro-joints soldered with lead-free solders using diode laser soldering technology. Trans. Nonferrous Met. Soc. China 2008, 18, 814–818. [Google Scholar] [CrossRef]

- Harikirubha, S.; Baranidharan, V.; Saranya, S.; Keerthana, K.; Nandhini, M. Different shapes of microstrip line design using FR4 substrate materials—A comprehensive review. Mater. Today Proc. 2021, 45, 3404–3408. [Google Scholar] [CrossRef]

- Ananthavel, S.; Padmanaban, S.; Shanmugham, S.; Blaabjerg, F.; Ertas, A.H.; Fedak, V. Analysis of enhancement in available power transfer capacity by STATCOM integrated SMES by numerical simulation studies. Eng. Sci. Technol. Int. J. 2016, 19, 671–675. [Google Scholar] [CrossRef]

- Jain, S.; Ramulu, C.; Padmanaban, S.; Ojo, J.O.; Ertas, A.H. Dual MPPT algorithm for dual PV source fed Open-End Winding Induction Motor Drive for pumping application. Eng. Sci. Technol. Int. J. 2016, 19, 1771–1780. [Google Scholar] [CrossRef]

- Sundaram, E.; Gunasekaran, M.; Krishnan, R.; Padmanaban, S.; Chenniappan, S.; Ertas, A.H. Genetic algorithm based reference current control extraction based shunt active power filter. Int. Trans. Electr. Energy Syst. 2021, 31, e12623. [Google Scholar] [CrossRef]

- Padmanaban, S.; Blaabjerg, F.; Wheeler, P.; Ojo, J.O.; Ertas, A.H. High-Voltage DC-DC Converter Topology for PV Energy Utilization—Investigation and Implementation. Electr. Power Compon. Syst. 2017, 45, 221–232. [Google Scholar] [CrossRef]

- Padmanaban, S.; Daya, F.J.; Blaabjerg, F.; Wheeler, P.W.; Szcześniak, P.; Oleschuk, V.; H.Ertas, A. Wavelet-fuzzy speed indirect field oriented controller for three-phase AC motor drive—Investigation and implementation. Eng. Sci. Technol. Int. J. 2016, 19, 1099–1107. [Google Scholar] [CrossRef]

- Mises, R.V. Mechanik der festen Körper im plastisch-deformablen Zustand. In Nachrichten von der Gesellschaft der Wissenschaften zu Göttingen, Mathematisch-Physikalische Klasse; Göttinger Digitalisierungszentrum: Göttingen, Germany, 1913; Volume 1913, pp. 582–592. [Google Scholar]

- Zhang, Y.; Wu, K.; Li, H.; Shen, S.; Cao, W.; Li, F.; Han, J. Thermal fatigue analysis of gold wire bonding solder joints in MEMS pressure sensors by thermal cycling tests. Microelectron. Reliab. 2022, 139, 114829. [Google Scholar] [CrossRef]

- Teja, M.B.K.; Sharma, A.; Das, S.; Das, K. A review on nanodispersed lead-free solders in electronics: Synthesis, microstructure and intermetallic growth characteristics. J. Mater. Sci. 2022, 57, 8597–8633. [Google Scholar] [CrossRef]

- Billah, M.; Aad, A.R.; Das, S.; Motalab, M.; Paul, R. Dependence of mechanical and thermal deformation behaviors on crystal size and direction of Cu3Sn intermetallic: A molecular dynamics study. Alex. Eng. J. 2023, 66, 79–96. [Google Scholar] [CrossRef]

- Wang, K.-K.; Gan, D.; Hsieh, K.-C. The orientation relationships of the Cu3Sn/Cu interfaces and a discussion of the formation sequence of Cu3Sn and Cu6Sn5. Thin Solid Films 2014, 562, 398–404. [Google Scholar] [CrossRef]

| Solder | Poisson Ratio V | Elastic Modulus E (GPa) | Coefficient of Expansion (ppm/°C) |

|---|---|---|---|

| SAC305 | 0.35 | 45 | 24.5 |

| Temperature (°C) | −18 | 10 | 22 | 40 | 80 | 155 |

|---|---|---|---|---|---|---|

| Maximum stress value | 1.8 | 0.72 | 0 | 1.08 | 3.51 | 8.05 |

| Minimum stress value | 0.24 | 0.055 | 0 | 0.083 | 0.27 | 0.62 |

| Temperature (°C) | −18 | 10 | 22 | 40 | 80 | 155 |

|---|---|---|---|---|---|---|

| Maximum strain value | 0.98 | 0.29 | 0 | 0.44 | 1.42 | 3.25 |

| Minimum strain value | 0.68 | 0.20 | 0 | 0.31 | 0.98 | 2.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Chen, J.; Yu, C.; Wang, Y.; Zhang, Y. Failure Analysis of Printed Circuit Board Solder Joint under Thermal Shock. Coatings 2023, 13, 572. https://doi.org/10.3390/coatings13030572

Zhou Z, Chen J, Yu C, Wang Y, Zhang Y. Failure Analysis of Printed Circuit Board Solder Joint under Thermal Shock. Coatings. 2023; 13(3):572. https://doi.org/10.3390/coatings13030572

Chicago/Turabian StyleZhou, Zhidai, Jiahuan Chen, Chen Yu, Yuxin Wang, and Yu Zhang. 2023. "Failure Analysis of Printed Circuit Board Solder Joint under Thermal Shock" Coatings 13, no. 3: 572. https://doi.org/10.3390/coatings13030572

APA StyleZhou, Z., Chen, J., Yu, C., Wang, Y., & Zhang, Y. (2023). Failure Analysis of Printed Circuit Board Solder Joint under Thermal Shock. Coatings, 13(3), 572. https://doi.org/10.3390/coatings13030572